Sustainable Rigid Polyurethane Foam from Wasted Palm Oil and Water Hyacinth Fiber Composite—A Green Sound-Absorbing Material

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

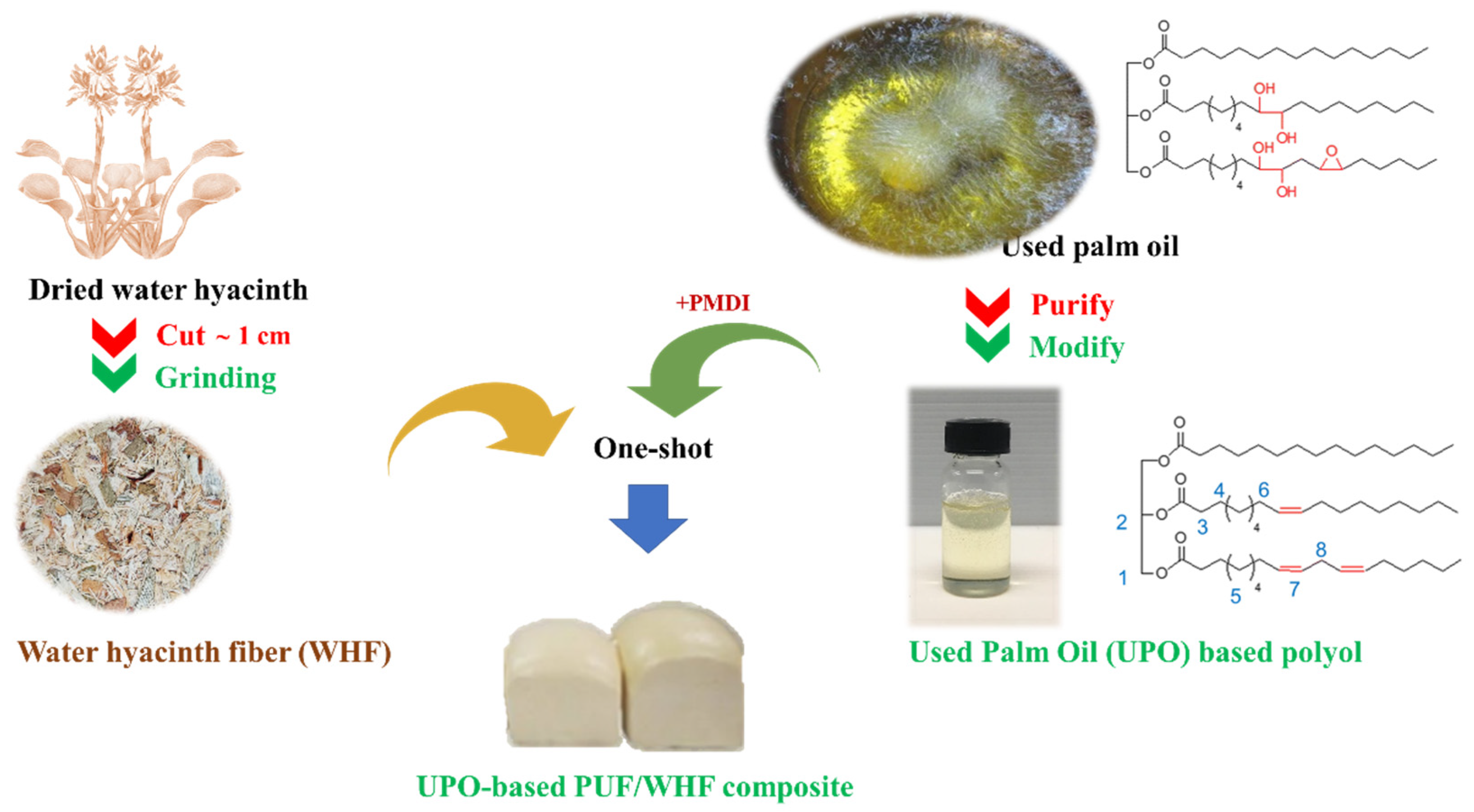

2.2.1. Preparation of Green Polyol from UPO

2.2.2. Preparation of WHF Fiber

2.2.3. Preparation of UPO-Based PUF/WHF Composite

2.3. Characterization

3. Results

