Microporous Formation Mechanism of Biaxial Stretching PA6/PP Membranes with High Porosity and Uniform Pore Size Distribution

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Characterization and Testing

2.3.1. X-ray Diffraction (XRD)

2.3.2. Scanning Electron Microscope (SEM)

2.3.3. Two-Dimensional Wide-Angle X-ray Diffraction (2D-WAXD)

2.3.4. Atomic Force Microscopy (AFM)

2.3.5. Membrane Porosity and Pore Size Distribution

2.3.6. Tensile Strength and Puncture Strength

2.3.7. Light Microscopy Observation (OM)

3. Results and Discussion

3.1. Structure Characterization of Precursor Films

3.2. Micropore-Forming Process during Longitudinal Stretching

3.3. Micropore-Forming Process during Transverse Stretching

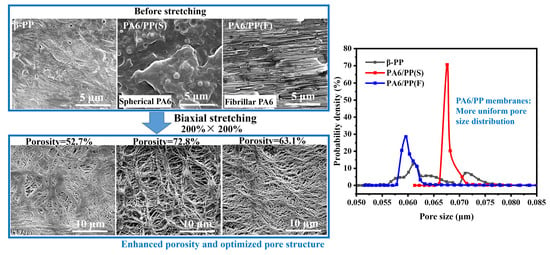

3.4. Structure and Performance Analysis of Biaxially Stretched Microporous Membranes (200% × 200%)

3.5. Micropore-Forming Mechanism of Biaxially Stretched Microporous Membranes

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xiong, B.; Chen, R.; Zeng, F.; Kang, J.; Men, Y. Thermal shrinkage and microscopic shutdown mechanism of polypropylene separator for lithium-ion battery: In-situ ultra-small angle X-ray scattering study. J. Membr. Sci. 2018, 545, 213–220. [Google Scholar] [CrossRef]

- Lin, Y.F.; Li, X.Y.; Meng, L.P.; Chen, X.W.; Lv, F.; Zhang, Q.L.; Zhang, R.; Li, L.B. Structural Evolution of Hard-Elastic Isotactic Polypropylene Film during Uniaxial Tensile Deformation: The Effect of Temperature. Macromolecules 2018, 51, 2690–2705. [Google Scholar] [CrossRef]

- Lei, C.; Xu, R.; Tian, Z.; Huang, H.; Xie, J.; Zhu, X. Stretching-Induced Uniform Micropores Formation: An in Situ SAXS/WAXS Study. Macromolecules 2018, 51, 3433–3442. [Google Scholar] [CrossRef]

- Deimede, V.; Elmasides, C. Separators for Lithium-Ion Batteries: A Review on the Production Processes and Recent Developments. Energy Technol. 2015, 3, 453–468. [Google Scholar] [CrossRef]

- Ding, L.; Xu, R.; Pu, L.; Yang, F.; Wu, T.; Xiang, M. Pore formation and evolution mechanism during biaxial stretching of β-iPP used for lithium-ion batteries separator. Mater. Des. 2019, 179, 107880. [Google Scholar] [CrossRef]

- Liao, H.; Hong, H.; Zhang, H.; Li, Z. Preparation of hydrophilic polyethylene/methylcellulose blend microporous membranes for separator of lithium-ion batteries. J. Membr. Sci. 2016, 498, 147–157. [Google Scholar] [CrossRef]

- Ihm, D.; Noh, J.; Kim, J. Effect of polymer blending and drawing conditions on properties of polyethylene separator prepared for Li-ion secondary battery. J. Power Sources 2002, 109, 388–393. [Google Scholar] [CrossRef]

- Deng, N.; Kang, W.; Liu, Y.; Ju, J.; Wu, D.; Li, L.; Hassan, B.S.; Cheng, B. A review on separators for lithium-sulfur battery: Progress and prospects. J. Power Sources 2016, 331, 132–155. [Google Scholar] [CrossRef]

- Xiang, Y.; Li, J.; Lei, J.; Liu, D.; Xie, Z.; Qu, D.; Li, K.; Deng, T.; Tang, H. Advanced Separators for Lithium-Ion and Lithium-Sulfur Batteries: A Review of Recent Progress. Chemsuschem 2016, 9, 3023–3039. [Google Scholar] [CrossRef]

- Lee, H.; Yanilmaz, M.; Toprakci, O.; Fu, K.; Zhang, X. A review of recent developments in membrane separators for rechargeable lithium-ion batteries. Energy Environ. Sci. 2014, 7, 3857–3886. [Google Scholar] [CrossRef]

