Toward Polymeric and Polymer Composites Impeller Fabrication

Abstract

:1. Introduction

2. Materials Used for Fabrication of Impellers

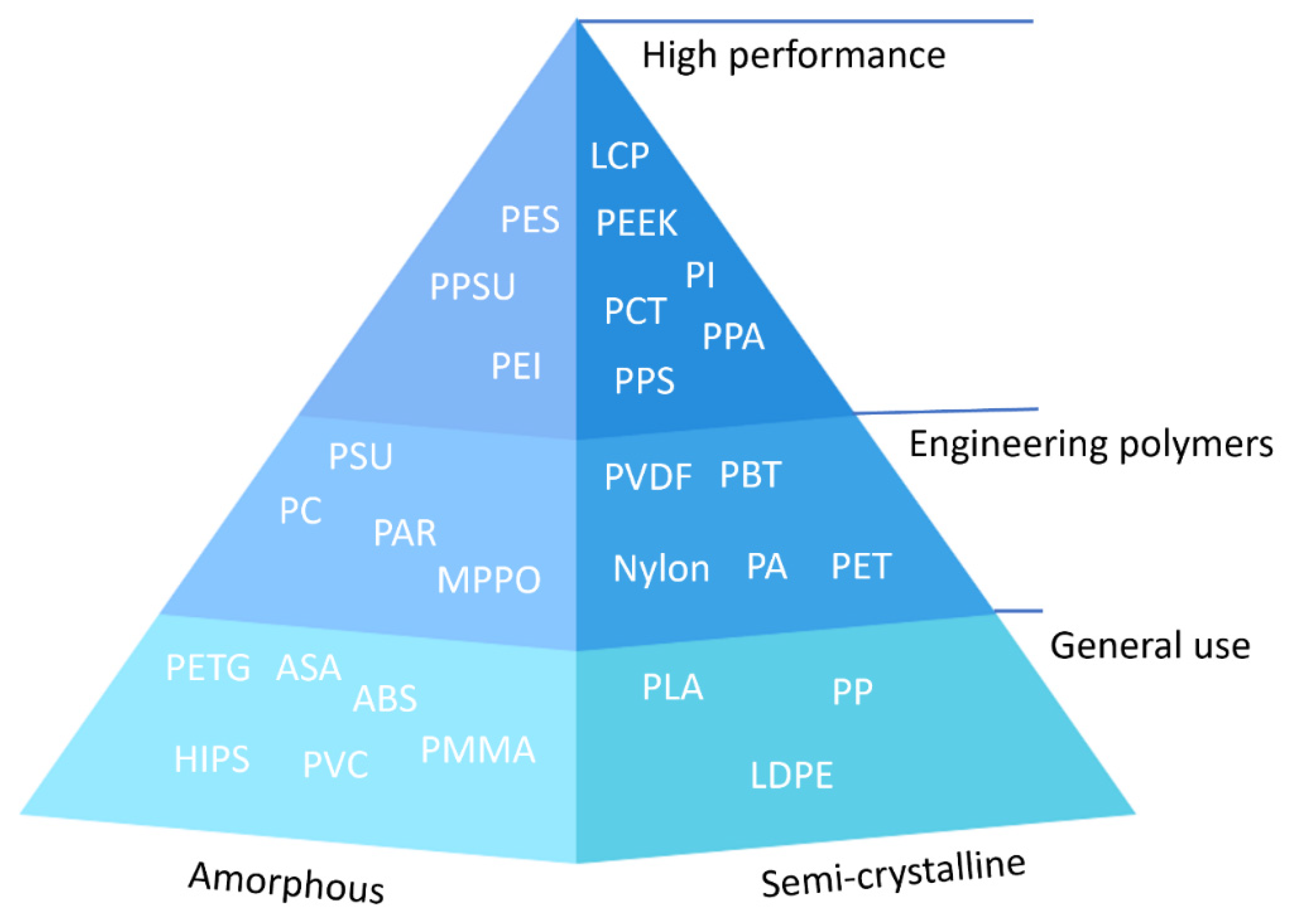

2.1. Polymeric Impellers

2.1.1. Impellers Based on Thermoplastics

2.1.2. Impellers Based on Thermosets

2.2. Polymer Composites Impellers

2.2.1. Carbon Fiber as Reinforcement in Fabrication of Impellers

2.2.2. Glass Fiber as Reinforcement in Fabrication of Impellers