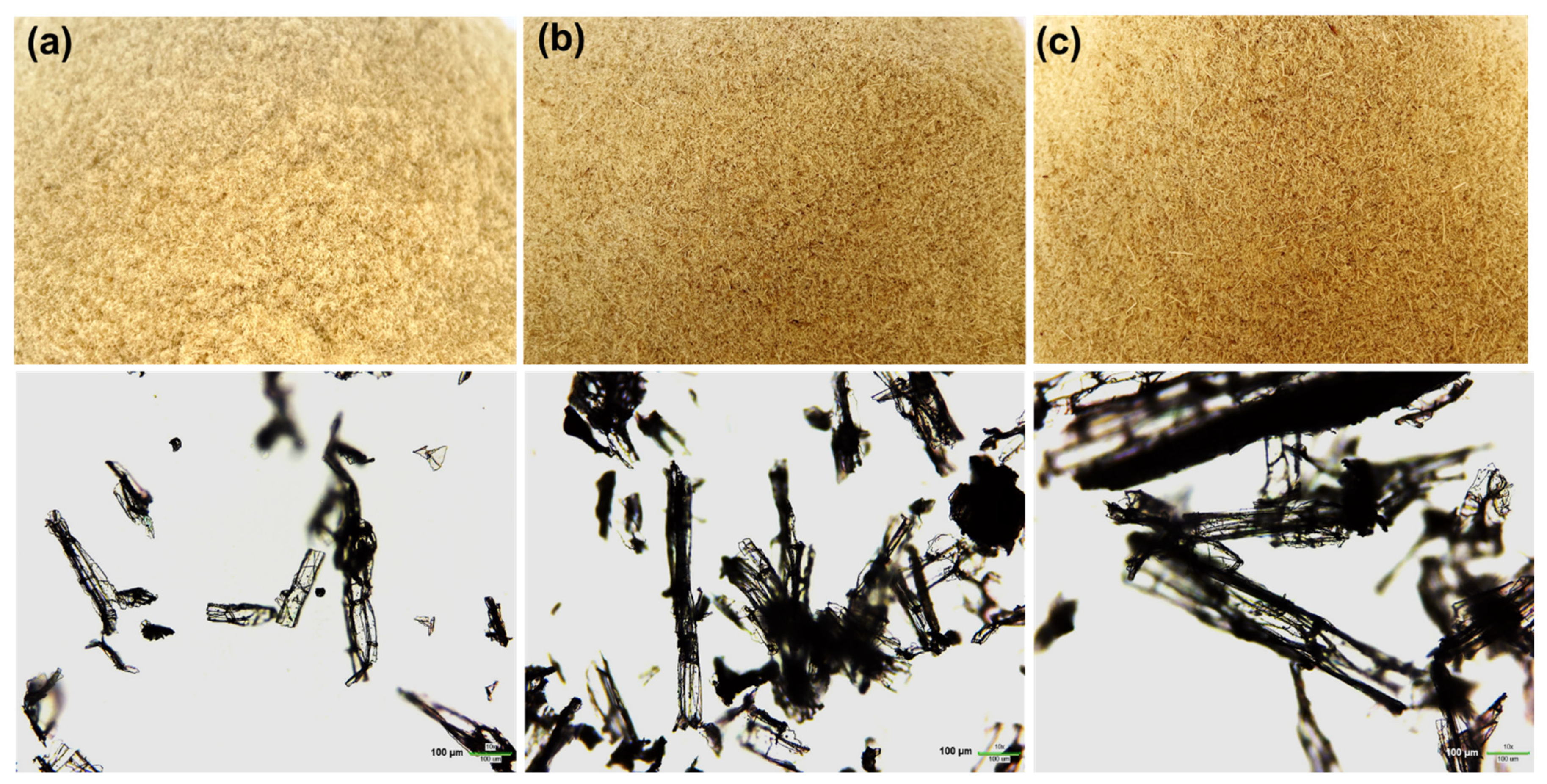

3.1. Characteristic of WHF

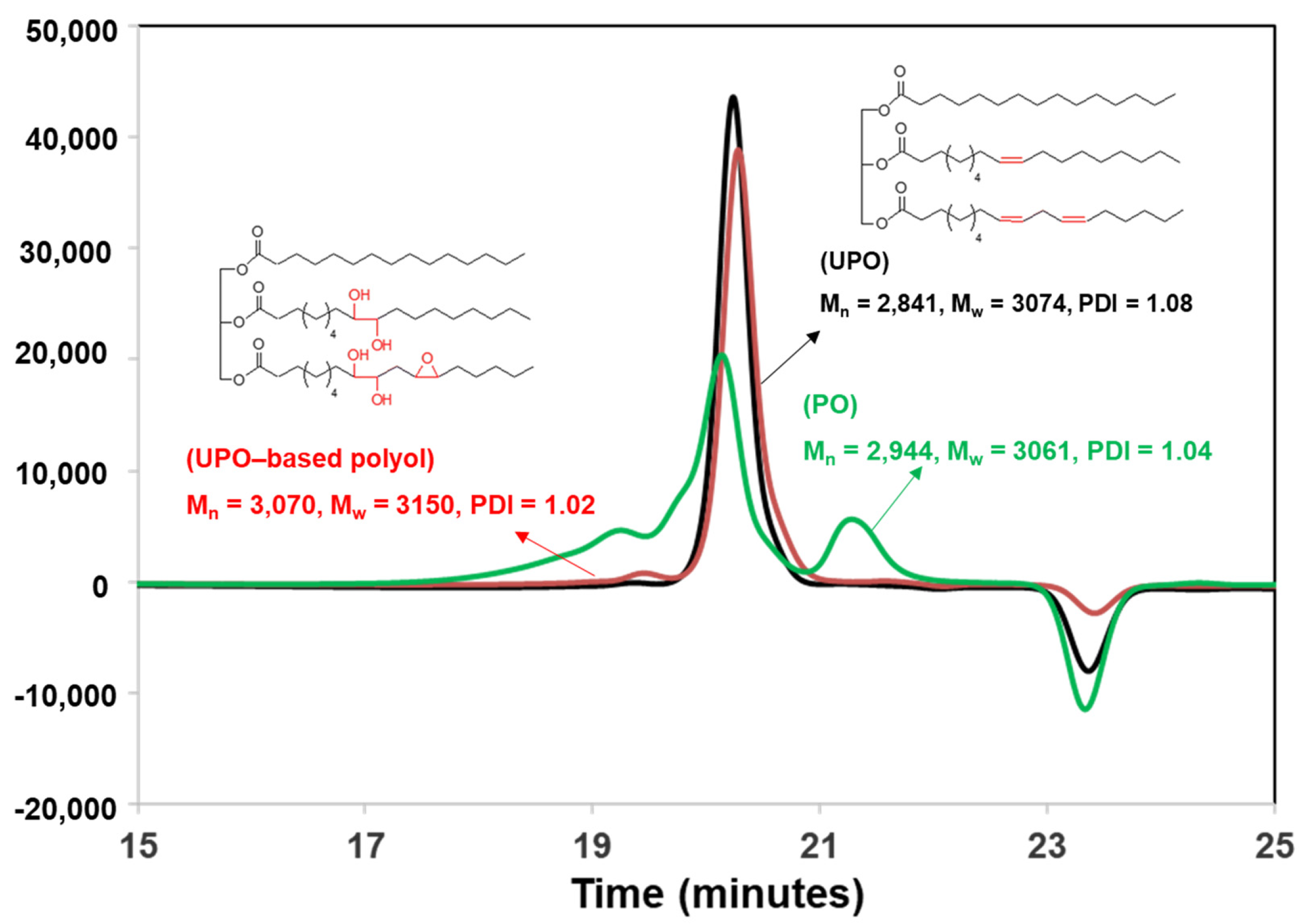

3.2. UPO and UPO-Based Polyol

3.2.1. Properties of UPO and UPO-Based Polyol

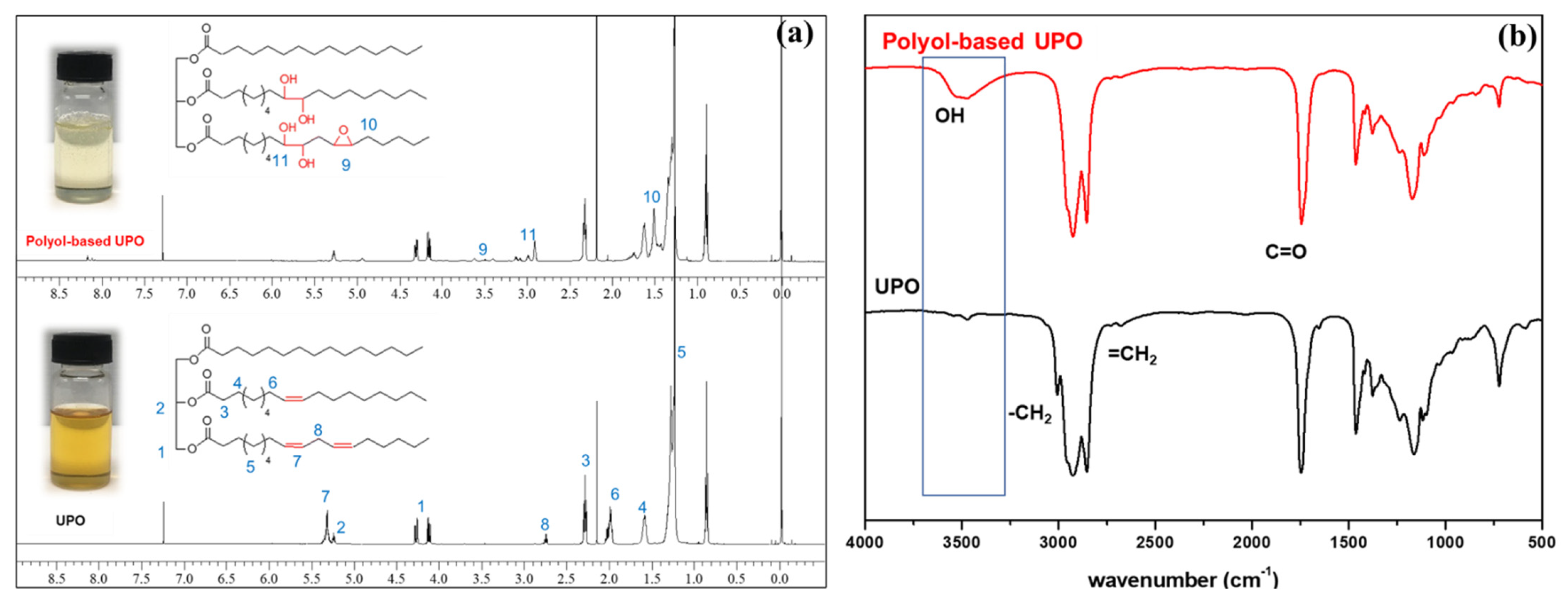

3.2.2. Chemical Structure Confirmation

3.3. PUF/WHF Composite

3.3.1. Properties of PUF/WHF Composite

3.3.2. Morphology of PUF/WHF Composite

3.3.3. Moisture Absorption of PUF/WHF Composite

3.3.4. Flammability

3.3.5. Sound Absorption Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Abdollahi Baghban, S.; Khorasani, M.; Mir Mohamad Sadeghi, G. Soundproofing flexible polyurethane foams: Effect of chemical structure of chain extenders on micro-phase separation and acoustic damping. J. Cell. Plast. 2019, 56, 167–185. [Google Scholar] [CrossRef]

- Cao, L.; Fu, Q.; Si, Y.; Ding, B.; Yu, J. Porous materials for sound absorption. Compos. Commun. 2018, 10, 25–35. [Google Scholar] [CrossRef]

- Rey, R.; Fernandez, J.; Arenas, J.; Sanchis, V. Sound absorbing materials made of recycled polyurethane foam. In Proceedings of the 40th International Congress and Exposition on Noise Control Engineering 2011, INTER-NOISE 2011, Osaka, Japan, 4–7 September 2011; pp. 1–6. [Google Scholar]