- Ding, L.; Zhang, D.; Wu, T.; Yang, F.; Lan, F.; Cao, Y.; Xiang, M. Three-dimensional crystal structure evolution and micropore formation of β-iPP during biaxial stretching. Polymer 2020, 196, 122471. [Google Scholar] [CrossRef]

- Luo, D.; Wei, F.; Shao, H.; Xie, L.; Cui, Z.; Qin, S.; Yu, J. Microstructure construction of polypropylene-based hollow fiber membranes with bimodal microporous structure for water flux enhancement and rejection performance retention. Sep. Purif. Technol. 2019, 213, 328–338. [Google Scholar] [CrossRef]

- Wang, B.; Ji, J.; Chen, C.; Li, K. Porous membranes prepared by a combined crystallisation and diffusion (CCD) method: Study on formation mechanisms. J. Membr. Sci. 2018, 548, 136–148. [Google Scholar] [CrossRef]

- Yabuno, Y.; Mihara, K.; Miyagawa, N.; Komatsu, K.; Nakagawa, K.; Shintani, T.; Matsuyama, H.; Yoshioka, T. Preparation of polyamide–PVDF composite hollow fiber membranes with well-developed interconnected bicontinuous structure using high-temperature rapid NIPS for forward osmosis. J. Membr. Sci. 2020, 612, 118468. [Google Scholar] [CrossRef]

- Kurihara, H.; Kitade, S.; Ichino, K.; Akiba, I.; Sakurai, K. Elongation induced β- to α-crystalline transformation and microvoid formation in isotactic polypropylene as revealed by time-resolved WAXS/SAXS. Polym. J. 2019, 51, 199–209. [Google Scholar] [CrossRef]

- Chu, F.; Yamaoka, T.; Ide, H.; Kimura, Y. Microvoid formation process during the plastic deformation of β-form polypropylene. Polymer 1994, 35, 3442–3448. [Google Scholar] [CrossRef]

- Chu, F.; Yamaoka, T.; Kimura, Y. Crystal transformation and micropore formation during uniaxial drawing of β-form polypropylene film. Polymer 1995, 36, 2523–2530. [Google Scholar] [CrossRef]

- Yang, F.; Wu, T.; Xiang, M.; Cao, Y. Deformation and pore formation mechanism of β nucleated polypropylene with different supermolecular structures. Eur. Polym. J. 2017, 91, 134–148. [Google Scholar] [CrossRef]

- Wu, G.-G.; Xu, L.-Y.; Chen, W.-B.; Ding, C.; Liu, Z.-Y.; Yang, W.; Yang, M.-B. Oriented polypropylene cast films consisted of β-transcrystals induced by the nucleating agent self-assembly and its homogeneous membranes with high porosity. Polymer 2018, 151, 136–144. [Google Scholar] [CrossRef]

- Wu, G.-G.; Chen, W.-B.; Ding, C.; Xu, L.-Y.; Liu, Z.-Y.; Yang, W.; Yang, M.-B. Pore formation mechanism of oriented β polypropylene cast films during stretching and optimization of stretching methods: In-situ SAXS and WAXD studies. Polymer 2019, 163, 86–95. [Google Scholar] [CrossRef]

- Ding, L.; Ge, Q.; Xu, G.; Wu, T.; Yang, F.; Xiang, M. Influence of oriented β-lamellae on deformation and pore formation in β-nucleated polypropylene. J. Polym. Sci. Part B Polym. Phys. 2017, 55, 1745–1759. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhao, Y.; Fu, Q. Toward uniform pore-size distribution and high porosity of isotactic polypropylene microporous membrane by adding a small amount of ultrafine full-vulcanized powder rubber. Polymer 2016, 103, 405–414. [Google Scholar] [CrossRef]

- Chang, B.; Schneider, K.; Vogel, R.; Heinrich, G. Influence of nucleating agent self-assembly on structural evolution of isotactic polypropylene during uniaxial stretching. Polymer 2018, 138, 329–342. [Google Scholar] [CrossRef]

- Liang, G.; Fang, W.; Li, J.; Guo, S. Micropore formation and crystalline evolution during biaxial stretching process of iPP film constructed of ordered and continuous β-transcrystallinity. J. Membr. Sci. 2021, 636, 119558. [Google Scholar] [CrossRef]

- Chandavasu, C.; Xanthos, M.; Sirkar, K.K.; Gogos, C.G. Polypropylene blends with potential as materials for microporous membranes formed by melt processing. Polymer 2002, 43, 781–795. [Google Scholar] [CrossRef]

