Influence of CNT Length on Dispersion, Localization, and Electrical Percolation in a Styrene-Butadiene-Based Star Block Copolymer

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Shortening and Characterization of CNTs

2.2.1. Ball Milling

2.2.2. Surface Characterization of CNT Powder

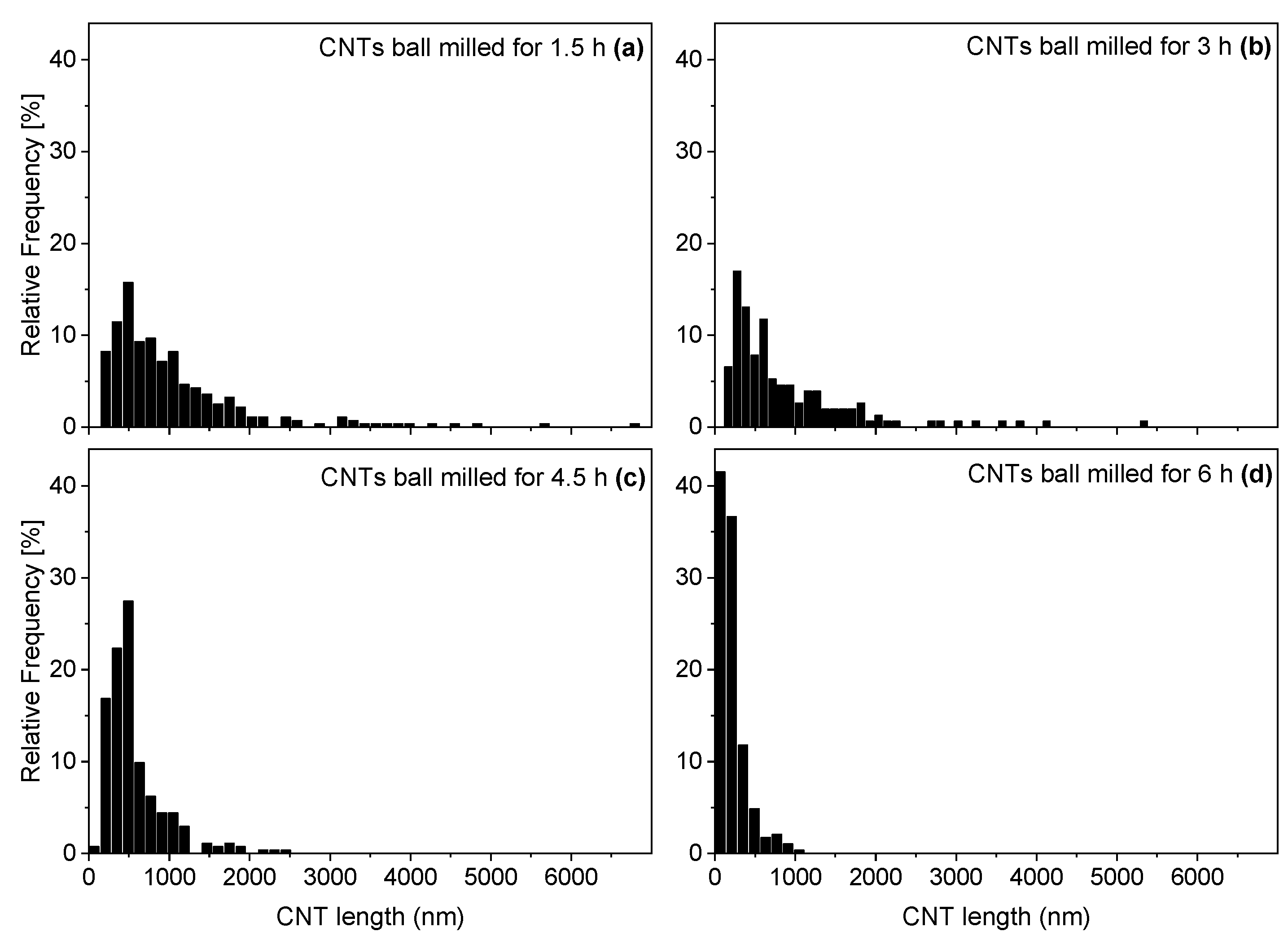

2.2.3. Evaluation of CNT Length Distribution

2.2.4. Dynamic Light Scattering

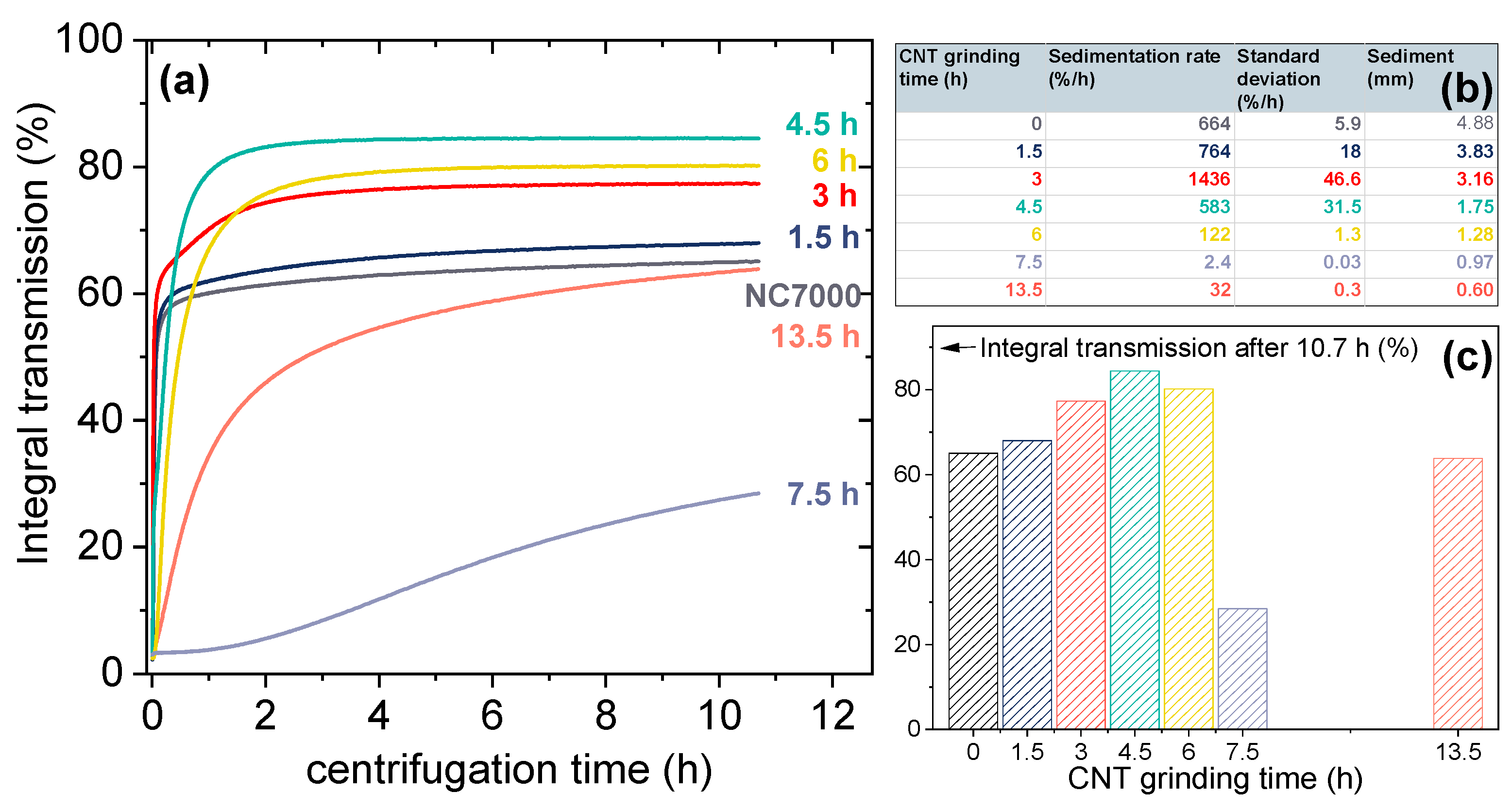

2.2.5. Sedimentation Analysis of CNTs in Polymer Solutions

2.3. Processing of BCP/CNT Composites

2.3.1. Solution Mixing

2.3.2. Dip Coating

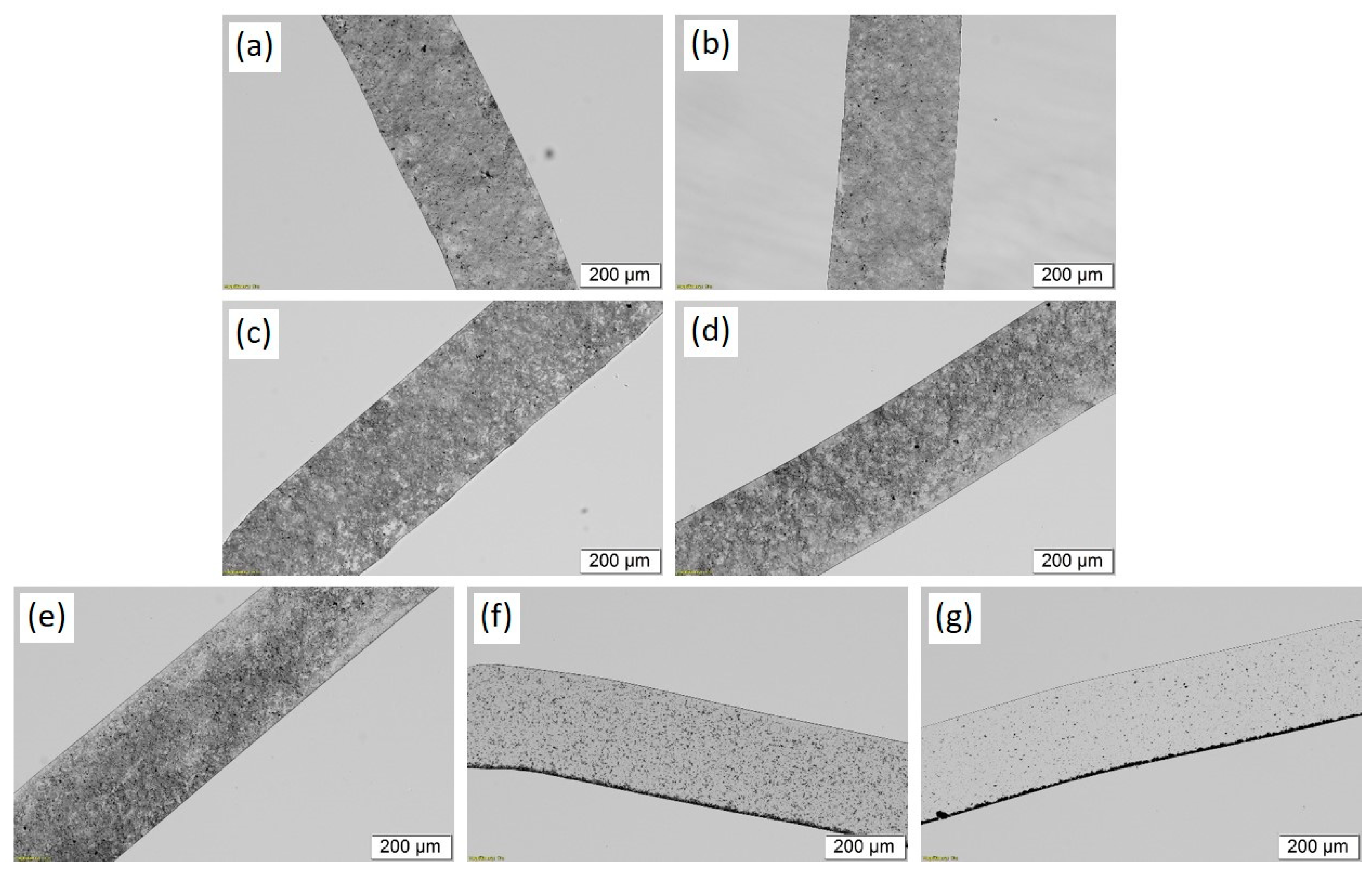

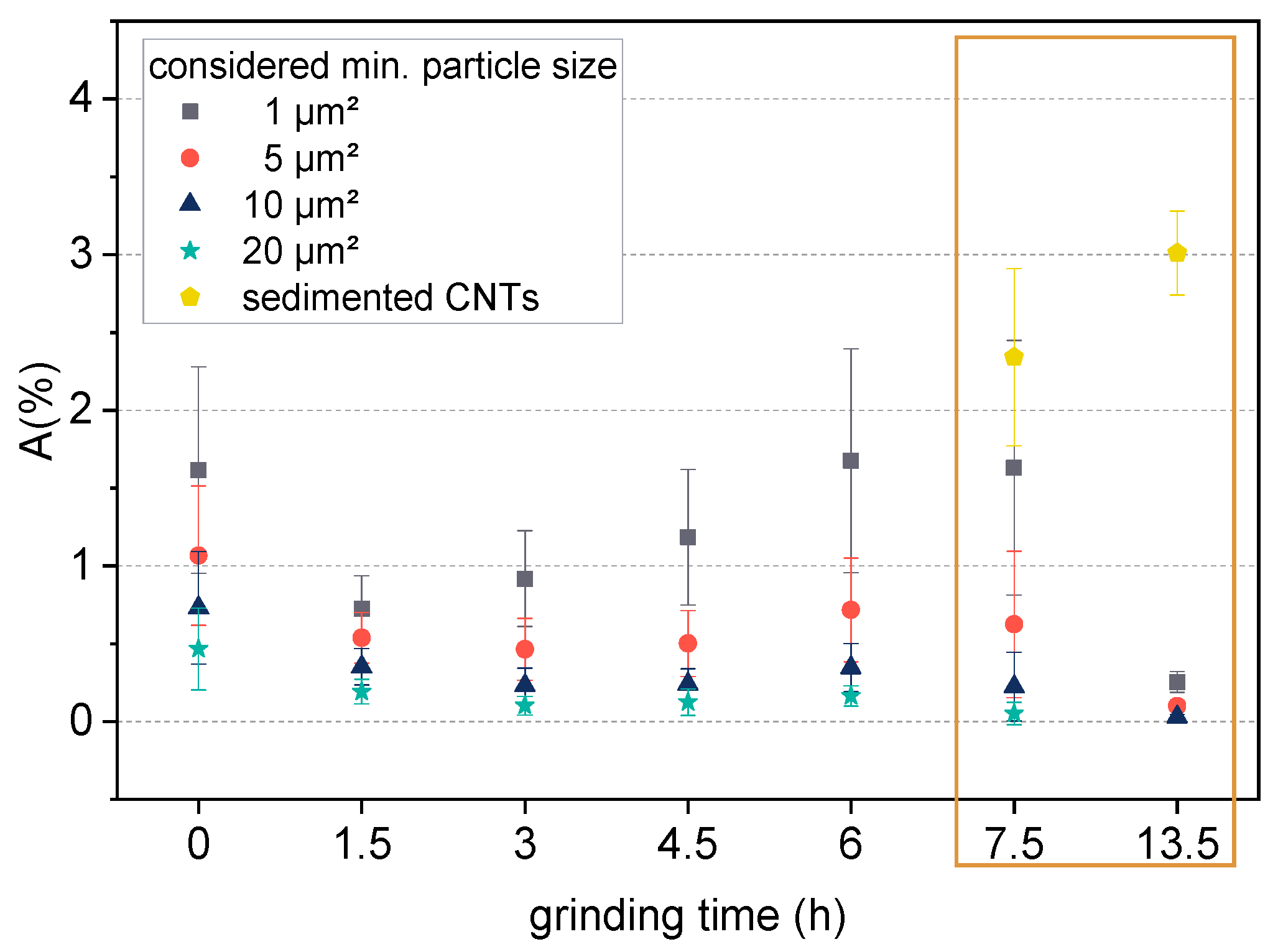

2.4. Evaluation of CNT Macrodispersion