- Kostopoulos, V.; Kotrotsos, A.; Baltopoulos, A.; Tsantzalis, S.; Tsokanas, P.; Loutas, T.; Bosman, A.W. Bio-based polyurethane prepared from Kraft lignin and modified castor oil. Express Polym. Lett. 2016, 10, 914–926. [Google Scholar] [CrossRef]

- Saetung, A.; Rungvichaniwat, A.; Campistron, I.; Klinpituksa, P.; Laguerre, A.; Phinyocheep, P.; Doutres, O.; Pilard, J.-F. Preparation and physico-mechanical, thermal and acoustic properties of flexible polyurethane foams based on hydroxytelechelic natural rubber. J. Appl. Polym. Sci. 2010, 117, 828–837. [Google Scholar] [CrossRef]

- Kwon, O.-J.; Yang, S.-R.; Kim, D.-H.; Park, J.-S. Characterization of polyurethane foam prepared by using starch as polyol. J. Appl. Polym. Sci. 2007, 103, 1544–1553. [Google Scholar] [CrossRef]

- Fan, H.; Tekeei, A.; Suppes, G.J.; Hsieh, F.-H. Properties of Biobased Rigid Polyurethane Foams Reinforced with Fillers: Microspheres and Nanoclay. Int. J. Polym. Sci. 2012, 2012, 474803. [Google Scholar] [CrossRef] [Green Version]

- Zhang, L.; Zhang, M.; Hu, L.; Zhou, Y. Synthesis of rigid polyurethane foams with castor oil-based flame retardant polyols. Ind. Crops Prod. 2014, 52, 380–388. [Google Scholar] [CrossRef]

- Fourati, Y.; Hassen, R.B.; Bayramoğlu, G.; Boufi, S. A one step route synthesis of polyurethane newtwork from epoxidized rapeseed oil. Prog. Org. Coatings 2017, 105, 48–55. [Google Scholar] [CrossRef]

- Członka, S.; Strąkowska, A.; Strzelec, K.; Kairytė, A.; Kremensas, A. Bio-Based Polyurethane Composite Foams with Improved Mechanical, Thermal, and Antibacterial Properties. Materials 2020, 13, 1108. [Google Scholar] [CrossRef] [Green Version]

- Polaczek, K.; Kurańska, M.; Auguścik-Królikowska, M.; Prociak, A.; Ryszkowska, J. Open-cell polyurethane foams of very low density modified with various palm oil-based bio-polyols in accordance with cleaner production. J. Clean. Prod. 2021, 290, 125875. [Google Scholar] [CrossRef]

- Chuayjuljit, S.; Sangpakdee, T.; Saravari, O. Processing and properties of palm oil-based rigid polyurethane foam. J. Met. Mater. Miner. 2017, 17, 17–23. [Google Scholar]

- Tanaka, R.; Hirose, S.; Hatakeyama, H. Preparation and characterization of polyurethane foams using a palm oil-based polyol. Bioresour. Technol. 2008, 99, 3810–3816. [Google Scholar] [CrossRef]

- Saifuddin, N.M.; Wen, C.; Zhan, W.; Ning, X. Palm Oil Based Polyols for Polyurethane Foams Application. In Proceedings of the International Conference on Advances in Renewable Energy Technologies, Putrajaya, Malaysia, 6–7 July 2010. [Google Scholar]

- Kairytė, A.; Kirpluks, M.; Ivdre, A.; Cabulis, U.; Vaitkus, S.; Pundienė, I. Cleaner production of polyurethane foam: Replacement of conventional raw materials, assessment of fire resistance and environmental impact. J. Clean. Prod. 2018, 183, 760–771. [Google Scholar] [CrossRef]

- Used Cooking Oils. Available online: http://brocklesby.org/used-cooking-oils/ (accessed on 9 October 2021).

