Parametric Design Studies of Mass-Related Global Warming Potential and Construction Costs of FRP-Reinforced Concrete Infrastructure

Abstract

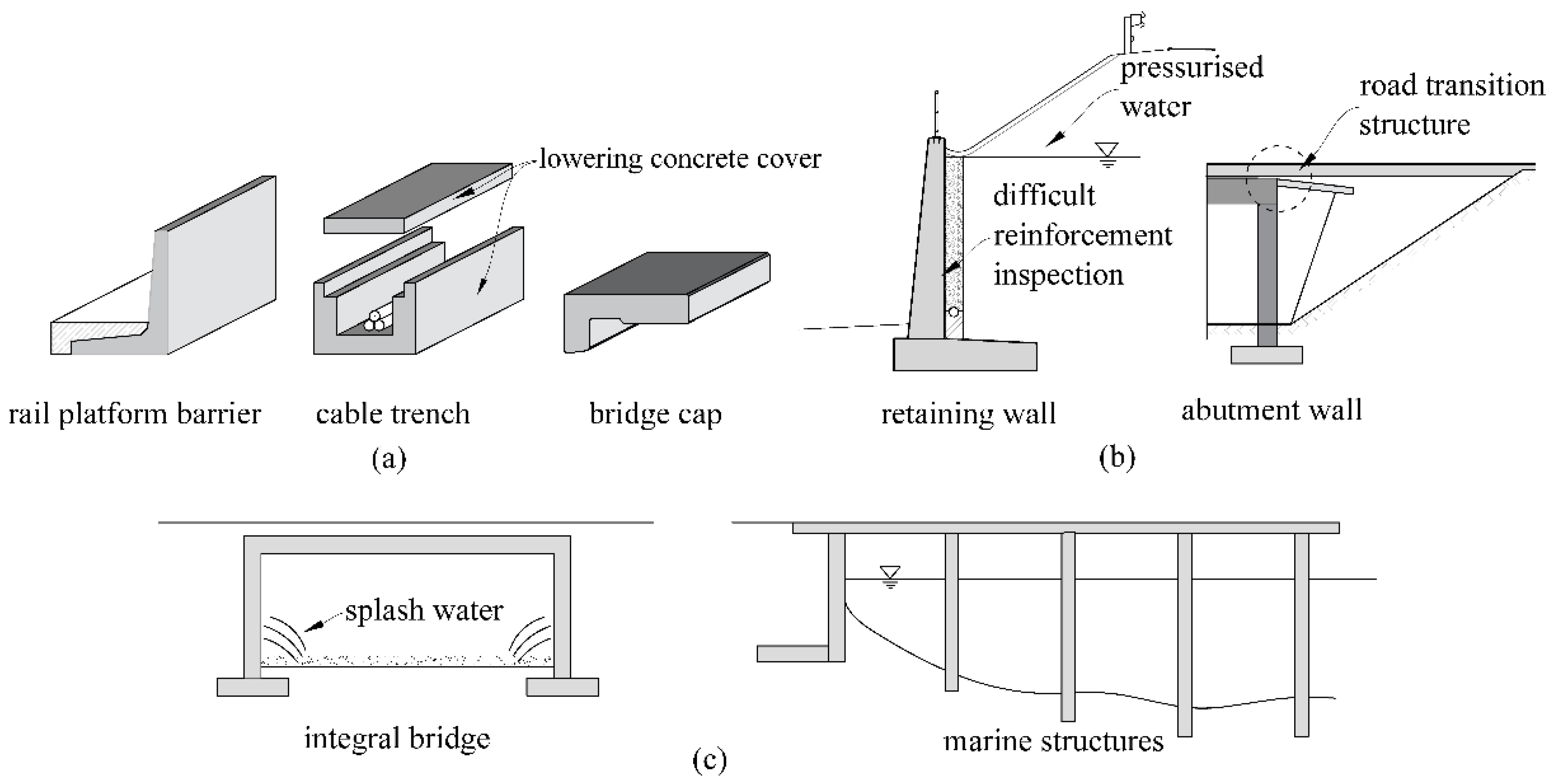

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Design Provisions

2.2.2. Parametrisation of Design

2.2.3. Economics and Environmental Considerations

3. Results

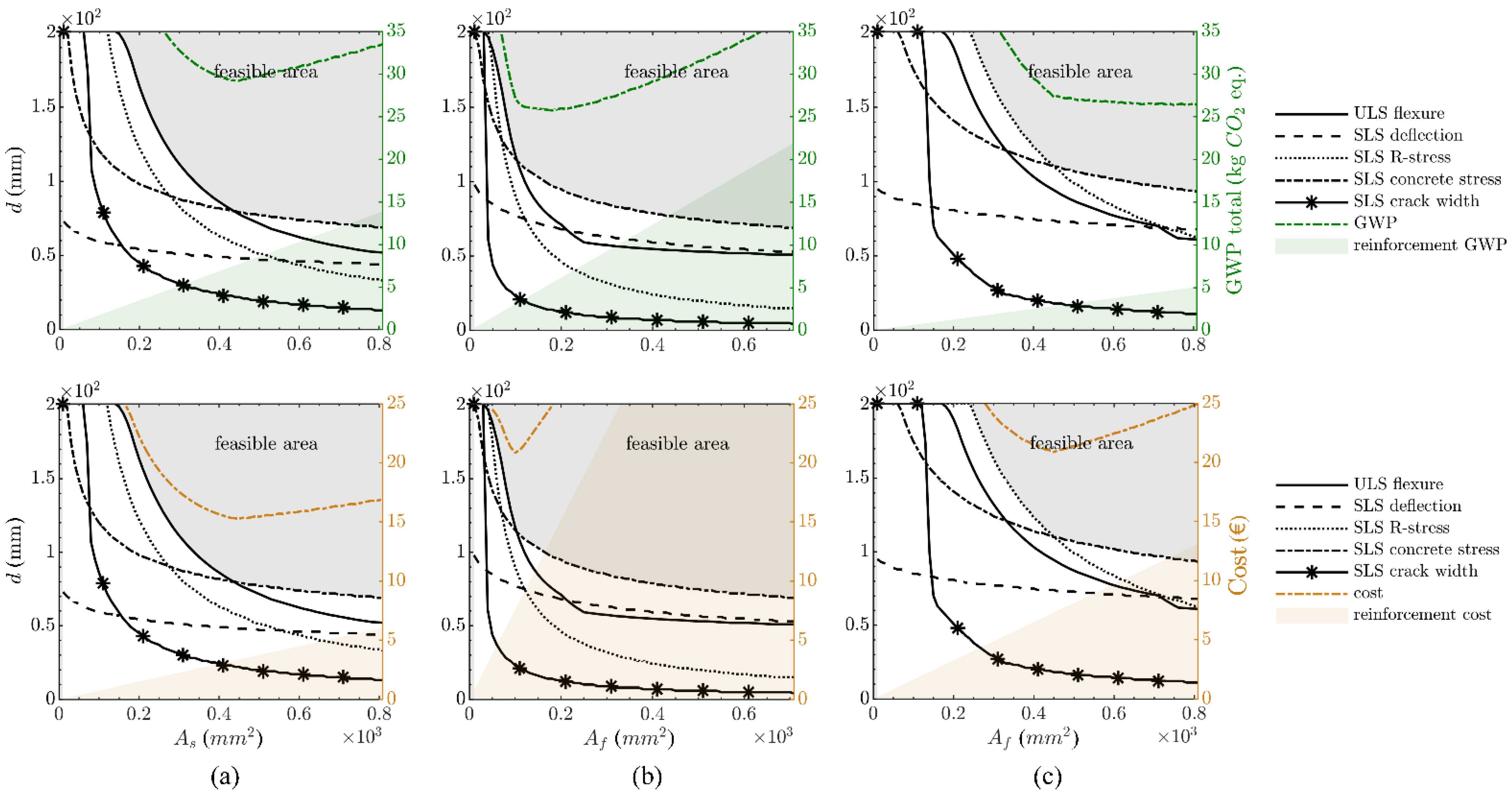

3.1. Small-Size Structures

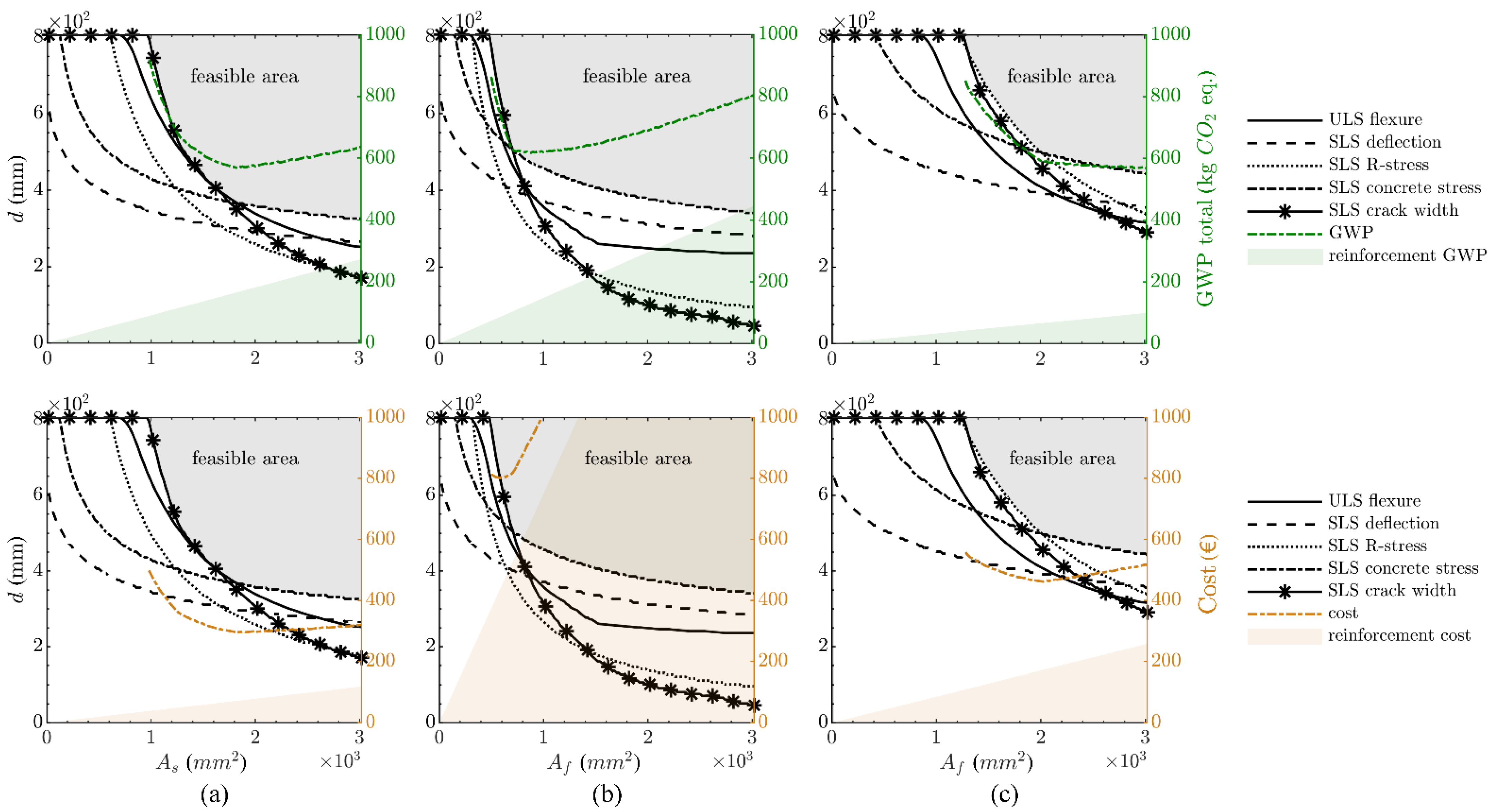

3.2. Medium-Size Structures

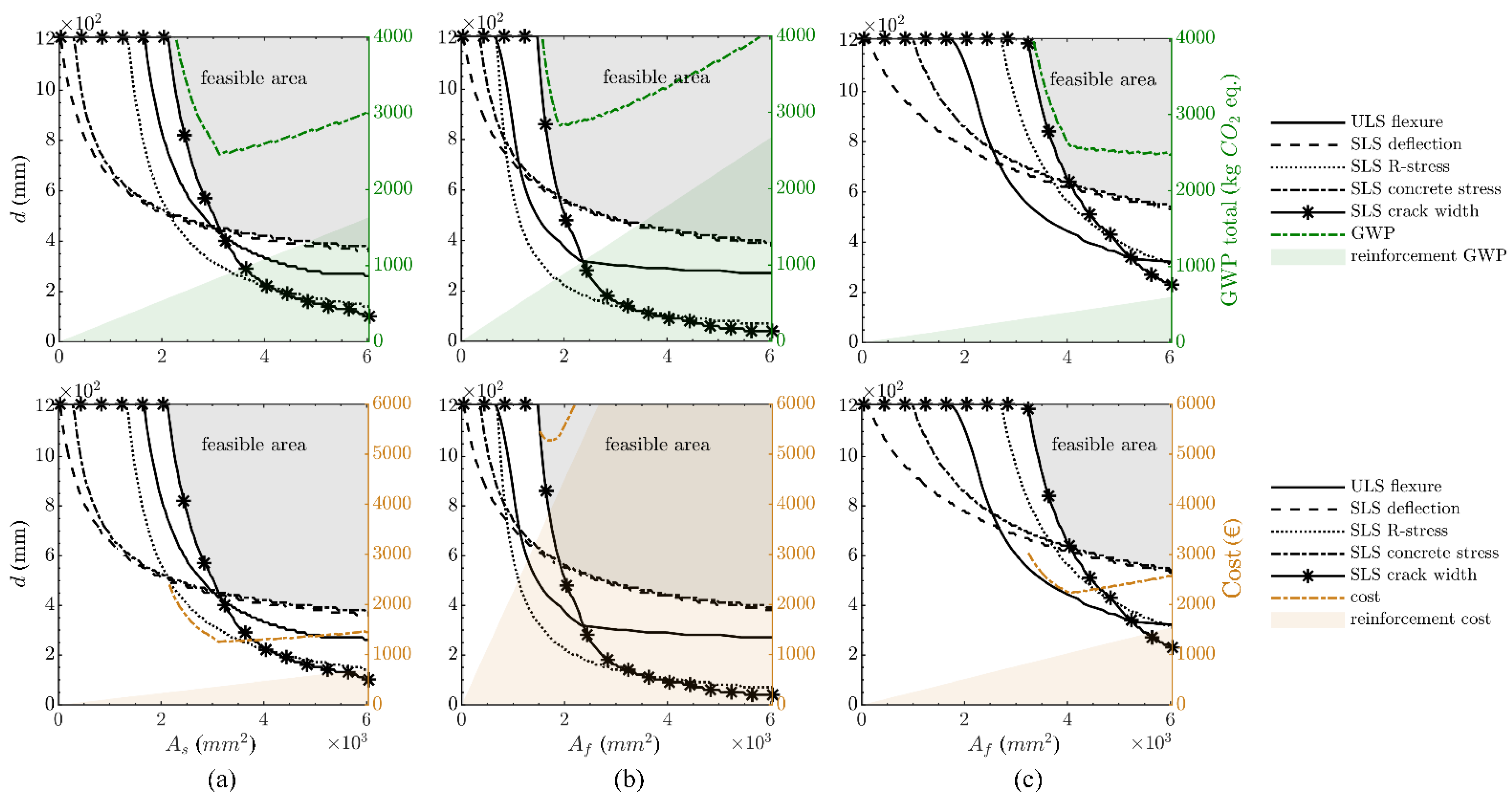

3.3. Large-Size Structures

4. Discussion

4.1. Decisive Influencing Parameters

4.1.1. Size of the Structure

4.1.2. Reinforcement Type

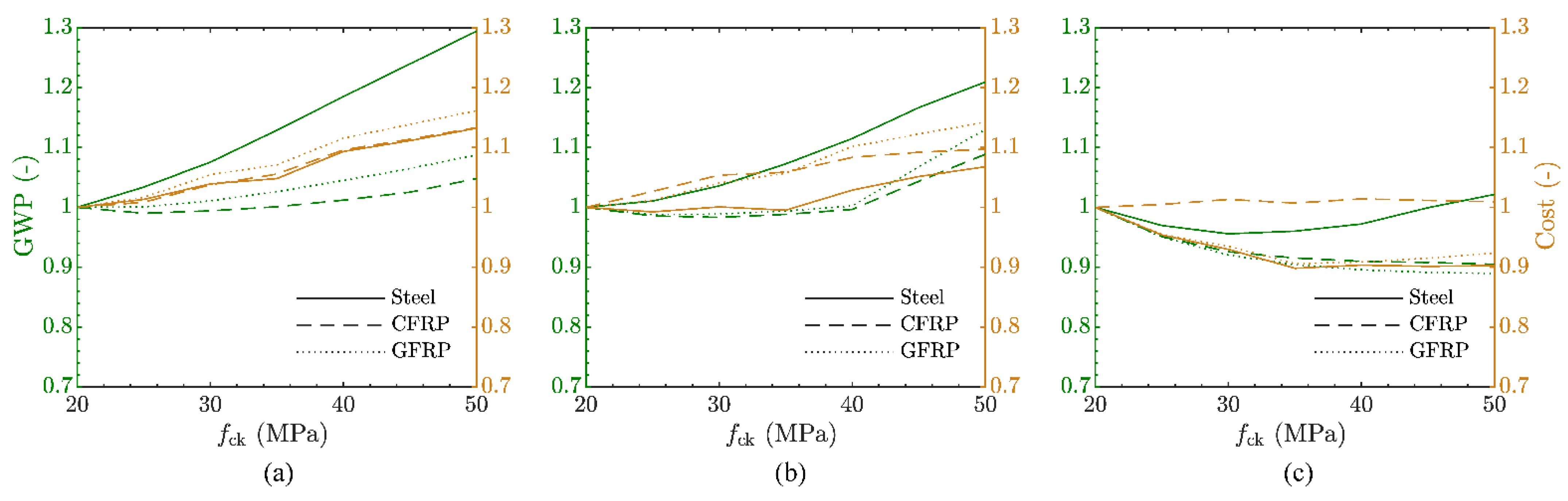

4.1.3. Concrete Compressive Strength

4.2. Outlook

4.2.1. Using Less GWP-Intense Concrete

4.2.2. Outlook II: Decreasing Cost of Reinforcement

5. Conclusions and Outlook

- The optimum design curves for rectangular FRP-reinforced structures under flexural loading are generally driven by SLS requirements rather than the ULS flexural capacity. An optimised balance between concrete and FRP strength, which differs for the various structures under consideration, allows for higher overall utilisation rates.