2.5. Characterization of Composite Morphology and CNT Localization

2.6. Dynamic Mechanical Analysis

2.7. Mechanical Properties

2.8. Electrical Characterization

2.8.1. Powder Conductivity of CNTs

2.8.2. Volume Resistivity of BCP/CNT Composites

2.8.3. Surface Resistivity of BCP/CNT Composites

3. Results and Discussion

3.1. Characteristics of Shortened CNTs

3.2. Stability of Polymer/CNT Dispersions

3.3. BCP/CNT Nanocomposites: CNT Dispersion and BCP Morphology

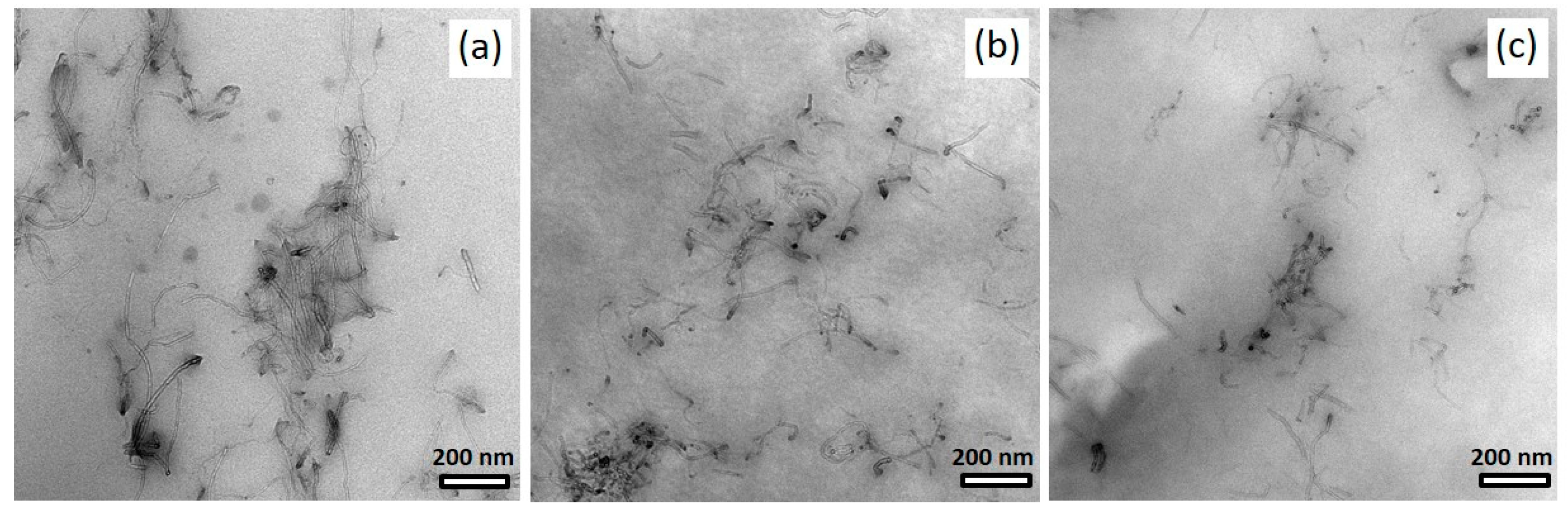

3.3.1. CNT Macro- and Microdispersion

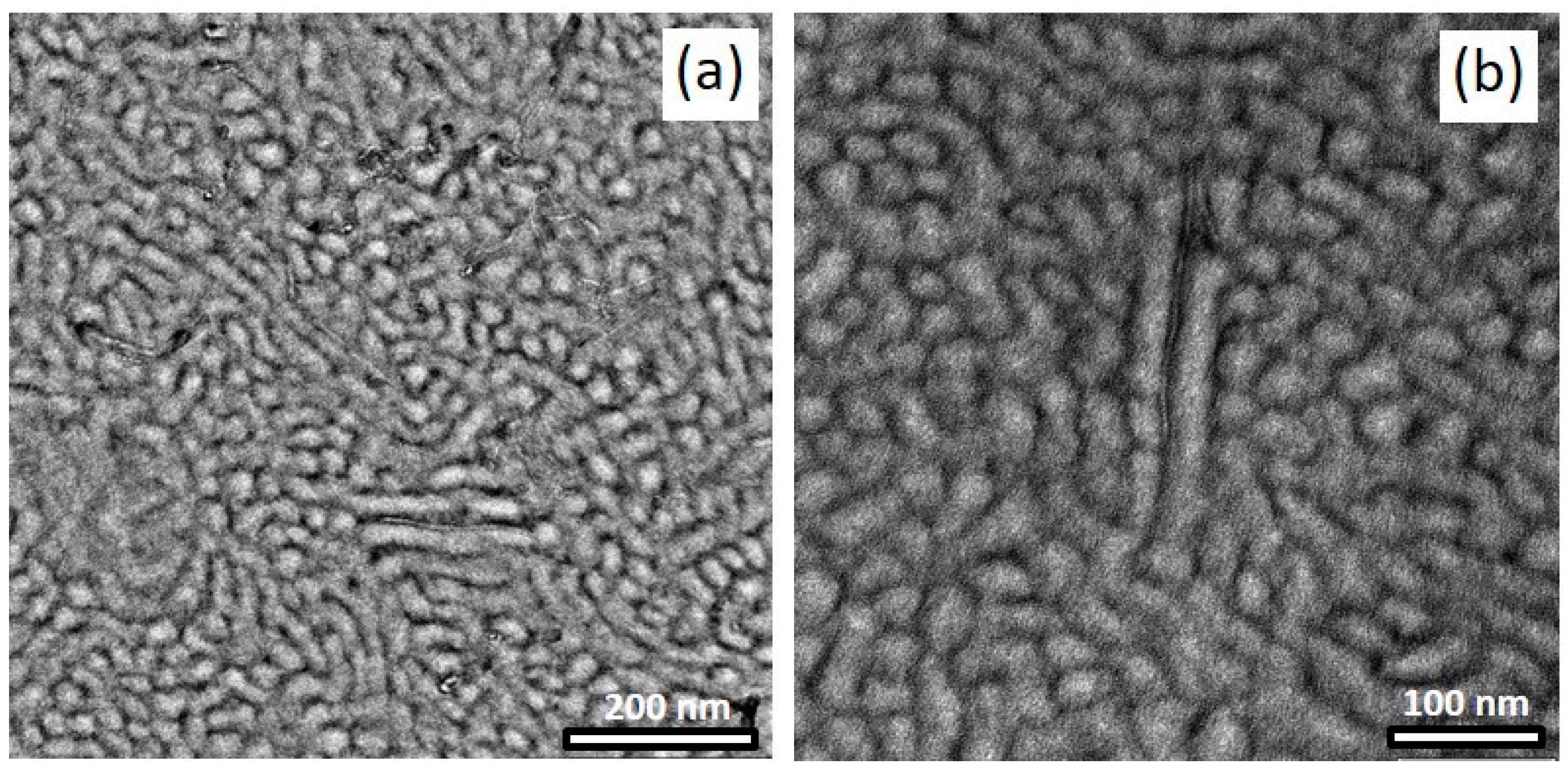

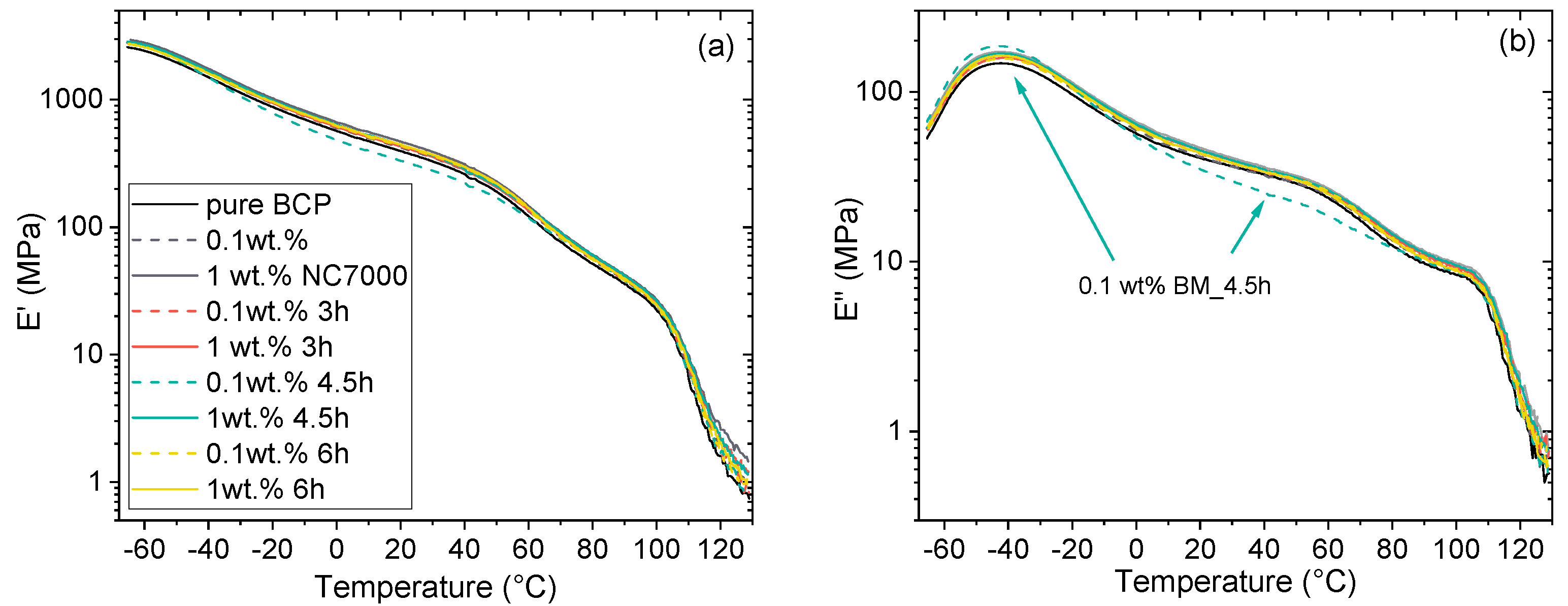

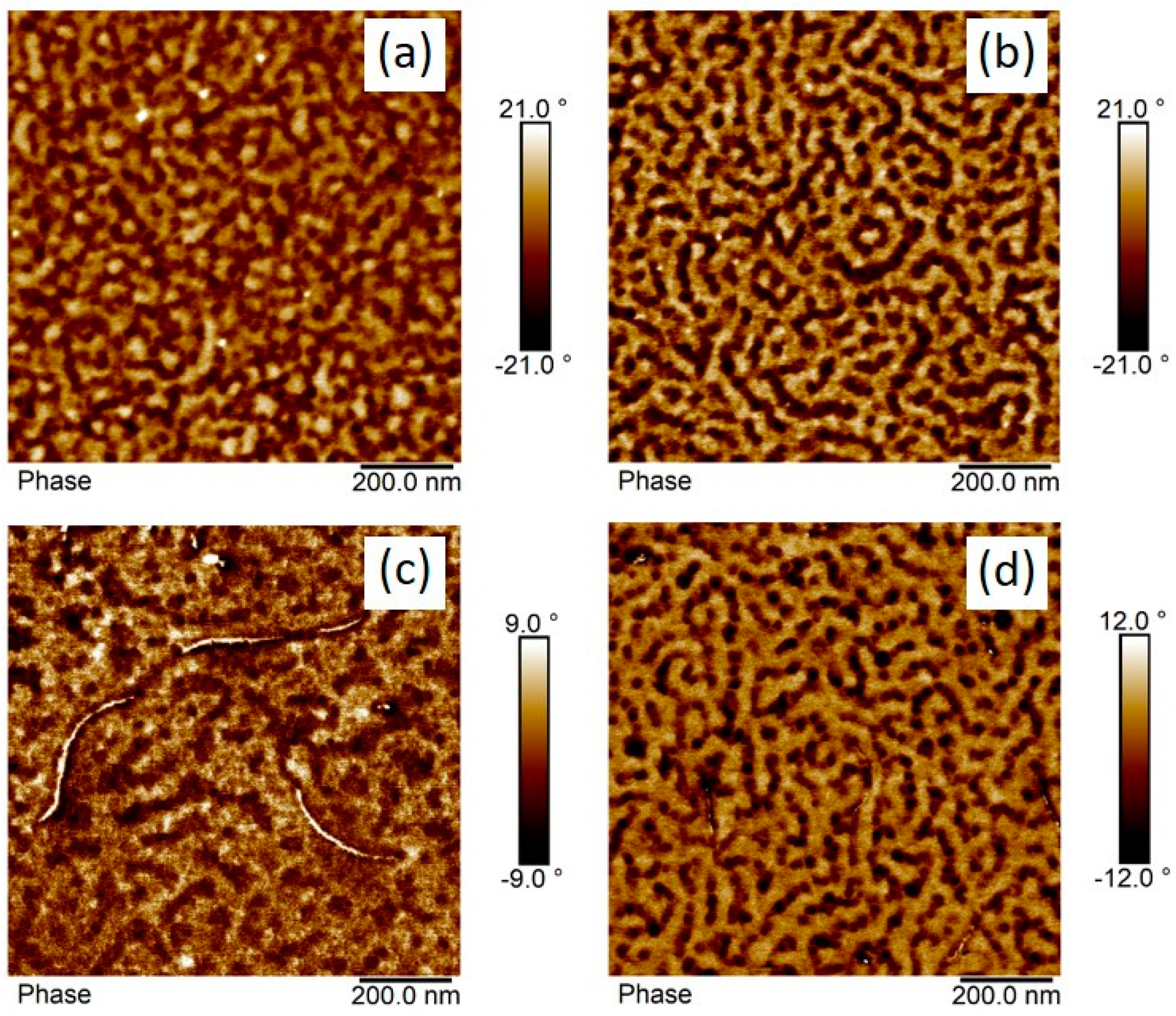

