A Systematic Review and Bibliometric Analysis of Flame-Retardant Rigid Polyurethane Foam from 1963 to 2021

Abstract

:1. Introduction

- (1)

- Which countries/companies have made important contributions to the development of flame-retardant RPUF? What led them to devote themselves to this theme?

- (2)

- Is there an extensive international exchange of cooperation on the theme of flame-retardant RPUF?

- (3)

- What types of flame retardant can improve the flame retardancy of RPUF? What is their flame-retardant mechanism?

- (4)

- Have the rapid developments in materials science in recent years had an impact on the research on this theme?

- (5)

- Are the flame-retardant properties that RPUF exhibits in the laboratory applicable when used as a building insulation material?

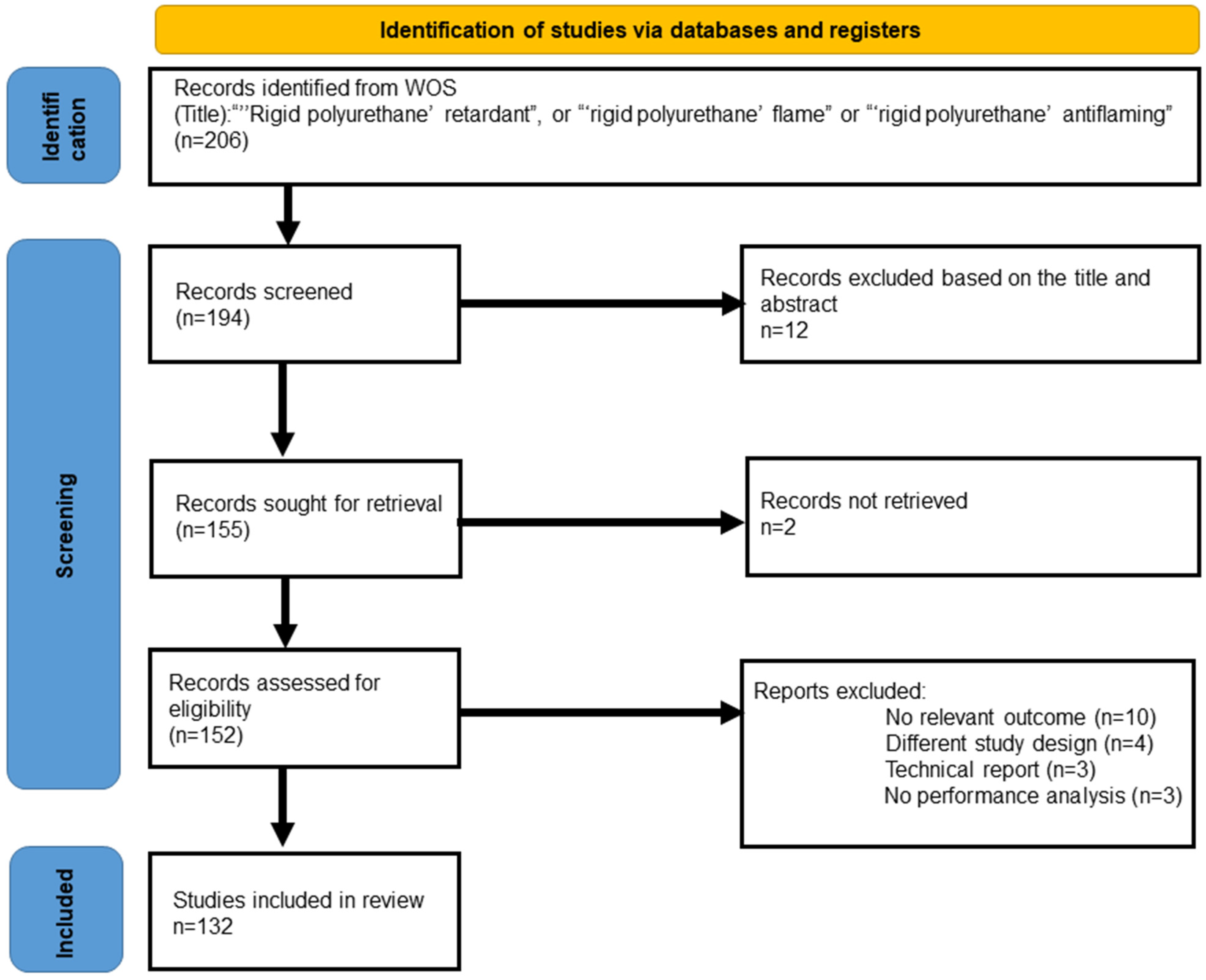

2. Methods

3. Results and Discussion

3.1. Developments in the Research Field

3.1.1. Literature Development Trends

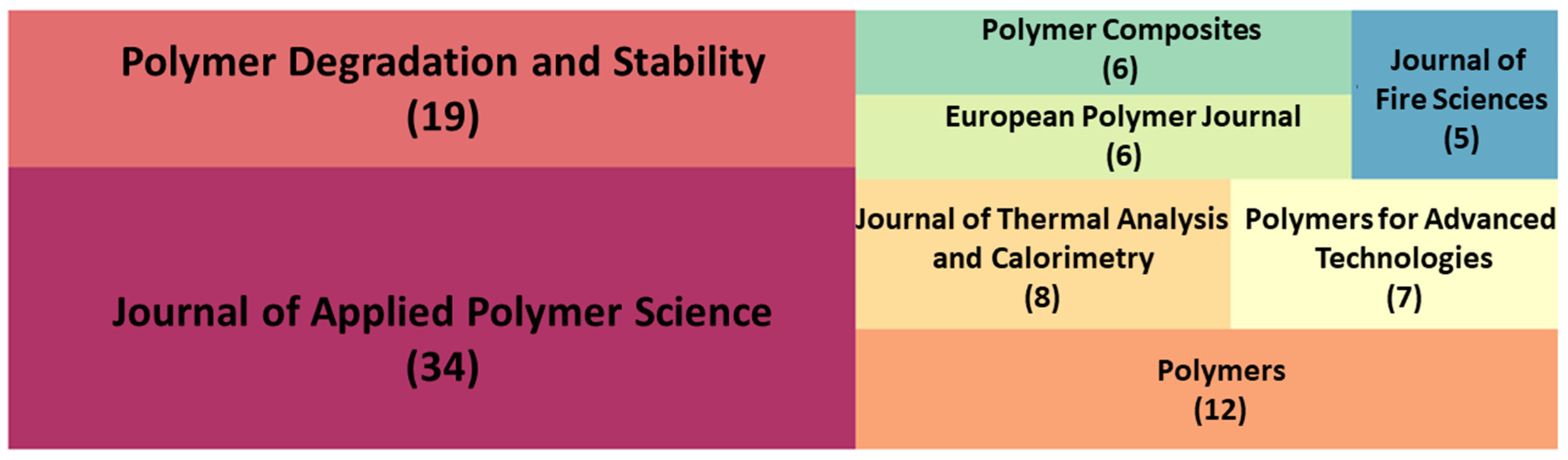

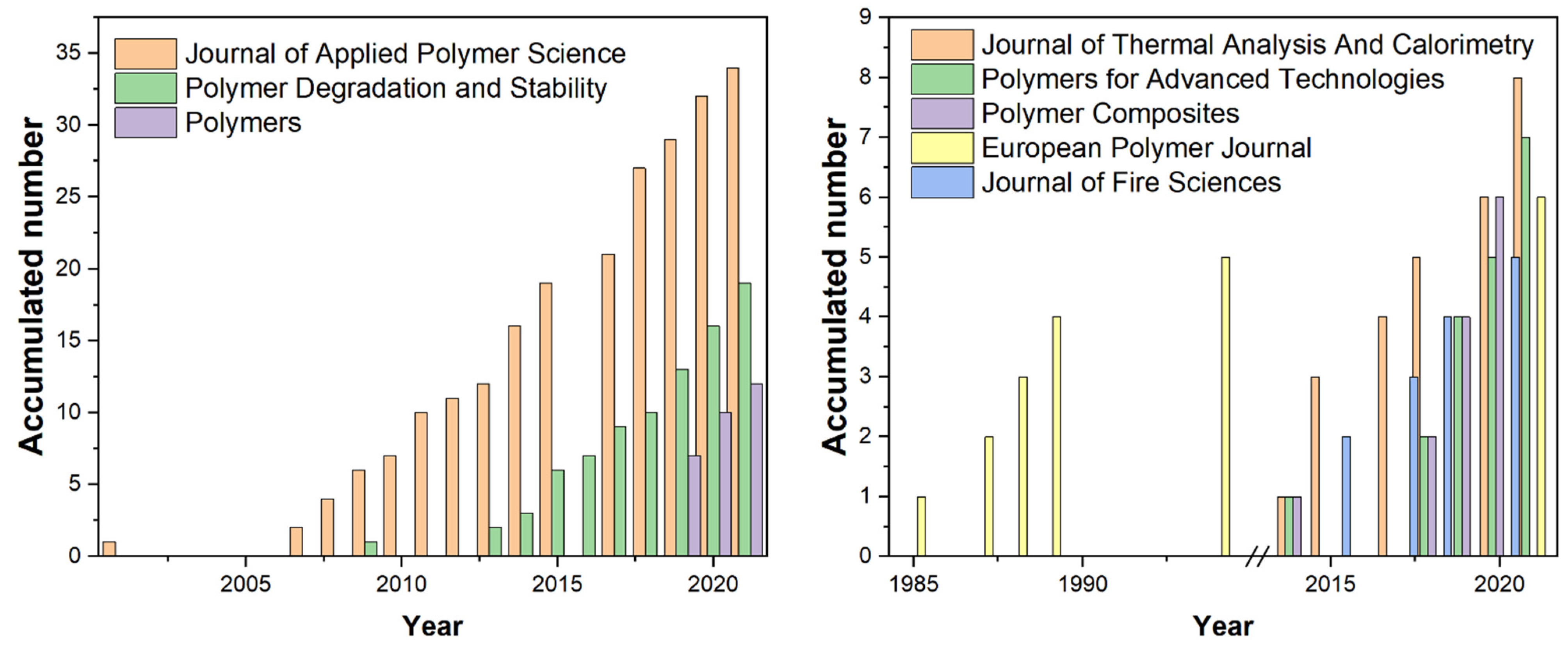

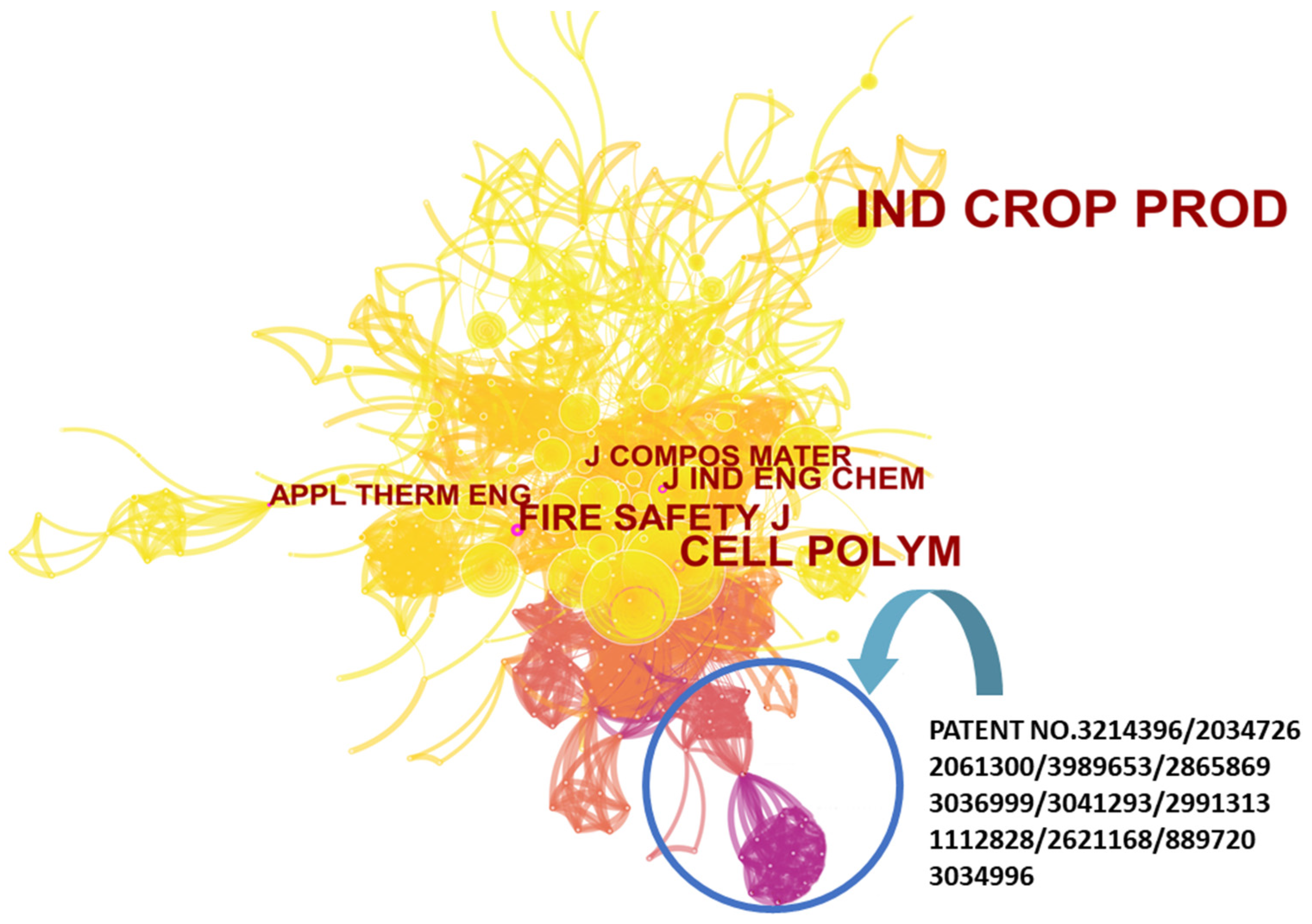

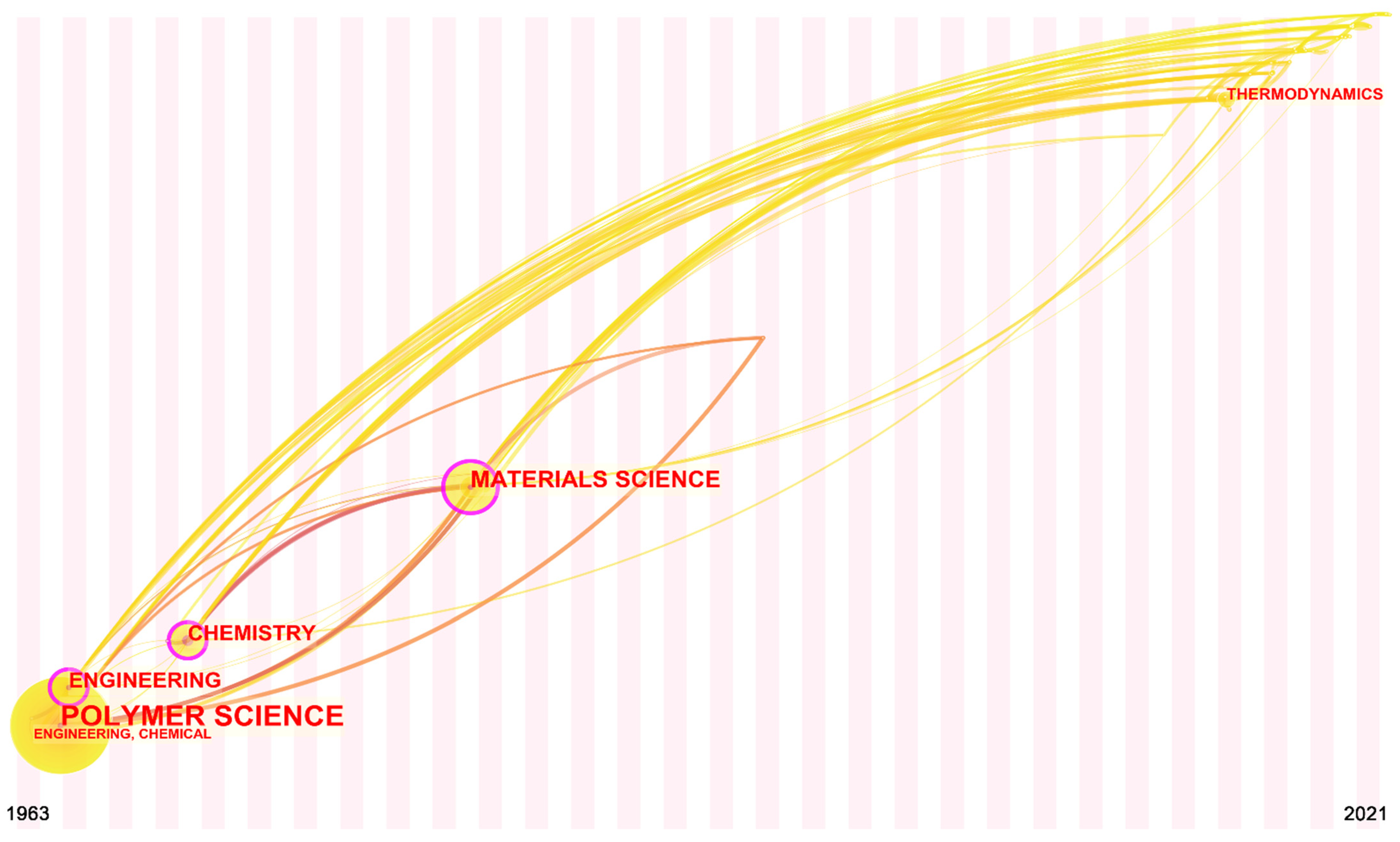

3.1.2. Journals, Cited Journals, and Research Subjects

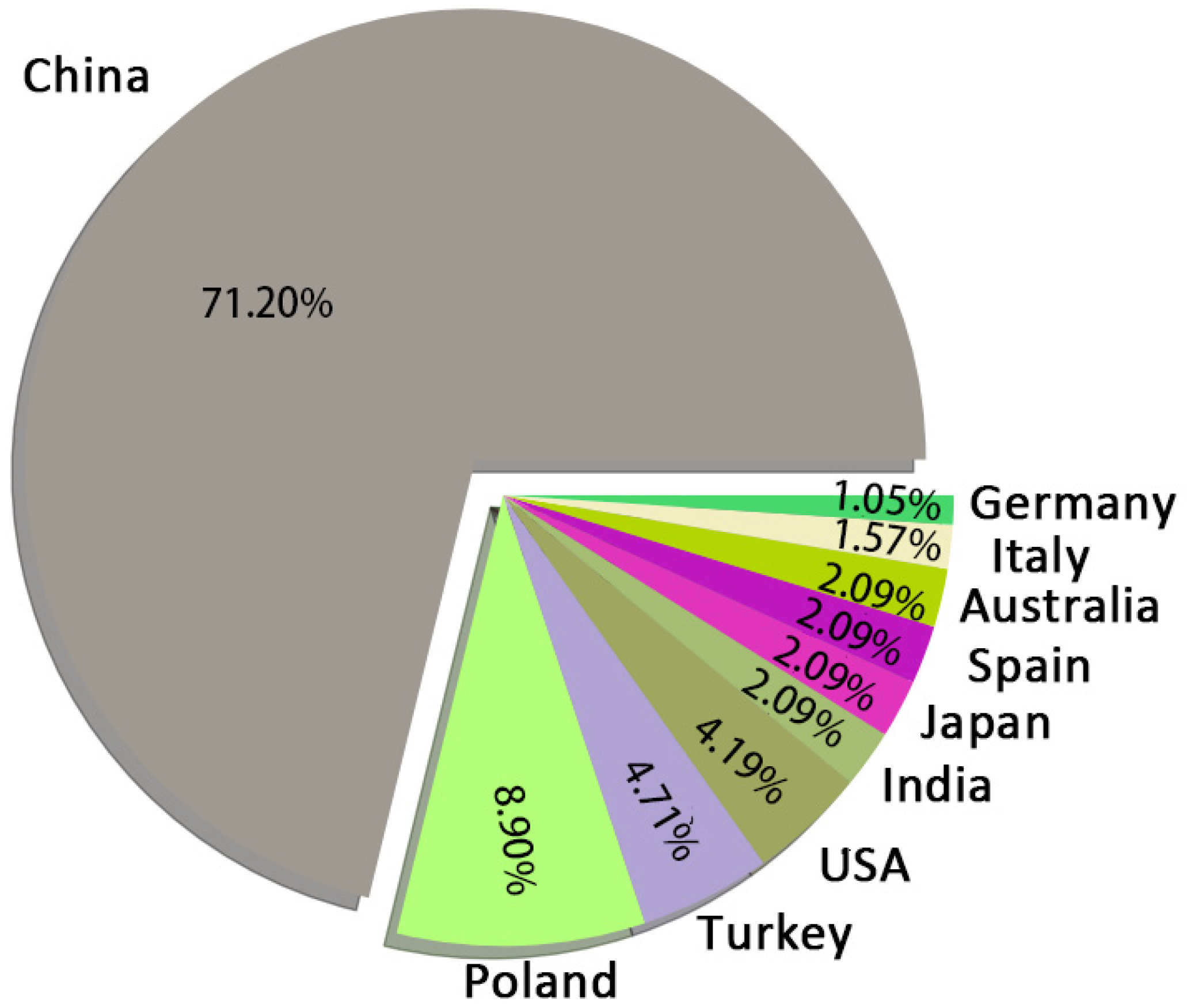

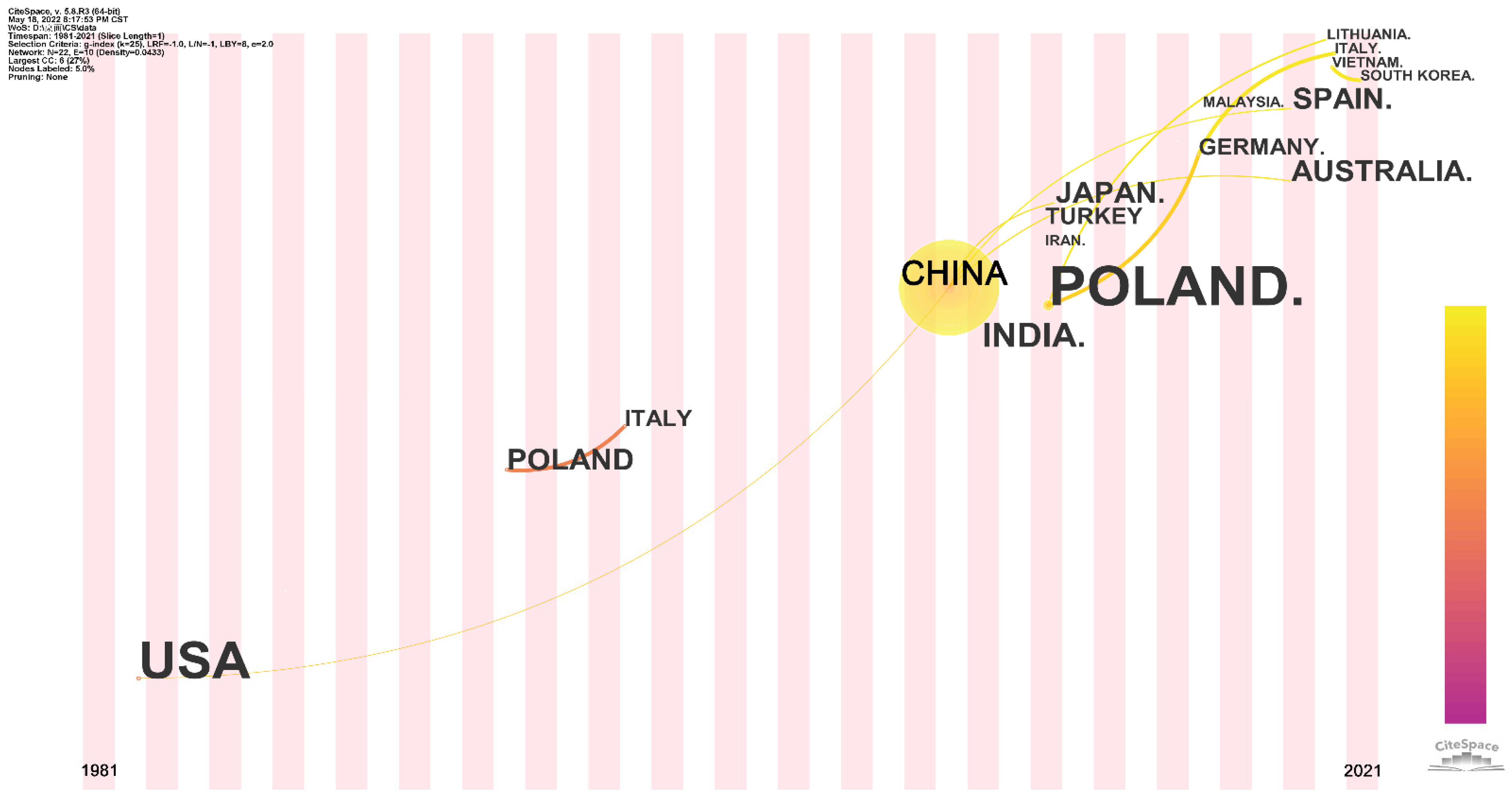

3.1.3. Geographic Distribution

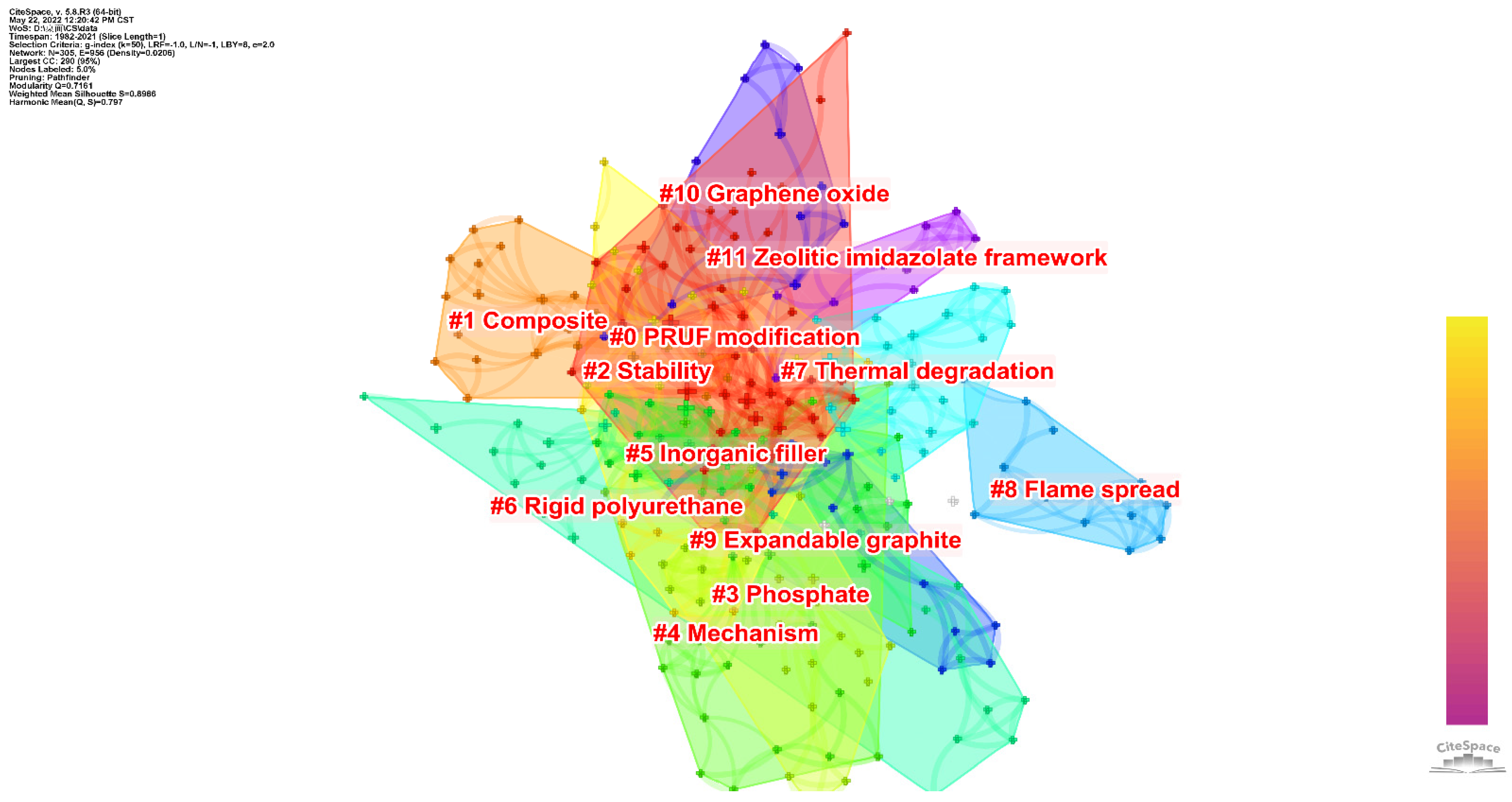

3.2. Keyword Analysis and Evolution of the Field

- (1)

- Additives play a significant role in improving the flame retardancy of RPUF. Most of the works focused on enhancing the flame-retardant properties of RPUF using expanded graphite, phosphate, hydroxide, and ammonia-containing additives;

- (2)

- Some new materials are also being tried to increase the flame retardancy of RPUF, such as graphene oxide and a zeolitic imidazolate framework. Additionally, preparing composites before adding them to RPUF is an option;

