Effects of MWCNTs on Char Layer Structure and Physicochemical Reaction in Ethylene Propylene Diene Monomer Insulators

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Preparation of EPDM-Based Insulators

2.3. Characterization and Tests

2.3.1. Ablation Tests

2.3.2. Thermal Stability and Thermal Conductivity Test

2.3.3. Morphology Observation

2.3.4. Mechanical Property

2.3.5. Component Analysis

3. Results and Discussion

3.1. Dispersion of MWCNTs and Thermal Stability of EPDM-Based Insulators

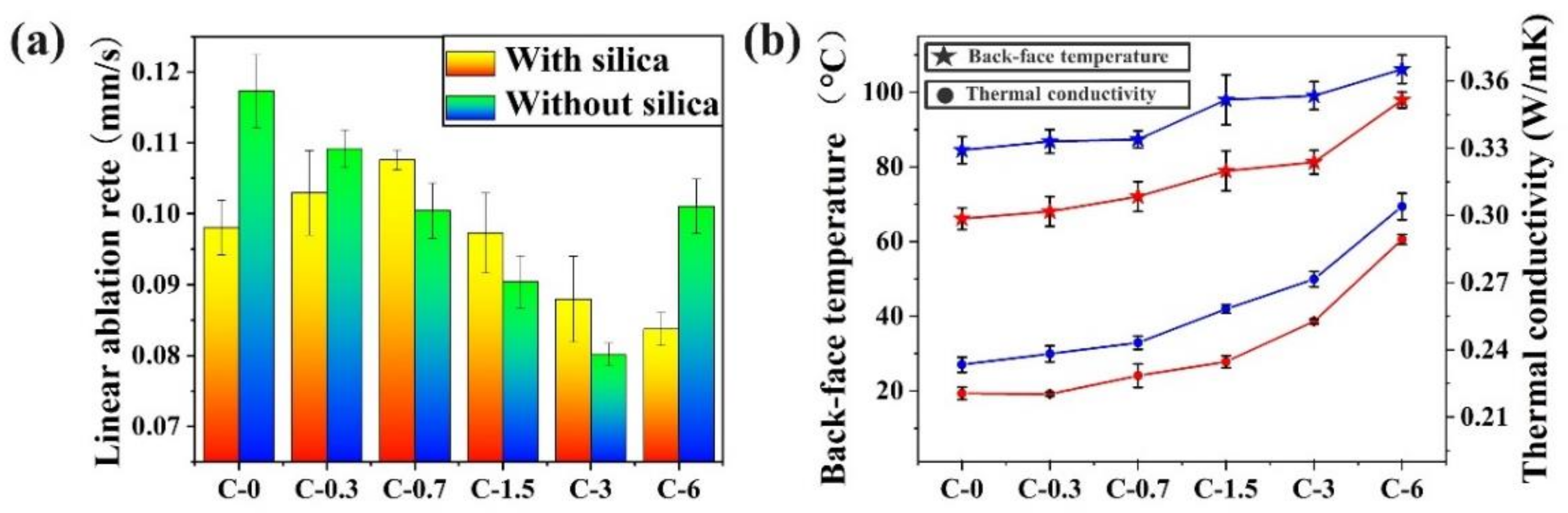

3.2. Ablative Resistance and Thermal Insulation Performance of EPDM-Based Insulators

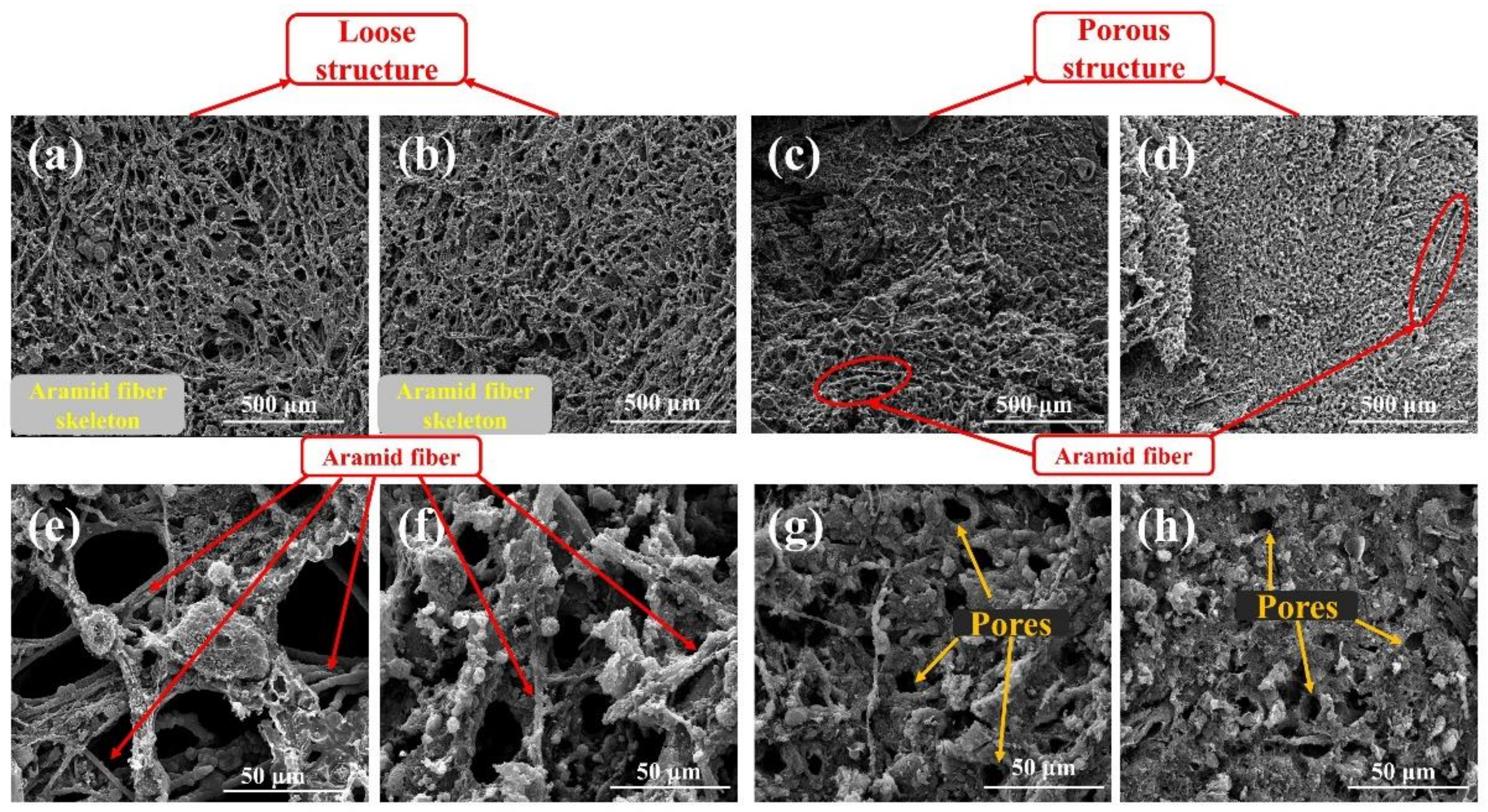

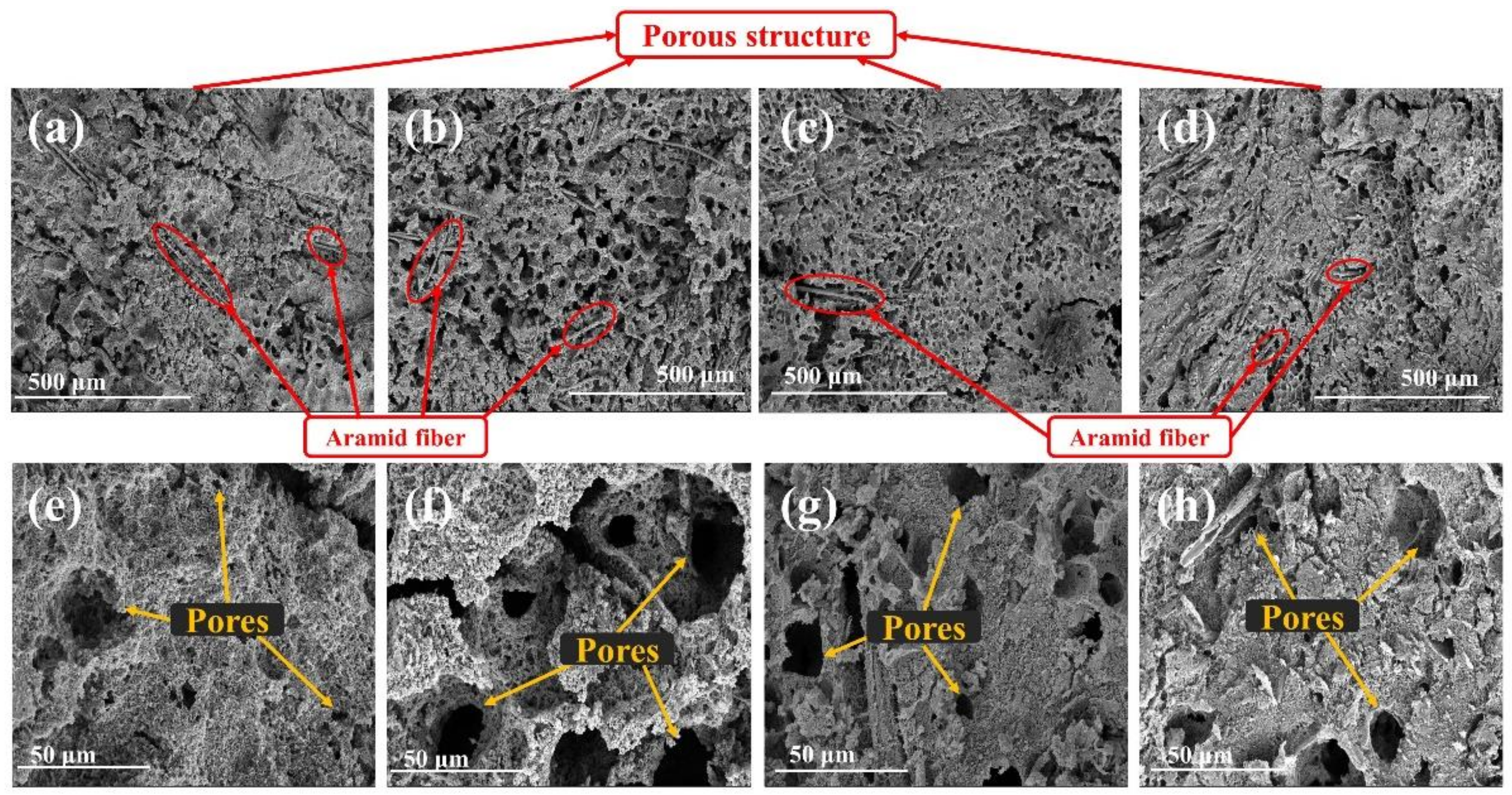

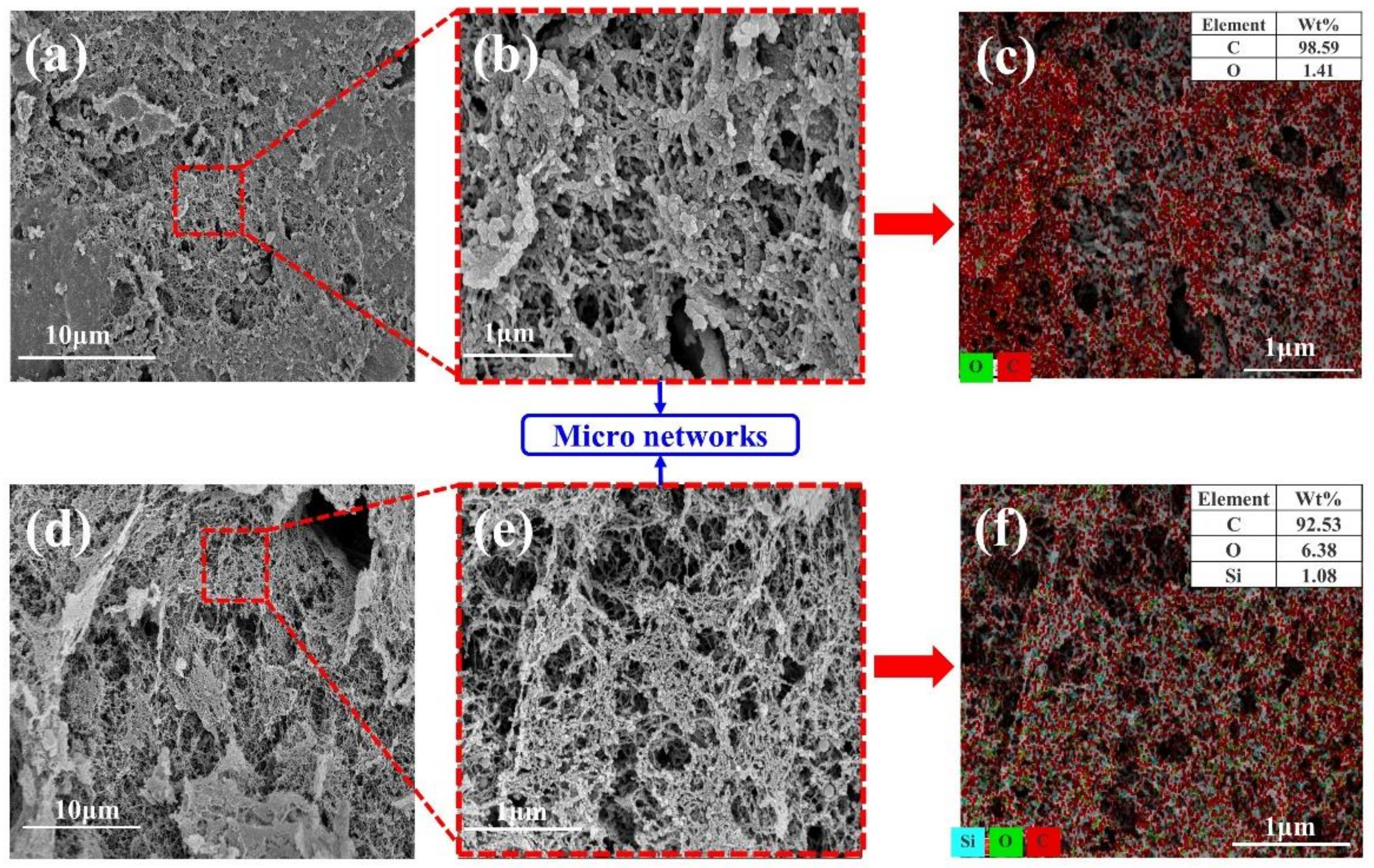