- Riyapan, D.; Saetung, A.; Saetung, N. A Novel Rigid PU Foam Based on Modified Used Palm Oil as Sound Absorbing Material. J. Polym. Environ. 2019, 27, 1693–1708. [Google Scholar] [CrossRef]

- Lin, J.H.; Chuang, Y.C.; Huang, C.H.; Li, T.T.; Lou, C.W. Organic/Inorganic Acoustic-Absorbing/Thermal Insulating Fiber-Reinforced PU Composite Foam Boards. Appl. Mech. Mater. 2015, 749, 270–273. [Google Scholar] [CrossRef]

- Berardi, U.; Iannace, G. Predicting the sound absorption of natural materials: Best-fit inverse laws for the acoustic impedance and the propagation constant. Appl. Acoust. 2017, 115, 131–138. [Google Scholar] [CrossRef]

- Ekici, B.; Kentli, A.; Küçük, H. Improving Sound Absorption Property of Polyurethane Foams by Adding Tea-Leaf Fibers. Arch. Acoust. 2012, 37, 515–520. [Google Scholar] [CrossRef]

- Jiang, D.; Wang, Y.; Li, B.; Sun, C.; Guo, Z. Environmentally friendly alternative to polyester polyol by corn straw on preparation of rigid polyurethane composite. Compos. Commun. 2020, 17, 109–114. [Google Scholar] [CrossRef]

- Chen, S.; Jiang, Y. The acoustic property study of polyurethane foam with addition of bamboo leaves particles. Polym. Compos. 2018, 39, 1370–1381. [Google Scholar] [CrossRef]

- Tao, Y.; Li, P.; Cai, L. Effect of Fiber Content on Sound Absorption, Thermal Conductivity, and Compression Strength of Straw Fiber-filled Rigid Polyurethane Foams. Bioresources 2016, 11, 4159–4167. [Google Scholar] [CrossRef] [Green Version]

- Potluri, R.; Sreenivasa Rao, M. Water Absorption and Density Tests on the Water Hyacinth-Based Partial Green Composite BT—Advances in Manufacturing Technology; Hiremath, S.S., Shanmugam, N.S., Bapu, B.R.R., Eds.; Springer: Singapore, 2019; pp. 77–88. [Google Scholar]

- Ibrahim, H.S.; Ammar, N.S.; Soylak, M.; Ibrahim, M. Removal of Cd(II) and Pb(II) from aqueous solution using dried water hyacinth as a biosorbent. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2012, 96, 413–420. [Google Scholar] [CrossRef] [PubMed]

- Saratale, R.G.; Cho, S.-K.; Ghodake, G.S.; Shin, H.-S.; Saratale, G.D.; Park, Y.; Lee, H.-S.; Bharagava, R.N.; Kim, D.-S. Utilization of Noxious Weed Water Hyacinth Biomass as a Potential Feedstock for Biopolymers Production: A Novel Approach. Polymers 2020, 12, 1704. [Google Scholar] [CrossRef] [PubMed]

- Abral, H.; Kadriadi, D.; Rodianus, A.; Mastariyanto, P.; Ilhamdi; Arief, S.; Sapuan, S.M.; Ishak, M.R. Mechanical properties of water hyacinth fibers—polyester composites before and after immersion in water. Mater. Des. 2014, 58, 125–129. [Google Scholar] [CrossRef]

- Buasri, A.; Chaiyut, N.; Petsungwan, T.; Boonyuen, Y.; Moonmanee, S. Effect of Surface Treatment on Interfacial and Properties of Water Hyacinth Fiber Reinforced Poly(Lactic Acid) Composites. Adv. Mater. Res. 2012, 463–464, 449–452. [Google Scholar] [CrossRef]

- Setyowati, E.; Yahya, I.; Supriyo, E.; Romadhona, I.C.; Minardi, A. On the Sound Absorption Improvement of Water Hyacinth and Coconut Husk based Fiber Reinforced Polymer Panel. MATEC Web Conf. 2018, 159, 02035. [Google Scholar] [CrossRef]

- Ji, Y.; Chen, S.; Zhu, W. The effect of pore numbers in the cell walls of soybean oil polyurethane foam on sound absorption performance. Appl. Acoust. 2020, 157, 107010. [Google Scholar] [CrossRef]

- Kemona, A.; Piotrowska, M. Polyurethane Recycling and Disposal: Methods and Prospects. Polymers 2020, 12, 1752. [Google Scholar] [CrossRef] [PubMed]