- (3)

- This theme is mainly performance-oriented, and LOI, cone calorimetry, and thermogravimetric analysis are the most commonly used evaluation techniques;

- (4)

- The flame-retardant properties of RPUF are related to the microstructure of RPUF and the nature of the additives;

- (5)

- RPUFs containing different additives have different flame-retardant mechanisms;

- (6)

- The burning behavior of RPUF toward different spatial regions during combustion is also a direction of investigation.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Choi, H.-J.; Kang, J.-S.; Huh, J.-H. A Study on Variation of Thermal Characteristics of Insulation Materials for Buildings According to Actual Long-Term Annual Aging Variation. Int. J. Thermophys 2017, 39, 2. [Google Scholar] [CrossRef] [Green Version]

- Hung Anh, L.D.; Pásztory, Z. An Overview of Factors Influencing Thermal Conductivity of Building Insulation Materials. J. Build. Eng. 2021, 44, 102604. [Google Scholar] [CrossRef]

- Yang, H.; Jiang, Y.; Liu, H.; Xie, D.; Wan, C.; Pan, H.; Jiang, S. Mechanical, Thermal and Fire Performance of an Inorganic-Organic Insulation Material Composed of Hollow Glass Microspheres and Phenolic Resin. J. Colloid Interface Sci. 2018, 530, 163–170. [Google Scholar] [CrossRef] [PubMed]

- Wi, S.; Yang, S.; Berardi, U.; Kim, S. Assessment of Recycled Ceramic-Based Inorganic Insulation for Improving Energy Efficiency and Flame Retardancy of Buildings. Environ. Int. 2019, 130, 104900. [Google Scholar] [CrossRef] [PubMed]

- Wi, S.; Park, J.H.; Kim, Y.U.; Kim, S. Evaluation of Environmental Impact on the Formaldehyde Emission and Flame-Retardant Performance of Thermal Insulation Materials. J. Hazard. Mater. 2021, 402, 123463. [Google Scholar] [CrossRef]

