Modeling of Polymer Composite Materials Chaotically Reinforced with Spherical and Cylindrical Inclusions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

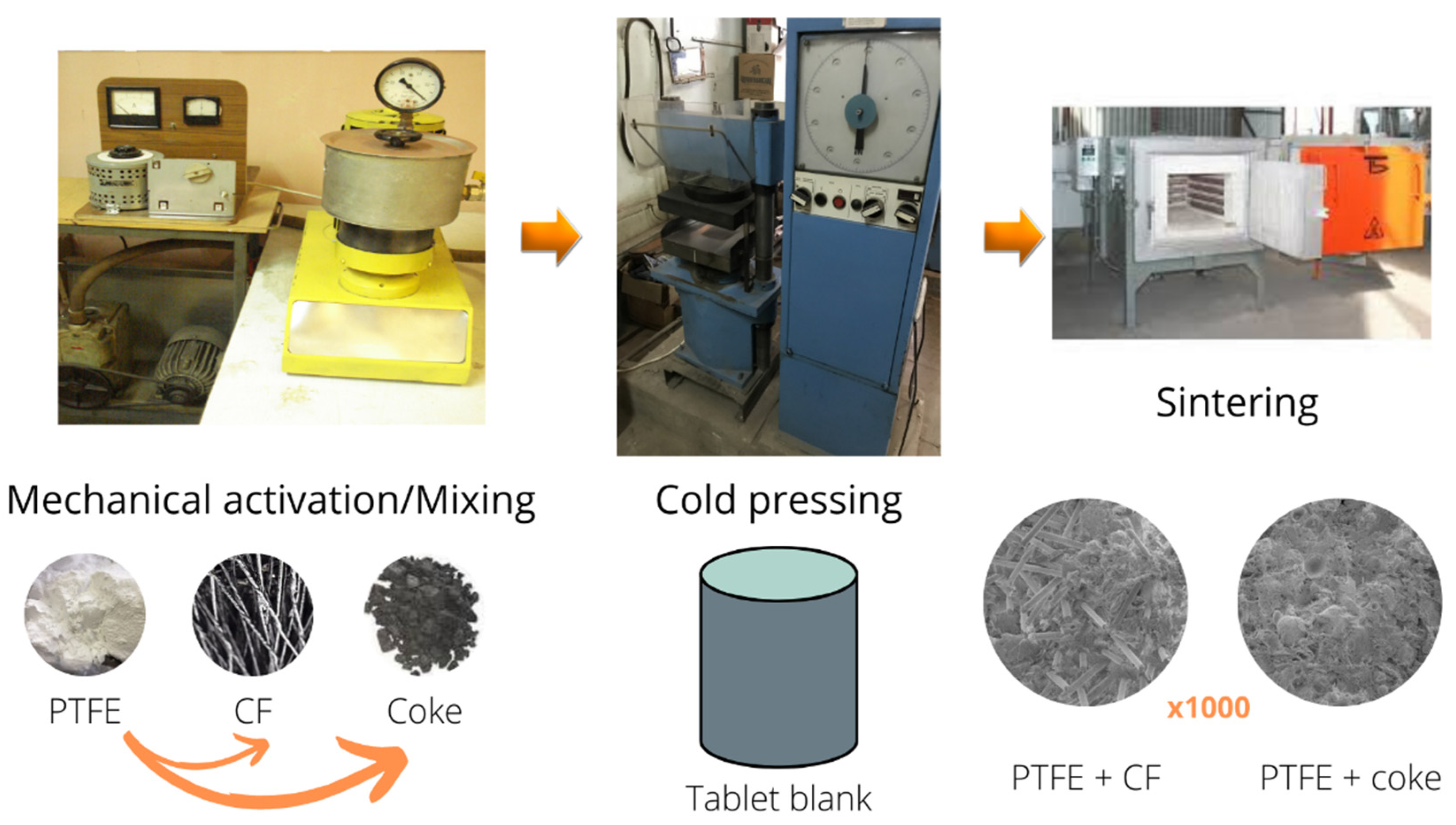

2.2. Technology of Obtaining of PCMs

2.3. Methods for Determining the Properties of PCMs

3. Numerical Approach Used for Simulation

- increased requirements for the accuracy of determining the stress–strain state of composite components, as the onset of composite fracture is usually associated with local physical processes, so it is impossible to use many simple structural models sufficient to analyze the integral (e.g., stiffness) characteristics of the composite.

- the need to consider the kinetics of fracture of the material because the local values of the parameters of the stress–strain state of the composite components often reach the limit values at the initial stages of loading the composite, but this does not lead to the depletion of its bearing capacity.

