Mechanical Properties of Nano-SiO2 Reinforced Geopolymer Concrete under the Coupling Effect of a Wet–Thermal and Chloride Salt Environment

Abstract

:1. Introduction

2. Experimental Investigation

2.1. Materials

2.2. Mix Proportions and Specimen Preparation

2.3. Simulation on Coupling Effect of Wet–Thermal and Chloride Salt Environment

2.4. Cube Compressive and Splitting Tensile Tests

2.5. Elastic Modulus Test

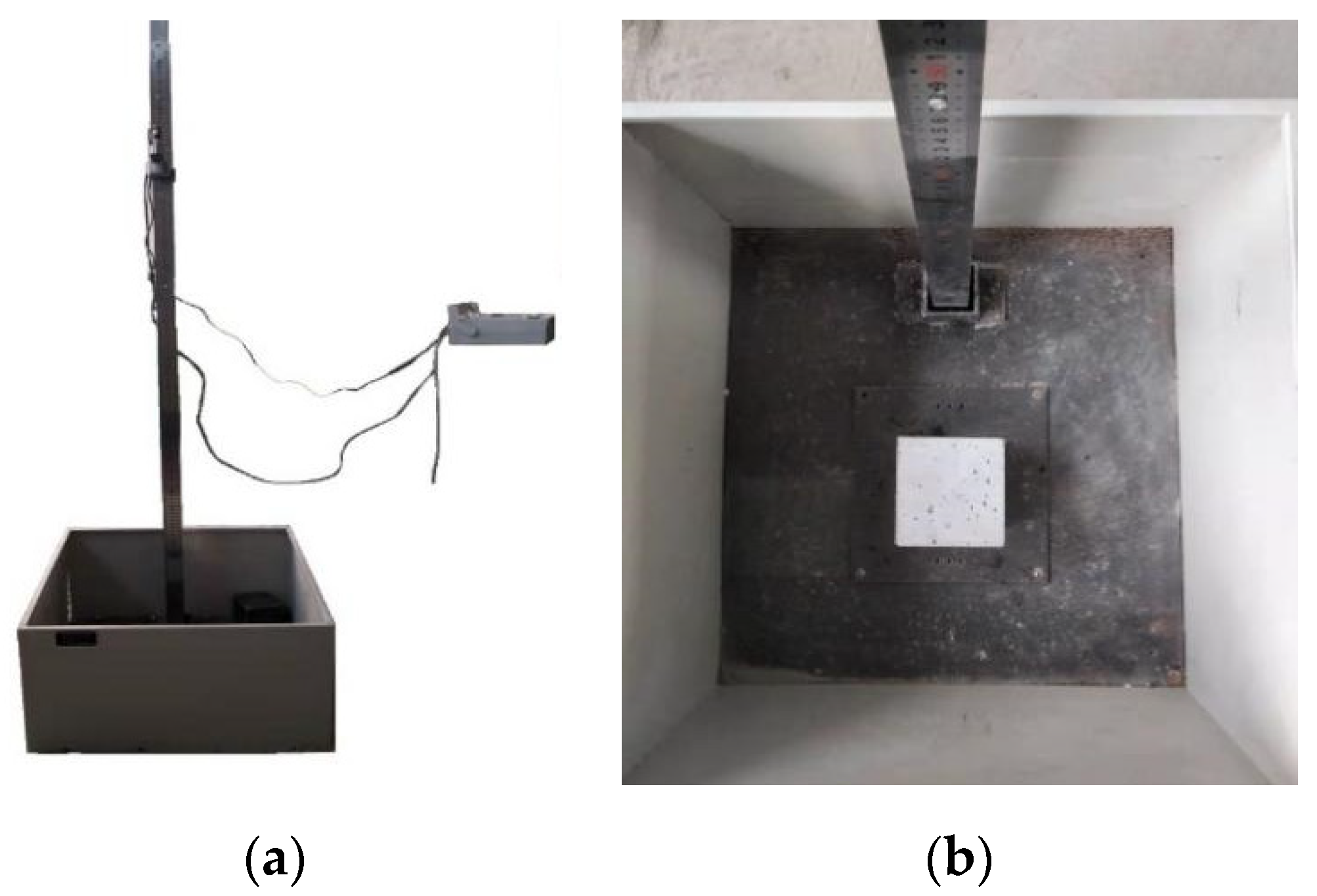

2.6. Impact Resistance Test

