Review of Tribological Failure Analysis and Lubrication Technology Research of Wind Power Bearings

Abstract

:1. Introduction

- The common tribological failures of wind turbine bearings are analyzed, and the typical failure modes of bearings are reviewed in detail, specifically in terms of both friction and lubrication. The application of analysis methods such as FTA helps the reader to understand the causes and effects of bearing failures.

- The research and developments in wind turbine bearings lubrication technology are discussed, with the goal of utilizing cutting-edge research techniques to increase predicted bearing life and lessen current tribological failure issues. The study on lubricants for wind turbine bearings, the state of lubrication method research, and the development of lubrication monitoring systems are all thoroughly discussed. To fill the gap left by the existing lubrication methods used on big wind turbine bearings, certain innovative lubrication approaches applied to conventional mechanical bearings are also summarized.

- The remainder of the paper is organized as follows. Section 2 collates the composition, classification and operating conditions of wind turbines and their bearings. Section 3 analyzes the typical tribological failure modes and causes of bearings, and the FTA analysis method is used to provide a summary and generalization. Section 4 presents a detailed overview of recent research on wind power bearings lubrication technology and summarizes the advantages and disadvantages of existing technologies and methods. Finally, Section 5 gives conclusions and provides an outlook on future research trends, which provides a direction for the future development of green lubrication of wind turbine bearings.

