Influence of Pre-Exposure on the Material Response of Epoxy-Based Volume Holographic Recording Material

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Holographic Exposure

2.3. Hologram Characterization

2.3.1. Real-Time Observation of Holographic Grating Growth

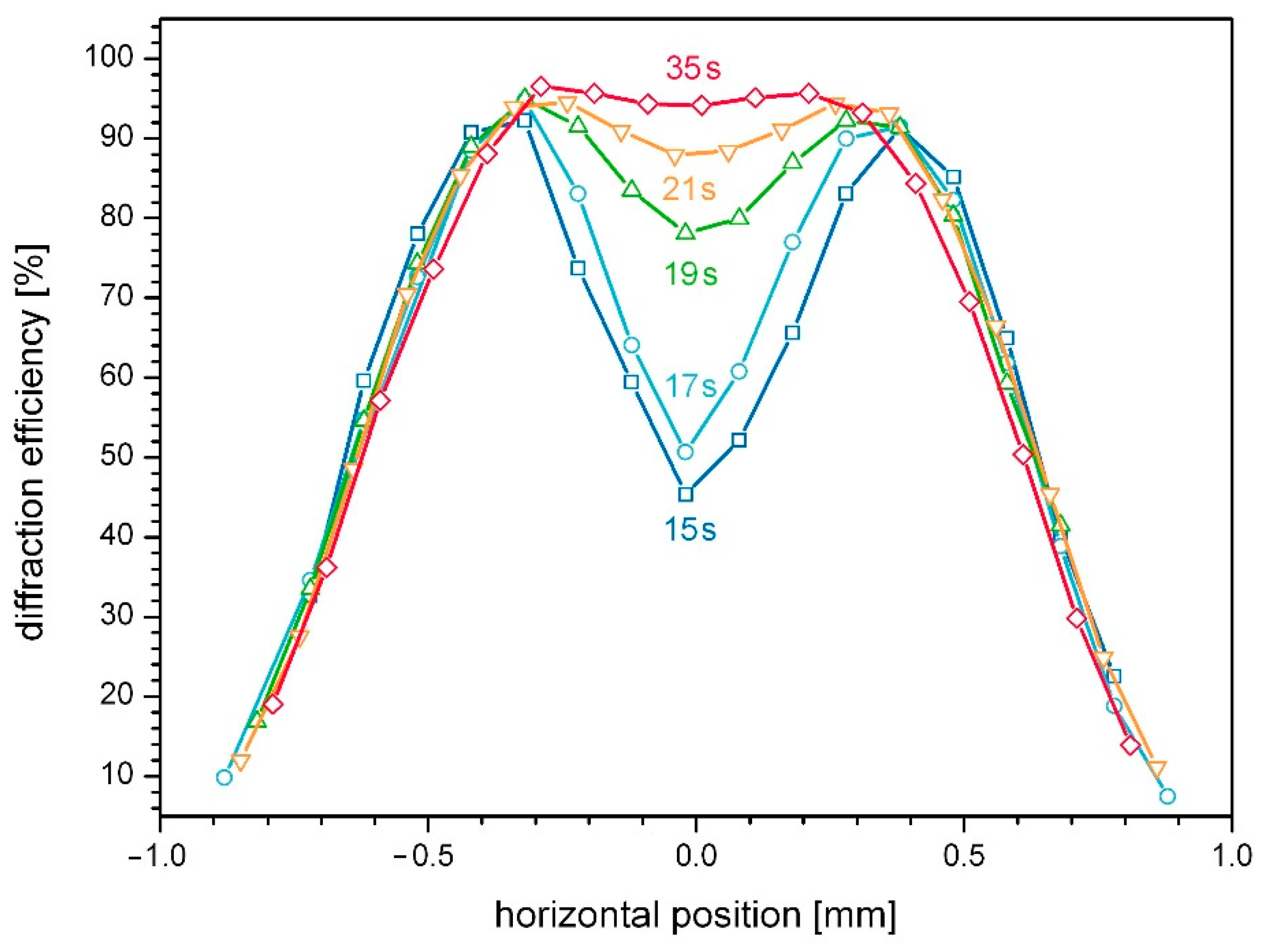

2.3.2. Angular-Resolved Analysis and Lateral Scanning

3. Results and Discussion

3.1. Real-Time Observation of Holographic Grating Growth