3.3.2. Influence of Shortened CNTs on BCP Morphology and Phase Behavior

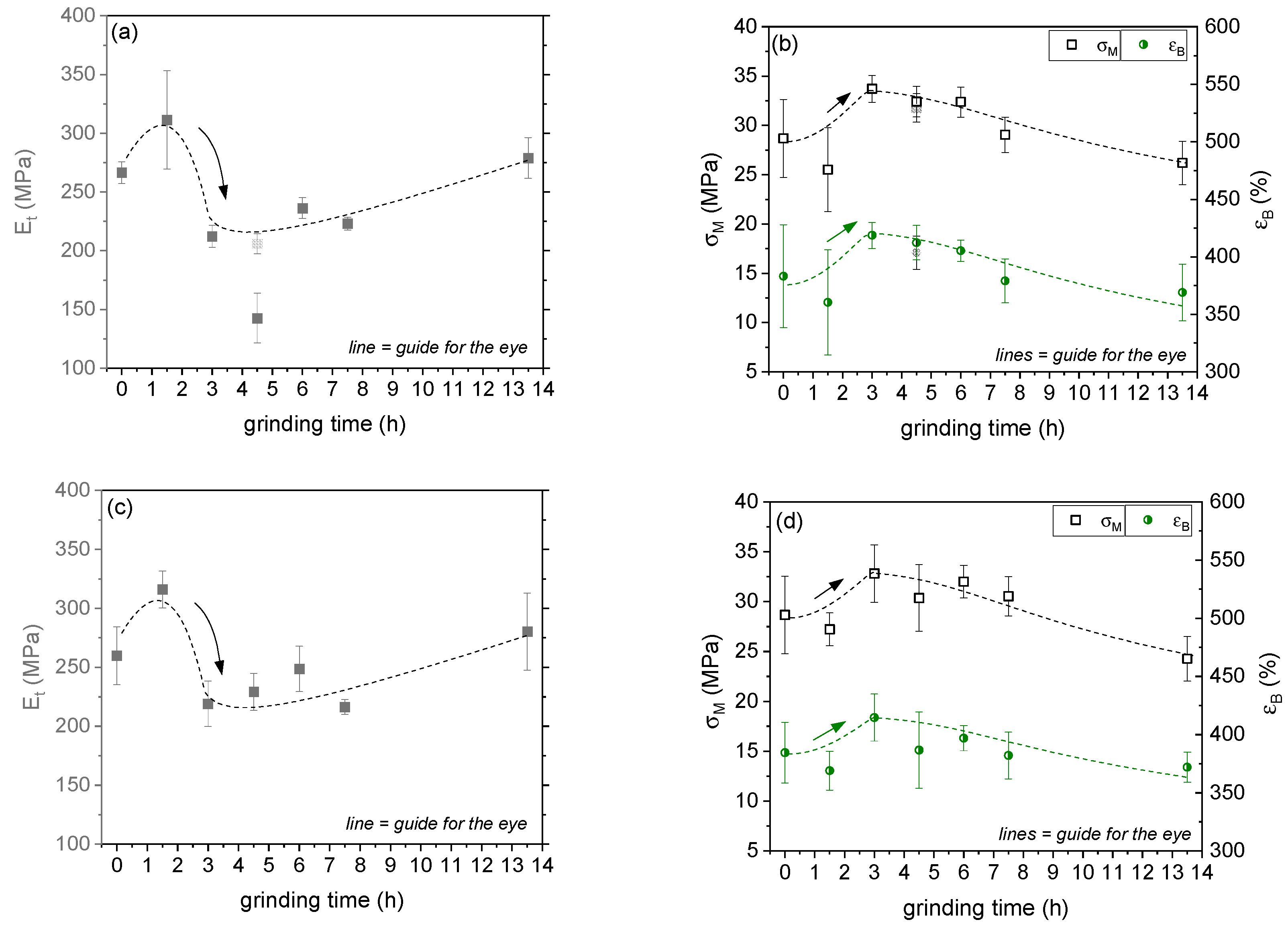

3.4. Stress-Strain Behavior

3.5. Electrical Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, F.; Cheng, H.M.; Bai, S.; Su, G.; Dresselhaus, M.S. Tensile strength of single-walled carbon nanotubes directly measured from their macroscopic ropes. Appl. Phys. Lett. 2000, 77, 3161–3163. [Google Scholar] [CrossRef]

- Gutsche, C.S.; Reich, C.; Thomsen, J. Maultzsch: Carbon nanotubes, basic concepts and physical properties. Colloid Polym. Sci. 2004, 282, 1299. [Google Scholar] [CrossRef]

- Kumanek, B.; Janas, D. Thermal conductivity of carbon nanotube networks: A review. J. Mater. Sci. 2019, 54, 7397–7427. [Google Scholar] [CrossRef] [Green Version]

