On the Use of Dolomite as a Mineral Filler and Co-Filler in the Field of Polymer Composites: A Review

Abstract

1. Introduction

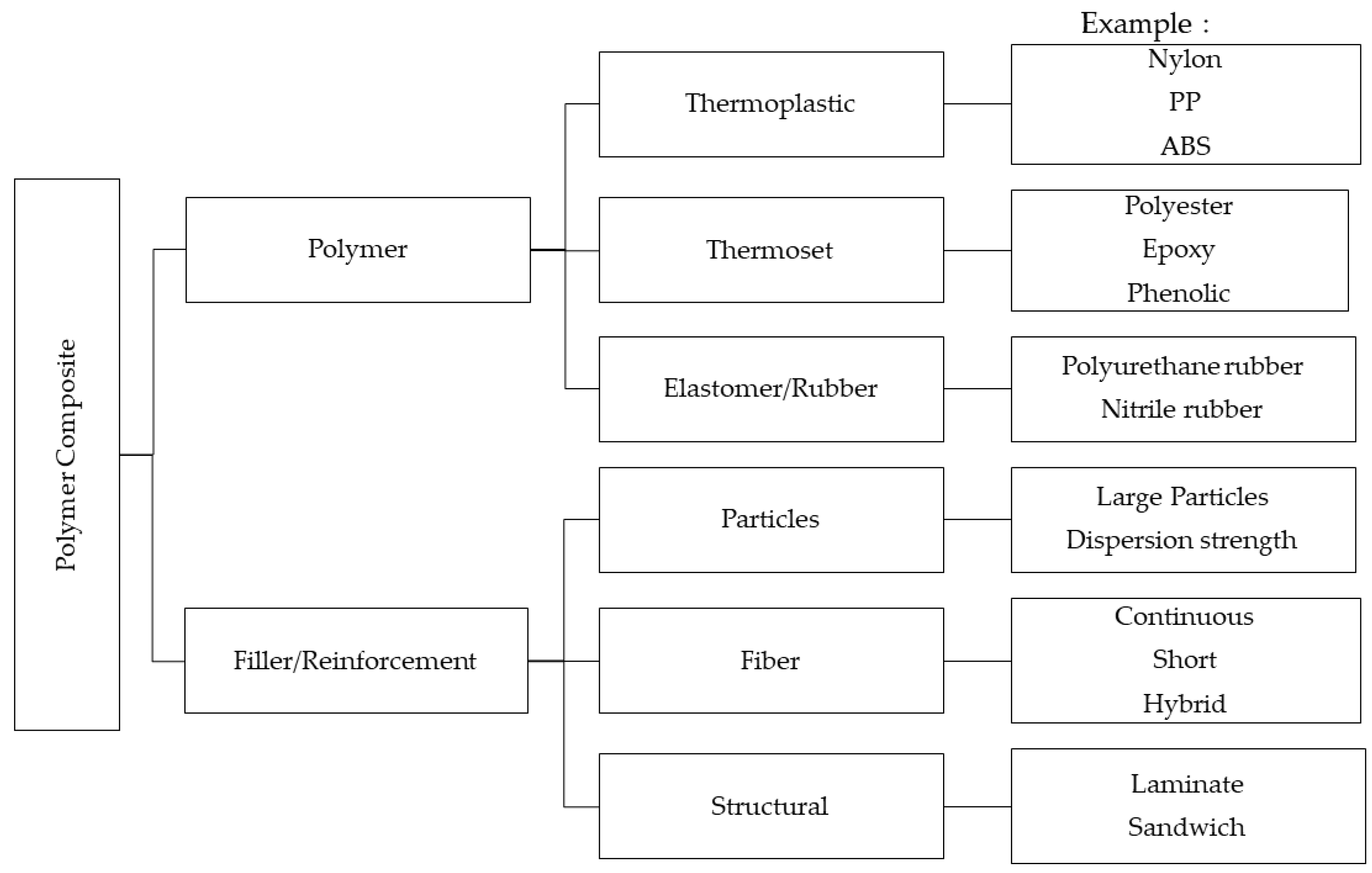

2. Filler

2.1. Mineral-Based Filler

2.2. Dolomite

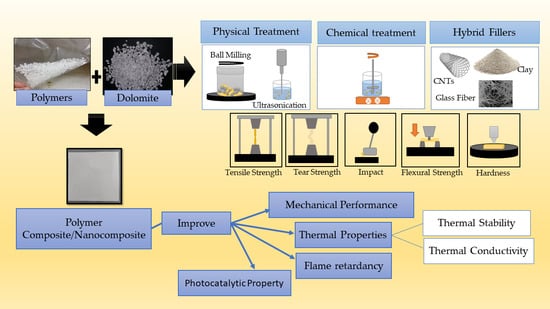

3. Dolomite as a Filler in a Polymer Composite

3.1. Pristine (Unmodified) Dolomite as a Filler in a Polymer Composite

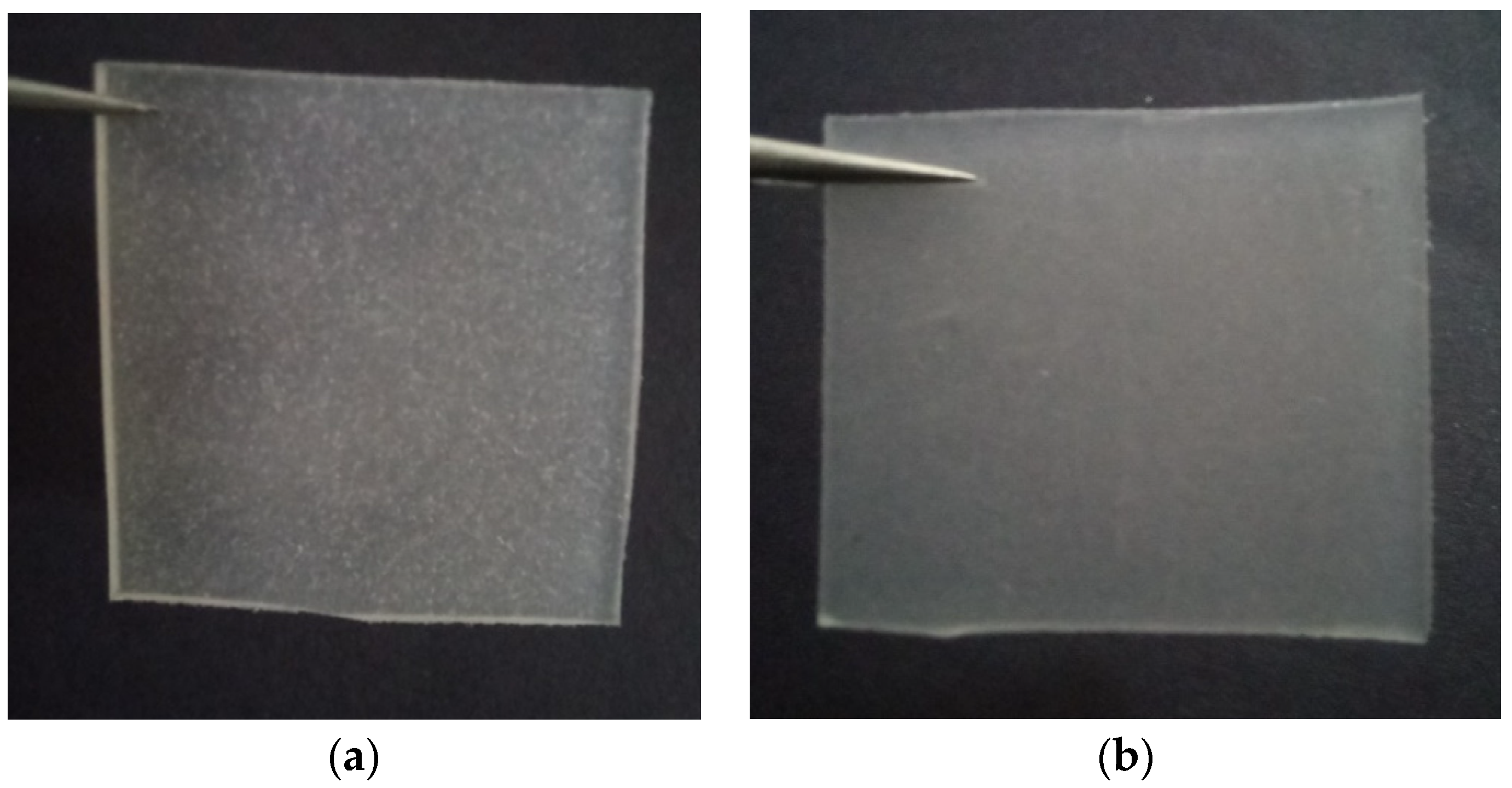

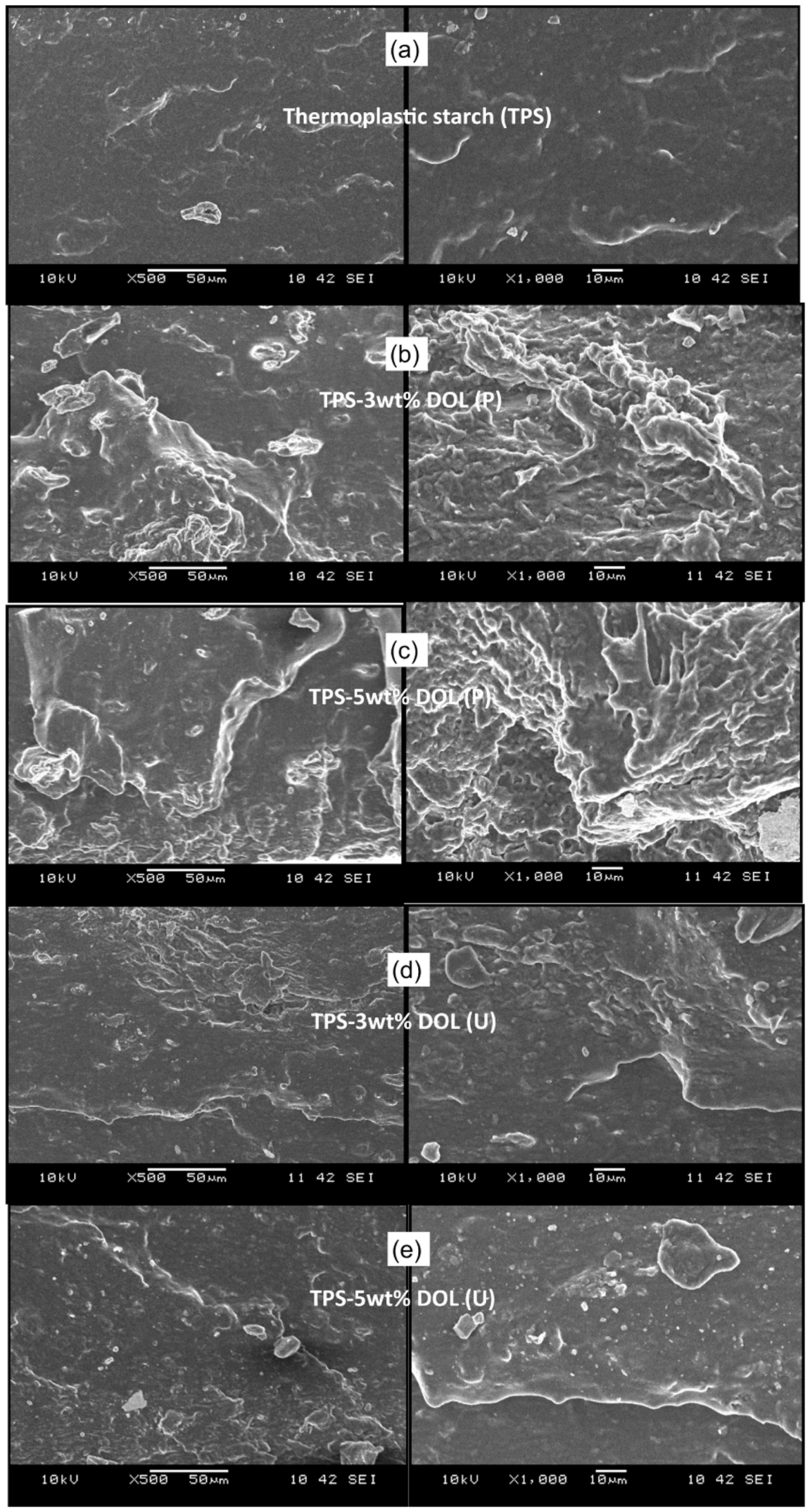

3.2. Physically Modified Dolomite as a Filler in a Polymer Composite

3.3. Chemically Modified Dolomite as a Filler in a Polymer Composite

3.4. Dolomite as a Hybrid Filler in a Polymer Composite

4. Summary

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Feldman, D. Polymer Nanocomposites in Medicine. J. Macromol. Sci. Part A 2016, 53, 55–62. [Google Scholar] [CrossRef]

- Müller, K.; Bugnicourt, E.; Latorre, M.; Jorda, M.; Echegoyen Sanz, Y.; Lagaron, J.; Miesbauer, O.; Bianchin, A.; Hankin, S.; Bölz, U.; et al. Review on the Processing and Properties of Polymer Nanocomposites and Nanocoatings and Their Applications in the Packaging, Automotive and Solar Energy Fields. Nanomaterials 2017, 7, 74. [Google Scholar] [CrossRef] [PubMed]

- Osman, A.F.; Alakrach, A.M.; Kalo, H.; Azmi, W.N.W.; Hashim, F. In Vitro Biostability and Biocompatibility of Ethyl Vinyl Acetate (EVA) Nanocomposites for Biomedical Applications. RSC Adv. 2015, 5, 31485–31495. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef] [PubMed]

- Shojaei, A.; Khasraghi, S.S. Self-Healing and Self-Sensing Smart Polymer Composites. In Composite Materials; Low, I.-M., Yu, D., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 307–357. [Google Scholar]

