Permeation Characteristics of CH4 in PVDF with Crude Oil-Containing

Abstract

:1. Introduction

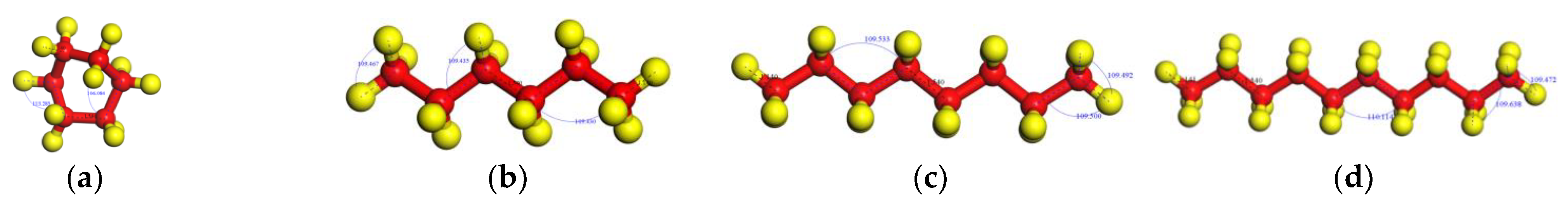

2. Theoretical Basis of Permeation

3. Simulation Method

4. Simulation Results and Discussion

4.1. Permeation Behavior of CH4 in PVDF Containing Crude Oil

4.1.1. Solubility

4.1.2. Diffusion

4.1.3. Permeation

4.2. Permeation Mechanism of CH4 in PVDF Containing Crude Oil

5. Conclusions

- Because the crude oil molecules absorbed into PVDF can occupy certain adsorption sites, the solubility coefficients of CH4 in PVDF containing crude oil are much lower than in pure PVDF, with drops between 58.74% and 73.01%.

- The diffusion coefficients of CH4 in PVDF containing crude oil are in the range of 2.961 × 10−6–8.274 × 10−6 cm2·s−1, which are about three times greater than in pure PVDF under the same conditions. It is considered that the absorption of oil molecules leads to the volume swelling of PVDF and then increases the free volume for diffusion.

- The absorbed crude oil molecules in PVDF have a significant effect on the permeation process of CH4 in PVDF. The absorption of crude oil molecules would improve the permeability of gas molecules in PVDF as a whole.

- The mechanism of CH4 molecules permeated into oil-containing PVDF can be concluded as follows. CH4 molecules are selective-aggregation adsorbed in the region with low potential energy in PVDF containing crude oil firstly, then the absorbed CH4 molecules vibrate in the holes in most cases, and the calculated movement displacement is always within 0.1 nm. At higher temperatures or pressures, CH4 molecules can jump into neighboring holes at certain times due to their stronger thermal motion, and the transition distance is more than 0.2 nm.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sarrasin, F.; Memari, P.; Klopffer, M.; Lachet, V.; Condat, C.T.; Rousseau, B.; Espuche, E. Influence of high pressures on CH4, CO2 and H2S solubility in polyethylene: Experimental and molecular simulation approaches for pure gas and gas mixtures. Modelling of the sorption isotherms. J. Membr. Sci. 2015, 490, 380–388. [Google Scholar]

- Osborne, J. Thermoplastic pipes-lighter, more flexible solutions for oil and gas extraction. Reinf. Plast. 2013, 57, 33–38. [Google Scholar]

- Zhang, D.; Li, H.; Qi, D.; Nan, D.; Xiaodong, S.; Bin, W.; Xuehua, C. Gas Permeation behaviors of high-density polyethylene as a liner material of flexible pipes. Nat. Gas Ind. 2017, 37, 104–109. [Google Scholar]

- Shamsuddoha, M.; Islam, M.M.; Aravinthan, T.; Manalo, A.; Lau, K. Effectiveness of using fibre-reinforced polymer composites for underwater steel pipeline repairs. Compos. Struct. 2013, 100, 40–54. [Google Scholar]

- Makino, Y.; Okamoto, T.; Goto, Y.; Araki, M. The problem of gas permeation in flexible pipe. In Proceedings of the Offshore Technology Conference (OTC-5745-MS), Houston, TX, USA, 2 May 1988. [Google Scholar]

- Teplyakov, V.; Meares, P. Correlation aspects of the selective gas permeabilities of polymeric materials and membranes. Gas Sep. Purif. 1990, 4, 66–74. [Google Scholar] [CrossRef]

- Mahallati, P.; Arefazar, A.; Naderi, G. Thermal and morphological properties of thermoplastic elastomer nanocomposites based on PA6/NBR. Iran. J. Chem. Eng. 2011, 8, 56–65. [Google Scholar]