3. Manufacturing Process

3.1. Conventional Impeller Manufacturing

3.2. Injection Molded Impellers

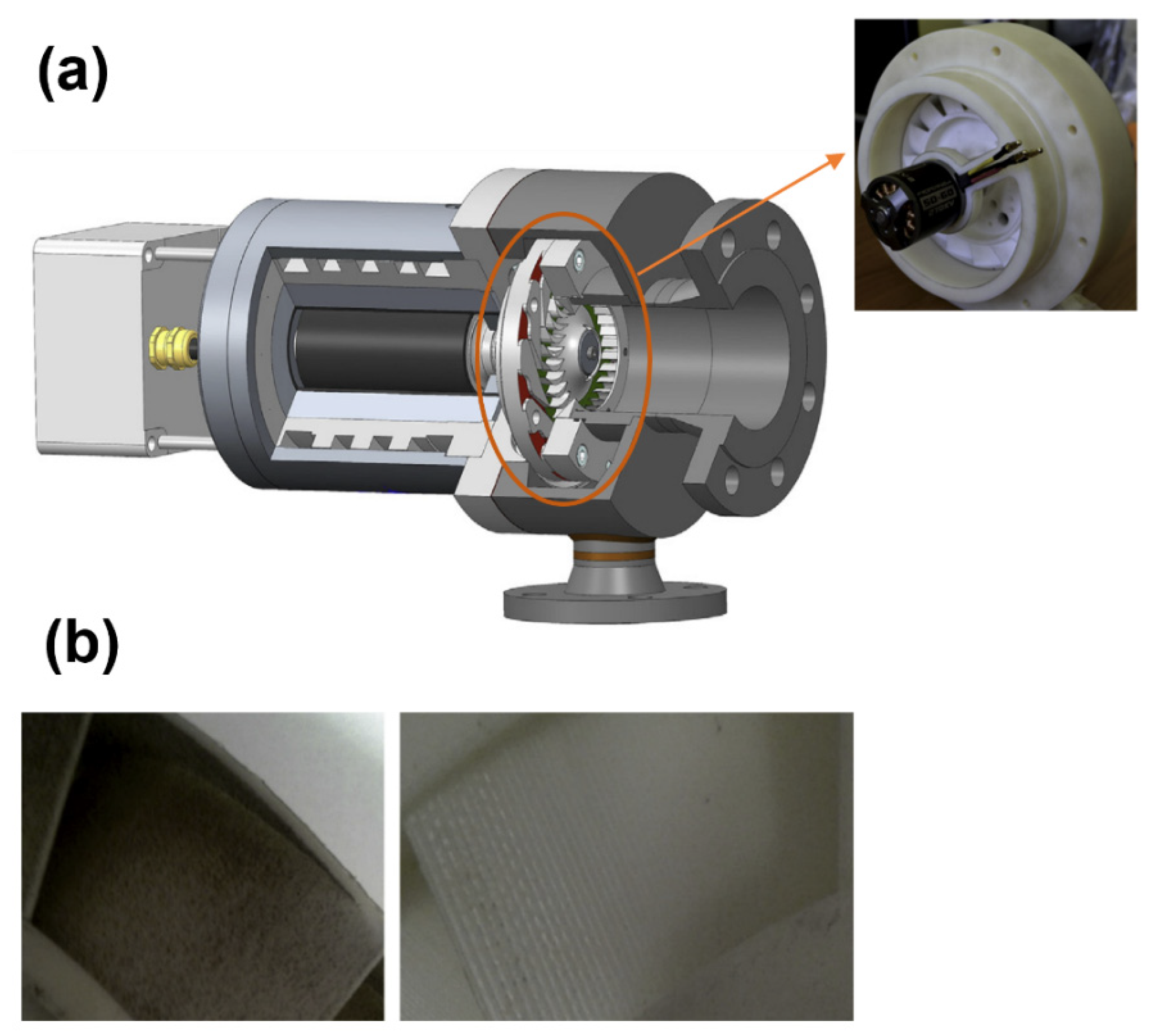

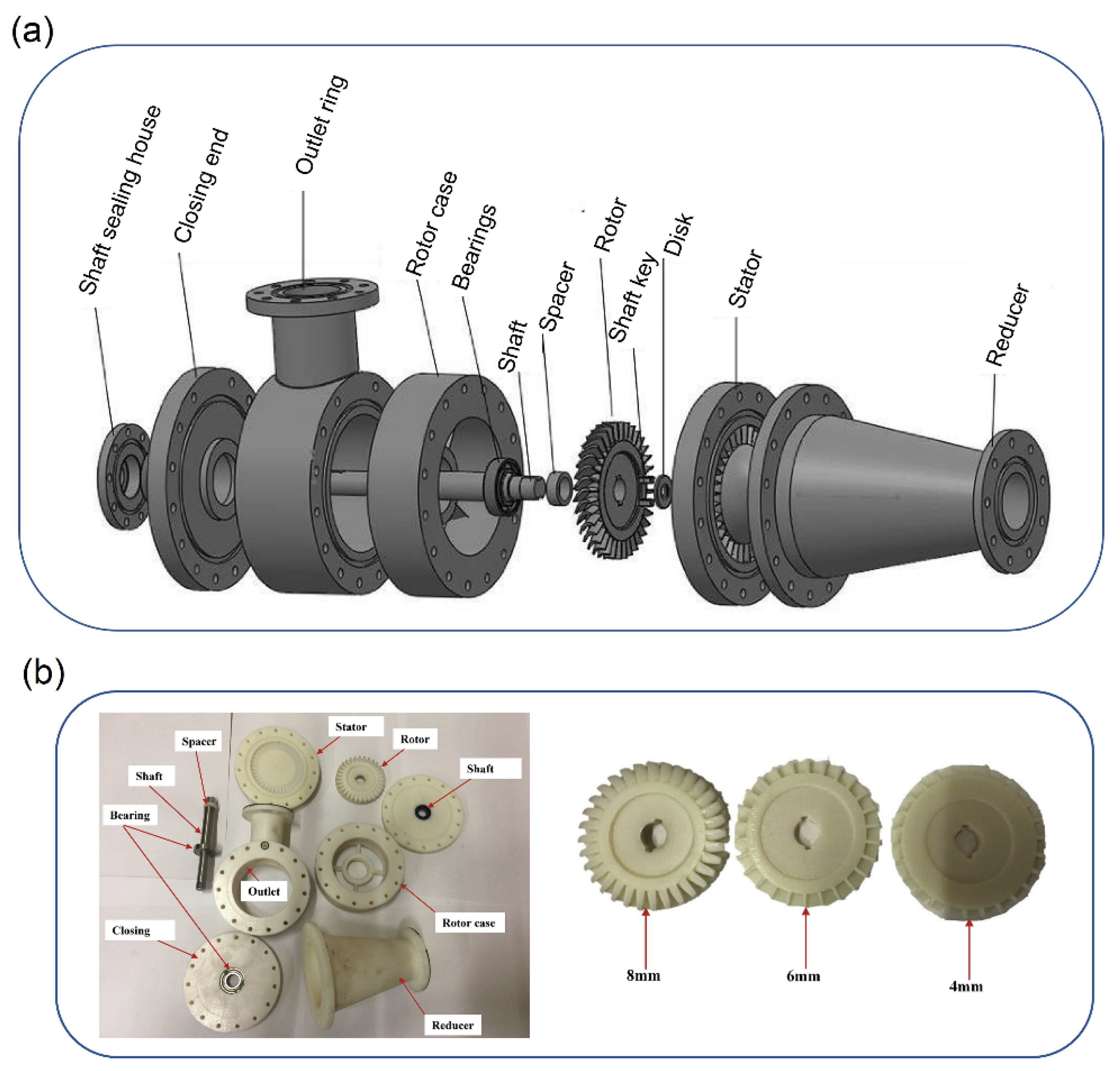

3.3. Additive Manufacturing (AM) in Fabrication of Impellers

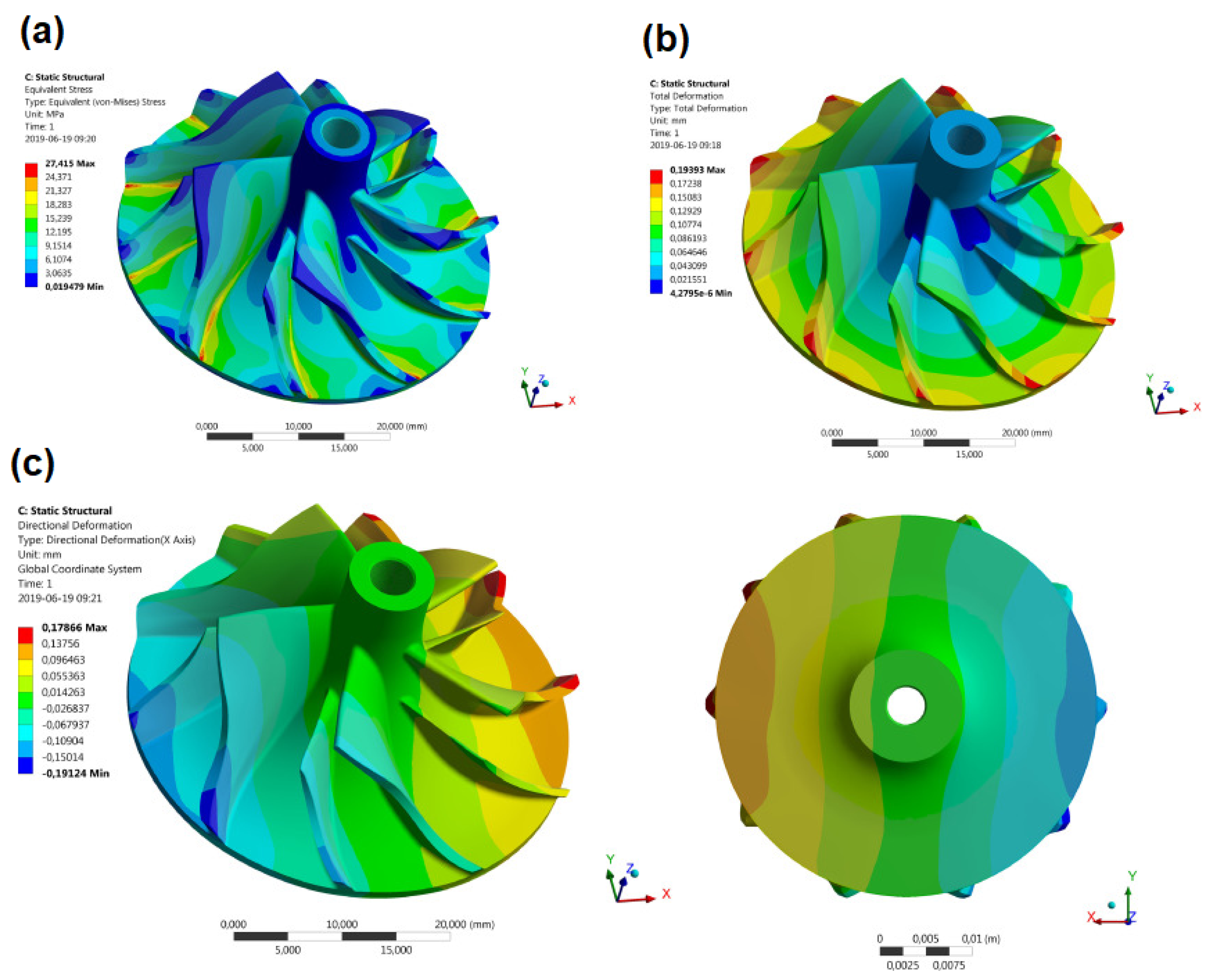

4. Structural Stress Analysis

5. Performance Evaluation

5.1. Pressure Measurements

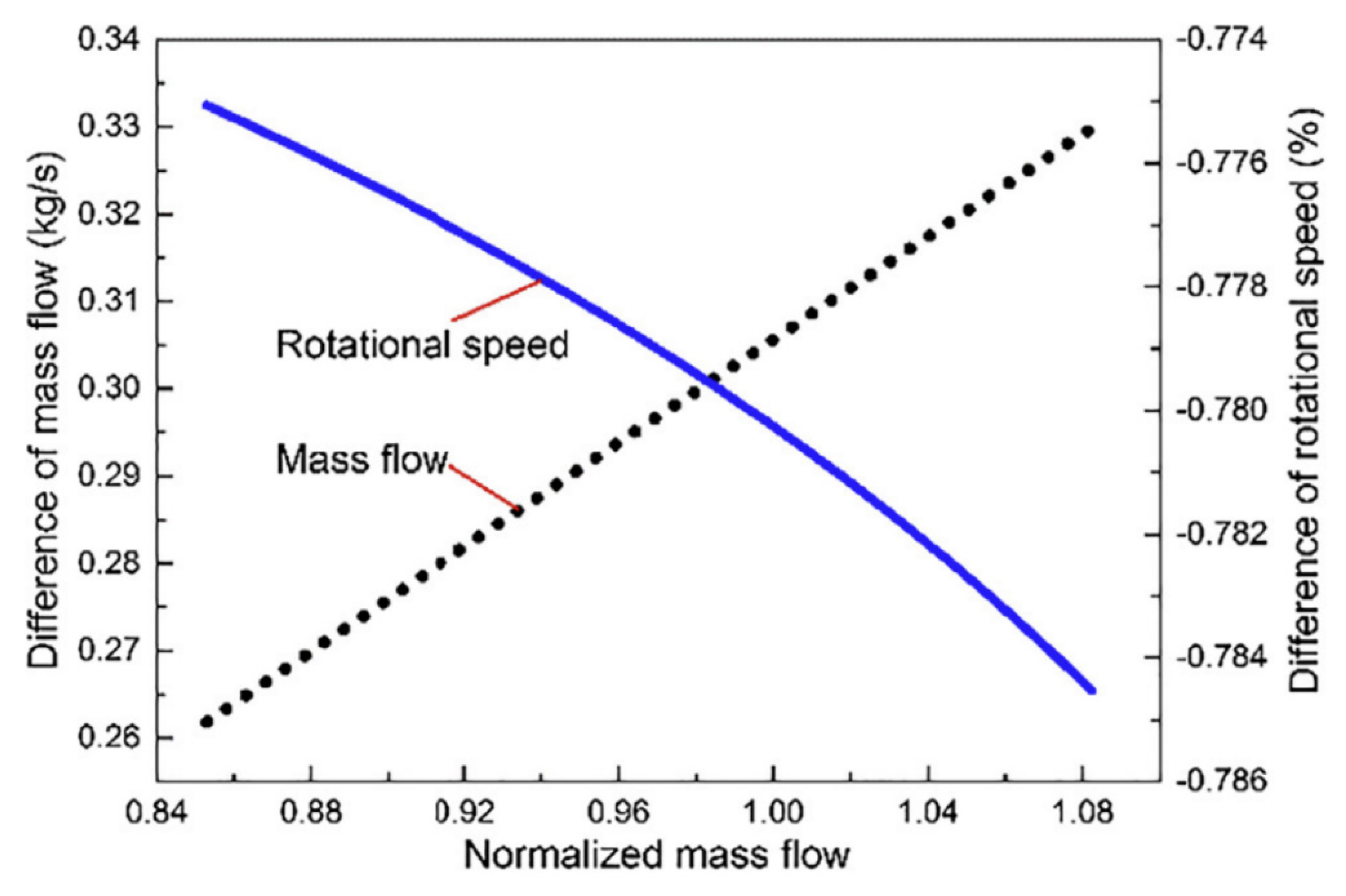

5.2. Mass Flow Measurements