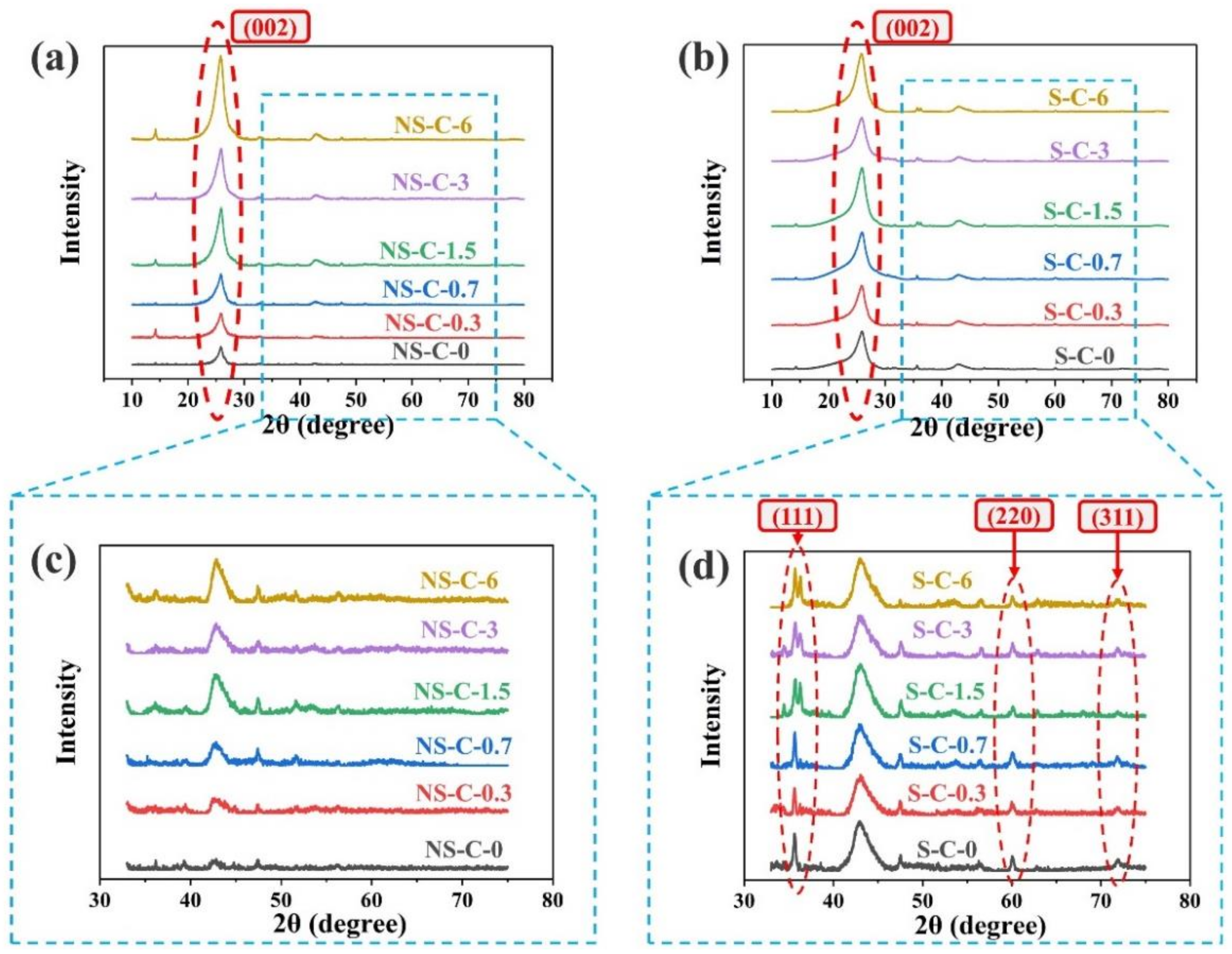

3.3. Morphological Analysis and Component Analysis of Char Layers

3.4. Compression Property and Component Analysis of Char Layers

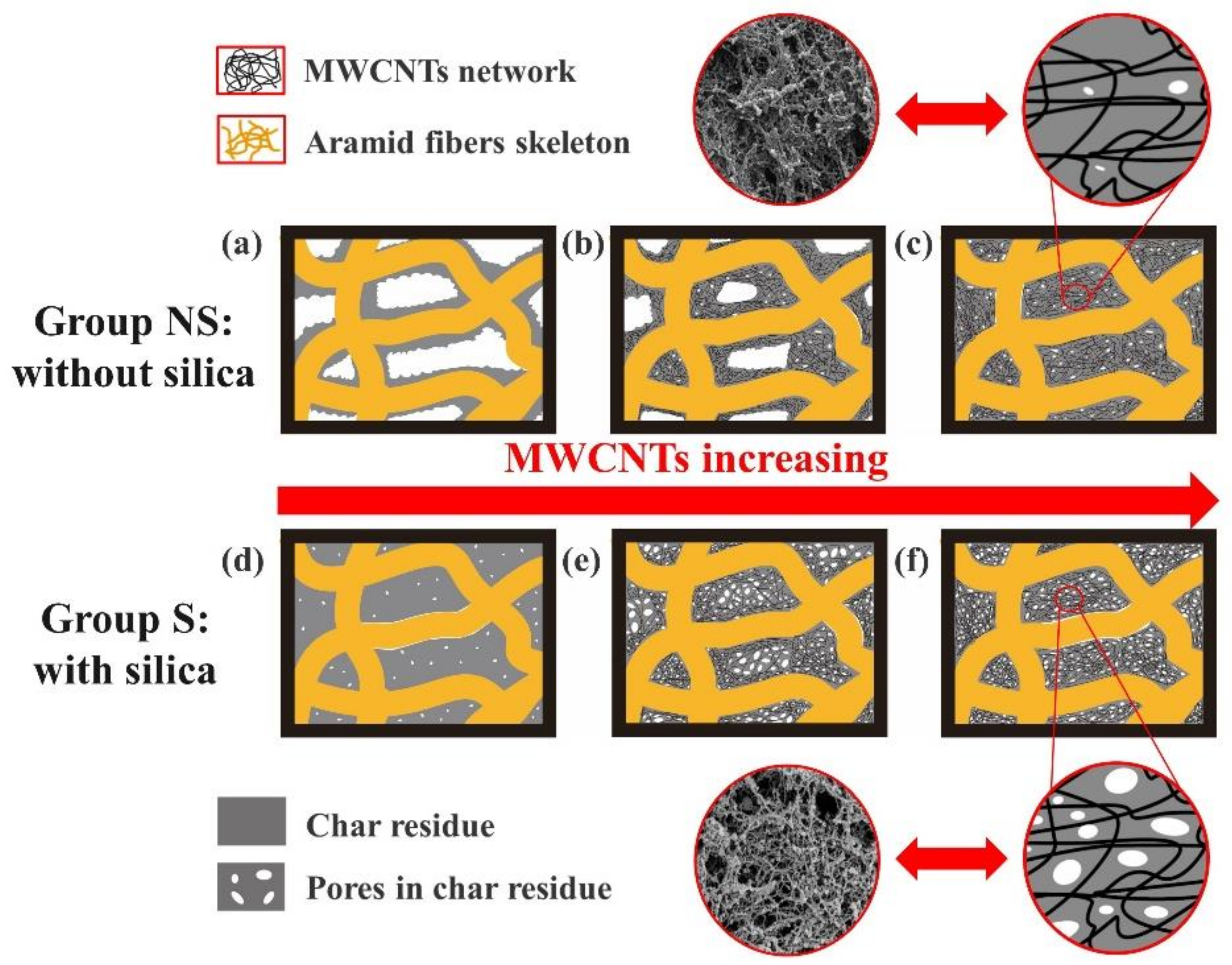

3.5. Ablation Mechanism

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Natali, M.; Kenny, J.M.; Torre, L. Science and technology of polymeric ablative materials for thermal protection systems and propulsion devices: A review. Prog. Mater. Sci. 2016, 84, 202–275. [Google Scholar] [CrossRef]