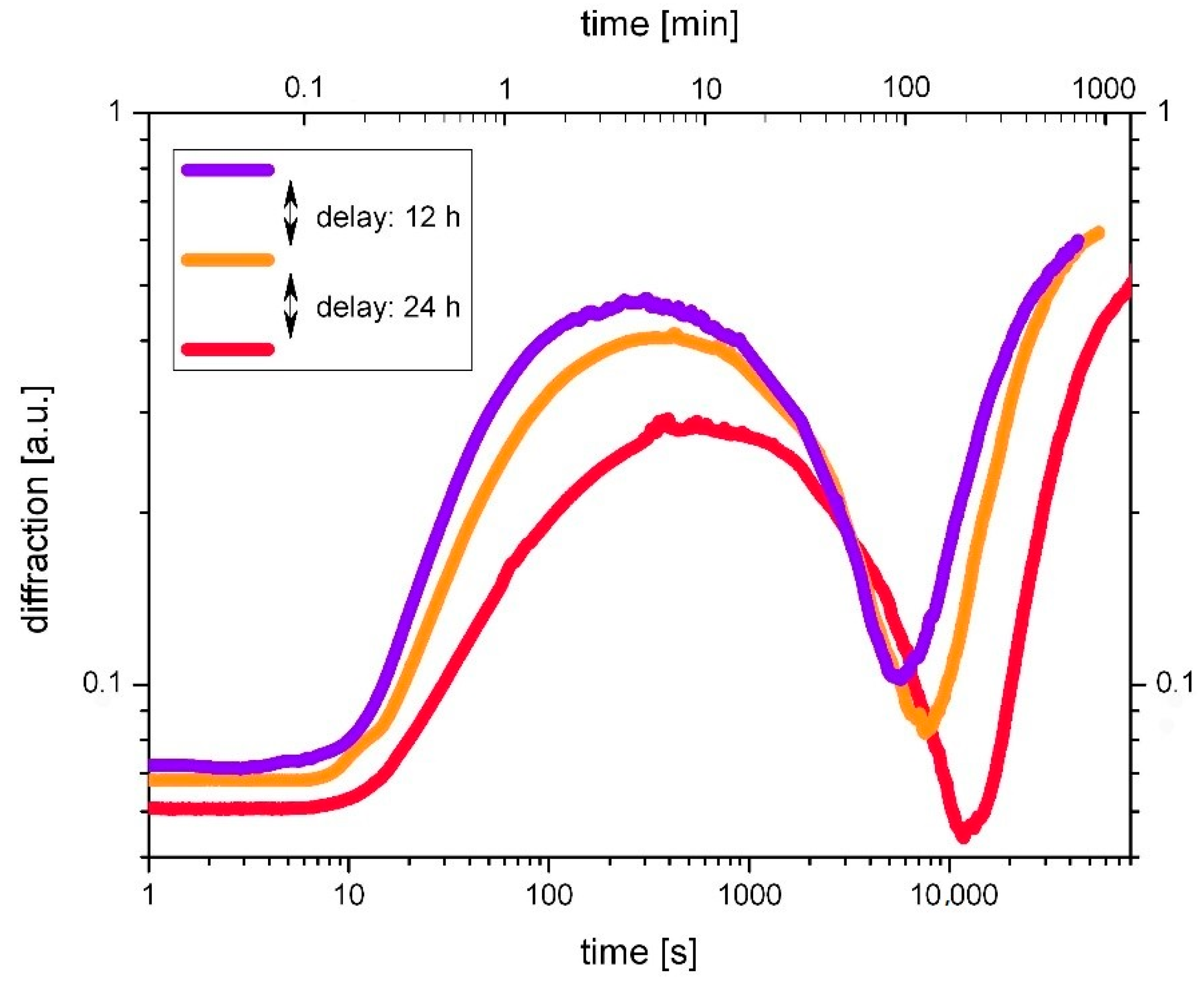

3.1.1. The Doped System

- (1)

- Lower rise of the first growth step, i.e., decrease of the parameter r+. The steepest rising positive-contrast-growth is achieved with the lowest pre-exposure dose. This effect can be traced back to the fact that photosensitive compounds are partially used up during exposure with the result of decreasing photosensitivity.