5.3. Vibration Analysis of Impeller

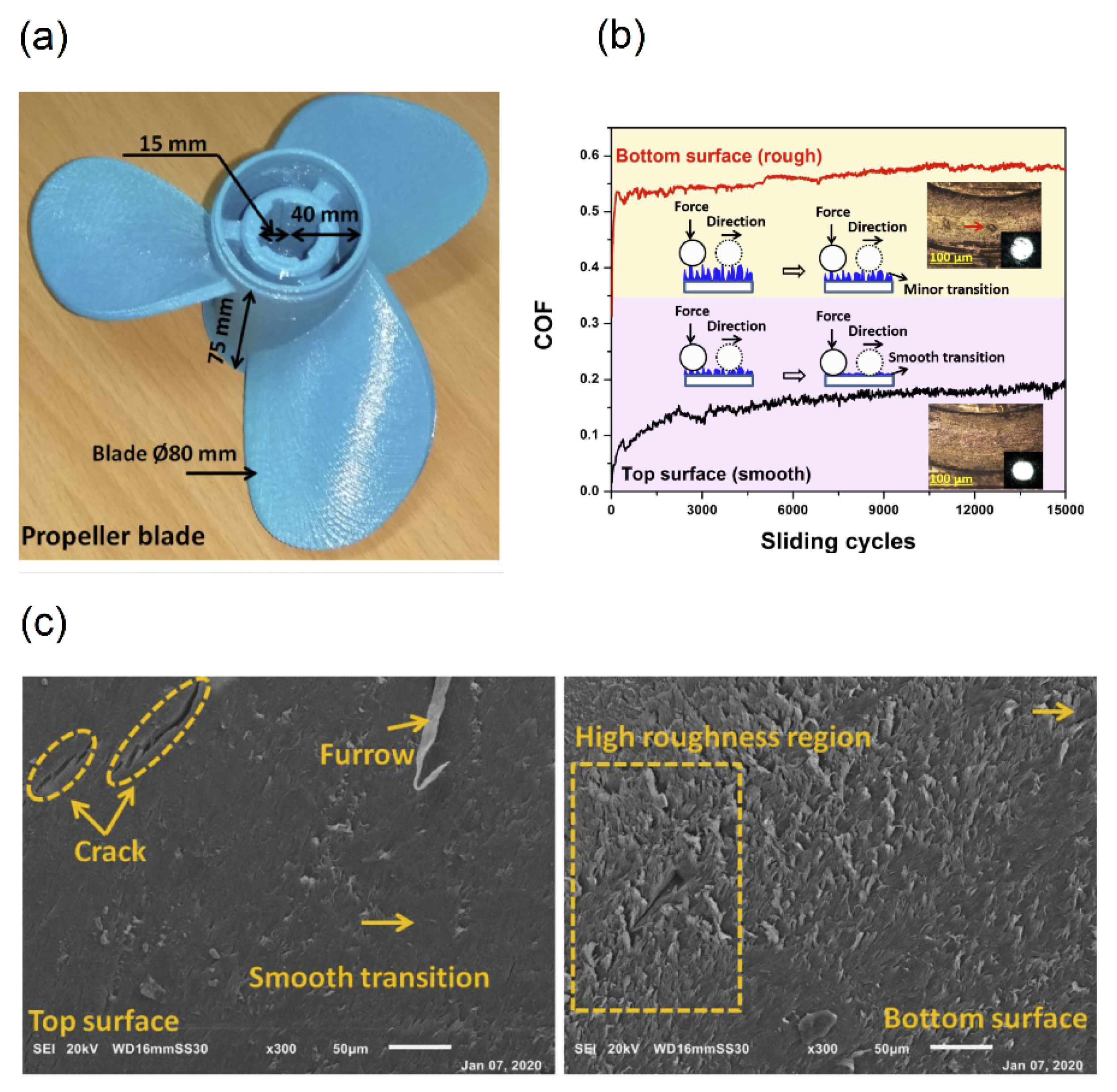

5.4. Tribology Behavior Analysis

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Peng, S.; Li, T.; Wang, X.; Dong, M.; Liu, Z.; Shi, J.; Zhang, H. Toward a sustainable impeller production: Environmental impact comparison of different impeller manufacturing methods. J. Ind. Ecol. 2017, 21, S216–S229. [Google Scholar] [CrossRef] [Green Version]