- For the CFRP-reinforced structures, distinct local minima for cost or GWP exist, meaning that an optimised cross-sectional design has a decisive influence on both parameters. For the cases considered here, it was generally found to be favourable to have a larger concrete cross-sectional area and smaller CFRP reinforcement area. However, this would lead to a heavier structure.

- For the GFRP-reinforced structures, due to the lower environmental impact of the reinforcement, a smaller concrete cross-sectional area and larger reinforcement area was generally found to be more favourable in terms of the overall GWP of the structure.

- It is observed that FRP-reinforced structures are competitive with steel-reinforced options in terms of the GWP where, in particular, the GFRP-reinforced structures exhibit relatively low mass-related GWP. This trend is amplified if greater cement reductions in the concrete mixes can be realised due to the high corrosion resistance of FRP reinforcement.

- In terms of the mass-related costs, FRP-reinforced structures remain more expensive than steel-reinforced variants. This was still the case even when a potential price reduction of up to 30% due to mass production was simulated.

- The smaller the structure, the smaller the difference in the material costs and GWP compared to steel structures. This observation can be traced back to the concrete cover having a more significant impact on the overall concrete volume in smaller structures. Hence, a reduction in the concrete cover due to the high corrosion resistance of the FRP reinforcement significantly reduces the GWP and costs of the overall structure. It is therefore more advantageous when the FRP textile reinforcement, which has a smaller reinforcement area and thus allows for a smaller wall thickness, is used in small structures. This type of reinforcement can also be more cost-efficient relative to FRP bars.

- Hybrid structures where only the reinforcement prone to corrosion is replaced by FRP reinforcement could suit medium-sized structures like the investigated retaining wall. A hybrid approach would lower the construction costs, while a structure with a lower GWP can still be achieved.

- Large-size FRP-reinforced structures such as bridges show significantly higher costs. This comparison was based on solid, reinforced cross sections and demonstrates that a simple replacement of steel reinforcement with FRP reinforcement, particularly CFRP, is not a suitable solution. Instead, a different design concept with more optimised, prestressed cross sections would take advantage of specific FRP reinforcement characteristics, such as the lower elongation stiffness, and thus better utilise the high-performance FRP reinforcement.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Design Provisions

