Agri-Food Wastes for Bioplastics: European Prospective on Possible Applications in Their Second Life for a Circular Economy

Abstract

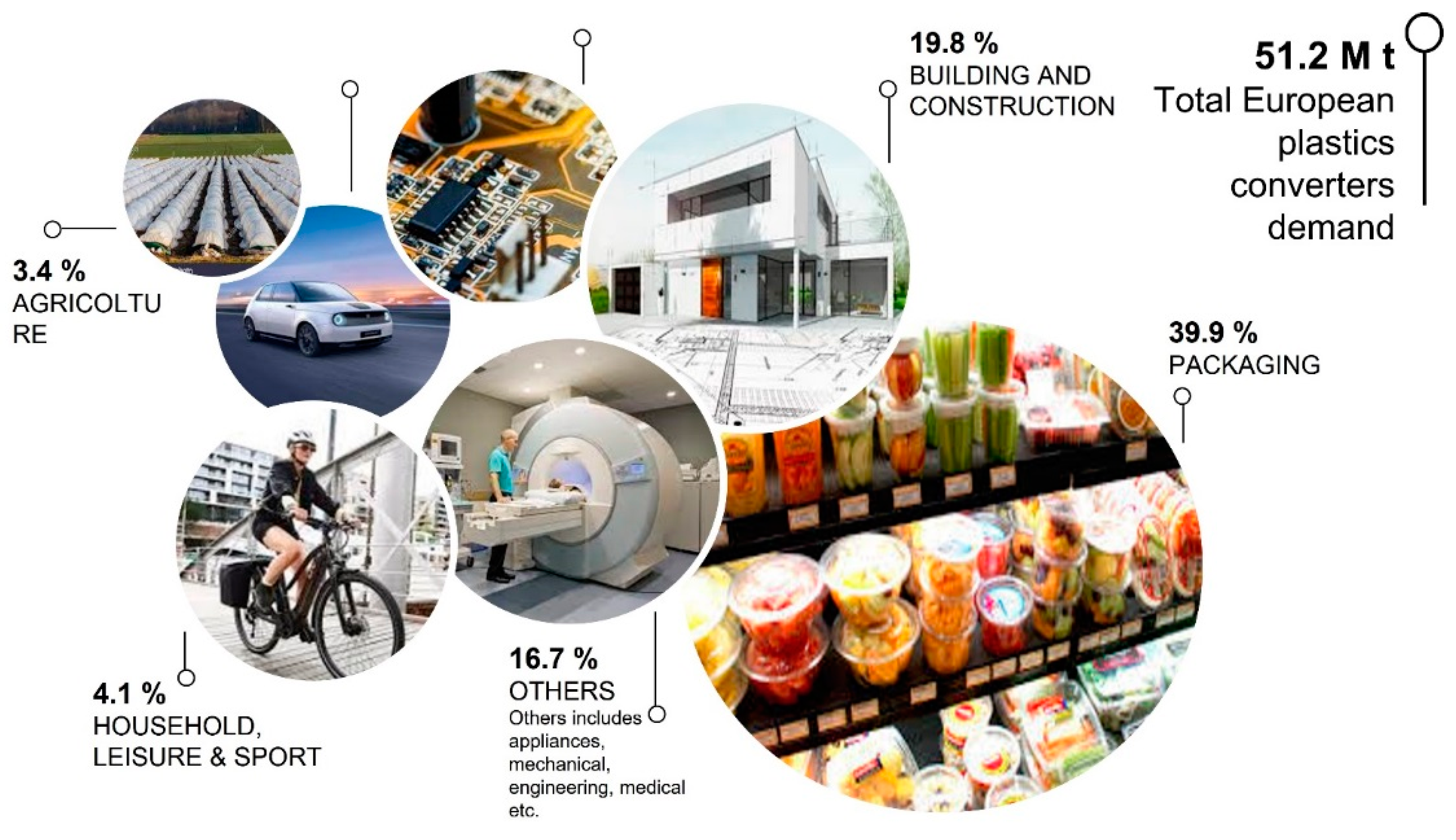

:1. Introduction

2. Bioplastic Upcycling

2.1. Blends of Bio-Based and Fossil-Based Polymers

2.2. The Composting/Landfilling of Bioplastics

3. BioWaste for Bioplastic: Pros and Cons

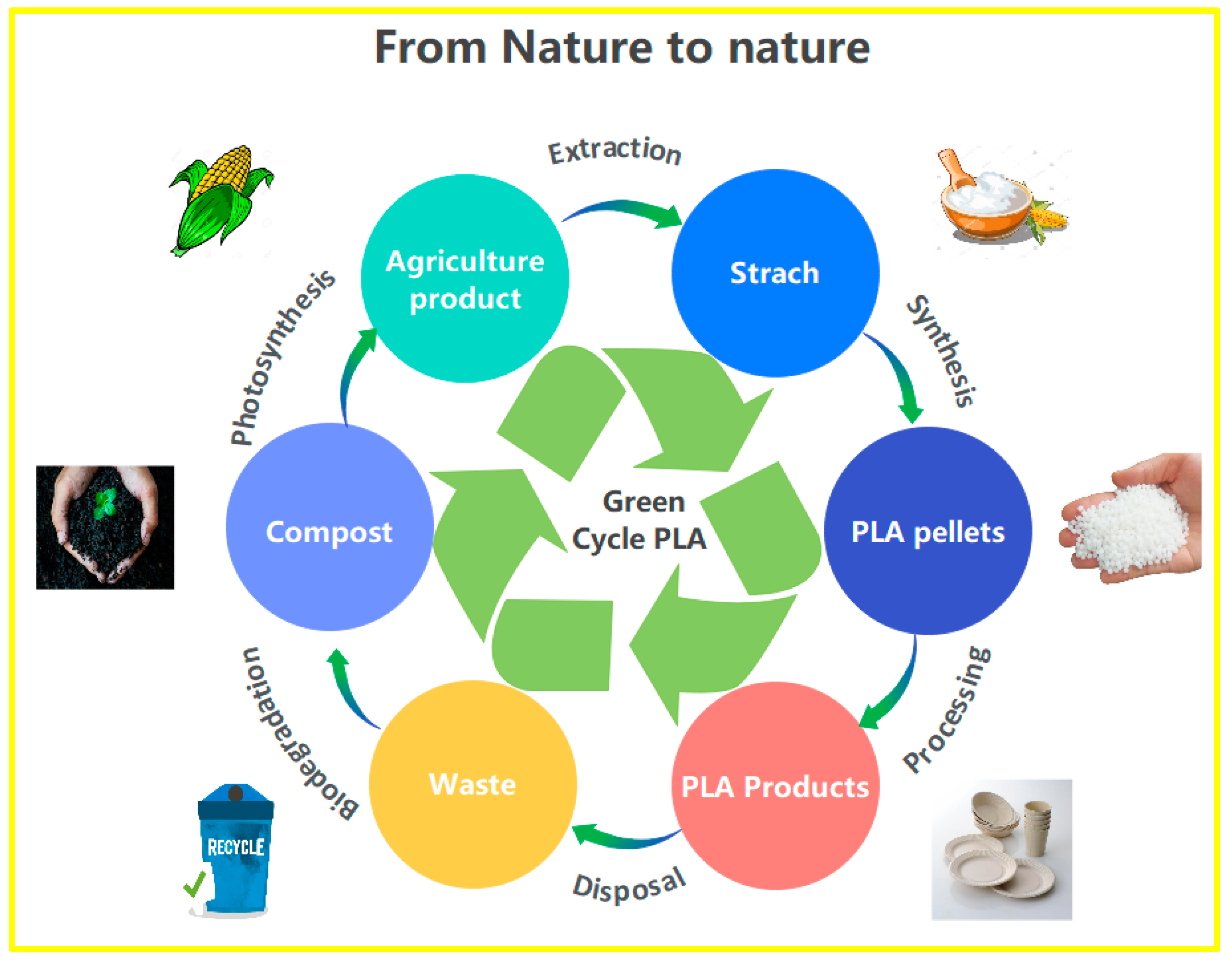

3.1. From Agri-Food Waste to Biopolymers

- The life of the product is limited by the fact that natural biopolymers are susceptible to hydrolytic attack by water, which compromises their mechanical strength;

- The final biodegradation process can be another problem because it can be long and difficult and should be carried out industrially according to the required standards;

- The availability of virgin biomass and of agri-food waste is linked to the global variability of the various geographical areas based on the typical crops of the various countries. Sustainability is a primary criterion that conditions the choice of the type of starting material;

- The production of biopolymers requires high quantities of agro-waste: this is made difficult by the fact that there is still no well-organised separate collection of agri-food waste.