2. Wind Turbine and Bearings Composition and Classification

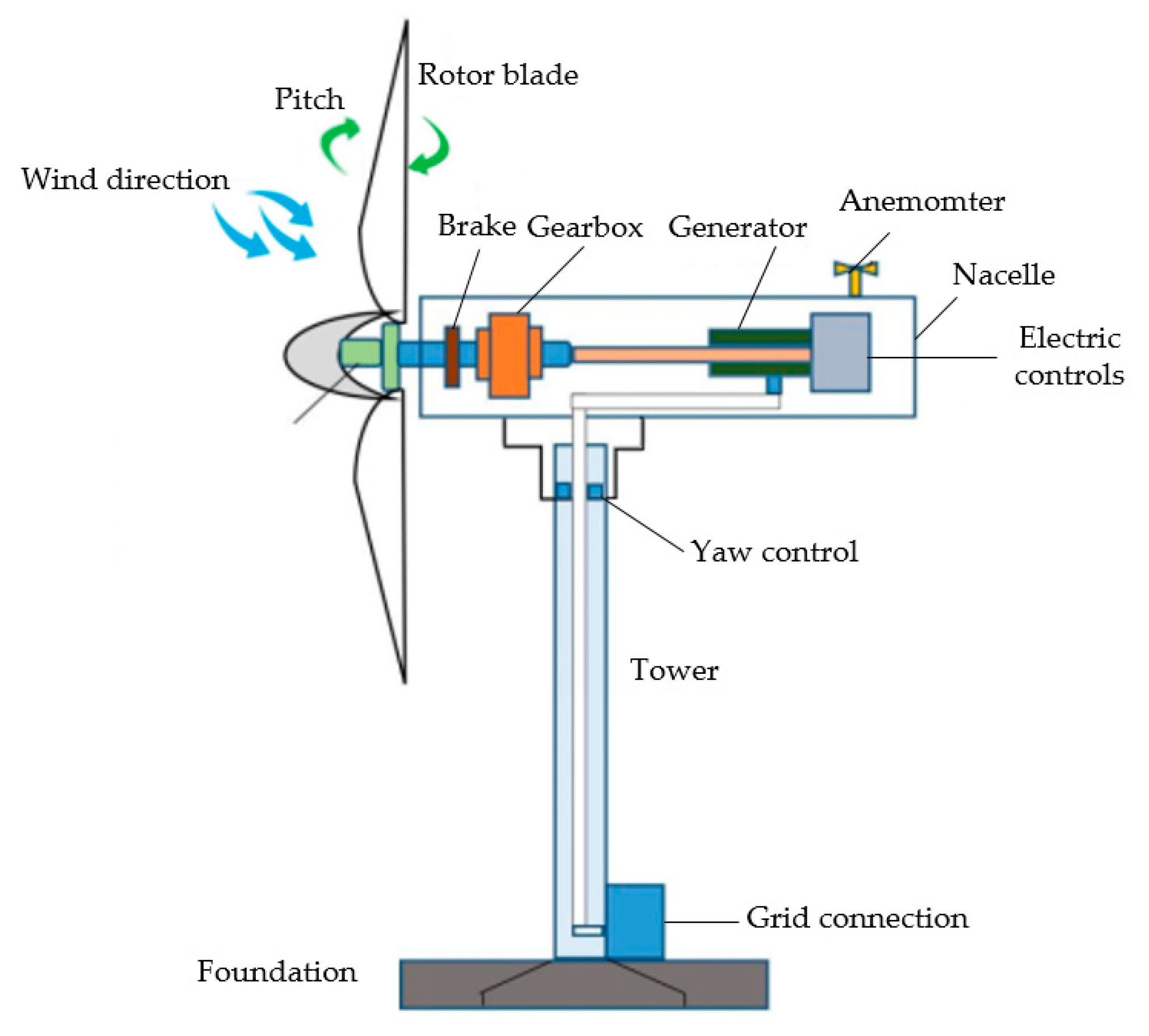

2.1. Composition and Classification of Wind Turbine

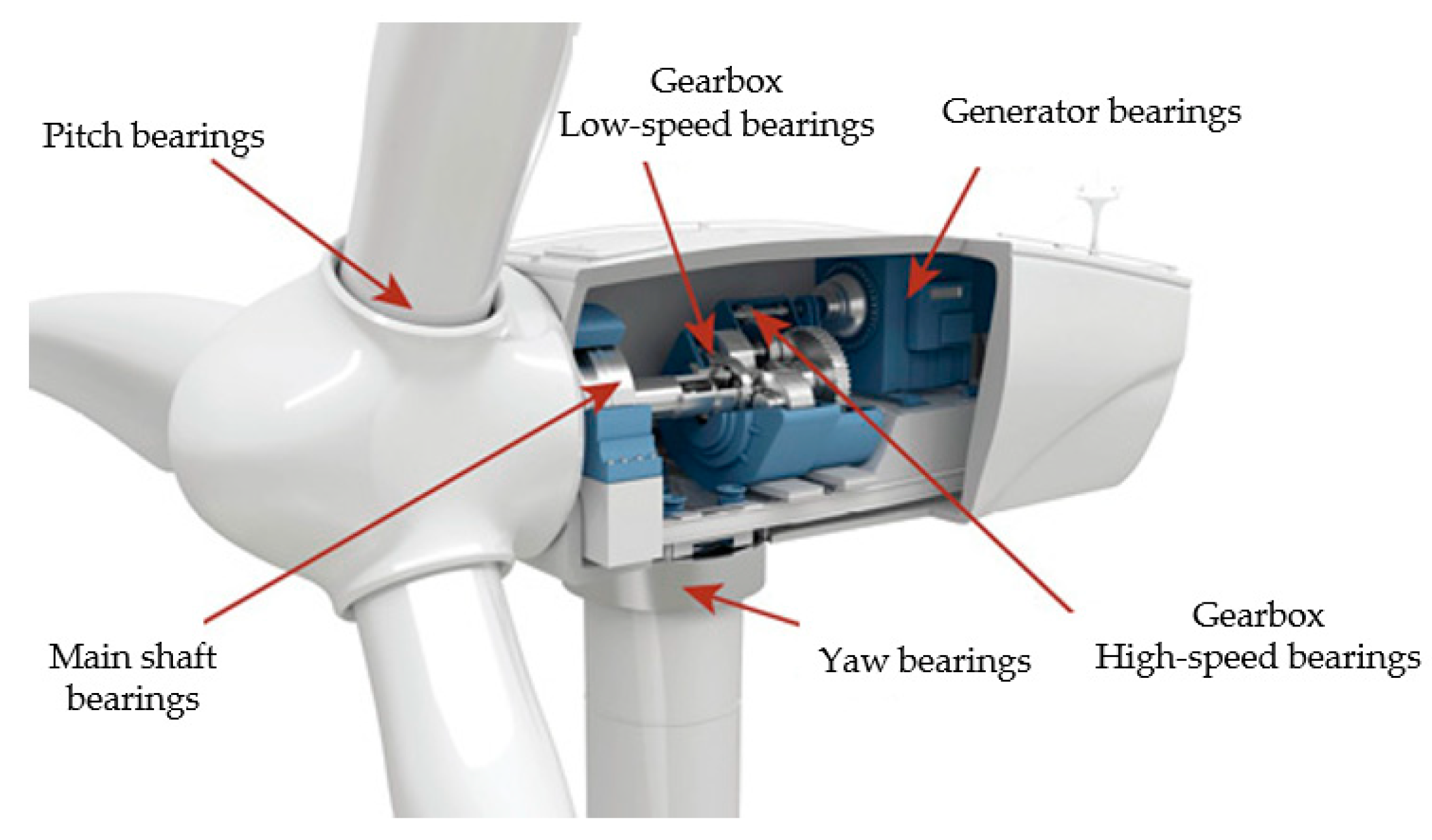

2.2. Composition and Classification of Wind Turbine Bearings

- Main shaft bearing is the central rotating component of the wind turbine [28], which mainly supports the weight of the hub and blades. It requires transmitting the torque generated by the blade to the gearbox. Since the spindle bearing has to bear the alternating load generated by the blade torque and the gravitational load of the blade itself [29], the requirements for its machining accuracy, mechanical performance, and service life are extremely high, and the spindle bearing is required to have good alignment performance, smoothness, and vibration resistance [30]. Therefore, spindle bearings are usually selected from roller bearings with high load carrying capacity (for example: cylinder roller, spherical roller, or conical roller bearings) [31].