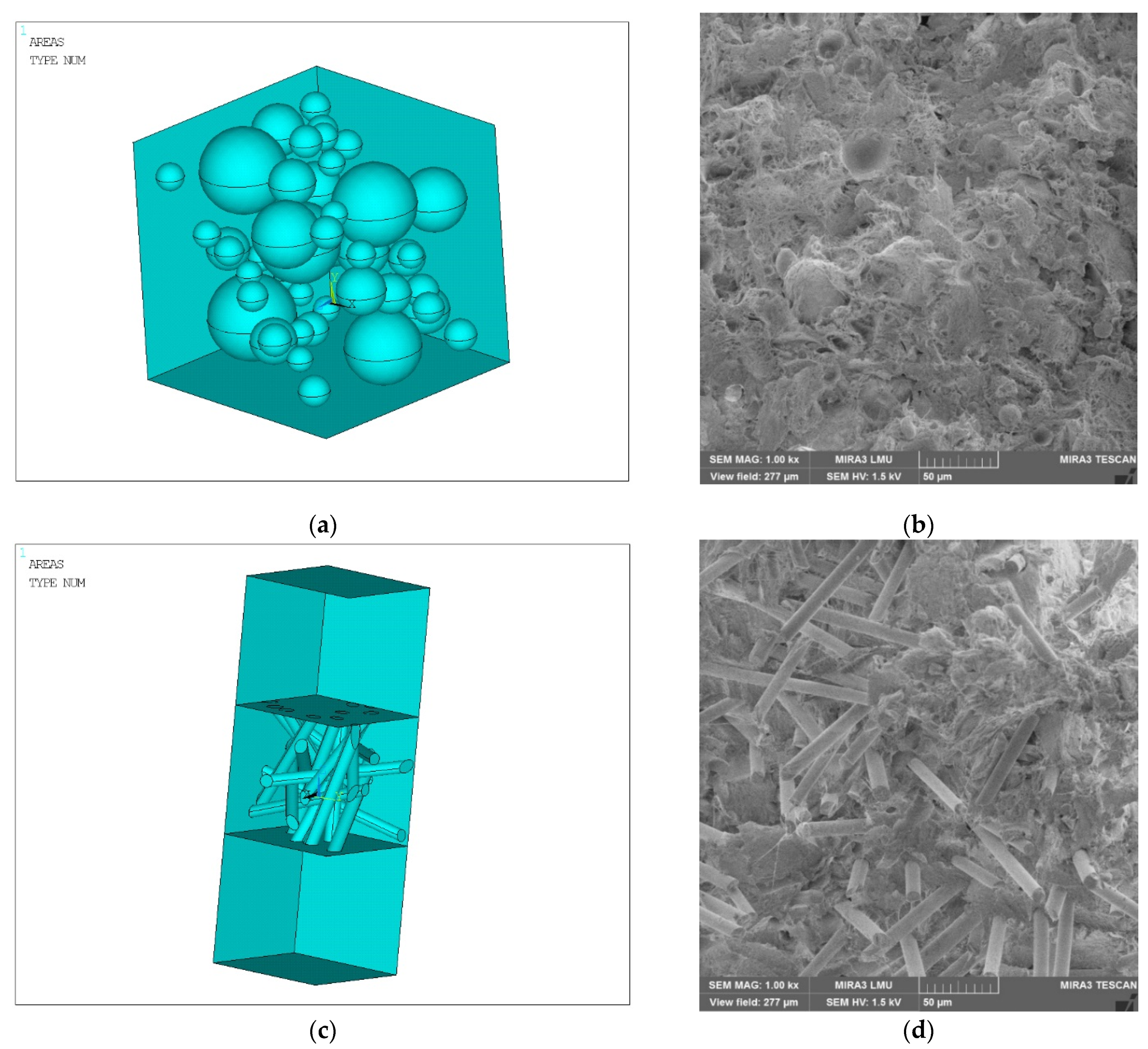

3.1. Construction of a Solid Model of a Composite Material

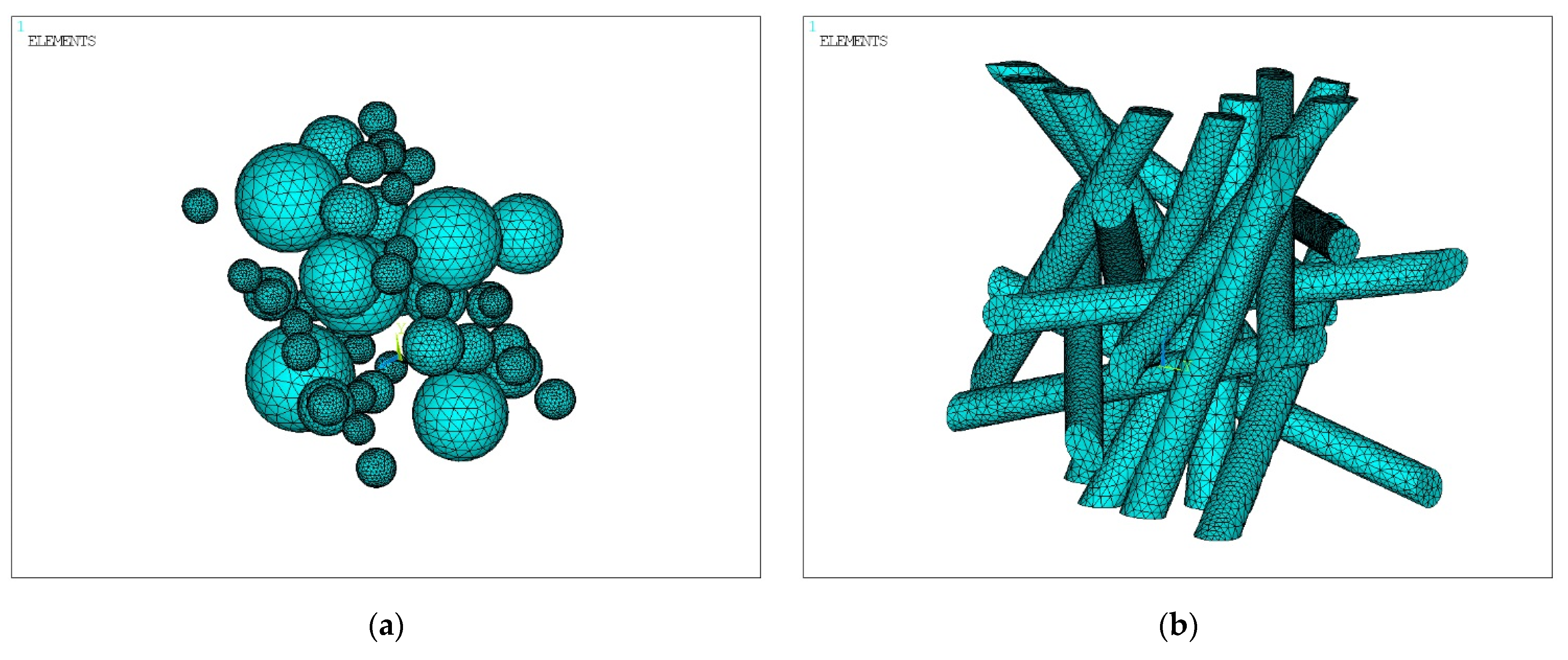

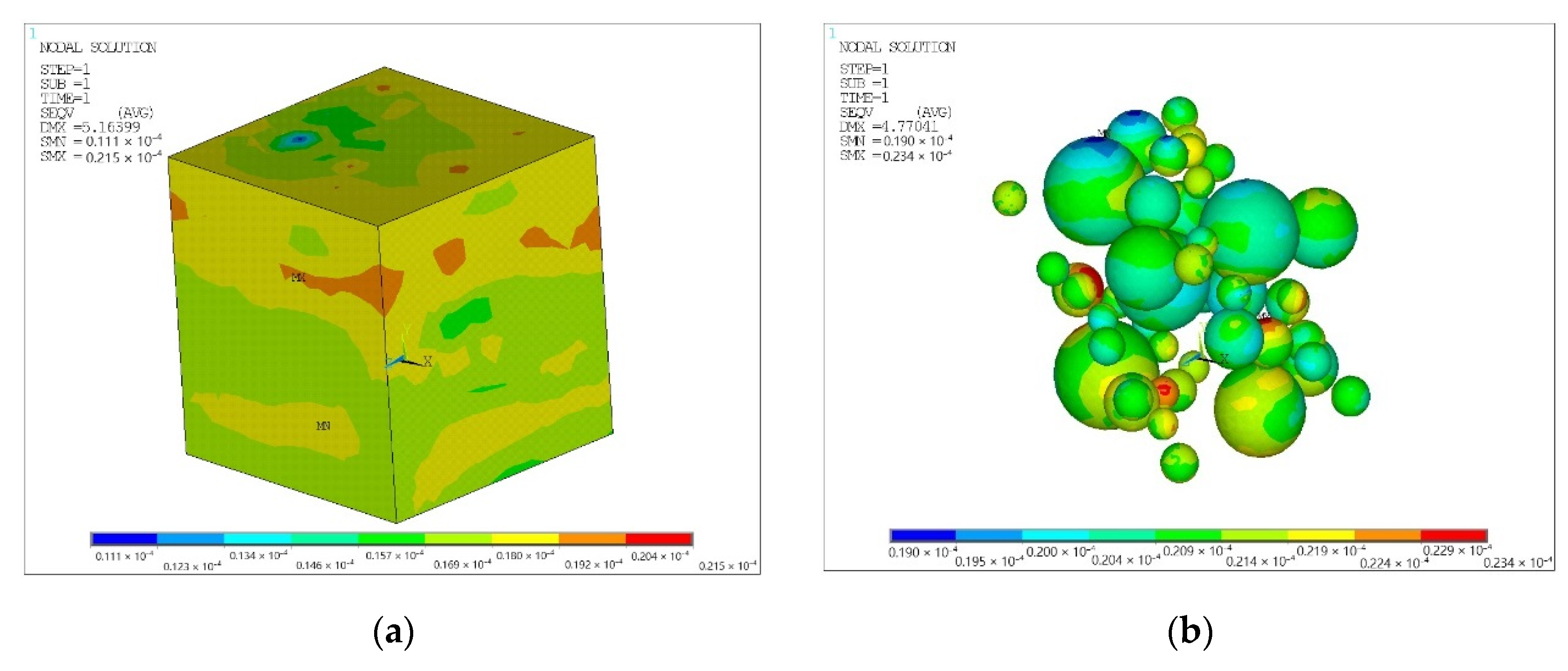

3.1.1. Modeling of Spherical Filler

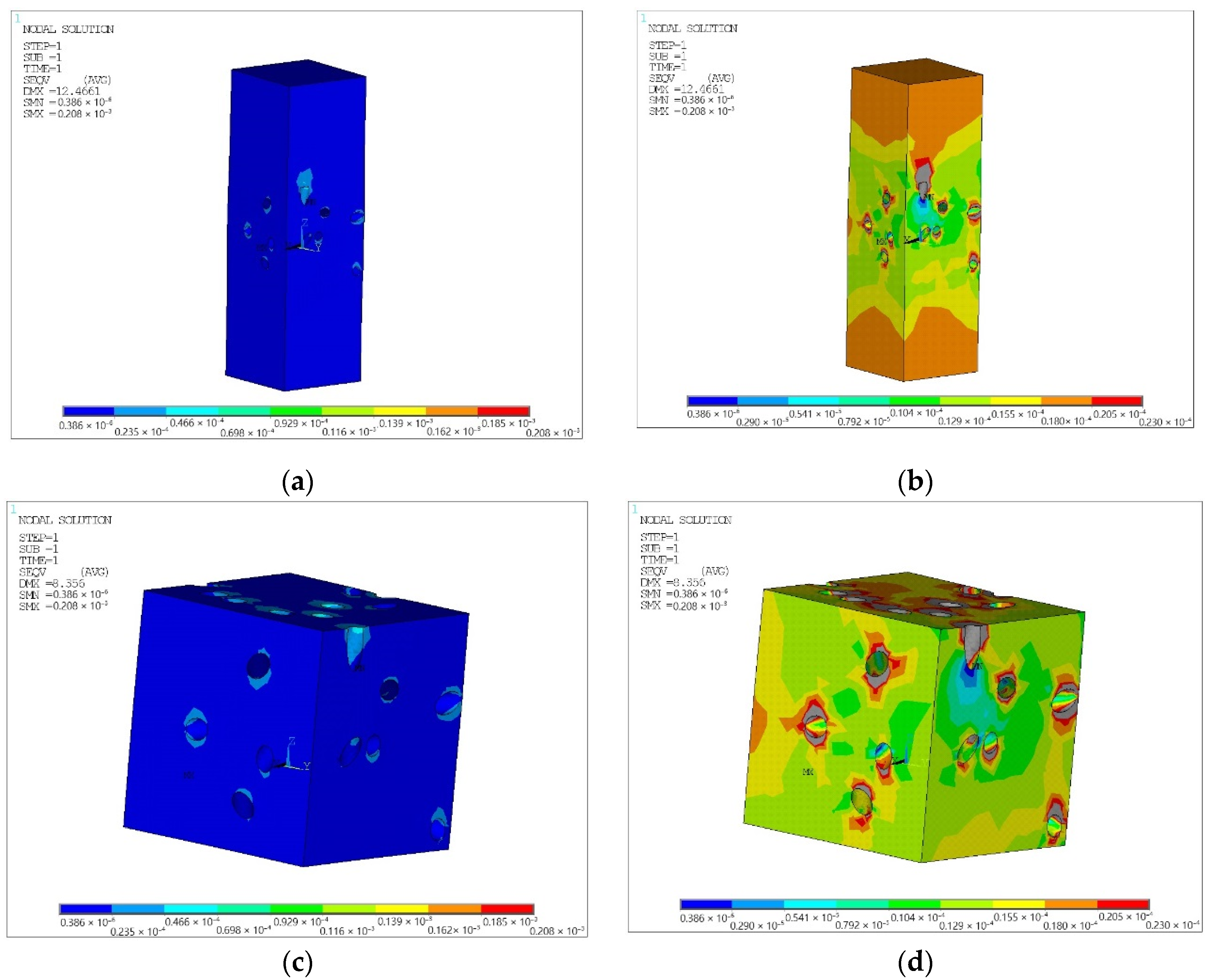

3.1.2. Modeling of Cylindrical Filler