3.2. Use of Agri-Food Waste as Filler

4. The European Prospective

4.1. EU Policy on the Environment for a Circular Economy

- Develop, demonstrate, and promote innovative products and processes to help reach the objectives of EU legislation and policy on the environment and to contribute to the implementation of Best Available Technologies (BAT) for the manufacturing industry and, therefore also for biopolymers production;

- Catalyse the large-scale deployment of successful technical and policy-related solutions for implementing the EU legislation and policy on the environment, integrating related objectives into other policies and into public and private sector practices, mobilizing investment, and improving access to finance. As Katri Kulmuni, Finland’s Minister of Finance, recently stated, “The goals of the Paris Climate Agreement will not be achieved by using public funds alone. We need the leverage from the whole economy, including financial and capital markets, to support the transition” [121];

- Support the implementation, monitoring, and enforcement of EU legislation and policy on the environment with the involvement of stakeholders at all levels (policymakers, public, private entities, and civil society). Pro-social and environmental attitudes can be encouraged by comprehensive public information and awareness and by adjusting social norms with the help of social media, stakeholders, and end-users.

4.2. EU Funded Projects on Waste Valorisation

- Nutraceutics and cosmetics (see for example CIRCULAR AGRONOMICS H2020—Efficient Carbon, Nitrogen and Phosphorus cycling in the European agri-food System and related up- and down-stream processes to mitigate emissions [122]; VALOWASTE: Valorisation of waste streams from the agro-food sector [123],\; WASEABI Optimal utilization of seafood side-streams through the design of new holistic process lines [124]; LIFE OLEA REGENERA: Valorisation of biowaste resulting from the olive oil extraction process [125], WILDBERRY: Novel application targets and products derived from wild arctic berries [126]; UP4HEALTH: Sustainable and cost-effective production process for the upcycling of olive, grape and nut by-products into four natural and healthy ingredients for nutraceutical and cosmetic applications [127]; INGREEN: Production of functional innovative ingredients from paper and agro-food side-streams through sustainable and efficient tailor-made biotechnological processes for food, feed, pharma and cosmetics [128]; PolyBioSkin, High performance functional bio-based polymers for skin-contact products in the biomedical, cosmetic and sanitary industries [129];

- Biofertilizers (Circular Agronomics [134]);

- Biofuels (LIFE CoWaCo: Communal and organic waste conversion [135]; LIFE CIRCforBIO: A circular economy system for multi-source biomass conversion to value-added products [136]; LIFE STEAM: Green waste valorisation through innovative low-temperature STEAM explosion into advanced biofuel and agro-products [137]):

- Starting from environmental problems related to agro-industry and waste minimization, the technological solutions allow the recovery of valuable biomass for biopolymer production, reducing the impact of fossil-based plastics and polymers;

- All the technologies had not been implemented to industrial-scale previously due to high processing costs, insufficient knowledge of the technology involved and scale-up procedures.

4.3. EU-Funded Projects on Bioplastics from Agri-Food Waste

4.4. EU-Funded Projects on Fillers from Agri-Food Waste

- Lignin: Lignin is a waste produced by biorefineries, starting from wood and lignocellulosic crops, and is the second most abundant natural aromatic polymer after cellulose in terrestrial ecosystems. Depending on the isolation process and feedstock source, lignin can differ in structure, although such differences are not limiting factors for potential industrial applications [146,147]. Many research papers have been published on the use of lignin as an anti-inflammatory, anticarcinogenic, antimicrobial, prebiotic and antioxidant led to the use of lignin in many different sectors [148]. Lignins have been widely applied as raw materials to produce polymeric materials, carbon fibres, fuels, construction, and agriculture [149]. In line with the scope of this review, the EU-funded projects employing lignin as fillers for biopolymers are reported below;

- The project, SSUCHY: Promoting sustainable development with advanced bio-based composites [151], is fully integrated into the research program of the Bio-Based Industries (BBI) Joint Technology Initiative operating under Horizon 2020 and is focused on the production of advanced biobased materials starting from lignocellulosic feedstock used as filler. The project is oriented toward the development of multifunctional biodegradable and/or recyclable bio-based composites with advanced functionalities based on renewable resources. The main application of this project falls in transportation (automotive and aerospace) and a high-value market niche (acoustic and electronics).

- Brewery Spent Grain: Brewery spent grain (BSG) is a food waste product, the main side-stream from the beer brewing process representing 85% of the total by-products obtained from beer production. For every 1 hL of beer produced, 20 kg of BSG are generated [152,153]. According to Eurostat’s 2020 report, almost 39.5 MioL of beer were produced in the EU with incomes of 138.649 M€ in 2017, expected to reach 159.687 M€ by 2025 [154]. Over 6.4 Mt of brewery spent grain waste are produced yearly, generating a crucial management issue from an ecological and economic standpoint. These figures are nevertheless bound to increase, as explained below. An overall scheme of EU beer production capacities, geographical distribution, and economic data are provided in Figure 5 and in Figure 6 [155].

- An increasing number of farmers (>60% in Northern EU) are declining to take BSG as animal feedstock;

- None of the breweries own technologies for on-site storage of the spent grain;

- Failure of BSG regular disposal would force the brewery to halt production;

- BSG waste disposal costs are between 75–100 €/t in the EU.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Di Bartolo, A.; Infurna, G.; Dintcheva, N.T. A review of bioplastics and their adoption in the circular economy. Polymers 2021, 13, 1229. [Google Scholar] [CrossRef]

- European Bioplastics. Market Update 2020: Bioplastics Continue to Become Mainstream as the Global Bioplastics Market Is Set to Grow by 36 Percent over the Next 5 Years. Available online: https://www.european-bioplastics.org/market-update-2020-bioplastics-continue-to-become-mainstream-as-the-global-bioplastics-market-is-set-to-grow-by-36-percent-over-the-next-5-years/ (accessed on 26 April 2022).

- Shafiee, S.; Topal, E. When will fossil fuel reserves be diminished? Energy Policy. 2009, 37, 181–189. [Google Scholar] [CrossRef]

- Payne, J.; McKeown, P.; Jones, M.D. Stability. A circular economy approach to plastic waste. Polym. Degrad. Stab. 2019, 165, 170–181. [Google Scholar] [CrossRef]

- Huysman, S.; De Schaepmeester, J.; Ragaert, K.; Dewulf, J.; De Meester, S. Performance indicators for a circular economy: A case study on post-industrial plastic waste. Resour. Conserv. Recycl. 2017, 120, 46–54. [Google Scholar] [CrossRef]

- The Earthbound Report. Plastics in a Linear Economy. Available online: https://earthbound.report/2016/01/26/plastics-in-a-linear-economy/ (accessed on 26 April 2022).