- Generator bearing is mainly designed to carry the high-speed rotation of the generator shaft. Cylindrical and spherical rolling ring bearings are commonly used as generator bearings. Through the structural design of these two types of bearings, the requirements of generators for high precision and low noise can be achieved [32,33]. Nevertheless, when selecting raw materials for the bearings, their insulating properties should be considered to avoid damage to the bearings caused by current pitting [34].

- Pitch bearing is being used to adjust the rotation angle of the blades for the purpose of regulating the windward direction of the blades and optimizing the electrical power delivery [35]. Failure of the pitch bearing can lead to loss of blade control, which can further affect the operational performance of the entire system of the wind turbine [36]. Due to the rotation of the hub and the instability of the wind direction and wind speed, the moment that the pitch bearing is subjected to also has time-varying and nonlinear characteristics [37]. Thus, the bearing mostly uses a four-point contact ball rotary bearing; this bearing groove is specifically machined for better wear and impact resistance and can withstand larger axial loads and higher moment loads [38,39,40].

- Yaw bearing is mounted between the tower and nacelle, which not only holds the weight, but also needs to adjust the windward angle of the wind turbine in time according to wind rotation [41] to optimize the power input and generation efficiency [42,43]. Since the yaw bearing is subjected to the impact load of the external wind and the internal overturning moment, the force situation is complicated. Consequently, the types of yaw bearings are generally the same as pitch bearings, i.e., one-row or two-row 4-point contact spherical bearings [44], for decreasing the wear of rolling contact surfaces [45].

- Gearbox bearing is a speed-increasing structure of wind turbines [46], and bearings with specific performance demands are selected for different positions. Thus, its bearings are comparatively large in number and contain various roller bearings and contact ball bearings, etc. [47]. According to the different load types, spindle support methods, and different gear stages, such bearings are provided to withstand shafts with different gear grades in high, medium, and low-speed stages [48]. For the low-speed stage, the bearing has to withstand the load from the main shaft, and cylindrical or tapered roller bearings with high load carrying capacity are typically used. However, medium and high-speed stage bearings only require the endurance of low axial and radial loads, so they regularly select 4-point contact ball, tapered roller, tubular roller, and others with lower loads capacity of bearings [49,50,51].

- Table 2 summarizes the specific application of bearings in different parts of wind turbines.