- Okada, A.; Kawasumi, M.; Kurauchi, T.; Kamigaito, O. Synthesis and characterization of Nylon 6-Clay Hybrid. Polym. Prepr. 1987, 28, 447–448. [Google Scholar]

- Kojima, Y.; Usuki, A.; Kawasumi, M.; Okada, A.; Kurauchi, T.; Kamigaito, O. Synthesis of Nylon 6–Clay Hybrid by Montmorillonite Intercalated with ε-Caprolactam. J. Polym. Sci. Part A Polym. Chem. 1993, 31, 983–986. [Google Scholar] [CrossRef]

- Murtaja, Y.; Lapčík, L.; Sepetcioglu, H.; Vlček, J.; Lapčíková, B.; Ovsík, M.; Staněk, M. Enhancement of the mechanical properties of HDPE mineral nanocomposites by filler particles modulation of the matrix plastic/elastic behavior. Nanotechnol. Rev. 2022, 11, 312–320. [Google Scholar] [CrossRef]

- Ahmad Saidi, M.A.; Mazlan, F.S.; Hassan, A.; Abd Rashid, R.; Rahmat, A.R. Flammability, Thermal and Mechanical Properties of Polybutylene Terephthalate/Dolomite Composites. J. Phys. Sci. 2019, 30, 175–189. [Google Scholar] [CrossRef]

- Adesakin, A.O.; Ajayi, O.O.; Imosili, P.E.; Attahdaniel, B.E.; Olusunle, S.O.O. Characterization and Evaluation of Mechanical Properties of Dolomite as Filler in Polyester. Chem. Mater. Res. 2013, 3, 36–40. [Google Scholar]

- Ridhwan, J.N.M.; Noimam, N.Z.; Mohd Salleh, M.A.A.; Sam, S.T.; Musa, L.; Nik Yahya, N.Z. The Effect of Different Sizes “Batu Reput” (Dolomite) as a Filler in SMR L and ENR-50. Adv. Mater. Res. 2013, 795, 383–387. [Google Scholar] [CrossRef]

- Osman, A.F.; Siah, L.; Alrashdi, A.A.; Ul-Hamid, A.; Ibrahim, I. Improving the Tensile and Tear Properties of Thermoplastic Starch/Dolomite Biocomposite Film through Sonication Process. Polymers 2021, 13, 274. [Google Scholar] [CrossRef] [PubMed]