- Japu, C.; de Ilarduya, A.M.; Alla, A.; Muñoz-Guerra, S. Bio-based poly (ethylene terephthalate) copolyesters made from cyclic monomers derived from tartaric acid. Polymer 2014, 55, 2294–2304. [Google Scholar] [CrossRef]

- Singhvi, M.; Zinjarde, S.; Gokhale, D. Polylactic acid: Synthesis and biomedical applications. J. Appl. Microbiol. 2019, 127, 1612–1626. [Google Scholar] [CrossRef] [Green Version]

- Saini, P.; Arora, M.; Kumar, M.R. Poly (lactic acid) blends in biomedical applications. Adv. Drug Deliver. Rev. 2016, 107, 47–59. [Google Scholar] [CrossRef]

- Nofar, M.; Sacligil, D.; Carreau, P.J.; Kamal, M.R.; Heuzey, M.C. Poly (lactic acid) blends: Processing, properties and applications. Int. J. Biol. Macromol. 2019, 125, 307–360. [Google Scholar]

- Rosenboom, J.G.; Langer, R.; Traverso, G. Bioplastics for a circular economy. Nat. Rev. Mater. 2022, 7, 117–137. [Google Scholar] [CrossRef]

- Wu, F.; Misra, M.; Mohanty, A.K. Challenges and new opportunities on barrier performance of biodegradable polymers for sustainable packaging. Prog. Polym. Sci. 2021, 117, 101395. [Google Scholar] [CrossRef]

- Siracusa, V.; Rocculi, P.; Romani, S.; Dalla Rosa, M. Biodegradable polymers for food packaging: A review. Trends Food Sci. Technol. 2008, 19, 634–643. [Google Scholar] [CrossRef]

- Stoica, M.; Antohi, V.M.; Zlati, M.L.; Stoica, D. The financial impact of replacing plastic packaging by biodegradable biopolymers-a smart solution for the food industry. J. Clean. Prod. 2020, 277, 124013. [Google Scholar] [CrossRef]

- Lionetto, F.; Esposito Corcione, C. Recent applications of biopolymers derived from fish industry waste in food packaging. Polymers 2021, 13, 2337. [Google Scholar] [CrossRef]

- Abdelhak, M.J. A Review: Application of Biopolymers in the Pharmaceutical Formulation. J. Adv. Bio-Pharm. Pharmacovigil. 2019, 1, 15–25. [Google Scholar]

- Varma, K.; Gopi, S. Biopolymers and their role in medicinal and pharmaceutical applications. In Biopolymers and Their Industrial Applications, 1st ed.; Sabu, T., Sreeraj, G., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; Volume 1, pp. 175–191. [Google Scholar]

- Jahandideh, A.; Ashkani, M.; Moini, N. Biopolymers in textile industries. In Biopolymers and Their Industrial Applications, 1st ed.; Sabu, T., Sreeraj, G., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; Volume 1, pp. 193–218. [Google Scholar]

- Grancarić, A.M.; Jerković, I.; Koncar, V.; Cochrane, C.; Kelly, F.M.; Soulat, D.; Legrand, X. Conductive polymers for smart textile applications. J. Ind. Text. 2018, 48, 612–642. [Google Scholar] [CrossRef]

- Ravenstijn, J. Bioplastics in consumer electronics. Ind. Biotechnol. 2010, 6, 252–263. [Google Scholar] [CrossRef]

- Plank, J. Applications of biopolymers and other biotechnological products in building materials. Appl. Microbiol. Biot. 2004, 66, 1–9. [Google Scholar] [CrossRef]

- Miękoś, E.; Zieliński, M.; Kołodziejczyk, K.; Jaksender, M. Application of industrial and biopolymers waste to stabilise the subsoil of road surfaces. Road Mater. Pavement 2019, 20, 440–453. [Google Scholar] [CrossRef]

- Elkamel, A.; Simon, L.; Tsai, E.; Vinayagamoorthy, V.; Bagshaw, I.; Al-Adwani, S.; Mahdi, K. Modeling the mechanical properties of biopolymers for automotive applications. In Proceedings of the 2015 International Conference on Industrial Engineering and Operations Management (IEOM), Dubia, United Arab Emirates, 3–5 March 2015. [Google Scholar]

- Barillari, F.; Chini, F. Biopolymers-Sustainability for the Automotive Value-added Chain. ATZ Worldw. 2020, 122, 36–39. [Google Scholar] [CrossRef]

- Kalia, S.; Dufresne, A.; Cherian, B.M.; Kaith, B.S.; Avérous, L.; Njuguna, J.; Nassiopoulos, E. Cellulose-based bio-and nanocomposites: A review. Int. J. Polym. Sci. 2011, 2011, 837875. [Google Scholar] [CrossRef]

- Klein, M.; Poverenov, E. Agriculture. Natural biopolymer-based hydrogels for use in food and agriculture. J. Sci. Food Agric. 2020, 100, 2337–2347. [Google Scholar] [CrossRef]

- George, A.; Sanjay, M.; Srisuk, R.; Parameswaranpillai, J.; Siengchin, S. A comprehensive review on chemical properties and applications of biopolymers and their composites. Int. J. Biol. Macromol. 2020, 154, 329–338. [Google Scholar] [CrossRef]

- Razza, F.; Briani, C.; Breton, T.; Marazza, D. Conservation; Recycling. Metrics for quantifying the circularity of bioplastics: The case of bio-based and biodegradable mulch films. Resour. Conserva. Recycl. 2020, 159, 104753. [Google Scholar] [CrossRef]

- Fredi, G.; Dorigato, A. Recycling of bioplastic waste: A review. Adv. Ind. Eng. Polym. Res. 2021, 4, 159–177. [Google Scholar] [CrossRef]

- Markets and Markets. Bioplastics & Biopolymers Market. Available online: https://www.marketsandmarkets.com/Maansdrket-Reports/biopolymers-bioplastics-market-88795240.html (accessed on 27 April 2022).

- Beghetto, V.; Gatto, V.; Conca, S.; Bardella, N.; Buranello, C.; Gasparetto, G.; Sole, R. Development of 4-(4, 6-dimethoxy-1, 3, 5-triazin-2-yl)-4-methyl-morpholinium chloride cross-linked carboxymethyl cellulose films. Carbohyd. Polym. 2020, 249, 116810. [Google Scholar] [CrossRef]

- European Bioplastics. Available online: https://www.european-bioplastics.org/ (accessed on 27 April 2022).