- Katoch, S.; Sharma, V.; Kundu, P.P. Swelling kinetics of unsaturated polyester and their montmorillonite filled nanocomposite synthesized from glycolyzed PET. Diffus. Fundam. 2011, 15, 1–28. [Google Scholar]

- Minelli, M.; Sarti, G.C. Permeability and diffusivity of CO2 in glassy polymers with and without plasticization. J. Membr. Sci. 2013, 435, 176–185. [Google Scholar]

- Li, H.; Freeman, B.D.; Ekiner, O.M. Gas permeation properties of Poly(urethane-urea) containing different polyethers. J. Membr. Sci. 2011, 369, 49–58. [Google Scholar]

- Georage, S.C.; Thomas, S. Transport phenomena through polymeric systems. Prog. Polym. Sci. 2011, 26, 985–1017. [Google Scholar]

- Yang, Y.; Nair, A.K.N.; Sun, S. Adsorption and diffusion of methane and carbon dioxide in amorphous regions of cross-linked polyethylene: A molecular simulation study. Ind. Eng. Chem. Res. 2019, 58, 8426–8436. [Google Scholar] [CrossRef]

- Dubbeldam, D.; Calero, S.; Ellis, D.E.; Snurr, R.Q. Molecular simulation software for adsorption and diffusion in flexible nanoporous materials. Mol. Simul. 2016, 42, 81–101. [Google Scholar] [CrossRef] [Green Version]

- Kadoura, A.; Nair, A.K.N. Molecular simulation study of montmorillonite in contact with variably wet supercritical carbon dioxide. J. Phys. Chem. C 2017, 121, 6199–6208. [Google Scholar] [CrossRef]

- Hui, W.; Yong, X. Molecular dynamics simulation of gas diffusion behavior in polyethylene terephthalate/aluminium/polyethylene interface. Compos. Interfaces 2017, 24, 915–926. [Google Scholar]

- Raptis, T.E.; Raptis, V.E.; Samios, J. Quantitative study of diffusion jumps in atomistic simulations of model gas–polymer systems. Mol. Phys. 2012, 110, 1171–1178. [Google Scholar] [CrossRef]

- Dutta, R.C.; Bhatia, S.K. Transport diffusion of light gases in Polyethylene using atomistic simulations. Langmuir 2017, 33, 936–946. [Google Scholar] [CrossRef]

- Lu, C.; Ni, S.; Chen, W.-K.; Liao, J.; Zhang, C. A molecular modeling study on small molecule gas transportation in poly (chloro-p-xylylene). Comput. Mater. Sci. 2010, 49, 65–69. [Google Scholar] [CrossRef]

- Börjesson, A.; Erdtman, E.; Ahlström, P.; Berlin, M.; Andersson, T.; Bolton, K. Molecular modelling of oxygen and water permeation in polyethylene. Polymer 2013, 54, 2988–2998. [Google Scholar] [CrossRef] [Green Version]

- Eslami, H.; Müller-Plathe, F. Molecular dynamics simulation of sorption of gases in polystyrene. Macromolecules 2007, 40, 6413–6421. [Google Scholar] [CrossRef]

- Mozaffari, F.; Eslami, H.; Moghadasi, J. Molecular dynamics simulation of diffusion and permeation of gases in polystyrene. Polymer 2010, 51, 300–307. [Google Scholar]

- van Goethem, C.; de Beeck, D.O.; Ilyas, A.; Thijs, M.; Aerts, P.; Vankelocom, I. Ultra-thin and highly porous PVDF-filters prepared via phase inversion for potential medical (COVID-19) and industrial use. J. Membr. Sci. 2021, 639, 119710. [Google Scholar] [CrossRef]

- Chen, B.; Qin, S.; Zhang, X. Preparation technology of high voltage thin film based on PVDF. Sens. Microsyst. J. Cent. South Univ. 2019, 39, 33–43. [Google Scholar]

- Kar, G.P.; Biswas, S.; Bose, S. X-ray micro computed tomography, segmental relaxation and crystallization kinetics in interfacial stabilized co-continuous immiscible PVDF/ABS blends. Polymer 2016, 101, 291–304. [Google Scholar] [CrossRef]

- Governal, R.A. Ultrapure Water: A battle every step of the way. Semicond. Int. 1994, 17, 176. [Google Scholar]

- Kim, H.; Lee, S.; Shin, Y.R.; Choi, Y.-N.; Yoon, J.; Ryu, M.; Lee, J.W.; Lee, H. Durable superhydrophobic poly(vinylidene fluoride) (PVDF)-based nanofibrous membranes for reusable air filters. Appl. Polym. Mater. 2022, 4, 338–347. [Google Scholar] [CrossRef]