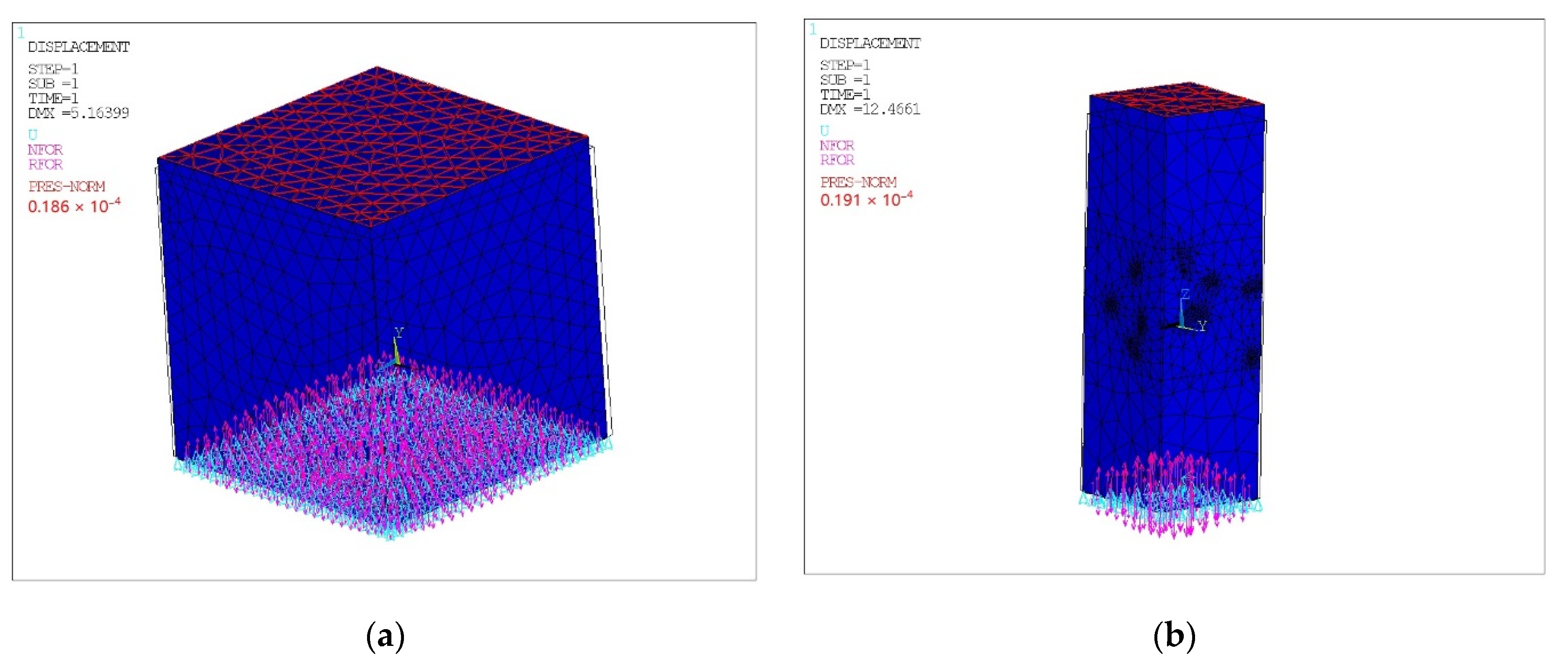

3.2. Construction of a Finite Element Model of Composite Material

4. Results and Discussion

4.1. Experimental Results

4.1.1. Influence of Coke Concentration on Properties of PTFE PCMs

4.1.2. Influence of CF Concentration on Properties of PTFE PCMs

4.1.3. Influence of Mechanical Activation of PTFE Matrix and Fillers on Properties of PCMs

- when filling 15 wt.% CF, breaking strength increases by 9.5% and 18.6%, relative elongation at break is increased by 6.2% and 28%, and wear intensity reduces by 5.4 times and 6.4 times compared to inactivated CF and inactivated PTFE, respectively;

