Structure and Dielectric Properties of TPU Composite Filled with CNTs@PDA Nanofibers and MXene Nanosheets

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

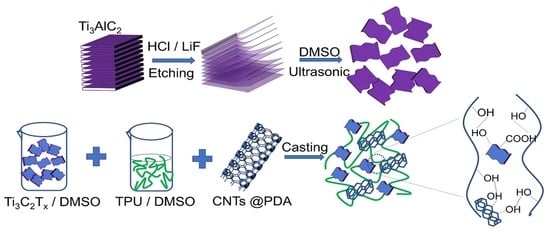

2.2. The Preparation of Sample

2.2.1. The Preparation of Ti3C2Tx (MXene)

2.2.2. Modification of CNT Nanofibers

2.2.3. The Preparation of TPU Solution

2.2.4. The Preparation of MXene/CNTs@PDA/TPU Composite

2.3. Characterization

3. Results and Discussion

3.1. The Characterization of MAX and MXene

3.2. The Modification of CNTs

3.3. Micro-Morphology of TPU Composites

3.4. The Mechanical Properties of Dielectric Composites

3.5. The Dielectric Properties of TPU Composites with MXene/CNTs or MXene/CNTs@PDA

3.6. The Interface between Filler Particles and TPU Matrix

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Pelrine, R.; Pei, Q.; Kornbluh, R. Dielectric elastomers: Past, present, and potential future. In Proceedings of the SPIE Smart Structures and Materials + Nondestructive Evaluation and Health Monitoring, Denver, CO, USA, 4–8 March 2018; Volume 10594. [Google Scholar] [CrossRef]

- Zhang, Q.M.; Li, H.; Poh, M.; Xia, F.; Cheng, Z.Y.; Xu, H.; Huang, C. An all-organic composite actuator material with a high dielectric constant. Nature 2002, 419, 284–287. [Google Scholar] [CrossRef]

- Rus, D.; Tolley, M.T. Design, fabrication and control of soft robots. Nature 2015, 521, 467–475. [Google Scholar] [CrossRef] [Green Version]

- Li, G.; Chen, X.; Zhou, F.; Liang, Y.; Xiao, Y.; Cao, X.; Zhang, Z.; Zhang, M.; Wu, B.; Yin, S.; et al. Self-powered soft robot in the Mariana Trench. Nature 2021, 591, 66–71. [Google Scholar] [CrossRef]

- Li, F.; Xu, Z.; Hu, H.; Kong, Z.; Chen, C.; Tian, Y.; Zhang, W.; Bin Ying, W.; Zhang, R.; Zhu, J. A polyurethane integrating self-healing, anti-aging and controlled degradation for durable and eco-friendly E-skin. Chem. Eng. J. 2021, 410, 128363. [Google Scholar] [CrossRef]

- Chen, Y.; Zhao, H.; Mao, J.; Chirarattananon, P.; Helbling, E.F.; Hyun, N.-s.P.; Clarke, D.R.; Wood, R.J. Controlled flight of a microrobot powered by soft artificial muscles. Nature 2019, 575, 324–329. [Google Scholar] [CrossRef]

- Maziz, A.; Concas, A.; Khaldi, A.; Stålhand, J.; Persson, N.-K.; Jager, E.W.H. Knitting and weaving artificial muscles. Sci. Adv. 2017, 3, e1600327. [Google Scholar] [CrossRef] [Green Version]

- Acome, E.; Mitchell, S.K.; Morrissey, T.G.; Emmett, M.B.; Benjamin, C.; King, M.; Radakovitz, M.; Keplinger, C. Hydraulically amplified self-healing electrostatic actuators with muscle-like performance. Science 2018, 359, 61–65. [Google Scholar] [CrossRef] [Green Version]

- Perju, E.; Shova, S.; Opris, D.M. Electrically Driven Artificial Muscles Using Novel Polysiloxane Elastomers Modified with Nitroaniline Push–Pull Moieties. ACS Appl. Mater. Interfaces 2020, 12, 23432–23442. [Google Scholar] [CrossRef]