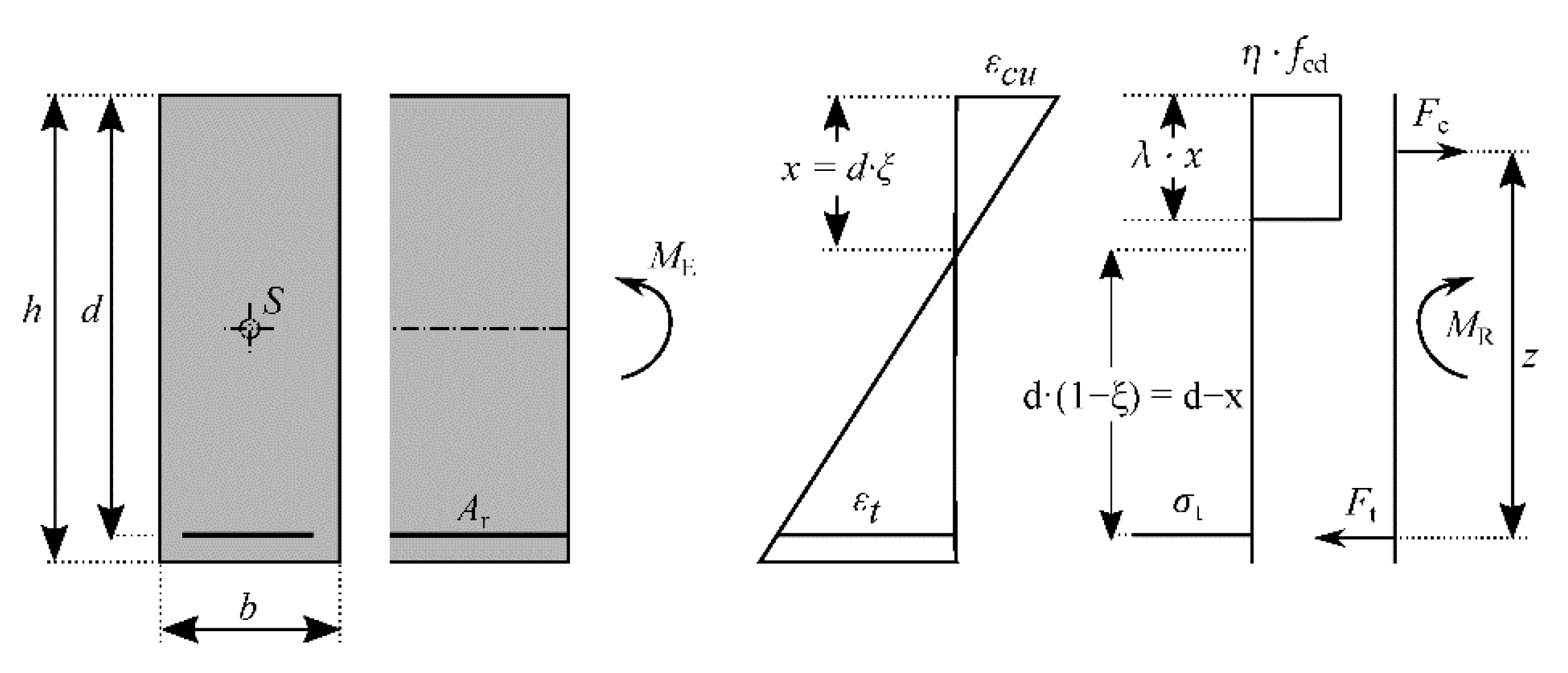

Appendix A.1. Flexural Capacity

Appendix A.2. Deflection Control

Appendix A.3. Crack-Width Limitation

Appendix A.4. Stress Limitation

Appendix B

Appendix B.1. Rail Platform Barrier

| LC1 | LC2 | LC3 | |

|---|---|---|---|

| ek (kN/m) | 9.50 | 2.50 | |

| Ek (kN) | 10.0 | ||

| ψ0 | 1.00 | 0.70 | 1.00 |

| ψ2 | 1.00 | 0.60 | 0.30 |

| γD | 1.35 | 1.50 | 1.50 |

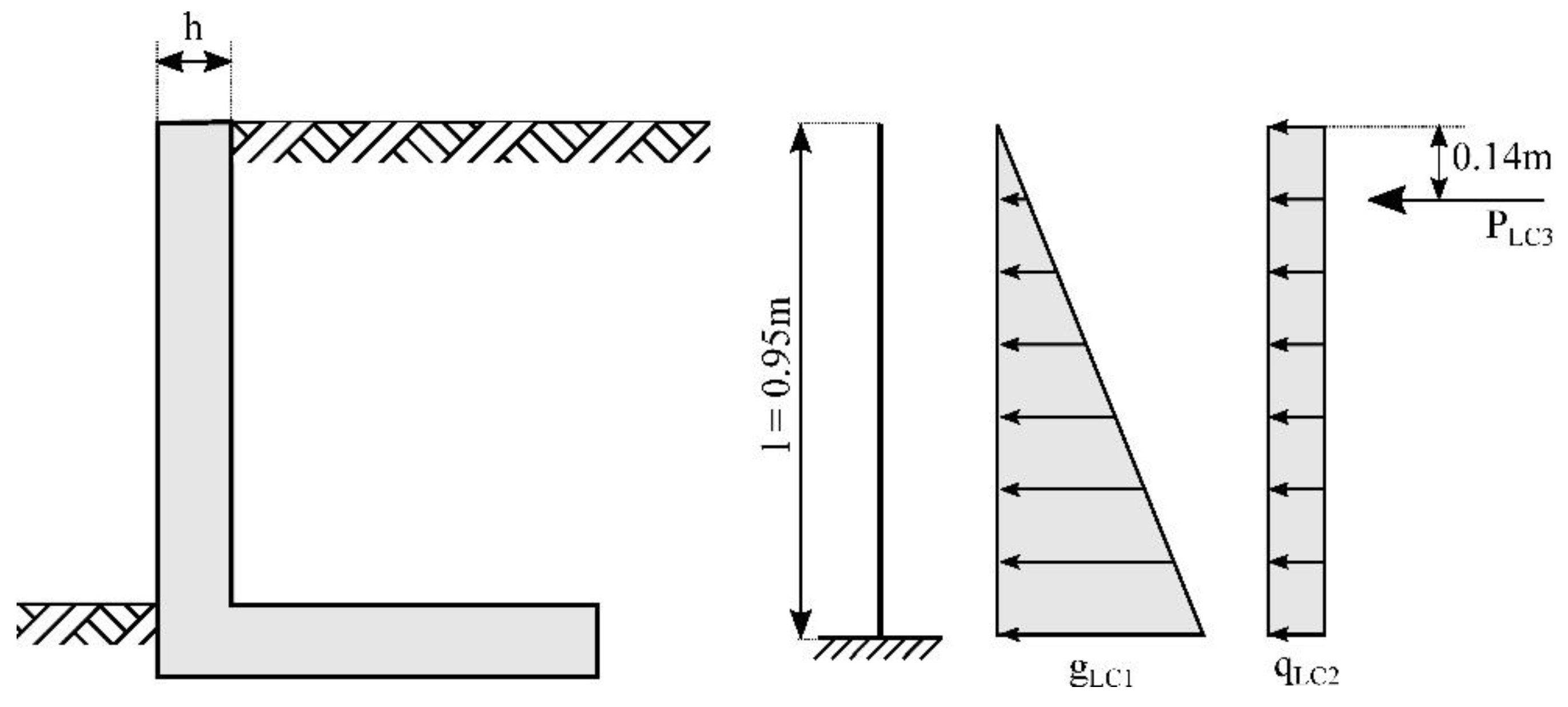

Appendix B.2. Retaining Wall

| LC1 | LC2 | |

|---|---|---|

| ek (kN/m) | 33.45 | 5.59 |

| ψ0 | 1.00 | 1.00 |

| ψ2 | 1.00 | 0.30 |

| γD | 1.35 | 1.50 |

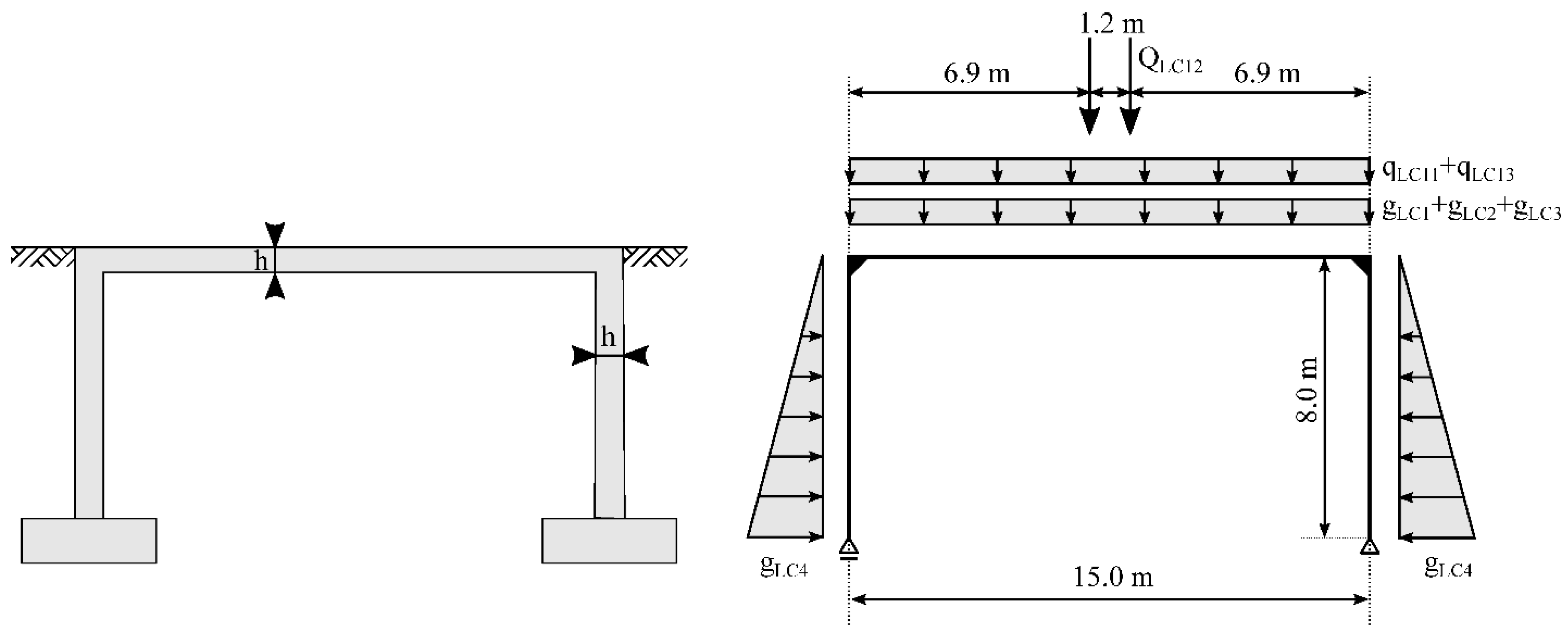

Appendix B.3. Integral Bridge

| LC1 | LC2 | LC3 | LC4 | LC11 | LC12 | LC13 | |

|---|---|---|---|---|---|---|---|

| ek (kN/m) | Var. | 2.80 | 3.04 | 40 | 3 | − | 2.22 |

| Ek (kN) | − | − | − | − | − | 33.3 | − |

| ψ0 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| ψ2 | 1.00 | 1.00 | 1.00 | 1.00 | 0.4 | 0.75 | 0.4 |

| γD | 1.35 | 1.35 | 1.35 | 1.00 | 1.35 | 1.35 | 1.35 |

References

- Mark, P.; Neugebauer, P. Erhalt Unserer Bausubstanz: Zentrale Forschungsaufgabe mit Modernen Methoden; Brill Schöningh: Leiden, The Netherlands, 2019; ISBN 978-3-657-77942-0. [Google Scholar]

- Burgoyne, C. Does FRP Have an Economic Future? ACMBS MCAPC IV: Calgary, Canada, 2004. [Google Scholar]

- Balafas, I.; Burgoyne, C.J. Economic design of beams with FRP rebar or prestress. Mag. Concr. Res. 2012, 64, 885–898. [Google Scholar] [CrossRef]

- Stoiber, N.; Hammerl, M.; Kromoser, B. Cradle-to-gate life cycle assessment of CFRP reinforcement for concrete structures: Calculation basis and exemplary application. J. Clean. Prod. 2021, 280, 124300. [Google Scholar] [CrossRef]

- Burgoyne, C.J. Advanced Composites in Civil Engineering in Europe. Struct. Eng. Int. 1999, 9, 267–273. [Google Scholar] [CrossRef]

- Taerwe, L.R. FRP Developments and Applications in Europe. In Fiber-Reinforced-Plastic (FRP) Reinforcement for Concrete Structures; Nanni, A., Ed.; Elsevier: Oxford, UK, 1993; pp. 99–114. ISBN 01676288. [Google Scholar]

- Nanni, A. North American design guidelines for concrete reinforcement and strengthening using FRP: Principles, applications and unresolved issues. Constr. Build. Mater. 2003, 17, 439–446. [Google Scholar] [CrossRef]

- Fukuyama, H. FRP Composites in Japan. Concr. Int. 1999, 21, 29–32. [Google Scholar]

- Bakis, C.E.; Bank Lawrence, C.; Brown, V.L.; Cosenza, E.; Davalos, J.F.; Lesko, J.J.; Machida, A.; Rizkalla, S.H.; Triantafillou, T.C. Fiber-Reinforced Polymer Composites for Construction—State-of-the-Art Review. J. Compos. Constr. 2002, 6, 73–87. [Google Scholar] [CrossRef]