- (2)

- Retarded transition point tT. Meeting the expectations out of the Δn-transition theory, it is apparent from Figure 2 that from exposure to exposure, the transition point tT is located at later times, indicating slower diffusion. This fact is plausible under the conception of a certain loss in mobility of the matrix throughout prior cross-linking, thereby impeding particle movement.

- (3)

- Lower rise of the second growth step, i.e., decrease of the parameter r−: this can be apprehended as a consequence and co-action of the first two effects. As expected from the Δn-transition theory, the rise of the second growth is progressively reduced with increased pre-exposure dose.

- (4)

- Less incomplete null. The effect of an incomplete zero in the growth curve can be attributed to a non-zero average value of the diffraction efficiency due to significantly unequal transition times across the probe beam diameter, which could be the case if the polymerization and/or diffusion rates are intensity dependent. Here the influence of the pre-exposure is difficult to explain. Subsequently generated gratings show a less and less pronounced incomplete null.

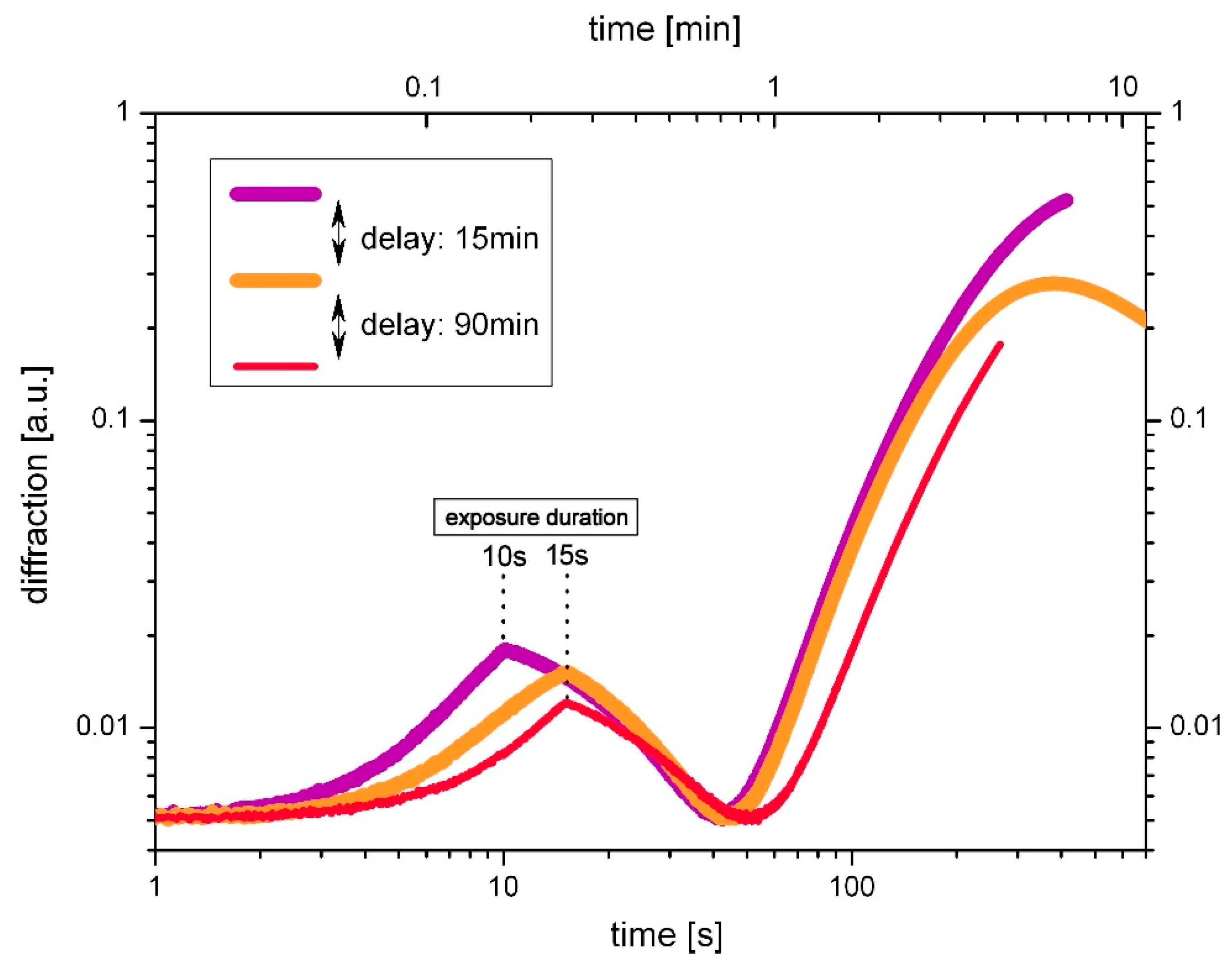

3.1.2. The Undoped System: SU-8

- (1)

- The initial growth of subsequent holograms rises slower, indicating a consumption of photoacid by previous exposures.

- (2)

- The depletion area is slightly shifted to later times.

- (3)

- The rise of the second growth step is decreasing with the number of pre-exposures. The two latter issues suggest deceleration of the cross-linking.

- (4)

- Finally, the saturation and decrease of diffraction starts earlier in a pre-exposed sample (apparent in view of the orange curve in Figure 3). This meets the expectations with respect to the reduction of the dynamic range as a result of photoacid consumption and exhaustion of non-cross-linked chains.