- Brochu, P.; Pei, Q. Advances in Dielectric Elastomers for Actuators and Artificial Muscles. Macromol. Rapid Commun. 2010, 31, 10–36. [Google Scholar] [CrossRef] [PubMed]

- Almanza, M.; Clavica, F.; Chavanne, J.; Moser, D.; Obrist, D.; Carrel, T.; Civet, Y.; Perriard, Y. Feasibility of a Dielectric Elastomer Augmented Aorta. Adv. Sci. 2021, 8, 2001974. [Google Scholar] [CrossRef]

- Pu, J.; Meng, Y.; Xie, Z.; Peng, Z.; Wu, J.; Shi, Y.; Plamthottam, R.; Yang, W.; Pei, Q. A unimorph nanocomposite dielectric elastomer for large out-of-plane actuation. Sci. Adv. 2022, 8, eabm6200. [Google Scholar] [CrossRef] [PubMed]

- Carpi, F.; Gallone, G.; Galantini, F.; De Rossi, D. Silicone–Poly(hexylthiophene) Blends as Elastomers with Enhanced Electromechanical Transduction Properties. Adv. Funct. Mater. 2008, 18, 235–241. [Google Scholar] [CrossRef]

- Liu, X.; Sun, H.; Liu, S.; Jiang, Y.; Yu, B.; Ning, N.; Tian, M.; Zhang, L. Mechanical, dielectric and actuated properties of carboxyl grafted silicone elastomer composites containing epoxy-functionalized TiO2 filler. Chem. Eng. J. 2020, 393, 124791. [Google Scholar] [CrossRef]

- Hu, W.; Ren, Z.; Li, J.; Askounis, E.; Xie, Z.; Pei, Q. New Dielectric Elastomers with Variable Moduli. Adv. Funct. Mater. 2015, 25, 4827–4836. [Google Scholar] [CrossRef]

- Chen, Z.; Xiao, Y.; Fang, J.; He, J.; Gao, Y.; Zhao, J.; Gao, X.; Luo, Y. Ultrasoft-yet-strong pentablock copolymer as dielectric elastomer highly responsive to low voltages. Chem. Eng. J. 2021, 405, 126634. [Google Scholar] [CrossRef]

- Risse, S.; Kussmaul, B.; Krüger, H.; Kofod, G. Synergistic Improvement of Actuation Properties with Compatibilized High Permittivity Filler. Adv. Funct. Mater. 2012, 22, 3958–3962. [Google Scholar] [CrossRef]

- Huang, J.; Wang, F.; Ma, L.; Zhang, Z.; Meng, E.; Zeng, C.; Zhang, H.; Guo, D. Vinylsilane-rich silicone filled by polydimethylsiloxane encapsulated carbon black particles for dielectric elastomer actuator with enhanced out-of-plane actuations. Chem. Eng. J. 2022, 428, 131354. [Google Scholar] [CrossRef]

- Byrne, M.T.; Gun’ko, Y.K. Recent Advances in Research on Carbon Nanotube–Polymer Composites. Adv. Mater. 2010, 22, 1672–1688. [Google Scholar] [CrossRef]

- Sahoo, N.G.; Rana, S.; Cho, J.W.; Li, L.; Chan, S.H. Polymer nanocomposites based on functionalized carbon nanotubes. Prog. Polym. Sci. 2010, 35, 837–867. [Google Scholar] [CrossRef]

- Schnorr, J.M.; Swager, T.M. Emerging Applications of Carbon Nanotubes. Chem. Mater. 2011, 23, 646–657. [Google Scholar] [CrossRef] [Green Version]

- Lee, H.; Dellatore, S.M.; Miller, W.M.; Messersmith, P.B. Mussel-Inspired Surface Chemistry for Multifunctional Coatings. Science 2007, 318, 426–430. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, G.S.; Yun, T.; Kim, H.; Kim, I.H.; Choi, J.; Lee, S.H.; Lee, H.J.; Hwang, H.S.; Kim, J.G.; Kim, D.-w.; et al. Mussel Inspired Highly Aligned Ti3C2Tx MXene Film with Synergistic Enhancement of Mechanical Strength and Ambient Stability. ACS Nano 2020, 14, 11722–11732. [Google Scholar] [CrossRef] [PubMed]