- Hegger, J.; Horstmann, M.; Voss, S.; Will, N. Textilbewehrter Beton: Tragverhalten, Bemessung und Anwendung. Beton-Und Stahlbetonbau 2007, 102, 362–370. [Google Scholar] [CrossRef]

- Lieboldt, M.; Tietze, M.; Schladitz, F. C3-Projekt—Erfolgreiche Partnerschaft für Innovation im Bauwesen. Bauingenieur 2018, 93, 265–273. [Google Scholar] [CrossRef]

- Curbach, M.; Jesse, F. Eigenschaften und Anwendung von Textilbeton. Beton-Und Stahlbetonbau 2009, 104, 9–16. [Google Scholar] [CrossRef]

- Helbig, T.; Unterer, K.; Kulas, C.; Rempel, S.; Hegger, J. Fuß- und Radwegbrücke aus Carbonbeton in Albstadt-Ebingen: Die weltweit erste ausschließlich carbonfaserbewehrte Betonbrücke. Beton-Und Stahlbetonbau 2016, 111, 676–685. [Google Scholar] [CrossRef]

- Ehlig, D.; Schladitz, F.; Frenzel, M.; Curbach, M. Textilbeton—Ausgeführte Projekte im Überblick. Beton-Und Stahlbetonbau 2012, 107, 777–785. [Google Scholar] [CrossRef]

- Burkhardt, H.; Keller, A.; Schwegler, G. Stahlbetonverbund-Bruecke mit CFK-Spannkabeln. Rad-/Gehwegbruecke ueber die Kleine Emme. Schweiz. Ing. Und Archit. 1999, 117, 347–350. [Google Scholar]

- Grace, N.; Navarre, F.; Nacey, R.; Bonus, W.; Collavino, L. Design-Construction of Bridge Street Bridge—First CFRP Bridge in the United States. PCI J. 2002, 47, 20–35. [Google Scholar] [CrossRef]

- El-Hacha, R. Prestressing Concrete Structures with FRP Tendons (ACI 440.4R-04); American Concrete Institute: Farmington Hills, MI, USA, 2004. [Google Scholar]

- CSA S806-12; Design and Construction of Building Structures with Fibre-Reinforced Polymers. CSA Group (CSA): Toronto, ON, Canada, 2017.

- fib Bulletin. FRP Reinforcement in RC structures; Fédération Internationale du Béton (fib): Lausanne, Switzerland, 2007. [Google Scholar]

- Nystrom, H.E.; Watkins, S.E.; Nanni, A.; Murray, S. Financial Viability of Fiber-Reinforced Polymer (FRP) Bridges. J. Manag. Eng. 2003, 19, 2–8. [Google Scholar] [CrossRef]

- Preinstorfer, P.; Reichenbach, S.; Huber, T.; Kromoser, B. Potential fields of application for CFRP reinforcement in concrete infrastructure engineering: Material availability, application areas and static parametric study with consideration of the GWP. In Proceedings of the Concrete Structures: New Trends for Eco-Efficiency and Performance, Lisbon, Portugal, 14–16 June 2021; pp. 1269–1277. [Google Scholar]

- Angst, U.M. Challenges and opportunities in corrosion of steel in concrete. Mater. Struct. 2018, 51, 4. [Google Scholar] [CrossRef]

- Yilmaz, D.; Angst, U. Korrosionsbedingte Kosten an Ingenieurbauwerken im Schweizer Straßennetz. Beton-Und Stahlbetonbau 2020, 115, 448–458. [Google Scholar] [CrossRef]