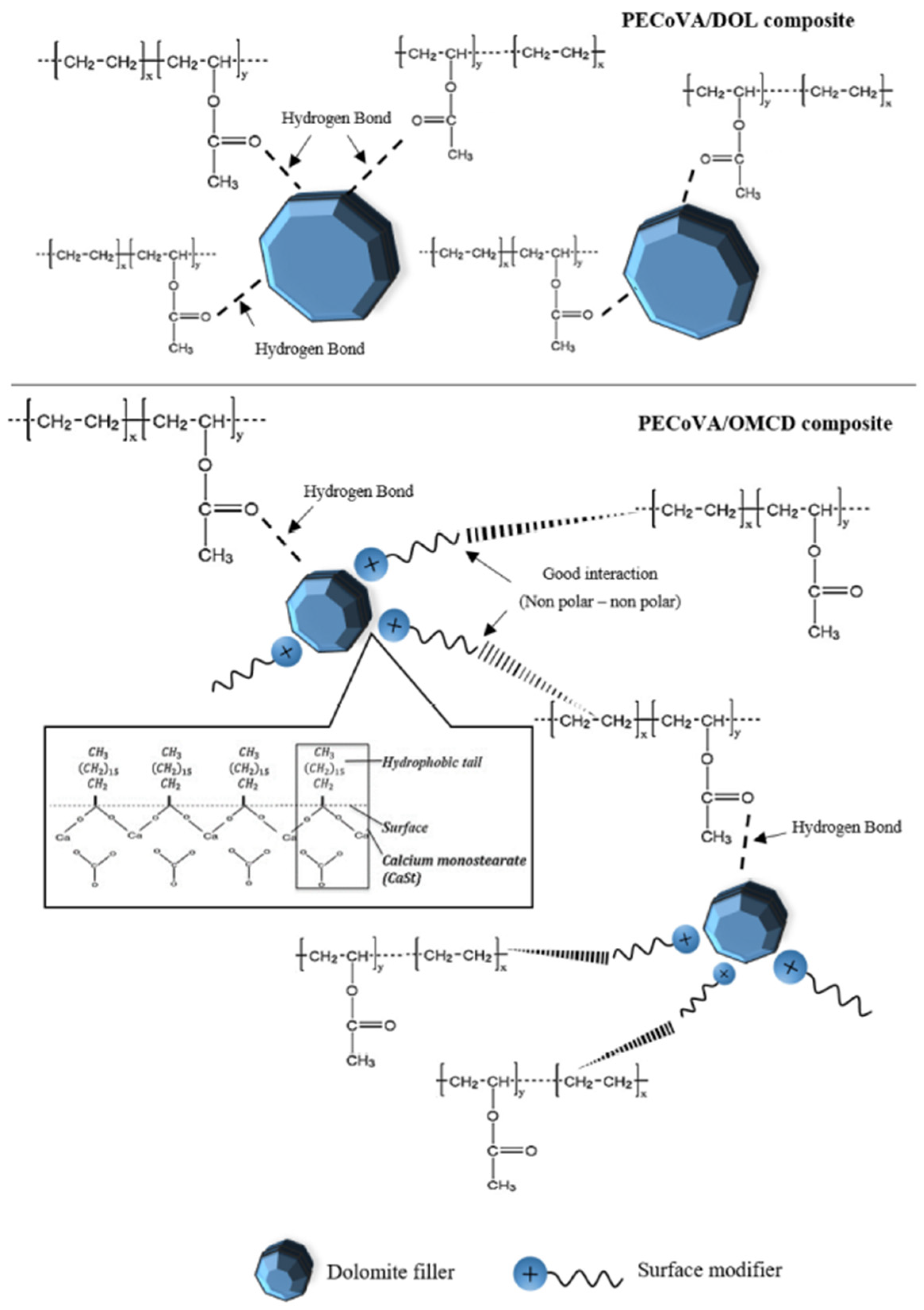

- Lim, K.C.; Osman, A.F.; Ahmad Fauzi, A.A.; Alrashdi, A.A.; Abdul Halim, K.A. The Mechanical and Thermal Properties of Poly(Ethylene-Co-Vinyl Acetate) (PECoVA) Composites with Pristine Dolomite and Organophilic Microcrystalline Dolomite (OMCD). Polymers 2021, 13, 3034. [Google Scholar] [CrossRef]

- Haldar, S.K.; Tišljar, J. Sedimentary Rocks. In Introduction to Mineralogy and Petrology; Elsevier: Amsterdam, The Netherlands, 2014; pp. 121–212. [Google Scholar] [CrossRef]

- Mehmood, M. Dolomite and Dolomitization Model—A Short Review. Int. J. Hydrol. 2018, 2, 549–553. [Google Scholar] [CrossRef]

- Banerjee, A. Estimation of Dolomite Formation: Dolomite Precipitation and Dolomitization. J. Geol. Soc. India 2016, 87, 561–572. [Google Scholar] [CrossRef]

- Nik Adik, N.N.A.; Ong, H.L.; Akil, H.M.; Sandu, A.V.; Villagracia, A.R.; Santos, G.N. Effects of stearic acid on tensile, morphological and thermal analysis of polypropylene (PP)/dolomite (Dol) composites. Mater. Plast. 2016, 53, 61–64. [Google Scholar]

- Manni, A.; Matadi Boumbimba, R.; Mikdam, A.; El Bouari, A.; Addiego, F.; Meziani, J.; Wary, M. Magnesite and Dolomite Micro-Particles: Preparation, Physical Properties and Application in Bio-Based Polymer Composite. Polym. Bull. 2021, 79, 2149–2171. [Google Scholar] [CrossRef]

- Akanbi, M.; Ogbobe, O.; Uzodinma Obidiegwu, M.; Uzoma, P. Effect of Dolomite Filler and Compatibilizer on Mechanical Properties of Polypropylene. IREJEST 2015, 13, 11–16. [Google Scholar]

- Ghada, B.; Rachida, Z.; Faycal, D. Effect of Marble Powder and Dolomite on the Mechanical Properties and the Thermal Stability of Poly(Vinyl Chloride). Asian J. Chem. 2010, 22, 6687–6692. [Google Scholar]

- Saleh, S.S.M.; Wei, Y.S.; Mohammad, N.F.; Abdullah, S.F.A.; Akil, H.M.; Saliu, H.R. Tensile Properties of CNTs-Dolomite Hybrid Filled Epoxy Composites. In Proceedings of the AIP Conference Proceedings, Ariyalur, India, 29 June 2021; AIP Publishing LLC: Melville, NY, USA, 2021. [Google Scholar] [CrossRef]

- Verma, S.K.; Gupta, A.; Singh, T.; Gangil, B.; Jánosi, E.; Fekete, G. Influence of Dolomite on Mechanical, Physical and Erosive Wear Properties of Natural-Synthetic Fiber Reinforced Epoxy Composites. Mater. Res. Express 2019, 6, 125704. [Google Scholar] [CrossRef]

- Verma, S.K.; Gangil, B.; Gupta, A.; Rajput, N.S.; Singh, T. Dolomite Dust Filled Glass Fiber Reinforced Epoxy Composite: Influence of Fabrication Techniques on Physicomechanical and Erosion Wear Properties. Polym. Compos. 2021, 43, 551–565. [Google Scholar] [CrossRef]

- Shamsuri, A.A.; Mohd Zolkepli, M.N.; Mohamed Ariff, A.H.; Sudari, A.K.; Abu Zarin, M. A Preliminary Investigation on Processing, Mechanical and Thermal Properties of Polyethylene/Kenaf Biocomposites with Dolomite Added as Secondary Filler. J. Compos. 2015, 2015, 760909. [Google Scholar] [CrossRef][Green Version]

- Saleh, S.S.M.; Akil, H.M.; Abdul Kudus, M.H.; Zakaria, M.R. A comparative Study of Dolomite and MWCNTS-Dolomite as Fillers in Phenolic Composites. Malays. Polym. J. 2014, 9, 67–69. [Google Scholar]

- Saleh, S.S.M.; Akil, H.M.; Abdul Kudus, M.H.; Ahmad, K.R.; Ahmad Bakhtiar, N.S.A. Effect of Different Hybrid Method on Properties of Carbon Nanotubes/Dolomite Hybrid Filled Phenolic Composites. Procedia Chem. 2016, 19, 45–49. [Google Scholar] [CrossRef][Green Version]

- Ni, L.; Mao, Y.; Liu, Y.; Cai, P.; Jiang, X.; Gao, X.; Cheng, X.; Chen, J. Synergistic Reinforcement of Waterborne Polyurethane Films Using Palygorskite and Dolomite as Micro/Nano-Fillers. J. Polym. Res. 2020, 27, 23. [Google Scholar] [CrossRef]

