Progressive Damage Behaviour Analysis and Comparison with 2D/3D Hashin Failure Models on Carbon Fibre–Reinforced Aluminium Laminates

Abstract

:1. Introduction

2. Experimental Process

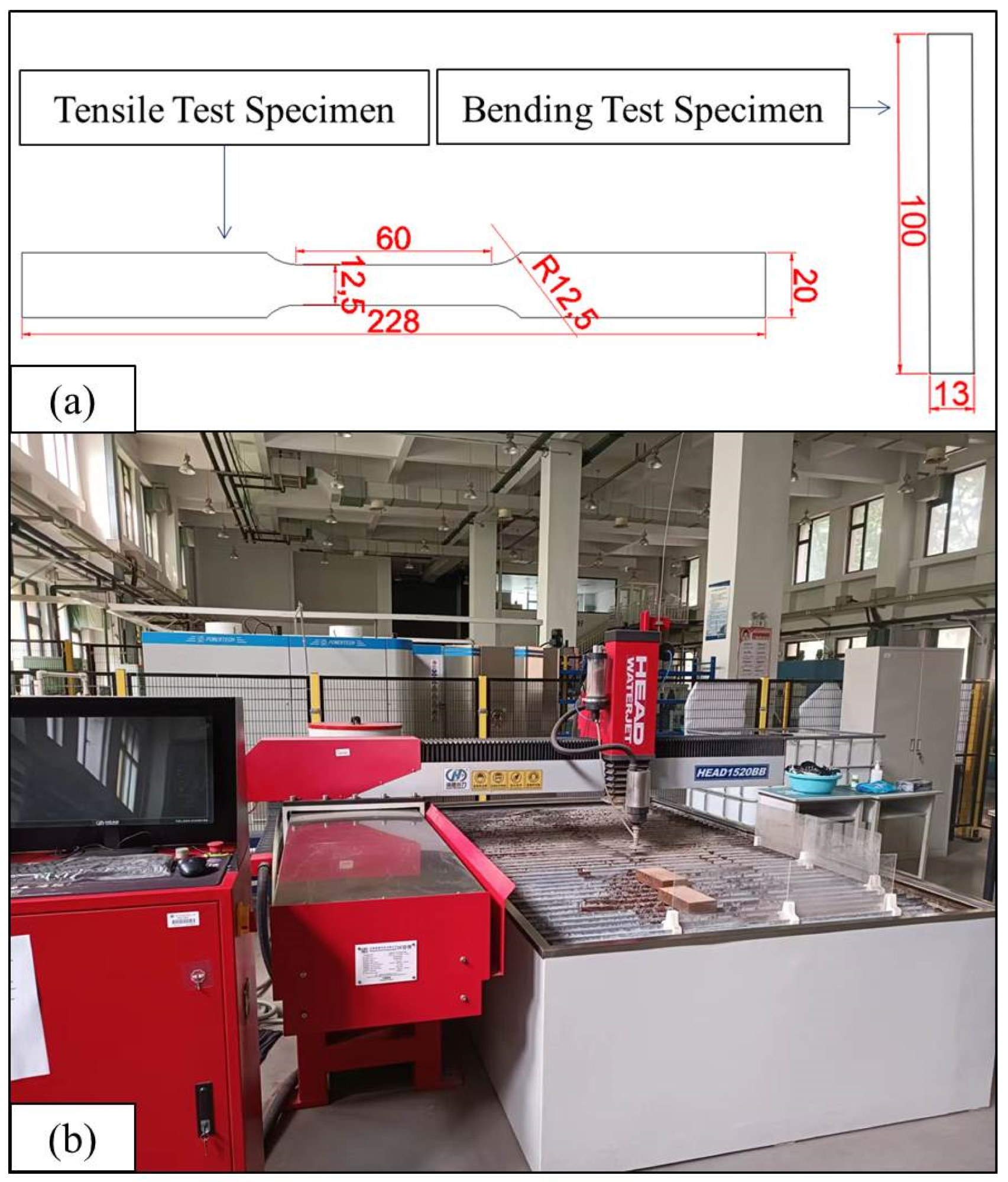

2.1. Specimen Preparation

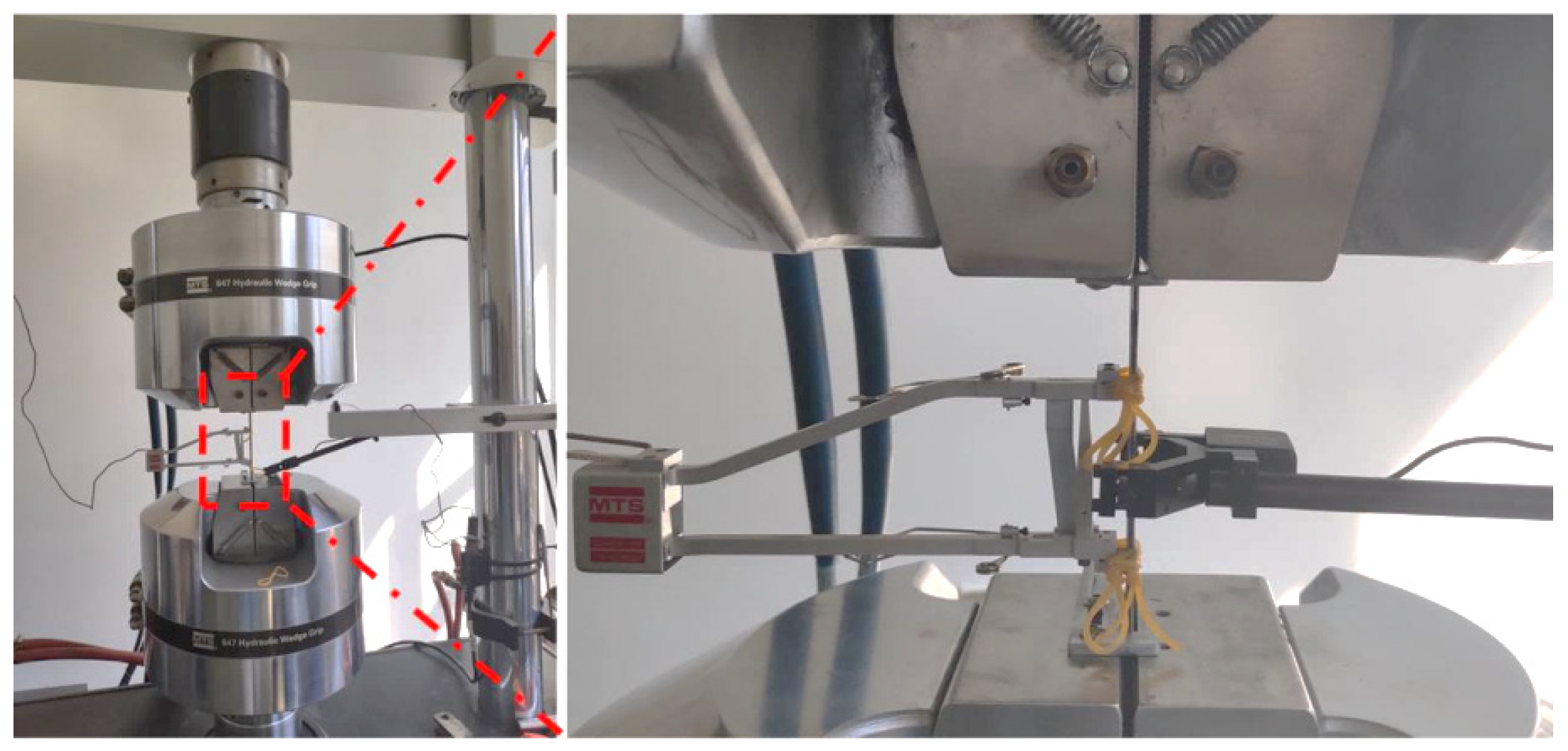

2.2. Tensile and Three-Point Bending Tests

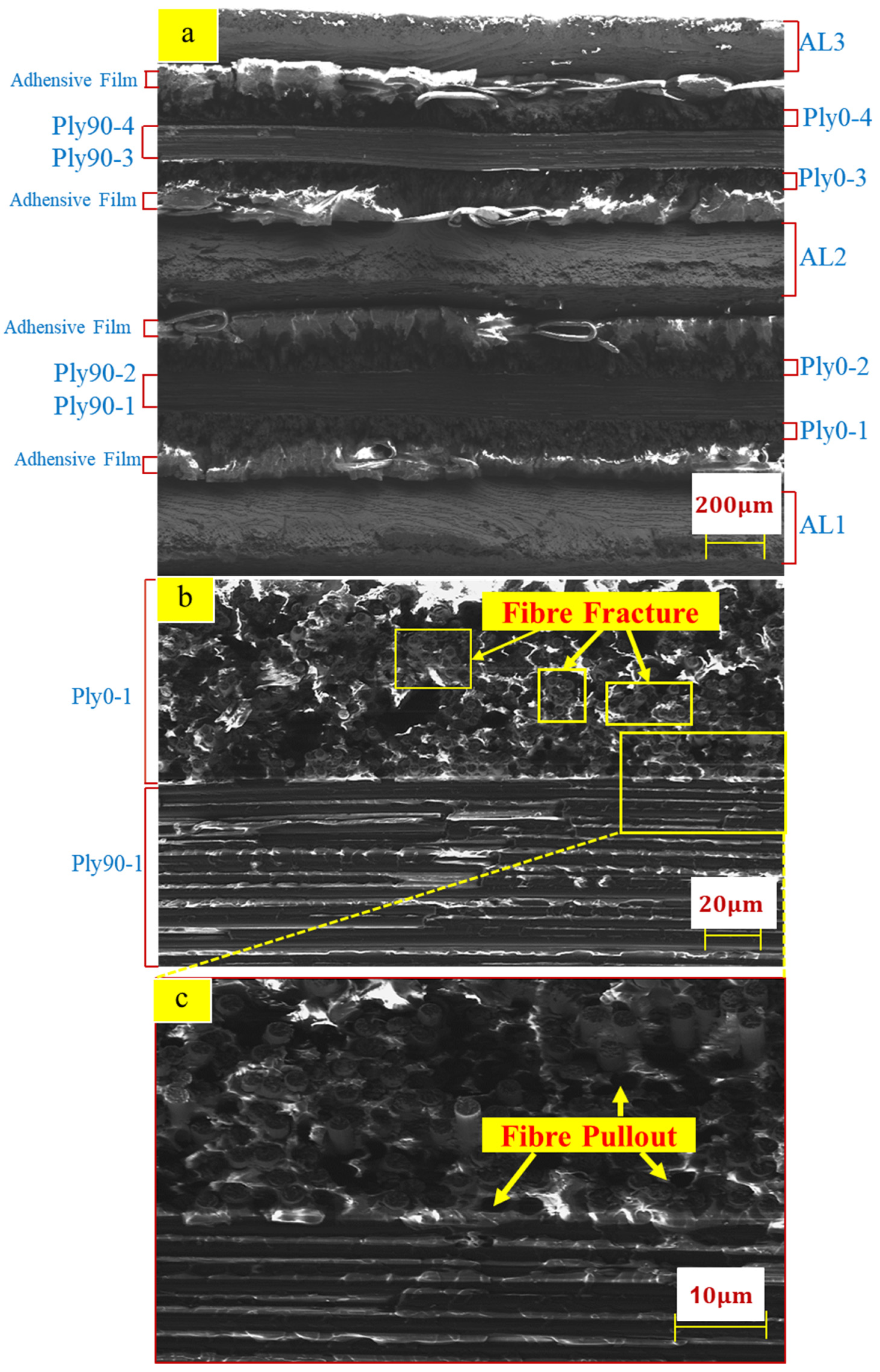