- Xanthos, M.; Chandavasu, C.; Sirkar, K.K.; Gogos, C.G. Melt processed microporous films from compatibilized immiscible blends with potential as membranes. Polym. Eng. Sci. 2002, 42, 810–825. [Google Scholar] [CrossRef]

- Chandavasu, C.; Xanthos, M.; Sirkar, K.K.; Gogos, C.G. Fabrication of microporous polymeric membranes by melt processing of immiscible blends. J. Membr. Sci. 2003, 211, 167–175. [Google Scholar] [CrossRef]

- Fang, W.; Liang, G.; Li, J.; Guo, S. Microporous formation and evolution mechanism of PTFE fibers/isotactic polypropylene membranes by interface separation. J. Membr. Sci. 2021, 631, 119333. [Google Scholar] [CrossRef]

- Samthong, C.; Seemork, J.; Nobukawa, S.; Yamaguchi, M.; Praserthdam, P.; Somwangthanaroj, A. Morphology, structure, and properties of poly(lactic acid) microporous films containing poly(butylene terephthalate) fine fibers fabricated by biaxial stretching. J. Appl. Polym. Sci. 2015, 132, 41415. [Google Scholar] [CrossRef]

- Feng, J.; Zhang, G.; MacInnis, K.; Olah, A.; Baer, E. Formation of microporous membranes by biaxial orientation of compatibilized PP/Nylon 6 blends. Polymer 2017, 123, 301–310. [Google Scholar] [CrossRef]

- Mural, P.K.S.; Madras, G.; Bose, S. Polymeric membranes derived from immiscible blends with hierarchical porous structures, tailored bio-interfaces and enhanced flux: Potential and key challenges. Nano-Struct. Nano-Objects 2018, 14, 149–165. [Google Scholar] [CrossRef]

- Luo, D.; Xie, G.; Qin, S. The hydrophilic polypropylene/poly(ethylene-co-vinyl alcohol) hollow fiber membrane with bimodal microporous structure prepared by melt-spinning and stretching. Sep. Purif. Technol. 2021, 274, 118890. [Google Scholar] [CrossRef]

- Kakroodi, A.R.; Kazemi, Y.; Ding, W.; Ameli, A.; Park, C.B. Poly(lactic acid)-Based in Situ Microfibrillar Composites with Enhanced Crystallization Kinetics, Mechanical Properties, Rheological Behavior, and Foaming Ability. Biomacromolecules 2015, 16, 3925–3935. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.; Yu, H.; Lei, F.; Li, J.; Guo, S.; Wu, H.; Shen, J.; Xiong, Y.; Chen, R. Formation Mechanism and Morphology of β-Transcrystallinity of Polypropylene Induced by Two-Dimensional Layered Interface. Macromolecules 2015, 48, 3965–3973. [Google Scholar] [CrossRef]

- Li, C.; Jiang, T.; Wang, J.; Wu, H.; Guo, S.; Zhang, X.; Li, J.; Shen, J.; Chen, R.; Xiong, Y. In Situ Formation of Microfibrillar Crystalline Superstructure: Achieving High-Performance Polylactide. Acs Appl. Mater. Interfaces 2017, 9, 25818–25829. [Google Scholar] [CrossRef] [PubMed]

- Zuo, J.-H.; Li, Z.-K.; Wei, C.; Yan, X.; Chen, Y.; Lang, W.-Z. Fine tuning the pore size and permeation performances of thermally induced phase separation (TIPS) -prepared PVDF membranes with saline water as quenching bath. J. Membr. Sci. 2019, 577, 79–90. [Google Scholar] [CrossRef]

- Sun, Y.; Yang, Z.; Li, L.; Wang, Z.; Sun, Q. Facile preparation of isotactic polypropylene microporous membranes with bioinspired hierarchical morphology for nano-scale water-in-oil emulsion separation. J. Membr. Sci. 2019, 581, 224–235. [Google Scholar] [CrossRef]

- Islam, M.A.; Ulbricht, M. Microfiltration membrane characterization by gas-liquid displacement porometry: Matching experimental pore number distribution with liquid permeability and bulk porosity. J. Membr. Sci. 2019, 569, 104–116. [Google Scholar] [CrossRef]

- Wang, M.; Huang, M.-L.; Cao, Y.; Ma, X.-H.; Xu, Z.-L. Fabrication, characterization and separation properties of three-channel stainless steel hollow fiber membrane. J. Membr. Sci. 2016, 515, 144–153. [Google Scholar] [CrossRef]