- Jia, Y.; Yao, X.; Sun, J.; Li, H. Effect of ZrC particle size on the ablation resistance of C/C-ZrC-SiC composites. Mater. Des. 2020, 191, 108623. [Google Scholar] [CrossRef]

- Li, K.; Shen, X.; Li, H.; Zhang, S.; Zhang, L. Ablation of the carbon/carbon composite nozzle-throats in a small solid rocket motor. Carbon 2011, 49, 1208–1215. [Google Scholar] [CrossRef]

- Shen, L.; Wu, H.; Guo, S. Improvement of hardness and compression set properties of EPDM seals with alternating multilayered structure for PEM fuel cells. Int. J. Hydrogen Energy 2016, 41, 23164–23172. [Google Scholar] [CrossRef]

- Rallini, M.; Puri, I.; Torre, L.; Natali, M. Boron based fillers as char enhancers of EPDM based heat shielding materials for SRMs: A comparative analysis. Compos. Struct. 2018, 198, 73–83. [Google Scholar] [CrossRef]

- Natali, M.; Rallini, M.; Torre, L. Effect of Wollastonite on the ablation resistance of EPDM based elastomeric heat shielding materials for solid rocket motors. Polym. Degrad. Stabil. 2016, 130, 47–57. [Google Scholar] [CrossRef]

- Hao, H.; Zhou, X.; Shen, Z.; He, J.; Yang, R. Study on the ablative properties of ethylene propylene diene terpolymer/silsesquioxane insulation materials. J. Appl. Polym. Sci. 2020, 137, 48365. [Google Scholar] [CrossRef]

- Li, J.; Xi, K.; Lv, X.; Li, Q.; Wang, S. Characteristics and formation mechanism of compact/porous structures in char layers of EPDM insulation materials. Carbon 2018, 127, 498–509. [Google Scholar] [CrossRef]

- Rallini, M.; Puri, I.; Torre, L.; Natali, M. Thermal and ablation properties of EPDM based heat shielding materials modified with density reducer fillers. Compos. Appl. Sci. Manuf. 2018, 112, 71–80. [Google Scholar] [CrossRef]

- Dimitrienko, Y. Modeling of erosion combustion of energetic materials in high-enthalpy flows. Combust. Flame 1997, 111, 161–174. [Google Scholar] [CrossRef]

- Dimitrienko, Y.; Dimitrienko, I. Effect of thermomechanical erosion on heterogeneous combustion of composite materials in high-speed flows. Combust. Flame 2000, 122, 211–226. [Google Scholar] [CrossRef]

- Jia, X.; Li, G.; Sui, G.; Li, P.; Yu, Y.; Liu, H.; Yang, X. Effects of pretreated polysulfonamide pulp on the ablation behavior of EPDM composites. Mater. Chem. Phys. 2008, 112, 823–830. [Google Scholar] [CrossRef]

- Gao, G.; Zhang, Z.; Li, X.; Meng, Q.; Zheng, Y. An excellent ablative composite based on PBO reinforced EPDM. Polym. Bull. 2010, 64, 607–622. [Google Scholar] [CrossRef]

- Han, Z.; Qi, S.; Liu, W.; Han, E.; Wu, Z.; Wu, D. Surface-modified polyimide fiber-filled ethylenepropylenediene monomer insulations for a solid rocket motor: Processing, morphology, and properties. Ind. Eng. Chem. Res. 2013, 52, 1284–1290. [Google Scholar] [CrossRef]

- Ji, Y.; Han, S.D.; Xia, L.C.; Li, C.H.; Wu, H.; Guo, S. Synergetic effect of aramid fiber and carbon fiber to enhance ablative resistance of EPDM-based insulators via constructing high-strength char layer. Compos. Sci. Technol. 2021, 201, 108494. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, P.; Ali, S.; Akram, R.; Wu, D.; Wu, Z. Effects of PAN-based carbon fibers and its precursors on ethylenepropylenediene monomer insulations: Morphology and properties. Polym. Compos. 2018, 39, 3336–3340. [Google Scholar] [CrossRef]