- Sohn, Y.J.; Kim, H.T.; Baritugo, K.A.; Jo, S.Y.; Song, H.M.; Park, S.Y.; Park, S.K.; Pyo, J.; Cha, H.G.; Kim, H.J. Recent advances in sustainable plastic upcycling and biopolymers. Biotechnol. J. 2020, 15, 1900489. [Google Scholar] [CrossRef]

- Lamberti, F.M.; Román-Ramírez, L.A.; Wood, J. Environment, t. Recycling of bioplastics: Routes and benefits. J. Polym. Environ. 2020, 28, 2551–2571. [Google Scholar] [CrossRef]

- Goodship, V. Plastic recycling. Sci. Prog. 2007, 90, 245–268. [Google Scholar] [CrossRef]

- Hottle, T.A.; Bilec, M.M.; Landis, A.E. Biopolymer production and end of life comparisons using life cycle assessment. Resour. Conserva. Recycl. 2017, 122, 295–306. [Google Scholar] [CrossRef] [Green Version]

- Ramesh, P.; Vinodh, S. State of art review on Life Cycle Assessment of polymers. Int. J. Sust. Eng. 2020, 13, 411–422. [Google Scholar] [CrossRef]

- Bishop, G.; Styles, D.; Lens, P.N. Environmental performance comparison of bioplastics and petrochemical plastics: A review of life cycle assessment (LCA) methodological decisions. Resour. Conserv. Recycl. 2021, 168, 105451. [Google Scholar] [CrossRef]

- Cosate de Andrade, M.F.; Souza, P.; Cavalett, O.; Morales, A.R. Life cycle assessment of poly (lactic acid)(PLA): Comparison between chemical recycling, mechanical recycling and composting. J. Polym. Environ. 2016, 24, 372–384. [Google Scholar] [CrossRef]

- Hubbe, M.A.; Lavoine, N.; Lucia, L.A.; Dou, C. Formulating bioplastic composites for biodegradability, recycling, and performance: A Review. Bioresources 2021, 16, 2021–2083. [Google Scholar] [CrossRef]

- Cornell, D.D. Biopolymers in the existing postconsumer plastics recycling stream. J. Polym. Environ. 2007, 15, 295–299. [Google Scholar] [CrossRef]

- Beltrán, F.R.; Gaspar, G.; Dadras Chomachayi, M.; Jalali-Arani, A.; Lozano-Pérez, A.A.; Cenis, J.L.; de la Orden, M.U.; Pérez, E.; Martínez Urreaga, J.M. Influence of addition of organic fillers on the properties of mechanically recycled PLA. Environ. Sci. Pollut. Res. 2021, 28, 24291–24304. [Google Scholar] [CrossRef]

- Niaounakis, M. Recycling of biopolymers–the patent perspective. Eur. Polym. J. 2019, 114, 464–475. [Google Scholar] [CrossRef]

- Soroudi, A.; Jakubowicz, I. Recycling of bioplastics, their blends and biocomposites: A review. Eur. Polym. J. 2013, 49, 2839–2858. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Velidakis, E.; Tzounis, L.; Mountakis, N.; Kechagias, J.; Grammatikos, S.J. Optimization of the filler concentration on fused filament fabrication 3d printed polypropylene with titanium dioxide nanocomposites. Materials 2021, 14, 3076. [Google Scholar] [CrossRef]

- Fallon, J.J.; McKnight, S.H.; Bortner, M.J. Highly loaded fiber filled polymers for material extrusion: A review of current understanding. Addit. Manuf. 2019, 30, 100810. [Google Scholar] [CrossRef]

- Luzi, F.; Torre, L.; Kenny, J.M.; Puglia, D. Bio-and fossil-based polymeric blends and nanocomposites for packaging: Structure–property relationship. Materials 2019, 12, 471. [Google Scholar] [CrossRef] [Green Version]

- Aontee, A.; Sutapun, W. Effect of blend ratio on phase morphology and mechanical properties of high density polyethylene and poly (butylene succinate) blend. Proc. Adv. Mater. Res. 2013, 747, 555–559. [Google Scholar] [CrossRef]

- Lackner, M. Bioplastics-Biobased plastics as renewable and/or biodegradable alternatives to petroplastics. In Kirk-Othmer Encyclopedia of Chemical Technology, 6th ed.; Wiley: Hoboken, NJ, USA, 2015; Volume 1, pp. 1–41. [Google Scholar]

- Alaerts, L.; Augustinus, M.; Van Acker, K. Impact of bio-based plastics on current recycling of plastics. Sustainability 2018, 10, 1487. [Google Scholar] [CrossRef] [Green Version]

- Lambert, S.; Wagner, M. Environmental performance of bio-based and biodegradable plastics: The road ahead. Chem. Soc. Rev. 2017, 46, 6855–6871. [Google Scholar] [CrossRef] [PubMed]

- Gironi, F.; Piemonte, V. Bioplastics and petroleum-based plastics: Strengths and weaknesses. Energ. Source, Part A 2011, 33, 1949–1959. [Google Scholar] [CrossRef]

- McKeown, P.; Jones, M.D. The chemical recycling of PLA: A review. Sustain. Chem. 2020, 1, 1. [Google Scholar] [CrossRef]

- Haider, T.P.; Völker, C.; Kramm, J.; Landfester, K.; Wurm, F.R. Plastics of the future? The impact of biodegradable polymers on the environment and on society. Angew. Chem. Int. Ed. 2019, 58, 50–62. [Google Scholar] [CrossRef] [Green Version]

- Choudhury, A.; Mukherjee, M.; Adhikari, B. Thermal stability and degradation of the post-use reclaim milk pouches during multiple extrusion cycles. Thermochim. Acta 2005, 430, 87–94. [Google Scholar] [CrossRef]

- Jansson, A.; Möller, K.; Gevert, T. Degradation of post-consumer polypropylene materials exposed to simulated recycling—mechanical properties. Polym. Degrad. Stab. 2003, 82, 37–46. [Google Scholar] [CrossRef]

- Tsang, Y.F.; Kumar, V.; Samadar, P.; Yang, Y.; Lee, J.; Ok, Y.S.; Song, H.; Kim, K.-H.; Kwon, E.E.; Jeon, Y.J. Production of bioplastic through food waste valorization. Environ. Int. 2019, 127, 625–644. [Google Scholar] [CrossRef]

- Otoni, C.G.; Azeredo, H.M.; Mattos, B.D.; Beaumont, M.; Correa, D.S.; Rojas, O.J. The Food–Materials Nexus: Next Generation Bioplastics and Advanced Materials from Agri-Food Residues. Adv. Mater. 2021, 33, 2102520. [Google Scholar] [CrossRef]

- Yu, J. Production of green bioplastics from agri-food chain residues and co-products. In Handbook of Waste Management and Co-Product Recovery in Food Processing; Woodhead Publishing: Cambridge, UK, 2009; Volume 2, pp. 515–536. [Google Scholar]

- Gill, M. Bioplastic: A better alternative to plastics. Int. J. Res. Appl. Nat. Soc. Sci. 2014, 2, 115–120. [Google Scholar]

- Ohga. A Sustainable Bioplastic from a Milk Protein. Available online: https://www.ohga.it/una-bioplastica-sostenibile-da-una-proteina-del-latte/ (accessed on 27 April 2022).