- Wang, J.; Liu, Y.; Liu, T.; Xu, X.; Hu, Y. Improving the perm-selectivity and anti-fouling property of UF membrane through the micro-phase separation of PSf-b-PEG block copolymers. J. Membr. Sci. 2020, 599, 117851. [Google Scholar] [CrossRef]

- Sun, G.; Liu, B.; Niu, H.; Hao, F.; Chen, N.; Zhang, M.; Tian, G.; Qi, S.; Wu, D. In situ welding: Superb strength, good wettability and fire resistance tri-layer separator with shutdown function for high-safety lithium ion battery. J. Membr. Sci. 2020, 595, 117509. [Google Scholar] [CrossRef]

- Zhang, C.L.; Li, C.; Wang, L.; Feng, L.F.; Lin, T. Dual effects of compatibilizer on the formation of oriented ribbon-like dispersed phase domains in polystyrene/polyamide 6 blends. Chem. Eng. Sci. 2018, 178, 146–156. [Google Scholar] [CrossRef]

- Li, L.; Li, W.; Geng, L.; Chen, B.; Mi, H.; Hong, K.; Peng, X.; Kuang, T. Formation of stretched fibrils and nanohybrid shish-kebabs in isotactic polypropylene-based nanocomposites by application of a dynamic oscillatory shear. Chem. Eng. J. 2018, 348, 546–556. [Google Scholar] [CrossRef]

- Xie, L.; Xu, H.; Niu, B.; Ji, X.; Chen, J.; Li, Z.-M.; Hsiao, B.S.; Zhong, G.-J. Unprecedented Access to Strong and Ductile Poly(lactic acid) by Introducing In Situ Nanofibrillar Poly(butylene succinate) for Green Packaging. Biomacromolecules 2014, 15, 4054–4064. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, G.; Zhang, L.; Mu, Y.; Park, C.B. Lightweight and tough nanocellular PP/PTFE nanocomposite foams with defect-free surfaces obtained using in situ nanofibrillation and nanocellular injection molding. Chem. Eng. J. 2018, 350, 1–11. [Google Scholar] [CrossRef]

- Chen, J.; Zhu, J.; Wu, H.; Guo, S.; Qiu, J. Constructing highly aligned crystalline structure to enhance sliding wear performance of bulk polyamide 6. Polymer 2021, 237, 124353. [Google Scholar] [CrossRef]

| Title 1 | iPP (wt.%) | PA6 (wt.%) | PPgMA (wt.%) | TMB-5 (wt.%) | Antioxidant 1010 (wt.%) |

|---|---|---|---|---|---|

| β-PP | 99.2 | 0 | 0 | 0.5 | 0.3 |

| PA6/PP(S) | 76.2 | 18 | 5 | 0.5 | 0.3 |

| PA6/PP(F) | 76.2 | 18 | 5 | 0.5 | 0.3 |

| Samples | β-PP | PA6/PP(S) | PA6/PP(F) |

|---|---|---|---|

| Thickness (μm) | 75 ± 4 | 80 ± 3 | 75 ± 5 |

| Average pore size (μm) | 0.0643 | 0.0685 | 0.0603 |

| Porosity (%) | 52.7 ± 2.8 | 72.8 ± 5.4 | 63.1 ± 4.0 |

| Pure water flux (L/(m2·h·bar)) | 69.3 ± 14.3 | 172.6 ± 23.6 | 146.0 ± 20.1 |

| Tensile strength-MD (MPa) | 85.4 ± 2.0 | 74.3 ± 11.3 | 57.3 ± 3.4 |

| Tensile strength-TD (MPa) | 49.5 ± 0.5 | 53.0 ± 2.1 | 52.7 ± 1.4 |

| Puncture strength (N/mm) | 90.4 ± 3.7 | 65.8 ± 6.9 | 94.8 ± 4.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, W.; Liang, G.; Li, J.; Guo, S. Microporous Formation Mechanism of Biaxial Stretching PA6/PP Membranes with High Porosity and Uniform Pore Size Distribution. Polymers 2022, 14, 2291. https://doi.org/10.3390/polym14112291

Fang W, Liang G, Li J, Guo S. Microporous Formation Mechanism of Biaxial Stretching PA6/PP Membranes with High Porosity and Uniform Pore Size Distribution. Polymers. 2022; 14(11):2291. https://doi.org/10.3390/polym14112291

Chicago/Turabian StyleFang, Wenxiang, Guixue Liang, Jiang Li, and Shaoyun Guo. 2022. "Microporous Formation Mechanism of Biaxial Stretching PA6/PP Membranes with High Porosity and Uniform Pore Size Distribution" Polymers 14, no. 11: 2291. https://doi.org/10.3390/polym14112291