Effect of Thermal Aging on Mechanical Properties and Color Difference of Glass Fiber/Polyetherimide (GF/PEI) Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Sample Preparation

2.2. Thermal Aging Procedure

2.3. Mechanical Testing

2.4. Fracture Surface Observation

2.5. Color Characterization

3. Results and Discussion

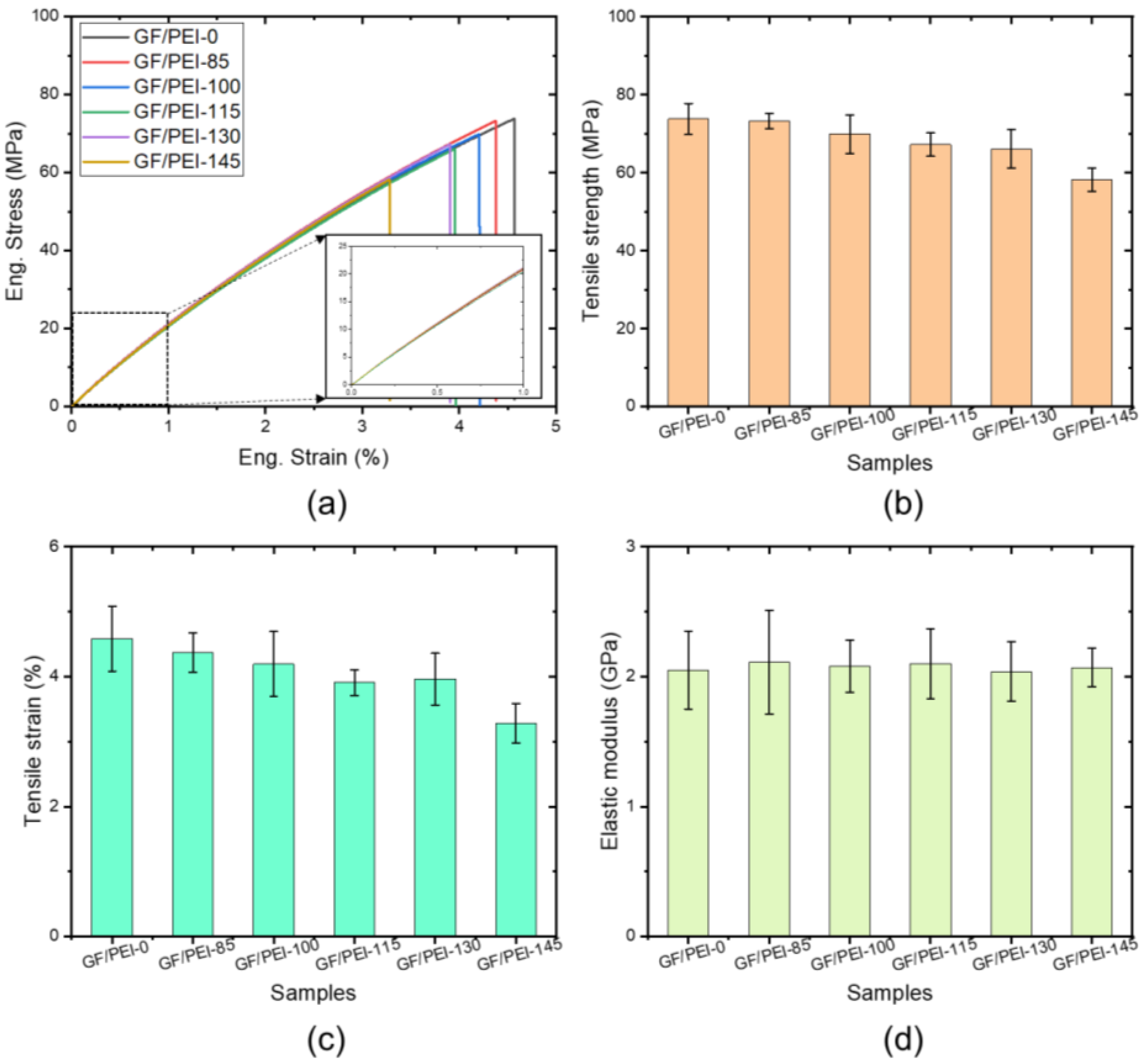

3.1. Mechanical Behavior

3.2. Microscopy Investigation

3.3. Color Difference

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Biddlestone, F.; Goodwin, A.A.; Hay, J.N.; Mouledous, G.A.C. The relaxation spectrum and physical ageing of polyetherimide. Polymers 1991, 32, 3119–3125. [Google Scholar] [CrossRef]