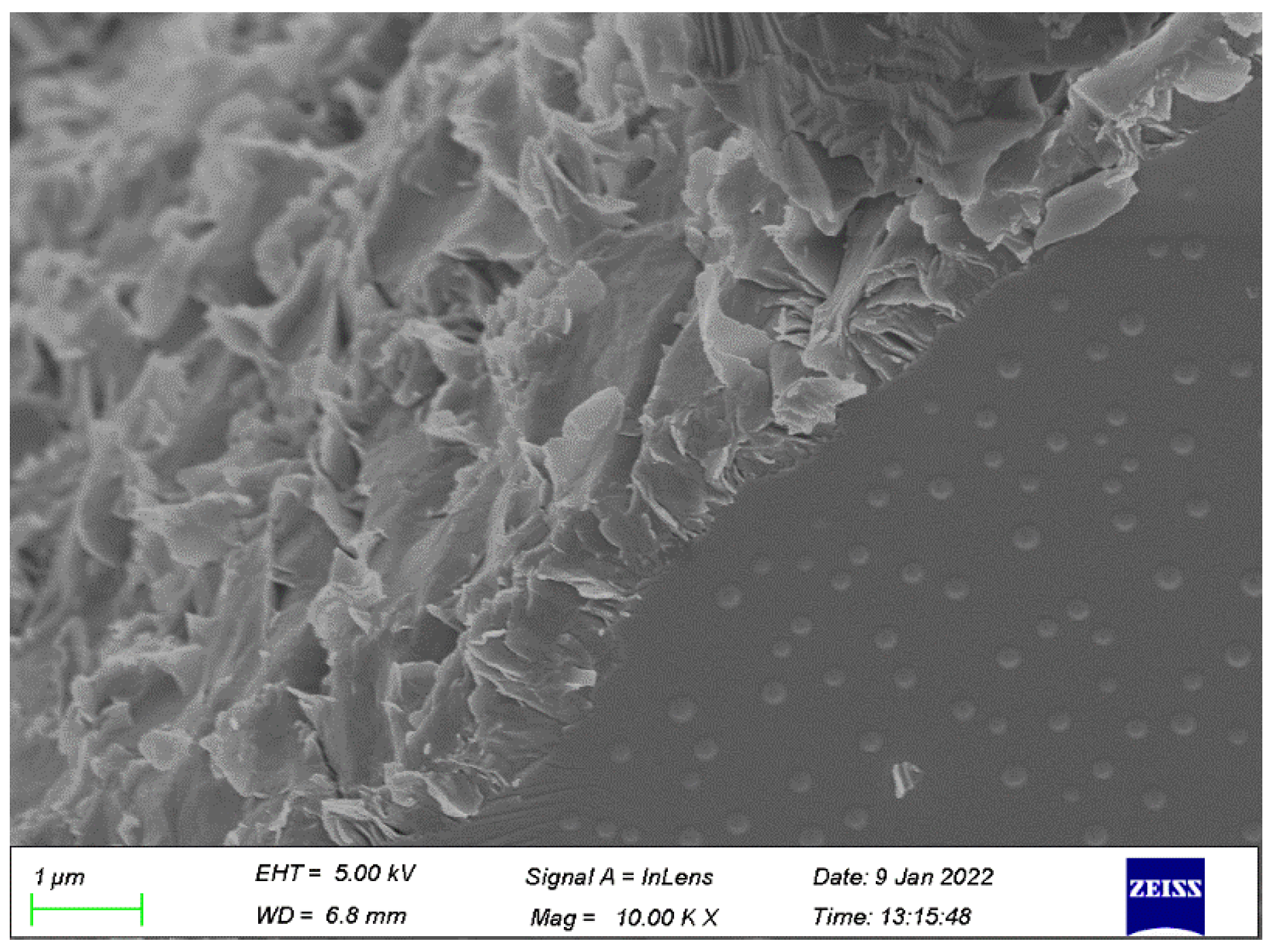

2.7. Microscopic Test

3. Results and Discussion

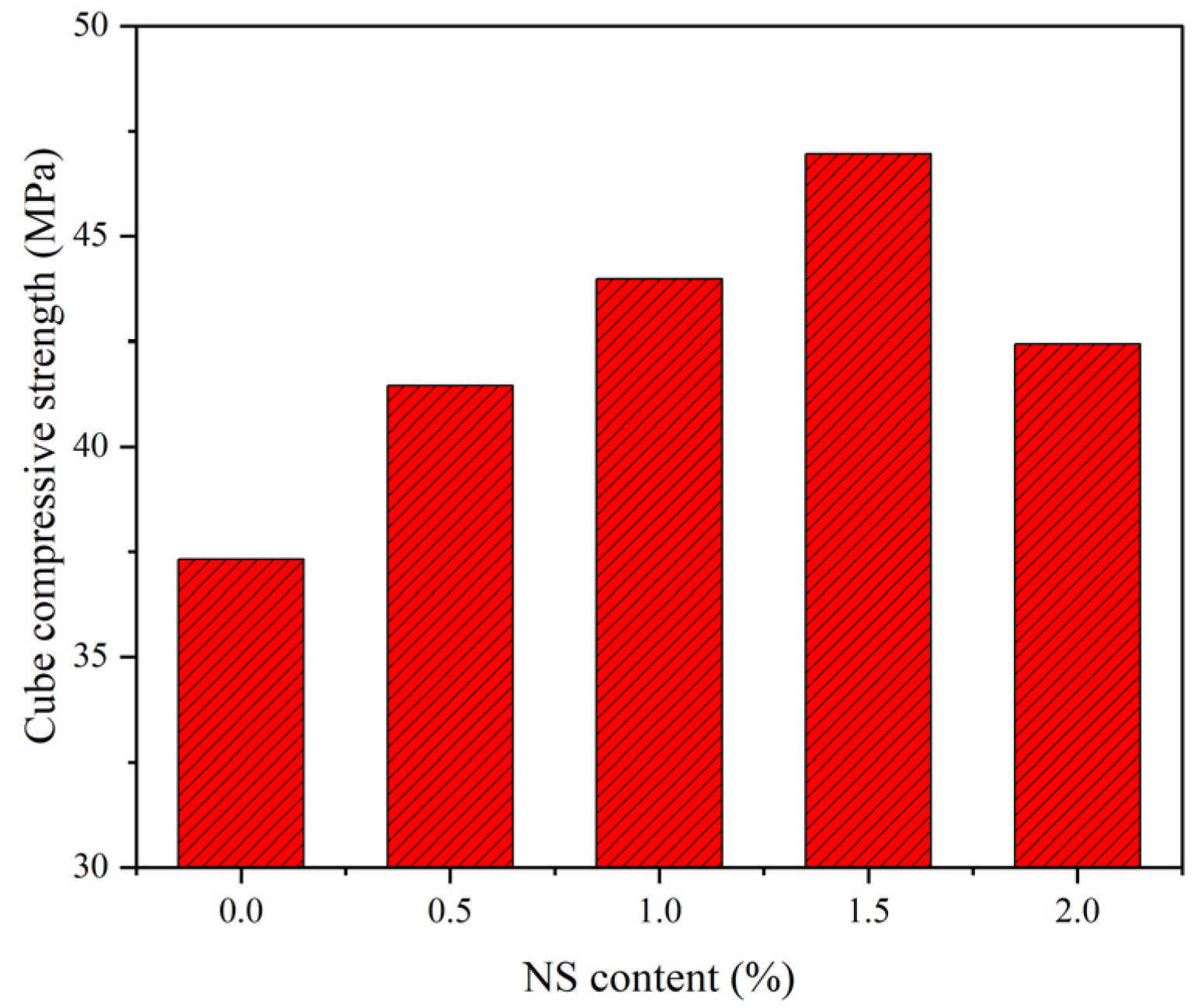

3.1. Cube Compressive Strength

3.2. Splitting Tensile Strength

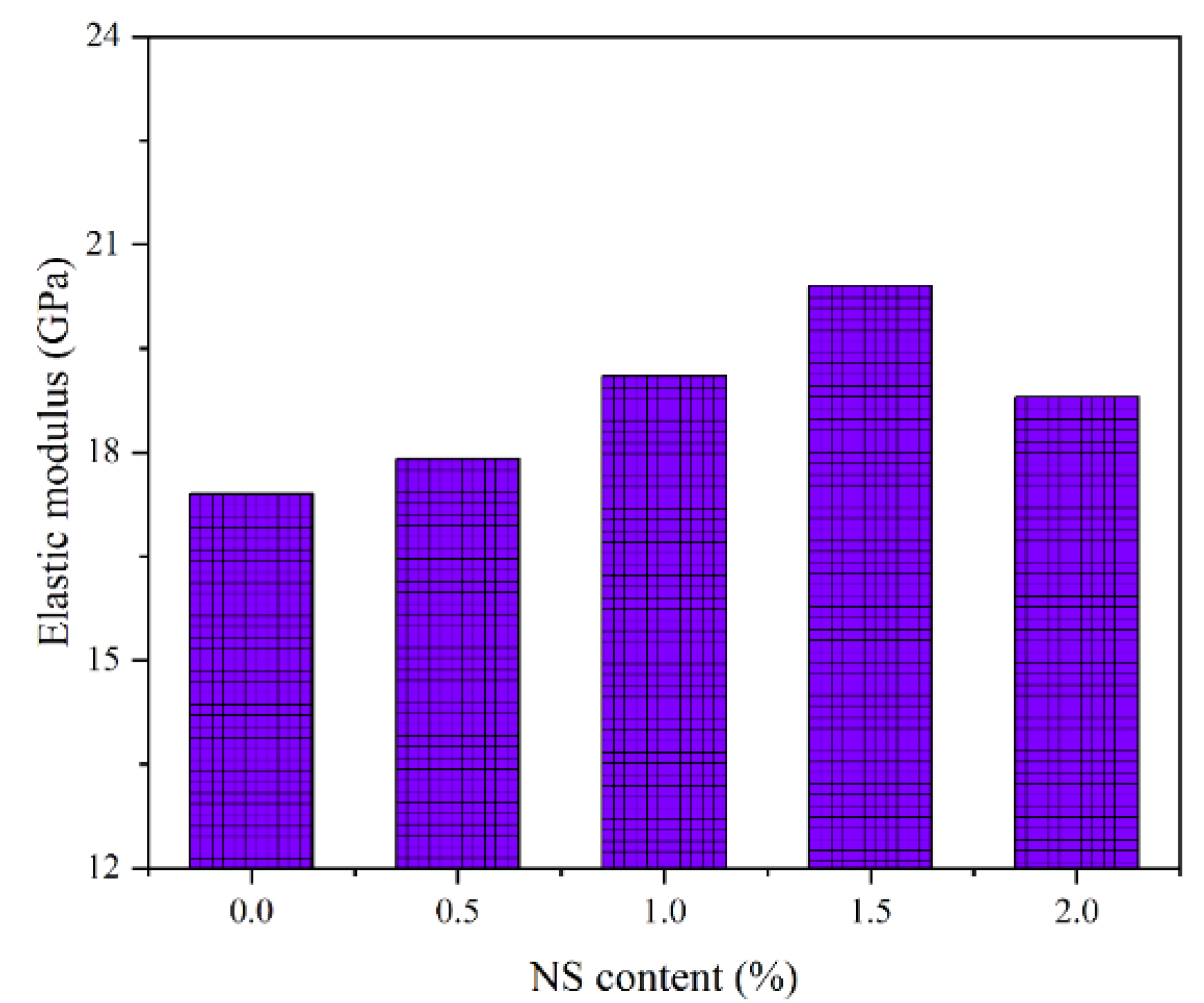

3.3. Elastic Modulus