- Boyce, M.P. Centrifugal Compressors: A Basic Guide; PennWell Corporation: Nashville, TN, USA, 2003. [Google Scholar]

- González-Barrio, H.; Calleja-Ochoa, A.; Lamikiz, A.; de Lacalle, L.N.L. Manufacturing Processes of Integral Blade Rotors for Turbomachinery, Processes and New Approaches. Appl. Sci. 2020, 10, 3063. [Google Scholar] [CrossRef]

- Andrearczyk, A.; Konieczny, B.; Sokołowski, J. Additively Manufactured Parts Made of a Polymer Material Used for the Experimental Verification of a Component of a High-Speed Machine with an Optimised Geometry—Preliminary Research. Polymers 2021, 13, 137. [Google Scholar] [CrossRef] [PubMed]

- Agarwal, S.; High, K.M. Newer-generation ventricular assist devices. Best Pract. Res. Clin. Anaesthesiol. 2012, 26, 117–130. [Google Scholar] [CrossRef] [PubMed]

- Bozorgasareh, H.; Khalesi, J.; Jafari, M.; Gazori, H.O. Performance improvement of mixed-flow centrifugal pumps with new impeller shrouds: Numerical and experimental investigations. Renew. Energy 2021, 163, 635–648. [Google Scholar] [CrossRef]

- Novaković, T.; Ogris, M.; Prezelj, J. Validating impeller geometry optimization for sound quality based on psychoacoustics metrics. Appl. Acoust. 2020, 157, 107013. [Google Scholar] [CrossRef]

- Dhere, M.M.C.; Badadhe, A.M.; Patil, A.S.; Bankar, M.B.; Tarange, A.K. Design, Analysis & Material Optimization of Submersible Pump Impeller by FEA & Experimentation. Int. J. Sci. Technol. Eng. 2018, 5, 46–55. [Google Scholar]

- Andrearczyk, A.; Bagiński, P.; Klonowicz, P. Numerical and experimental investigations of a turbocharger with a compressor wheel made of additively manufactured plastic. Int. J. Mech. Sci. 2020, 178, 105613. [Google Scholar] [CrossRef]

- Sun, J.; Chen, S.; Qu, Y.; Li, J. Review on stress corrosion and corrosion fatigue failure of centrifugal compressor impeller. Chin. J. Mech. Eng. 2015, 28, 217–225. [Google Scholar] [CrossRef]

- Hernandez-Carrillo, I.; Wood, C.J.; Liu, H. Advanced materials for the impeller in an ORC radial microturbine. Energy Procedia 2017, 129, 1047–1054. [Google Scholar] [CrossRef]

- Martynyuk, L.A.; Afanasiev, D.V.; Bykov, L.V.; Ezhov, A.D.; Mezintsev, M.A. The study of the applicability of polymer composite materials for the manufacture of the impeller of a centrifugal compressor. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1060, 12026. [Google Scholar] [CrossRef]

- Fernández, S.; Jiménez, M.; Porras, J.; Romero, L.; Espinosa, M.M.; Dominguez, M. Additive manufacturing and performance of functional hydraulic pump impellers in fused deposition modeling technology. J. Mech. Des. 2016, 138, 24501. [Google Scholar] [CrossRef]

- Upadhyay, R.K.; Mishra, A.K.; Kumar, A. Mechanical degradation of 3D printed PLA in simulated marine environment. Surf. Interfaces 2020, 21, 100778. [Google Scholar] [CrossRef]

- Zywica, G.; Kaczmarczyk, T.Z.; Ihnatowicz, E.; Baginski, P.; Andrearczyk, A. Application OF a heat resistant plastic IN a high-speed microturbine designed for the domestic ORC system. Int. Semin. ORC Power Syst. 2019, 1–8. [Google Scholar]

- Azevedo, T.F.; Cardoso, R.C.; da Silva, P.R.T.; Silva, A.S.; Griza, S. Analysis of turbo impeller rotor failure. Eng. Fail. Anal. 2016, 63, 12–20. [Google Scholar] [CrossRef]

- Maier, R.; VINTILĂ, S.; Mihalache, R.; Vilag, V.; Sima, M.; Dragan, V. Decreasing the Mass of Turbomachinery Subansamblies Using Advanced Polymer Composites. Mater. Plast. 2019, 56, 687–692. [Google Scholar] [CrossRef]

- Kar, N.K.; Hu, Y.; Kar, N.J.; Kar, R.J. Failure analysis of a polymer centrifugal impeller. Case Stud. Eng. Fail. Anal. 2015, 4, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Jiang, C. Investigating Impeller Wear and Its Effect on Pump Performance Using Soft Materials. 2019. Available online: https://doi.org/10.7939/r3-cdza-bx11 (accessed on 20 December 2020).

- Gebäck, T.; Heintz, A. A Pore Scale Model for Osmotic Flow: Homogenization and Lattice Boltzmann Simulations. Transp. Porous Media 2019, 126, 161–176. [Google Scholar] [CrossRef] [Green Version]

- Škorpík, J. 15. Shapes of Parts and Materials of Turbomachines. Available online: https://www.transformacni-technologie.cz/en_15_shapes-of-parts-and-materials-of-turbomachines_part-1.pdf (accessed on 20 December 2020).

- Gad, S.E. Polymers. In Encycl Toxicol, 3rd ed.; Wexler, P., Ed.; Academic Press: Oxford, UK, 2014; pp. 1045–1050. Available online: https://www.sciencedirect.com/science/article/pii/B978012386454300912X (accessed on 20 December 2014).

- Jafferson, J.M.; Chatterjee, D. A review on polymeric materials in additive manufacturing. Mater. Today Proc. 2021, 46, 1349–1365. [Google Scholar] [CrossRef]

- Mallick, P.K. Thermoplastics and thermoplastic–matrix composites for lightweight automotive structures. In Materials, Design and Manufacturing for Lightweight Vehicles; Woodhead Publishing: Sawston, UK, 2021; pp. 187–228. [Google Scholar]

- Ogorodnyk, O.; Martinsen, K. Monitoring and control for thermoplastics injection molding a review. Procedia Cirp. 2018, 67, 380–385. [Google Scholar] [CrossRef]

- Garzon-Hernandez, S.; Arias, A.; Garcia-Gonzalez, D. A continuum constitutive model for FDM 3D printed thermoplastics. Compos. Part B Eng. 2020, 201, 108373. [Google Scholar] [CrossRef]

- Drummer, D.; Rietzel, D.; Kühnlein, F. Development of a characterization approach for the sintering behavior of new thermoplastics for selective laser sintering. Phys. Procedia 2010, 5, 533–542. [Google Scholar] [CrossRef] [Green Version]

- Ponticelli, G.S.; Tagliaferri, F.; Venettacci, S.; Horn, M.; Giannini, O.; Guarino, S. Re-Engineering of an Impeller for Submersible Electric Pump to Be Produced by Selective Laser Melting. Appl. Sci. 2021, 11, 7375. [Google Scholar] [CrossRef]

- Umaras, E.; Barari, A.; Tsuzuki, M.S.G. Tolerance analysis based on Monte Carlo simulation: A case of an automotive water pump design optimization. J. Intell. Manuf. 2020, 32, 1883–1897. [Google Scholar] [CrossRef]

- Garlotta, D. A literature review of poly (lactic acid). J. Polym. Environ. 2001, 9, 63–84. [Google Scholar] [CrossRef]