3. Fault Analysis and Research on Tribological Faults of Wind Turbine Bearings

3.1. Analysis of Common Frictional Failure Problems in Wind Turbine Bearings

3.2. Analysis of Common Lubrication Failure Problems in Wind Turbine Bearings

- Physical factors of lubrication failure

- Chemical factors of lubrication failure

- Contaminant factors of lubrication failure

4. Research on Bearings Lubrication Technology of Wind Turbine

4.1. Research of Wind Turbine Bearings Lubrication Technology Based on Lubricants

4.2. Research of Wind Turbine Bearings Lubrication Technology Based on Lubrication Methods

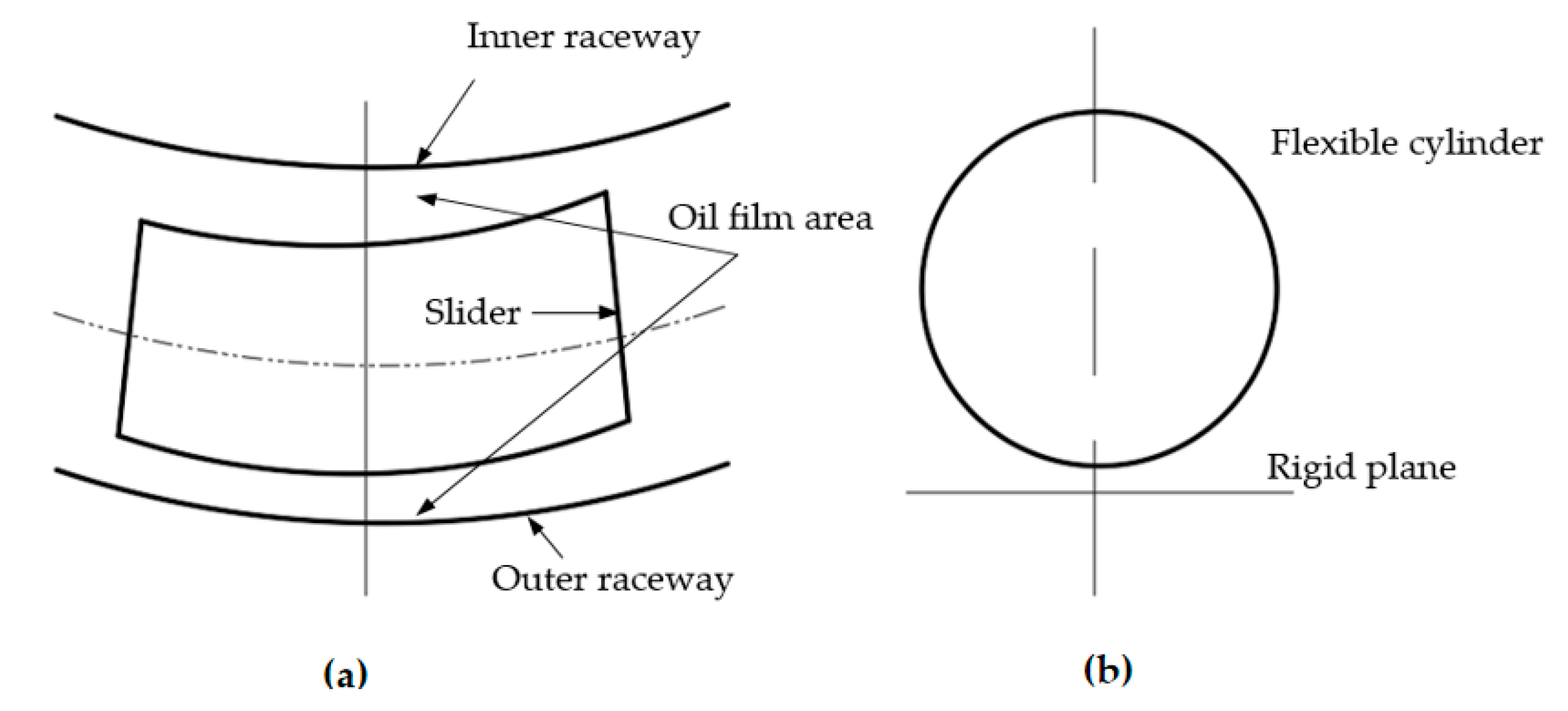

- The oil and gas mixed lubrication mode forms an effective lubricant film in the contact area.

- Lubricant accumulation is caused by the oil and gas pipe clamping angle and excessive air inlet velocity and small oil inlet velocity.

- The adhesion effect of oil droplets on the slider is determined by the lubricant viscosity.

4.3. Research of Wind Turbine Bearings Lubrication Technology Based on Lubrication Monitoring Methods

5. Conclusions and Future Perspectives

5.1. Conclusions

- Research on wind turbine bearings failure analysis

- Research on wind turbine bearings lubrication technology

5.2. Future Perspective and Recommendations

- Research on lubricants for wind power bearings:

- Choosing the right lubrication method:

- Bearing lubrication monitoring:

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hossain, M.L.; Abu-Siada, A.; Muyeen, S.M. Methods for advanced wind turbine condition monitoring and early diagnosis: A literature review. Energies 2018, 11, 1309. [Google Scholar] [CrossRef] [Green Version]

- Shakeel, S.R.; Takala, J.; Shakeel, W. Renewable energy sources in power generation in Pakistan. Renew. Sustain. Energy Rev. 2016, 64, 421–434. [Google Scholar] [CrossRef]

- Dai, J.; Yang, X.; Wen, L. Development of wind power industry in China: A comprehensive assessment. Renew. Sustain. Energy Rev. 2018, 97, 156–164. [Google Scholar] [CrossRef]

- Sahu, B.K. Wind energy developments and policies in China: A short review. Renew. Sust. Energy Rev. 2018, 81, 1393–1405. [Google Scholar] [CrossRef]

- IEA. Net Annual Wind Capacity Additions, 2018–2020; IEA: Paris, France; Available online: https://www.iea.org/ (accessed on 14 March 2022).

- Stephens, A.; Walwyn, D.R. Wind energy in the United Kingdom: Modelling the effect of increases in installed capacity on generation efficiency. Renew Energy Focus 2018, 27, 44–58. [Google Scholar] [CrossRef] [Green Version]

- Agarwal, T.; Verma, S.; Gaurh, A. Issues and challenges of wind energy. In Proceedings of the 2016 International Conference on Electrical, Electronics, and Optimization Techniques (ICEEOT), Chennai, India, 3–5 March 2016; pp. 67–72. [Google Scholar]

- Qiao, W.; Lu, D. A survey on wind turbine condition monitoring and fault diagnosis—Part I: Components and subsystems. IEEE Trans. Ind. Electron. 2015, 62, 6536–6545. [Google Scholar] [CrossRef]

- de Azevedo, H.D.M.; Araújo, A.M.; Bouchonneau, N. A review of wind turbine bearing condition monitoring: State of the art and challenges. Renew. Sust. Energy Rev. 2016, 56, 368–379. [Google Scholar] [CrossRef]

- Dhanola, A.; Garg, H.C. Tribological challenges and advancements in wind turbine bearings: A review. Eng. Fail. Anal. 2020, 118, 104885. [Google Scholar] [CrossRef]

- Uhlmann, E.; Bilz, M.; Baumgarten, J. MRO–challenge and chance for sustainable enterprises. Procedia Cirp. 2013, 11, 239–244. [Google Scholar] [CrossRef]

- Igba, J.; Alemzadeh, K.; Durugbo, C.; Eiriksson, E.T. Through-life engineering services of wind turbines. CIRP J. Manuf. Sci. Tec. 2017, 17, 60–70. [Google Scholar] [CrossRef] [Green Version]

- Herbert, G.M.J.; Iniyan, S.; Goic, R. Performance, reliability and failure analysis of wind farm in a developing country. Renew. Energy 2010, 35, 2739–2751. [Google Scholar] [CrossRef]