- Özdemir, E.; Ayrilmis, N.; Mengeloglu, F. Effect of Dolomite Powder on Combustion and Technological Properties of WPC and Neat Polyproppylene. J. Chil. Chem. Soc. 2017, 62, 3716–3720. [Google Scholar] [CrossRef]

- Amiri, R.-S.N.; Tirri, T.; Wilen, C.-E. Flame Retardant Polyurethane Nanocomposite: Study of Clay Dispersion and Its Synergistic Effect with Dolomite. J. Appl. Polym. Sci. 2012, 129, 1678–1685. [Google Scholar] [CrossRef]

- Wypych, G. Handbook of Fillers, 4th ed.; ChemTec Publishing: Toronto, ON, Canada, 2016. [Google Scholar]

- DeArmitt, C.; Rothon, R. Particulate Fillers, Selection, and Use in Polymer Composites. In Encyclopedia of Polymers and Composites; Sanjay, P., Ed.; Springer: Berlin/Heidelberg, Germany, 2014; pp. 1–19. [Google Scholar] [CrossRef]

- Morreale, M.; Liga, A.; Mistretta, M.; Ascione, L.; Mantia, F. Mechanical, Thermomechanical and Reprocessing Behavior of Green Composites from Biodegradable Polymer and Wood Flour. Materials 2015, 8, 7536–7548. [Google Scholar] [CrossRef]

- Baur, E. Chemical Resistance of Commodity Thermoplastics; William Andrew: Oxford, UK; Cambridge, MA, USA, 2016. [Google Scholar]

- Hsissou, R.; Seghiri, R.; Benzekri, Z.; Hilali, M.; Rafik, M.; Elharfi, A. Polymer composite materials: A comprehensive review. Compos. Struct. 2021, 262, 113640. [Google Scholar] [CrossRef]

- Post, W.; Kuijpers, L.J.; Zijlstra, M.; van der Zee, M.; Molenveld, K. Effect of Mineral Fillers on the Mechanical Properties of Commercially Available Biodegradable Polymers. Polymers 2021, 13, 394. [Google Scholar] [CrossRef]

- Saba, N.; Tahir, P.; Jawaid, M. A Review on Potentiality of Nano Filler/Natural Fiber Filled Polymer Hybrid Composites. Polymers 2014, 6, 2247–2273. [Google Scholar] [CrossRef]

- Osman, A.F.; Fitri, T.F.M.; Rakibuddin, M.; Hashim, F.; Tuan Johari, S.A.T.; Ananthakrishnan, R.; Ramli, R. Pre-Dispersed Organo-Montmorillonite (Organo-MMT) Nanofiller: Morphology, Cytocompatibility and Impact on Flexibility, Toughness and Biostability of Biomedical Ethyl Vinyl Acetate (EVA) Copolymer. Mater. Sci. Eng. C 2017, 74, 194–206. [Google Scholar] [CrossRef] [PubMed]

- Abdul Hamid, A.R.; Osman, A.F.; Mustafa, Z.; Mandal, S.; Ananthakrishnan, R. Tensile, Fatigue and Thermomechanical Properties of Poly (Ethylene-Co-Vinyl Acetate) Nanocomposites Incorporating Low and High Loadings of Pre-Swelled Organically Modified Montmorillonite. Polym. Test. 2020, 85, 106426. [Google Scholar] [CrossRef]

- Alakrach, A.M.; Osman, A.F.; Noriman, N.Z.; Betar, B.O.; Dahham, O.S. Thermal Properties of Ethyl Vinyl Acetate (EVA)/Montmorillonite (MMT) Nanocomposites for Biomedical Applications. In Proceedings of the MATEC Web of Conferences, Phuket, Thailand, 1–2 May 2016; Volume 78, p. 1074. [Google Scholar] [CrossRef]

- Neghab, M.; Abedini, R.; Soltanzadeh, A.; Iloon Kashkooli, A.; Ghayoomi, S.M.A. Respiratory Disorders Associated with Heavy Inhalation Exposure to Dolomite Dust. Iran. Red Crescent Med. J. 2012, 14, 549–557. [Google Scholar]

- John, V.M.; Damineli, B.L.; Quattrone, M.; Pileggi, R.G. Fillers in Cementitious Materials—Experience, Recent Advances and Future Potential. Cem. Concr. Res. 2018, 114, 65–78. [Google Scholar] [CrossRef]

- Hussin, K.; Jamaludin, S.; Mohd, C.; Ghazali, R.; Idris, S.; Salleh, N.; Nizar, K. The Development of Artificial Marble from Dolomite (Batu Reput) in Perlis. KUKUM Eng. Res. Semin. 2006, 101–106. [Google Scholar]

- Cao, Z.; Chen, P.; Yang, F.; Wang, S.; Zhong, H. Transforming Structure of Dolomite to Enhance Its Ion-Exchange Capacity for Copper (II). Colloids Surf. A Physicochem. Eng. Asp. 2018, 539, 201–208. [Google Scholar] [CrossRef]

- Nik Nur Azza, N.A.; Ong, H.L.; Noorina Hidayu, J.; Akil, H.M.; Sam, S.T. Analysis of Ground Dolomite: Effect of Grinding Time on the Production of Submicron Particles. Appl. Mech. Mater. 2014, 679, 145–148. [Google Scholar] [CrossRef]

- Salleh, M.N.; Kasim, F.H.; Ismail, K.N.; Ghazali, C.M.R.; Saad, S.A.; DAud, S. Characterization and Application of Dolomite Rock in Perlis. In Proceedings of the 1st International Conference on Natural Resources Engineering & Technology 2006, Putrajaya, Malaysia, 24–25 July 2006; pp. 465–470. [Google Scholar]

- Tengku Mustafa, T.N.A.S.; Munusamy, S.R.R.; Uy Lan, D.N.; Yunos, N.F.M. Physical and Structural Transformations of Perlis Carbonate Rocks via Mechanical Activation Route. Procedia Chem. 2016, 19, 673–680. [Google Scholar] [CrossRef][Green Version]

- Gregg, J.M.; Bish, D.L.; Kaczmarek, S.E.; Machel, H.G. Mineralogy, Nucleation and Growth of Dolomite in the Laboratory and Sedimentary Environment: A Review. Sedimentology 2015, 62, 1749–1769. [Google Scholar] [CrossRef]

- Abdul Samad, H.; Abd Rashid, R. Influence of Dolomite and Granite Waste Content on the Properties of Artificial Marble. IOP Conf. Ser. Mater. Sci. Eng. 2020, 713, 012017. [Google Scholar] [CrossRef]

- Perlis Dolomite Industries. Available online: https://www.perlisdolomite.com.my/?playlist=30d262f&video=2f0c00c (accessed on 26 June 2022).

- Iqbal, Y.; Leu, L.-C.; Fahad, M.; Ubic, R. Characterization of Mineral Ores from Northern and Northwest Pakistan. JOM 2012, 65, 73–79. [Google Scholar] [CrossRef]

- Dolomite Mineral Physical—Optical Properties, Occurrence and Uses. Available online: https://geologyscience.com/minerals/dolomite/ (accessed on 26 June 2022).

- Calcite Mineral|Uses and Properties. Available online: https://geology.com/minerals/calcite.shtml (accessed on 26 June 2022).