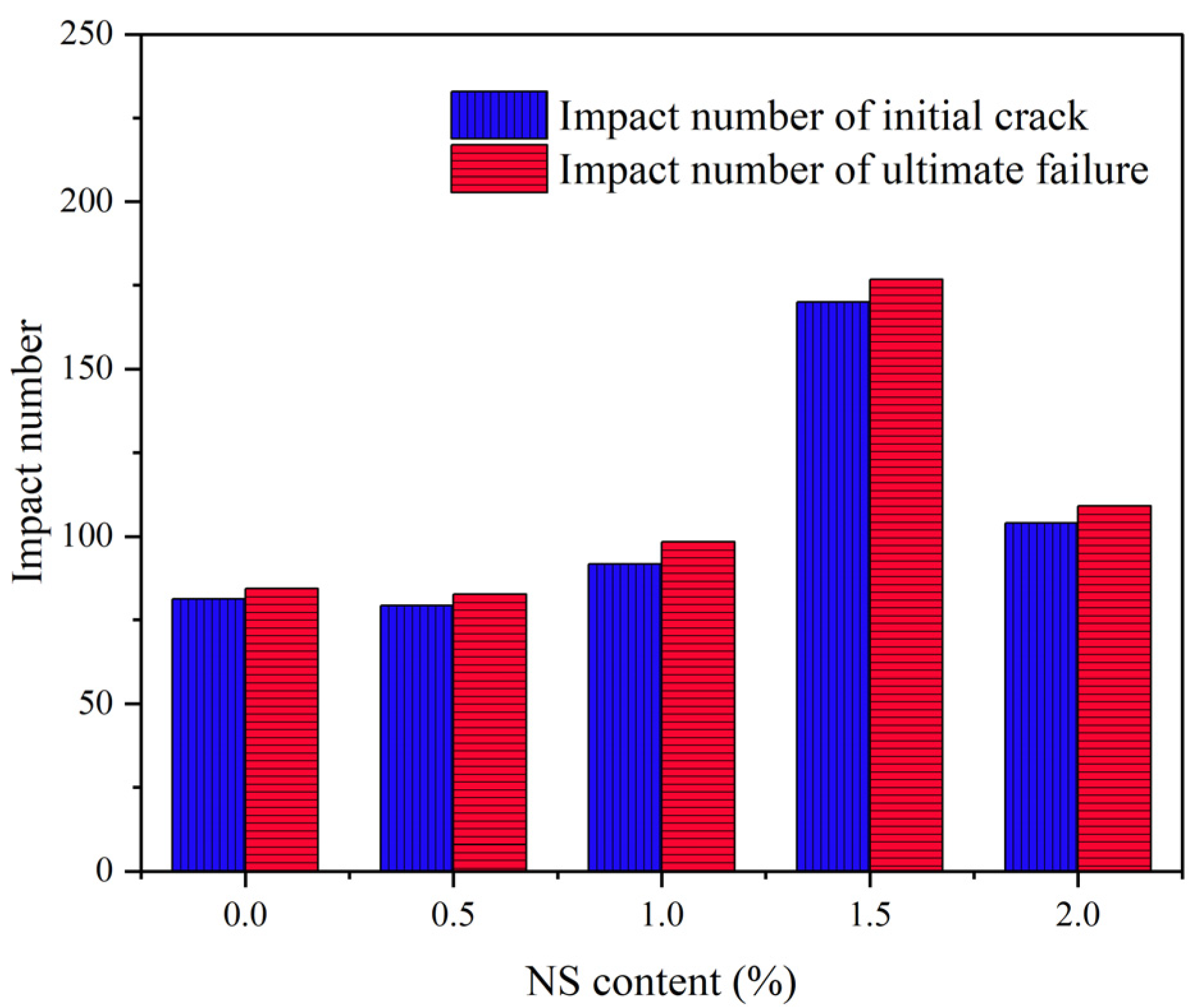

3.4. Impact Resistance

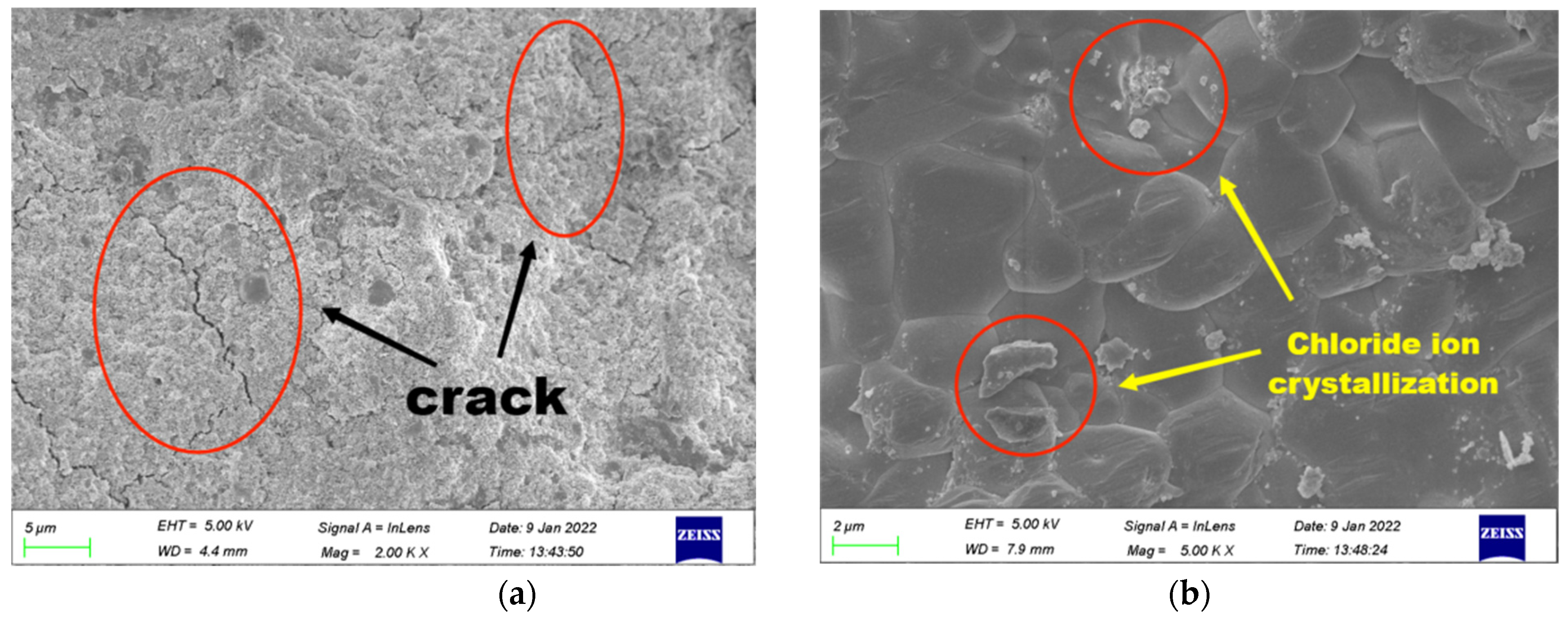

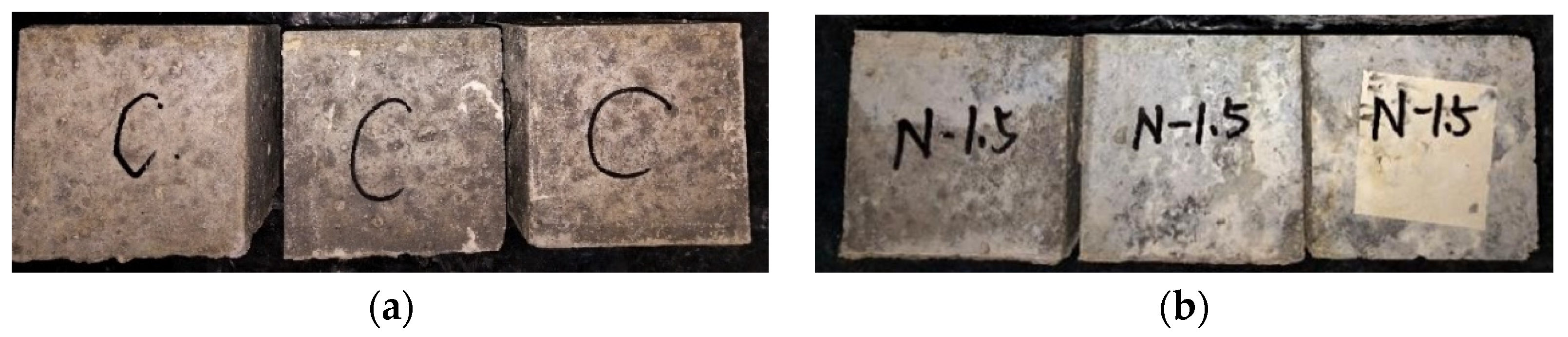

3.5. Coupling Effect of Wet–Thermal and Chloride Salt Environment

4. Conclusions

- (1)