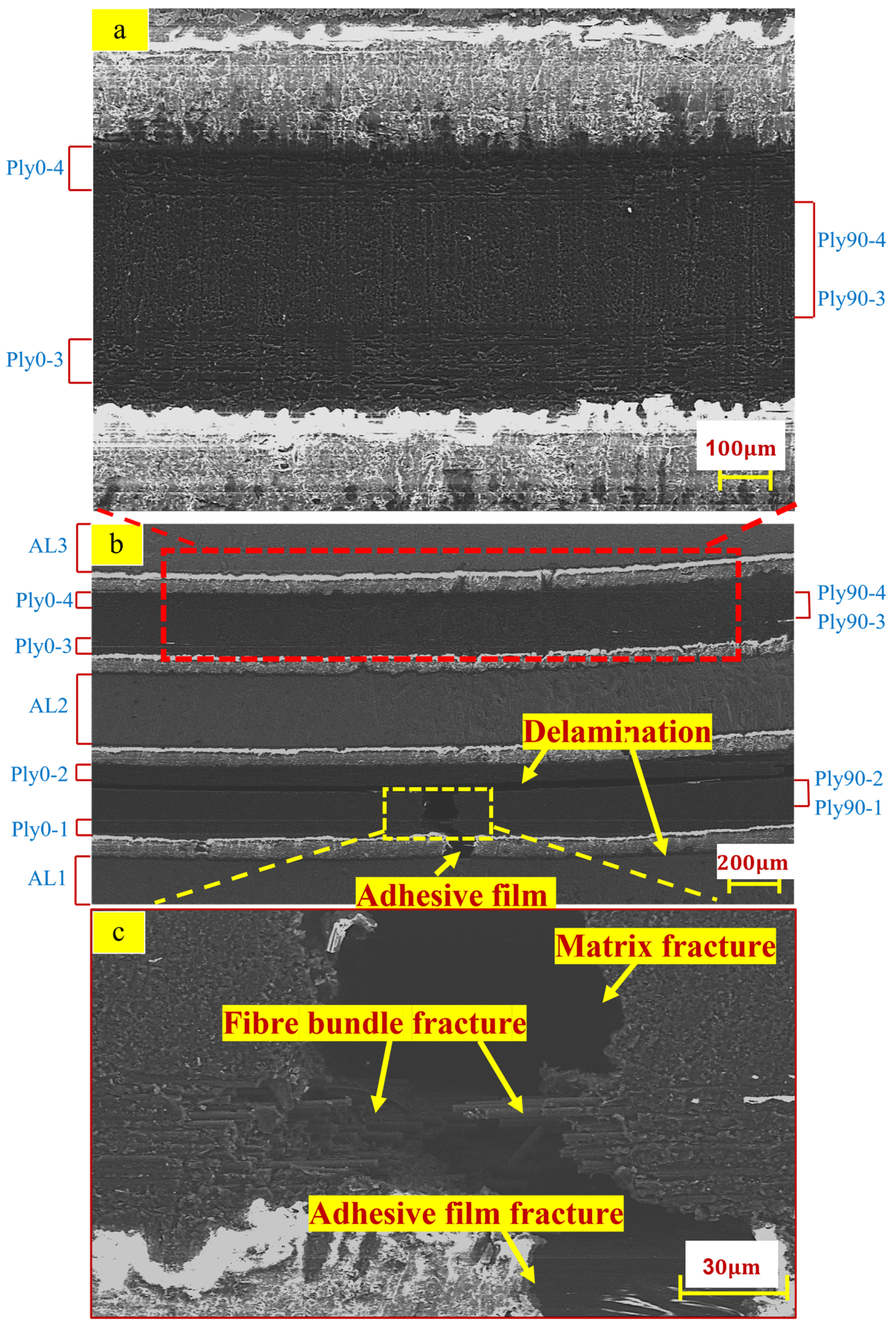

2.3. Characterization Observation of Fracture Morphology

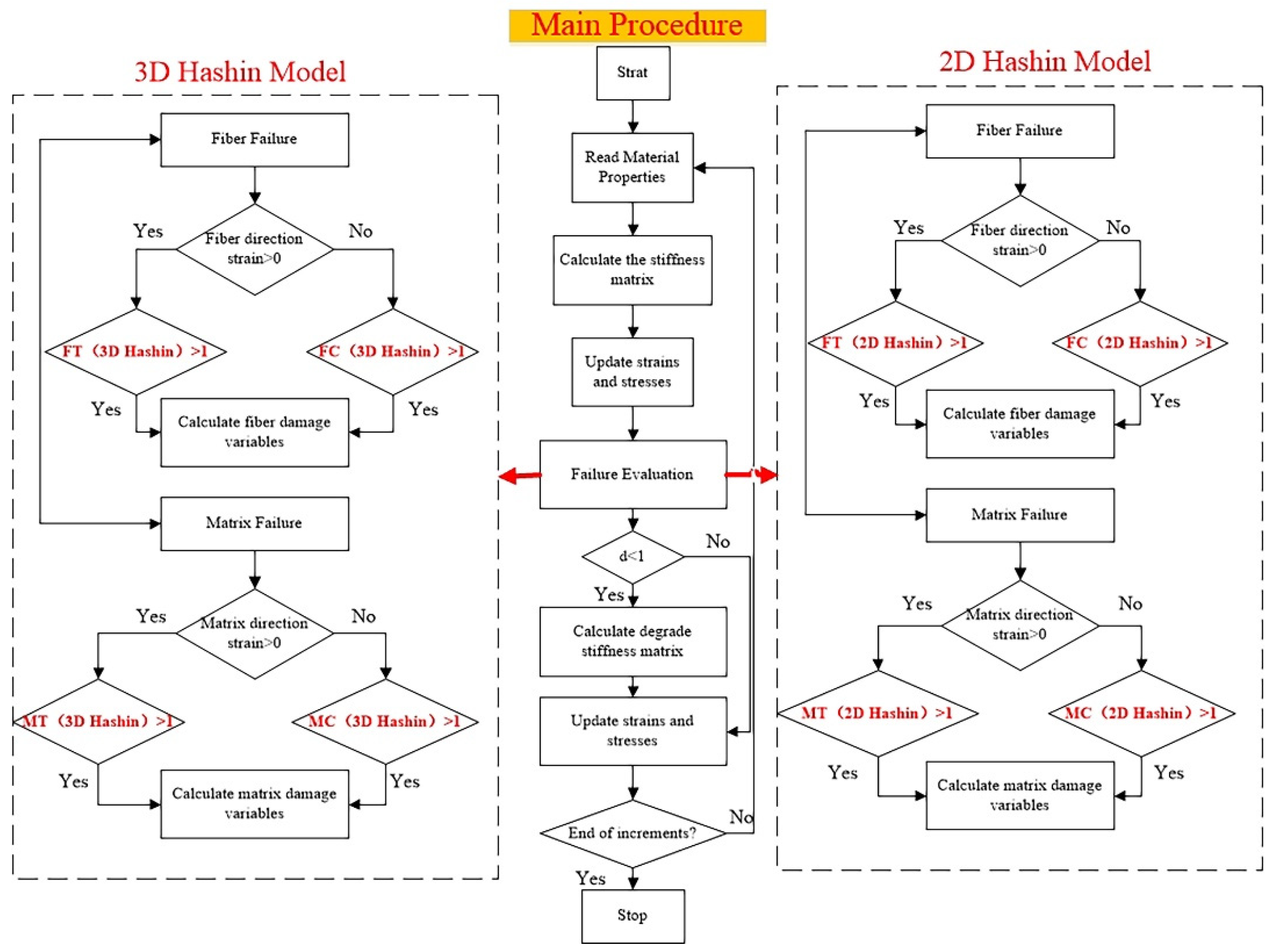

3. Progressive Damage Models of CFRP/Al Composite Laminates

3.1. Johnson–Cook Model for 6061 Aluminium Alloy Layers

3.2. Failure Criteria for CFRP Layer

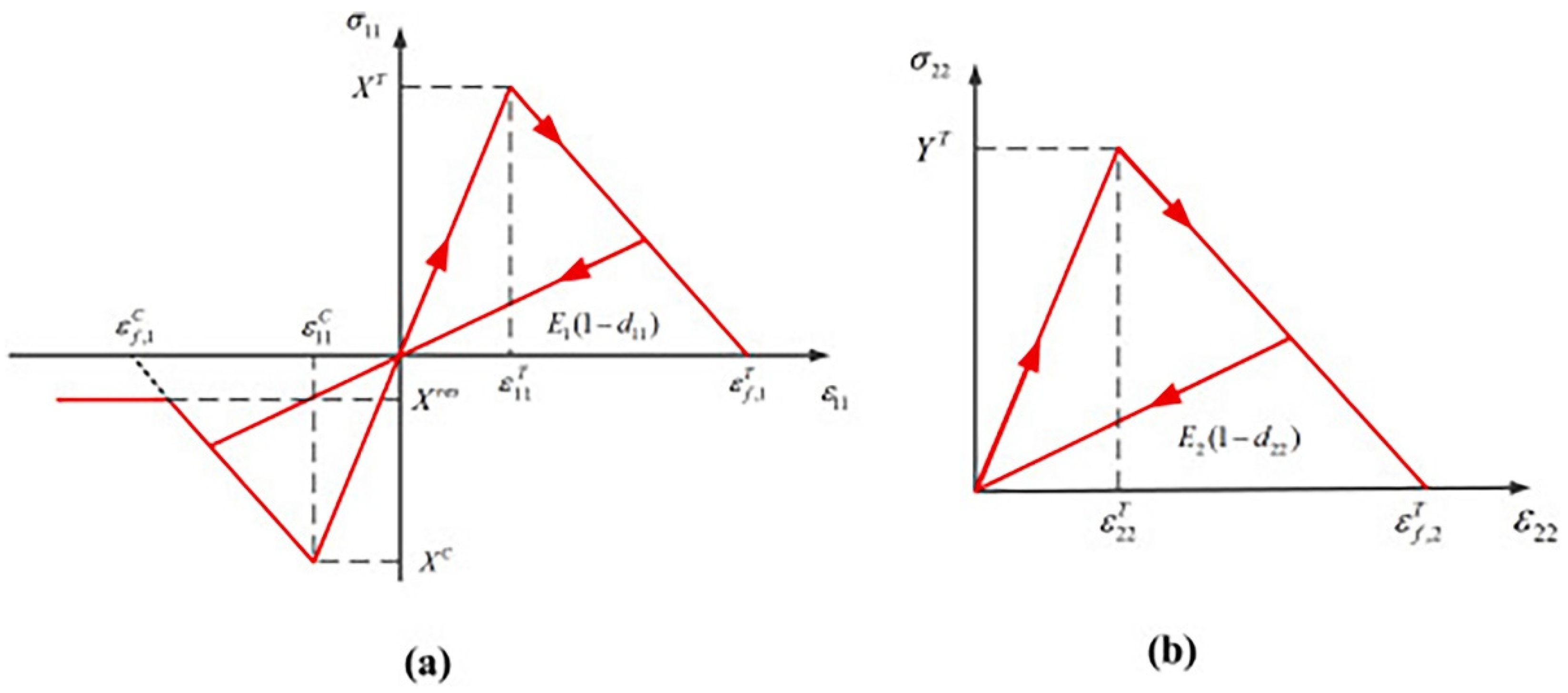

3.3. 2D and 3D Hashin Progressive Damage Model Description