- Tazi, N.; Châtelet, E.; Bouzidi, Y. Wear analysis of wind turbine bearings. Int. J. Renew. Energy Res. 2017, 7, 2120–2129. [Google Scholar]

- Liang, Y.; An, Z.; Liu, B. Fatigue life prediction for wind turbine main shaft bearings. In Proceedings of the 2013 International Conference on Quality, Reliability, Risk, Maintenance, and Safety Engineering (QR2MSE), Chengdu, China, 15–18 July 2013; pp. 888–893. [Google Scholar]

- Saidi, L.; Ali, J.B.; Bechhoefer, E.; Benbouzid, M. Wind turbine high-speed shaft bearings health prognosis through a spectral Kurtosis-derived indices and SVR. Appl. Acoust. 2017, 120, 1–8. [Google Scholar] [CrossRef]

- Jian, L.; Chau, T.; Jiang, J.Z. A magnetic-geared outer-rotor permanent-magnet brushless machine for wind power generation. IEEE Trans. Ind. Appl. 2009, 45, 954–962. [Google Scholar] [CrossRef]

- Saad, M.M.M.; Asmuin, N. Comparison of horizontal axis wind turbines and vertical axis wind turbines. IOSR J. Eng. 2014, 4, 27–30. [Google Scholar] [CrossRef]

- Schubel, P.J.; Crossley, R.J. Wind turbine blade design. Energies 2012, 5, 3425–3449. [Google Scholar] [CrossRef] [Green Version]

- Serrano-González, J.; Lacal-Arántegui, R. Technological evolution of onshore wind turbines—A market-based analysis. Wind Energy 2016, 19, 2171–2187. [Google Scholar] [CrossRef] [Green Version]

- Johari, M.K.; Jalil, M.; Shariff, M.F.M. Comparison of horizontal axis wind turbine (HAWT) and vertical axis wind turbine (VAWT). Int. J. Eng. Technol. 2018, 7, 74–80. [Google Scholar] [CrossRef]

- Lee, M.H.; Shiah, Y.C.; Bai, C.J. Experiments and numerical simulations of the rotor-blade performance for a small-scale horizontal axis wind turbine. J. Wind Eng. Ind. Aerodyn. 2016, 149, 17–29. [Google Scholar] [CrossRef]

- Horizontal Axis Wind Turbines (HAwind Turbine): Schematic Structure, Advantage, Disadvantages. Available online: https://www.brainkart.com/ (accessed on 14 March 2022).

- Semken, R.S.; Polikarpova, M.; Röyttä, P.; Alexandrova, J.; Pyrhönen, J.; Nerg, J.; Mikkola, A.; Backman, J. Direct-drive permanent magnet generators for high-power wind turbines: Benefits and limiting factors. IET Renew. Power Gener. 2012, 6, 1–8. [Google Scholar] [CrossRef]

- Veers, P.S.; Ashwill, T.D.; Sutherland, H.J.; Sutherland, H.J.; Laird, D.L.; Lobitz, D.W.; Griffin, J.F.; Mandell, W.D.; Musial, K.J.; Michael, Z.; et al. Trends in the design, manufacture and evaluation of wind turbine blades. Wind Energy 2003, 6, 245–259. [Google Scholar] [CrossRef]

- Velásquez, R.M.A.; Tataje, F.A.O.; Ancaya-Martínez, M.C.E. Early detection of faults and stall effects associated to wind farms. Sustain. Energy Technol. Assess. 2021, 47, 101441. [Google Scholar] [CrossRef]

- Extending Bearing Life in Wind Turbine Mainshafts. Available online: https://www.power-eng.com/ (accessed on 14 March 2022).

- Napolitano, F.; Paolone, M.; Borghetti, A.; Nucci, C.A.; Cristofolini, A.; Mazzetti, C.; Fiamingo, F.; Marzinotto, M. Models of wind-turbine main-shaft bearings for the development of specific lightning protection systems. IEEE Trans. Electromagn. Compat. 2010, 53, 99–107. [Google Scholar] [CrossRef]

- Islam, M.; Fartaj, A.; Carriveau, R. Analysis of the design parameters related to a fixed-pitch straight-bladed vertical axis wind turbine. Wind. Eng. 2008, 32, 491–507. [Google Scholar] [CrossRef]

- Aso, T.; Seki, K.; Ushiyama, I. Study on the bearing resistance in a wind turbine generator system. Wind. Eng. 2015, 39, 113–128. [Google Scholar] [CrossRef]

- Vafaei, S.; Rahnejat, H.; Aini, R. Vibration monitoring of high speed spindles using spectral analysis techniques. Int. J. Mach. Tools Manuf. 2002, 42, 1223–1234. [Google Scholar] [CrossRef]

- Whittle, M. Wind Turbine Generator Reliability: An Exploration of the Root Causes of Generator Bearing Failures. Ph.D. Thesis, Durham University, Durham, UK, 2013. [Google Scholar]