- Huang, F.; Wang, X.; Li, S. The thermal stability of polyetherimide. Polym. Degrad. Stab. 1987, 18, 247–259. [Google Scholar] [CrossRef]

- Tatlıdilli, A.; Çetin Altındal, D.; Gümüşderelioğlu, M. Effects of carbon fiber type and resin ratio on thermal and mechanical lifetime of polyetherimide composites. Polym. Compos. 2021, 42, 2920–2932. [Google Scholar] [CrossRef]

- Xian, G.; Zhang, Z. Sliding wear of polyetherimide matrix composites: I. Influence of short carbon fibre reinforcement. Wear 2005, 258, 776–782. [Google Scholar] [CrossRef]

- Shard, A.; Chand, R.; Nauriyal, S.; Gupta, V.; Garg, M.P.; Batra, N.K. Fabrication and Analysis of Wear Properties of Polyetherimide Composite Reinforced with Carbon Fiber. J. Fail. Anal. Preven. 2020, 20, 1388–1398. [Google Scholar] [CrossRef]

- Yu, T.; Zhang, Z.; Song, S.; Bai, Y.; Wu, D. Tensile and flexural behaviors of additively manufactured continuous carbon fiber-reinforced polymer composites. Compos. Struct. 2019, 225, 111147. [Google Scholar] [CrossRef]

- Riaz, S.; Park, S.J. Effective Reinforcement of Melamine-functionalized WS2 Nanosheets in Epoxy Nanocomposites at Low Loading via Enhanced Interfacial Interaction. Macromol. Res. 2020, 28, 1116–1126. [Google Scholar] [CrossRef]

- Yao, S.S.; Jin, F.L.; Rhee, K.Y.; Hui, D.; Park, S.J. Recent advances in carbon-fiber-reinforced thermoplastic composites: A review. Compos. Part B Eng. 2018, 142, 241–250. [Google Scholar] [CrossRef]

- Zhang, R.; Huang, Y.; Min, M.; Gao, Y.; Yu, X.; Lu, A.; Lu, Z. Isothermal crystallization of pure and glass fiber reinforced poly(phenylene sulfide) composites. Polym. Compos. 2009, 30, 460–466. [Google Scholar] [CrossRef]

- Auriga, R.; Gumowska, A.; Szymanowski, K.; Wronka, A.; Robles, E.; Ocipka, P.; Kowaluk, G. Performance properties of plywood composites reinforced with carbon fibers. Compos. Struct. 2020, 248, 112533. [Google Scholar] [CrossRef]

- Kim, S.H.; Park, S.J.; Rhee, K.Y.; Park, S.J. Effects of ozonized carbon black on fracture and post-cracking toughness of carbon fiber-reinforced epoxy composites. Compos. B Eng. 2019, 177, 107379. [Google Scholar] [CrossRef]

- Liu, H.; Zhao, Y.; Li, N.; Li, S.; Li, X.; Liu, Z.; Cheng, S.; Wang, K.; Du, S. Effect of polyetherimide sizing on surface properties of carbon fiber and interfacial strength of carbon fiber/polyetheretherketone composites. Polym. Compos. 2021, 42, 931–943. [Google Scholar] [CrossRef]

- Jia, S.; Wang, F.; Zhou, J.; Jiang, Z.; Xu, B. Study on the mechanical performances of carbon fiber/epoxy composite material subjected to dynamical compression and high temperature loads. Compos. Struct. 2021, 258, 113421. [Google Scholar] [CrossRef]