- when filling 20 wt.% coke, breaking strength increases by 8.1% and 16.3%, relative elongation at break is increased by 4.5% and 15%, and wear intensity reduces by 1.4 times and 1.7 times compared to inactivated coke and inactivated PTFE, respectively

4.2. Model Simulation Results

4.3. Discussion

- From the point of view of the accuracy of determining the stress–strain state, it is necessary to consider the boundary conditions applied to the cut surface of the filler:

- under the boundary conditions formulated in stresses, anomalous displacement in proportion to the stiffness will be inappropriate for the experiment;

- when formulating the kinematic boundary conditions, the stress state will behave as a classical stress concentrator—local stress perturbation.

- From the point of view of accuracy in determining the kinetics of material destruction, common nodes of elements on the boundary line with the matrix of the dissected surface of the filler may have mixed boundary conditions, which can lead to errors in numerical solution (artifacts).

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Oladele, I.O.; Omotosho, T.F.; Adediran, A.A. Polymer-Based Composites: An Indispensable Material for Present and Future Applications. Int. J. Polym. Sci. 2020, 2020, 8834518. [Google Scholar] [CrossRef]

- Shah, S.Z.H.; Choudhry, R.S.; Mahadzir, S. A new approach for strength and stiffness prediction of discontinuous fibre reinforced composites (DFC). Compos. Part B Eng. 2020, 183, 107676. [Google Scholar] [CrossRef]

- Baran, I.; Cinar, K.; Ersoy, N.; Akkerman, R.; Hattel, J.H. A Review on the Mechanical Modeling of Composite Manufacturing Processes. Arch Comput. Methods Eng. 2017, 24, 365–395. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rajak, D.K.; Pagar, D.D.; Kumar, R.; Pruncu, C.I. Recent progress of reinforcement materials: A comprehensive overview of composite materials. J. Mater. Res. Technol. 2019, 8, 6354–6374. [Google Scholar] [CrossRef]

- Kolosov, A.E.; Sivetskii, V.I.; Kolosova, E.P.; Vanin, V.V.; Gondlyakh, A.V.; Sidorov, D.E.; Ivitskiy, I.I. Creation of Structural Polymer Composite Materials for Functional Application Using Physicochemical Modification. Adv. Polym. Technol. 2019, 2019, 3501456. [Google Scholar] [CrossRef]

- Melnyk, L.; Svidersky, V.; Chernyak, L.; Dorogan, N. Aspects of making of a composite material when using red mud. East.-Eur. J. Enterp. Technol. 2018, 2, 23–28. [Google Scholar] [CrossRef] [Green Version]

- Puts, G.J.; Crouse, P.; Ameduri, B.M. Polytetrafluoroethylene: Synthesis and Characterization of the Original Extreme Polymer. Chem. Rev. 2019, 119, 1763–1805. [Google Scholar] [CrossRef]

- Wang, H.; Sun, A.; Qi, X.; Dong, Y.; Fan, B. Experimental and Analytical Investigations on Tribological Properties of PTFE/AP Composites. Polymers 2021, 13, 4295. [Google Scholar] [CrossRef]

- Friedrich, K. Polymer composites for tribological applications. Adv. Ind. Eng. Polym. Res. 2018, 1, 3–39. [Google Scholar] [CrossRef]

- Dhanumalayan, E.; Joshi, G.M. Performance properties and applications of polytetrafluoroethylene (PTFE)—A review. Adv. Compos. Hybrid Mater. 2018, 1, 247–268. [Google Scholar] [CrossRef]

- Rae, P.; Brown, E. The properties of poly(tetrafluoroethylene) (PTFE) in tension. Polymer 2005, 46, 8128–8140. [Google Scholar] [CrossRef]

- Brownell, M.; Nair, A. Deformation mechanisms of polytetrafluoroethylene at the nano- and microscales. Phys. Chem. Chem. Phys. 2019, 21, 490–503. [Google Scholar] [CrossRef] [PubMed]

- Sampaio Valente, C.A.G.; Boutin, F.F.; Rocha, L.P.C.; do Vale, J.L.; da Silva, C.H. Effect of Graphite and Bronze Fillers on PTFE Tribological Behavior: A Commercial Materials Evaluation. Tribol. Trans. 2020, 63, 356–370. [Google Scholar] [CrossRef]

- Vasilev, A.P.; Struchkova, T.S.; Nikiforov, L.A.; Okhlopkova, A.A.; Grakovich, P.N.; Shim, E.L.; Cho, J.-H. Mechanical and Tribological Properties of Polytetrafluoroethylene Composites with Carbon Fiber and Layered Silicate Fillers. Molecules 2019, 24, 224. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Han, K.; Zhou, J.; Li, Q.; Shen, J.; Qi, Y.; Yao, X.; Chen, W. Effect of filler structure on the dielectric and thermal properties of SiO2/PTFE composites. J. Mater. Sci. Mater. Electron. 2020, 31, 9196–9202. [Google Scholar] [CrossRef]

- Zhang, F.; Zhang, J.; Zhu, Y.; Wang, X.; Jin, Y. Microstructure and Properties of Polytetrafluoroethylene Composites Modified by Carbon Materials and Aramid Fibers. Coatings 2020, 10, 1103. [Google Scholar] [CrossRef]