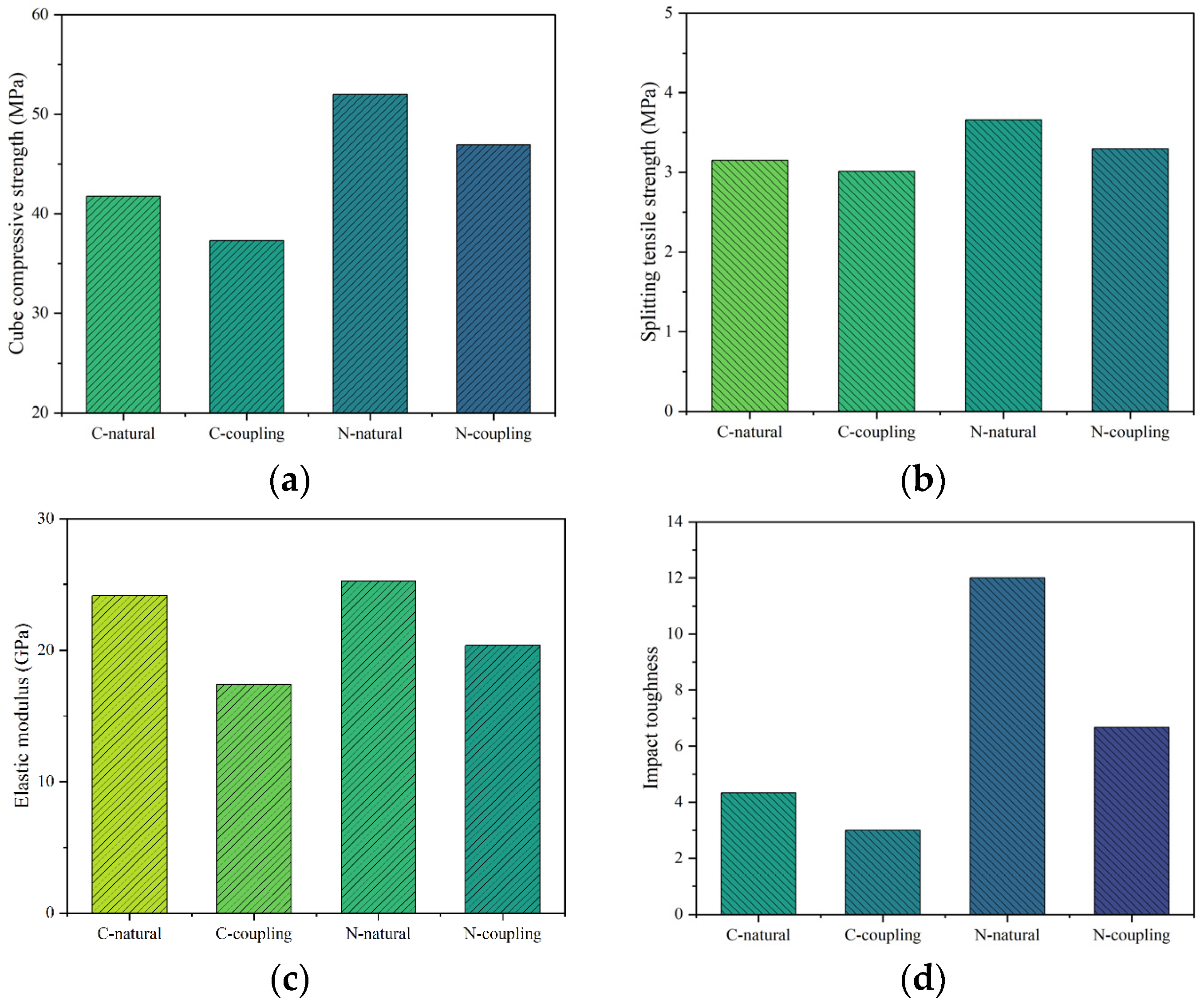

- NS can effectively enhance the cube compressive strength of GPC under the coupling effect of a wet–thermal and chloride salt environment. The cube compressive strength of NS–GPC exhibited a developmental tendency to increase primarily and decrease later as the growth of NS substitute rate. Specifically, when the NS content was 1.5%, the cube compressive strength achieved an optimal value of 46.95 MPa, which was a rise of 25.8% compared to that of the control group without NS.

- (2)

- The addition of NS improved the splitting tensile strength of GPC under the coupling effect of a wet–thermal and chloride salt environment. When NS content increased from 0.5% to 2.0%, the splitting tensile strength of NS–GPC under the coupling effect of a wet–thermal and chloride salt environment presented a changing law of increasing primarily and decreasing later as the NS content increased. Distinctly, the splitting tensile strength of NS–GPC reached an optimal value of 3.30 MPa, which was an enhancement of 9.6% compared to that of the control group without NS.

- (3)

- It can be concluded through experiments that 1.5% is an optimal NS content for reinforcement in the elastic modulus of GPC under the coupling effect of a wet–thermal and chloride salt environment. Additionally, the elastic modulus of GPC exhibited a tendency of increasing primarily and decreasing later as the rise of NS content. An excess of NS will adversely affect the stability of the network structure at the molecular level, resulting in a decrease of the elastic modulus of GPC.

- (4)

- NS distinctly improved the impact resistance of GPC under the coupling effect of a wet–thermal and chloride salt environment. When the NS content was increased from 0.5% to 2.0%, impact toughness, impact numbers of initial crack and ultimate failure of GPC under the coupling effect of a wet–thermal and chloride salt environment exhibited a tendency of increasing primarily and declining later. Moreover, the SEM test results revealed that the incorporation of NS particles can effectively fulfill the pores and tiny cracks in GPC and make the internal structure of concrete more compact, allowing for more of the impact energy to be absorbed by GPC materials.

- (5)

- Compared to the control group in the natural environment, the mechanical properties of NS–GPC decreased under the coupling effect of a wet–thermal and chloride salt environment. Experimental results indicated that NS had an inhibitory influence on the decline of the elastic modulus and the impact toughness of GPC; however, NS contents had almost no obvious influence on the decline of the cube compressive and splitting tensile strength of GPC. In general, it can be concluded that NS can actively resist the severe environmental impact on GPC.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Gao, Z.; Zhang, P.; Wang, J.; Wang, K.X.; Zhang, T.H. Interfacial properties of geopolymer mortar and concrete substrate: Effect of polyvinyl alcohol fiber and nano-SiO2 contents. Constr. Build. Mater. 2022, 315, 125735. [Google Scholar] [CrossRef]

- Wang, L.; Luo, R.; Zhang, W.; Jin, M.; Tang, S. Effects of fineness and content of phosphorus slag on cement hydration, permeability, pore structure and fractal dimension of concrete. Fractals 2021, 29, 2140004. [Google Scholar] [CrossRef]

- Shilar, F.A.; Ganachari, S.V.; Patil, V.B.; Khan, T.M.Y.; Khadar, S.D.A. Molarity activity effect on mechanical and microstructure properties of geopolymer concrete: A review. Case. Stud. Constr. Mater. 2022, 16, e01014. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymers and geopolymeric materials. J. Therm. Anal. 1989, 35, 429–441. [Google Scholar] [CrossRef]

- Firdous, R.; Stephan, D.; Djobo, J.N.Y. Natural pozzolan based geopolymers: A review on mechanical, microstructural and durability characteristics. Constr. Build. Mater. 2018, 190, 1251–1263. [Google Scholar] [CrossRef]

- Kozhukhova, N.I.; Chizhov, R.V.; Zhernovsky, I.V.; Strokova, V.V. Structure formation of geopolymer perlite binder vs. type of alkali activating agent. ARPN J. Eng. Appl. Sci. 2016, 11, 12275–12281. [Google Scholar]

- Kozhukhova, N.I.; Zhernovski, I.V.; Osadchaya, M.S.; Strokova, V.V.; Chizhov, R.V. On the question of the choice of natural and man-made materials for geopolymer binders. Res. J. Appl. Sci. 2014, 9, 1034–1039. [Google Scholar]

- Wong, L.S. Durability performance of geopolymer concrete: A review. Polymers 2022, 14, 868. [Google Scholar] [CrossRef]

- Billong, N.; Kinuthia, J.; Oti, J.; Melo, U.C. Performance of sodium silicate free geopolymers from metakaolin (MK) and rice husk ash (RHA): Effect on tensile strength and microstructure. Constr. Build. Mater. 2018, 189, 307–313. [Google Scholar] [CrossRef]