3.4. Failure Criteria and Damage Evolution Law for Interface

3.5. Discretization of CARALL Specimens

4. Results and Discussion

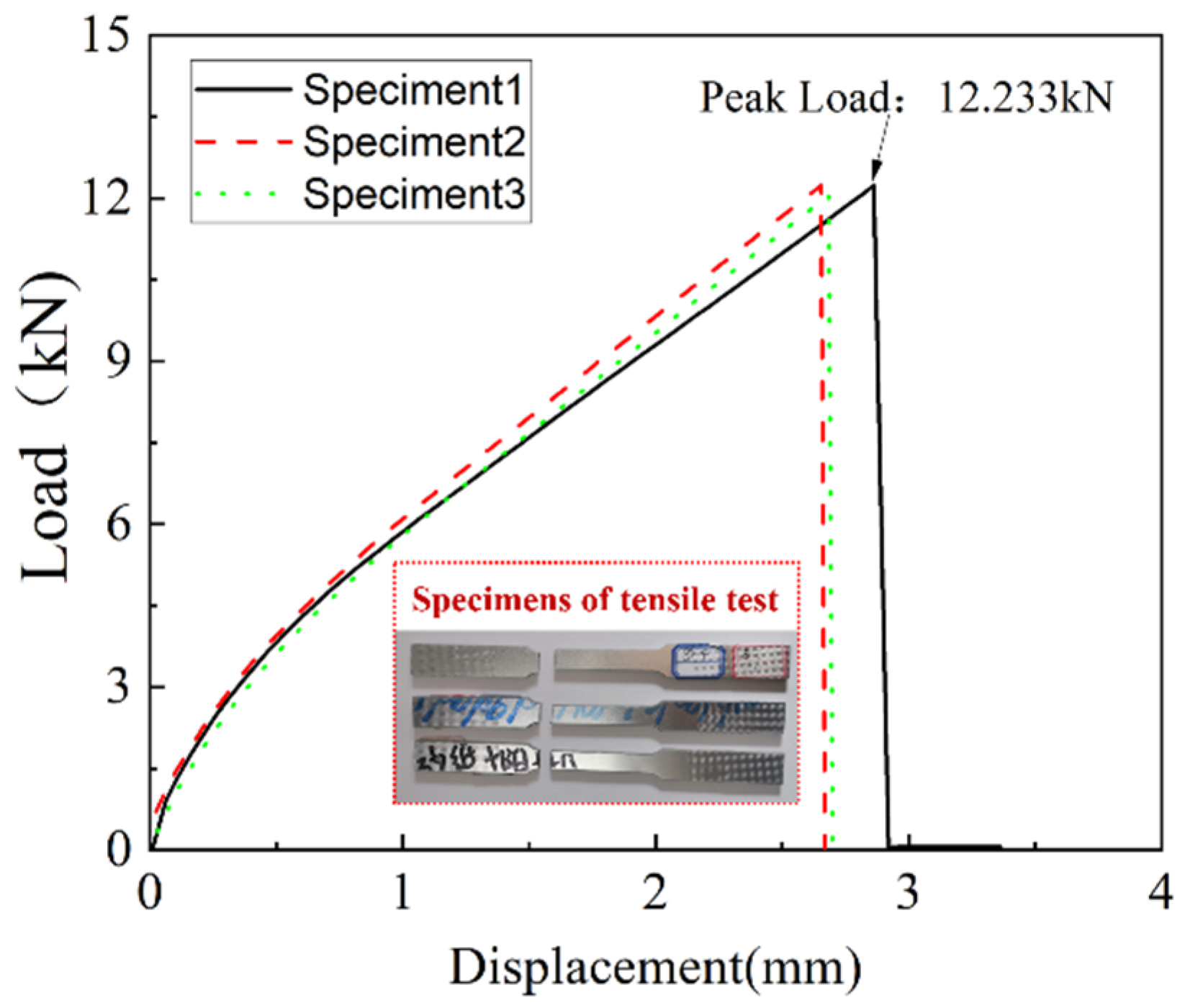

4.1. Experimental Analysis of Tensile Test

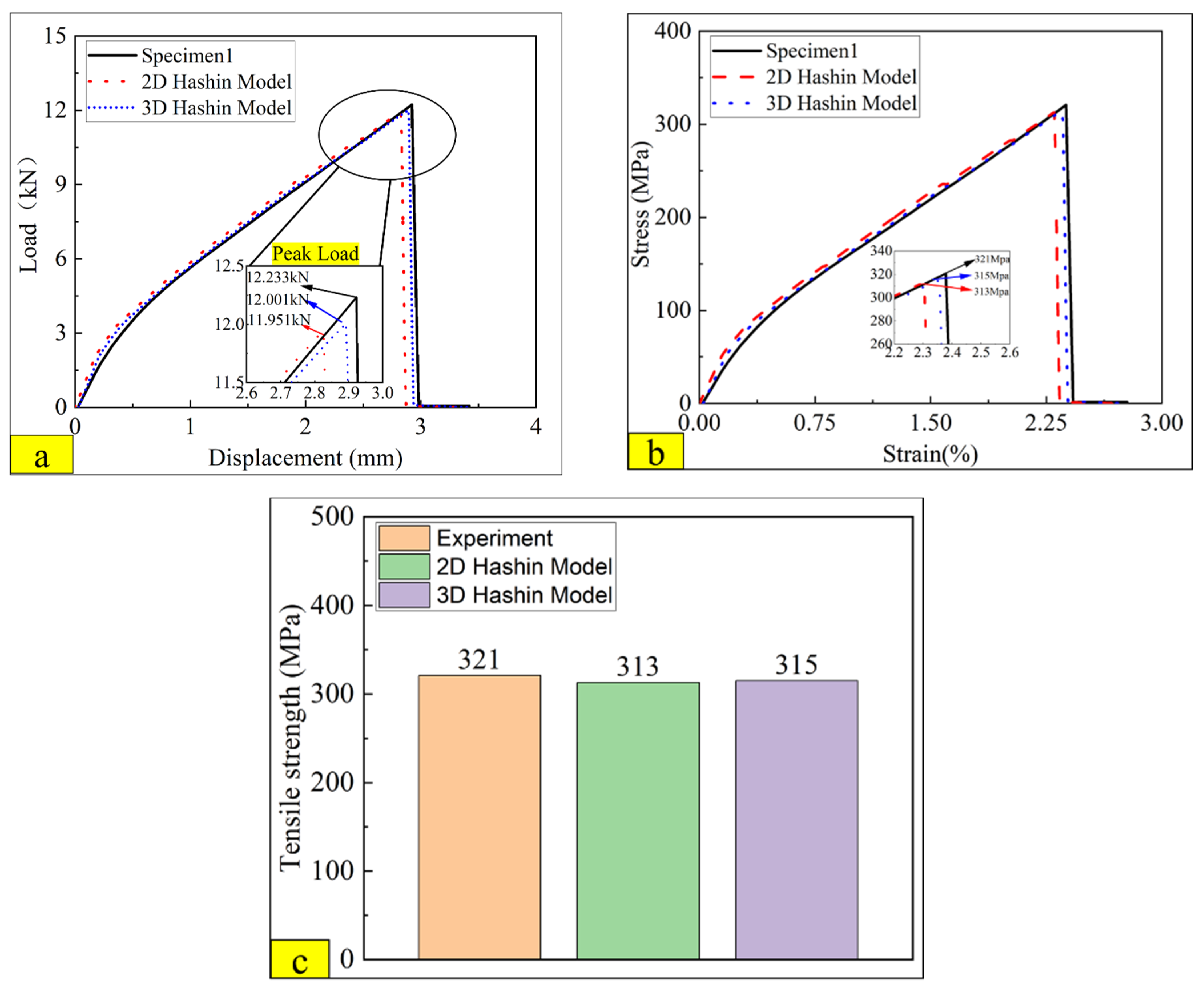

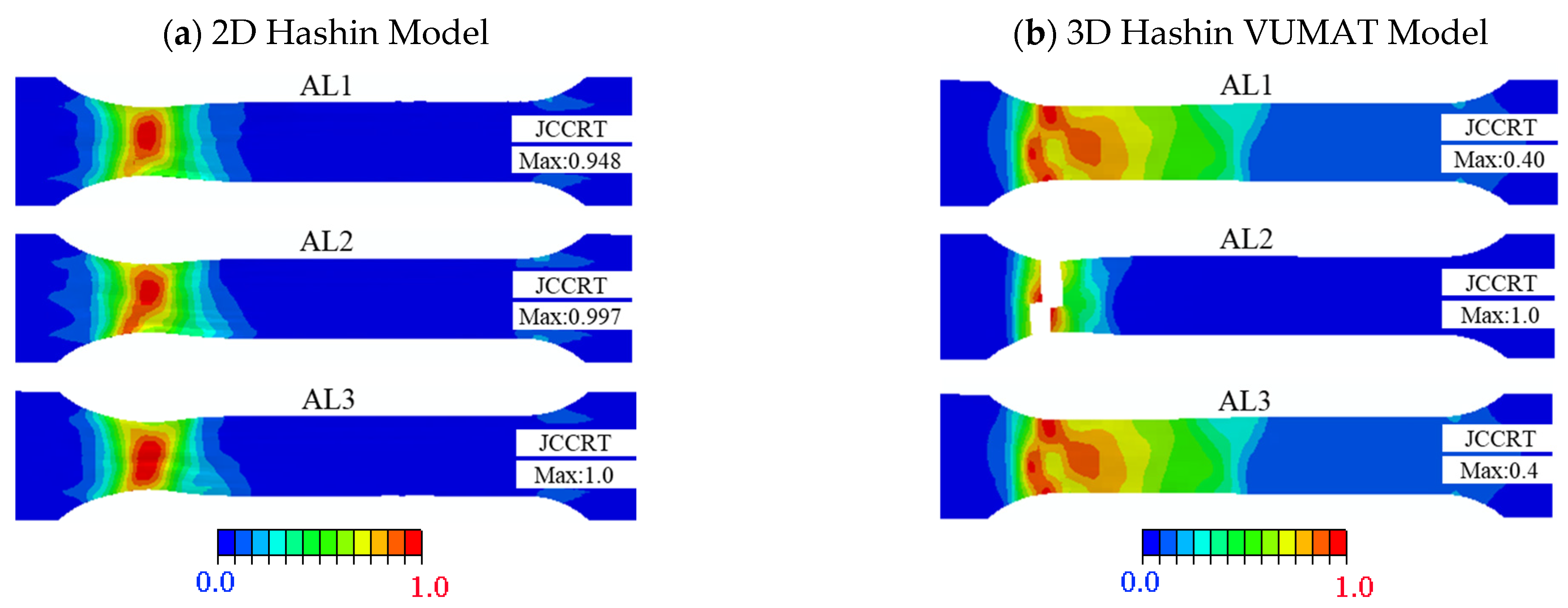

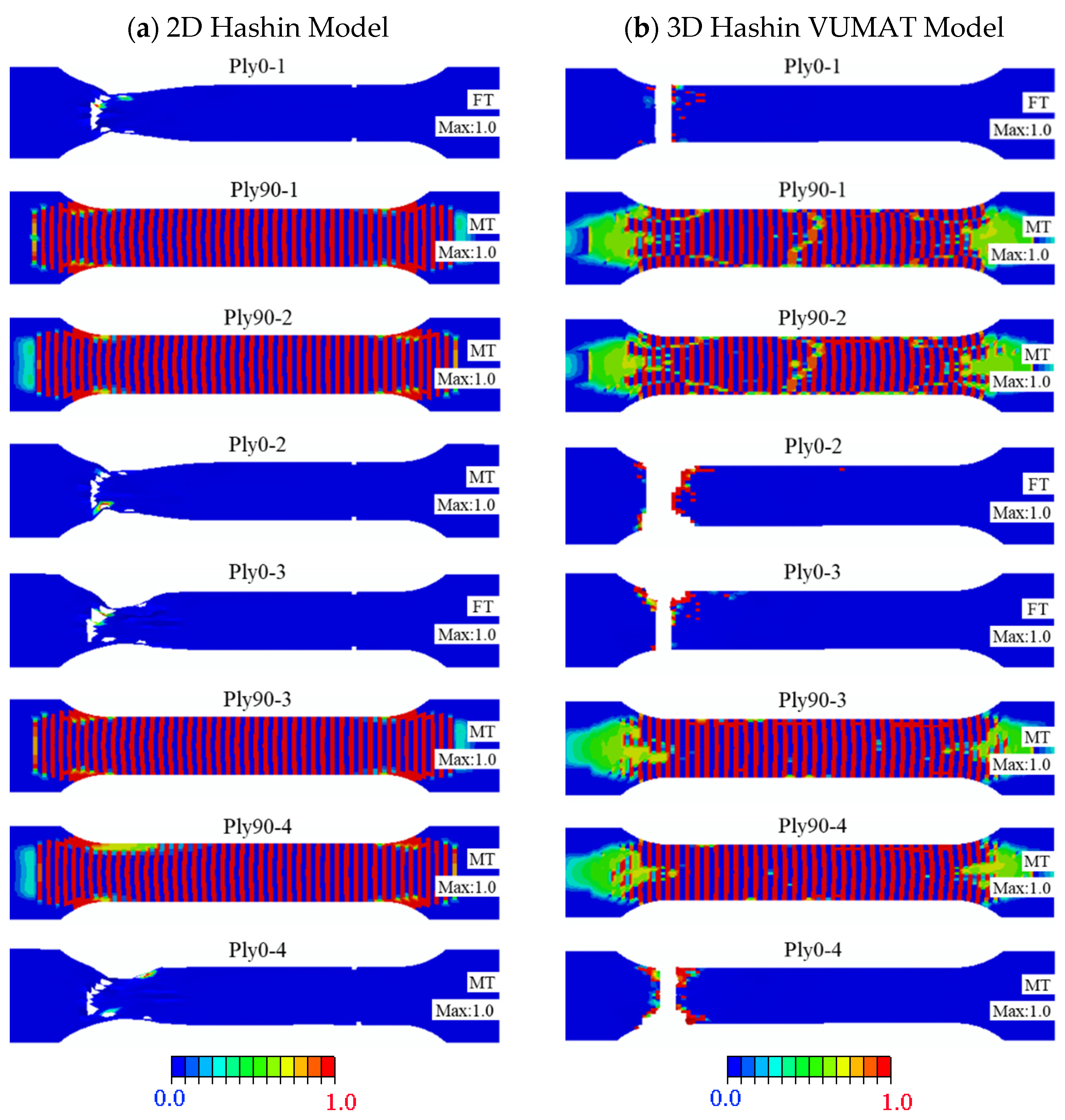

4.2. Comparison between Tensile Test Results, 2D, and 3D Hashin Models