- Abdalqader, A.; Sonebi, M. Dolomitic Filler in Self-Compacting Concrete: A Review. RILEM Tech. Lett. 2020, 5, 75–84. [Google Scholar] [CrossRef]

- Karaca, S.; Gurses, A.; Ejder, M.; Acikyildiz, M. Adsorptive Removal of Phosphate from Aqueous Solutions Using Raw and Calcinated Dolomite. J. Hazard. Mater. 2006, 128, 273–279. [Google Scholar] [CrossRef] [PubMed]

- Ye, H.; Fu, C.; Yang, G. Influence of Dolomite on the Properties and Microstructure of Alkali-Activated Slag with and without Pulverized Fly Ash. Cem. Concr. Compos. 2019, 103, 224–232. [Google Scholar] [CrossRef]

- Kavitha, M.; Linga, D.; Adhikari, S.; Anikuttan, K.; Prabu, D. Effect of Lime, Dolomite and Gypsum on Phosphorus Reduction Potential in Freshwater. Int. J. Appl. Pure Sci. Agric. 2016, 2, 44–50. [Google Scholar]

- Wonyen, D.G.; Kromah, V.; Gibson, B.; Nah, S.; Chelgani, S.C. A Review of Flotation Separation of Mg Carbonates (Dolomite and Magnesite). Minerals 2018, 8, 354. [Google Scholar] [CrossRef]

- Hamizah, A.S.; Rashita, A.R.; Malek, S. Characterization and Evaluation of Dolomite and Kaolin as Filler on the Properties of Poly Art Marble. Mater. Today Proc. 2020, 29, 173–178. [Google Scholar] [CrossRef]

- Haritonovs, V.; Tihonovs, J.; Smirnovs, J. High Modulus Asphalt Concrete with Dolomite Aggregates. Transp. Res. Procedia 2016, 14, 3485–3492. [Google Scholar] [CrossRef]

- Solihin; Sulistiyono, E. Synthesis of Magnesium Carbonate Using Indonesian Dolomite. Adv. Mater. Res. 2015, 1112, 546–549. [Google Scholar] [CrossRef]

- Youssef, E.A.M. Characterization, surface modification, and evaluation of Egyptian dolomite ore as an extender pigment for paint. Pigment. Resin Technol. 2002, 31, 226–233. [Google Scholar] [CrossRef]

- Bessa, L.P.; Terra, N.M.; Cardoso, V.L.; Reis, M.H.M. Macro-Porous Dolomite Hollow Fibers Sintered at Different Temperatures toward Widened Applications. Ceram. Int. 2017, 43, 16283–16291. [Google Scholar] [CrossRef]

- Mohamed El-Mezayen, A.; Mohamed Saleh, G.; Mohamed Abdou El-Desoky, H.; Mohd Said Khalil, B.; Samy, A.M. Mineralogical and Chemical Studies on Some Minerals Used in Pharmaceuticl Industries in Egypt. Al-Azhar J. Pharm. Sci. 2014, 50, 181–190. [Google Scholar] [CrossRef][Green Version]

- Mohd Din, S.F.; Abdul Rashid, R.; Ahmad Saidi, M.A.; Othman, N. Mechanical, Thermal and Flammability Properties of Dolomite Filled Polypropylene Composites. PERINTIS eJ. 2018, 8, 58–73. [Google Scholar]

- Ali, V.; Neelkamal; Haque, F.Z.; Zulfequar, M.; Husain, M. Preparation and Characterization of Polyether-Based Polyurethane Dolomite Composite. J. Appl. Polym. Sci. 2006, 103, 2337–2342. [Google Scholar] [CrossRef]

- Lee, C.; Pang, M.M.; Koay, S.C.; Choo, H.L.; Tshai, K.Y. Talc Filled Polylactic-Acid Biobased Polymer Composites: Tensile, Thermal and Morphological Properties. SN Appl. Sci. 2020, 2, 354. [Google Scholar] [CrossRef]

- Poh, C.L.; Mariatti, M.; Ahmad Fauzi, M.N.; Ng, C.H.; Chee, C.K.; Chuah, T.P. Tensile, Dielectric, and Thermal Properties of Epoxy Composites Filled with Silica, Mica, and Calcium Carbonate. J. Mater. Sci. Mater. Electron. 2014, 25, 2111–2119. [Google Scholar] [CrossRef]

- Yu, F.; Liu, T.; Zhao, X.; Yu, X.; Lu, A.; Wang, J. Effects of Talc on the Mechanical and Thermal Properties of Polylactide. J. Appl. Polym. Sci. 2012, 125, E99–E109. [Google Scholar] [CrossRef]

- Ahmad Fauzi, A.A.; Osman, A.F.; Abdul Halim, K.A.; Ismail, H. Ultrasonicated Dolomite as Potential Reinforcing Mineral Filler in Polymer and Copolymer-Based Composites. In Mineral-Filled Polymer Composites: Selection, Processing, and Applications; Ismail, H., Sapuan, S.M., Ilyas, R.A., Eds.; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar]

- Ahmad Fauzi, A.A.; Osman, A.F.; Abdul Halim, K.A.; Mustafa, Z.; Alakrach, A.M.; Salleh, M.N. The Use of Ground & Ultrasonicated Dolomite (GUD) for Improving the Tensile Performance of Poly (Ethylene-Co-Vinyl Acetate) Copolymer Composite. J. Phys. Conf. Ser. 2021, 2080, 012029. [Google Scholar] [CrossRef]

- Syed Bakar, S.S.; Zakaria, N.S.; Wahab, J.A.; Salleh, M.A.A.M. Batu Reput Filled Recycled Polypropylene Eco-Polymer Composites. Bdg. Indones. Adv. Environ. Biol. 2013, 7, 3596–3600. [Google Scholar]

- Decker, A.; Bukit, N.; Frida, E.; Harahap, M. Preparation Natural Bentonite in Nano Particle Material as Filler Nanocomposite High Density Poliethylene (Hdpe). IISTE Int. J. 2013, 3, 10–20. [Google Scholar]

- Rajaee, P.; Ashenai Ghasemi, F.; Fasihi, M.; Saberian, M. Effect of Styrene-Butadiene Rubber and Fumed Silica Nano-Filler on the Microstructure and Mechanical Properties of Glass Fiber Reinforced Unsaturated Polyester Resin. Compos. Part B Eng. 2019, 173, 106803. [Google Scholar] [CrossRef]

- Ashraf, M.A.; Peng, W.; Zare, Y.; Rhee, K.Y. Effects of Size and Aggregation/Agglomeration of Nanoparticles on the Interfacial/Interphase Properties and Tensile Strength of Polymer Nanocomposites. Nanoscale Res. Lett. 2018, 13, 214. [Google Scholar] [CrossRef] [PubMed]

- Vergnes, B. Influence of Processing Conditions on the Preparation of Clay-Based Nanocomposites by Twin-Screw Extrusion. Int. Polym. Process. 2019, 34, 482–501. [Google Scholar] [CrossRef]

- Dennis, H.R.; Hunter, D.L.; Chang, D.; Kim, S.; White, J.L.; Cho, J.W.; Paul, D.R. Effect of Melt Processing Conditions on the Extent of Exfoliation in Organoclay-Based Nanocomposites. Polymer 2001, 42, 9513–9522. [Google Scholar] [CrossRef]

- Kracalik, M.; Laske, S.; Gschweitl, M.; Friesenbichler, W.; Langecker, G.R. Advanced Compounding: Extrusion of Polypropylene Nanocomposites Using the Melt Pump. J. Appl. Polym. Sci. 2009, 113, 1422–1428. [Google Scholar] [CrossRef]

- Cho, J.; Joshi, M.S.; Sun, C.T. Effect of Inclusion Size on Mechanical Properties of Polymeric Composites with Micro and Nano Particles. Compos. Sci. Technol. 2006, 66, 1941–1952. [Google Scholar] [CrossRef]

- Asgari, M.; Sundararaj, U. Silane Functionalization of Sodium Montmorillonite Nanoclay: The Effect of Dispersing Media on Intercalation and Chemical Grafting. Appl. Clay Sci. 2018, 153, 228–238. [Google Scholar] [CrossRef]

- Koohestani, B.; Ganetri, I.; Yilmaz, E. Effects of Silane Modified Minerals on Mechanical, Microstructural, Thermal, and Rheological Properties of Wood Plastic Composites. Compos. Part B Eng. 2017, 111, 103–111. [Google Scholar] [CrossRef]

- Sönmez, M.; Juganaru, M.; Ficai, A.; Ficai, D.; Oprea, O.; Gurau, D.; Alexandrescu, L.; Stelescu, M.D.; Georgescu, M.; Nituica, M.; et al. Dolomite Surface Modification with Titanium and Silicon Precursors and Its Morphostructural and Thermal Characterisation. In Proceedings of the 8th International Conference on Advanced Materials and Systems, Bucharest, Romania, 1–3 October 2020. [Google Scholar] [CrossRef]

- Przekop, R.E.; Jakubowska, P.; Sztorch, B.; Kozera, R.; Dydek, K.; Jałbrzykowski, M.; Osiecki, T.; Marciniak, P.; Martyła, A.; Kloziński, A.; et al. Opoka—Sediment Rock as New Type of Hybrid Mineral Filler for Polymer Composites. AppliedChem 2021, 1, 90–110. [Google Scholar] [CrossRef]

- Kumar, A.; Sharma, K.; Dixit, A.R. A Review of the Mechanical and Thermal Properties of Graphene and Its Hybrid Polymer Nanocomposites for Structural Applications. J. Mater. Sci. 2018, 54, 5992–6026. [Google Scholar] [CrossRef]