- Dykha, A.; Svidersky, V.; Danilenko, I.; Bilichenko, V.; Kukurudzyak, Y.; Kirichenko, L. Design and study of nanomodified composite fluoropolymer materials for tribotechnical purposes. East.-Eur. J. Enterp. Technol. 2020, 5, 38–48. [Google Scholar] [CrossRef]

- Mazur, K.; Gądek-Moszczak, A.; Liber-Kneć, A.; Kuciel, S. Mechanical Behavior and Morphological Study of Polytetrafluoroethylene (PTFE) Composites under Static and Cyclic Loading Condition. Materials 2021, 14, 1712. [Google Scholar] [CrossRef]

- Wang, Y.; Jiang, C.; Wang, Z. Effect of Sintering Factors on Properties of Al-Rich PTFE/Al/TiH2 Active Materials. Polymers 2021, 13, 1705. [Google Scholar] [CrossRef]

- Ma, L.; Liu, F.; Liu, D.; Liu, Y. Review of Strain Rate Effects of Fiber-Reinforced Polymer Composites. Polymers 2021, 13, 2839. [Google Scholar] [CrossRef]

- Wang, H.; Feng, X.; Shi, Y.; Lu, X. Effects of fibrous fillers on friction and wear properties of polytetrafluoroethylene composites under dry or wet conditions. China Particuol. 2007, 5, 414–419. [Google Scholar] [CrossRef]

- Woldemariam, M.H.; Belingardi, G.; Koricho, E.G.; Reda, D.T. Effects of nanomaterials and particles on mechanical properties and fracture toughness of composite materials: A short review. AIMS Mater. Sci. 2019, 6, 1191–1212. [Google Scholar] [CrossRef]

- Panin, S.V.; Nguyen, D.A.; Buslovich, D.G.; Alexenko, V.O.; Pervikov, A.V.; Kornienko, L.A.; Berto, F. Effect of Various Type of Nanoparticles on Mechanical and Tribological Properties of Wear-Resistant PEEK + PTFE-Based Composites. Materials 2021, 14, 1113. [Google Scholar] [CrossRef] [PubMed]

- Yu, P.; Manalo, A.; Ferdous, W.; Abousnina, R.; Salih, C.; Heyer, T.; Schubel, P. Investigation on the physical, mechanical and microstructural properties of epoxy polymer matrix with crumb rubber and short fibres for composite railway sleepers. Constr. Build. Mater. 2021, 295, 123700. [Google Scholar] [CrossRef]

- Abousnina, R.; Alsalmi, H.I.; Manalo, A.; Allister, R.L.; Alajarmeh, O.; Ferdous, W.; Jlassi, K. Effect of Short Fibres in the Mechanical Properties of Geopolymer Mortar Containing Oil-Contaminated Sand. Polymers 2021, 13, 3008. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef] [Green Version]

- Yao, S.S.; Jin, F.L.; Rhee, K.Y.; Hui, D.; Park, S.J. Recent advances in carbon-fiber-reinforced thermoplastic composites: A review. Compos. B Eng. 2018, 142, 241–250. [Google Scholar] [CrossRef]

- Li, J.; Ran, Y. Evaluation of the friction and wear properties of PTFE composites filled with glass and carbon fiber. Mater. Werkst. 2010, 41, 115–118. [Google Scholar] [CrossRef]

- Oshima, A.; Udagawa, A.; Tanaka, S. Fabrication of polytetrafluoroethylene/carbon fiber composites using radiation crosslinking. Radiat. Phys. Chem. 2001, 62, 77–81. [Google Scholar] [CrossRef]

- Struchkova, T.S.; Vasilev, A.P.; Okhlopkova, A.A.; Danilova, S.N.; Alekseev, A.G. Mechanical and Tribological Properties of Polytetrafluoroethylene Composites Modified by Carbon Fibers and Zeolite. Lubricants 2022, 10, 4. [Google Scholar] [CrossRef]

- Lee, J.-Y.; Lim, D.-P.; Lim, D.-S. Tribological behavior of PTFE nanocomposite films reinforced with carbon nanoparticles. Compos. Part B Eng. 2007, 38, 810–816. [Google Scholar] [CrossRef]

- Vasilev, A.P.; Struchkova, T.S.; Alekseev, A.G. Development of Antifriction Materials Based on Polytetrafluoroethylene with Carbon Fibers and Tungsten Disulfide. Mater. Sci. Forum 2020, 992, 745–750. [Google Scholar] [CrossRef]

- Ye, S.; Zeng, X. Tribological properties of PTFE and PTFE composites at different temperatures. Tribol. Trans. 2014, 57, 382–386. [Google Scholar] [CrossRef]

- Markova, M.A.; Petrova, P.N. Influence of Carbon Fibers and Composite Technologies on the Properties of PCM Based on Polytetrafluoroethylene. Inorg. Mater. Appl. Res. 2021, 12, 551–557. [Google Scholar] [CrossRef]

- Zhang, K.; Ji, X.; Mi, Y.; Gao, L.; Wang, T. Effects of carbon fibers with different particle sizes on the physical properties of MoS2-filled PTFE composites. Philos. Mag. Lett. 2021, 101, 277–286. [Google Scholar] [CrossRef]

- Jin, Z.; Chen, X.; Wang, Y.; Wang, D. Thermal conductivity of PTFE composites filled with graphite particles and carbon fibers. Comput. Mater. Sci. 2015, 102, 45–50. [Google Scholar] [CrossRef]

- Tevruz, T. Tribological behaviours of bronze-filled polytetrafluoroethylene dry journal bearings. Wear 1999, 230, 61–69. [Google Scholar] [CrossRef]