- Bernal, S.A.; Rodriguez, E.D.; Gutierrez, R.M.; Gordillo, M.; Provis, J.L. Mechanical and thermal characterisation of geopolymers based on silicate-activated metakaolin/slag blends. J. Mater. Sci. 2011, 46, 5477–5486. [Google Scholar] [CrossRef]

- Gao, Z.; Zhang, P.; Guo, J.J.; Wang, K.X. Bonding behavior of concrete matrix and alkali-activated mortar incorporating nano-SiO2 and polyvinyl alcohol fiber: Theoretical analysis and prediction model. Ceram. Int. 2021, 47, 31638–31649. [Google Scholar] [CrossRef]

- Golewski, G.L. Green concrete composite incorporating fly ash with high strength and fracture toughness. J. Clean. Prod. 2018, 172, 218–226. [Google Scholar] [CrossRef]

- Kan, L.L.; Zhang, L.; Zhao, Y.J.; Wu, M. Properties of polyvinyl alcohol fiber reinforced fly ash based engineered geopolymer composites with zeolite replacement. Constr. Build. Mater. 2020, 231, 117161. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, K.X.; Wang, J.; Guo, J.J.; Ling, Y.F. Macroscopic and microscopic analyses on mechanical performance of metakaolin/fly ash based geopolymer mortar. J. Clean. Prod. 2021, 294, 126193. [Google Scholar] [CrossRef]

- Zhang, H.Y.; Kodur, V.; Wu, B.; Cao, L.; Qi, S.L. Comparative thermal and mechanical performance of geopolymers derived from metakaolin and fly ash. J. Mater. Civ. Eng. 2016, 28, 04015092. [Google Scholar] [CrossRef]

- Castel, A.; Foster, S.J. Bond strength between blended slag and Class F fly ash geopolymer concrete with steel reinforcement. Cem. Concr. Res. 2015, 72, 48–53. [Google Scholar] [CrossRef]

- Ramujee, K.; PothaRaju, M. Mechanical properties of geopolymer concrete composites. Mater. Today. 2017, 4, 2937–2945. [Google Scholar] [CrossRef]

- Kozhukhova, N.I.; Lebedev, M.S.; Vasilenko, M.I.; Goncharova, E.N. Fly ash impact from thermal power stations on the environment. J. Phys. Conf. Ser. 2018, 1066, 012010. [Google Scholar] [CrossRef]

- Kozhukhova, N.I.; Lebedev, M.S.; Vasilenko, M.I.; Goncharova, E.N. Toxic effect of fly ash on biological environment. IOP Conf. Ser. Earth Environ. Sci. 2019, 272, 022065. [Google Scholar] [CrossRef]

- Vasilenko, M.I.; Lebedev, M.S.; Goncharova, E.N.; Kozhukhova, N.I.; Kozhukhova, M.I. The study of ecological impact of fly ash-based geopolymer binders on soil and aquatic biota. IOP Conf. Ser. Mater. Sci. Eng. 2020, 791, 012049. [Google Scholar] [CrossRef]

- Hussin, M.W.; Bhutta, M.A.R.; Azreen, M.; Ramadhansyah, P.J.; Mirza, J. Performance of blended ash geopolymer concrete at elevated temperatures. Mater. Struct. 2014, 48, 709–720. [Google Scholar] [CrossRef]

- Hassan, A.; Arif, M.; Shariq, M. A review of properties and behaviour of reinforced geopolymer concrete structural elements- A clean technology option for sustainable development. J. Clean. Prod. 2020, 245, 118762. [Google Scholar] [CrossRef]

- Reiterman, P.; Holcapek, O.; Zobal, O.; Keppert, M. Freeze-thaw resistance of cement screed with various supplementary cementitious materials. Rev. Adv. Mater. Sci. 2019, 58, 66–74. [Google Scholar] [CrossRef]

- Zhuang, X.Y.; Chen, L.; Komarneni, S.; Zhou, C.H.; Tong, D.S.; Yang, H.M.; Yu, W.H.; Wang, H. Fly ash-based geopolymer: Clean production, properties and applications. J. Clean. Prod. 2016, 125, 253–267. [Google Scholar] [CrossRef]

- Al Bakri, A.M.M.; Kamarudin, H.; Bnhussain, M.; Nizar, I.K.; Rafiza, A.R.; Zarina, Y. The processing, characterization, and properties of fly ash based geopolymer concrete. Rev. Adv. Mater. Sci. 2012, 30, 90–97. [Google Scholar]

- Izquierdo, M.; Querol, X.; Davidovits, J.; Antenucci, D.; Nugteren, H.; Fernandez-Pereira, C. Coal fly ash-slag-based geopolymers: Microstructure and metal leaching. J. Hazard. Mater. 2009, 166, 561–566. [Google Scholar] [CrossRef]

- Zhang, N.; Yan, C.Y.; Li, L.; Khan, M. Assessment of fiber factor for the fracture toughness of polyethylene fiber reinforced geopolymer. Constr. Build. Mater. 2022, 319, 126130. [Google Scholar] [CrossRef]

- Lao, J.C.; Xu, L.Y.; Huang, B.T.; Dai, J.G.; Shah, S.P. Strain-hardening ultra-high-performance geopolymer concrete (UHPGC): Matrix design and effect of steel fibers. Compos. Commun. 2022, 30, 101081. [Google Scholar] [CrossRef]

- Shilar, F.A.; Ganachari, S.V.; Patil, V.B.; Khan, T.M.Y.; Almakayeel, N.M.; Alghamdi, S. Review on the relationship between nano modifications of geopolymer concrete and their structural characteristics. Sci. Eng. Compos. Mater. 2022, 14, 1421. [Google Scholar] [CrossRef]

- Wang, L.; Guo, F.X.; Yang, H.M.; Wang, Y. Comparison of fly ash, PVA fiber, MgO and shrinkage-reducing admixture on the frost resistance of face slab concrete via pore structural and fractal analysis. Fractals 2021, 29, 2140002. [Google Scholar] [CrossRef]

- Du, H.J.; Du, S.H.; Liu, X.M. Durability performances of concrete with nano-silica. Constr. Build. Mater. 2014, 73, 705–712. [Google Scholar] [CrossRef] [Green Version]

- Li, W.G.; Huang, Z.Y.; Cao, F.L.; Sun, Z.H.; Shah, S.P. Effects of nano-silica and nano-limestone on flowability and mechanical properties of ultra-high-performance concrete matrix. Constr. Build. Mater. 2015, 95, 366–374. [Google Scholar] [CrossRef]

- Wang, J.L.; Dong, S.F.; Wang, D.N.; Yu, X.; Han, B.G.; Ou, J.P. Enhanced impact properties of concrete modified with nanofiller inclusions. J. Mater. Civ. Eng. 2019, 31, 04019030. [Google Scholar] [CrossRef]