- Wi, S.; Kang, Y.; Yang, S.; Kim, Y.U.; Kim, S. Hazard Evaluation of Indoor Environment Based on Long-Term Pollutant Emission Characteristics of Building Insulation Materials: An Empirical Study. Environ. Pollut. 2021, 285, 117223. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Ju, Y.; Santibanez Gonzalez, E.D.R.; Wang, A.; Dong, P.; Giannakis, M. A New Framework to Select Energy-Efficient Retrofit Schemes of External Walls: A Case Study. J. Clean. Prod. 2021, 289, 125718. [Google Scholar] [CrossRef]

- Hongisto, V.; Saarinen, P.; Alakoivu, R.; Hakala, J. Acoustic Properties of Commercially Available Thermal Insulators—An Experimental Study. J. Build. Eng. 2022, 54, 104588. [Google Scholar] [CrossRef]

- Karimi-Maleh, H.; Orooji, Y.; Karimi, F.; Alizadeh, M.; Baghayeri, M.; Rouhi, J.; Tajik, S.; Beitollahi, H.; Agarwal, S.; Gupta, V.K. A Critical Review on the Use of Potentiometric Based Biosensors for Biomarkers Detection. Biosens. Bioelectron. 2021, 184, 113252. [Google Scholar] [CrossRef]

- Bergamonti, L.; Taurino, R.; Cattani, L.; Ferretti, D.; Bondioli, F. Lightweight Hybrid Organic-Inorganic Geopolymers Obtained Using Polyurethane Waste. Constr. Build. Mater. 2018, 185, 285–292. [Google Scholar] [CrossRef]

- Członka, S.; Bertino, M.F.; Strzelec, K. Rigid Polyurethane Foams Reinforced with Industrial Potato Protein. Polym. Test. 2018, 68, 135–145. [Google Scholar] [CrossRef]

- Barczewski, M.; Kurańska, M.; Sałasińska, K.; Michałowski, S.; Prociak, A.; Uram, K.; Lewandowski, K. Rigid Polyurethane Foams Modified with Thermoset Polyester-Glass Fiber Composite Waste. Polym. Test. 2020, 81, 106190. [Google Scholar] [CrossRef]