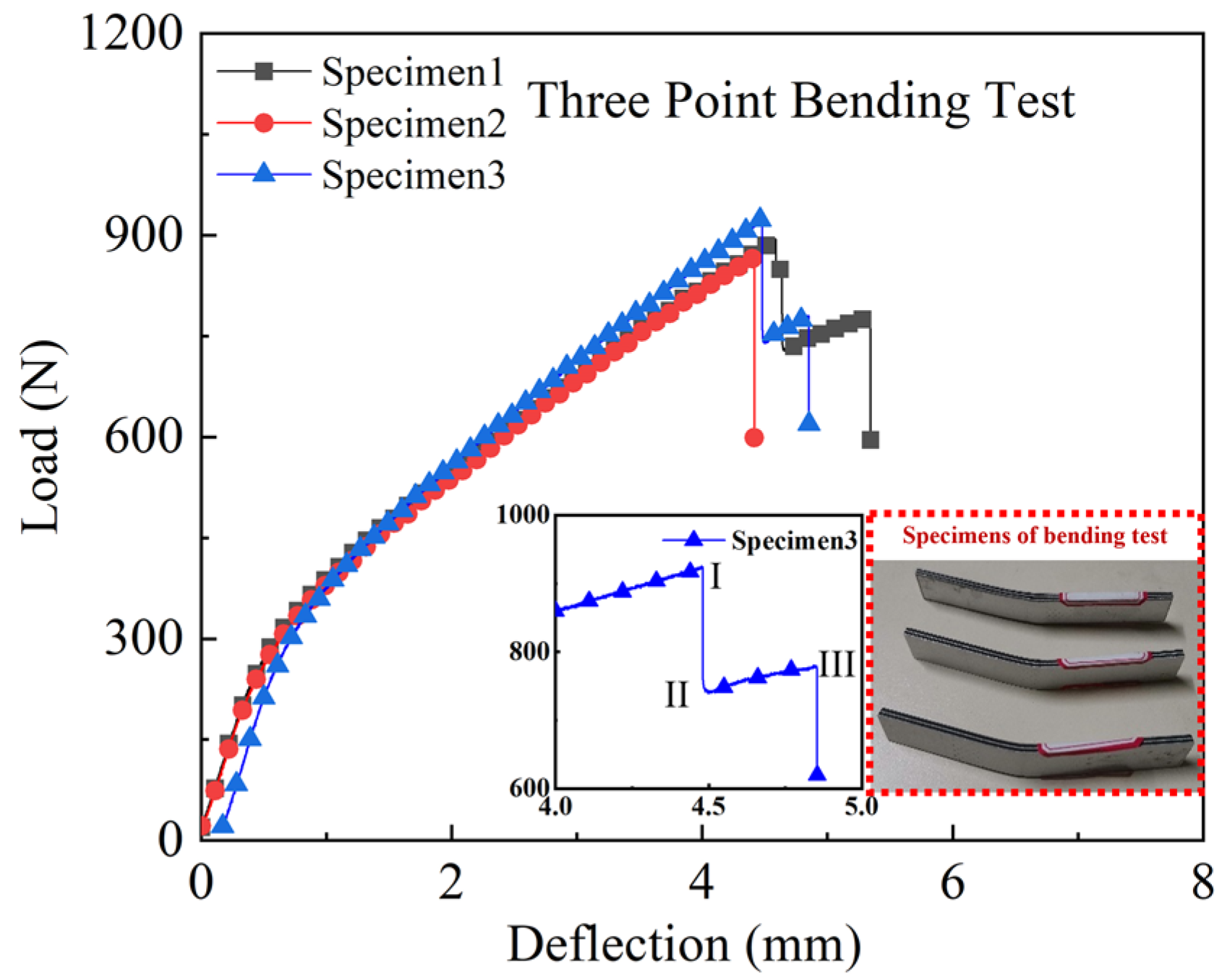

4.3. Experimental Analysis of the Three-Point Bending Test

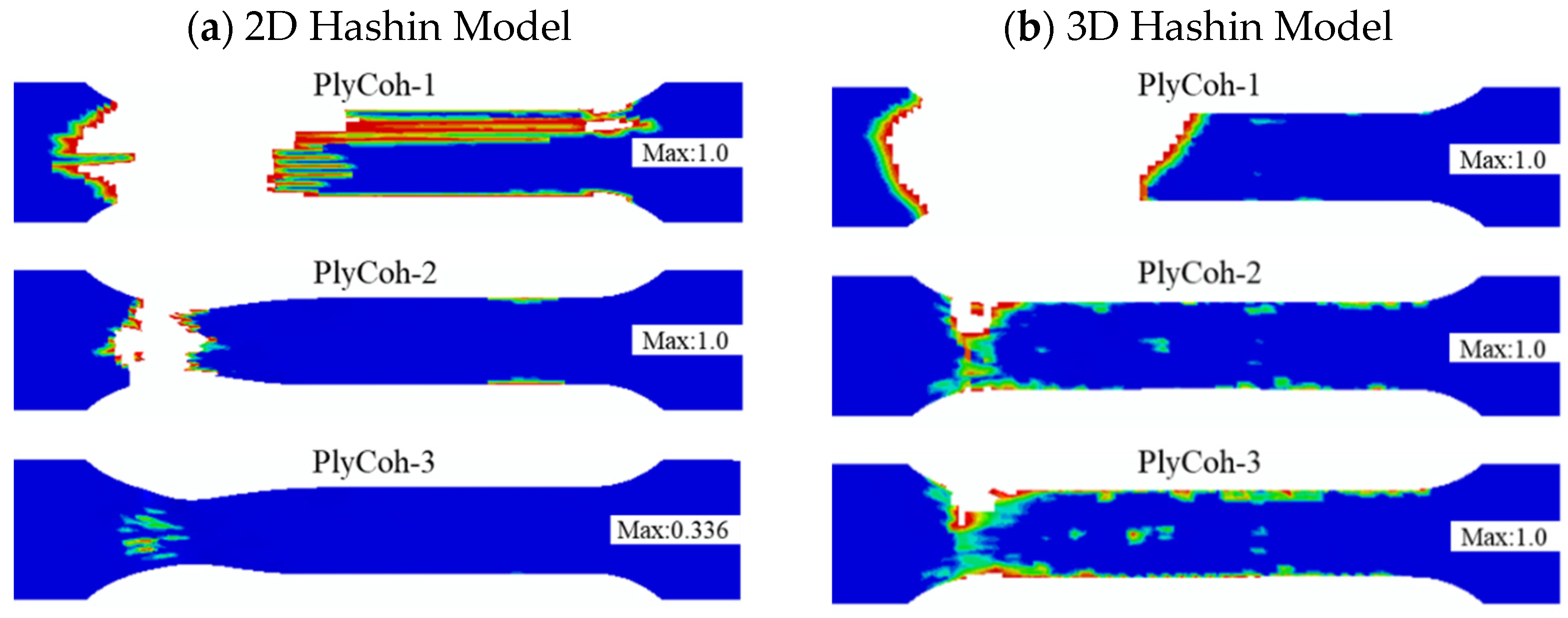

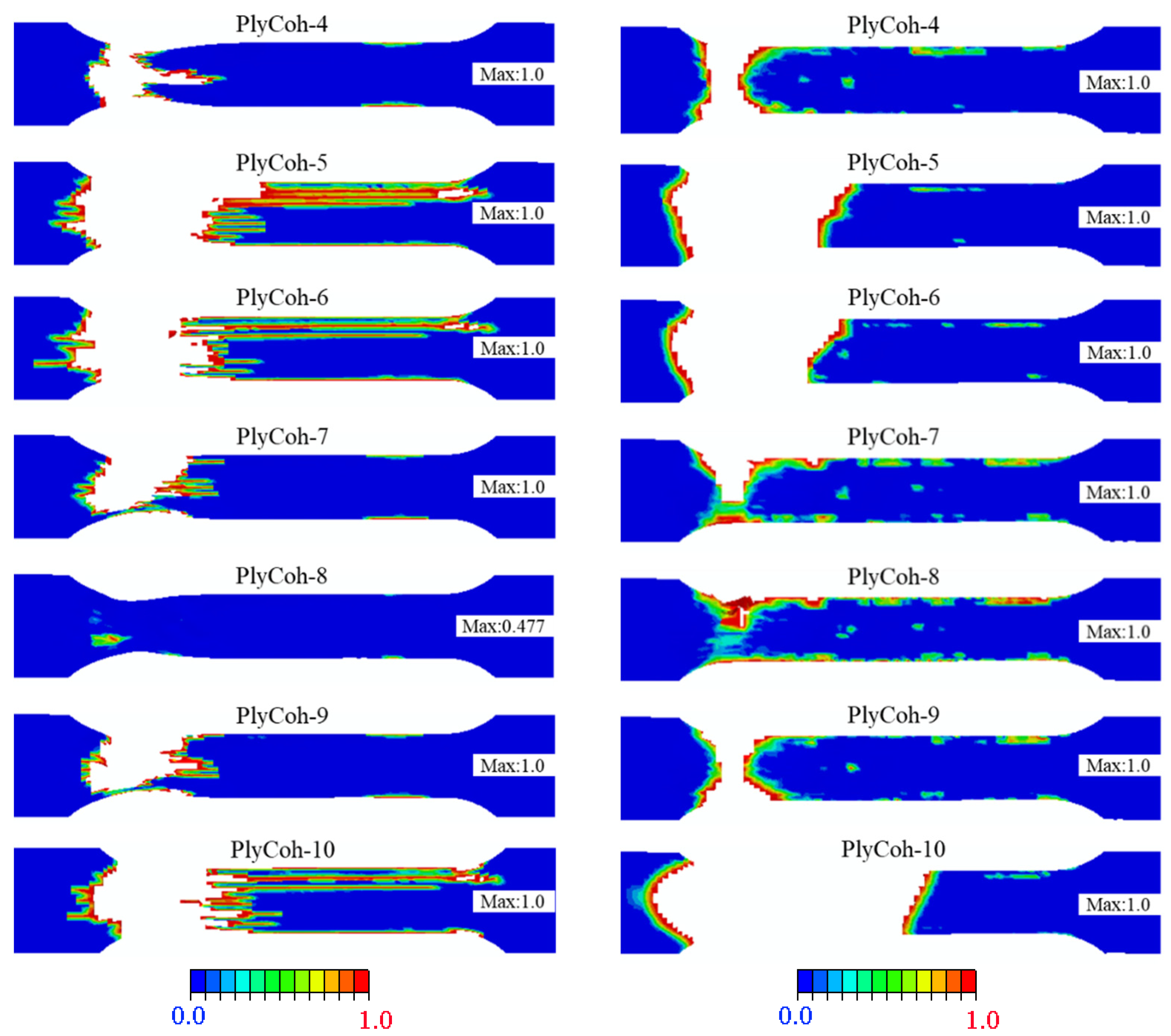

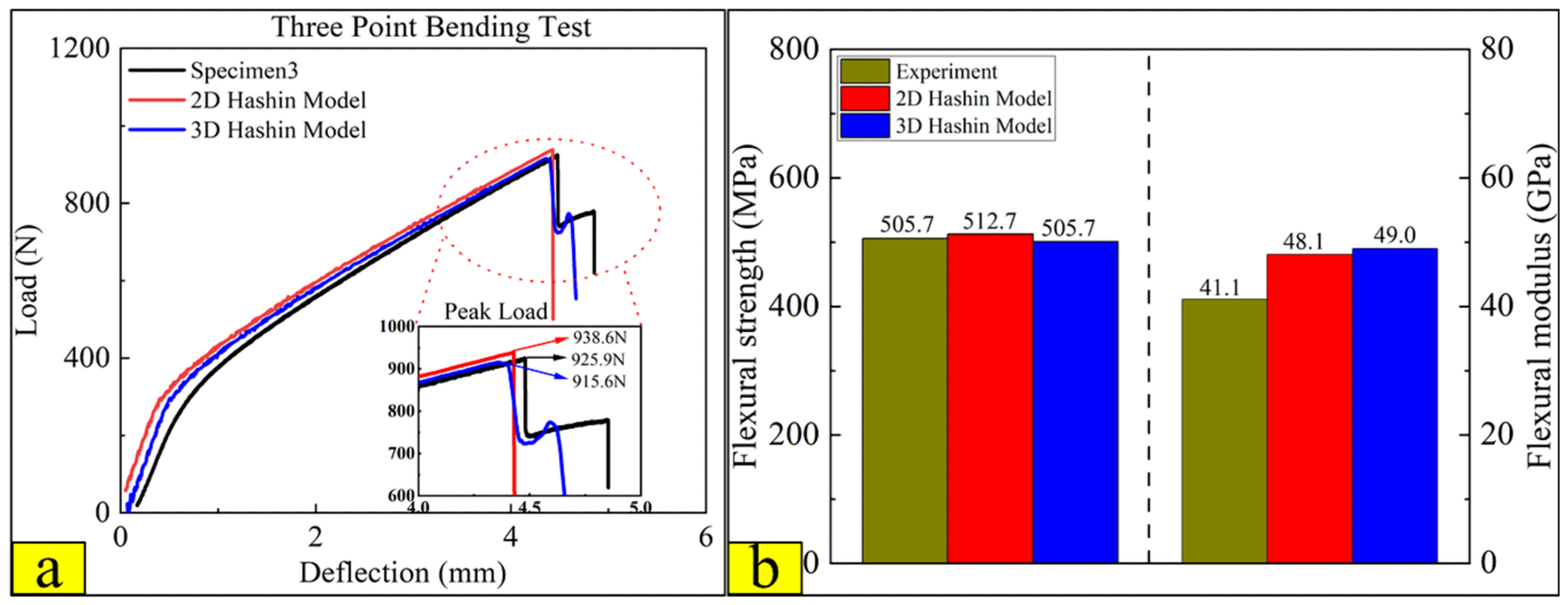

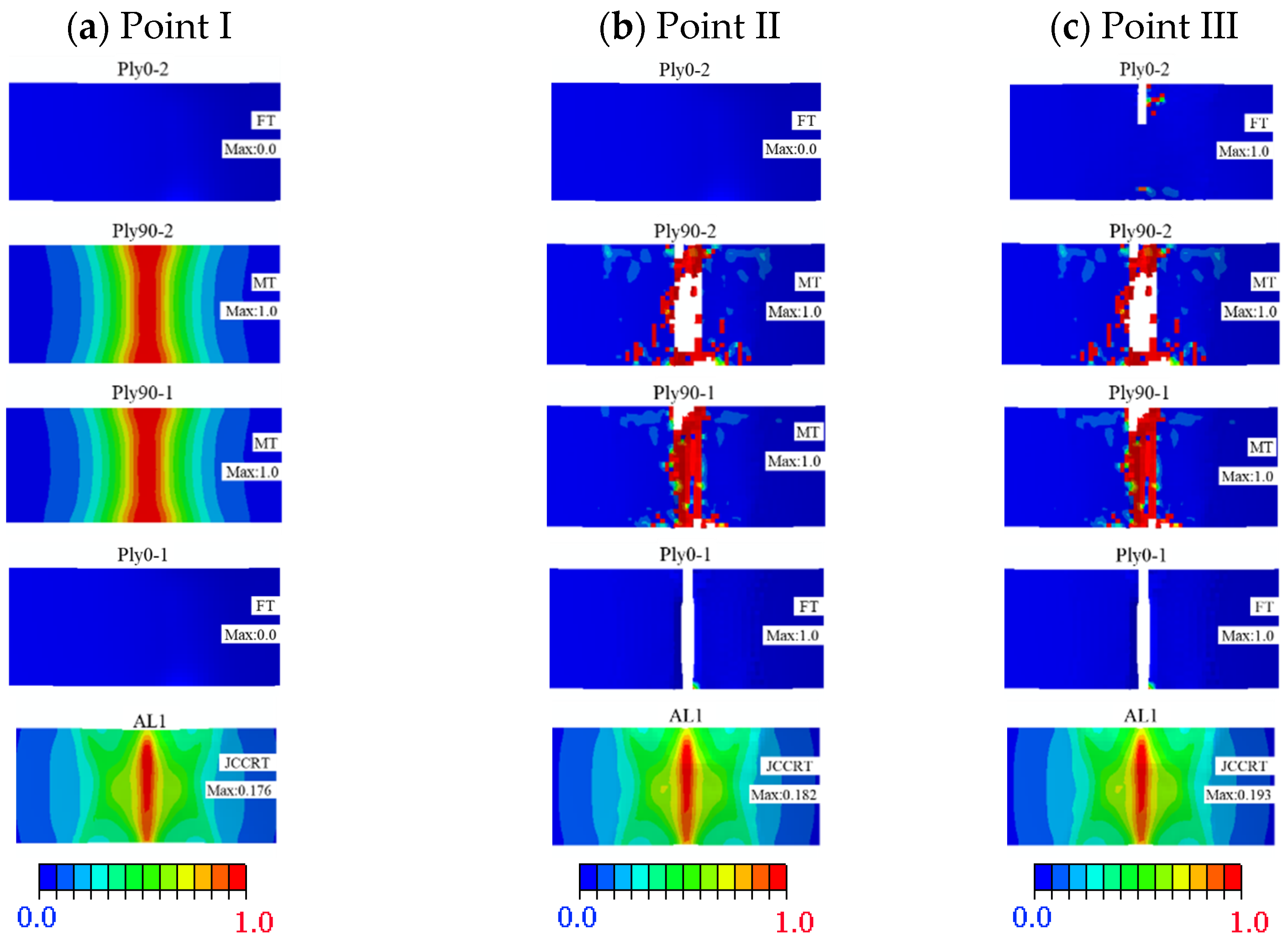

4.4. Comparison between Three-Point Test Results, 2D, and 3D Hashin Models

5. Conclusions

- (1)

- Microscopic observation shows that the failure forms of CARALL under the tensile loading mainly show aluminium layer fracture, fibre pull-out and fracture, and matrix tensile fracture. The load versus displacement curve of tension is obviously bilinear. It is noted that the load decreases rapidly after reaching the peak load. The peak load is 12.23 kN, and the tensile strength is 321 MPa.