- Krause, B.; Ritschel, M.; Täschner, C.; Oswald, S.; Gruner, W.; Leonhardt, A.; Pötschke, P. Comparison of nanotubes produced by fixed bed and aerosol-CVD methods and their electrical percolation behaviour in melt mixed polyamide 6.6 composites. Compos. Sci. Technol. 2010, 70, 151–160. [Google Scholar] [CrossRef]

- Sandler, J.K.W.; Kirk, J.E.; Kinloch, I.A.; Shaffer, M.S.P.; Windle, A.H. Ultra-low electrical percolation threshold in carbon-nanotube-epoxy composites. Polymer 2003, 44, 5893–5899. [Google Scholar] [CrossRef]

- Qi, X.-d.; Yang, J.-h.; Zhang, N.; Huang, T.; Zhou, Z.-w.; Kühnert, I.; Pötschke, P.; Wang, Y. Selective localization of carbon nanotubes and its effect on the structure and properties of polymer blends. Prog. Polym. Sci. 2021, 123, 101471. [Google Scholar] [CrossRef]

- Sumita, M.; Sakata, K.; Hayakawa, Y.; Asai, S.; Miyasaka, K.; Tanemura, M. Double percolation effect on the electrical conductivity of conductive particles filled polymer blends. Colloid Polym. Sci. 1992, 270, 134–139. [Google Scholar] [CrossRef]

- Narkis, M.; Srivastava, S.; Tchoudakov, R.; Breuer, O. Sensors for liquids based on conductive immiscible polymer blends. Synth. Met. 2000, 113, 29–34. [Google Scholar] [CrossRef]

- Li, Y.; Pionteck, J.; Pötschke, P.; Voit, B. Thermal annealing to influence the vapor sensing behavior of co-continuous poly(lactic acid)/polystyrene/multiwalled carbon nanotube composites. Mater. Des. 2020, 187, 108383. [Google Scholar] [CrossRef]

- Garate, H.; Fascio, M.L.; Mondragon, I.; D’Accorso, N.B.; Goyanes, S. Surfactant-aided dispersion of polystyrene-functionalized carbon nanotubes in a nanostructured poly(styrene-b-isoprene-b-styrene) block copolymer. Polymer 2011, 52, 2214–2220. [Google Scholar] [CrossRef]

- Peponi, L.; Tercjak, A.; Gutierrez, J.; Cardinali, M.; Mondragon, I.; Valentini, L.; Kenny, J.M. Mapping of carbon nanotubes in the polystyrene domains of a polystyrene-b-polyisoprene-b-polystyrene block copolymer matrix using electrostatic force microscopy. Carbon 2010, 48, 2590–2595. [Google Scholar] [CrossRef]