- Matykiewicz, D.; Barczewski, M.; Mousa, M.S.; Sanjay, M.R.; Siengchin, S. Impact Strength of Hybrid Epoxy–Basalt Composites Modified with Mineral and Natural Fillers. ChemEngineering 2021, 5, 56. [Google Scholar] [CrossRef]

- Jaafar, M. Development of Hybrid Fillers/Polymer Nanocomposites for Electronic Applications. In Hybrid Nanomaterials: Advances in Energy, Environment and Polymer Nanocomposites; Kumar Srivastava, S., Mittal, V., Eds.; Scrivener Publishing: Beverly, MA, USA, 2017; pp. 349–369. [Google Scholar]

- Gangil, B.; Ranakoti, L.; Verma, S.K.; Singh, T. Utilization of Waste Dolomite Dust in Carbon Fiber Reinforced Vinylester Composites. J. Mater. Res. Technol. 2022, 18, 3291–3301. [Google Scholar] [CrossRef]

- Vijayaraghavan, J.; Jeevakkumar, R.; Venkatesan, G.; Rengasamy, M.; Thivya, J. Influence of Kaolin and Dolomite as Filler on Bond Strength of Polyurethane Coated Reinforcement Concrete. Constr. Build. Mater. 2022, 325, 126675. [Google Scholar] [CrossRef]

| Physical Properties | Dolomite [51] | Calcite [52] |

|---|---|---|

| Chemical composition | (CaMg(CO3)2) | CaCO3 |

| Color | Colorless, white, pink, gray, brown, black | White, colorless, gray, red, green, blue, yellow, orange, brown |

| Streak | White | White |

| Cleavage | Perfect, rhombohedral, three directions | Perfect, rhombohedral, three directions |

| Mohs hardness | 3.5–4 | 3 |

| Specific gravity | 2.8–2.9 | 2.7 |

| Diagnostic properties | Rhombohedral cleavage | Rhombohedral cleavage |

| Crystal system | Hexagonal | Trigonal |

| Field | Purpose |

|---|---|

| Agriculture | As fertilizer [53] To decrease the acidity of soil [54] To adjust magnesium concentration in soil [54] |

| Aquaculture | To reduce phosphorus [56] |

| Ceramics | As a source of lime [46] In kiln control [53] |

| Chemical | To make salts, e.g., magnesia [57] |

| Construction | In cement and concrete manufacturing [41,53,55] As flooring material [42,58] As road construction material [58,59] |

| Plastic for structural application | As a filler [10] |

| Paint | As a filler [60] As an aid in pigmentation [61] |

| Wastewater treatment | For copper ion adsorption [43] |

| Membrane application | As low-cost membranes or substrates [62] |

| Plastics | As a filler to improve the mechanical properties [12,13] |

| Pharmaceutical | As a supplementary source of calcium and magnesium [63] As an osmotic oral laxative [63] |

| Type of Polymer | Processing Method | Dolomite Loading | Tensile Strength (MPa) | Elongation at Break (%) | Young’s Modulus (MPa) | Compression Strength (kg/m2) | Impact Strength (J/m) | Hardness (HV) | Flexural Strength (MPa) | Flexural Modulus (MPa) | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Polyester | Manually stir | 0% | 49 | N/A | 700 | N/A | N/A | 8 | N/A | N/A | [10] |

| 5% | 22 | N/A | 500 | N/A | N/A | 5 | N/A | N/A | |||

| 10% | 22.5 | N/A | 820 | N/A | N/A | 5.5 | N/A | N/A | |||

| 20% | 24 | N/A | 1010 | N/A | N/A | 24.9 | N/A | N/A | |||

| 30% | 19 | N/A | 1100 | N/A | N/A | 12 | N/A | N/A | |||

| 40% | 11 | N/A | 690 | N/A | N/A | 6 | N/A | N/A | |||

| 50% | 18 | N/A | 810 | N/A | N/A | 6.5 | N/A | N/A | |||

| Polyether-based Polyurethane | Casting | 0% | 30 | 85 | N/A | 7 | N/A | N/A | N/A | N/A | [65] |

| 10% | 29 | 62 | N/A | 8 | N/A | N/A | N/A | N/A | |||

| 20% | 23 | 50 | N/A | 11.8 | N/A | N/A | N/A | N/A | |||

| 30% | 17 | 30 | N/A | 12.2 | N/A | N/A | N/A | N/A | |||

| 45% | 16 | 20 | N/A | 14.2 | N/A | N/A | N/A | N/A | |||

| Polypropylene (PP) | Extrusion (by a twin-screw extruder) | 0% | 19 | 12 | 650 | N/A | 103.87 | N/A | 25 | 700 | [64] |

| 5% | 17 | 13 | 610 | N/A | 65.83 | N/A | 23 | 900 | |||

| 10% | 16.5 | 18 | 710 | N/A | 50.42 | N/A | 24 | 2200 | |||

| 15% | 16.2 | 17.9 | 790 | N/A | 41.35 | N/A | 23.5 | 1300 |

| Type of Polymer | Processing Method | Dolomite Loading | Tensile | Elongation at Break (%) | Young’s Modulus (MPa) | Impact Strength (MPa) | Flexural | Ref. | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Strength (MPa) | Toughness | Strength (MPa) | Modulus (MPa) | |||||||

| Epoxidize natural rubber (ENR 50) | Two-roll mill | Sample 1 (<63 µm) | [11] | |||||||

| 0 phr | N/A | N/A | N/A | N/A | N/A | N/A | N/A | |||

| 5 phr | 9.97 | N/A | 1070.56 | N/A | N/A | N/A | N/A | |||

| 15 phr | 11.81 | N/A | 1264.21 | N/A | N/A | N/A | N/A | |||

| 25 phr | 9.92 | N/A | 1198.24 | N/A | N/A | N/A | N/A | |||

| 35 phr | 8.22 | N/A | 1062.74 | N/A | N/A | N/A | N/A | |||

| 50 phr | 7.29 | N/A | 998.56 | N/A | N/A | N/A | N/A | |||

| Sample 2 (75–150 µm) | ||||||||||

| 0 phr | N/A | N/A | N/A | N/A | N/A | N/A | N/A | |||

| 5 phr | 7.42 | N/A | 1019.75 | N/A | N/A | N/A | N/A | |||

| 15 phr | 10.94 | N/A | 1175.21 | N/A | N/A | N/A | N/A | |||

| 25 phr | 8.94 | N/A | 1074.31 | N/A | N/A | N/A | N/A | |||

| 35 phr | 7.86 | N/A | 1012.23 | N/A | N/A | N/A | N/A | |||

| 50 phr | 5.83 | N/A | 942.45 | N/A | N/A | N/A | N/A | |||

| Polyethylene vinyl acetate (PEVA) | Twin-screw extruder | 0% | 10.5 | 130 | 410 | 0.74 | N/A | N/A | N/A | [69] |

| 1% | 11 | 142 | 350 | 0.85 | N/A | N/A | N/A | |||

| 3% | 12.9 | 175 | 270 | 0.94 | N/A | N/A | N/A | |||

| 5% | 13.9 | 198 | 250 | 1.05 | N/A | N/A | N/A | |||

| Polyethylene vinyl acetate (PEVA) | Heated two-roll mill | 0% | 6.2 | 3600 | 900 | 1.0 | N/A | N/A | N/A | [70] |

| 1% | 7.8 | 5300 | 1180 | 1.1 | N/A | N/A | N/A | |||

| 3% | 7.5 | 5100 | 1100 | 0.95 | N/A | N/A | N/A | |||

| 5% | 7.2 | 5000 | 1090 | 0.8 | N/A | N/A | N/A | |||

| Polybutylene terephthalate (PBT) | Twin-screw extruder | 0% | 37 | N/A | 19 | 990 | 61 | 62 | 2100 | [9] |

| 5% | 40.1 | N/A | 13 | 1250 | 49 | 62.2 | 2400 | |||

| 10% | 43 | N/A | 9 | 1300 | 31 | 68 | 2500 | |||

| 15% | 41 | N/A | 8 | 1500 | 20 | 64 | 2700 | |||

| Standard Malaysian rubber (SMR L) | Two-roll mill | Sample 1 (<63 µm) | ||||||||