- Han, B.G.; Sun, S.W.; Ding, S.Q.; Zhang, L.Q.; Yu, X.; Ou, J.P. Review of nanocarbon-engineered multifunctional cementitious composites. Compos. Part. A Appl. Sci. Manuf. 2015, 70, 69–81. [Google Scholar] [CrossRef]

- Phoo-ngernkham, T.; Chindaprasirt, P.; Sata, V.; Hanjitsuwan, S.; Hatanaka, S. The effect of adding nano-SiO2 and nano-Al2O3 on properties of high calcium fly ash geopolymer cured at ambient temperature. Mater. Design. 2014, 55, 58–65. [Google Scholar] [CrossRef]

- Supit, S.W.M.; Shaikh, F.U.A. Effect of nano-CaCO3 on compressive strength development of high volume fly ash mortars and concretes. J. Adv. Concr. Technol. 2014, 12, 178–186. [Google Scholar] [CrossRef] [Green Version]

- Wan, J.B.; Kim, C.H.; Lim, J.H. Investigations on the development of powder concrete with nano-SiO2 particles. KSCE J. Civ. Eng. 2007, 11, 37–42. [Google Scholar]

- Nazari, A.; Riahi, S. Microstructural, thermal, physical and mechanical behavior of the self compacting concrete containing SiO2 nanoparticles. Mat. Sci. Eng. A 2011, 528, 7663–7672. [Google Scholar] [CrossRef]

- Said, A.M.; Zeidan, M.S.; Bassuoni, M.T.; Tian, Y. Properties of concrete incorporating nano-silica. Constr. Build. Mater. 2012, 36, 838–844. [Google Scholar] [CrossRef]

- Liu, X.Y.; Liu, L.; Lyu, K.; Li, T.Y.; Zhao, P.Z.; Liu, R.D.; Zou, J.Q.; Fu, F.; Shah, S.P. Enhanced early hydration and mechanical properties of cement-based materials with recycled concrete powder modified by nano-silica. J. Build. Eng. 2022, 50, 104175. [Google Scholar] [CrossRef]

- Mokhtar, M.M.; Morsy, M.; Taha, N.A.; Ahmed, E.M. Investigating the mechanical performance of nano additives reinforced high-performance concrete. Constr. Build. Mater. 2022, 320, 125537. [Google Scholar] [CrossRef]

- Han, Q.Y.; Zhang, P.; Wu, J.J.; Jing, Y.T.; Zhang, D.; Zhang, T.H. Comprehensive review of the properties of fly ash-based geopolymer with additive of nano-SiO2. Nanotechnol. Rev. 2022, 11, 1478–1498. [Google Scholar] [CrossRef]

- Wang, K.X.; Zhang, P.; Guo, J.J.; Gao, Z. Single and synergistic enhancement on durability of geopolymer mortar by polyvinyl alcohol fiber and nano-SiO2. J. Mater. Res. Technol. 2021, 15, 1801–1814. [Google Scholar] [CrossRef]

- Zhang, P.; Kang, L.Y.; Zheng, Y.X.; Zhang, T.H.; Zhang, B. Influence of SiO2 /Na2O molar ratio on mechanical properties and durability of metakaolin-fly ash blend alkali-activated sustainable mortar incorporating manufactured sand. J. Mater. Res. Technol. 2022, 18, 3553–3563. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, K.X.; Wang, J.; Guo, J.J.; Hu, S.W.; Ling, Y.F. Mechanical properties and prediction of fracture parameters of geopolymer/alkali-activated mortar modified with PVA fiber and nano-SiO2. Ceram. Int. 2020, 46, 20027–20037. [Google Scholar] [CrossRef]

- Alomayri, T.; Raza, A.; Shaikh, F. Effect of nano SiO2 on mechanical properties of micro-steel fibers reinforced geopolymer composites. Ceram. Int. 2021, 47, 33444–33453. [Google Scholar] [CrossRef]

- Sakai, Y. Relationship between pore structure and chloride diffusion in cementitious materials. Constr. Build. Mater. 2019, 229, 116868. [Google Scholar] [CrossRef]

- Wang, L.; Lu, X.; Liu, L.; Xiao, J.; Zhang, G.; Guo, F.; Li, L. Influence of MgO on the hydration and shrinkage behavior of low heat Portland cement-based materials via pore structural and fractal analysis. Fractal Fract. 2022, 6, 40. [Google Scholar] [CrossRef]

- Liang, F. Water absorption and chloride ion penetrability of concrete damaged by freeze-thawing and loading. J. Wuhan Univ. Technol. 2017, 32(2), 330–337. [Google Scholar]

- Qiao, C.Y.; Suraneni, P.; Weiss, J. Damage in cement pastes exposed to NaCl solutions. Constr. Build. Mater. 2018, 171, 120–127. [Google Scholar] [CrossRef]

- Wang, Y.; Ueda, T.; Gong, F.Y.; Zhang, D.W. Meso-scale mechanical deterioration of mortar due to sodium chloride attack. Cem. Concr. Compos. 2019, 96, 163–173. [Google Scholar] [CrossRef]

- Pillay, D.L.; Olalusi, O.B.; Awoyera, P.O.; Rondon, C.; Echeverria, A.M.; Kolawole, J.T. A review of the engineering properties of metakaolin based concrete: Towards combatting chloride attack in coastal/marine structures. Adv. Civ. Eng. 2020, 2020, 8880974. [Google Scholar] [CrossRef]

- Wang, D.Z.; Zhou, X.M.; Fu, B.; Zhang, L.R. Chloride ion penetration resistance of concrete containing fly ash and silica fume against combined freezing-thawing and chloride attack. Constr. Build. Mater. 2018, 169, 740–747. [Google Scholar] [CrossRef] [Green Version]

- Tadayon, M.H.; Shekarchi, M.; Tadayon, M. Long-term field study of chloride ingress in concretes containing pozzolans exposed to severe marine tidal zone. Constr. Build. Mater. 2016, 123, 611–616. [Google Scholar] [CrossRef]

- Çevik, A.; Alzeebaree, R.; Humur, G.; Niş, A.; Gülşan, M.E. Effect of nano-silica on the chemical durability and mechanical performance of fly ash based geopolymer concrete. Ceram. Int. 2018, 44, 12253–12264. [Google Scholar] [CrossRef]

- Nuaklong, P.; Sata, V.; Wongsa, A.; Srinavin, K.; Chindaprasirt, P. Recycled aggregate high calcium fly ash geopolymer concrete with inclusion of OPC and nano-SiO2. Constr. Build. Mater. 2018, 174, 244–252. [Google Scholar] [CrossRef]

- JGJ 55-2011; Specification for Mix Proportion Design of Ordinary Concrete. China Architecture and Building Press: Beijing, China, 2011.