- Liu, Y.T.; Zhang, Z.L.; Zhao, W.; Xie, X.M.; Ye, X.Y. Selective self-assembly of surface-functionalized carbon nanotubes in block copolymer template. Carbon 2009, 47, 1883–1885. [Google Scholar] [CrossRef]

- Park, I.; Lee, W.; Kim, J.; Park, M.; Lee, H. Selective sequestering of multi-walled carbon nanotubes in self-assembled block copolymer. Sens. Actuator B-Chem. 2007, 126, 301–305. [Google Scholar] [CrossRef]

- Albuerne, J.; Boschetti-de-Fierro, A.; Abetz, C.; Fierro, D.; Abetz, V. Block Copolymer Nanocomposites Based on Multiwall Carbon Nanotubes: Effect of the Functionalization of Multiwall Carbon Nanotubes on the Morphology of the Block Copolymer. Adv. Eng. Mater. 2012, 13, 803–810. [Google Scholar] [CrossRef]

- Wode, F.; Tzounis, L.; Kirsten, M.; Constantinou, M.; Georgopanos, P.; Rangou, S.; Zafeiropoulos, N.E.; Avgeropoulos, A.; Stamm, M. Selective localization of multi-wall carbon nanotubes in homopolymer blends and a diblock copolymer. Rheological orientation studies of the final nanocomposites. Polymer 2012, 53, 4438–4447. [Google Scholar] [CrossRef]

- Hasanabadi, N.; Nazockdast, H.; Gajewska, B.; Balog, S.; Gunkel, I.; Bruns, N.; Lattuada, M. Structural Behavior of Cylindrical Polystyrene-block-Poly(ethylene-butylene)-block-Polystyrene (SEBS) Triblock Copolymer Containing MWCNTs: On the Influence of Nanoparticle Surface Modification. Macromol. Chem. Phys. 2017, 218, 1700231. [Google Scholar] [CrossRef] [Green Version]

- Staudinger, U.; Jakisch, L.; Hilbig, L. Dispersion and Localization Behavior of Modified MWCNTs in Immiscible Polymer Blends of Polystyrene and Polybutadiene and in Corresponding Nanostructured Block Copolymers. J. Compos. Sci. 2020, 4, 40. [Google Scholar] [CrossRef] [Green Version]

- Staudinger, U.; Satapathy, B.K.; Jehnichen, D. Nanofiller dispersion, morphology, mechanical behavior and electrical properties of nanostructured styrene-butadiene based triblock copolymer/CNT composites. Polymers 2019, 11, 1831. [Google Scholar] [CrossRef] [Green Version]

- Dai, W.; Wang, D. Cutting Methods and Perspectives of Carbon Nanotubes. J. Phys. Chem. C 2021, 125, 9593–9617. [Google Scholar] [CrossRef]

- Vimalanathan, K.; Gascooke, J.R.; Suarez-Martinez, I.; Marks, N.A.; Kumari, H.; Garvey, C.J.; Atwood, J.L.; Lawrance, W.D.; Raston, C.L. Fluid dynamic lateral slicing of high tensile strength carbon nanotubes. Sci. Rep. 2016, 6, 22865. [Google Scholar] [CrossRef] [Green Version]

- Alharbi, T.M.D.; Vimalanathan, K.; Lawrance, W.D.; Raston, C.L. Controlled slicing of single walled carbon nanotubes under continuous flow. Carbon 2018, 140, 428–432. [Google Scholar] [CrossRef]

- Alharbi, T.M.D.; Vimalanathan, K.; Alsulami, I.K.; Raston, C.L. Vertically aligned laser sliced MWCNTs. Nanoscale 2019, 11, 21394–21403. [Google Scholar] [CrossRef] [PubMed]

- Pierard, N.; Fonseca, A.; Colomer, J.F.; Bossuot, C.; Benoit, J.M.; Van Tendeloo, G.; Pirard, J.P.; Nagy, J.B. Ball milling effect on the structure of single-wall carbon nanotubes. Carbon 2004, 42, 1691–1697. [Google Scholar] [CrossRef]

- Liu, F.; Zhang, X.; Cheng, J.; Tu, J.; Kong, F.; Huang, W.; Chen, C. Preparation of short carbon nanotubes by mechanical ball milling and their hydrogen adsorption behavior. Carbon 2003, 41, 2527–2532. [Google Scholar] [CrossRef]

- Krause, B.; Villmow, T.; Boldt, R.; Mende, M.; Petzold, P.; Pötschke, P. Influence of dry grinding in a ball mill on the length of multiwalled carbon nanotubes and their dispersion and percolation behaviour in melt mixed polycarbonate composites. Compos. Sci. Technol. 2011, 71, 1145–1153. [Google Scholar] [CrossRef] [Green Version]

- NANOCYL NC7000TM-Technical Datasheet: DM-TI-02-TDS-NC7000-V08. Available online: www.nanocyl.com (accessed on 3 June 2020).

- Knoll, K.; Niessner, N. Styrolux(+) and Styroflex(+)-From transparent high impact polystyrene to new thermoplastic elastomers-Syntheses, applications and blends with other styrene based polymers. Macromol. Symp. 1998, 132, 231–243. [Google Scholar] [CrossRef]

- Saalwächter, K.; Thomann, Y.; Hasenhindl, A.; Schneider, H. Direct Observation of Interphase Composition in Block Copolymers. Macromolecules 2008, 41, 9187–9191. [Google Scholar] [CrossRef] [Green Version]

- Krause, B.; Boldt, R.; Pötschke, P. A method for determination of length distributions of multiwalled carbon nanotubes before and after melt processing. Carbon 2011, 49, 1243–1247. [Google Scholar] [CrossRef]

- Lerche, D. Dispersion stability and particle characterization by sedimentation kinetics in a centrifugal field. J. Dispers. Sci. Technol. 2002, 23, 699–709. [Google Scholar] [CrossRef]

- Bittrich, E.; Eichhorn, K.-J. 8. Advances of spectroscopic ellipsometry in the analysis of thin polymer films-polymer interfaces. In Polymer Surface Characterization; Luigia, S., Ed.; De Gruyter: Berlin, Germany, 2014; pp. 247–286. [Google Scholar] [CrossRef]