- Jonjaroen, V.; Ummartyotin, S.; Chittapun, S. Algal Cellulose as a Reinforcement in Rigid Polyurethane Foam. Algal Res. 2020, 51, 102057. [Google Scholar] [CrossRef]

- Członka, S.; Bertino, M.F.; Kośny, J.; Strąkowska, A.; Masłowski, M.; Strzelec, K. Linseed Oil as a Natural Modifier of Rigid Polyurethane Foams. Ind. Crops Prod. 2018, 115, 40–51. [Google Scholar] [CrossRef]

- Karimi-Maleh, H.; Khataee, A.; Karimi, F.; Baghayeri, M.; Fu, L.; Rouhi, J.; Karaman, C.; Karaman, O.; Boukherroub, R. A Green and Sensitive Guanine-Based DNA Biosensor for Idarubicin Anticancer Monitoring in Biological Samples: A Simple and Fast Strategy for Control of Health Quality in Chemotherapy Procedure Confirmed by Docking Investigation. Chemosphere 2021, 291, 132928. [Google Scholar] [CrossRef]

- Kirpluks, M.; Kalnbunde, D.; Benes, H.; Cabulis, U. Natural Oil Based Highly Functional Polyols as Feedstock for Rigid Polyurethane Foam Thermal Insulation. Ind. Crops Prod. 2018, 122, 627–636. [Google Scholar] [CrossRef]

- Hayati, A.N.; Evans, D.A.C.; Laycock, B.; Martin, D.J.; Annamalai, P.K. A Simple Methodology for Improving the Performance and Sustainability of Rigid Polyurethane Foam by Incorporating Industrial Lignin. Ind. Crops Prod. 2018, 117, 149–158. [Google Scholar] [CrossRef]

- Karimi-Maleh, H.; Karimi, F.; Fu, L.; Sanati, A.L.; Alizadeh, M.; Karaman, C.; Orooji, Y. Cyanazine Herbicide Monitoring as a Hazardous Substance by a DNA Nanostructure Biosensor. J. Hazard. Mater. 2022, 423, 127058. [Google Scholar] [CrossRef]

- Ma, Z.; Zhang, J.; Liu, L.; Zheng, H.; Dai, J.; Tang, L.-C.; Song, P. A Highly Fire-Retardant Rigid Polyurethane Foam Capable of Fire-Warning. Compos. Commun. 2022, 29, 101046. [Google Scholar] [CrossRef]

- Singh, H.; Jain, A.K. Ignition, Combustion, Toxicity, and Fire Retardancy of Polyurethane Foams: A Comprehensive Review. J. Appl. Polym. Sci. 2009, 111, 1115–1143. [Google Scholar] [CrossRef]

- Zhu, M.; Ma, Z.; Liu, L.; Zhang, J.; Huo, S.; Song, P. Recent Advances in Fire-Retardant Rigid Polyurethane Foam. J. Mater. Sci. Technol. 2022, 112, 315–328. [Google Scholar] [CrossRef]

- Levchik, S.V.; Weil, E.D. Thermal Decomposition, Combustion and Fire-Retardancy of Polyurethanes—a Review of the Recent Literature. Polym. Int. 2004, 53, 1585–1610. [Google Scholar] [CrossRef]

- Börner, K.; Chen, C.; Boyack, K.W. Visualizing Knowledge Domains. Annu. Rev. Inf. Sci. Technol. 2003, 37, 179–255. [Google Scholar] [CrossRef]

- Chen, C. CiteSpace II: Detecting and Visualizing Emerging Trends and Transient Patterns in Scientific Literature. J. Am. Soc. Inf. Sci. Technol. 2006, 57, 359–377. [Google Scholar] [CrossRef] [Green Version]

- Chen, C. Searching for Intellectual Turning Points: Progressive Knowledge Domain Visualization. Proc. Natl. Acad. Sci. USA 2004, 101, 5303–5310. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, C.; Ibekwe-SanJuan, F.; Hou, J. The Structure and Dynamics of Cocitation Clusters: A Multiple-perspective Cocitation Analysis. J. Am. Soc. Inf. Sci. Technol. 2010, 61, 1386–1409. [Google Scholar] [CrossRef] [Green Version]

- Xueshu, D. Wenxian COOC Is a Software for Bibliometrics and Knowledge Mapping [CP/OL]. 2022. Available online: https://gitee.com/academic_2088904822/academic-drip (accessed on 5 February 2022).

- Anderson, J. Retention of Flame Properties of Rigid Polyurethane Foams. Ind. Eng. Chem. Prod. Res. Dev. 1963, 2, 260–263. [Google Scholar] [CrossRef]

- Slezak, F.; Stallings, J.; Rosen, I. Chlorinated Xylene Derivatives for Flame-Retardant Rigid Polyurethane Foams. Ind. Eng. Chem. Prod. Res. Dev. 1964, 3, 292–294. [Google Scholar] [CrossRef]

- Nametz, R.; Deanin, R.; Lambert, P. Flame-resistant Rigid Polyurethance Foams from Monobrominated Toluene Diisocyanate. Polym. Eng. Sci. 1964, 4, 251–255. [Google Scholar] [CrossRef]

- Hu, X.; Wang, D. Enhanced Fire Behavior of Rigid Polyurethane Foam by Intumescent Flame Retardants. J. Appl. Polym. Sci. 2013, 129, 238–246. [Google Scholar] [CrossRef]

- Xu, D.; Hao, J.; Liu, G.; Xie, S. Thermal Degradation and Smoke Production during Combustion for Intumescent Flame Retardant Rigid Polyurethane Foams. Acta Polym Sin 2013, 7, 832–840. [Google Scholar]

- Wu, D.; Zhao, P.; Liu, Y. Flame Retardant Property of Novel Intumescent Flame Retardant Rigid Polyurethane Foams. Polym. Eng. Sci. 2013, 53, 2478–2485. [Google Scholar] [CrossRef]

- Wu, D.; Zhao, P.; Zhang, M.; Liu, Y. Preparation and Properties of Flame Retardant Rigid Polyurethane Foam with Phosphorus–Nitrogen Intumescent Flame Retardant. High Perform. Polym. 2013, 25, 868–875. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, M.; Hu, L.; Zhou, Y. Synthesis of Rigid Polyurethane Foams with Castor Oil-Based Flame Retardant Polyols. Ind. Crops Prod. 2014, 52, 380–388. [Google Scholar] [CrossRef]

- Zhang, M.; Pan, H.; Zhang, L.; Hu, L.; Zhou, Y. Study of the Mechanical, Thermal Properties and Flame Retardancy of Rigid Polyurethane Foams Prepared from Modified Castor-Oil-Based Polyols. Ind. Crops Prod. 2014, 59, 135–143. [Google Scholar] [CrossRef]

- Fu, L.; Mao, S.; Chen, F.; Zhao, S.; Su, W.; Lai, G.; Yu, A.; Lin, C.-T. Graphene-Based Electrochemical Sensors for Antibiotic Detection in Water, Food and Soil: A Scientometric Analysis in CiteSpace (2011–2021). Chemosphere 2022, 297, 134127. [Google Scholar] [CrossRef]

- Jin, M.; Liu, J.; Wu, W.; Zhou, Q.; Fu, L.; Zare, N.; Karimi, F.; Yu, J.; Lin, C.-T. Relationship between Graphene and Pedosphere: A Scientometric Analysis. Chemosphere 2022, 300, 134599. [Google Scholar] [CrossRef]

- Shen, Y.; Mao, S.; Chen, F.; Zhao, S.; Su, W.; Fu, L.; Zare, N.; Karimi, F. Electrochemical Detection of Sudan Red Series Azo Dyes: Bibliometrics Based Analysis. Food Chem. Toxicol. 2022, 163, 112960. [Google Scholar] [CrossRef]

- Zheng, Y.; Mao, S.; Zhu, J.; Fu, L.; Zare, N.; Karimi, F. Current Status of Electrochemical Detection of Sunset Yellow Based on Bibliometrics. Food Chem. Toxicol. 2022, 164, 113019. [Google Scholar] [CrossRef]

- Zheng, Y.; Karimi-Maleh, H.; Fu, L. Evaluation of Antioxidants Using Electrochemical Sensors: A Bibliometric Analysis. Sensors 2022, 22, 3238. [Google Scholar] [CrossRef]

- Quinn, E.J. Properties and Stability of Fire-Retardant Rigid Polyurethane Foams from Phosphonopropionate Polyols. Ind. Eng. Chem. Prod. Res. Dev. 1970, 9, 48–53. [Google Scholar] [CrossRef]

- Jensen, J.; Rose, R. Tetrabromophthalate Diol-A Versatile Approach To Flame Retarding Rigid Polyurethane Foam With Low Smoke Evolution. J. Fire Retard. Chem. 1982, 9, 209–214. [Google Scholar]

- Ye, L.; Meng, X.; Liu, X.; Tang, J.; Li, Z. Flame-retardant and Mechanical Properties of High-density Rigid Polyurethane Foams Filled with Decabrominated Dipheny Ethane and Expandable Graphite. J. Appl. Polym. Sci. 2009, 111, 2372–2380. [Google Scholar] [CrossRef]

- Gao, M.; Wu, W.; Liu, S.; Wang, Y.; Shen, T. Thermal Degradation and Flame Retardancy of Rigid Polyurethane Foams Containing a Novel Intumescent Flame Retardant. J. Therm. Anal. Calorim. 2014, 117, 1419–1425. [Google Scholar] [CrossRef]

- Lu, W.; Li, Q.; Zhang, Y.; Yu, H.; Hirose, S.; Hatakeyama, H.; Matsumoto, Y.; Jin, Z. Lignosulfonate/APP IFR and Its Flame Retardancy in Lignosulfonate-Based Rigid Polyurethane Foams. J. Wood Sci. 2018, 64, 287–293. [Google Scholar] [CrossRef] [Green Version]

- Xu, W.; Wang, G.; Xu, J.; Liu, Y.; Chen, R.; Yan, H. Modification of Diatomite with Melamine Coated Zeolitic Imidazolate Framework-8 as an Effective Flame Retardant to Enhance Flame Retardancy and Smoke Suppression of Rigid Polyurethane Foam. J. Hazard. Mater. 2019, 379, 120819. [Google Scholar] [CrossRef]

- Wei, B.; Yang, S. Polymer Composites with Expanded Graphite Network with Superior Thermal Conductivity and Electromagnetic Interference Shielding Performance. Chem. Eng. J. 2021, 404, 126437. [Google Scholar] [CrossRef]

- Karimi-Maleh, H.; Alizadeh, M.; Orooji, Y.; Karimi, F.; Baghayeri, M.; Rouhi, J.; Tajik, S.; Beitollahi, H.; Agarwal, S.; Gupta, V.K.; et al. Guanine-Based DNA Biosensor Amplified with Pt/SWCNTs Nanocomposite as Analytical Tool for Nanomolar Determination of Daunorubicin as an Anticancer Drug: A Docking/Experimental Investigation. Ind. Eng. Chem. Res. 2021, 60, 816–823. [Google Scholar] [CrossRef]

- Wang, X.; Li, B.; Qu, Z.; Zhang, J.; Jin, Z. Effects of Graphite Microstructure Evolution on the Anisotropic Thermal Conductivity of Expanded Graphite/Paraffin Phase Change Materials and Their Thermal Energy Storage Performance. Int. J. Heat Mass Transf. 2020, 155, 119853. [Google Scholar] [CrossRef]