- Ding, J.; Huang, Z.X.; Qin, Y.; Shi, M.X.; Huang, C.; Mao, J.W. Improved ablation resistance of carbon-phenolic composites by introducing zirconium silicide particles. Compos. B Eng. 2015, 82, 100–107. [Google Scholar] [CrossRef]

- Li, J.; Liu, K.; Guo, M.; Liu, Y.; Wang, J.; Lv, X. Ablation and erosion characteristics of EPDM composites under SRM operating conditions. Compos. Appl. Sci. Manuf. 2018, 109, 392–401. [Google Scholar] [CrossRef]

- Liu, W.W.; Chai, S.P.; Mohamed, A.R.; Hashim, U. Synthesis and characterization of graphene and carbon nanotubes: A review on the past and recent developments. J. Ind. Eng. Chem. 2014, 20, 1171–1185. [Google Scholar] [CrossRef]

- Seong, J.J.; Minhee, K.; Jee, Y.L.; Young, K.P.; Jae, H.K. Development of Mode-Switchable Touch Sensor Using MWCNT Composite Conductive Nonwoven Fabric. Polymers 2022, 14, 1545. [Google Scholar]

- Giofrè, S.V.; Tiecco, M.; Celesti, C.; Patanè, S.; Triolo, C.; Gulino, A.; Iannazzo, D. Eco-Friendly 1, 3-Dipolar Cycloaddition Reactions on Graphene Quantum Dots in Natural Deep Eutectic Solvent. Nanomaterials 2020, 10, 2549. [Google Scholar] [CrossRef]

- Areeba, K.; Vinars, D.; Mohammed, A.A.; Vineet, T.; Byong, H.J. Advances in the Methods for the Synthesis of Carbon Dots and Their Emerging Applications. Polymers 2021, 13, 3190. [Google Scholar]

- Nunzio, T.; Lorenzo, R.; Agatino, Z.; Luca, S.; Giovanni, L.D.; Gianfranco, S.; Giuseppe, N.; Andrea, P.; Giacomo, C.; Giuseppe, T.S. Functionalized Carbon Nanoparticle-Based Sensors for Chemical Warfare Agents. ACS Appl. Nano Mater. 2020, 3, 8182–8191. [Google Scholar]

- Nunzio, T.; Lucas, S.; Giovanni, L.D.; Andrea, P.; Antonino, G.; Giuseppe, T.S. Supramolecular Sensing of a Chemical Warfare Agents Simulant by Functionalized Carbon Nanoparticles. Molecules 2020, 25, 5731. [Google Scholar]

- Guo, M.F.; Li, J.; Liu, Y.; Ji, J.B. Effect of multi-walled carbon nanotubes on thermal stability and ablation properties of EPDM insulation materials for solid rocket motors. Acta. Astronaut. 2019, 159, 508–516. [Google Scholar] [CrossRef]

- Guo, M.F.; Li, J.; Xi, K.; Liu, Y.; Ji, J.B.; Ye, C.Q. Effects of multi-walled carbon nanotubes on char residue and carbothermal reduction reaction in ethylene propylene diene monomer composites at high temperature. Compos. Sci. Technol. 2020, 186, 107916. [Google Scholar] [CrossRef]

- Li, J.; Hu, B.W.; Hui, K.; Li, K.; Wang, L. Effects of inorganic nanofibers and high char yield fillers on char layer structure and ablation resistance of ethylene propylene diene monomer composites. Compos. Appl. Sci. Manuf. 2021, 150, 106633. [Google Scholar] [CrossRef]

- Guo, M.F.; Li, J.; Wang, Y.W. Effects of carbon nanotubes on char structure and heat transfer in ethylene propylene diene monomer composites at high temperature. Compos. Sci. Technol. 2021, 211, 108852. [Google Scholar] [CrossRef]

- Xi, K.; Li, J.; Wang, Y.W.; Guo, M.F.; Li, K. Thermal insulation and char layer mechanical properties of a novel ethylene propylene diene monomer composite reinforced with carbon nanotubes coated via chemical vapour deposition. Compos. Sci. Technol. 2021, 201, 108537. [Google Scholar] [CrossRef]

- Natali, M.; Monti, M.; Puglia, D.; Kenny, J.M.; Torre, L. Ablative properties of carbon black and MWNT/phenolic composite: A comparative study. Compos. Appl. Sci. Manuf. 2012, 43, 174–182. [Google Scholar] [CrossRef]