- Olivera, S.; Muralidhara, H.B.; Venkatesh, K.; Gopalakrishna, K.; Vivek, C.S. Plating on acrylonitrile–butadiene–styrene (ABS) plastic: A review. J. Mater. Sci. 2016, 51, 3657–3674. [Google Scholar] [CrossRef]

- Sastri, V.R. 8-High-Temperature Engineering Thermoplastics: Polysulfones, Polyimides, Polysulfides, Polyketones, Liquid Crystalline Polymers, and Fluoropolymers. In Plast Med Devices, 2nd ed.; Sastri, V.R., Ed.; William Andrew Publishing: Oxford, UK, 2014; pp. 173–213. [Google Scholar]

- Dolzyk, G.; Jung, S. Tensile and fatigue analysis of 3D-printed polyethylene terephthalate glycol. J. Fail. Anal. Prev. 2019, 19, 511–518. [Google Scholar] [CrossRef]

- Latko-Durałek, P.; Dydek, K.; Boczkowska, A. Thermal, rheological and mechanical properties of PETG/RPETG blends. J. Polym. Environ. 2019, 27, 2600–2606. [Google Scholar] [CrossRef] [Green Version]

- Garcia-Gonzalez, D.; Rusinek, A.; Jankowiak, T.; Arias, A. Mechanical impact behavior of polyether–ether–ketone (PEEK). Compos. Struct. 2015, 124, 88–99. [Google Scholar] [CrossRef] [Green Version]

- Hernandez-Carrillo, I.; Wood, C.; Liu, H. Development of a 1000 W organic Rankine cycle micro-turbine-generator using polymeric structural materials and its performance test with compressed air. Energy Convers. Manag. 2019, 190, 105–120. [Google Scholar] [CrossRef]

- Pavlović, A.; Šljivić, M.; Kraisnik, M.; Ilić, J.; Anić, J. Polymers in additive manufacturing: The case of a water pump impeller. FME Trans. 2017, 45, 354–359. [Google Scholar] [CrossRef]

- Polák, M. Behaviour of 3D printed impellers in performance tests of hydrodynamic pump. In Proceedings of the 7th International Conference on Trends in Agricultural Engineering, Prague, Czech Republic, 17–20 September 2019; pp. 17–20. [Google Scholar]

- Premkumar, T.M.; Pushpak, V.; Krishna, K.V.; Reddy, D.G.; Kumar, N.S.; Hariram, V.; Seralathan, S.; Nakandhrakumar, R. Design and fusion deposit modelling of radial flow centrifugal pump. Mater. Today Proc. 2020, 33, 3497–3503. [Google Scholar] [CrossRef]

- Jang, J.; Cho, K.; Yang, G.-H. Design and experimental study of dragonfly-inspired flexible blade to improve safety of drones. IEEE Robot. Autom. Lett. 2019, 4, 4200–4207. [Google Scholar] [CrossRef]

- Li, T.; Wen, B.; Tian, Y.; Li, Z.; Wang, S. Numerical simulation and experimental analysis of small drone rotor blade polarimetry based on RCS and micro-Doppler signature. IEEE Antennas Wirel. Propag. Lett. 2018, 18, 187–191. [Google Scholar] [CrossRef]

- Zirak, N.; Shirinbayan, M.; Farzaneh, S.; Tcharkhtchi, A. Effect of molecular weight on crystallization behavior of Poly Lactic Acid (PLA) under isotherm and non-isotherm conditions. Polym. Adv. Technol. 2021. [CrossRef]

- Kyzyrov, U.; Turgali, D. Performance Enhancement of a Centrifugal Pump by Impeller Retrofitting; Nazarbayev University School of Engineering and Digital Sciences, 2019; Available online: https://nur.nu.edu.kz/bitstream/handle/123456789/4476/Performance%20Enhancement%20of%20a%20Centrifugal%20Pump%20by%20Impeller%20Retrofitting.pdf;jsessionid=3A3B30B32BD593170B53A63F8FFC63C9?sequence=5 (accessed on 20 December 2020).

- Kopparapu, R.; Mathew, S.; Siciliano, E.; Stasick, G.; Dias, M. Designing a Centrifugal Pump System for High Altitude Water Crises. 2017.

- Birosz, M.T.; Andó, M.; Jeganmohan, S. Finite Element Method modeling of Additive Manufactured Compressor Wheel. J. Inst. Eng. Ser. D 2021, 102, 79–85. [Google Scholar] [CrossRef]

- Yu, Z.; Lei, M.; Ou, Y.; Yang, G. Toughening of polyethylene terephthalate/amorphous copolyester blends with a maleated thermoplastic elastomer. J. Appl. Polym. Sci. 2003, 89, 797–805. [Google Scholar] [CrossRef]

- Machalski, A.; Skrzypacz, J.; Szulc, P.; Błoński, D. Experimental and numerical research on influence of winglets arrangement on vortex pump performance. J. Phys. Conf. Ser. 2021, 1741, 12019. [Google Scholar] [CrossRef]

- Odetti, A.; Altosole, M.; Bruzzone, G.; Caccia, M.; Viviani, M. Design and construction of a modular pump-jet thruster for autonomous surface vehicle operations in extremely shallow water. J. Mar. Sci. Eng. 2019, 7, 222. [Google Scholar] [CrossRef] [Green Version]

- Huynh, A.V.; Stein, P.; Buhr, E.D. 3D-printed assistive pipetting system for gel electrophoresis for technicians with low acuity vision. Biotechniques 2020, 70, 49–53. [Google Scholar] [CrossRef] [PubMed]

- Ling, X.; Jing, X.; Zhang, C.; Chen, S. Polyether Ether Ketone (PEEK) Properties and Its Application Status. IOP Conf. Ser. Earth Environ. Sci. 2020, 453, 12080. [Google Scholar] [CrossRef]

- Platt, D.K. Engineering and High Performance Plastics Market Report: A Rapra Market Report; Smithers Rapra Publishing: Shrewsbury, UK, 2003. [Google Scholar]

- Berry, D. Use of Victrex® PEEKTM Thermoplastic to Drive New Designs, Processing Flexibility, and Cost Reduction in Aerospace Components. SAE Trans. 2002, 111, 426–431. [Google Scholar]

- Pedersen, K.; Bengtsson, A.F.; Edlund, J.S.; Eriksson, L.C. Sulphate-controlled diversity of subterranean microbial communities over depth in deep groundwater with opposing gradients of sulphate and methane. Geomicrobiol. J. 2014, 31, 617–631. [Google Scholar] [CrossRef]

- Pedersen, K. Analysis of copper corrosion in compacted bentonite clay as a function of clay density and growth conditions for sulfate-reducing bacteria. J. Appl. Microbiol. 2010, 108, 1094–1104. [Google Scholar] [CrossRef] [PubMed]

- Gotro, J.; Prime, R.B. Thermosets. Encycl. Polym. Sci. Technol. 2002, 1–75. [Google Scholar]

- Pascault, J.-P.; Williams, R.J.J. Overview of thermosets: Structure, properties and processing for advanced applications. Thermosets 2012, 3–27. [Google Scholar]

- Li, J.H.; Huang, X.D.; Durandet, Y.; Ruan, D. A review of the mechanical properties of additively manufactured fiber reinforced composites. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1067, 12105. [Google Scholar] [CrossRef]

- Mullins, M.J.; Liu, D.; Sue, H.-J. Mechanical properties of thermosets; Thermosets: Woodhead, UK, 2018; pp. 35–68. [Google Scholar]

- Sano, Y.; Matsuzaki, R.; Ueda, M.; Todoroki, A.; Hirano, Y. 3D Printing of Discontinuous and Continuous Fibre Composites Using Stereolithography. Addit. Manuf. 2018, 24, 521–527. Available online: https://www.sciencedirect.com/science/article/pii/S2214860418303282 (accessed on 20 December 2018). [CrossRef]