- Fu, W.; Zou, T.; Liang, X.; Wang, S.; Gao, X.; Zhang, Z.; Fang, Y. Thermal Properties and Thermal Conductivity Enhancement of Composite Phase Change Material Using Sodium Acetate Trihydrate–Urea/Expanded Graphite for Radiant Floor Heating System. Appl. Therm. Eng. 2018, 138, 618–626. [Google Scholar] [CrossRef]

- Karimi-Maleh, H.; Karaman, C.; Karaman, O.; Karimi, F.; Vasseghian, Y.; Fu, L.; Baghayeri, M.; Rouhi, J.; Senthil Kumar, P.; Show, P.-L.; et al. Nanochemistry Approach for the Fabrication of Fe and N Co-Decorated Biomass-Derived Activated Carbon Frameworks: A Promising Oxygen Reduction Reaction Electrocatalyst in Neutral Media. J. Nanostructure Chem. 2022, 12, 429–439. [Google Scholar] [CrossRef]

- Song, Z.; Deng, Y.; Li, J.; Nian, H. Expanded Graphite for Thermal Conductivity and Reliability Enhancement and Supercooling Decrease of MgCl2 6H2O Phase Change Material. Mater. Res. Bull. 2018, 102, 203–208. [Google Scholar] [CrossRef]

- Wang, Q.; Zhou, D.; Chen, Y.; Eames, P.; Wu, Z. Characterization and Effects of Thermal Cycling on the Properties of Paraffin/Expanded Graphite Composites. Renew. Energy 2020, 147, 1131–1138. [Google Scholar] [CrossRef]

- Karimi-Maleh, H.; Beitollahi, H.; Kumar, P.S.; Tajik, S.; Jahani, P.M.; Karimi, F.; Karaman, C.; Vasseghian, Y.; Baghayeri, M.; Rouhi, J. Recent Advances in Carbon Nanomaterials-Based Electrochemical Sensors for Food Azo Dyes Detection. Food Chem. Toxicol. 2022, 164, 112961. [Google Scholar] [CrossRef]

- Qureshi, Z.A.; Ali, H.M.; Khushnood, S. Recent Advances on Thermal Conductivity Enhancement of Phase Change Materials for Energy Storage System: A Review. Int. J. Heat Mass Transf. 2018, 127, 838–856. [Google Scholar] [CrossRef]

- Gama, N.V.; Silva, R.; Mohseni, F.; Davarpanah, A.; Amaral, V.; Ferreira, A.; Barros-Timmons, A. Enhancement of Physical and Reaction to Fire Properties of Crude Glycerol Polyurethane Foams Filled with Expanded Graphite. Polym. Test. 2018, 69, 199–207. [Google Scholar] [CrossRef]

- Asimakopoulou, E.; Zhang, J.; Mckee, M.; Wieczorek, K.; Krawczyk, A.; Andolfo, M.; Kozlecki, T.; Scatto, M.; Sisani, M.; Bastianini, M. Effect of Layered Double Hydroxide, Expanded Graphite and Ammonium Polyphosphate Additives on Thermal Stability and Fire Performance of Polyisocyanurate Insulation Foam. Thermochim. Acta 2020, 693, 178724. [Google Scholar] [CrossRef]

- Zhang, T.; Tao, Y.; Zhou, F.; Sheng, H.; Qiu, S.; Ma, C.; Hu, Y. Synthesis of a Hyperbranched Phosphorus-Containing Polyurethane as Char Forming Agent Combined with Ammonium Polyphosphate for Reducing Fire Hazard of Polypropylene. Polym. Degrad. Stab. 2019, 165, 207–219. [Google Scholar] [CrossRef]

- Karimi-Maleh, H.; Ayati, A.; Ghanbari, S.; Orooji, Y.; Tanhaei, B.; Karimi, F.; Alizadeh, M.; Rouhi, J.; Fu, L.; Sillanpää, M. Recent Advances in Removal Techniques of Cr (VI) Toxic Ion from Aqueous Solution: A Comprehensive Review. J. Mol. Liq. 2021, 329, 115062. [Google Scholar] [CrossRef]

- Xu, X.; Wang, S.; Ma, S.; Yuan, W.; Li, Q.; Feng, J.; Zhu, J. Vanillin-derived Phosphorus-containing Compounds and Ammonium Polyphosphate as Green Fire-resistant Systems for Epoxy Resins with Balanced Properties. Polym. Adv. Technol. 2019, 30, 264–278. [Google Scholar] [CrossRef]

- Cavdar, A.D.; Torun, S.B.; Ertas, M.; Mengeloglu, F. Ammonium Zeolite and Ammonium Phosphate Applied as Fire Retardants for Microcrystalline Cellulose Filled Thermoplastic Composites. Fire Saf. J. 2019, 107, 202–209. [Google Scholar] [CrossRef]

- Li, S.; Zhong, L.; Huang, S.; Wang, D.; Zhang, F.; Zhang, G. A Novel Flame Retardant with Reactive Ammonium Phosphate Groups and Polymerizing Ability for Preparing Durable Flame Retardant and Stiff Cotton Fabric. Polym. Degrad. Stab. 2019, 164, 145–156. [Google Scholar] [CrossRef]

- Shao, Z.-B.; Zhang, J.; Jian, R.-K.; Sun, C.-C.; Li, X.-L.; Wang, D.-Y. A Strategy to Construct Multifunctional Ammonium Polyphosphate for Epoxy Resin with Simultaneously High Fire Safety and Mechanical Properties. Compos. Part A Appl. Sci. Manuf. 2021, 149, 106529. [Google Scholar] [CrossRef]

- Yang, G.; Cai, J.; Geng, Y.; Xu, B.; Zhang, Q. Cu-Modified ZSM Zeolite Has SYNERGISTIC Flame Retardance, Smoke Suppression, and Catalytic Conversion Effects on Pulp Fiber after Ammonium Polyphosphate Flame-Retardant Treatment. ACS Sustain. Chem. Eng. 2020, 8, 14365–14376. [Google Scholar] [CrossRef]

- Karimi-Maleh, H.; Ayati, A.; Davoodi, R.; Tanhaei, B.; Karimi, F.; Malekmohammadi, S.; Orooji, Y.; Fu, L.; Sillanpää, M. Recent Advances in Using of Chitosan-Based Adsorbents for Removal of Pharmaceutical Contaminants: A Review. J. Clean. Prod. 2021, 291, 125880. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, F.; Dong, Q.; Yuan, W.; Liu, P.; Ding, Y.; Zhang, S.; Yang, M.; Zheng, G. Expandable Graphite Encapsulated by Magnesium Hydroxide Nanosheets as an Intumescent Flame Retardant for Rigid Polyurethane Foams. J. Appl. Polym. Sci. 2018, 135, 46749. [Google Scholar] [CrossRef]

- Peng, H.-K.; Wang, X.; Li, T.-T.; Lou, C.-W.; Wang, Y.; Lin, J.-H. Mechanical Properties, Thermal Stability, Sound Absorption, and Flame Retardancy of Rigid PU Foam Composites Containing a Fire-Retarding Agent: Effect of Magnesium Hydroxide and Aluminum Hydroxide. Polym. Adv. Technol. 2019, 30, 2045–2055. [Google Scholar] [CrossRef]

- Usta, N. Investigation of Fire Behavior of Rigid Polyurethane Foams Containing Fly Ash and Intumescent Flame Retardant by Using a Cone Calorimeter. J. Appl. Polym. Sci. 2012, 124, 3372–3382. [Google Scholar] [CrossRef]

- Lu, W.; Ye, J.; Zhu, L.; Jin, Z.; Matsumoto, Y. Intumescent Flame Retardant Mechanism of Lignosulfonate as a Char Forming Agent in Rigid Polyurethane Foam. Polymers 2021, 13, 1585. [Google Scholar] [CrossRef]

- Wang, L.; Tawiah, B.; Shi, Y.; Cai, S.; Rao, X.; Liu, C.; Yang, Y.; Yang, F.; Yu, B.; Liang, Y. Highly Effective Flame-Retardant Rigid Polyurethane Foams: Fabrication and Applications in Inhibition of Coal Combustion. Polymers 2019, 11, 1776. [Google Scholar] [CrossRef] [Green Version]

- Thirumal, M.; Singha, N.K.; Khastgir, D.; Manjunath, B.; Naik, Y. Halogen-free Flame-retardant Rigid Polyurethane Foams: Effect of Alumina Trihydrate and Triphenylphosphate on the Properties of Polyurethane Foams. J. Appl. Polym. Sci. 2010, 116, 2260–2268. [Google Scholar] [CrossRef]

- Xia, Z.; Wang, Z. Rigid Polyurethane/Expanded Vermiculite/Melamine Phenylphosphate Composite Foams with Good Flame Retardant and Mechanical Properties. e-Polymers 2019, 19, 563–573. [Google Scholar] [CrossRef] [Green Version]

- Xing, W.; Yuan, H.; Yang, H.; Song, L.; Hu, Y. Functionalized Lignin for Halogen-Free Flame Retardant Rigid Polyurethane Foam: Preparation, Thermal Stability, Fire Performance and Mechanical Properties. J. Polym. Res. 2013, 20, 234. [Google Scholar] [CrossRef]

- Han, S.; Zhu, X.; Chen, F.; Chen, S.; Liu, H. Flame-Retardant System for Rigid Polyurethane Foams Based on Diethyl Bis (2-Hydroxyethyl) Aminomethylphosphonate and in-Situ Exfoliated Clay. Polym. Degrad. Stab. 2020, 177, 109178. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, D.; Xu, M.; Li, B. Synthesis of a Novel Phosphorus and Nitrogen-Containing Flame Retardant and Its Application in Rigid Polyurethane Foam with Expandable Graphite. Polym. Degrad. Stab. 2020, 173, 109077. [Google Scholar] [CrossRef]

- Yuan, Y.; Yang, H.; Yu, B.; Shi, Y.; Wang, W.; Song, L.; Hu, Y.; Zhang, Y. Phosphorus and Nitrogen-Containing Polyols: Synergistic Effect on the Thermal Property and Flame Retardancy of Rigid Polyurethane Foam Composites. Ind. Eng. Chem. Res. 2016, 55, 10813–10822. [Google Scholar] [CrossRef]

- Liu, L.; Wang, Z. High Performance Nano-Zinc Amino-Tris-(Methylenephosphonate) in Rigid Polyurethane Foam with Improved Mechanical Strength, Thermal Stability and Flame Retardancy. Polym. Degrad. Stab. 2018, 154, 62–72. [Google Scholar] [CrossRef]

- Yang, H.; Wang, X.; Song, L.; Yu, B.; Yuan, Y.; Hu, Y.; Yuen, R.K. Aluminum Hypophosphite in Combination with Expandable Graphite as a Novel Flame Retardant System for Rigid Polyurethane Foams. Polym. Adv. Technol. 2014, 25, 1034–1043. [Google Scholar] [CrossRef]

- Pang, X.; Chang, R.; Weng, M. Halogen-free Flame Retarded Rigid Polyurethane Foam: The Influence of Titanium Dioxide Modified Expandable Graphite and Ammonium Polyphosphate on Flame Retardancy and Thermal Stability. Polym. Eng. Sci. 2018, 58, 2008–2018. [Google Scholar] [CrossRef]