- Aspnes, D.E. Optical properties of thin films. Thin Solid Film. 1982, 89, 249–262. [Google Scholar] [CrossRef]

- Magonov, S.N.; Elings, V.; Whangbo, M.H. Phase imaging and stiffness in tapping-mode atomic force microscopy. Surf. Sci. 1997, 375, L385–L391. [Google Scholar] [CrossRef]

- Krause, B.; Boldt, R.; Häußler, L.; Pötschke, P. Ultralow percolation threshold in polyamide 6.6/MWCNT composites. Compos. Sci. Technol. 2015, 114, 119–125. [Google Scholar] [CrossRef]

- Kourki, H.; Famili, M.H.N. Particle sedimentation: Effect of polymer concentration on particle–particle interaction. Powder Technol. 2012, 221, 137–143. [Google Scholar] [CrossRef]

- Adhikari, R.; Buschnakowski, M.; Henning, S.; Goerlitz, S.; Huy, T.A.; Lebek, W.; Godehardt, R.; Michler, G.H.; Lach, R.; Geiger, K.; et al. Double Yielding in a Styrene/Butadiene Star Block Copolymer. Macromol. Rapid Commun. 2004, 25, 653–658. [Google Scholar] [CrossRef]

- Satapathy, B.K.; Lach, R.; Weidisch, R.; Schneider, K.; Janke, A.; Knoll, K. Morphology and crack toughness behaviour of nanostructured block copolymer/homopolyrner blends. Eng. Fract. Mech. 2006, 73, 2399–2412. [Google Scholar] [CrossRef]

- Thomann, Y.; Thomann, R.; Hasenhindl, A.; Mulhaupt, R.; Heck, B.; Knoll, K.; Steininger, H.; Saalwächter, K. Gradient Interfaces in SBS and SBS/PS Blends and Their Influence on Morphology Development and Material Properties. Macromolecules 2009, 42, 5684–5699. [Google Scholar] [CrossRef]

- Staudinger, U.; Satapathy, B.K. Influence of Carbon Nanotubes on the Morphology and Properties of Styrene-Butadiene Based Block Copolymers. Macromol. Symp. 2017, 373, 1700030. [Google Scholar] [CrossRef]

- Ganß, M.; Staudinger, U.; Satapathy, B.K.; Leuteritz, A.; Weidisch, R. Mechanism of strengthening and toughening of a nanostructured styrene-butadiene based block copolymer by oligostyrene-modified montmorillonites. Polymer 2021, 213, 123328. [Google Scholar] [CrossRef]

- Adhikari, R.; Michler, G.H.; Huy, T.A.; Ivan’kova, E.; Godehardt, R.; Lebek, W.; Knoll, K. Correlation between Molecular Architecture, Morphology, and Deformation Behaviour of Styrene/Butadiene Block Copolymers. Macromol. Chem. Phys. 2003, 204, 488–499. [Google Scholar] [CrossRef]

- Pospiech, D.; Jehnichen, D.; Eckstein, K.; Scheibe, P.; Komber, H.; Sahre, K.; Janke, A.; Reuter, U.; Häußler, L.; Schellkopf, L.; et al. Semifluorinated PMMA Block Copolymers: Synthesis, Nanostructure, and Thin Film Properties. Macromol. Chem. Phys. 2017, 218, 1600599. [Google Scholar] [CrossRef] [Green Version]

- Krishnamoorti, R.; Silva, A.S.; Mitchell, C.A. Effect of silicate layer anisotropy on cylindrical and spherical microdomain ordering in block copolymer nanocomposites. J. Chem. Phys. 2001, 115, 7175–7181. [Google Scholar] [CrossRef] [Green Version]

- Silva, A.S.; Mitchell, C.A.; Tse, M.F.; Wang, H.-C.; Krishnamoorti, R. Templating of cylindrical and spherical block copolymer microdomains by layered silicates. J. Chem. Phys. 2001, 115, 7166–7174. [Google Scholar] [CrossRef]

- Adhikari, R.; Huy, T.A.; Buschnakowski, M.; Michler, G.H.; Knoll, K. Asymmetric PS-block-(PS-co-PB)-block-PS block copolymers: Morphology formation and deformation behaviour. New J. Phys. 2004, 6, 28. [Google Scholar] [CrossRef] [Green Version]

- Staudinger, U.; Krause, B.; Steinbach, C.; Pötschke, P.; Voit, B. Dispersability of multiwalled carbon nanotubes in polycarbonate-chloroform solutions. Polymer 2014, 55, 10. [Google Scholar] [CrossRef]

- Cheng, Q.H.; Debnath, S.; O’Neill, L.; Hedderman, T.G.; Gregan, E.; Byrne, H.J. Systematic Study of the Dispersion of SWNTs in Organic Solvents. J. Phys. Chem. C 2010, 114, 4857–4863. [Google Scholar] [CrossRef] [Green Version]

- Giordani, S.; Bergin, S.D.; Nicolosi, V.; Lebedkin, S.; Kappes, M.M.; Blau, W.J.; Coleman, J.N. Debundling of single-walled nanotubes by dilution: Observation of large populations of individual nanotubes in amide solvent dispersions. J. Phys. Chem. B 2006, 110, 15708–15718. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Staudinger, U.; Janke, A.; Steinbach, C.; Reuter, U.; Ganß, M.; Voigt, O. Influence of CNT Length on Dispersion, Localization, and Electrical Percolation in a Styrene-Butadiene-Based Star Block Copolymer. Polymers 2022, 14, 2715. https://doi.org/10.3390/polym14132715

Staudinger U, Janke A, Steinbach C, Reuter U, Ganß M, Voigt O. Influence of CNT Length on Dispersion, Localization, and Electrical Percolation in a Styrene-Butadiene-Based Star Block Copolymer. Polymers. 2022; 14(13):2715. https://doi.org/10.3390/polym14132715

Chicago/Turabian StyleStaudinger, Ulrike, Andreas Janke, Christine Steinbach, Uta Reuter, Martin Ganß, and Oliver Voigt. 2022. "Influence of CNT Length on Dispersion, Localization, and Electrical Percolation in a Styrene-Butadiene-Based Star Block Copolymer" Polymers 14, no. 13: 2715. https://doi.org/10.3390/polym14132715