- Dedenaro, G.; Costa, S.; Rugiero, I.; Pedrini, P.; Tamburini, E. Valorization of agri-food waste via fermentation: Production of L-lactic acid as a building block for the synthesis of biopolymers. Appl. Sci. 2016, 6, 379. [Google Scholar] [CrossRef] [Green Version]

- Awasthi, M.K.; Kumar, V.; Yadav, V.; Sarsaiya, S.; Awasthi, S.K.; Sindhu, R.; Binod, P.; Kumar, V.; Pandey, A.; Zhang, Z. Current state of the art biotechnological strategies for conversion of watermelon wastes residues to biopolymers production: A review. Chemosphere 2021, 290, 133310. [Google Scholar] [CrossRef]

- Hamid, L.; Elhady, S.; Abdelkareem, A.; Fahim, I. Fabricating Starch-Based Bioplastic Reinforced with Bagasse for Food Packaging. Circ. Econ. Sustain. 2022, 2, 1–12. [Google Scholar] [CrossRef]

- Manimaran, D.S.; Nadaraja, K.; Vellu, J.; Francisco, V.; Kanesen, K.; BinYusoff, Z. Production of biodegradable plastic from banana peel. Petrochem. Eng. 2016, 1, 1–7. [Google Scholar]

- Wang, J.; Liu, S.; Huang, J.; Qu, Z. A review on polyhydroxyalkanoate production from agricultural waste Biomass: Development, Advances, circular Approach, and challenges. Bioresour. Technol. 2021, 342, 126008. [Google Scholar] [CrossRef]

- Koul, B.; Yakoob, M.; Shah, M.P. Agricultural waste management strategies for environmental sustainability. Environ. Res. 2022, 206, 112285. [Google Scholar] [CrossRef]

- Jiménez-Rosado, M.; Maigret, J.-E.; Perez-Puyana, V.; Romero, A.; Lourdin, D. Revaluation of a Soy Protein By-product in Eco-friendly Bioplastics by Extrusion. J. Polym. Environ. 2022, 30, 1587–1599. [Google Scholar] [CrossRef]

- Giosafatto, C.V.L.; Al-Asmar, A.; D’Angelo, A.; Roviello, V.; Esposito, M.; Mariniello, L. Preparation and characterization of bioplastics from grass pea flour cast in the presence of microbial transglutaminase. Coatings 2018, 8, 435. [Google Scholar] [CrossRef] [Green Version]

- Chia, W.Y.; Tang, D.Y.Y.; Khoo, K.S.; Lup, A.N.K.; Chew, K.W. Nature’s fight against plastic pollution: Algae for plastic biodegradation and bioplastics production. Envir. Sci. Ecotech. 2020, 4, 100065. [Google Scholar] [CrossRef]

- Maraveas, C. Production of sustainable and biodegradable polymers from agricultural waste. Polymers 2020, 12, 1127. [Google Scholar] [CrossRef] [PubMed]

- Álvarez-Castillo, E.; Felix, M.; Bengoechea, C.; Guerrero, A. Proteins from agri-food industrial biowastes or co-products and their applications as green materials. Foods 2021, 10, 981. [Google Scholar] [CrossRef] [PubMed]

- Standard Eurobarometer 96—Winter 2021–2022. Available online: https://europa.eu/eurobarometer/surveys/detail/2553 (accessed on 8 June 2022).

- Abba, H.A.; Nur, I.Z.; Salit, S.M. Review of agro waste plastic composites production. J. Miner. Mater. Charact. Eng. 2013, 1, 271–279. [Google Scholar] [CrossRef] [Green Version]

- Taj, S.; Munawar, M.A.; Khan, S. Natural fiber-reinforced polymer composites. Proc. Pakistan Acad. Sci. 2007, 44, 129. [Google Scholar]

- Raju, G.; Kumarappa, S.; Gaitonde, V.N. Mechanical and physical characterization of agricultural waste reinforced polymer composites. J. Mater. Environ. Sci. 2012, 3, 907–916. [Google Scholar]

- Zaaba, N.F.; Ismail, H. A review on peanut shell powder reinforced polymer composites. Polym-Plast. Technol. Mater. 2019, 58, 349–365. [Google Scholar]

- Dubey, S.C.; Mishra, V.; Sharma, A. A review on polymer composite with waste material as reinforcement. Mater. Today-Proc. 2021, 47, 2846–2851. [Google Scholar] [CrossRef]

- Ojha, S.; Raghavendra, G.; Acharya, S.K. A comparative investigation of bio waste filler (wood apple-coconut) reinforced polymer composites. Polym. Compos. 2014, 35, 180–185. [Google Scholar] [CrossRef]

- Turmanova, S.; Genieva, S.; Vlaev, L. Obtaining some polymer composites filled with rice husks ash-a review. Int. J. Chem. 2012, 4, 62. [Google Scholar] [CrossRef] [Green Version]

- Georgopoulos, S.T.; Tarantili, P.; Avgerinos, E.; Andreopoulos, A.; Koukios, E.G. Thermoplastic polymers reinforced with fibrous agricultural residues. Polym. Degrad. Stab. 2005, 90, 303–312. [Google Scholar] [CrossRef]

- Väisänen, T.; Haapala, A.; Lappalainen, R.; Tomppo, L. Utilization of agricultural and forest industry waste and residues in natural fiber-polymer composites: A review. Waste Manag. 2016, 54, 62–73. [Google Scholar] [CrossRef] [PubMed]

- Gallardo-Cervantes, M.; González-García, Y.; Pérez-Fonseca, A.A.; González-López, M.E.; Manríquez-González, R.; Rodrigue, D.; Robledo-Ortíz, J.R. Biodegradability and improved mechanical performance of polyhydroxyalkanoates/agave fiber biocomposites compatibilized by different strategies. J. Appl. Polym. Sci. 2021, 138, 50182. [Google Scholar] [CrossRef]

- De la Ossa, J.G.; Fusco, A.; Azimi, B.; Esposito Salsano, J.; Digiacomo, M.; Coltelli, M.-B.; De Clerck, K.; Roy, I.; Macchia, M.; Lazzeri, A.J.A.S. Immunomodulatory Activity of electrospun polyhydroxyalkanoate fiber scaffolds incorporating olive leaf extract. Appl. Sci. 2021, 11, 4006. [Google Scholar] [CrossRef]

- Gigante, V.; Cinelli, P.; Righetti, M.C.; Sandroni, M.; Polacco, G.; Seggiani, M.; Lazzeri, A. On the use of biobased waxes to tune thermal and mechanical properties of polyhydroxyalkanoates–bran biocomposites. Polymers 2020, 12, 2615. [Google Scholar] [CrossRef] [PubMed]

- Wu, C.-S.; Wu, D.-Y.; Wang, S.S. Preparation, characterization, and functionality of bio-based polyhydroxyalkanoate and renewable natural fiber with waste oyster shell composites. Polym. Bull. 2021, 78, 4817–4834. [Google Scholar] [CrossRef]

- Kaouche, N.; Mebrek, M.; Mokaddem, A.; Doumi, B.; Belkheir, M.; Boutaous, A. Theoretical study of the effect of the plant and synthetic fibers on the fiber-matrix interface damage of biocomposite materials based on PHAs (polyhydroxyalkanoates) biodegradable matrix. Polym. Bull. 2021, 78, 1–21. [Google Scholar] [CrossRef]

- Giubilini, A.; Sciancalepore, C.; Messori, M.; Bondioli, F. Valorization of oat hull fiber from agri-food industrial waste as filler for poly (3-hydroxybutyrate-co-3-hydroxyhexanoate). J. Mater. Cycles Waste 2021, 23, 402–408. [Google Scholar] [CrossRef]

- Nanni, A.; Messori, M. Effect of the wine wastes on the thermal stability, mechanical properties, and biodegradation’s rate of poly (3-hydroxybutyrate). J. Appl. Polym. Sci. 2021, 138, 49713. [Google Scholar] [CrossRef]

- Chan, C.M.; Pratt, S.; Halley, P.; Richardson, D.; Werker, A.; Laycock, B.; Vandi, L.J. Mechanical and physical stability of polyhydroxyalkanoate (PHA)-based wood plastic composites (WPCs) under natural weathering. Polym. Test. 2019, 73, 214–221. [Google Scholar] [CrossRef]

- Dordevic, D.; Necasova, L.; Antonic, B.; Jancikova, S.; Tremlová, B. Plastic Cutlery Alternative: Case Study with Biodegradable Spoons. Foods 2021, 10, 1612. [Google Scholar] [CrossRef]