- Wang, J.; Xu, B.; Wang, X.; Liu, Y. A Phosphorous-Based Bi-Functional Flame Retardant for Rigid Polyurethane Foam. Polym. Degrad. Stab. 2021, 186, 109516. [Google Scholar] [CrossRef]

- Chen, Y.; Li, L.; Wu, X. Construction of an Efficient Ternary Flame Retardant System for Rigid Polyurethane Foam Based on Bi-phase Flame Retardant Effect. Polym. Adv. Technol. 2020, 31, 3202–3210. [Google Scholar] [CrossRef]

- Tang, G.; Liu, X.; Zhou, L.; Zhang, P.; Deng, D.; Jiang, H. Steel Slag Waste Combined with Melamine Pyrophosphate as a Flame Retardant for Rigid Polyurethane Foams. Adv. Powder Technol. 2020, 31, 279–286. [Google Scholar] [CrossRef]

- Yuan, Y.; Ma, C.; Shi, Y.; Song, L.; Hu, Y.; Hu, W. Highly-Efficient Reinforcement and Flame Retardancy of Rigid Polyurethane Foam with Phosphorus-Containing Additive and Nitrogen-Containing Compound. Mater. Chem. Phys. 2018, 211, 42–53. [Google Scholar] [CrossRef]

- Chen, Y.; Jia, Z.; Luo, Y.; Jia, D.; Li, B. Environmentally Friendly Flame-Retardant and Its Application in Rigid Polyurethane Foam. Int. J. Polym. Sci. 2014, 2014, 263716. [Google Scholar] [CrossRef]

- Michałowski, S.; Pielichowski, K. 1, 2-Propanediolizobutyl POSS as a Co-Flame Retardant for Rigid Polyurethane Foams. J. Therm. Anal. Calorim. 2018, 134, 1351–1358. [Google Scholar] [CrossRef] [Green Version]

- Acuña, P.; Santiago-Calvo, M.; Villafañe, F.; Rodríguez-Perez, M.A.; Rosas, J.; Wang, D. Impact of Expandable Graphite on Flame Retardancy and Mechanical Properties of Rigid Polyurethane Foam. Polym. Compos. 2019, 40, E1705–E1715. [Google Scholar] [CrossRef]

- Gao, L.; Zheng, G.; Zhou, Y.; Hu, L.; Feng, G. Improved Mechanical Property, Thermal Performance, Flame Retardancy and Fire Behavior of Lignin-Based Rigid Polyurethane Foam Nanocomposite. J. Therm. Anal. Calorim. 2015, 120, 1311–1325. [Google Scholar] [CrossRef]

- Akdogan, E.; Erdem, M.; Ureyen, M.E.; Kaya, M. Rigid Polyurethane Foams with Halogen-free Flame Retardants: Thermal Insulation, Mechanical, and Flame Retardant Properties. J. Appl. Polym. Sci. 2020, 137, 47611. [Google Scholar] [CrossRef]

- Liu, D.; Zhao, B.; Wang, J.; Liu, P.; Liu, Y. Flame Retardation and Thermal Stability of Novel Phosphoramide/Expandable Graphite in Rigid Polyurethane Foam. J. Appl. Polym. Sci. 2018, 135, 46434. [Google Scholar] [CrossRef]

- Bo, G.; Xu, X.; Tian, X.; Wu, J.; He, X.; Xu, L.; Yan, Y. Enhancing the Flame Retardancy for Castor Oil-Based Rigid Polyurethane Foams via Silica Aerogel. J. Non-Cryst. Solids 2021, 562, 120783. [Google Scholar] [CrossRef]

- Salasinska, K.; Borucka, M.; Leszczyńska, M.; Zatorski, W.; Celiński, M.; Gajek, A.; Ryszkowska, J. Analysis of Flammability and Smoke Emission of Rigid Polyurethane Foams Modified with Nanoparticles and Halogen-Free Fire Retardants. J. Therm. Anal. Calorim. 2017, 130, 131–141. [Google Scholar] [CrossRef] [Green Version]

- Zhu, H.; Xu, S. Preparation of Flame-Retardant Rigid Polyurethane Foams by Combining Modified Melamine–Formaldehyde Resin and Phosphorus Flame Retardants. ACS Omega 2020, 5, 9658–9667. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; Feng, Z.; Han, X.; Wang, B.; Yang, S.; Chen, D.; Peng, J.; Yang, Y.; Liu, X.; Tang, G. Effect of Ammonium Polyphosphate/Cobalt Phytate System on Flame Retardancy and Smoke & Toxicity Suppression of Rigid Polyurethane Foam Composites. J. Polym. Res. 2021, 28, 407. [Google Scholar]

- Chen, Y.; Luo, Y.; Guo, X.; Chen, L.; Xu, T.; Jia, D. Structure and Flame-Retardant Actions of Rigid Polyurethane Foams with Expandable Graphite. Polymers 2019, 11, 686. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Czech-Polak, J.; Oliwa, R.; Oleksy, M.; Budzik, G. Rigid Polyurethane Foams with Improved Flame Resistance. Polimery 2018, 63, 115–124. [Google Scholar] [CrossRef]

- Cheng, J.; Qu, W.; Sun, S. Effects of Flame-retardant Flax-fiber on Enhancing Performance of the Rigid Polyurethane Foams. J. Appl. Polym. Sci. 2018, 135, 46436. [Google Scholar] [CrossRef]

- Wrześniewska-Tosik, K.; Ryszkowska, J.; Mik, T.; Wesołowska, E.; Kowalewski, T.; Pałczyńska, M.; Sałasińska, K.; Walisiak, D.; Czajka, A. Composites of Semi-Rigid Polyurethane Foams with Keratin Fibers Derived from Poultry Feathers and Flame Retardant Additives. Polymers 2020, 12, 2943. [Google Scholar] [CrossRef]

- Zhang, M.; Luo, Z.; Zhang, J.; Chen, S.; Zhou, Y. Effects of a Novel Phosphorus–Nitrogen Flame Retardant on Rosin-Based Rigid Polyurethane Foams. Polym. Degrad. Stab. 2015, 120, 427–434. [Google Scholar] [CrossRef]

- Tang, G.; Zhou, L.; Zhang, P.; Han, Z.; Chen, D.; Liu, X.; Zhou, Z. Effect of Aluminum Diethylphosphinate on Flame Retardant and Thermal Properties of Rigid Polyurethane Foam Composites. J. Therm. Anal. Calorim. 2020, 140, 625–636. [Google Scholar] [CrossRef]

- Shi, X.; Jiang, S.; Zhu, J.; Li, G.; Peng, X. Establishment of a Highly Efficient Flame-Retardant System for Rigid Polyurethane Foams Based on Bi-Phase Flame-Retardant Actions. Rsc Adv. 2018, 8, 9985–9995. [Google Scholar] [CrossRef] [Green Version]

- Ye, L.; Meng, X.-Y.; Ji, X.; Li, Z.-M.; Tang, J.-H. Synthesis and Characterization of Expandable Graphite–Poly (Methyl Methacrylate) Composite Particles and Their Application to Flame Retardation of Rigid Polyurethane Foams. Polym. Degrad. Stab. 2009, 94, 971–979. [Google Scholar] [CrossRef]

- Zhang, X.; Ge, L.; Zhang, W.; Tang, J.; Ye, L.; Li, Z. Expandable Graphite-methyl Methacrylate-acrylic Acid Copolymer Composite Particles as a Flame Retardant of Rigid Polyurethane Foam. J. Appl. Polym. Sci. 2011, 122, 932–941. [Google Scholar] [CrossRef]

- Hamidov, M.; Çakmakçi, E.; Kahraman, M.V. Autocatalytic Reactive Flame Retardants for Rigid Polyurethane Foams. Mater. Chem. Phys. 2021, 267, 124636. [Google Scholar] [CrossRef]

- Zhao, Q.; Chen, C.; Fan, R.; Yuan, Y.; Xing, Y.; Ma, X. Halogen-Free Flame-Retardant Rigid Polyurethane Foam with a Nitrogen–Phosphorus Flame Retardant. J. Fire Sci. 2017, 35, 99–117. [Google Scholar] [CrossRef]

- Gao, M.; Li, J.; Zhou, X. A Flame Retardant Rigid Polyurethane Foam System Including Functionalized Graphene Oxide. Polym. Compos. 2019, 40, E1274–E1282. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, G.; Yu, F.; Liu, M.; Yang, S.; Tang, G.; Xu, X.; Wang, B.; Liu, X. Flame Retardant Rigid Polyurethane Foam Composites Based on Iron Tailings and Aluminum Phosphate: A Novel Strategy for Utilizing Industrial Solid Wastes. Polym. Adv. Technol. 2021, 32, 4826–4839. [Google Scholar] [CrossRef]

- Tian, H.; Yao, Y.; Zhang, S.; Wang, Y.; Xiang, A. Enhanced Thermal Stability and Flame Resistance of Rigid Polyurethane-Imide Foams by Varying Copolymer Composition. Polym. Test. 2018, 67, 68–74. [Google Scholar] [CrossRef]

- Luo, F.; Wu, K.; Li, Y.; Zheng, J.; Guo, H.; Lu, M. Reactive Flame Retardant with Core-shell Structure and Its Flame Retardancy in Rigid Polyurethane Foam. J. Appl. Polym. Sci. 2015, 132, 42800. [Google Scholar] [CrossRef]

- Tang, Z.; Maroto-Valer, M.M.; Andrésen, J.M.; Miller, J.W.; Listemann, M.L.; McDaniel, P.L.; Morita, D.K.; Furlan, W.R. Thermal Degradation Behavior of Rigid Polyurethane Foams Prepared with Different Fire Retardant Concentrations and Blowing Agents. Polymer 2002, 43, 6471–6479. [Google Scholar] [CrossRef]

- Wang, S.-X.; Zhao, H.-B.; Rao, W.-H.; Huang, S.-C.; Wang, T.; Liao, W.; Wang, Y.-Z. Inherently Flame-Retardant Rigid Polyurethane Foams with Excellent Thermal Insulation and Mechanical Properties. Polymer 2018, 153, 616–625. [Google Scholar] [CrossRef]

- Akdogan, E.; Erdem, M.; Ureyen, M.E.; Kaya, M. Synergistic Effects of Expandable Graphite and Ammonium Pentaborate Octahydrate on the Flame-retardant, Thermal Insulation, and Mechanical Properties of Rigid Polyurethane Foam. Polym. Compos. 2020, 41, 1749–1762. [Google Scholar] [CrossRef]

- Tang, G.; Jiang, H.; Yang, Y.; Chen, D.; Liu, C.; Zhang, P.; Zhou, L.; Huang, X.; Zhang, H.; Liu, X. Preparation of Melamine–Formaldehyde Resin-Microencapsulated Ammonium Polyphosphate and Its Application in Flame Retardant Rigid Polyurethane Foam Composites. J. Polym. Res. 2020, 27, 375. [Google Scholar] [CrossRef]

- Ranaweera, C.; Ionescu, M.; Bilic, N.; Wan, X.; Kahol, P.; Gupta, R.K. Biobased Polyols Using Thiol-Ene Chemistry for Rigid Polyurethane Foams with Enhanced Flame-Retardant Properties. J. Renew. Mater. 2017, 5, 1–12. [Google Scholar] [CrossRef]

- Huang, Y.; Jiang, S.; Liang, R.; Liao, Z.; You, G. A Green Highly-Effective Surface Flame-Retardant Strategy for Rigid Polyurethane Foam: Transforming UV-Cured Coating into Intumescent Self-Extinguishing Layer. Compos. Part A Appl. Sci. Manuf. 2019, 125, 105534. [Google Scholar] [CrossRef]