- (2)

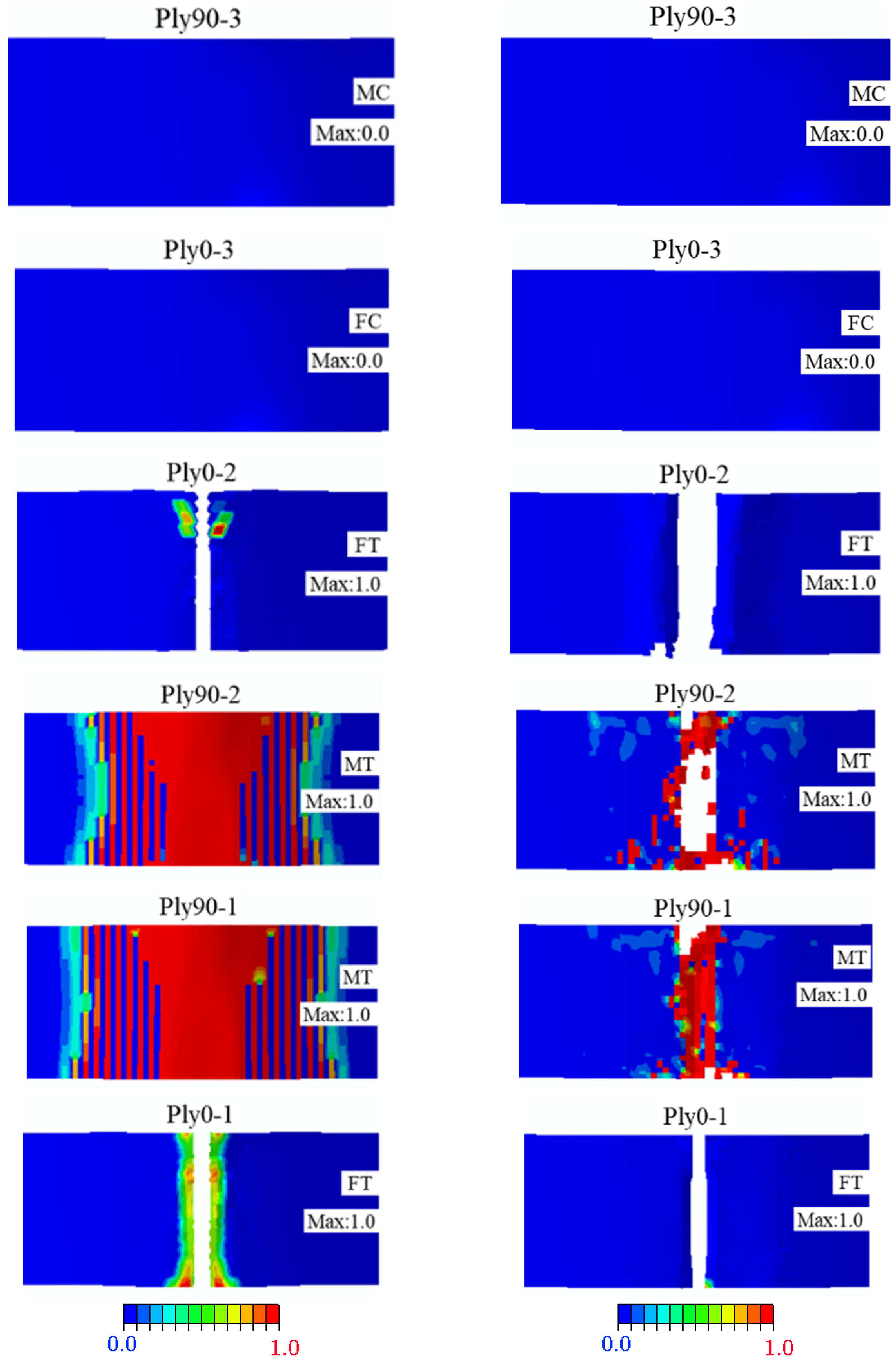

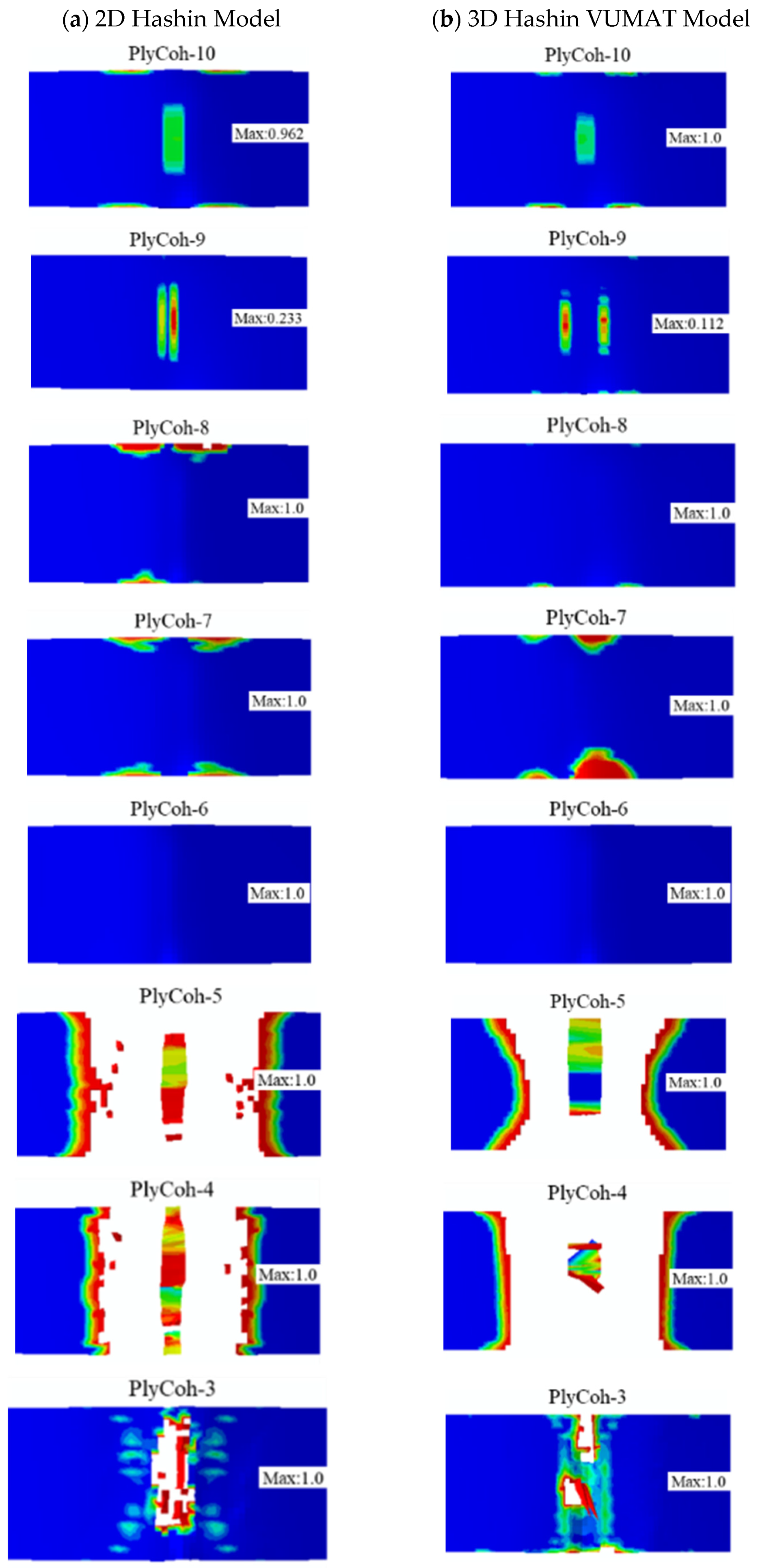

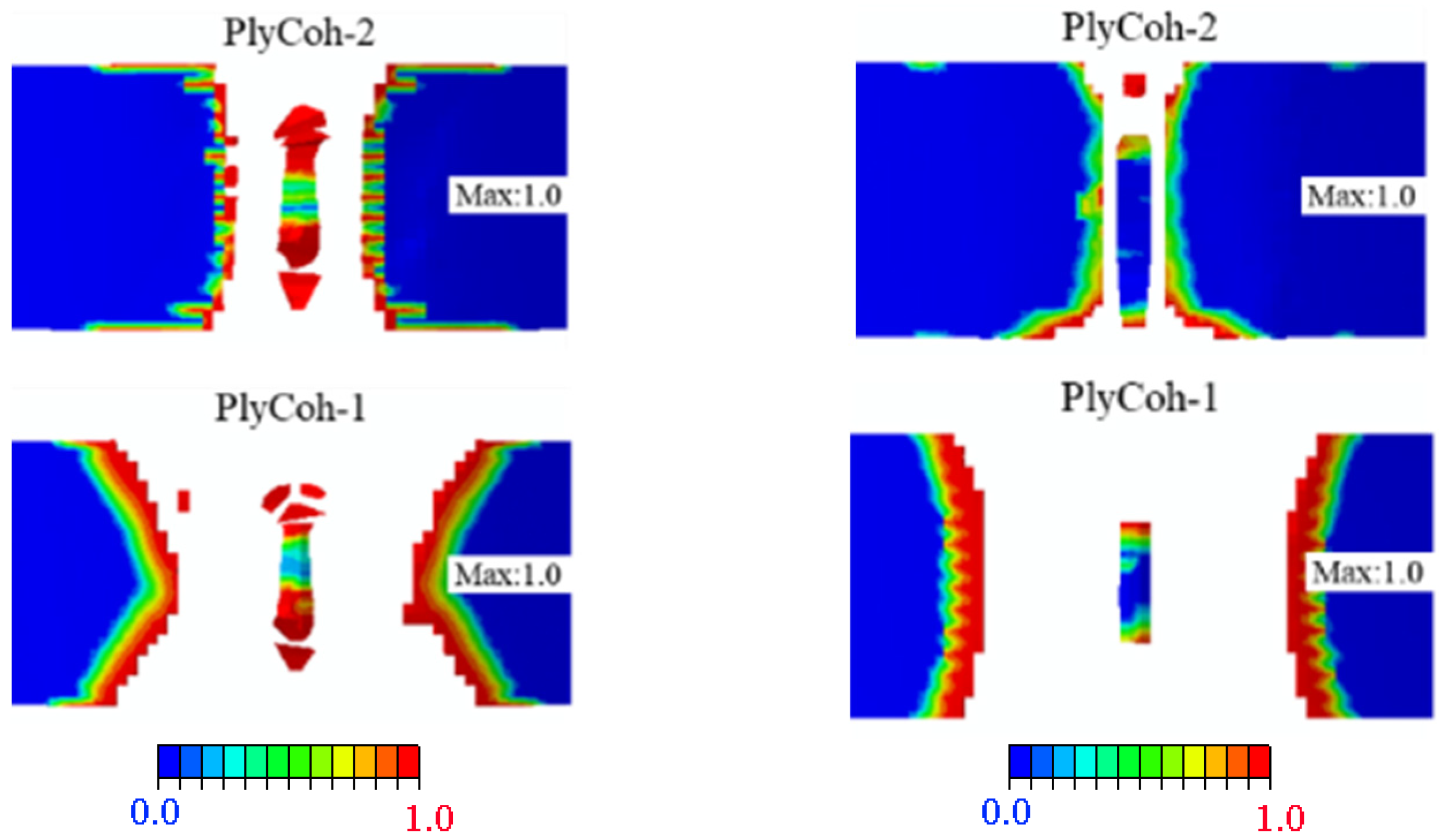

- The failure response of CARALL under three-point bending loading mainly exists below the neutral axis, and the failure modes are as follows: matrix fracture failure (Ply90-1 and Ply90-2), fibre fracture (Ply0-1), adhesive film failure (PlyCoh-1) and delamination failure (PlyCoh-1, PlyCoh-4). The load-displacement curve presents bilinearity before reaching the ultimate strength, and after reaching the ultimate strength, the damage evolution stage has three obvious breaking points in the stepped decline. The peak flexural loading, flexural strength, and modulus are 925.9 N, 505.7 MPa, and 41.1 GPa, respectively.

- (3)

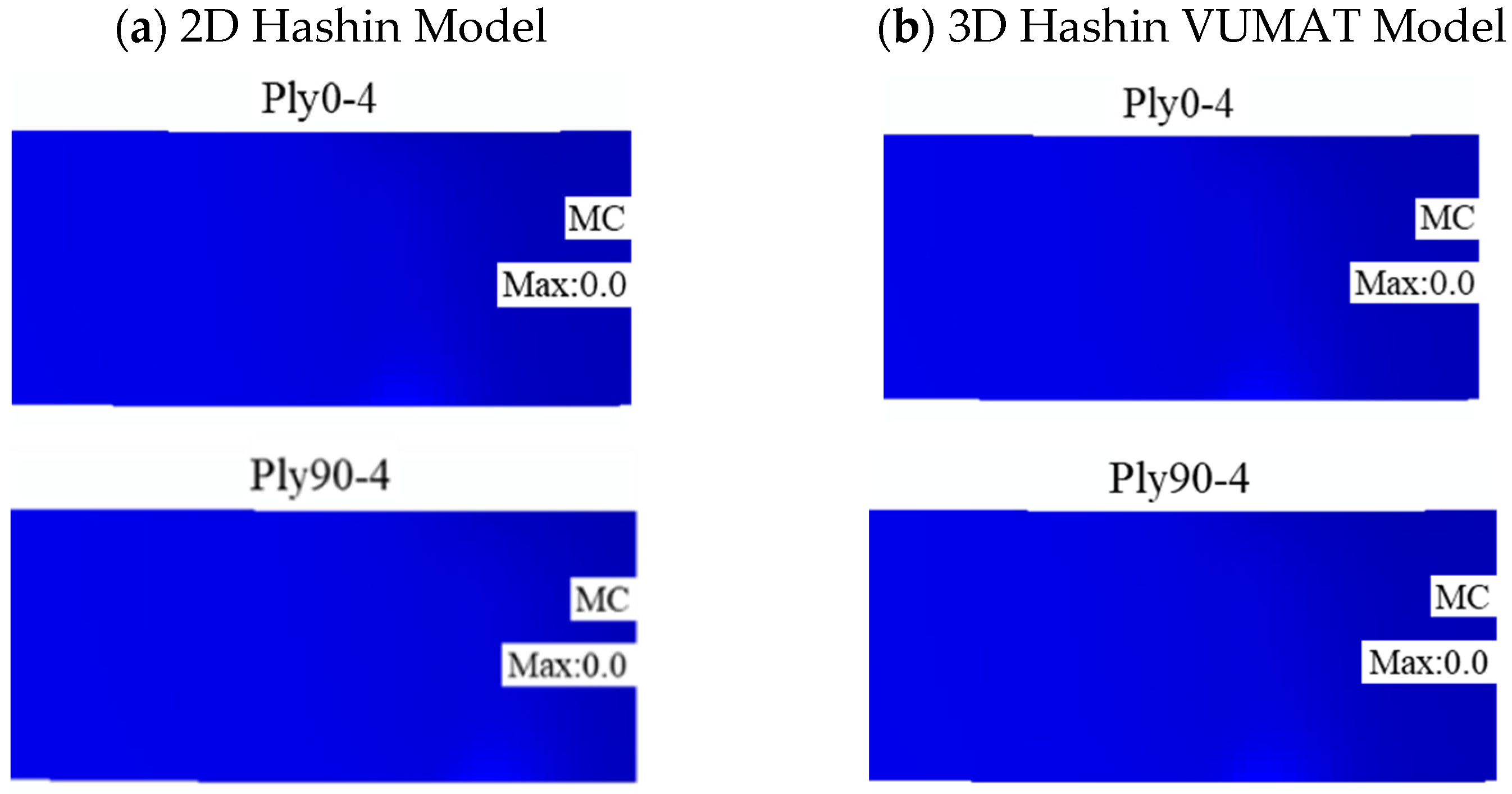

- The 2D Hashin and 3D Hashin models provide similar capabilities in predicting typical tensile and flexural properties before peak load points and final failure modes. Out-of-plane stress components are considered in the 3D Hashin model, and additional element deletion is introduced to calculate the damaged area, which is more accurate and avoids large deformation of the mesh. It is highlighted that the 3D Hashin model successfully predicted the step drop phenomenon in the load-displacement curve in the bending test. It is revealed that the step drop is mainly due to the failure of Ply90-1, 2, Ply0-1, and Ply0-2. Therefore, the 3D Hashin model revealed the failure mechanism and failure propagation of the CARALL more accurately.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Merzuki, M.N.M.; Ma, Q.; Rejab, M.R.M.; Sani, M.S.M.; Zhang, B. Experimental and numerical investigation of fi-bre-metal-laminates (fmls) under free vibration analysis. Mater. Today Proc. 2022, 48, 854–860. [Google Scholar]

- Merzuki, M.N.M.; Rejab, R.; Sani, S.; Zhang, B. Experimental investigation of free vibration analysis on fibre metal composite laminates. J. Mech. Eng. Sci. 2019, 13, 5753–5763. [Google Scholar] [CrossRef] [Green Version]

- Chow, Z.P.; Ahmad, Z.; Wong, K.J.; Abdullah, S.I.B.S. Experimental and numerical analyses of temperature effect on glare panels under quasi-static perforation. Compos. Struct. 2021, 275, 114434. [Google Scholar] [CrossRef]

- He, W.; Wang, L.; Liu, H.; Wang, C.; Yao, L.; Li, Q.; Sun, G. On impact behavior of fiber metal laminate (fml) structures: A state-of-the-art review. Thin-Walled Struct. 2021, 167, 108026. [Google Scholar] [CrossRef]

- Jin, K.; Wang, H.; Tao, J.; Du, D. Mechanical analysis and progressive failure prediction for fibre metal laminates using a 3d constitutive model. Compos. Part A Appl. Sci. Manuf. 2019, 124, 105490. [Google Scholar] [CrossRef]