- Bijwe, J.; Rattan, R.; Fahim, M. Abrasive wear performance of carbon fabric reinforced polyetherimide composites: Influence of content and orientation of fabric. Tribol. Int. 2007, 40, 844–854. [Google Scholar] [CrossRef]

- Bergeret, A.; Pires, I.; Foulc, M.P.; Abadie, B.; Ferry, L.; Crespy, A. The Hygrothermal Behaviour of Glass-fibre-reinforced Thermoplastic Composites: A Prediction of the Composite Lifetime. Polym. Test. 2001, 20, 753–763. [Google Scholar] [CrossRef]

- Ray, B.C. Effects of Crosshead Velocity and Sub-zero Temperature on Mechanical Behaviour of Hygrothermally Conditioned Glass Fibre Reinforced Epoxy Composites. Mater. Sci. Eng. A 2004, 379, 39–44. [Google Scholar] [CrossRef]

- Foulc, M.P.; Bergeret, A.; Ferry, L.; Ienny, P.; Crespy, A. Study of Hygrothermal Ageing of Glass Fibre Reinforced PET Composites. Polym. Degrad. Stab. 2005, 89, 461–470. [Google Scholar] [CrossRef]

- Sinmazçelİk, T.; Armağan Arici, A. Thermal cycles effects on interlaminar shear strength (ILSS) and impact behaviour of carbon/PEI composites. J. Mater. Sci. 2006, 41, 1233–1241. [Google Scholar] [CrossRef]

- Ramiro, J.; Eguiazábal, J.; Nazábal, J. Phase Structure and Mechanical Properties of Blends of Poly(ether imide) and Bisphenol A Polycarbonate. Polym. J. 2004, 36, 705–715. [Google Scholar] [CrossRef]

- Zuo, P.; Tcharkhtchi, A.; Fitoussi, J.; Shirinbayan, M.; Bakir, F. Multiscale thermal study of virgin and aged polyphenylene sulfide reinforced by glass fiber. J. Appl. Polym. Sci. 2020, 137, e49031. [Google Scholar] [CrossRef]

- Zuo, P.; Fitoussi, J.; Shirinbayan, M.; Bakir, F.; Tcharkhtchi, A. Thermal aging effects on overall mechanical behavior of short glass fiber-reinforced polyphenylene sulfide composites. Polym. Eng. Sci. 2019, 59, 765–772. [Google Scholar] [CrossRef]

- Zuo, P.; Tcharkhtchi, A.; Shirinbayan, M.; Fitoussi, J.; Bakir, F. Multi-scale physicochemical characterization of a short glass fiber reinforced polyphenylene sulfide composite under aging and its thermo-oxidative mechanism. Polym. Adv. Technol. 2019, 30, 584–597. [Google Scholar] [CrossRef] [Green Version]

- Zuo, P.; Tcharkhtchi, A.; Shirinbayan, M.; Fitoussi, J.; Bakir, F. Effect of thermal aging on crystallization behaviors and dynamic mechanical properties of glass fiber reinforced polyphenylene sulfide (PPS/GF) composites. J. Polym. Res. 2020, 27, 77. [Google Scholar] [CrossRef]

- Patel, J.P.; Xiang, Z.G.; Hsu, S.L.; Schoch, A.B.; Carleen, S.A.; Matsumoto, D. Characterization of the crosslinking reaction in high performance adhesives. Int. J. Adhesion Adhes. 2017, 78, 256–262. [Google Scholar] [CrossRef]

- Patel, J.P.; Xiang, Z.G.; Hsu, S.L.; Schoch, A.B.; Carleen, S.A.; Matsumoto, D. Path to achieving molecular dispersion in a dense reactive mixture. J. Polym. Sci. Part B Polym. Phys. 2015, 53, 1519–1526. [Google Scholar] [CrossRef]

- Yilmaz, T.; Sinmazcelik, T. Effects of hydrothermal aging on glass–fiber/polyetherimide (PEI) composites. J. Mater. Sci. 2010, 45, 399–404. [Google Scholar] [CrossRef]