| 0 phr | N/A | N/A | N/A | N/A | N/A | N/A | N/A | [11] | ||

| 5 phr | 11.92 | N/A | 1378.24 | N/A | N/A | N/A | N/A | |||

| 15 phr | 13.43 | N/A | 1582.24 | N/A | N/A | N/A | N/A | |||

| 25 phr | 11.73 | N/A | 1293.51 | N/A | N/A | N/A | N/A | |||

| 35 phr | 10.57 | N/A | 1210.95 | N/A | N/A | N/A | N/A | |||

| 50 phr | 7.88 | N/A | 1187.24 | N/A | N/A | N/A | N/A | |||

| Sample 2 (75–150 µm) | ||||||||||

| 0 phr | N/A | N/A | N/A | N/A | N/A | N/A | N/A | |||

| 5 phr | 10.23 | N/A | 1287.42 | N/A | N/A | N/A | N/A | |||

| 15 phr | 12.16 | N/A | 1394.13 | N/A | N/A | N/A | N/A | |||

| 25 phr | 10.38 | N/A | 1253.12 | N/A | N/A | N/A | N/A | |||

| 35 phr | 9.71 | N/A | 1184.38 | N/A | N/A | N/A | N/A | |||

| 50 phr | 7.88 | N/A | 991.13 | N/A | N/A | N/A | N/A | |||

| Recycled polypropylene (rPP) | Z-blade mixer | Sample 1 (63 µm) | [71] | |||||||

| 0% | 9 | N/A | 4.4 | N/A | N/A | N/A | N/A | |||

| 10% | 9.8 | N/A | 5.8 | N/A | N/A | N/A | N/A | |||

| 20% | 10 | N/A | 6.2 | N/A | N/A | N/A | N/A | |||

| 30% | 12 | N/A | 9 | N/A | N/A | N/A | N/A | |||

| 40% | 11 | N/A | 5 | N/A | N/A | N/A | N/A | |||

| 50% | 8.8 | N/A | 4 | N/A | N/A | N/A | N/A | |||

| Sample 2 (300 µm) | ||||||||||

| 0% | 9 | N/A | 4.4 | N/A | N/A | N/A | N/A | |||

| 10% | 10 | N/A | 6 | N/A | N/A | N/A | N/A | |||

| 20% | 11 | N/A | 8.9 | N/A | N/A | N/A | N/A | |||

| 30% | 12 | N/A | 13.9 | N/A | N/A | N/A | N/A | |||

| 40% | 10.8 | N/A | 9 | N/A | N/A | N/A | N/A | |||

| 50% | 9.8 | N/A | 6.2 | N/A | N/A | N/A | N/A | |||

| Thermoplastic starch (TPS) | Mechanical stir | Sample 1 (150 µm) | ||||||||

| 0% | 2.64 ± 0.13 | N/A | 95.6 ± 1.8 | 7.10 ± 0.69 | N/A | N/A | N/A | [12] | ||

| 1% | 1.76 ± 0.12 | N/A | 126.13 ± 7.17 | 7.13 ± 0.23 | N/A | N/A | N/A | |||

| 2% | 1.73 ± 0.04 | N/A | 100.57 ± 5.9 | 8.90 ± 1.06 | N/A | N/A | N/A | |||

| 3% | 1.98 ± 0.24 | N/A | 94.7 ± 4.75 | 9.07 ± 1.06 | N/A | N/A | N/A | |||

| 4% | 2.67 ± 0.02 | N/A | 85.67 ± 0.68 | 10.10 ± 0.1 | N/A | N/A | N/A | |||

| 5% | 2.68 ± 0.07 | N/A | 66.37 ± 3.85 | 10.23 ± 0.99 | N/A | N/A | N/A | |||

| Sample 2 (U-50 µm) | ||||||||||

| 0% | 2.64 ± 0.13 | N/A | 95.6 ± 1.8 | 7.10 ± 0.69 | N/A | N/A | N/A | |||

| 1% | 1.88 ± 0.05 | N/A | 165.77 ± 0.76 | 10.43 ± 0.95 | N/A | N/A | N/A | |||

| 2% | 1.87 ± 0.10 | N/A | 134.13 ± 7.89 | 10.87 ± 0.85 | N/A | N/A | N/A | |||

| 3% | 2.74 ± 0.17 | N/A | 106.90 ± 1.08 | 11.27 ± 0.06 | N/A | N/A | N/A | |||

| 4% | 3.06 ± 0.16 | N/A | 100.37 ± 4.21 | 12.67 ± 0.15 | N/A | N/A | N/A | |||

| 5% | 3.61 ± 0.30 | N/A | 96.17 ± 4.26 | 13.30 ± 0.2 | N/A | N/A | N/A | |||

| Type of Polymer | Treatment on Dolomite | Processing Method | Dolomite Loading | Tensile Strength | Break of Elongation (%) | Young’s Modulus (MPa) | Impact Strength (J/m) | Hardness (BHN) | Flexural Strength (N/mm2) | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|

| Polyethylene vinyl acetate (PECoVA) | Modification of dolomite with stearic acid | Heated two-roll mill | 0% | 15.4 ± 2 (MPa) | 1151 ± 47 | 1.7 ± 0.1 | N/A | N/A | N/A | [13] |

| 1% | 20.7 ± 1 (MPa) | 1354 ± 68 | 1.9 ± 0.1 | N/A | N/A | N/A | ||||

| 3% | 22.1 ± 1 (MPa) | 1413 ± 87 | 2.0 ± 0.1 | N/A | N/A | N/A | ||||

| 5% | 18.5 ± 1 (MPa) | 1252 ± 34 | 1.8 ± 0.1 | N/A | N/A | N/A | ||||

| Polypropylene | Modification of dolomite with stearic acid | Twin-screw extruder | 0% | 24 (MPa) | 290 | 1300 | N/A | N/A | N/A | [17] |

| 5% | 30 (MPa) | 210 | 1290 | N/A | N/A | N/A | ||||

| 10% | 28 (MPa) | 200 | 1510 | N/A | N/A | N/A | ||||

| 15% | 27 (MPa) | 180 | 1512 | N/A | N/A | N/A | ||||

| 20% | 26.5 (MPa) | 151 | 1513 | N/A | N/A | N/A | ||||

| 25% | 26 (MPa) | 50 | 1700 | N/A | N/A | N/A | ||||

| Polypropylene | Maleic anhydride as a compatibilizer | Not mentioned | 0% | 5 (MPa) | 6 | N/A | N/A | 9 | 5 | [19] |

| 5% | 7 (MPa) | 5 | N/A | N/A | 10 | 6 | ||||

| 10% | 10 (MPa) | 4.2 | N/A | N/A | 13 | 7 | ||||

| 15% | 14(MPa) | 4 | N/A | N/A | 17 | 13 | ||||

| 20% | 16 (MPa) | 3 | N/A | N/A | 30 | 18 | ||||

| Polyvinyl chloride (PVC) | Dolomite + stabilizer | Internal mixer | 0 phr | 53.2 (N/m2) | 3.4 | 2200 | 50 | N/A | N/A | [20] |

| 5 phr | 56.9(N/m2) | 4.6 | 2357 | 57 | N/A | N/A | ||||

| 10 phr | 63 (N/m2) | 4.7 | 2450 | 60 | N/A | N/A | ||||

| 15 phr | 55.4 (N/m2) | 4.3 | 2550 | 54 | N/A | N/A | ||||

| 20 phr | 45.5 (N/m2) | 4.2 | 2655 | 52 | N/A | N/A |

| Polymer Matrix | Primary Filler | Secondary Filler | Processing Method | Filler Loading | Tensile | Elongation at Break (%) | Impact Strength | Hardness | Flexural | Ref. | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Strength (MPa) | Modulus | Stress (MPa) | Strength (MPa) | Modulus (MPa) | |||||||||

| Epoxy resin | Carbon nanotubes (CNTs) | Dolomite | Mechanical stirrer | Chemical vapor deposition | [21] | ||||||||