- Kotzalas, M.N.; Doll, G.L. Tribological advancements for reliable wind turbine performance. Philos. Trans. R. Soc. London. Ser. A Math. Phys. Eng. Sci. 2010, 368, 4829–4850. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lösche, T. New aspects in the realistic prediction of the fatigue life of rolling bearings. Wear 1989, 134, 357–375. [Google Scholar] [CrossRef]

- Howell, R.; Qin, N.; Edwards, J.; Durrani, N. Wind tunnel and numerical study of a small vertical axis wind turbine. Renew. Energy 2010, 35, 412–422. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.; Zhang, L. Naturally damaged wind turbine blade bearing fault detection using novel iterative nonlinear filter and morphological analysis. IEEE Trans. Ind. Electron. 2019, 67, 8713–8722. [Google Scholar] [CrossRef]

- Cirelli, M.; Valentini, P.P.; Pennestrì, E. A study of the non-linear dynamic response of spur gear using a multibody contact based model with flexible teeth. J. Sound Vib. 2019, 445, 148–167. [Google Scholar] [CrossRef]

- He, P.; Wang, Y.; Liu, H.; Wang, H. Optimization design of structural parameters of single-row four-point contact ball slewing bearing. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 1–12. [Google Scholar] [CrossRef]

- Han, J.W.; Nam, J.S.; Park, Y.J.; Lee, G.H.; Nam, Y.Y. An experimental study on the performance and fatigue life of pitch bearing for wind turbine. J. Mech. Sci. Technol. 2015, 29, 1963–1971. [Google Scholar] [CrossRef]

- He, P.; Hong, R.; Wang, H.; Lu, C. Fatigue life analysis of slewing bearings in wind turbines. Int. J. Fatigue 2018, 111, 233–242. [Google Scholar] [CrossRef]

- Guo, P.; Chen, S.; Chu, J.; Infield, D. Wind direction fluctuation analysis for wind turbines. Renew. Energy 2020, 162, 1026–1035. [Google Scholar]

- Dar, Z.; Kar, K.; Sahni, O.; Chow, J.H. Windfarm power optimization using yaw angle control. IEEE Trans. Sustain. Energy. 2016, 8, 104–116. [Google Scholar] [CrossRef]

- Nam, J.S.; Park, Y.J.; Chang, H.S. Dynamic life prediction of pitch and yaw bearings for wind turbine. J. Mech. Sci. Technol. 2016, 30, 249–256. [Google Scholar] [CrossRef]

- Taherian-Fard, E.; Sahebi, R.; Niknam, T.; Izadian, A.; Shasadeghi, M. Wind turbine drivetrain technologies. IEEE Trans. Ind. Appl. 2020, 56, 1729–1741. [Google Scholar] [CrossRef]

- Stammler, M.; Thomas, P.; Reuter, A.; Schwack, F.; Poll, G. Effect of load reduction mechanisms on loads and blade bearing movements of wind turbines. Wind Energy 2020, 23, 274–290. [Google Scholar] [CrossRef] [Green Version]

- Struggl, S.; Berbyuk, V.; Johansson, H. Review on wind turbines with focus on drive train system dynamics. Wind Energy 2015, 18, 567–590. [Google Scholar] [CrossRef]

- Bhardwaj, U.; Teixeira, A.P.; Soares, C.G. Reliability prediction of an offshore wind turbine gearbox. Renew. Energy 2019, 141, 693–706. [Google Scholar] [CrossRef]

- Ragheb, A.; Ragheb, M. Wind turbine gearbox technologies. In Proceedings of the 2010 1st International Nuclear & Renew. Energy Conference (INREC), Amman, Jordan, 21–24 March 2010; pp. 1–8. [Google Scholar]

- Malinowski, J.; Snyder, D.R. Choosing an antifriction bearing. IEEE Ind. Appl. Mag. 2006, 12, 49–56. [Google Scholar] [CrossRef]

- Aikin, A.R. Bearing and gearbox failures: Challenge to wind turbines. Tribol. Lubr. Technol. 2020, 76, 38–44. [Google Scholar]

- Guo, Y.; Parsons, T.; Dykes, K.; King, R.N. A systems engineering analysis of three-point and four-point wind turbine drivetrain configurations. Wind Energy 2017, 20, 537–550. [Google Scholar] [CrossRef]

- What Bearings are Used in Wind Turbines? Available online: https://www.acorn-ind.co.uk/ (accessed on 20 March 2022).