- Li, Q.; Wang, J.; Chen, L.; Shi, H.; Hao, J. Ammonium Polyphosphate Modified with β-Cyclodextrin Crosslinking Rigid Polyurethane Foam: Enhancing Thermal Stability and Suppressing Flame Spread. Polym. Degrad. Stab. 2019, 161, 166–174. [Google Scholar] [CrossRef]

- Hu, Y.; Zhou, Z.; Li, S.; Yang, D.; Zhang, S.; Hou, Y. Flame Retarded Rigid Polyurethane Foams Composites Modified by Aluminum Diethylphosphinate and Expanded Graphite. Front. Mater. 2021, 471, 629284. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, M.; Zhou, Y.; Hu, L. The Study of Mechanical Behavior and Flame Retardancy of Castor Oil Phosphate-Based Rigid Polyurethane Foam Composites Containing Expanded Graphite and Triethyl Phosphate. Polym. Degrad. Stab. 2013, 98, 2784–2794. [Google Scholar] [CrossRef]

- Dong-Mei, X.; Fei, D.; Jian-Wei, H.; Jian-Xin, D. Preparation of Modified Expandable Graphite and Its Flame Retardant Application in Rigid Polyurethane Foam. Chem. J. Chin. Univ.-Chin. 2013, 34, 2674–2680. [Google Scholar]

- Li, L.; Chen, Y.; Qian, L.; Xu, B.; Xi, W. Addition Flame-retardant Effect of Nonreactive Phosphonate and Expandable Graphite in Rigid Polyurethane Foams. J. Appl. Polym. Sci. 2018, 135, 45960. [Google Scholar] [CrossRef]

- Günther, M.; Lorenzetti, A.; Schartel, B. From Cells to Residues: Flame-Retarded Rigid Polyurethane Foams. Combust. Sci. Technol. 2020, 192, 2209–2237. [Google Scholar] [CrossRef]

- Liu, Y.; He, J.; Yang, R. The Synthesis of Melamine-Based Polyether Polyol and Its Effects on the Flame Retardancy and Physical–Mechanical Property of Rigid Polyurethane Foam. J. Mater. Sci. 2017, 52, 4700–4712. [Google Scholar] [CrossRef]

- Acuña, P.; Lin, X.; Calvo, M.S.; Shao, Z.; Pérez, N.; Villafañe, F.; Rodríguez-Pérez, M.Á.; Wang, D.-Y. Synergistic Effect of Expandable Graphite and Phenylphosphonic-Aniline Salt on Flame Retardancy of Rigid Polyurethane Foam. Polym. Degrad. Stab. 2020, 179, 109274. [Google Scholar] [CrossRef]

- Liu, L.; Wang, Z.; Xu, X. Melamine Amino Trimethylene Phosphate as a Novel Flame Retardant for Rigid Polyurethane Foams with Improved Flame Retardant, Mechanical and Thermal Properties. J. Appl. Polym. Sci. 2017, 134, 45234. [Google Scholar] [CrossRef]

- Bian, X.; Tang, J.; Li, Z.; Lu, Z.; Lu, A. Dependence of Flame-retardant Properties on Density of Expandable Graphite Filled Rigid Polyurethane Foam. J. Appl. Polym. Sci. 2007, 104, 3347–3355. [Google Scholar] [CrossRef]

- Bian, X.; Tang, J.; Li, Z. Flame Retardancy of Hollow Glass Microsphere/Rigid Polyurethane Foams in the Presence of Expandable Graphite. J. Appl. Polym. Sci. 2008, 109, 1935–1943. [Google Scholar] [CrossRef]

- Chen, X.; Huang, Z.; Xi, X.; Li, J.; Fan, X.; Wang, Z. Synergistic Effect of Carbon and Phosphorus Flame Retardants in Rigid Polyurethane Foams. Fire Mater. 2018, 42, 447–453. [Google Scholar] [CrossRef]

- Acuña, P.; Zhang, J.; Yin, G.-Z.; Liu, X.-Q.; Wang, D.-Y. Bio-Based Rigid Polyurethane Foam from Castor Oil with Excellent Flame Retardancy and High Insulation Capacity via Cooperation with Carbon-Based Materials. J. Mater. Sci. 2021, 56, 2684–2701. [Google Scholar] [CrossRef]

- Członka, S.; Strąkowska, A.; Strzelec, K.; Kairytė, A.; Kremensas, A. Melamine, Silica, and Ionic Liquid as a Novel Flame Retardant for Rigid Polyurethane Foams with Enhanced Flame Retardancy and Mechanical Properties. Polym. Test. 2020, 87, 106511. [Google Scholar] [CrossRef]

- Jia, D.; Tong, Y.; Hu, J. The Effects of N, N-(Pyromellitoyl)-Bis-l-Phenylalanine Diacid Ester Glycol on the Flame Retardancy and Physical–Mechanical Properties of Rigid Polyurethane Foams. J. Fire Sci. 2018, 36, 535–545. [Google Scholar] [CrossRef]

- Cheng, J.; Shi, B.; Zhou, F.; Chen, X. Effects of Inorganic Fillers on the Flame-retardant and Mechanical Properties of Rigid Polyurethane Foams. J. Appl. Polym. Sci. 2014, 131, 40253. [Google Scholar] [CrossRef]

- Li, J.; Mo, X.; Li, Y.; Zou, H.; Liang, M.; Chen, Y. Influence of Expandable Graphite Particle Size on the Synergy Flame Retardant Property between Expandable Graphite and Ammonium Polyphosphate in Semi-Rigid Polyurethane Foam. Polym. Bull. 2018, 75, 5287–5304. [Google Scholar] [CrossRef]

- Barikani, M.; Askari, F.; Barmar, M. A Comparison of the Effect of Different Flame Retardants on the Compressive Strength and Fire Behaviour of Rigid Polyurethane Foams. Cell. Polym. 2010, 29, 343–358. [Google Scholar] [CrossRef]

- Li, L.; Chen, Y.; Wu, X.; Xu, B.; Qian, L. Bi-phase Flame-retardant Effect of Dimethyl Methylphosphonate and Modified Ammonium Polyphosphate on Rigid Polyurethane Foam. Polym. Adv. Technol. 2019, 30, 2721–2728. [Google Scholar] [CrossRef]

- Lin, Z.; Zhao, Q.; Fan, R.; Yuan, X.; Tian, F. Flame Retardancy and Thermal Properties of Rigid Polyurethane Foam Conjugated with a Phosphorus–Nitrogen Halogen-Free Intumescent Flame Retardant. J. Fire Sci. 2020, 38, 235–252. [Google Scholar] [CrossRef]

- Pang, X.; Xin, Y.; Shi, X.; Xu, J. Effect of Different Size-modified Expandable Graphite and Ammonium Polyphosphate on the Flame Retardancy, Thermal Stability, Physical, and Mechanical Properties of Rigid Polyurethane Foam. Polym. Eng. Sci. 2019, 59, 1381–1394. [Google Scholar] [CrossRef]

- Jia, D.; Guo, X.; He, J.; Yang, R. An Anti-Melt Dripping, High Char Yield and Flame-Retardant Polyether Rigid Polyurethane Foam. Polym. Degrad. Stab. 2019, 167, 189–200. [Google Scholar] [CrossRef]

- Yang, H.; Liu, H.; Jiang, Y.; Chen, M.; Wan, C. Density Effect on Flame Retardancy, Thermal Degradation, and Combustibility of Rigid Polyurethane Foam Modified by Expandable Graphite or Ammonium Polyphosphate. Polymers 2019, 11, 668. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, X.; Li, J.; Gao, M. Thermal Degradation and Flame Retardant Mechanism of the Rigid Polyurethane Foam Including Functionalized Graphene Oxide. Polymers 2019, 11, 78. [Google Scholar] [CrossRef] [Green Version]

- Liu, L.; Wang, Z. Synergistic Effect of Nano Magnesium Amino-Tris-(Methylenephosphonate) and Expandable Graphite on Improving Flame Retardant, Mechanical and Thermal Insulating Properties of Rigid Polyurethane Foam. Mater. Chem. Phys. 2018, 219, 318–327. [Google Scholar] [CrossRef]

- Wu, S.; Deng, D.; Zhou, L.; Zhang, P.; Tang, G. Flame Retardancy and Thermal Degradation of Rigid Polyurethane Foams Composites Based on Aluminum Hypophosphite. Mater. Res. Express 2019, 6, 105365. [Google Scholar] [CrossRef]

- Li, A.; Yang, D.; Li, H.; Jiang, C.; Liang, J. Flame-retardant and Mechanical Properties of Rigid Polyurethane Foam/MRP/Mg (OH) 2/GF/HGB Composites. J. Appl. Polym. Sci. 2018, 135, 46551. [Google Scholar] [CrossRef]

- Huang, X.; Wang, C.; Gao, J.; Zhou, Z.; Tang, G.; Wang, C. Research on Two Sides Horizontal Flame Spread over Rigid Polyurethane with Different Flame Retardants. J. Therm. Anal. Calorim. 2021, 146, 2141–2150. [Google Scholar] [CrossRef]

- Zhou, Y.; Xiao, H.; Yan, W.; An, W.; Jiang, L.; Sun, J. Horizontal Flame Spread Characteristics of Rigid Polyurethane and Molded Polystyrene Foams under Externally Applied Radiation at Two Different Altitudes. Fire Technol. 2015, 51, 1195–1216. [Google Scholar] [CrossRef]

- Xu, W.; Liu, L.; Wang, S.; Hu, Y. Synergistic Effect of Expandable Graphite and Aluminum Hypophosphite on Flame-retardant Properties of Rigid Polyurethane Foam. J. Appl. Polym. Sci. 2015, 132, 42842. [Google Scholar] [CrossRef]

- Wang, C.; Wu, Y.; Li, Y.; Shao, Q.; Yan, X.; Han, C.; Wang, Z.; Liu, Z.; Guo, Z. Flame-retardant Rigid Polyurethane Foam with a Phosphorus-nitrogen Single Intumescent Flame Retardant. Polym. Adv. Technol. 2018, 29, 668–676. [Google Scholar] [CrossRef]

- Tsuyumoto, I.; Onoda, Y.; Hashizume, F.; Kinpara, E. Flame-retardant Rigid Polyurethane Foams Prepared with Amorphous Sodium Polyborate. J. Appl. Polym. Sci. 2011, 122, 1707–1711. [Google Scholar] [CrossRef]

- Wu, N.; Niu, F.; Lang, W.; Yu, J.; Fu, G. Synthesis of Reactive Phenylphosphoryl Glycol Ether Oligomer and Improved Flame Retardancy and Mechanical Property of Modified Rigid Polyurethane Foams. Mater. Des. 2019, 181, 107929. [Google Scholar] [CrossRef]

- Xi, W.; Qian, L.; Li, L. Flame Retardant Behavior of Ternary Synergistic Systems in Rigid Polyurethane Foams. Polymers 2019, 11, 207. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Y.; Bu, R.; Gong, J.; Yan, W.; Fan, C. Experimental Investigation on Downward Flame Spread over Rigid Polyurethane and Extruded Polystyrene Foams. Exp. Therm. Fluid Sci. 2018, 92, 346–352. [Google Scholar] [CrossRef]