| 0% | 20.89 | 961.31 (MPa) | N/A | N/A | N/A | N/A | N/A | N/A | |||||

| 1% | 28.52 | 1152.87 (MPa) | N/A | N/A | N/A | N/A | N/A | N/A | |||||

| 3% | 33.83 | 1188.1 (MPa) | N/A | N/A | N/A | N/A | N/A | N/A | |||||

| 5% | 4.93 | 1216.5 (MPa) | N/A | N/A | N/A | N/A | N/A | N/A | |||||

| Physically hybrid | |||||||||||||

| 0% | 20.89 | 961.31 (MPa) | N/A | N/A | N/A | N/A | N/A | N/A | |||||

| 1% | 26.71 | 1139 (MPa) | N/A | N/A | N/A | N/A | N/A | N/A | |||||

| 3% | 29.97 | 1159.8 (MPa) | N/A | N/A | N/A | N/A | N/A | N/A | |||||

| 5% | 27.94 | 1148.7 (MPa) | N/A | N/A | N/A | N/A | N/A | N/A | |||||

| Epoxy resin | Glass fiber | Dolomite | Hand layup | 0% | 59.8 | N/A | N/A | N/A | 2.4 (J) | 102.12 (HRL) | 72.3 | N/A | [22] |

| 5% | 52 | N/A | N/A | N/A | 2.7 (J) | 107.27 (HRL) | 62.8 | N/A | |||||

| 10% | 45.9 | N/A | N/A | N/A | 3.4 (J) | 109.60 (HRL) | 54.3 | N/A | |||||

| 15% | 42.8 | N/A | N/A | N/A | 3.8 (J) | 112.26 (HRL) | 48..8 | N/A | |||||

| Epoxy resin | Glass fiber | Dolomite | Hand layup | 0% | 282.58 ± 12.96 | 2.32 ± 0.14 (GPa) | N/A | N/A | 6.1 ± 0.37 (J) | 101.32 ± 3.08 (HV) | 285.3 ± 13.12 | N/A | [23] |

| 5% | 268.59 ± 9.43 | 2.94 ± 0.l5 (GPa) | N/A | N/A | 7.2 ± 0.36 (J) | 103.76 ± 2.89 (HV) | 273 ± 9.65 | N/A | |||||

| 10% | 244.69 ± 7.80 | 3.26 ± 0.13 (GPa) | N/A | N/A | 8.8 ± 0.35 (J) | 105.64 ± 3.23 (HV) | 262.8 ± 7.12 | N/A | |||||

| 15% | 227.6 ± 7.10 | 2.44 ± 0.10 (GPa) | N/A | N/A | 10.2 ± 0.41 (J) | 108.22 ± 2.3 (HV) | 249.9 ± 7.24 | N/A | |||||

| VTRM | 0% | 374.46 ± 17.80 | 3.54 ± 0.21 (GPa) | N/A | N/A | 8.1 ± 0.46 (J) | 102.94 ± 3.18 (HV) | 337.4 ± 14.25 | N/A | ||||

| 5% | 337.33 ± 10.80 | 4.15 ± 0.17 (GPa) | N/A | N/A | 9.2 ± 0.37 (J) | 106.3 ± 225 (HV) | 331.8 ± 10.12 | N/A | |||||

| 10% | 293.05 ± 11.65 | 4.33 ± 0.22 (GPa) | N/A | N/A | 10.6 ± 0.48 (J) | 109.06 ± 3.08 (HV) | 327.6 ± 12.38 | N/A | |||||

| 15% | 270.43 ± 7.12 | 4.02 ± 0.12 (GPa) | N/A | N/A | 13.4 ± 0.39 (J) | 112.08 ± 2.38 (HV) | 319.9 ± 7.60 | N/A | |||||

| Low-density polyethylene (LDPE) | Kenaf core fiber (KCF) | Dolomite | Internal mixer | 0% | N/A | 109.37 (MPa) | 1.47 | N/A | 3.52 (kJ/m2) | N/A | N/A | N/A | [24] |

| 3% | N/A | 116.72 (MPa) | 1.50 | N/A | 3.73 (kJ/m2) | N/A | N/A | N/A | |||||

| 6% | N/A | 122.52 (MPa) | 1.53 | N/A | 3.82 (kJ/m2) | N/A | N/A | N/A | |||||

| 9% | N/A | 123.48 (MPa) | 1.60 | N/A | 4.03 (kJ/m2) | N/A | N/A | N/A | |||||

| 12% | N/A | 124.50 (MPa) | 1.81 | N/A | 4.11 (kJ/m2) | N/A | N/A | N/A | |||||

| 15% | N/A | 131.30 (MPa) | 1.86 | N/A | 4.69 (kJ/m2) | N/A | N/A | N/A | |||||

| 18% | N/A | 143.46 (MPa) | 1.91 | N/A | 5.29 (kJ/m2) | N/A | N/A | N/A | |||||

| Phenolic | Dolomite | Multiwalled carbon nanotubes (MWCNTs) | Ball milling machine | 0% | N/A | N/A | N/A | N/A | N/A | 25(HR) | N/A | N/A | [25] |

| 1% | N/A | N/A | N/A | N/A | N/A | 36(HR) | N/A | N/A | |||||

| 3% | N/A | N/A | N/A | N/A | N/A | 45(HR) | N/A | N/A | |||||

| 5% | N/A | N/A | N/A | N/A | N/A | 52(HR) | N/A | N/A | |||||

| Phenolic | Dolomite | Carbon nanotubes (CNTs) | Mechanical stirrer | Chemical vapor deposition | [26] | ||||||||

| 0 | N/A | N/A | N/A | N/A | N/A | 25 | N/A | N/A | |||||

| 1 | N/A | N/A | N/A | N/A | N/A | 39 | N/A | N/A | |||||

| 3 | N/A | N/A | N/A | N/A | N/A | 46 | N/A | N/A | |||||

| 5 | N/A | N/A | N/A | N/A | N/A | 50 | N/A | N/A | |||||

| Physically hybrid | |||||||||||||

| 0 | N/A | N/A | N/A | N/A | N/A | 25 | N/A | N/A | |||||

| 1 | N/A | N/A | N/A | N/A | N/A | 30 | N/A | N/A | |||||

| 3 | N/A | N/A | N/A | N/A | N/A | 37 | N/A | N/A | |||||

| 5 | N/A | N/A | N/A | N/A | N/A | 38 | N/A | N/A | |||||

| Waterborne polyurethane (WPU) | Fibrous palygorskite (PAL) | Dolomite | Mechanical stirring | 0% | 4.9 | N/A | N/A | 9.4 | N/A | N/A | N/A | N/A | [27] |

| WPU/PAL10% | 3.5 | N/A | N/A | 8.8 | N/A | N/A | N/A | N/A | |||||

| WPU/DOL 10% | 4. | N/A | N/A | 9.5 | N/A | N/A | N/A | N/A | |||||

| WPU/MIX 10% | 8. | N/A | N/A | 8.1 | N/A | N/A | N/A | N/A | |||||

| Polypropylene (PP) | Wood flour | Dolomite | High-intensity mixer and single-screw extruder | 0% | 27.1 | 474 (MPa) | N/A | 29.4 | N/A | N/A | 37.1 | 1013 | [28] |

| 3% | 24.8 | 615 (MPa) | N/A | 20.1 | N/A | N/A | 42.4 | 1592 | |||||

| 6% | 24.4 | 620 (MPa) | N/A | 22.2 | N/A | N/A | 41.0 | 1617 | |||||

| 9% | 22.8 | 627 (MPa) | N/A | 19.4 | N/A | N/A | 41.8 | 1673 | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmad Fauzi, A.A.; Osman, A.F.; Alrashdi, A.A.; Mustafa, Z.; Abdul Halim, K.A. On the Use of Dolomite as a Mineral Filler and Co-Filler in the Field of Polymer Composites: A Review. Polymers 2022, 14, 2843. https://doi.org/10.3390/polym14142843

Ahmad Fauzi AA, Osman AF, Alrashdi AA, Mustafa Z, Abdul Halim KA. On the Use of Dolomite as a Mineral Filler and Co-Filler in the Field of Polymer Composites: A Review. Polymers. 2022; 14(14):2843. https://doi.org/10.3390/polym14142843

Chicago/Turabian StyleAhmad Fauzi, Asfa Amalia, Azlin Fazlina Osman, Awad A. Alrashdi, Zaleha Mustafa, and Khairul Anwar Abdul Halim. 2022. "On the Use of Dolomite as a Mineral Filler and Co-Filler in the Field of Polymer Composites: A Review" Polymers 14, no. 14: 2843. https://doi.org/10.3390/polym14142843

APA StyleAhmad Fauzi, A. A., Osman, A. F., Alrashdi, A. A., Mustafa, Z., & Abdul Halim, K. A. (2022). On the Use of Dolomite as a Mineral Filler and Co-Filler in the Field of Polymer Composites: A Review. Polymers, 14(14), 2843. https://doi.org/10.3390/polym14142843