- Ayu, R.S.; Khalina, A.; Harmaen, A.S.; Zaman, K.; Isma, T.; Liu, Q.; Ilyas, R.; Lee, C.H. Characterization study of empty fruit bunch (EFB) fibers reinforcement in poly (butylene) succinate (PBS)/starch/glycerol composite sheet. Polymers 2020, 12, 1571. [Google Scholar] [CrossRef] [PubMed]

- Pivsa-Art, S.; Pivsa-Art, W. Eco-friendly bamboo fiber-reinforced poly (butylene succinate) biocomposites. Polym. Compos. 2021, 42, 1752–1759. [Google Scholar] [CrossRef]

- Bhattacharjee, S.K.; Chakraborty, G.; Kashyap, S.P.; Gupta, R.; Katiyar, V. Study of the thermal, mechanical and melt rheological properties of rice straw filled poly (butylene succinate) bio-composites through reactive extrusion process. J. Polym. Environ. 2021, 29, 1477–1488. [Google Scholar] [CrossRef]

- Picard, M.C.; Rodriguez-Uribe, A.; Thimmanagari, M.; Misra, M.; Mohanty, A.K.; Valorization, B. Sustainable biocomposites from poly (butylene succinate) and apple pomace: A study on compatibilization performance. Waste Biomass Valoriz. 2020, 11, 3775–3787. [Google Scholar] [CrossRef]

- Reddy, S.R.T.; Prasad, A.R.; Ramanaiah, K. Tensile and flexural properties of biodegradable jute fiber reinforced poly lactic acid composites. Mater. Today-Proc. 2021, 44, 917–921. [Google Scholar] [CrossRef]

- Kanakannavar, S.; Pitchaimani, J. Fabrication and mechanical properties of braided flax fabric polylactic acid bio-composites. J. Text. Inst. 2021, 113, 833–845. [Google Scholar] [CrossRef]

- Jing, H.; He, H.; Liu, H.; Huang, B.; Zhang, C. Study on properties of polylactic acid/lemongrass fiber biocomposites prepared by fused deposition modeling. Polym. Compos. 2021, 42, 973–986. [Google Scholar] [CrossRef]

- Ketata, N.; Seantier, B.; Guermazi, N.; Grohens, Y. On the development of a green composites based on poly (lactic acid)/poly (butylene succinate) blend matrix reinforced by long flax fibers. Mater. Today-Proc. 2022, 52, 95–103. [Google Scholar] [CrossRef]

- Rasheed, M.; Jawaid, M.; Parveez, B. Bamboo fiber based cellulose nanocrystals/poly (Lactic acid)/poly (butylene succinate) nanocomposites: Morphological, mechanical and thermal properties. Polymers 2021, 13, 1076. [Google Scholar] [CrossRef]

- Alias, N.F.; Ismail, H.; Ishak, K.M.K. Poly (lactic acid)/natural rubber/kenaf biocomposites production using poly (methyl methacrylate) and epoxidized natural rubber as co-compatibilizers. Iran. Polym. J. 2021, 30, 737–749. [Google Scholar] [CrossRef]

- Hejna, A. Poly (ε-Caprolactone)/Brewers’ Spent Grain Composites—The Impact of Filler Treatment on the Mechanical Performance. J. Compos. Sci. 2020, 4, 167. [Google Scholar] [CrossRef]

- Zeng, D.; Zhang, L.; Jin, S.; Zhang, Y.; Xu, C.; Zhou, K.; Lu, W. Mechanical Properties and Tensile Model of Hemp-Fiber-Reinforced Poly (butylene adipate-co-terephthalate) Composite. Materials 2022, 15, 2445. [Google Scholar] [CrossRef] [PubMed]

- Spada, J.C.; Seibert, S.F.; Tessaro, I.C. Impact of PLA Poly (Lactic Acid) and PBAT Poly (butylene adipate-co-terephthalate) coating on the properties of composites with high content of rice husk. J. Polym. Environ. 2021, 29, 1324–1331. [Google Scholar] [CrossRef]

- Giri, J.; Lach, R.; Le, H.H.; Grellmann, W.; Saiter, J.-M.; Henning, S.; Radusch, H.-J.; Adhikari, R. Structural, thermal and mechanical properties of composites of poly (butylene adipate-co-terephthalate) with wheat straw microcrystalline cellulose. Polym. Bull. 2021, 78, 4779–4795. [Google Scholar] [CrossRef]

- Lule, Z.C.; Wondu, E.; Kim, J. Highly rigid, fire-resistant, and sustainable polybutylene adipate terephthalate/polybutylene succinate composites reinforced with surface-treated coffee husks. J. Clean. Prod. 2021, 315, 128095. [Google Scholar] [CrossRef]

- Savio, L.; Pennacchio, R.; Patrucco, A.; Manni, V.; Bosia, D. Natural Fibre Insulation Materials: Use of Textile and Agri-food Waste in a Circular Economy Perspective. Mater. Circ. Econ. 2022, 4, 1–13. [Google Scholar] [CrossRef]

- Hidayat, W.; Aprilliana, N.; Asmara, S.; Bakri, S.; Hidayati, S.; Banuwa, I.S.; Lubis, M.A.R.; Iswanto, A.H. Performance of eco-friendly particleboard from agro-industrial residues bonded with formaldehyde-free natural rubber latex adhesive for interior applications. Polym. Compos. 2022, 43, 2222–2233. [Google Scholar] [CrossRef]

- Masłowski, M.; Miedzianowska, J.; Strzelec, K. Natural rubber biocomposites containing corn, barley and wheat straw. Polym. Test. 2017, 63, 84–91. [Google Scholar] [CrossRef]

- Okieimen, F.; Imanah, J.E. Studies in the utilization of agricultural waste products as filler in natural rubber compounds. J. Appl. Polym. Sci. 2006, 100, 2561–2564. [Google Scholar] [CrossRef]

- The New Plastics Economy: Rethinking the Future of Plastics. Available online: https://emf.thirdlight.com/link/faarmdpz93ds-5vmvdf/@/preview/1?o (accessed on 27 April 2022).

- Beghetto, V.; Sole, R.; Buranello, C.; Al-Abkal, M.; Facchin, M. Recent advancements in plastic packaging recycling: A mini-review. Materials 2021, 14, 4782. [Google Scholar] [CrossRef]

- Beghetto, V.; Bardella, N.; Samiolo, R.; Gatto, V.; Conca, S.; Sole, R.; Molin, G.; Gattolin, A.; Ongaro, N. By-products from mechanical recycling of polyolefins improve hot mix asphalt performance. J. Clean. Prod. 2021, 318, 128627. [Google Scholar] [CrossRef]

- Packaging Europe: Reviewed European Bioeconomy Strategy Strengthens Defossilisation of Plastics Sector. Available online: https://packagingeurope.com/reviewed-european-bioeconomy-strategy-strengthens-defossilisation-of-plastics-sector/1280.article (accessed on 27 April 2022).