- Hou, B.; Li, X.; Ma, X.; Du, C.; Zhang, D.; Zheng, M.; Xu, W.; Lu, D.; Ma, F. The cost of corrosion in China. npj Mater. Degrad. 2017, 1, 4. [Google Scholar] [CrossRef]

- Koch, G.H.; Brongers, M.P.H.; Thompson, N.G.; Virmani, Y.P.; Payer, J.H.; CC Technologies, Inc.; NACE International. Corrosion Cost and Preventive Strategies in the United States [Final report]; NACE International: Houston, TX, USA, 2002. [Google Scholar]

- Nepomuceno, E.; Sena-Cruz, J.; Correia, L.; D’Antino, T. Review on the bond behavior and durability of FRP bars to concrete. Constr. Build. Mater. 2021, 287, 123042. [Google Scholar] [CrossRef]

- Spelter, A.; Bergmann, S.; Bielak, J.; Hegger, J. Long-Term Durability of Carbon-Reinforced Concrete: An Overview and Experimental Investigations. Appl. Sci. 2019, 9, 1651. [Google Scholar] [CrossRef]

- Wu, G.; Wang, X.; Wu, Z.; Dong, Z.; Xie, Q. Degradation of basalt FRP bars in alkaline environment. Sci. Eng. Compos. Mater. 2015, 22. [Google Scholar] [CrossRef]

- Guo, R.; Xian, G.; Li, F.; Li, C.; Hong, B. Hygrothermal resistance of pultruded carbon, glass and carbon/glass hybrid fiber reinforced epoxy composites. Constr. Build. Mater. 2022, 315, 125710. [Google Scholar] [CrossRef]

- Reichenbach, S.; Preinstorfer, P.; Hammerl, M.; Kromoser, B. A review on embedded fibre-reinforced polymer reinforcement in structural concrete in Europe. Constr. Build. Mater. 2021, 307, 124946. [Google Scholar] [CrossRef]

- Al-Khafaji, A.F.; Myers, J.J.; Nanni, A. Assessment Study of Glass Fiber-Reinforced Polymer Reinforcement Used in Two Concrete Bridges after More than 15 Years of Service. ACI Mater. J. 2020, 117, 209–220. [Google Scholar] [CrossRef]

- Cadenazzi, T.; Dotelli, G.; Rossini, M.; Nolan, S.; Nanni, A. Life-cycle cost and life-cycle assessment analysis at the design stage of a fiber-reinforced polymer-reinforced concrete bridge in Florida. Adv. Civ. Eng. Mater. 2019, 8, ACEM20180113. [Google Scholar] [CrossRef]

- Drießen-Ohlenforst, C.; Faulhaber, A.; Raupach, M. SMART-DECK: Monitoring des Feuchtegehaltes und kathodischer Korrosionsschutz des Bewehrungsstahles in Brückenfahrbahnen durch Zwischenschicht aus Textilbeton. Bauingenieur 2020, 95, 96–104. [Google Scholar] [CrossRef]

- Nigro, E.; Cefarelli, G.; Bilotta, A.; Manfredi, G.; Cosenza, E. Fire resistance of concrete slabs reinforced with FRP bars. Part I: Experimental investigations on the mechanical behavior. Compos. Part B Eng. 2011, 42, 1739–1750. [Google Scholar] [CrossRef]

- Kapsalis, P.; El Kadi, M.; Vervloet, J.; De Munck, M.; Wastiels, J.; Triantafillou, T.; Tysmans, T. Thermomechanical Behavior of Textile Reinforced Cementitious Composites Subjected to Fire. Appl. Sci. 2019, 9, 747. [Google Scholar] [CrossRef]

- Ceroni, F.; Cosenza, E.; Gaetano, M.; Pecce, M. Durability issues of FRP rebars in reinforced concrete members. Cem. Concr. Compos. 2006, 28, 857–868. [Google Scholar] [CrossRef]

- Frigione, M.; Lettieri, M. Durability Issues and Challenges for Material Advancements in FRP Employed in the Construction Industry. Polymers 2018, 10, 247. [Google Scholar] [CrossRef]

- ACI 440.1R-15; Guide for the Design and Construction of Structural Concrete Reinforced with Fiber-Reinforced Polymer Bars. American Concrete Institute: Farmington Hills, MI, USA, 2015.

- Rempel, S.; Ricker, M.; Hegger, J. Safety Concept for Textile-Reinforced Concrete Structures with Bending Load. Appl. Sci. 2020, 10, 7328. [Google Scholar] [CrossRef]

- Preinstorfer, P.; Kollegger, J. New insights into the splitting failure of textile-reinforced concrete. Compos. Struct. 2020, 243, 112203. [Google Scholar] [CrossRef]

- Hammerl, M.; Stoiber, N.; Hämmerle, J.; Shams, A.; Bischoff, T.; Kromoser, B. Verbundverhalten umwickelter CFK-Stäbe in Beton—Kurzzeituntersuchung der Verbundeigenschaften mittels Pull-out-Tests. Beton-Und Stahlbetonbau 2021, 116, 935–946. [Google Scholar] [CrossRef]

- preEN 1992–1–1; Design of concrete structures. CEN: Brussels, Belgium, 2021.

- Otto, J.; Adam, R. Carbonbeton und Stahlbeton im wirtschaftlichen Vergleich. Bauingenieur 2019, 94, 246–252. [Google Scholar] [CrossRef]

- Schöck Bauteile GmbH (2019) Schöck Preisliste 2020. Available online: https://www.schoeck.com/de-at/downloads (accessed on 1 March 2020).

- OENORM EN 1992–1–1; Design of Concrete Structures—Part 1-1: General Rules and Rules for Buildings. Austrian Standards Institute: Vienna, Austria, 2015.

- CNR-DT 203/2006; Guide for the Design and Construction of Concrete Structures Reinforced with Fiber-Reinforced Polymer Bars. CNR—Advisory Committee on Technical Recommendations for Construction: Rome, Italy, 2007.

- Sonobe, Y.; Fukuyama, H.; Okamoto, T.; Kani, N.; Kimura, K.; Kobayashi, K.; Masuda, Y.; Matsuzaki, Y.; Mochizuki, S.; Nagasaka, T.; et al. Design Guidelines of FRP Reinforced Concrete Building Structures. J. Compos. Constr. 1997, 1, 90–115. [Google Scholar] [CrossRef]

- Institution of Structural Engineers (Great Britain). Interim Guidance on the Design of Reinforced Concrete Structures Using Fibre Composite Reinforcement; SETO Limited: London, UK, 2004; ISBN 978-1-874266-47-1. [Google Scholar]

- AASHTO. AASHTO LRFD Bridge Design Guide Specifications for GFRP-Reinforced Concrete; AASHTO: Washington, DC, USA, 2018; ISBN 978-1-56051-717-7. [Google Scholar]

- ISO 10406-1; Fibre-Reinforced Polymer (FRP) Reinforcement of Concrete—Test Methods—Part 1: FRP Bars and Grids. International Organization for Standardization: Geneva, Switzerland, 2015.