- Ko, S.J.; Yum, S.H.; Kim, H.S. Improvement of ablation resistance of epoxy composites reinforced with low concentrations of multi walled carbon nanotubes. Compos. Appl. Sci. Manuf. 2019, 124, 105471. [Google Scholar] [CrossRef]

- Wang, Z.J.; Kwon, D.J.; Gu, G.Y.; Lee, W.I.; Park, J.K.; DeVries, K.L. Ablative and mechanical evaluation of CNT/phenolic composites by thermal and microstructural analyses. Compos. B Eng. 2014, 60, 597–602. [Google Scholar] [CrossRef]

- Wang, S.R.; Qiu, J.J. Enhancing thermal conductivity of glass fiber/polymer composites through carbon nanotubes incorporation. Compos. B Eng. 2010, 41, 533–536. [Google Scholar] [CrossRef]

- Yum, S.H.; Kim, S.H.; Lee, W.I.; Kim, H.S. Improvement of ablation resistance of phenolic composites reinforced with low concentrations of carbon nanotubes. Compos. Sci. Technol. 2015, 121, 16–24. [Google Scholar] [CrossRef]

- Mirzapour, M.; Farshad, Y. Thermal and mechanical properties of phenolic-based composites reinforced by carbon fibres and multiwall carbon nanotubes. Compos. Appl. Sci. Manuf. 2015, 72, 22–31. [Google Scholar]

- Torben, S.; Henriette, L.; Lucas, B.; Melanie, F.; Christian, B.F. Plasma Supported Deposition of AmorphousHydrogenated Carbon (a-C:H) on Polyamide 6:Determining Interlayer Completion and Dehydrogenation Effects during Layer Growth. Polymers 2021, 13, 1886. [Google Scholar]

- Massimo, D.P.; Luca, S.; Dario, T.; Francesco, P.; Maria, E.F.; Corrado, B.; Antonino, G.S. Characterization of Plasma-Etched Trenches on 4H-Sic Wafers. ACS Omega 2021, 6, 20667–20675. [Google Scholar]

| Samples | Char Layer Thickness (mm) | Compress Stress (MPa) Compress Strain 10% |

|---|---|---|

| S-C-0 | 1.57 ± 0.06 | 0.50 ± 0.15 |

| S-C-0.3 | 1.62 ± 0.04 | 0.47 ± 0.22 |

| S-C-0.7 | 1.76 ± 0.06 | 1.26 ± 0.22 |

| S-C-1.5 | 1.90 ± 0.03 | 1.65 ± 0.24 |

| S-C-3 | 2.02 ± 0.02 | 2.07 ± 0.04 |

| S-C-6 | 2.03 ± 0.02 | 2.11 ± 0.08 |

| NS-C-0 | 1.60 ± 0.11 | 0.44 ± 0.13 |

| NS-C-0.3 | 1.89 ± 0.07 | 0.69 ± 0.23 |

| NS-C-0.7 | 1.98 ± 0.04 | 0.93 ± 0.12 |

| NS-C-1.5 | 1.92 ± 0.05 | 1.12 ± 0.11 |

| NS-C-3 | 1.93 ± 0.07 | 1.16 ± 0.27 |

| NS-C-6 | 1.84 ± 0.14 | 1.15 ± 0.25 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Z.; Han, S.; Ji, Y.; Wu, H.; Guo, S.; Yan, N.; Li, H. Effects of MWCNTs on Char Layer Structure and Physicochemical Reaction in Ethylene Propylene Diene Monomer Insulators. Polymers 2022, 14, 3016. https://doi.org/10.3390/polym14153016

Chen Z, Han S, Ji Y, Wu H, Guo S, Yan N, Li H. Effects of MWCNTs on Char Layer Structure and Physicochemical Reaction in Ethylene Propylene Diene Monomer Insulators. Polymers. 2022; 14(15):3016. https://doi.org/10.3390/polym14153016

Chicago/Turabian StyleChen, Zhiheng, Shida Han, Yuan Ji, Hong Wu, Shaoyun Guo, Ning Yan, and Hongyan Li. 2022. "Effects of MWCNTs on Char Layer Structure and Physicochemical Reaction in Ethylene Propylene Diene Monomer Insulators" Polymers 14, no. 15: 3016. https://doi.org/10.3390/polym14153016

APA StyleChen, Z., Han, S., Ji, Y., Wu, H., Guo, S., Yan, N., & Li, H. (2022). Effects of MWCNTs on Char Layer Structure and Physicochemical Reaction in Ethylene Propylene Diene Monomer Insulators. Polymers, 14(15), 3016. https://doi.org/10.3390/polym14153016