- Vina, J.; Castrillo, M.A.; Arguelles, A.; Vina, I. Effects of Natural and Accelerated Aging on the Static and Dynamic Behavior of Glass-fiber-reinforced Polyetherimide. J. Mater. Sci. Lett. 1998, 17, 1711–1713. [Google Scholar] [CrossRef]

- Vina, J.; Garcia, E.A.; Argüelles, A.; Vina, I. The effect of moisture on the tensile and interlaminar shear strengths of glass or carbon fiber reinforced PEI. J. Mater. Sci. Lett. 2000, 19, 579–581. [Google Scholar] [CrossRef]

- Murmu, M.M.; Panchal, J. Analysis of Polyetherimide Reinforced with Glass Fiber & Graphite Powder. Int. J. Eng. Res. Technol. 2017, 6, 5. [Google Scholar]

- Arici, A.A. Effect of Hygrothermal Aging on Polyetherimide Composites. J. Reinf. Plast. Compos. 2007, 26, 1937–1942. [Google Scholar] [CrossRef]

- Srivastava, V.K. Influence of water immersion on mechanical properties of quasi-isotropic glass fibre reinforced epoxy vinylester resin composites. Mater. Sci. Eng. A 1999, 263, 56–63. [Google Scholar] [CrossRef]

- Valarmathi, T.N.; Sangeetha, M.; Venkata, G.G.; Muppala, D.; Siva, R. Hygro-thermal degradation studies on E-glass woven rovings and aramid fiber composites. Mater. Today Proc. 2021, 44, 3823–3828. [Google Scholar] [CrossRef]

- Boyd, R.H. Relaxation processes in crystalline polymers: Experimental behavior—A review. Polymers 1985, 26, 323–347. [Google Scholar] [CrossRef]

| Temperature (°C) | L | a | b | ΔE | Gray | G60 |

|---|---|---|---|---|---|---|

| Original | 10.24 | −0.32 | −0.16 | 0 | 28 ± 2 | 90.7 ± 4.8 |

| 85 | 9.48 | −1.34 | −0.14 | 1.27 ± 0.25 | 32 ± 3 | 87.6 ± 6.7 |

| 100 | 9.18 | −1.17 | −0.52 | 1.41 ± 0.31 | 25 ± 2 | 81.3 ± 5.2 |

| 115 | 12.46 | −0.56 | −0.04 | 2.23 ± 0.52 | 25 ± 2 | 80.5 ± 4.3 |

| 130 | 12.83 | 0.19 | −0.25 | 2.64 ± 0.32 | 33 ± 3 | 70.8 ± 3.9 |

| 145 | 12.58 | −1.2 | 1.54 | 3.02 ± 0.25 | 32 ± 3 | 71.0 ± 4.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, Y.; Deng, J.; Xu, Z.; Nie, Y.; Lan, Z. Effect of Thermal Aging on Mechanical Properties and Color Difference of Glass Fiber/Polyetherimide (GF/PEI) Composites. Polymers 2022, 14, 67. https://doi.org/10.3390/polym14010067

Song Y, Deng J, Xu Z, Nie Y, Lan Z. Effect of Thermal Aging on Mechanical Properties and Color Difference of Glass Fiber/Polyetherimide (GF/PEI) Composites. Polymers. 2022; 14(1):67. https://doi.org/10.3390/polym14010067

Chicago/Turabian StyleSong, You, Jiangang Deng, Zhuolin Xu, Yu Nie, and Zhenbo Lan. 2022. "Effect of Thermal Aging on Mechanical Properties and Color Difference of Glass Fiber/Polyetherimide (GF/PEI) Composites" Polymers 14, no. 1: 67. https://doi.org/10.3390/polym14010067

APA StyleSong, Y., Deng, J., Xu, Z., Nie, Y., & Lan, Z. (2022). Effect of Thermal Aging on Mechanical Properties and Color Difference of Glass Fiber/Polyetherimide (GF/PEI) Composites. Polymers, 14(1), 67. https://doi.org/10.3390/polym14010067