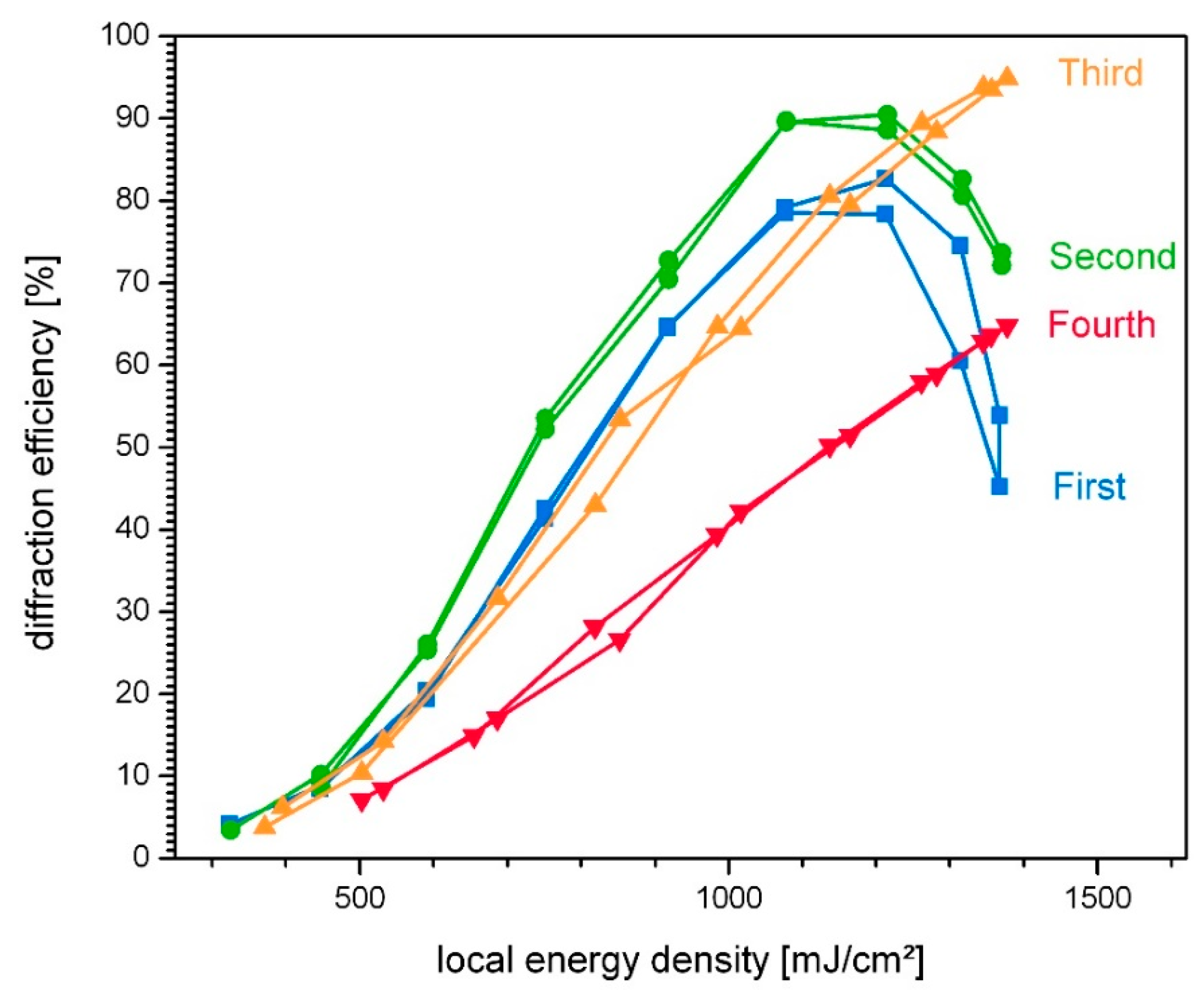

3.2. Analysis of Final Gratings

3.2.1. Impact of Pre-Exposure on the Intensity Response

3.2.2. Interplay of Pre-Exposure and Energy Density of Exposure

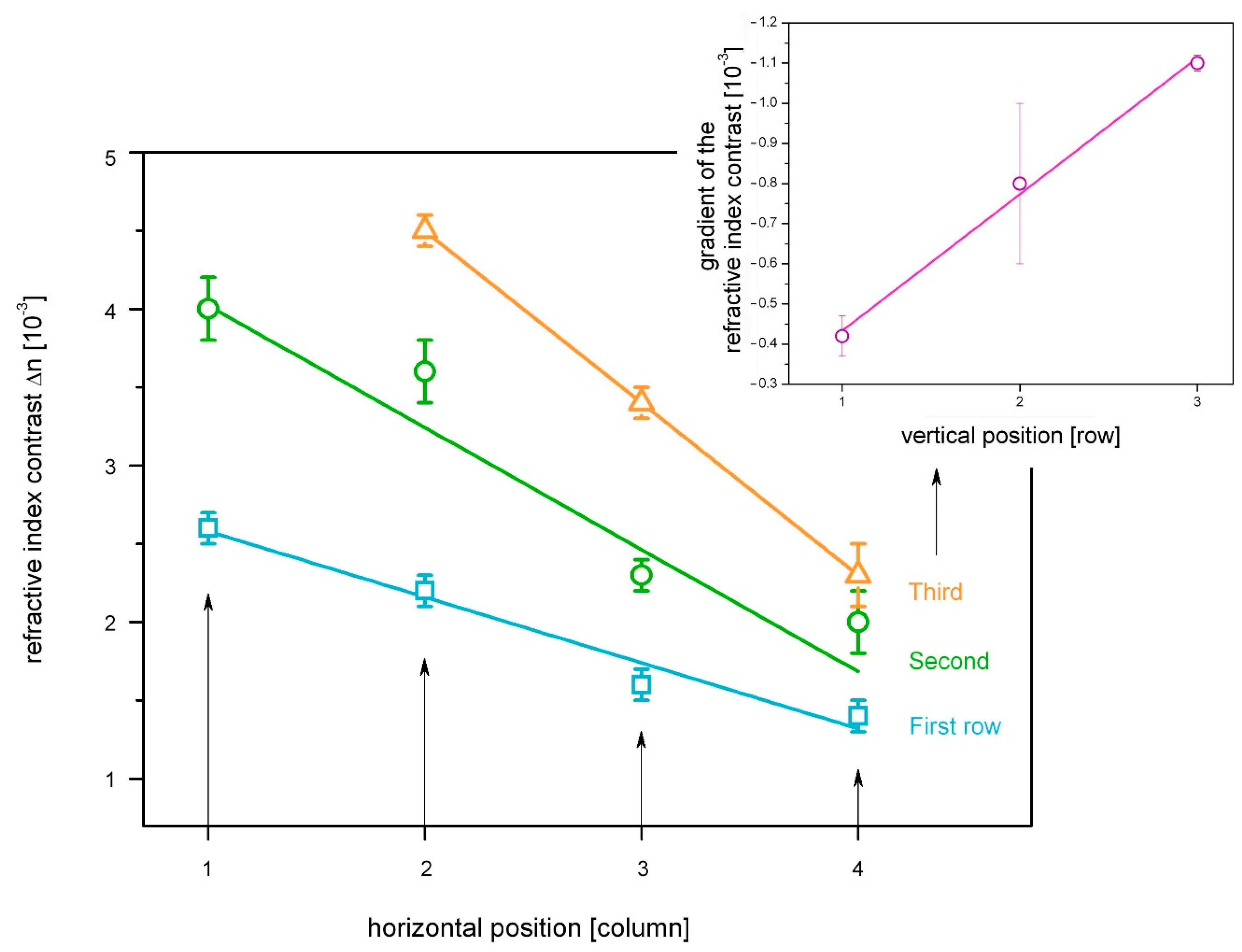

3.2.3. Impact of Pre-Exposure on the Refractive Index Contrast

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sheridan, J.T.; Kostuk, R.; Fimia, A.; Wang, Y. Roadmap on Holography. J. Opt. 2020, 22, 65. [Google Scholar] [CrossRef]

- Sabel, T.; Lensen, M.C. Volume Holography: Novel Materials, Methods and Applications. In Holographic Materials and Optical Systems; Naydenova, I., Babeva, T., Nazarova, D., Eds.; InTech: Rijeka, Croatia, 2017. [Google Scholar]

- Gallego, S.; Fernández, R.; Márquez, A.; Ortuño, M.; Neipp, C.; Gleeson, M.R.; Sheridan, J.T.; Beléndez, A. Two diffusion photopolymer for sharp diffractive optical elements recording. Opt. Lett. 2015, 40, 3221–3224. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Guo, J.; Gleeson, M.R.; Sheridan, J.T. A Review of the Optimisation of Photopolymer Materials for Holographic Data Storage. Phys. Res. Int. 2012, 2012, 803439. [Google Scholar] [CrossRef] [Green Version]

- Malallah, R.; Li, H.; Kelly, D.P.; Healy, J.J.; Sheridan, J.T. A Review of Hologram Storage and Self-Written Waveguides Formation in Photopolymer Media. Polymers 2017, 9, 337. [Google Scholar] [CrossRef]

- Naydenova, I.; Akbari, H.; Dalton, C.; Mohamed, M.Y.; Wei, C.P.T.; Toal, V.; Martin, S. Photopolymer Holographic Optical Elements for Application in Solar Energy Concentrators. In Holography—Basic Principles and Contemporary Applications; Mihaylova, E., Ed.; InTech: Rijeka, Croatia, 2013; pp. 129–145. [Google Scholar]

- Sabel-Grau, T.; Tyushina, A.; Babalik, C.; Lensen, M.C. UV-VIS Curable PEG Hydrogels for Biomedical Applications with Multifunctionality. Gels 2022, 8, 8. [Google Scholar] [CrossRef]

- Barachevsky, V.A. The Current Status of the Development of Light-Sensitive Media for Holography (a Review). Opt. Spectrosc. 2018, 124, 373–407. [Google Scholar] [CrossRef]