- Zhou, Y.; Gong, J.; Jiang, L.; Chen, C. Orientation Effect on Upward Flame Propagation over Rigid Polyurethane Foam. Int. J. Therm. Sci. 2018, 132, 86–95. [Google Scholar] [CrossRef]

- Zhang, X.; Duan, H.; Yan, D.; Kang, L.; Zhang, W.; Tang, J.; Li, Z. A Facile Strategy to Fabricate Microencapsulated Expandable Graphite as a Flame-retardant for Rigid Polyurethane Foams. J. Appl. Polym. Sci. 2015, 132, 42364. [Google Scholar] [CrossRef]

- Shi, L.; Li, Z.-M.; Yang, M.-B.; Yin, B.; Zhou, Q.-M.; Tian, C.-R.; Wang, J.-H. Expandable Graphite for Halogen-Free Flame-Retardant of High-Density Rigid Polyurethane Foams. Polym.-Plast. Technol. Eng. 2005, 44, 1323–1337. [Google Scholar] [CrossRef]

- Zhang, C.; Bhoyate, S.; Ionescu, M.; Kahol, P.; Gupta, R.K. Highly Flame Retardant and Bio-based Rigid Polyurethane Foams Derived from Orange Peel Oil. Polym. Eng. Sci. 2018, 58, 2078–2087. [Google Scholar] [CrossRef]

- Duan, H.; Kang, H.; Zhang, W.; Ji, X.; Li, Z.; Tang, J. Core–Shell Structure Design of Pulverized Expandable Graphite Particles and Their Application in Flame-retardant Rigid Polyurethane Foams. Polym. Int. 2014, 63, 72–83. [Google Scholar] [CrossRef]

- Wang, X.; Yang, K.; Wang, Y. Physical and Chemical Effects of Diethyl N, N′-diethanolaminomethylphosphate on Flame Retardancy of Rigid Polyurethane Foam. J. Appl. Polym. Sci. 2001, 82, 276–282. [Google Scholar] [CrossRef]

- Cheng, J.; Ma, D.; Li, S.; Qu, W.; Wang, D. Preparation of Zeolitic Imidazolate Frameworks and Their Application as Flame Retardant and Smoke Suppression Agent for Rigid Polyurethane Foams. Polymers 2020, 12, 347. [Google Scholar] [CrossRef] [Green Version]

- Zhao, B.; Liu, D.-Y.; Liang, W.-J.; Li, F.; Wang, J.-S.; Liu, Y.-Q. Bi-Phase Flame-Retardant Actions of Water-Blown Rigid Polyurethane Foam Containing Diethyl-N, N-Bis (2-Hydroxyethyl) Phosphoramide and Expandable Graphite. J. Anal. Appl. Pyrolysis 2017, 124, 247–255. [Google Scholar] [CrossRef]

- Xi, W.; Qian, L.; Chen, Y.; Wang, J.; Liu, X. Addition Flame-Retardant Behaviors of Expandable Graphite and [Bis (2-Hydroxyethyl) Amino]-Methyl-Phosphonic Acid Dimethyl Ester in Rigid Polyurethane Foams. Polym. Degrad. Stab. 2015, 122, 36–43. [Google Scholar] [CrossRef]

- Qian, L.; Feng, F.; Tang, S. Bi-Phase Flame-Retardant Effect of Hexa-Phenoxy-Cyclotriphosphazene on Rigid Polyurethane Foams Containing Expandable Graphite. Polymer 2014, 55, 95–101. [Google Scholar] [CrossRef]

- Xi, W.; Qian, L.; Huang, Z.; Cao, Y.; Li, L. Continuous Flame-Retardant Actions of Two Phosphate Esters with Expandable Graphite in Rigid Polyurethane Foams. Polym. Degrad. Stab. 2016, 130, 97–102. [Google Scholar] [CrossRef]

- Chen, Y.; Li, L.; Wang, W.; Qian, L. Preparation and Characterization of Surface-modified Ammonium Polyphosphate and Its Effect on the Flame Retardancy of Rigid Polyurethane Foam. J. Appl. Polym. Sci. 2017, 134, 45369. [Google Scholar] [CrossRef]

- Wang, Z.; Li, X. Mechanical Properties and Flame Retardancy of Rigid Polyurethane Foams Containing SiO2 Nanospheres/Graphene Oxide Hybrid and Dimethyl Methylphosphonate. Polym.-Plast. Technol. Eng. 2018, 57, 884–892. [Google Scholar] [CrossRef]

| No. | Citation | Cited Journal |

|---|---|---|

| 1 | 159 | Journal of Applied Polymer Science |

| 2 | 155 | Polymer Degradation and Stability |

| 3 | 96 | Polymer |

| 4 | 94 | Polymers for Advanced Technologies |

| 5 | 91 | Industrial & Engineering Chemistry Research |

| 6 | 84 | Polymer International |

| 7 | 69 | Journal of Thermal Analysis and Calorimetry |

| 8 | 68 | Fire and Materials |

| 9 | 68 | European Polymer Journal |

| 10 | 61 | Polymer Composites |

| 11 | 59 | Progress in Polymer Science |

| 12 | 57 | Industrial Crops and Products |

| 13 | 54 | RSC Advances |

| 14 | 49 | Journal of Analytical and Applied Pyrolysis |

| 15 | 49 | Composites Science and Technology |

| Year | Journals | Standardizations/Reports |

|---|---|---|

| 2021 | Chemical Engineering and Processing; Current Opinion in Food Science; Chemical Papers; Applied Biochemistry and Biotechnology; Engineering Science; Catalysis Reviews; Applied Sciences; Advanced Science; Environmental Science & Technology Letters; Chemical Society Reviews; ES Energy & Environment; ACS Materials Letters; Energy Procedia; Additive Manufacturing; Reviews on Environmental Health; Journal of Cleaner Production; The Journal of Supercritical Fluids; Materials Science and Engineering: C; Waste Management; Materials Research Express; Molecules; ACS Omega | CEN/TC 127N1424 |

| 2020 | Advances in Cement Research; Adsorption Science & Technology; Austral Ecology; Bulletin of Materials Science; Agronomy; Archives of Materials Science and Engineering; Advances in Polymer Technology; Advances in Materials Science and Engineering; Advances in Civil Engineering; Applied Mechanics and Materials; Plastics, Rubber and Composites; Applied Acoustics; Isi Bilimi Ve Teknigi Dergisi; Journal of Coatings Technology and Research; Journal of Porous Materials; Experimental Thermal and Fluid Science; Solar Energy Materials & Solar Cells; International Journal of Heat and Mass Transfer; Surface and Coatings Technology; Advances in Polymer Technology; Advances in Materials Science and Engineering; Advanced Powder Technology; Materials | ISO: 566012015; ISO: 8442014; ISO: 458922017; ISO: 1135742014; NISTIR:4664; ISO: 83011991; IOS: 8452009 |

| No. | Freq | Centrality | Keywords |

|---|---|---|---|

| 1 | 54 | 0.19 | Expandable graphite |

| 2 | 44 | 0.22 | Mechanical property |

| 3 | 42 | 0.24 | Behavior |

| 4 | 39 | 0.10 | Composite |

| 5 | 34 | 0.10 | Phosphorus |

| 6 | 28 | 0.08 | Ammonium polyphosphate |

| 7 | 26 | 0.05 | Fire behavior |

| 8 | 26 | 0.09 | Thermal degradation |

| 9 | 21 | 0.08 | Density |

| 10 | 21 | 0.06 | Degradation |

| 11 | 20 | 0.11 | Nanocomposite |

| 12 | 18 | 0.04 | Polyol |

| 13 | 17 | 0.16 | Flammability |

| 14 | 14 | 0.03 | Stability |

| 15 | 13 | 0.04 | Combustion |

| Cluster ID | Size | Silhouette | Keywords | References |

|---|---|---|---|---|

| 0 | 50 | 0.867 | Expandable graphite; Mechanical property; Composite; Ammonium polyphosphate; Density; Degradation; Polyol; Flammability; Combustion; Thermal stability | [69,70,71,72,73,74,75,76,77,78,79,80,81,82,83,84,85,86,87,88,89,90,91,92,93,94,95,96,97,98] |

| 1 | 25 | 0.872 | Epoxy resin; Graphene; Thermal property; DOPO; Nanoparticle; RPUF; Silica; Formulation; Hypophosphite; Styrene | [47,99,100,101,102,103,104,105] |

| 2 | 24 | 0.854 | Stability; Oil; Phosphazene; Polypropylene Dimethylmethyl phosphonate; Montmorillonite; Fire hazard; Thermoplastic polyurethane | [46,76,106,107,108,109,110,111,112,113] |

| 3 | 24 | 0.955 | Polymer; System; Chemical; Property; Construction; Retardant behavior; Aluminum; Insulation | [114,115,116,117,118,119,120] |

| 4 | 24 | 0.863 | Firebehavior; Nitrogen; Fire retardant; Aluminum hydroxide; Nanocomposite foam; Layered silicate; Phosphorus containing compound | [70,78,79,121,122,123,124] |

| 5 | 24 | 0.907 | Behavior; Phosphorus; Performance; Particle; Mechanism | [33,71,73,76,79,84,85,109,125,126,127,128,129,130,131,132,133,134,135,136,137,138] |

| 6 | 23 | 0.930 | Nanocomposite; Combination; Polyphosphate; PU foam; Foam | [35,82,100,139,140,141,142,143,144,145,146] |

| 7 | 22 | 0.852 | Thermal degradation; Fire behavior; Fire retardancy; Halogen free; Thermal decomposition; Additive; Dimethyl methylphosphonate | [75,81,106,129,130,132,134,145,146,147,148,149] |

| 8 | 13 | 0.913 | Cyclotriphosphazene; Insulation material; Sample width; Thermal insulation; PMMA surface | [150,151] |

| 9 | 13 | 0.940 | Coating; Composite particle; Graphite; Thermal conductivity | [87,152,153,154,155] |

| 10 | 12 | 0.910 | Phosphate; Graphene oxide; Phase change material; Oxide | [68,71,83,156] |

| 11 | 11 | 0.972 | fabrication; Agent; Fire safety; Silicon | [47,157] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, Y.; Yin, C.; Fernandez, C.; Fu, L.; Lin, C.-T. A Systematic Review and Bibliometric Analysis of Flame-Retardant Rigid Polyurethane Foam from 1963 to 2021. Polymers 2022, 14, 3011. https://doi.org/10.3390/polym14153011

Pan Y, Yin C, Fernandez C, Fu L, Lin C-T. A Systematic Review and Bibliometric Analysis of Flame-Retardant Rigid Polyurethane Foam from 1963 to 2021. Polymers. 2022; 14(15):3011. https://doi.org/10.3390/polym14153011

Chicago/Turabian StylePan, Ying, Chengliang Yin, Carlos Fernandez, Li Fu, and Cheng-Te Lin. 2022. "A Systematic Review and Bibliometric Analysis of Flame-Retardant Rigid Polyurethane Foam from 1963 to 2021" Polymers 14, no. 15: 3011. https://doi.org/10.3390/polym14153011

APA StylePan, Y., Yin, C., Fernandez, C., Fu, L., & Lin, C.-T. (2022). A Systematic Review and Bibliometric Analysis of Flame-Retardant Rigid Polyurethane Foam from 1963 to 2021. Polymers, 14(15), 3011. https://doi.org/10.3390/polym14153011