- Kaszycki, P.; Głodniok, M.; Petryszak, P. Towards a bio-based circular economy in organic waste management and wastewater treatment—The Polish perspective. New Biotechnol. 2021, 61, 80–89. [Google Scholar] [CrossRef] [PubMed]

- Santolini, E.; Bovo, M.; Barbaresi, A.; Torreggiani, D.; Tassinari, P. Turning Agricultural Wastes into Biomaterials: Assessing the Sustainability of Scenarios of Circular Valorization of Corn Cob in a Life-Cycle Perspective. Appl. Sci. 2021, 11, 6281. [Google Scholar] [CrossRef]

- Teigiserova, D.A.; Hamelin, L.; Thomsen, M. Towards transparent valorization of food surplus, waste and loss: Clarifying definitions, food waste hierarchy, and role in the circular economy. Sci. Total Environ. 2020, 706, 136033. [Google Scholar] [CrossRef] [PubMed]

- Freitas, L.C.; Barbosa, J.R.; da Costa, A.L.C.; Bezerra, F.W.F.; Pinto, R.H.H.; de Carvalho Junior, R.N. From waste to sus-tainable industry: How can agro-industrial wastes help in the development of new products? Resour. Conserv. Recycl. 2021, 69, 105466. [Google Scholar] [CrossRef]

- Regulation (EU, Euratom) 2018/1046 of the European Parliament and of the Council of 18 July 2018 on the financial rules applicable to the general budget of the Union, amending Regulations (EU) No 1296/2013, (EU) No 1301/2013, (EU) No 1303/2013, (EU) No 1304/2013, (EU) No 1309/2013, (EU) No 1316/2013, (EU) No 223/2014, (EU) No 283/2014, and Decision No 541/2014/EU and repealing Regulation (EU, Euratom) No 966/2012′ (2018). Off. J. Eur. Union L 2018, 193, 1–222. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX%3A32018R1046 (accessed on 9 June 2022).

- Regulation (EU) 2021/783 of the European Parliament and of the Council of 29 April 2021 establishing a Programme for the Environment and Climate Action (LIFE), and repealing Regulation (EU) No 1293/2013′ (2021). Off. J. Eur. Union L 2021, 172, 53–78. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX:32021R0783 (accessed on 9 June 2022).

- Finnish Government. Speech Given by Minister of Economic Affairs Katri Kulmuni during an Exchange of Views with the European Parliament’s Committee on Industry, Research and Energy (ITRE) on 23 July 2019. Available online: https://valtioneuvosto.fi/en/-/1410877/speech-given-by-minister-of-economic-affairs-katri-kulmuni-during-an-exchange-of-views-with-the-european-parliament-s-committee-on-industry-research-a (accessed on 27 April 2022).

- RISE Foundation. CIRCULAR AGRONOMICS H2020—Efficient Carbon, Nitrogen and Phosphorus Cycling in the European Agri-Food System and Related up- and down-Stream Processes to Mitigate Emissions. Available online: https://risefoundation.eu/circular-agronomics/ (accessed on 27 April 2022).

- Final Report Summary—VALOWASTE (Valorisation of Waste Streams from the Agro Food Sector). Available online: https://cordis.europa.eu/project/id/624609/reporting (accessed on 27 April 2022).

- Waseabi. Technology Infrastructure and Logistics. Available online: https://www.waseabi.eu/ (accessed on 27 April 2022).

- LIFE OLEA REGENERA: Valorization of Bio-Waste Resulting from the Olive Oil Extraction Process. Available online: https://lifeolearegenera.com/en/ (accessed on 27 April 2022).

- WILDBERRY. Novel Application Targets and Products Derived from Wild Arctic Berries. Available online: https://cordis.europa.eu/project/id/739638 (accessed on 27 April 2022).

- UP4HEALTH. Sustainable and Cost-Effective Production Process for the Upcycling of Olive, Grape and Nut by-Products into 4 Natural and Healthy Ingredients for Nutraceutical and Cosmet-Ic Applications. Available online: https://cordis.europa.eu/project/id/888003 (accessed on 27 April 2022).

- INGREEN. Production of Functional Innovative Ingredients from Paper and Agro-Food Side-Streams through Sustainable and Efficient Tailor-Made Biotechnological Processes for Food, Feed, Pharma and Cosmetics. Available online: https://cordis.europa.eu/project/id/838120 (accessed on 27 April 2022).

- PolyBi-OSkin. High Performance Functional Bio-Based Polymers for Skin-Contact Prod-Ucts In Biomedical, Cosmetic and Sanitary Industry. Available online: https://cordis.europa.eu/article/id/428503-novel-materials-for-high-performance-eco-friendly-skin-contact-products (accessed on 27 April 2022).

- VIDA. Value Added Innovation in Food Chain. Available online: www.vidaproject.eu (accessed on 27 April 2022).

- UP-GRAD. Upgrading Anaerobic Digestion by Cascade Fermentation Coupled with Biogas-Based Biopolymer Production. Available online: https://cordis.europa.eu/project/id/894515 (accessed on 27 April 2022).

- NoAW (No Agricultural Waste). Available online: https://noaw2020.eu/about-noaw/ (accessed on 27 April 2022).

- SolReGen Solar-Driven Reforming of Waste into Hydrogen. Available online: https://cordis.europa.eu/project/id/966581 (accessed on 27 April 2022).

- Circular Agronomics. Available online: https://www.circularagronomics.eu/the-project/ (accessed on 27 April 2022).

- LIFE CoWaCo. Communal and Organic Waste Conversion. Available online: https://www.infinitefuels.de/life-cowaco-project/ (accessed on 27 April 2022).

- LIFE CIRCforBIO. A Circular Economy System for Multi-Source Biomass Conversion to Added Value Products. Available online: https://circforbio.eu/it/home-it/ (accessed on 27 April 2022).

- LIFE STEAM. Green waste Valorisation through Innovative Low Temperature STEAM Explosion into Advanced Biofuel and Agri-Products. Available online: https://www.lifesteam.eu/ (accessed on 27 April 2022).

- Gatto, V.; Conca, S.; Bardella, N.; Beghetto, V. Efficient Triazine Derivatives for Collagenous Materials Stabilization. Materials 2021, 14, 3069. [Google Scholar] [CrossRef]

- Beghetto, V.; Gatto, V.; Conca, S.; Bardella, N.; Scrivanti, A. Polyamidoamide dendrimers and cross–linking agents for stabilized bioenzymatic resistant metal–free bovine collagen. Molecules 2019, 24, 3611. [Google Scholar] [CrossRef] [Green Version]

- Sole, R.; Agostinis, L.; Conca, S.; Gatto, V.; Bardella, N.; Morandini, A.; Buranello, C.; Beghetto, V. Synthesis of Amidation Agents and Their Reactivity in Condensation Reactions. Synthesis 2021, 53, 1672–1682. [Google Scholar] [CrossRef]

- Biotransformation of by-Products from Fruit and Vegetable Processing Industry into Valuable BIOproducts. Available online: https://cordis.europa.eu/article/id/150410-how-to-create-plastic-from-a-potato-peel (accessed on 27 April 2022).

- United Nations Environnent Programme. UNEP Food Waste Index Report 2021; United Nations Environnent Programme: Nairobi, Kenya, 2021. [Google Scholar]

- BARBARA Biopolymers with Advanced Functionalities for Building and Automotive Parts Processed through Additive Manufacturing. Available online: https://cordis.europa.eu/article/id/429511-natural-extracts-improve-properties-of-industrial-bioplastics (accessed on 27 April 2022).

- BIOREFINE-2G: Development of 2nd Generation Biorefineries—Production of Dicarboxylic Acids and Bio-based Polymers Derived Thereof. Available online: https://cordis.europa.eu/article/id/169910-novel-biopolymers-from-biorefinery-wastestreams (accessed on 27 April 2022).

- European Commission. Sustainable and Efficient Bio-Chemical Catalytic Cascade Conversion of Residual Biomass to High Quality Biopolymers. Available online: https://cordis.europa.eu/project/id/760802. (accessed on 27 April 2022).