- Ni, X.; Wu, Z.; Zhang, W.; Lu, K.; Ding, Y.; Mao, S. Energy Utilization of Building Insulation Waste Expanded Polystyrene: Pyrolysis Kinetic Estimation by a New Comprehensive Method. Polymers 2020, 12, 1744. [Google Scholar] [CrossRef]

- Building Decorative Stone. In Woodhead Publishing Series in Civil and Structural Engineering; Li, Y.; Ren, S.B.T.-B.D.M. (Eds.) Woodhead Publishing: Cambridge, UK, 2011; pp. 25–53. ISBN 978-0-85709-257-1. [Google Scholar]

| Sample Name | PUF Precursors (mol) | Additives (%wt) | ||||

|---|---|---|---|---|---|---|

| RPO | H2O | PMDI | WHF-20 | WHF-40 | WHF-80 | |

| PUF | 1 | 1 | 2 | - | - | - |

| PU-WHF-20 | 1 | 1 | 2 | 1 | - | - |

| PU-WHF-40 | 1 | 1 | 2 | - | 1 | - |

| PU-WHF-80 | 1 | 1 | 2 | - | - | 1 |

| Sample Name | Iodine Number | OH Value (mg. KOH/g) | Acid Number (mg. KOH/g) | Molecular Weight by SEC | ||

|---|---|---|---|---|---|---|

| Mn (g/mol) | Mw (g/mol) | PDI | ||||

| UPO | 40.1 | 0 | 1.41 | 2841 | 3074 | 1.08 |

| UPO-based polyol | 0.51 | 192.19 | 1.76 | 3073 | 3150 | 1.02 |

| Sample Name | Cream Time (s) | Rise Time (s) | Track Free Time (s) | Height (cm) | Density (g/mL) | Hardness (Shore OO) | Compressive Strength (kPa) |

|---|---|---|---|---|---|---|---|

| PUF | 12 | 23 | 1282 | 8.4 | 0.095 | 29 | 0.027 ± 0.003 |

| PUF-WHF-20 | 14 | 35 | 1154 | 6.2 | 0.066 | 33 | 0.047 ± 0.005 |

| PUF-WHF-40 | 14 | 32 | 1205 | 7.5 | 0.062 | 37 | 0.042 ± 0.007 |

| PUF-WHF-80 | 13 | 27 | 1255 | 8.0 | 0.061 | 45 | 0.033 ± 0.003 |

| Sample | Burning Time (s) | ||

| 25 mm | 60 mm | 125 mm | |

| PUF |  |  |  |

| PUF-WHF-20 |  |  |  |

| PUF-WHF-40 |  |  |  |

| PUF-WHF-80 |  |  |  |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sukhawipat, N.; Saengdee, L.; Pasetto, P.; Junthip, J.; Martwong, E. Sustainable Rigid Polyurethane Foam from Wasted Palm Oil and Water Hyacinth Fiber Composite—A Green Sound-Absorbing Material. Polymers 2022, 14, 201. https://doi.org/10.3390/polym14010201

Sukhawipat N, Saengdee L, Pasetto P, Junthip J, Martwong E. Sustainable Rigid Polyurethane Foam from Wasted Palm Oil and Water Hyacinth Fiber Composite—A Green Sound-Absorbing Material. Polymers. 2022; 14(1):201. https://doi.org/10.3390/polym14010201

Chicago/Turabian StyleSukhawipat, Nathapong, Laksana Saengdee, Pamela Pasetto, Jatupol Junthip, and Ekkachai Martwong. 2022. "Sustainable Rigid Polyurethane Foam from Wasted Palm Oil and Water Hyacinth Fiber Composite—A Green Sound-Absorbing Material" Polymers 14, no. 1: 201. https://doi.org/10.3390/polym14010201

APA StyleSukhawipat, N., Saengdee, L., Pasetto, P., Junthip, J., & Martwong, E. (2022). Sustainable Rigid Polyurethane Foam from Wasted Palm Oil and Water Hyacinth Fiber Composite—A Green Sound-Absorbing Material. Polymers, 14(1), 201. https://doi.org/10.3390/polym14010201