- Wu, G.; Yang, J.-M. The mechanical behabior of glare laminates for aircraft structures. J. Miner. Mater. Soc. 2005, 57, 72–79. [Google Scholar] [CrossRef]

- Wu, X.-t.; Zhan, L.-h.; Huang, M.-h.; Zhao, X.; Wang, X.; Zhao, G.-Q. Corrosion damage evolution and mechanical properties of carbon fiber reinforced aluminum laminate. J. Cent. South Univ. 2021, 28, 657–668. [Google Scholar] [CrossRef]

- Khalid, M.Y.; Arif, Z.U.; Al Rashid, A.; Shahid, M.I.; Ahmed, W.; Tariq, A.F.; Abbas, Z. Interlaminar shear strength (ilss) characterization of fiber metal laminates (fmls) manufactured through vartm process. Forces Mech. 2021, 4, 100038. [Google Scholar] [CrossRef]

- Vogelesang, L.B.; Vlot, A. Development of fibre metal laminates for advanced aerospace structures. J. Mater. Processing Technol. 2000, 103, 1–5. [Google Scholar] [CrossRef]

- Dhaliwal, G.S.; Newaz, G.M. Compression after impact characteristics of carbon fiber reinforced aluminum laminates. Compos. Struct. 2017, 160, 1212–1224. [Google Scholar] [CrossRef]

- Zhu, W.; Xiao, H.; Wang, J.; Fu, C. Characterization and properties of aa6061-based fiber metal laminates with different aluminum-surface pretreatments. Compos. Struct. 2019, 227, 111321. [Google Scholar] [CrossRef]

- Samal, S. Interface failure and delamination resistance of fiber-reinforced geopolymer composite by simulation and ex-perimental method. Cem. Concr. Compos. 2022, 128, 104420. [Google Scholar] [CrossRef]

- Chen, Y.; Li, M.; Su, T.; Yang, X. Mechanical degradation and corrosion characterization of riveted joints for cfrp/al stacks in simulated marine environments. Eng. Fail. Anal. 2022, 137, 106382. [Google Scholar] [CrossRef]

- Liang, H.; Li, S.; Lu, Y.; Hu, J.; Liu, Z. Electrochemical performance of corroded reinforced concrete columns strengthened with fiber reinforced polymer. Compos. Struct. 2019, 207, 576–588. [Google Scholar] [CrossRef]

- Wu, C.; Yu, Y.-Z.; Tam, L.-H.; Orr, J.; He, L. Effect of glass fiber sheet in adhesive on the bond and galvanic corrosion behaviours of cfrp-steel bonded system. Compos. Struct. 2021, 259, 113218. [Google Scholar] [CrossRef]

- Lin, Y.; Huang, Y.; Huang, T.; Liao, B.; Zhang, D.; Li, C. Characterization of progressive damage behaviour and failure mechanisms of carbon fibre reinforced aluminium laminates under three-point bending. Thin-Walled Struct. 2019, 135, 494–506. [Google Scholar] [CrossRef]

- Trzepiecinski, T.; Kubit, A.; Kudelski, R.; Kwolek, P.; Obłój, A. Strength properties of aluminium/glass-fiber-reinforced laminate with additional epoxy adhesive film interlayer. Int. J. Adhes. Adhes. 2018, 85, 29–36. [Google Scholar] [CrossRef]