- Fei, F.; Le Phuong, H.A.; Blanford, C.F.; Szekely, G. Tailoring the Performance of Organic Solvent Nanofiltration Membranes with Biophenol Coatings. Appl. Polym. Mater. 2019, 1, 452–460. [Google Scholar] [CrossRef]

- Gao, J.; Wang, J.; Xu, Q.; Wu, S.; Chen, Y. Regenerated cellulose strongly adhered by a supramolecular adhesive onto the PVDF membrane for a highly efficient oil/water separation. Green Chem. 2021, 23, 5633–5646. [Google Scholar] [CrossRef]

- Mansha, M.; Salhi, B.; Ali, S.; Khan, S.; Baig, N. Novel procaine-based gemini zwitterion incorporated PVDF membranes for efficient treatment of oily waste water. J. Environ. Chem. Eng. 2022, 10, 107935. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, P.; Li, H.; Chu, H.; Ding, H.; Gao, X. Molecular simulation of permeation behavior and mechanism of CH4 in PVDF. China Plast. 2021, 35, 97–104. [Google Scholar]

- Theodorou, D.N.; Suter, U.W. Atomistic modeling of mechanical properties of polymeric glasses. Macromolecules 1986, 19, 139–154. [Google Scholar] [CrossRef]

- Boyd, R.H.; Pant, P.V.K. Molecular packing and diffusion in polyisobutylene. Macromolecules 1991, 24, 6325–6331. [Google Scholar] [CrossRef]

- Sakher, F.; Imqum, A. An experimental investigation of immiscible carbon dioxide interactions with crude oil: Oil swelling and asphaltene agitation. Fuel 2020, 269, 117380. [Google Scholar]

- Yang, C.; Gu, Y. Diffusion coefficients and oil swelling factors of carbon dioxide, methane, ethane, propane, and their Mixtures in heavy oil. Fluid Phase Equilibria 2006, 243, 64–73. [Google Scholar] [CrossRef]

- Zhang, R.; Mattice, W.L. Flexibility of a new thermoplastic polyimide studied with molecular simulations. Macromolecules 1993, 26, 6100–6105. [Google Scholar] [CrossRef]

- SY 6662.2-2020; Non-Metallic Composite pipe for Petroleum and Natural gas Industries—Part 2: Flexible Composite Pipe for High Pressure Transmission. National Energy Administration: Beijing; China, 2020.

- Laney, P. Use of composite pipe materials in the transportation of natural gas. INEEL Field Work Proposal. 2002, 4430–4470. Available online: https://www.sciencedirect.com/book/9780323462006/plasticizers-derived-from-post-consumer-pet#book-info (accessed on 25 May 2022).

- Langer, E.; Bortel, K.; Waskiewicz, S. Plasticizers Derived from Post-Consumer PET; Elsevier: Cham, Switzerland, 2019. [Google Scholar] [CrossRef]

- Trohalaki, S.; Kloczkowski, A.; Mark, J.E. Estimation of diffusion coefficient for small molecular penetrants in amorphous polyethylene. Comput. Simul. Polym. 1991, 2, 147–152. [Google Scholar]

- Fried, J.R.; Sadat-Akhavi, M.; Mark, J.E. Molecular simulation of gas permeability: Poly (2,6-dimethyl-1,4-phenylene oxide). J. Membr. Sci. 1998, 149, 115–126. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Chu, H.; Li, H.; Qi, G.; Feng, J.; Gao, X.; Yang, W. Permeation Characteristics of CH4 in PVDF with Crude Oil-Containing. Polymers 2022, 14, 2723. https://doi.org/10.3390/polym14132723

Zhang X, Chu H, Li H, Qi G, Feng J, Gao X, Yang W. Permeation Characteristics of CH4 in PVDF with Crude Oil-Containing. Polymers. 2022; 14(13):2723. https://doi.org/10.3390/polym14132723

Chicago/Turabian StyleZhang, Xuemin, Huifang Chu, Houbu Li, Guoquan Qi, Jinmao Feng, Xiong Gao, and Wenhui Yang. 2022. "Permeation Characteristics of CH4 in PVDF with Crude Oil-Containing" Polymers 14, no. 13: 2723. https://doi.org/10.3390/polym14132723

APA StyleZhang, X., Chu, H., Li, H., Qi, G., Feng, J., Gao, X., & Yang, W. (2022). Permeation Characteristics of CH4 in PVDF with Crude Oil-Containing. Polymers, 14(13), 2723. https://doi.org/10.3390/polym14132723