- Ming, X.; Ming, X. Influence of conventional dispersed nano-CaCO3 on performance of concrete. J. Highw. Trans. Res. Develop. 2019, 36, 25–30. [Google Scholar]

- Fu, Z.Q.; Huang, J.; Zhang, J.Z.; Wu, L.J.; Zhu, Y.D. Similarity analysis of chloride penetration experiment for hydraulic concrete. In Proceedings of the 2nd International Conferene on Structures and Building Materials (ICSBM2012), Hangzhou, China, 9–11 March 2012; 446–449, pp. 2727–2730. [Google Scholar]

- Amey, S.L.; Johnson, D.A.; Miltenberger, M.A.; Farzam, H. Predicting the service life of concrete marine structures: An environmental methodology. Aci. Struct. J. 1998, 95, 205–214. [Google Scholar]

- GB/T 2423.17-2008; Environmental Testing for Electronic Products—Part 2: Test Methods-Test Ka: Salt Mist. China Architecture and Building Press: Beijing, China, 2008.

- Zhang, Y.; Zhou, X.Y.; Zhao, J.; Zhuang, H.X.; Gao, Y.H.; Zhang, Y.R. Time dependency and similarity of decay process of chloride diffusion in concrete under simulated marine tidal environment. Constr. Build. Mater. 2019, 205, 332–343. [Google Scholar] [CrossRef]

- Zhang, X.M.; Zhang, P.; Wang, T.Y.; Zheng, Y.; Qiu, L.H.; Sun, S.W. Compressive strength and anti-chloride ion penetration assessment of geopolymer mortar merging PVA fiber and nano-SiO2 using RBF–BP composite neural network. Nanotechnol. Rev. 2022, 11, 1181–1192. [Google Scholar] [CrossRef]

- GB/T 50081-2016; Standard for Test Methods of Mechanical Properties on Ordinary Concrete. China Architecture and Building Press: Beijing, China, 2016.

- Balapour, M.; Joshaghani, A.; Althoey, F. Nano-SiO2 contribution to mechanical, durability, fresh and microstructural characteristics of concrete: A review. Constr. Build. Mater. 2018, 181, 27–41. [Google Scholar] [CrossRef]

- Chougan, M.; Ghaffar, S.H.; Jahanzat, M.; Albar, A.; Mujaddedi, N.; Swash, R. The influence of nano-additives in strengthening mechanical performance of 3D printed multi-binder geopolymer composites. Constr. Build. Mater. 2020, 250, 118928. [Google Scholar] [CrossRef]

- Cong, P.L.; Cheng, Y.Q. Advances in geopolymer materials: A comprehensive review. J. Traffic. Transp. Eng. 2021, 8, 283–314. [Google Scholar] [CrossRef]

- Camiletti, J.; Soliman, A.M.; Nehdi, M.L. Effects of nano- and micro-limestone addition on early-age properties of ultra-high-performance concrete. Mater. Struct. 2013, 46, 881–898. [Google Scholar] [CrossRef]

- Hosan, A.; Shaikh, F.U.A.; Sarker, P.; Aslani, F. Nano- and micro-scale characterisation of interfacial transition zone (ITZ) of high volume slag and slag-fly ash blended concretes containing nano SiO2 and nano CaCO3. Constr. Build. Mater. 2021, 269, 121311. [Google Scholar] [CrossRef]

- Li, W.G.; Long, C.; Tam, V.W.Y.; Poon, C.S.; Duan, W.H. Effects of nano-particles on failure process and microstructural properties of recycled aggregate concrete. Constr. Build. Mater. 2017, 142, 42–50. [Google Scholar] [CrossRef]

| Chemical Compositions (wt.%) | SiO2 | Al2O3 | Fe2O3 | CaO + MgO | K2O + Na2O | SO3 |

|---|---|---|---|---|---|---|

| MK | 54 | 43 | ≤1.3 | ≤0.8 | ≤0.7 | – |

| FA | 60.98 | 24.47 | 6.70 | 5.58 | – | 0.27 |

| Whiteness (%) | Activity Index (%) | Availability of Lime (mL) | Average Particle Size (µm) | Ignition Loss (%) |

|---|---|---|---|---|

| 75 | 12 | 1350 | 1.2 | 0.5 |

| Water Demand Ratio (%) | Standard Consistency (%) | Bulk Density (g/cm3) | Density (g/cm3) |

|---|---|---|---|

| 105 | 47.1 | 0.77 | 2.16 |

| SiO2 Content (%) | Specific Surface Area (m2/g) | Bulk Density (g/cm3) | Average Particle Size (nm) | pH |

|---|---|---|---|---|

| 99.5 | 200 | 0.035 | 30 | 6 |

| Mix ID | FA | MK | NS | Alkali Activator | River Sand | Coarse Aggregate | Water-Reducing Agent |

|---|---|---|---|---|---|---|---|

| kg/m3 | kg/m3 | % | kg/m3 | kg/m3 | kg/m3 | % | |

| C-0 | 195.0 | 273.0 | 0 | 418.5 | 577.4 | 1072.4 | 2.5 |

| N-0.5 | 194.0 | 271.5 | 0.5 | 418.5 | 577.4 | 1072.4 | 2.5 |

| N-1.0 | 193.0 | 270.0 | 1.0 | 418.5 | 577.4 | 1072.4 | 2.5 |

| N-1.5 | 192.0 | 269.0 | 1.5 | 418.5 | 577.4 | 1072.4 | 2.5 |

| N-2.0 | 191.0 | 267.6 | 2.0 | 418.5 | 577.4 | 1072.4 | 2.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, Q.; Zhang, P.; Wu, J.; Sha, D. Mechanical Properties of Nano-SiO2 Reinforced Geopolymer Concrete under the Coupling Effect of a Wet–Thermal and Chloride Salt Environment. Polymers 2022, 14, 2298. https://doi.org/10.3390/polym14112298

Jin Q, Zhang P, Wu J, Sha D. Mechanical Properties of Nano-SiO2 Reinforced Geopolymer Concrete under the Coupling Effect of a Wet–Thermal and Chloride Salt Environment. Polymers. 2022; 14(11):2298. https://doi.org/10.3390/polym14112298

Chicago/Turabian StyleJin, Qingqing, Peng Zhang, Jingjiang Wu, and Dehao Sha. 2022. "Mechanical Properties of Nano-SiO2 Reinforced Geopolymer Concrete under the Coupling Effect of a Wet–Thermal and Chloride Salt Environment" Polymers 14, no. 11: 2298. https://doi.org/10.3390/polym14112298

APA StyleJin, Q., Zhang, P., Wu, J., & Sha, D. (2022). Mechanical Properties of Nano-SiO2 Reinforced Geopolymer Concrete under the Coupling Effect of a Wet–Thermal and Chloride Salt Environment. Polymers, 14(11), 2298. https://doi.org/10.3390/polym14112298