- Hao, W.; Liu, Y.; Zhou, H.; Chen, H.; Fang, D. Preparation and Characterization of 3D Printed Continuous Carbon Fiber Reinforced Thermosetting Composites. Polym. Test. 2018, 65, 29–34. Available online: https://www.sciencedirect.com/science/article/pii/S0142941817314149 (accessed on 10 December 2018). [CrossRef]

- Biron, M. Thermosets and Composites: Material Selection, Applications, Manufacturing and Cost Analysis; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Matveev, V.N.; Shabliy, L.S.; Krivcov, A.V. Application of stereolithography prototypes for gas dynamic tests and visualization. J. Phys. Conf. Ser. 2017, 803, 12097. [Google Scholar] [CrossRef]

- Paul, R.C.; Ramachandran, B.; Sushma, G.; Harshavardhan, K.H.A.; Rohith, I. An empirical research on areca fiber polymer composite for automotive components in modern industry. Mater. Today Proc. 2020, 33, 4493–4497. [Google Scholar] [CrossRef]

- Wang, R.-M.; Zheng, S.-R.; Zheng, Y.G. Polymer Matrix Composites and Technology; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Kaundal, R. Role of process variables on solid particle erosion of polymer composites: A critical review. Silicon 2017, 9, 223–238. [Google Scholar] [CrossRef]

- Mallick, V. Thermoplastic Composite Based Processing Technologies for High Performance Turbomachinery Components. Compos. Part A Appl. Sci. Manuf. 2001, 32, 1167–1173. Available online: https://www.sciencedirect.com/science/article/pii/S1359835X01000641 (accessed on 12 December 2001). [CrossRef]

- Li, Q.; Piechna, J.; Mueller, N. Static, Dynamic and Failure Behavior of a Novel Axial Composite Impeller for Water Chiller. ASME Int. Mech. Eng. Congr. Expo. 2010, 44298, 81–87. [Google Scholar]

- Chung, D. Carbon Fiber Composites; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Rashedi, A.; Sridhar, I.; Tseng, K.J. Multi-objective material selection for wind turbine blade and tower: Ashby’s approach. Mater. Des. 2012, 37, 521–532. [Google Scholar] [CrossRef]

- Patil, M.; Müller, N. Structural Analysis of Continuous Fiber Wound Composite Impellers of a Multistage High-Speed Counter Rotating Axial Compressor for Compressing Water Vapor (R-718) as Refrigerant Using Finite Element Analysis. Mater. Des. 2013, 50, 683–693. Available online: https://www.sciencedirect.com/science/article/pii/S0261306913002045 (accessed on 21 December 2013). [CrossRef]

- Goerke, D.; Le Denmat, A.-L.; Schmidt, T.; Kocian, F.; Nicke, E. Aerodynamic and mechanical optimization of CF/PEEK blades of a counter rotating fan. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: New York, NY, USA, 2012; pp. 21–33. [Google Scholar]

- Wu, D.; Liu, Y.; Li, D.; Zhao, X.; Li, C. Effect of Materials on the Noise of a Water Hydraulic Pump Used in Submersible. Ocean Eng. 2017, 131, 107–113. Available online: https://www.sciencedirect.com/science/article/pii/S0029801816306060 (accessed on 20 December 2017). [CrossRef]

- Henriques, B.; Fabris, D.; Mesquita-Guimarães, J.; Sousa, A.C.; Hammes, N.; Souza, J.C.; Silva, F.S.; Fredel, M.C. Influence of laser structuring of PEEK, PEEK-GF30 and PEEK-CF30 surfaces on the shear bond strength to a resin cement. J. Mech. Behav. Biomed. Mater. 2018, 84, 225–234. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Gonzalez, D.; Rodriguez-Millan, M.; Rusinek, A.; Arias, A. Investigation of mechanical impact behavior of short carbon-fiber-reinforced PEEK composites. Compos. Struct. 2015, 133, 1116–1126. [Google Scholar] [CrossRef] [Green Version]

- Kumar, D.; Rajmohan, T.; Venkatachalapathi, S. Wear behavior of PEEK matrix composites: A review. Mater. Today Proc. 2018, 5, 14583–14589. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, T.; Wang, S.; Cong, X.; Zhang, S.; Zhang, M.; Luan, J.; Wang, G. Strong Interface Construction of Carbon Fiber–reinforced PEEK Composites: An Efficient Method for Modifying Carbon Fiber with Crystalline PEEK. Macromol. Rapid Commun. 2020, 41, 2000001. [Google Scholar] [CrossRef] [PubMed]

- Suresha, B.; Ramesh, B.N.; Subbaya, K.M.; Chandramohan, G. Mechanical and three-body abrasive wear behavior of carbon-epoxy composite with and without graphite filler. J. Compos. Mater. 2010, 44, 2509–2519. [Google Scholar] [CrossRef]

- Shah, D.B.; Patel, K.M.; Joshi, S.J.; Modi, B.A.; Patel, A.I.; Pariyal, V. Thermo-mechanical characterization of carbon fiber composites with different epoxy resin systems. Thermochim. Acta 2019, 676, 39–46. [Google Scholar] [CrossRef]

- Ming, Y.; Zhang, S.; Han, W.; Wang, B.; Duan, Y.; Xiao, H. Investigation on process parameters of 3D printed continuous carbon fiber-reinforced thermosetting epoxy composites. Addit. Manuf. 2020, 33, 101184. [Google Scholar] [CrossRef]

- Pérez-Pacheco, E.; Cauich-Cupul, J.I.; Valadez-González, A.; Herrera-Franco, P.J. Effect of moisture absorption on the mechanical behavior of carbon fiber/epoxy matrix composites. J. Mater. Sci. 2013, 48, 1873–1882. [Google Scholar] [CrossRef]

- Uhlig, K.; Spickenheuer, A.; Bittrich, L.; Heinrich, G. Development of a highly stressed bladed rotor made of a cfrp using the tailored fiber placement technology. Mech. Compos. Mater. 2013, 49, 201–210. [Google Scholar] [CrossRef]

- Liu, Y.; Guo, Y.; Zhao, J.; Chen, X.; Zhang, H.; Hu, G.; Yu, X.; Zhang, Z. Carbon fiber reinforced shape memory epoxy composites with superior mechanical performances. Compos. Sci. Technol. 2019, 177, 49–56. Available online: https://www.sciencedirect.com/science/article/pii/S0266353818325223 (accessed on 25 February 2019). [CrossRef]

- Higbee, R.W.; Giacomelli, J.J.; Wyczalkowski, W.R. Advanced impeller design: Anti-ragging impeller, ARI2. Chem. Eng. Res. Des. 2013, 91, 2190–2197. [Google Scholar] [CrossRef]

- Morampudi, P.; Namala, K.K.; Gajjela, Y.K.; Barath, M.; Prudhvi, G. Review on glass fiber reinforced polymer composites. Mater. Today Proc. 2021, 43, 314–319. Available online: https://www.sciencedirect.com/science/article/pii/S2214785320393445 (accessed on 16 January 2021). [CrossRef]

- Fan, Y.; Gomez, A.; Ferraro, S.; Pinto, B.; Muliana, A.; La Saponara, V. Diffusion of water in glass fiber reinforced polymer composites at different temperatures. J. Compos. Mater. 2019, 53, 1097–1110. [Google Scholar] [CrossRef] [Green Version]

- Nayak, R.K.; Ray, B.C. Water absorption, residual mechanical and thermal properties of hydrothermally conditioned nano-Al2O3 enhanced glass fiber reinforced polymer composites. Polym. Bull. 2017, 74, 4175–4194. [Google Scholar] [CrossRef]

- Pun, A.K.; Singh, A.K. Thermo-mechanical and erosion wear peculiarity of hybrid composites filled with micro and nano silicon dioxide fillers–a comparative Study. Silicon 2019, 11, 1885–1901. [Google Scholar] [CrossRef]

- Mohan, N.; Mahesha, C.R.; Rajaprakash, B.M. Erosive wear behaviour of WC filled glass epoxy composites. Procedia Eng. 2013, 68, 694–702. [Google Scholar] [CrossRef] [Green Version]