- Jensen, J.P. Evaluating the environmental impacts of recycling wind turbines. Wind Energy 2019, 22, 316–326. [Google Scholar] [CrossRef]

- Tchakoua, P.; Wamkeue, R.; Ouhrouche, M.; Slaoui-Hasnaoui, F.; Tameghe, T.A.; Ekemb, G. Wind turbine condition monitoring: State-of-the-art review, new trends, and future challenges. Energies 2014, 7, 2595–2630. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Zhang, X.; Zhou, X.; Lu, L. Reliability assessment of wind turbine bearing based on the degradation-Hidden-Markov model. Renew. Energy 2019, 132, 1076–1087. [Google Scholar] [CrossRef]

- Zimroz, R.; Bartelmus, W.; Barszcz, T.; Urbanek, J. Diagnostics of bearings in presence of strong operating conditions non-stationarity—A procedure of load-dependent features processing with application to wind turbine bearings. Mech. Syst. Signal Process. 2014, 46, 16–27. [Google Scholar] [CrossRef]

- Ruiz de la Hermosa González-Carrato, R.; García Márquez, F.P.; Alexander, K.; Papaelias, M. Methods and tools for the operational reliability optimisation of large-scale industrial wind turbines. In Proceedings of the Ninth International Conference on Management Science and Engineering Management, Karlsruhe, Germany, 21–23 July 2015; pp. 1175–1188. [Google Scholar]

- Vencl, A.; Rac, A. Diesel engine crankshaft journal bearings failures: Case study. Eng. Fail. Anal. 2014, 44, 217–228. [Google Scholar] [CrossRef]

- Shen, G.; Xiang, D.; Zhu, K.; Jiang, L.; Shen, Y.; Li, Y. Fatigue failure mechanism of planetary gear train for wind turbine gearbox. Eng. Fail. Anal. 2018, 87, 96–110. [Google Scholar] [CrossRef]

- Arno, R.; Dowling, N.; Schuerger, R. Equipment failure characteristics & RCM for optimizing maintenance cost. In Proceedings of the 2015 IEEE/IAS 51st Industrial & Commercial Power Systems Technical Conference (I&CPS), Calgary, AB, Canada, 5–8 May 2015; pp. 1–8. [Google Scholar]

- Rolink, A.; Jacobs, G.; Schröder, T.; Keller, D.; Jakobs, T.; Bosse, D.; Jochen, L.; Knoll, G. Methodology for the systematic design of conical plain bearings for use as main bearings in wind turbines. Forsch. Ing. 2021, 85, 629–637. [Google Scholar] [CrossRef]

- Wind Energy Technologies Office. Zeroing in on the No.1 Cause of Wind Turbine Gearbox Failures. Available online: https://www.energy.gov/ (accessed on 28 March 2022).

- Evans, M.H. White structure flaking (WSF) in wind turbine gearbox bearings: Effects of ‘butterflies’ and white etching cracks (WECs). Mater. Sci. Technol. 2012, 28, 3–22. [Google Scholar] [CrossRef]

- Morales-Espejel, G.E.; Gabelli, A. The progression of surface rolling contact fatigue damage of rolling bearings with artificial dents. Tribol. Trans. 2015, 58, 418–431. [Google Scholar] [CrossRef]

- Lai, J.; Stadler, K. Investigation on the mechanisms of white etching crack (WEC) formation in rolling contact fatigue and identification of a root cause for bearing premature failure. Wear 2016, 364, 244–256. [Google Scholar] [CrossRef]

- Electric Current Damage—How Bearings Fail Part 2 of 6. Available online: https://www.linearmotiontips.com/ (accessed on 20 March 2022).

- Craig, B.D. Material failure modes, Part II: A brief tutorial on impact, spalling, wear, brinelling, thermal shock, and radiation damage. J. Fail. Anal. Prev. 2005, 5, 7–12. [Google Scholar] [CrossRef]

- Radu, C. The most common causes of bearing failure and the importance of bearing lubrication. RKB Tec. Rev. 2010, 1, 1–7. [Google Scholar]

- DIN ISO 15243; Rolling Bearings—Damages and Failures—Terms Characteristics and Causes. British Standards Institution (BSI): Buckinghamshire, UK, 2004.

- Howard, T.P. Development of a Novel Bearing Concept for Improved Wind Turbine Gearbox Reliability. Ph.D. Thesis, University of Sheffield, Sheffield, UK, 2016. [Google Scholar]

- Amirat, Y.; Benbouzid, M.E.H.; Al-Ahmar, E.; Bensaker, B.; Turri, S. A brief status on condition monitoring and fault diagnosis in wind energy conversion systems. Renew. Sust. Energy Rev. 2009, 13, 2629–2636. [Google Scholar] [CrossRef] [Green Version]

- Arabian-Hoseynabadi, H.; Oraee, H.; Tavner, P.J. Failure modes and effects analysis (FMEA) for wind turbines. Int. J. Elec. Power. 2010, 32, 817–824. [Google Scholar] [CrossRef] [Green Version]

- McFadden, P.D.; Smith, J.D. Model for the vibration produced by a single point defect in a rolling element bearing. J. Sound Vib. 1984, 96, 69–82. [Google Scholar] [CrossRef]

- Saruhan, H.; Saridemir, S.; Qicek, A.; Uygur, I. Vibration analysis of rolling element bearings defects. J. Appl. Res. Technol. 2014, 12, 384–395. [Google Scholar] [CrossRef]

- Gould, B.; Greco, A. The influence of sliding and contact severity on the generation of white etching cracks. Tribol. Lett. 2015, 60, 1–13. [Google Scholar] [CrossRef]