- Emparanza, A.R.; Kampmann, R.; De Caso y Basalo, F. State-of-the-Practice of Global Manufacturing of FRP Rebar and Specifications. ACI Fall Conv. 2017, 327, 45.1–45.14. [Google Scholar]

- Weber, A. Coming European Standard for R/C Design EC2-Integration of FRP rebars. In Proceedings of the SMAR 2015-Third Conference on Smart Monitoring Assessment and Rehabilitation of Civil Structures, Antalya, Turkey, 7–9 September 2015. [Google Scholar]

- Steinbock, O.; Bösche, T.; Schumann, A. Carbonbeton—Eine neue Verstärkungsmethode für Massivbrücken: Teil 2: Carbonbeton im Brückenbau und Informationen zur Zustimmung im Einzelfall für das Pilotprojekt „Brücken über die Nidda im Zuge der BAB A 648“. Beton-Und Stahlbetonbau 2021, 116, 109–117. [Google Scholar] [CrossRef]

- Rempel, S.; Ricker, M.; Hegger, J. Design model with an iterative and closed approach for textile reinforced concrete structures with bending load—clear bending load and a combination with normal force. Beton-Und Stahlbetonbau 2020, 115, 218–230. [Google Scholar] [CrossRef]

- Bielak, J.; Schmidt, M.; Hegger, J.; Jesse, F. Structural Behavior of Large-Scale I-Beams with Combined Textile and CFRP Reinforcement. Appl. Sci. 2020, 10, 4625. [Google Scholar] [CrossRef]

- Lee, M.; Mata-Falcón, J.; Kaufmann, W. Analysis of the tension chord in the flexural response of concrete elements: Methodology and application to weft-knitted textile reinforcement. Eng. Struct. 2022, 261, 114270. [Google Scholar] [CrossRef]

- Reichenbach, S.; Preinstorfer, P.; Huber, T.; Kromoser, B. Application potential of textile reinforcement in concrete construction for infrastructure buildings: Environmental performance and availability. In Proceedings of the Structural Engineering for Future Societal Needs, Ghent, Belgium, 22–24 September 2021. [Google Scholar]

- OENORM EN 15804; Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products. Austrian Standards Institute: Vienna, Austria, 2022.

- Dong, S.; Li, C.; Xian, G. Environmental Impacts of Glass- and Carbon-Fiber-Reinforced Polymer Bar-Reinforced Seawater and Sea Sand Concrete Beams Used in Marine Environments: An LCA Case Study. Polymers 2021, 13, 154. [Google Scholar] [CrossRef]

- Cadenazzi, T.; Dotelli, G.; Rossini, M.; Nolan, S.; Nanni, A. Cost and environmental analyses of reinforcement alternatives for a concrete bridge. Struct. Infrastruct. Eng. 2020, 16, 787–802. [Google Scholar] [CrossRef]

- Burgoyne, C.J. Rational use of advanced composites in concrete. Proc. Inst. Civ. Eng.-Struct. Build. 2001, 146, 253–262. [Google Scholar] [CrossRef]

- Hammerl, M.; Kromoser, B. The influence of pretensioning on the load-bearing behaviour of concrete beams reinforced with carbon fibre reinforced polymers. Compos. Struct. 2021, 273, 114265. [Google Scholar] [CrossRef]

- Preinstorfer, P.; Kromoser, B.; Kollegger, J. Flexural behaviour of filigree slab elements made of carbon reinforced UHPC. Constr. Build. Mater. 2019, 199, 416–423. [Google Scholar] [CrossRef]

- Kromoser, B.; Preinstorfer, P.; Kollegger, J. Building lightweight structures with carbon-fiber-reinforced polymer-reinforced ultra-high-performance concrete: Research approach, construction materials, and conceptual design of three building components. Struct. Concr. 2019, 20, 730–744. [Google Scholar] [CrossRef]

- Osman-Letelier, J.P.; Hückler, A.; Schlaich, M. Dünnwandige Fertigteile aus vorgespanntem Carbonbeton. Beton-Und Stahlbetonbau 2021, 116, 786–797. [Google Scholar] [CrossRef]

- Schneider, K.; Butler, M.; Mechtcherine, V. Carbon Concrete Composites C3—Nachhaltige Bindemittel und Betone für die Zukunft. Beton-Und Stahlbetonbau 2017, 112, 784–794. [Google Scholar] [CrossRef]

- Purnell, P.; Black, L. Embodied carbon dioxide in concrete: Variation with common mix design parameters. Cem. Concr. Res. 2012, 42, 874–877. [Google Scholar] [CrossRef]

- Rimkus, A.; Barros, J.A.O.; Gribniak, V.; Rezazadeh, M. Mechanical behavior of concrete prisms reinforced with steel and GFRP bar systems. Compos. Struct. 2019, 220, 273–288. [Google Scholar] [CrossRef]

- Tavakkolizadeh, M.; Saadatmanesh, H. Galvanic Corrosion of Carbon and Steel in Aggressive Environments. J. Compos. Constr. 2001, 5, 200–210. [Google Scholar] [CrossRef]

- OENORM EN 1992–2; Design of Concrete Structures—Part 2: Concrete Bridges—Design and Detailing Rules. Austrian Standards Institute: Vienna, Austria, 2012.

| ftk1 (MPa) | Er 1 (GPa) | ρ1 (t/m³) | CT 2 (–) | CC 2 (–) | CE 2 (–) | τm 3 (MPa) | wlim 2 (mm) | γm 4 (–) | GWP 5 (kgCO2 equ/kg) | Cost 6 (EUR/kg) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Carbon bar | 2100 | 162 | 1.50 | 0.8 | 0.55 | 0.90 | 1.8 | 0.5 | 1.5 | 19.7 | 100 |

| Carbon textile | 3000 | 230 | 1.77 | 0.55 | 0.90 | 1.3 | 18.4 | 45 | |||

| Glass bar | 1300 | 59.5 | 2.13 | 0.35 | 0.70 | 1.5 | 3.1 | 8 | |||

| Steel | 550 | 200 | 7.86 | − | − | − | 1.8 | 0.3 | 1.15 | 2.3 | 1.0 |

| fck (MPa) | fctm (MPa) | Ecm (GPa) | εcu2 (‰) | ρ (t/m³) | γm (–) | GWP (kgCO2 equ/m³) | Cost (EUR/m³) | |

|---|---|---|---|---|---|---|---|---|

| C20/25 | 20 | 2.2 | 30 | 3.5 | 2.4 | 1.5 | 178 | 100 |

| C25/30 | 25 | 2.6 | 31 | 198.5 | 110 | |||

| C30/37 | 30 | 2.9 | 33 | 219 | 120 | |||

| C35/45 | 35 | 3.2 | 34 | 239.5 | 125 | |||

| C40/50 | 40 | 3.5 | 35 | 260 | 135 | |||

| C45/55 | 45 | 3.8 | 36 | 280.5 | 140 | |||

| C50/60 | 50 | 4.1 | 37 | 300 | 145 |

| GWP Tot | GWP-R | GWP-C | Cost Tot | Cost-R | Cost-C | ||

|---|---|---|---|---|---|---|---|

| (kg CO2 eq/m) | (kg CO2 eq/m) | (kg CO2 eq/m) | (EUR/m) | (EUR/m) | (EUR/m) | ||

| Rail Platform Barrier | Steel | 29.2 | 7.7 | 21.5 | 15.3 | 3.4 | 11.9 |

| CFRP | 25.7 (−11.9%) | 5.6 (−27.9%) | 20.2 (−6.1%) | 20.9 (+36.6%) | 7.6 (+125.2%) | 13.3 (+11.6%) | |

| GFRP | 26.4 (−9.7%) | 5.1 (−34.3%) | 21.3 (−0.9%) | 20.9 (+36.6%) | 7.3 (+116.8%) | 13.6 (+14%) | |

| Retaining wall | Steel | 569.0 | 164.5 | 404.4 | 295.2 | 74.7 | 220.6 |

| CFRP | 617.3 (+8.5%) | 130 (−21%) | 487.3 (+20.5%) | 801.3 (+171.4%) | 435 (+482.6%) | 366.3 (+66.1%) | |

| GFRP | 567.2 (−0.3%) | 99.7 (−39.4%) | 467.5 (+15.6%) | 461.4 (+56.3%) | 172.1 (+130.5%) | 289.3 (+31.2%) | |

| Integral Bridge | Steel | 2459.0 | 846.1 | 1612.9 | 1251.6 | 367.8 | 883.8 |

| CFRP | 2825.3 (+14.9%) | 851 (+0.6%) | 1974.3 (+22.4%) | 5275.8 (+321.5%) | 3870 (+952.1%) | 1405.8 (+59.1%) | |

| GFRP | 2470 (+0.4%) | 594.3 (−29.8%) | 1875.7 (+16.3%) | 2232.6 (+78.4%) | 1042.8 (+183.5%) | 1189.8 (+34.6%) |

| GWP Tot | GWP-R | GWP-C | Cost Tot | Cost-R | Cost-C | ||

|---|---|---|---|---|---|---|---|

| (kg CO2 eq/m) | (kg CO2 eq/m) | (kg CO2 eq/m) | (EUR/m) | (EUR/m) | (EUR/m) | ||