- Roy, D.; Cambre, J.N.; Sumerlin, B.S. Future perspectives and recent advances in stimuli-responsive materials. Prog. Polym. Sci. 2010, 35, 278–301. [Google Scholar] [CrossRef]

- Colburn, W.S.; Haines, K.A. Volume Hologram Formation in Photopolymer Materials. Appl. Opt. 1971, 10, 1636–1641. [Google Scholar] [CrossRef]

- Zhao, G.; Mouroulis, P. Diffusion Model of Hologram Formation in Dry Photopolymer Materials. J. Mod. Opt. 1994, 41, 1929–1939. [Google Scholar] [CrossRef]

- Sabel, T. Volume hologram formation in SU-8 photoresist. Polymers 2017, 9, 198. [Google Scholar] [CrossRef] [Green Version]

- Liu, S.; Gleeson, M.R.; Guo, J.; Sheridan, J.T. High Intensity Response of Photopolymer Materials for Holographic Grating Formation. Macromolecules 2010, 43, 9462–9472. [Google Scholar] [CrossRef]

- Sheridan, J.T.; Lawrence, J.R. Nonlocal-response diffusion model of holographic recording in photopolymer. J. Opt. Soc. Am. A 2000, 17, 1108–1114. [Google Scholar] [CrossRef] [PubMed]