- Yevtushenko, A.; Grzes, P.; Ilyushenko, A.; Liashok, A. An Effect of a Carbon-Containing Additive in the Structure of a Friction Material on Temperature of the Wet Clutch Disc. Materials 2022, 15, 464. [Google Scholar] [CrossRef]

- Chan, J.X.; Wong, J.F.; Petrů, M.; Hassan, A.; Nirmal, U.; Othman, N.; Ilyas, R.A. Effect of Nanofillers on Tribological Properties of Polymer Nanocomposites: A Review on Recent Development. Polymers 2021, 13, 2867. [Google Scholar] [CrossRef]

- Aglan, H.; Gan, Y.; El-Hadik, M.; Faughnan, P.; Bryan, C. Evaluation of the fatigue fracture resistance of unfilled and filled polytetrafluoroethylene materials. J. Mater. Sci. 1999, 34, 83–97. [Google Scholar] [CrossRef]

- Sydow, Z.; Sydow, M.; Wojciechowski, Ł.; Bieńczak, K. Tribological Performance of Composites Reinforced with the Agricultural, Industrial and Post-Consumer Wastes: A Review. Materials 2021, 14, 1863. [Google Scholar] [CrossRef] [PubMed]

- Avdeychik, S.; Voropaev, V.; Auchynnikau, Y.; Sarokin, V.; Struk, A. Energy-Saving Technology Obtaining of High Mechanical Engineering Fluorine Composites. In Proceedings of the 20th International Scientific Conference on Mechanika, Kaunas, Lithuania, 23–24 April 2015. [Google Scholar]

- Obvintsev, A.Y.; Serov, S.A.; Sadovskaya, N.V.; Khatipov, S.A.; Bouznik, V.M. Mechanism of the Effect of Gamma Irradiation on the Surface Properties of Polytetrafluoroethylene. J. Synch. Investig. 2018, 12, 988–993. [Google Scholar] [CrossRef]

- Mashkov, Y.K.; Ruban, A.S.; Rogachev, E.A.; Chemisenko, O.V. PTFE-nanocomposites structure and wear-resistance changing in various methods of structural modification. J. Phys. Conf. Ser. 2018, 944, 012078. [Google Scholar] [CrossRef]

- Ebnesajjad, S. Manufacturing and Properties of Polytetrafluoroethylene. In Plastics Design Library, Introduction to Fluoropolymers, 2nd ed.; Ebnesajjad, S., Ed.; William Andrew Publishing: Norwich, NY, USA, 2021; pp. 63–110. [Google Scholar] [CrossRef]

- Ren, L.; Wang, T.; Chen, Z.; Li, Y.; Qian, L. Self-Lubricating PEO–PTFE Composite Coating on Titanium. Metals 2019, 9, 170. [Google Scholar] [CrossRef] [Green Version]

- Amenta, F.; Bolelli, G.; De Lorenzis, S.; Bertarini, A.; Lusvarghi, L. Tribological Behavior of Reinforced PTFE Composites and Un-Reinforced Polyketone-Based Materials against Coated Steel. Lubricants 2022, 10, 5. [Google Scholar] [CrossRef]

- Jia, Z.; Yang, Y. Self-lubricating properties of PTFE/serpentine nanocomposite against steel at different loads and sliding velocities. Compos. Part B Eng. 2012, 43, 2072–2078. [Google Scholar] [CrossRef]

- Ponomarenko, A.T.; Tameev, A.R.; Shevchenko, V.G. Action of Mechanical Forces on Polymerization and Polymers. Polymers 2022, 14, 604. [Google Scholar] [CrossRef]

- Kharissova, O.V.; Kharisov, B.I.; Oliva, G.C.M.; Méndez, Y.P.; López, I. Greener synthesis of chemical compounds and materials. R. Soc. Open Sci. 2019, 6, 191378. [Google Scholar] [CrossRef] [Green Version]

- Sarokin, V.; Avdeychik, S.; Struk, V.; Antonov, A. Activation of components functional polymer materials according to energy technologies. In Proceedings of the 21th International Scientific Conference on Mechanika, Kaunas, Lithuania, 12–13 May 2016. [Google Scholar]

- Budnik, O.A.; Budnik, A.F.; Rudenko, P.V.; Sviderskiy, V.A.; Berladir, K.V. Influence of mechanical activation polytetrafluoroethylene matrix of tribotechnical composites at its structural and phase transformations and properties. Funct. Mater. 2015, 22, 499–506. [Google Scholar] [CrossRef] [Green Version]

- Joo, C.; Park, H.; Lim, J.; Cho, H.; Kim, J. Development of physical property prediction models for polypropylene composites with optimizing random forest hyperparameters. Int. J. Intell. Syst. 2021, 37, 3625–3653. [Google Scholar] [CrossRef]

- Prokhorova, I.A.; Bkkar, M. Prediction of Strength Properties of Elastic Polymeric Composite Materials Based on Polypropylene Woven Tapes. Fibre Chem. 2020, 52, 173–178. [Google Scholar] [CrossRef]

- Pathan, M.V.; Ponnusami, S.A.; Pathan, J.; Pitisongsawat, R.; Erice, B.; Petrinic, N.; Tagarielli, V.L. Predictions of the mechanical properties of unidirectional fibre composites by supervised machine learning. Sci. Rep. 2019, 9, 13964. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kosicka, E.; Krzyzak, A.; Dorobek, M.; Borowiec, M. Prediction of Selected Mechanical Properties of Polymer Composites with Alumina Modifiers. Materials 2022, 15, 882. [Google Scholar] [CrossRef] [PubMed]