- Öztürk, B.; Gedikli, H.; Kılıçarslan, Y.S. Erosive wear characteristics of E-glass fiber reinforced silica fume and zinc oxide-filled epoxy resin composites. Polym. Compos. 2020, 41, 326–337. [Google Scholar] [CrossRef]

- Gülich, J.F. Effect of Reynolds number and surface roughness on the efficiency of centrifugal pumps. J. Fluids Eng. 2003, 125, 670–679. [Google Scholar] [CrossRef]

- Caggiano, A. Machining of fibre reinforced plastic composite materials. Materials 2018, 11, 442. [Google Scholar] [CrossRef] [Green Version]

- Mentzos, M.D.; Markopoulos, A.P.; Galanis, N.I.; Margaris, D.P.; Manolakos, D.E. Design, Numerical Analysis and Manufacture of Radial Pump Impellers with Various Blade Geometries. Int. Rev. Mech. Eng. (IREME) 2015, 9, 104. [Google Scholar] [CrossRef]

- Quail, F.J.; Scanlon, T.; Strickland, M. Development of a regenerative pump impeller using rapid manufacturing techniques. Rapid Prototyp. J. 2010, 16, 337–344. [Google Scholar] [CrossRef] [Green Version]

- Sheikh-Ahmad, J.Y. Machining of Polymer Composites; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Khosravani, M.R.; Nasiri, S. Injection molding manufacturing process: Review of case-based reasoning applications. J. Intell. Manuf. 2020, 31, 847–864. [Google Scholar] [CrossRef]

- Shi, W.; Zhou, L.; Lu, W.; Pei, B.; Lang, T. Numerical prediction and performance experiment in a deep-well centrifugal pump with different impeller outlet width. Chin. J. Mech. Eng. 2013, 26, 46–52. [Google Scholar] [CrossRef]

- Kim, J.-M.; Chai, S.-H.; Yoon, M.-H.; Hong, J.-P. Plastic injection molded rotor of concentrated flux-type ferrite magnet motor for dual-clutch transmission. IEEE Trans. Magn. 2015, 51, 1–4. [Google Scholar] [CrossRef]

- Bari, K. Experimental and simulation performance for fan extraction system. Glob. J. Res. Eng. 2017, 17, 5–26. [Google Scholar]

- Fernandes, C.; Pontes, A.J.; Viana, J.C.; Gaspar-Cunha, A. Modeling and Optimization of the Injection-Molding Process: A Review. Adv. Polym. Technol. 2018, 37, 429–449. [Google Scholar] [CrossRef]

- Rosli, M.U.; Termizi, S.N.A.A.; Khor, C.Y.; Nawi, M.A.M.; Omar, A.A.; Ishak, M.I. Optimisation of Process Parameters in Plastic Injection Moulding Simulation for Blower Impeller’s Fan Using Response Surface Methodology. In Intelligent Manufacturing and Mechatronics; Springer: Singapore, 2021; pp. 309–318. [Google Scholar]

- Shen, Z.; Zheng, J.; Hu, D.; Meng, W.; Jiao, Z. Intelligent Mold Tooling Design with Plastic Injection, CFD and Structural Simulation. Available online: https://www.3ds.com/fileadmin/PRODUCTS-SERVICES/SIMULIA/Resources-center/PDF/2018-SAoE-Intelligent_Mold_Tooling_Design_with_Plastic_Injection__CFD_and_Structural_Simulation.pdf (accessed on 20 December 2021).

- Arifin, M.; Wahono, B.; Junianto, E.; Pasek, A.D. Process manufacture rotor radial turbo-expander for small scale organic Rankine cycles using selective laser melting machine. Energy Procedia 2015, 68, 305–310. [Google Scholar] [CrossRef] [Green Version]

- Jia, D.; Li, F.; Yuan, Z. 3D-printing process design of lattice compressor impeller based on residual stress and deformation. Sci. Rep. 2020, 10, 1–11. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tang, H.P.; Wang, Q.B.; Yang, G.Y.; Gu, J.; Liu, N.; Jia, L.; Qian, M. A honeycomb-structured Ti-6Al-4V oil–gas separation rotor additively manufactured by selective electron beam melting for aero-engine applications. JOM 2016, 68, 799–805. [Google Scholar] [CrossRef]

- Tan, X.; Kok, Y.; Tor, S.B.; Chua, C.K. Application of electron beam melting (EBM) in additive manufacturing of an impeller. In Proceedings of the 1st International Conference on Progress in Additive Manufacturing (Pro-AM 2014), Singapore, 26–28 May 2014. pp. 327–332.

- Solomon, I.J.; Sevvel, P.; Gunasekaran, J. A review on the various processing parameters in FDM. Mater. Today Proc. 2021, 37, 509–514. [Google Scholar] [CrossRef]

- Quail, F.; Stickland, M.; Scanlon, T. Rapid Manufacturing Technique Used in the Development of a Regenerative Pump Impeller; International Association of Engineers: Hong Kong, China, 2009; pp. 1730–1736. [Google Scholar]

- Priyanka, G.; Rao, M.V. Design and Additive Manufacturing of Pump Impeller using 3D Printing Technology. Int. J. Sci. Res. Sci. Eng. Technol. 2018, 4, 2394–4099. [Google Scholar]

- Gao, X.; Qi, S.; Kuang, X.; Su, Y.; Li, J.; Wang, D. Fused filament fabrication of polymer materials: A review of interlayer bond. Addit. Manuf. 2020, 37, 101658. [Google Scholar] [CrossRef]

- Badarinath, R.; Prabhu, V. Integration and evaluation of robotic fused filament fabrication system. Addit. Manuf. 2021, 41, 101951. [Google Scholar] [CrossRef]

- Weiß, A.P.; Novotný, V.; Popp, T.; Streit, P.; Špale, J.; Zinn, G.; Kolovratník, M. Customized ORC micro turbo-expanders-From 1D design to modular construction kit and prospects of additive manufacturing. Energy 2020, 209, 118407. [Google Scholar] [CrossRef]

- Dikshit, V.; Goh, G.D.; Nagalingam, A.P.; Goh, G.L.; Yeong, W.Y. Recent progress in 3D printing of fiber-reinforced composite and nanocomposites. Fiber-Reinf. Nanocomposites Fundam Appl. 2020, 1, 371–394. [Google Scholar]

- Budzik, G. Properties of made by different methods of RP impeller foundry patterns. Arch. Foundry Eng. 2007, 7, 83–86. [Google Scholar]

- Przybylski, W.; Dzionk, S. Impeller pump development using rapid prototyping methods. Adv. Manuf. Sci. Technol. 2011, 35, 15–23. [Google Scholar]

- Manthiram, A.; Zhao, X.; Li, W. Developments in membranes, catalysts and membrane electrode assemblies for direct methanol fuel cells (DMFCs). In Functional Materials for Sustainable Energy Applications; Woodhead Publishing: Sawston, UK, 2012; pp. 312–369. [Google Scholar]

- Mieloszyk, M.; Andrearczyk, A.; Majewska, K.; Jurek, M.; Ostachowicz, W. Polymeric structure with embedded fiber Bragg grating sensor manufactured using multi-jet printing method. Measurement 2020, 166, 108229. [Google Scholar] [CrossRef]

- Andrearczyk, A.; Żywica, G. A concept of a test stand for the investigation of a 3D printed turbochargers and selected fluid-flow machinery. Trans. Inst. Fluid-Flow Mach. 2016, 133, 3–11. [Google Scholar]

- Khalil, K.M.; Mahmoud, S.; Al-Dadah, R.K. Experimental and numerical investigation of blade height effects on micro-scale axial turbines performance using compressed air open cycle. Energy 2020, 211, 118660. [Google Scholar] [CrossRef]

- Mourtzis, D.; Doukas, M.; Bernidaki, D. Simulation in manufacturing: Review and challenges. Procedia Cirp. 2014, 25, 213–229. [Google Scholar] [CrossRef] [Green Version]