- Kubit, A.; Trzepieciński, T.; Krasowski, B.; Slota, J.; Spišák, E. Strength analysis of a rib-stiffened glare-based thin-walled structure. Materials 2020, 13, 2929. [Google Scholar] [CrossRef]

- Shiratori, H.; Todoroki, A.; Ueda, M.; Matsuzaki, R.; Hirano, Y. Testing method for evaluating mechanical properties of 3d printed cfrp with curved fibers by four-point bending test of l-shaped specimen. Compos. Part C Open Access 2021, 6, 100187. [Google Scholar] [CrossRef]

- Jiang, F.; Han, X.; Wang, Y.; Wang, P.; Zhao, T.; Zhang, K. Effect of freeze-thaw cycles on tensile properties of cfrp, bond behavior of cfrp-concrete, and flexural performance of cfrp-strengthened concrete beams. Cold Reg. Sci. Technol. 2022, 194, 103461. [Google Scholar] [CrossRef]

- Ferdous, W.; Manalo, A.; Yu, P.; Salih, C.; Abousnina, R.; Heyer, T.; Schubel, P. Tensile fatigue behavior of polyester and vinyl ester based gfrp laminates-a comparative evaluation. Polymers 2021, 13, 386. [Google Scholar] [CrossRef] [PubMed]

- Hashim, M.K.R.; Abdul Majid, M.S.; Jamir, M.R.M.; Kasim, F.H.; Sultan, M.T.H. The effect of stacking sequence and ply ori-entation on the mechanical properties of pineapple leaf fibre (palf)/carbon hybrid laminate composites. Polymers 2021, 13, 455. [Google Scholar] [CrossRef] [PubMed]

- Koloor, S.S.R.; Karimzadeh, A.; Abdullah, M.R.; Petru, M.; Yidris, N.; Sapuan, S.M.; Tamin, M.N. Linear-nonlinear stiffness responses of carbon fiber-reinforced polymer composite materials and structures: A numerical study. Polymers 2021, 13, 344. [Google Scholar] [CrossRef] [PubMed]

- Vicente, A.; Rivero, P.J.; Palacio, J.F.; Rodriguez, R. The role of the fiber/bead hierarchical microstructure on the properties of pvdf coatings deposited by electrospinning. Polymers 2021, 13, 464. [Google Scholar] [CrossRef]

- Zhang, S.; Xing, T.; Zhu, H.; Chen, X. Experimental identification of statistical correlation between mechanical properties of frp composite. Materials 2020, 13, 674. [Google Scholar] [CrossRef] [Green Version]

- Yao, L.; Zhang, S.; Cao, X.; Gu, Z.; Wang, C.; He, W. Tensile mechanical behavior and failure mechanisms of fiber metal laminates under various temperature environments. Compos. Struct. 2022, 284, 115142. [Google Scholar] [CrossRef]

- Hu, C.; Sang, L.; Jiang, K.; Xing, J.; Hou, W. Experimental and numerical characterization of flexural properties and failure behavior of cfrp/al laminates. Compos. Struct. 2022, 281, 115036. [Google Scholar] [CrossRef]

- Kubit, A.; Trzepiecinski, T.; Kłonica, M.; Hebda, M.; Pytel, M. The influence of temperature gradient thermal shock cycles on the interlaminar shear strength of fibre metal laminate composite determined by the short beam test. Compos. Part B Eng. 2019, 176, 107217. [Google Scholar] [CrossRef]

- Wu, Z.; Zhang, Z.; Wu, J.; Liang, J.; Ge, J.; Liu, X.; Fang, G. A new time-frequency domain simulation method for damage accumulation and life prediction of composite thin-wall structures under random cyclic loadings. Compos. Struct. 2022, 281, 114999. [Google Scholar] [CrossRef]

- Tumarkin, A.; Tyurnina, N.; Mukhin, N.; Tyurnina, Z.; Sinelshchikova, O.; Gagarin, A.; Sapego, E.; Kretser, Y. Glass-ceramic ferroelectric composite material batio3/kfesi for microwave applications. Compos. Struct. 2022, 281, 114992. [Google Scholar] [CrossRef]

- Quan, D.; Murphy, N.; Ivanković, A.; Zhao, G.; Alderliesten, R. Fatigue delamination behaviour of carbon fibre/epoxy composites interleaved with thermoplastic veils. Compos. Struct. 2022, 281, 114903. [Google Scholar] [CrossRef]

- Ma, Y.; Lei, Z.; Huang, G.; Bai, R.; Xu, Y.; Hong, X. Energy absorption analysis of stf/kevlar composite fabric based on 3d morphology of impact basin under low-speed impact. Compos. Struct. 2022, 283, 115152. [Google Scholar] [CrossRef]

- Kumar, A.; Arockiarajan, A. Numerical interpretation and experimental investigation of enhanced magnetoelectric effect in ni/pzt distributed disc structured composite. Compos. Struct. 2022, 280, 114958. [Google Scholar] [CrossRef]

- Zhang, B.; Li, Z.; Wu, H.; Nie, J. Research on damping performance and strength of the composite laminate. Sci. Rep. 2021, 11, 18281. [Google Scholar] [CrossRef]

- Hu, H.C.; Hu, N.; Wei, Q.; Liu, B.Y.; Wu, J.; Wang, Z.H.; Yang, C. Characterization of progressive damage behaviour and failure mechanism of carbon fibre reinforced dp590 laminates. Thin-Walled Struct. 2021, 168, 108293. [Google Scholar] [CrossRef]

- Liao, B.B.; Tan, H.C.; Zhou, J.W.; Jia, L.Y. Multi-scale modelling of dynamic progressive failure in composite laminates sub-jected to low velocity impact. Thin-Walled Struct. 2018, 131, 695–707. [Google Scholar] [CrossRef]

- Liao, B.B.; Jia, L.Y. Finite element analysis of dynamic responses of composite pressure vessels under low velocity impact by using a three-dimensional laminated media model. Thin-Walled Struct. 2018, 129, 488–501. [Google Scholar] [CrossRef]

- Arruda, M.R.T.; Almeida-Fernandes, L.; Castro, L.; Correia, J.R. Tsai–wu based orthotropic damage model. Compos. Part C Open Access 2021, 4, 100122. [Google Scholar] [CrossRef]

- Chang, F.-K.; Chang, K.-Y. A progressive damage model for laminated composites containing stress concentrations. J. Compos. Mater. 1987, 21, 834–855. [Google Scholar] [CrossRef]

- Hashin, Z. Fatigue failure criteria for unidirectional fiber composites. J. Appl. Mech. 1981, 48, 846–852. [Google Scholar] [CrossRef]

- Hashin, Z.; Rotem, A. A fatigue failure criterion for fiber reinforced materials. J. Compos. Mater. 1973, 7, 448–464. [Google Scholar] [CrossRef] [Green Version]

- Puck, A.; Kopp, J.; Knops, M. Guidelines for the determination of the parameters in puck’s action plane strength criterion. Compos. Sci. Technol. 2002, 62, 371–378. [Google Scholar] [CrossRef]

- Liu, P.; Cheng, X.; Wang, S.; Liu, S.; Cheng, Y. Numerical analysis of bearing failure in countersunk composite joints using 3d explicit simulation method. Compos. Struct. 2016, 138, 30–39. [Google Scholar] [CrossRef]

- Seo, H.; Hundley, J.; Hahn, H.T.; Yang, J.-M. Numerical simulation of glass-fiber-reinforced aluminum laminates with diverse impact damage. AIAA J. 2010, 48, 676–687. [Google Scholar] [CrossRef]

- Yu, G.-C.; Wu, L.-Z.; Ma, L.; Xiong, J. Low velocity impact of carbon fiber aluminum laminates. Compos. Struct. 2015, 119, 757–766. [Google Scholar] [CrossRef]

- Yamada, K.; Kötter, B.; Nishikawa, M.; Fukudome, S.; Matsuda, N.; Kawabe, K.; Fiedler, B.; Hojo, M. Mechanical properties and failure mode of thin-ply fiber metal laminates under out-of-plane loading. Compos. Part A Appl. Sci. Manuf. 2021, 143, 106267. [Google Scholar] [CrossRef]

| Properties | Value |

|---|---|

| Curing temperature (°C) | 120~140 |

| Glass transition temperature (Tg/°C) | 95 |

| Weave pattern | Unidirectional pattern (UD) |

| Fibre surface density (g/m2) | 100 ± 5 |

| Resin content (%) | 38 ± 3 |

| Recommended forming process | Vacuum bag moulding process Compression Moulding |

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|

| 0.68 | 0.5 | 0.33 | 0.12 | 0.9 | 0.28 | 0.05 | 0.02 | 97.12 |

| Properties | Value |

|---|---|

| Curing temperature (°C) | 130–150 |

| Film thickness (mm) | Before curing: 0.24 ± 0.02 After curing: 0.1 ± 0.01 |

| The surface density of adhesive film (g/m2) | 300 ± 20 |

| Shear strength at 25 °C (MPa) | 40 |

| Parameters | Material Parameters |

|---|---|

| Elastic parameters | 0,0 |

| Tensile strength | 205 MPa |

| Yield surface parameter | .34 |

| Failure parameters | = 0.011 |

| Fracture energy |

| Parameters | Material Parameters |

|---|---|

| Elastic modulus | |

| Poisson’s ratio | |

| Shear modulus | |

| Density | |

| Ultimate strength | |

| Fracture energy |

| Properties | Value |

|---|---|

| 1200 | |

| 106 | |

| 40 | |

| 50 | |

| 0.25 | |

| 0.75 | |

| 0.75 | |

| 1.45 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, H.; Wei, Q.; Liu, B.; Liu, Y.; Hu, N.; Ma, Q.; Wang, C. Progressive Damage Behaviour Analysis and Comparison with 2D/3D Hashin Failure Models on Carbon Fibre–Reinforced Aluminium Laminates. Polymers 2022, 14, 2946. https://doi.org/10.3390/polym14142946

Hu H, Wei Q, Liu B, Liu Y, Hu N, Ma Q, Wang C. Progressive Damage Behaviour Analysis and Comparison with 2D/3D Hashin Failure Models on Carbon Fibre–Reinforced Aluminium Laminates. Polymers. 2022; 14(14):2946. https://doi.org/10.3390/polym14142946

Chicago/Turabian StyleHu, Haichao, Qiang Wei, Boya Liu, Yun Liu, Ning Hu, Quanjin Ma, and Chuancai Wang. 2022. "Progressive Damage Behaviour Analysis and Comparison with 2D/3D Hashin Failure Models on Carbon Fibre–Reinforced Aluminium Laminates" Polymers 14, no. 14: 2946. https://doi.org/10.3390/polym14142946

APA StyleHu, H., Wei, Q., Liu, B., Liu, Y., Hu, N., Ma, Q., & Wang, C. (2022). Progressive Damage Behaviour Analysis and Comparison with 2D/3D Hashin Failure Models on Carbon Fibre–Reinforced Aluminium Laminates. Polymers, 14(14), 2946. https://doi.org/10.3390/polym14142946