- Fernández, R.; Gallego, S.; Márquez, A.; Neipp, C.; Calzado, E.M.; Francés, J.; Morales-Vidal, M.; Beléndez, A. Complex Diffractive Optical Elements Stored in Photopolymers. Polymers 2019, 11, 1920. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- McLeod, R.R. Numerical Technique for Study of Noise Grating Dynamics in Holographic Photopolymers. Polymers 2020, 12, 2744. [Google Scholar] [CrossRef]

- Sabel, T. Spatial Frequency Response of Epoxy-Based Volume Holographic Recording Material. Molecules 2019, 2, 1018. [Google Scholar] [CrossRef] [Green Version]

- Morales-Vidal, M.; Ramírez, M.; Sirvent, D.; Martínez Guardiola, F.; Álvarez, M.; Pascual, I. Efficient and stable holographic gratings stored in an environmentally friendly photopolymer. In Proceedings of the IV International Conference on Applications of Optics and Photonics, Lisbon, Portugal, 31 May–4 June 2019; p. 202. [Google Scholar]

- Bruder, F.-K.; Fäcke, T.; Hansen, S.; Manecke, C.; Rewitz, C.; Rölle, T.; Orselli, E.; Wewer, B. On the impact of incoherent pre-exposure on vHOE recording in Bayfol HX film for see-through applications. In Proceedings of the SPIE OPTO, 10558, Practical Holography XXXII: Displays, Materials, and Applications, San Francisco, CA, USA, 19 February 2018; p. 18. [Google Scholar]

- Sabel, T.; Orlic, S.; Pfeiffer, K.; Ostrzinski, U.; Grützner, G. Free-surface photopolymerizable recording material for volume holography. Opt. Mater. Express 2013, 3, 329–338. [Google Scholar] [CrossRef]

- Sabel, T.; Zschocher, M. Transition of refractive index contrast in course of grating growth. Sci. Rep. 2013, 3, 2552. [Google Scholar] [CrossRef]

- Hata, E.; Mitsube, K.; Momose, K.; Tomita, Y. Holographic nanoparticle-polymer composites based on step-growth thiol-ene photopolymerization. Opt. Mater. Express 2011, 1, 207–222. [Google Scholar] [CrossRef]

- Moharam, M.G.; Gaylord, T.K. Rigorous coupled-wave analysis of planar-grating diffraction. J. Opt. Soc. Am. 1981, 71, 811–818. [Google Scholar] [CrossRef]

- Steckman, G.; Havermeyer, F. High spatial resolution measurement of volume holographic gratings. Proc. SPIE Int. Soc. Opt. Eng. 2006, 6136, 613602. [Google Scholar]

- Sabel, T. Spatially resolved analysis of Bragg selectivity. Appl. Sci. 2015, 5, 1064–1075. [Google Scholar] [CrossRef]

- Veniaminov, A.; Bartsch, E.; Semenova, I.; Popov, A. Hologram Development by Diffusion in a Polymer Glass. In Proceedings of the SPIE 5216 Organic Holographic Materials and Applications, San Francisco, CA, USA, 8 December 2003; pp. 156–164. [Google Scholar]

- Sabel, T.; Zschocher, M. Dynamic Bragg Angle Shift in the Course of Volume Hologram Formation. Mater. Res. Lett. 2014, 2, 76–81. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sabel-Grau, T. Influence of Pre-Exposure on the Material Response of Epoxy-Based Volume Holographic Recording Material. Polymers 2022, 14, 2193. https://doi.org/10.3390/polym14112193

Sabel-Grau T. Influence of Pre-Exposure on the Material Response of Epoxy-Based Volume Holographic Recording Material. Polymers. 2022; 14(11):2193. https://doi.org/10.3390/polym14112193

Chicago/Turabian StyleSabel-Grau, Tina. 2022. "Influence of Pre-Exposure on the Material Response of Epoxy-Based Volume Holographic Recording Material" Polymers 14, no. 11: 2193. https://doi.org/10.3390/polym14112193

APA StyleSabel-Grau, T. (2022). Influence of Pre-Exposure on the Material Response of Epoxy-Based Volume Holographic Recording Material. Polymers, 14(11), 2193. https://doi.org/10.3390/polym14112193