- Ayyachamy, M.; Cliffe, F.E.; Coyne, J.M.; Collier, J.; Tuohy, M.G. Lignin: Untapped biopolymers in biomass conversion technologies. Biomass Conv. Bioref. 2013, 3, 255–269. [Google Scholar] [CrossRef]

- Sheng, Y.; Lam, S.S.; Wu, Y.; Ge, S.; Wu, J.; Cai, L.; Huang, Z.; Van Le, Q.; Sonne, C.; Xia, C. Enzymatic conversion of pre-treated lignocellulosic biomass: A review on influence of structural changes of lignin. Bioresour. Technol. 2021, 324, 124631. [Google Scholar] [CrossRef] [PubMed]

- Wang, R.; Zheng, L.; Xu, Q.; Xu, L.; Wang, D.; Li, J.; Lu, G.; Huang, C.; Wang, Y. Unveiling the structural properties of water-soluble lignin from gramineous biomass by autohydrolysis and its functionality as a bioactivator (anti-inflammatory and antioxidative). Int. J. Biol. Macromol. 2021, 191, 1087–1095. [Google Scholar] [CrossRef]

- Banu, J.R.; Kavitha, S.; Yukesh Kannah, R.; Poornima Devi, T.; Gunasekaran, M.; Kim, S.; Kumar, G. A review on bi-opolymer production via lignin valorization. Bioresour. Technol. 2019, 290, 121790. [Google Scholar] [CrossRef]

- SmartLi Biorefinery Concepts and Processes. SmartLi Meets the Growing Demand for Renewable Bio-Chemicals and Materials from More Sustainable and Renewable Alternatives. Available online: https://clicinnovation.fi/project/smartli/ (accessed on 27 April 2022).

- SSUCHY Developing Advanced Bio-Based Composites. SSUCHY PROJECT. Available online: https://www.ssuchy.eu/ (accessed on 27 April 2022).

- Mitri, S.; Salameh, S.-J.; Khelfa, A.; Leonard, E.; Maroun, R.G.; Louka, N.; Koubaa, M. Valorization of Brewers’ Spent Grains: Pretreatments and Fermentation, a Review. Fermentation 2022, 8, 50. [Google Scholar] [CrossRef]

- Bravi, E.; Francesco, G.D.; Sileoni, V.; Perretti, G.; Galgano, F.; Marconi, O. Brewing By-Product Upcycling Potential: Nutritionally Valuable Compounds and Antioxidant Activity Evaluation. Antioxidants 2021, 10, 165. [Google Scholar] [CrossRef] [PubMed]

- EUROSTAT. Sold Production, Exports and Imports by PRODCOM List (NACE Rev. 2)—Annual Data. Available online: https://appsso.eurostat.ec.europa.eu/nui/show.do?query=BOOKMARK_DS-066341_QID_6836050D_UID_-3F171EB0&layout=PERIOD,L,X,0;DECL,L,Y,0;PRCCODE,B,Z,0;INDICATORS,C,Z,1;&zSelection=DS-066341INDICATORS,PRODQNT;DS-066341PRCCODE,11051000;&rankName1=PRCCODE_1_0_-1_2&rankName2=INDICATORS_1_2_0_0&rankName3=PERIOD_1_0_0_0&rankName4=DECL_1_0_0_1&sortR=ASC_-1_FIRST&sortC=ASC_-1_FIRST&rStp=&cStp=&rDCh=&cDCh=&rDM=true&cDM=true&footnes=false&empty=false&wai=false&time_mode=ROLLING&time_most_recent=true&lang=EN&cfo=%23%23%23%2C%23%23%23.%23%23%23 (accessed on 27 April 2022).

- The Brewers of Europe Key Figures 2019. Available online: https://www.google.com/search?q=the+brewers+of+europe+key+figures+2019&client=firefox-b-d&sxsrf=ALiCzsbAXFHTrw-YJJWiHqSFRaAjcpwyUw:1656921706231&source=lnms&tbm=isch&sa=X&ved=2ahUKEwiwteGt4t74AhVHX_EDHfrkB5gQ_AUoAXoECAEQAw&biw=1280&bih=609&dpr=1.5#imgrc=bfs5hMbahMgXbM (accessed on 4 July 2022).

- Giner Santonja, G.; Karlis, P.; Stubdrup, K.; Brinkmann, T.; Roudier, S. Best Available Techniques (BAT) Reference Document for the Food, Drink and Milk Industries. In Industrial Emissions Directive 2010/75/EU (Integrated Pollution Prevention and Control); EUR 29978 EN.; Publications Office of the European Union: Luxembourg, Luxembourg, 2019. [Google Scholar]

- Kavalopoulos, M.; Stoumpou, V.; Christofi, A.; Mai, S.; Barampouti, E.M.; Moustakas, K.; Malamis, D.; Loizidou, M. Sustainable valorisation pathways mitigating environmental pollution from brewers’ spent grains. Environ. Pollut. 2021, 270, 116069. [Google Scholar] [CrossRef]

- Bolwig, S.; Mark, M.S.; Happel, M.K.; Brekke, A. Chapter 6: Beyond animal feed? The valorisation of brewers’ spent grain. In From Waste to Value: Valorisation Pathways for Organic Waste Streams in Circular Bioeconomies; Klitkou, A., Fevolden, A.M., Capasso, M., Eds.; Routledge: London, UK, 2019. [Google Scholar]

- Full Text of the Food Safety Modernization Act (FSMA). Available online: https://www.fda.gov/food/food-safety-modernization-act-fsma/full-text-food-safety-modernization-act-fsma (accessed on 27 April 2022).

- Friendly Knife. How to Get Rid of Plastic Cutlery? Biodegradable Products Made out of Beer Waste. Available online: https://cordis.europa.eu/project/id/868340 (accessed on 27 April 2022).

| Polymer Class | |||||

|---|---|---|---|---|---|

| Waste Source | Polyesters | Polyurethanes | Polyamides | Polyolefins | |

| Cuticle of fruits e vegetables |  | X | |||

| Roots e tubers |  | X | X | ||

| Nutshell liquids |  | X | |||

| Citrus fruits |  | X | X | ||

| Vegetable oils |  | X | X | X | |

| Baked goods Cooked/dried sugary foods |  | X | X | X | |

| Starchy biomass |  | X | X | X | X |

| (Ligno) Cellulosic |  | X | X | X | X |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Visco, A.; Scolaro, C.; Facchin, M.; Brahimi, S.; Belhamdi, H.; Gatto, V.; Beghetto, V. Agri-Food Wastes for Bioplastics: European Prospective on Possible Applications in Their Second Life for a Circular Economy. Polymers 2022, 14, 2752. https://doi.org/10.3390/polym14132752

Visco A, Scolaro C, Facchin M, Brahimi S, Belhamdi H, Gatto V, Beghetto V. Agri-Food Wastes for Bioplastics: European Prospective on Possible Applications in Their Second Life for a Circular Economy. Polymers. 2022; 14(13):2752. https://doi.org/10.3390/polym14132752

Chicago/Turabian StyleVisco, Annamaria, Cristina Scolaro, Manuela Facchin, Salim Brahimi, Hossem Belhamdi, Vanessa Gatto, and Valentina Beghetto. 2022. "Agri-Food Wastes for Bioplastics: European Prospective on Possible Applications in Their Second Life for a Circular Economy" Polymers 14, no. 13: 2752. https://doi.org/10.3390/polym14132752

APA StyleVisco, A., Scolaro, C., Facchin, M., Brahimi, S., Belhamdi, H., Gatto, V., & Beghetto, V. (2022). Agri-Food Wastes for Bioplastics: European Prospective on Possible Applications in Their Second Life for a Circular Economy. Polymers, 14(13), 2752. https://doi.org/10.3390/polym14132752