- Karuppannan Gopalraj, S.; Kärki, T. A Finite Element Study to Investigate the Mechanical Behaviour of Unidirectional Recycled Carbon Fibre/Glass Fibre−Reinforced Epoxy Composites. Polymers 2021, 13, 3192. [Google Scholar] [CrossRef] [PubMed]

- Berladir, K.V.; Hovorun, T.P.; Bilous, O.A.; Baranova, S.V. The modeling of the composition and properties of functional materials based on polytetrafluoroethylene. Funct. Mater. 2018, 25, 342–347. [Google Scholar] [CrossRef] [Green Version]

- Ge, C.; Dong, Y.; Maimaitituersun, W. Microscale Simulation on Mechanical Properties of Al/PTFE Composite Based on Real Microstructures. Materials 2016, 9, 590. [Google Scholar] [CrossRef] [Green Version]

- Islam, M.; Tudryn, G.J.; Picu, C.R. Microstructure modeling of random composites with cylindrical inclusions having high volume fraction and broad aspect ratio distribution. Comput. Mater. Sci. 2016, 125, 309–318. [Google Scholar] [CrossRef] [Green Version]

- Mortazavi, B.; Baniassadi, M.; Bardon, J.; Ahzi, S. Modeling of two-phase random composite materials by finite element, Mori–Tanaka and strong contrast methods. Compos. Part B Eng. 2013, 45, 1117–1125. [Google Scholar] [CrossRef]

- Muhlestein, M.B.; Haberman, M.R. A micromechanical approach for homogenization of elastic metamaterials with dynamic microstructure. Proc. R. Soc. A 2016, 472, 20160438. [Google Scholar] [CrossRef]

- Galindo-Torres, S.A.; Scheuermann, A.; Mühlhaus, H.B.; Williams, D.J. A micro-mechanical approach for the study of contact erosion. Acta Geotech. 2015, 10, 357–368. [Google Scholar] [CrossRef]

| Parameter | PTFE | CF | Coke |

|---|---|---|---|

| Size, μm | 50–500 | d = 10–12; l = 100–150 | 10–50 |

| Density, kg/m3 | 2200 | 1510 | 1730 |

| Tensile strength, MPa | 23 | 520–600 | 15–25 |

| Compressive strength, MPa | 11.8 | 500–550 | 9.8–19.6 |

| Modulus of elasticity, MPa | 410 | 27–47 | 500 |

| Poisson’s ratio | 685.5 | 0.10–0.30 | 0.30 |

| Concentration of Coke (wt.%) | Density ρ, kg/m3 | Breaking Strength σb, MPa | Relative Elongation at Break δ, % | Wear Intensity I × 10−6, mm3/N·m |

|---|---|---|---|---|

| 95:5 | 2130/2145 * | 18.9/19.5 * | 145/150 * | 67.5/63.0 * |

| 90:10 | 2115/2125 * | 17.6/18.1 * | 132/142 * | 63.5/60.0 * |

| 85:15 | 2105/2115 * | 16.9/17.7 * | 115/118 * | 56.5/53.5 * |

| 80:20 | 2090/2100 * | 16.0/17.2 * | 100/110 * | 47.5/40.0 * |

| Concentration of CF (wt.%) | Density ρ, kg/m3 | Breaking Strength σb, MPa | Relative Elongation at Break δ, % | Wear Intensity I × 10−6, mm3/N·m |

|---|---|---|---|---|

| 90:10 | 2010/2020 * | 17.5/17.9 * | 90/98 * | 42.5/36.0 * |

| 85:15 | 1980/1990 * | 20.4/22.1 * | 120/145 * | 32.0/27.0 * |

| 80:20 | 1960/1980 * | 18.3/19.1 * | 105/115 * | 35.0/29.5 * |

| 75:25 | 1950/1960 * | 16.9/18.4 * | 115/125 * | 29.0/24.5 * |

| Composition of PCM (wt.%) | Density ρ, kg/m3 | Breaking Strength σb, MPa | Relative Elongation at Break δ, % | Wear Intensity I × 10−6, mm3/N·m |

|---|---|---|---|---|

| 80 PTFE:15 CF | 1980/1990 * | 22.1/24.2 * | 145/154 * | 27.0/5.0 * |

| 80 PTFE:20 coke | 2100/2110 * | 17.2/18.6 * | 110/115 * | 40.0/28.0 * |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Berladir, K.; Zhyhylii, D.; Gaponova, O.; Krmela, J.; Krmelová, V.; Artyukhov, A. Modeling of Polymer Composite Materials Chaotically Reinforced with Spherical and Cylindrical Inclusions. Polymers 2022, 14, 2087. https://doi.org/10.3390/polym14102087

Berladir K, Zhyhylii D, Gaponova O, Krmela J, Krmelová V, Artyukhov A. Modeling of Polymer Composite Materials Chaotically Reinforced with Spherical and Cylindrical Inclusions. Polymers. 2022; 14(10):2087. https://doi.org/10.3390/polym14102087

Chicago/Turabian StyleBerladir, Kristina, Dmytro Zhyhylii, Oksana Gaponova, Jan Krmela, Vladimíra Krmelová, and Artem Artyukhov. 2022. "Modeling of Polymer Composite Materials Chaotically Reinforced with Spherical and Cylindrical Inclusions" Polymers 14, no. 10: 2087. https://doi.org/10.3390/polym14102087

APA StyleBerladir, K., Zhyhylii, D., Gaponova, O., Krmela, J., Krmelová, V., & Artyukhov, A. (2022). Modeling of Polymer Composite Materials Chaotically Reinforced with Spherical and Cylindrical Inclusions. Polymers, 14(10), 2087. https://doi.org/10.3390/polym14102087