| Rail Platform Barrier | Steel | 29.2 | 7.7 (26.4%) | 21.5 (73.6%) | 15.3 | 3.4 (22%) | 11.9 (78%) |

| CFRP | 25.7 | 5.6 (21.6%) | 20.2 (78.4%) | 20.9 | 7.6 (36.3%) | 13.3 (63.7%) | |

| GFRP | 26.4 | 5.1 (19.3%) | 21.3 (80.7%) | 20.9 | 7.3 (34.9%) | 13.6 (65.1%) | |

| Retaining wall | Steel | 569.0 | 164.5 (28.9%) | 404.4 (71.1%) | 295.2 | 74.7 (25.3%) | 220.6 (74.7%) |

| CFRP | 617.3 | 130 (21.1%) | 487.3 (78.9%) | 801.3 | 435 (54.3%) | 366.3 (45.7%) | |

| GFRP | 567.2 | 99.7 (17.6%) | 467.5 (82.4%) | 461.4 | 172.1 (37.3%) | 289.3 (62.7%) | |

| Integral Bridge | Steel | 2459.0 | 846.1 (34.4%) | 1612.9 (65.6%) | 1251.6 | 367.8 (29.4%) | 883.8 (70.6%) |

| CFRP | 2825.3 | 851 (30.1%) | 1974.3 (69.9%) | 5275.8 | 3870 (73.4%) | 1405.8 (26.6%) | |

| GFRP | 2470.0 | 594.3 (24.1%) | 1875.7 (75.9%) | 2232.6 | 1042.8 (46.7%) | 1189.8 (53.3%) |

| Conventional Concrete Mix Design | Concrete Mix Design with 40% Reduced GWP | ||||||

|---|---|---|---|---|---|---|---|

| GWP Tot | GWP-R | GWP-C | GWP Tot | GWP-R | GWP-C | ||

| (kg CO2 eq/m) | (kg CO2 eq/m) | (kg CO2 eq/m) | (kg CO2 eq/m) | (kg CO2 eq/m) | (kg CO2 eq/m) | ||

| Rail Platform Barrier | Steel | 29.2 | 7.7 | 21.5 | − | − | − |

| CFRP | 25.7 (−11.9%) | 5.6 (−27.9%) | 20.2 (−6.1%) | 17.2 (−41.2%) | 3.7 (−52%) | 13.5 (−37.4%) | |

| GFRP | 26.4 (−9.7%) | 5.1 (−34.3%) | 21.3 (−0.9%) | 17.5 (−40.3%) | 3.2 (−58.6%) | 14.3 (−33.7%) | |

| Retaining wall | Steel | 569.0 | 164.5 | 404.4 | − | − | − |

| CFRP | 617.3 (+8.5%) | 130 (−21%) | 487.3 (+20.5%) | 416.6 (−26.8%) | 109.3 (−33.5%) | 307.3 (−24%) | |

| GFRP | 567.2 (−0.3%) | 99.7 (−39.4%) | 467.5 (+15.6%) | 377.6 (−33.6%) | 85.2 (−48.2%) | 292.4 (−27.7%) | |

| Integral Bridge | Steel | 2459.0 | 846.1 | 1612.9 | − | − | − |

| CFRP | 2825.3 (+14.9%) | 851 (+0.6%) | 1974.3 (+22.4%) | 2035.6 (−17.2%) | 851 (+0.6%) | 1184.6 (−26.6%) | |

| GFRP | 2470 (+0.4%) | 594.3 (−29.8%) | 1875.7 (+16.3%) | 1695.2 (−31.1%) | 431.8 (−49%) | 1263.4 (−21.7%) | |

| FRP Costs as of Today | 30% FRP Cost Reduction | ||||||

|---|---|---|---|---|---|---|---|

| Cost Tot | Cost-R | Cost-C | Cost Tot | Cost-R | Cost-C | ||

| (EUR/m) | (EUR/m) | (EUR/m) | (EUR/m) | (EUR/m) | (EUR/m) | ||

| Rail Platform Barrier | Steel | 15.3 | 3.4 | 11.9 | − | − | − |

| CFRP | 20.9 (+36.6%) | 7.6 (+125.2%) | 13.3 (+11.6%) | 18.6 (+21.6%) | 5.8 (+73.4%) | 12.7 (+7%) | |

| GFRP | 20.9 (+36.6%) | 7.3 (+116.8%) | 13.6 (+14%) | 18.7 (+22.3%) | 5.1 (+51.8%) | 13.6 (+14%) | |

| Retaining wall | Steel | 295.2 | 74.7 | 220.6 | − | − | − |

| CFRP | 801.3 (+171.4%) | 435 (+482.6%) | 366.3 (+66.1%) | 657.3 (+122.6%) | 357 (+378.1%) | 300.3 (+36.2%) | |

| GFRP | 461.4 (+56.3%) | 172.1 (+130.5%) | 289.3 (+31.2%) | 409.8 (+38.8%) | 120.5 (+61.3%) | 289.3 (+31.2%) | |

| Integral Bridge | Steel | 1251.6 | 367.8 | 883.8 | − | − | − |

| CFRP | 5275.8 (+321.5%) | 3870 (+952.1%) | 1405.8 (+59.1%) | 4069.8 (+225.2%) | 2898 (+687.8%) | 1171.8 (+32.6%) | |

| GFRP | 2232.6 (+78.4%) | 1042.8 (+183.5%) | 1189.8 (+34.6%) | 1919.8 (+53.4%) | 730 (+98.4%) | 1189.8 (+34.6%) | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Preinstorfer, P.; Huber, T.; Reichenbach, S.; Lees, J.M.; Kromoser, B. Parametric Design Studies of Mass-Related Global Warming Potential and Construction Costs of FRP-Reinforced Concrete Infrastructure. Polymers 2022, 14, 2383. https://doi.org/10.3390/polym14122383

Preinstorfer P, Huber T, Reichenbach S, Lees JM, Kromoser B. Parametric Design Studies of Mass-Related Global Warming Potential and Construction Costs of FRP-Reinforced Concrete Infrastructure. Polymers. 2022; 14(12):2383. https://doi.org/10.3390/polym14122383

Chicago/Turabian StylePreinstorfer, Philipp, Tobias Huber, Sara Reichenbach, Janet M. Lees, and Benjamin Kromoser. 2022. "Parametric Design Studies of Mass-Related Global Warming Potential and Construction Costs of FRP-Reinforced Concrete Infrastructure" Polymers 14, no. 12: 2383. https://doi.org/10.3390/polym14122383

APA StylePreinstorfer, P., Huber, T., Reichenbach, S., Lees, J. M., & Kromoser, B. (2022). Parametric Design Studies of Mass-Related Global Warming Potential and Construction Costs of FRP-Reinforced Concrete Infrastructure. Polymers, 14(12), 2383. https://doi.org/10.3390/polym14122383