- Delhelay, D.S. Nonlinear Finite Element Analysis of the Coupled Thermomechanical Behaviour of Turbine DISC Assemblies. Ph.D. Thesis, University of Toronto, Toronto, ON, Canada, 2001. [Google Scholar]

- Dowson, P.; Bauer, D.; Laney, S. Selection of materials and material related processes for centrifugal compressors and steam turbines in the oil and petrochemical industry. In Proceedings of the 37th Turbomachinery Symposium, Houston, TX, USA, 8–11 September 2008; Texas A&M University, Turbomachinery Laboratories: College Station, TX, USA, 2008. [Google Scholar]

- Hannun, R.M.; Radhi, H.I.; Essi, N.A. The types of mechanical and thermal stresses on the first stage rotor blade of a turbine. Rev. Innovaciencia 2019, 7, 1–11. [Google Scholar] [CrossRef]

- Essi, N.A.; Hunnun, R.M.; Radhi, H.I. Prediction of mechanical stresses of single rotor blade of low pressure of Nasiriya power plant steam turbine. Univ Thi-Qar J. Eng. Sci. 2019, 10, 71–78. [Google Scholar] [CrossRef]

- Zheng, X.; Ding, C. Effect of temperature and pressure on stress of impeller in axial-centrifugal combined compressor. Adv. Mech. Eng. 2016, 8, 1687814016653547. [Google Scholar] [CrossRef] [Green Version]

- Benra, F.-K.; Dohmen, H.J.; Pei, J.; Schuster, S.; Wan, B. A comparison of one-way and two-way coupling methods for numerical analysis of fluid-structure interactions. J. Appl. Math. 2011, 853560. [Google Scholar] [CrossRef]

- Turbulent Flows; IOP Publishing: Bristol, UK, 2001.

- Siggeirsson, E.M.V.; Gunnarsson, S. Conceptual Design Tool for Radial Turbines. Master’s Thesis, Chalmers Univ. Technol Repro-Service Gothenburg, Gothenburg, Sweden, 2015. [Google Scholar]

- Lüdtke, K.H. Process Centrifugal Compressors: Basics, Function, Operation, Design, Application; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2004. [Google Scholar]

- Gresh, T. Compressor Performance: Aerodynamics for the User; Butterworth-Heinemann: Oxford, UK, 2018. [Google Scholar]

- Thin, K.C.; Khaing, M.M.; Aye, K.M. Design and performance analysis of centrifugal pump. World Acad. Sci. Eng. Technol. 2008, 46, 422–429. [Google Scholar]

- Mojaddam, M.; Torshizi, S.A.M. Design and optimization of meridional profiles for the impeller of centrifugal compressors. J. Mech. Sci. Technol. 2017, 31, 4853–4861. [Google Scholar] [CrossRef]

- Li, J.; Tang, L.; Zhang, Y. The influence of blade angle on the performance of plastic centrifugal pump. Adv. Mater. Sci. Eng. 2020, 7205717. [Google Scholar] [CrossRef]

- DiPippo, R. (Ed.) Chapter 8—Binary Cycle Power Plants. In Geotherm Power Plants, 4th ed.; Butterworth-Heinemann: Oxford, UK, 2016; pp. 193–239. Available online: https://www.sciencedirect.com/science/article/pii/B9780081008799000082 (accessed on 20 January 2016).

- Sharma, S.; Broatch, A.; García-Tíscar, J.; Allport, J.M.; Nickson, A.K. Acoustic characterisation of a small high-speed centrifugal compressor with casing treatment: An experimental study. Aerosp. Sci. Technol. 2019, 95, 105518. [Google Scholar] [CrossRef]

- Sun, J.; Zuo, Z.; Liang, Q.; Zhou, X.; Guo, W.; Chen, H. Theoretical and experimental study on effects of Humidity on Centrifugal compressor performance. Appl. Therm. Eng. 2020, 174, 115300. [Google Scholar] [CrossRef]

- Quyet, N.T. Evaluation of spring-mass-damping models of mistuned turbomachine impellers to analyse vibration and fatigue life. Вестник Иркутскoгo гoсударственнoгo техническoгo университета 2020, 24, 756–767. [Google Scholar]

- Matsushita, O.; Tanaka, M.; Kanki, H.; Kobayashi, M.; Keogh, P. Vibrations of Rotating Machinery; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- More, K.C.; Dongre, S.; Deshmukh, G.P. Experimental and numerical analysis of vibrations in impeller of centrifugal blower. SN Appl. Sci. 2020, 2, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Barone, S.; Neri, P.; Paoli, A.; Razionale, A.V. Low-frame-rate single camera system for 3D full-field high-frequency vibration measurements. Mech. Syst. Signal Process. 2019, 123, 143–152. [Google Scholar] [CrossRef]

- Neri, P.; Paoli, A.; Santus, C. Stereo-DIC Measurements of a Vibrating Bladed Disk: In-Depth Analysis of Full-Field Deformed Shapes. Appl. Sci. 2021, 11, 5430. [Google Scholar] [CrossRef]

- Mousmoulis, G.; Karlsen-Davies, N.; Aggidis, G.; Anagnostopoulos, I.; Papantonis, D. Experimental analysis of cavitation in a centrifugal pump using acoustic emission, vibration measurements and flow visualization. Eur. J. Mech. 2019, 75, 300–311. [Google Scholar] [CrossRef] [Green Version]

- McKeen, L.W. Fatigue and Tribological Properties of Plastics and Elastomers; William Andrew: Norwich, NY, USA, 2016. [Google Scholar]

- Kumar, S.; Singh, K.K. Tribological behaviour of fibre-reinforced thermoset polymer composites: A review. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2020, 234, 1439–1449. [Google Scholar] [CrossRef]

- Abazariyan, S.; Rafee, R.; Derakhshan, S. Experimental study of viscosity effects on a pump as turbine performance. Renew. Energy 2018, 127, 539–547. [Google Scholar] [CrossRef]

- Shojaeefard, M.H.; Tahani, M.; Ehghaghi, M.B.; Fallahian, M.A.; Beglari, M. Numerical study of the effects of some geometric characteristics of a centrifugal pump impeller that pumps a viscous fluid. Comput. Fluids 2012, 60, 61–70. [Google Scholar] [CrossRef]

| PLA | ABS | PPS | PETG | PEEK | |

|---|---|---|---|---|---|

| Glass transition temperature (°C) | 56–63 | 102–115 | 75–85 | 49–75 | 142.85 |

| Melting temperature (°C) | 125–178 | - | 285 | - | 342.85 |

| Modulus (GPa) | 1.03–4.0 | 1.8–2.39 | 3.9–4.1 | 0.9–1.6 | 3.6 |

| Tensile strength (MPa) | 51.7–80.9 | 42.5–44.8 | 79 | 44.12–57 | 107 |

| Ref. | [30] | [31] | [32] | [33,34] | [35] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zirak, N.; Shirinbayan, M.; Deligant, M.; Tcharkhtchi, A. Toward Polymeric and Polymer Composites Impeller Fabrication. Polymers 2022, 14, 97. https://doi.org/10.3390/polym14010097

Zirak N, Shirinbayan M, Deligant M, Tcharkhtchi A. Toward Polymeric and Polymer Composites Impeller Fabrication. Polymers. 2022; 14(1):97. https://doi.org/10.3390/polym14010097

Chicago/Turabian StyleZirak, Nader, Mohammadali Shirinbayan, Michael Deligant, and Abbas Tcharkhtchi. 2022. "Toward Polymeric and Polymer Composites Impeller Fabrication" Polymers 14, no. 1: 97. https://doi.org/10.3390/polym14010097

APA StyleZirak, N., Shirinbayan, M., Deligant, M., & Tcharkhtchi, A. (2022). Toward Polymeric and Polymer Composites Impeller Fabrication. Polymers, 14(1), 97. https://doi.org/10.3390/polym14010097