- Hui, X.; Ge, X.; Zhao, R.; Li, Z.; Yin, L. Interface Chemistry on MXene-Based Materials for Enhanced Energy Storage and Conversion Performance. Adv. Funct. Mater. 2020, 30, 2005190. [Google Scholar] [CrossRef]

- Naguib, M.; Mochalin, V.N.; Barsoum, M.W.; Gogotsi, Y. 25th Anniversary Article: MXenes: A New Family of Two-Dimensional Materials. Adv. Mater. 2014, 26, 992–1005. [Google Scholar] [CrossRef] [PubMed]

- Alhabeb, M.; Maleski, K.; Anasori, B.; Lelyukh, P.; Clark, L.; Sin, S.; Gogotsi, Y. Guidelines for Synthesis and Processing of Two-Dimensional Titanium Carbide (Ti3C2Tx MXene). Chem. Mater. 2017, 29, 7633–7644. [Google Scholar] [CrossRef]

- Ma, P.-C.; Siddiqui, N.A.; Marom, G.; Kim, J.-K. Dispersion and functionalization of carbon nanotubes for polymer-based nanocomposites: A review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1345–1367. [Google Scholar] [CrossRef]

| Specimens | Young’s Modulus (MPa) | β (MPa−1) | Dielectric Constant at 103 Hz | Dielectric Loss at 103 Hz | Conductivity (S/cm) | Eb (kV/mm) |

|---|---|---|---|---|---|---|

| TPU | 4.48 ± 0.06 | 1.5 | 6.7 | 0.047 | 2.02 × 10−10 | 14.18 |

| M1/TPU | 2.21 ± 0.03 | 3.18 | 7.0 | 0.411 | 1.21 × 10−9 | 37.92 |

| C1/TPU | 2.59 ± 0.02 | 4.86 | 12.6 | 0.441 | 3.56 × 10−9 | 66.67 |

| CA1/TPU | 4.45 ± 0.03 | 2.22 | 9.9 | 241.7 | 1.17 × 10−6 | 10.16 |

| M1/C1/TPU | 1.49 ± 0.03 | 15.32 | 22.8 | 0.476 | 6.97 × 10−9 | 2.44 |

| M1/CA1/TPU | 8.76 ± 0.05 | 1.02 | 9.0 | 0.086 | 4.94 × 10−10 | 21.09 |

| M2/TPU | 2.28 ± 0.05 | 3.43 | 7.8 | 0.240 | 1.85 × 10−9 | 67.21 |

| C2/TPU | 2.64 ± 0.04 | 9.23 | 24.4 | 1106.71 | 1.68 × 10−5 | 1.94 |

| CA2/TPU | 14.70 ± 0.06 | 1.21 | 17.8 | 1077.23 | 1.26 × 10−5 | 5.55 |

| M2/C2/TPU | 2.06 ± 0.05 | 12.67 | 26.1 | 0.463 | 7.75 × 10−9 | 0.397 |

| M2/CA2/TPU | 9.82 ± 0.08 | 1.08 | 10.6 | 0.382 | 2.60 × 10−9 | 5.04 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, Z.; Li, X.; Zhao, S.; Xu, L.; Liu, L. Structure and Dielectric Properties of TPU Composite Filled with CNTs@PDA Nanofibers and MXene Nanosheets. Polymers 2022, 14, 2157. https://doi.org/10.3390/polym14112157

Luo Z, Li X, Zhao S, Xu L, Liu L. Structure and Dielectric Properties of TPU Composite Filled with CNTs@PDA Nanofibers and MXene Nanosheets. Polymers. 2022; 14(11):2157. https://doi.org/10.3390/polym14112157

Chicago/Turabian StyleLuo, Zhaoxia, Xiaolin Li, Suhe Zhao, Lianghua Xu, and Li Liu. 2022. "Structure and Dielectric Properties of TPU Composite Filled with CNTs@PDA Nanofibers and MXene Nanosheets" Polymers 14, no. 11: 2157. https://doi.org/10.3390/polym14112157