- Yu, Z.Q.; Yang, Z.G. Fatigue failure analysis of a grease-lubricated roller bearing from an electric motor. J. Fail. Anal. Prev. 2011, 11, 158–166. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, J.; Zhou, E. Automatic discrete failure study of cage free ball bearings based on variable diameter contact. J. Mech. Sci. Technol. 2021, 35, 4943–4952. [Google Scholar] [CrossRef]

- Wang, H.; Liu, Z.; Zou, L.; Yang, J. Influence of both friction and wear on the vibration of marine water lubricated rubber bearing. Wear 2017, 376, 920–930. [Google Scholar] [CrossRef]

- Branch, N.A.; Arakere, N.K.; Svendsen, V.; Forster, N.H. Stress field evolution in a ball bearing raceway fatigue spall. J. ASTM Int. 2010, 7, 1–18. [Google Scholar] [CrossRef] [Green Version]

- Errichello, R.; Muller, J. How to analyze gear failures. J. Fail. Anal. Prev. 2002, 2, 8–16. [Google Scholar] [CrossRef]

- Gagg, C.R.; Lewis, P.R. Wear as a product failure mechanism—Overview and case studies. Eng. Fail. Anal. 2007, 14, 1618–1640. [Google Scholar] [CrossRef]

- Pateriya, A.; Mittal, N.D.; Pradhan, M.K. Identification of lubricant contamination in journal bearings using vibration signature analysis. In Advancement in Materials, Manufacturing and Energy Engineering; Springer: Singapore, 2022; pp. 35–44. [Google Scholar]

- Hart, E.; Clarke, B.; Nicholas, G.; Kazemi Amiri, A.; Stirling, J.; Carroll, J.; Dwyer-Joyce, R.; McDonald, A.; Long, H. A review of wind turbine main bearings: Design, operation, modelling, damage mechanisms and fault detection. Wind Energy. Sci. 2020, 5, 105–124. [Google Scholar] [CrossRef] [Green Version]

- MacPherson, I. Raising the bar for wind turbine lubrication. In Rationality and Scientific Lifestyle for Health; Springer: Cham, Denmark, 2005; pp. 24–28. [Google Scholar]

- Stammler, M.; Reuter, A.; Poll, G. Cycle counting of roller bearing oscillations–case study of wind turbine individual pitching system. Renew. Energy Focus 2018, 25, 40–47. [Google Scholar] [CrossRef]

- McGuire, N. Greases for slow and steady wind turbine bearings. Tribol. Lubr. Technol. 2021, 77, 42–53. [Google Scholar]

- Williams, J.A.; Tabor, D. The role of lubricants in machining. Wear 1977, 43, 275–292. [Google Scholar] [CrossRef]

- Paladugu, M.; Lucas, D.R.; Hyde, R.S. Effect of lubricants on bearing damage in rolling-sliding conditions: Evolution of white etching cracks. Wear 2018, 398, 165–177. [Google Scholar] [CrossRef]

- Cann, P.M.; Doner, J.; Webster, M.N.; Wikstrom, V. Grease degradation in rolling element bearings. Tribol. Trans. 2001, 44, 399–404. [Google Scholar] [CrossRef]

- Wang, Q. Seizure failure of journal-bearing conformal contacts. Wear 1997, 210, 8–16. [Google Scholar] [CrossRef]

- How Artificial Intelligence will Improve O&M. Available online: https://www.windpowerengineering.com/ (accessed on 19 March 2022).

- The Three Mistakes of Bearing Lubrication. Available online: https://www.maintworld.com/ (accessed on 19 March 2022).

- Muzakkir, S.M.; Lijesh, K.P.; Hirani, H. Failure mode and effect analysis of journal bearing. Int. J. Appl. Eng. Res. 2015, 10, 36843–36850. [Google Scholar]

- Márquez, F.P.G.; Pérez, J.M.P.; Marugán, A.P.; Papaelias, M. Identification of critical components of wind turbines using FTA over the time. Renew. Energy 2016, 87, 869–883. [Google Scholar] [CrossRef] [Green Version]

- Fernandes, C.M.; Martins, R.C.; Seabra, J.H. Friction torque of thrust ball bearings lubricated with wind turbine gear oils. Tribol. Int. 2013, 58, 47–54. [Google Scholar] [CrossRef]

- Patidar, S.; Soni, P.K. An overview on vibration analysis techniques for the diagnosis of rolling element bearing faults. Int. J. Eng. Trends Technol. 2013, 4, 1804–1809. [Google Scholar]

- Rezasoltani, A.; Khonsari, M.M. An engineering model to estimate consistency reduction of lubricating grease subjected to mechanical degradation under shear. Tribol. Int. 2016, 103, 465–474. [Google Scholar] [CrossRef]

- Gershuni, L.; Larson, M.G.; Lugt, P.M. Lubricant replenishment in rolling bearing contacts. Tribol. Trans. 2008, 51, 643–651. [Google Scholar] [CrossRef]

- Marko, M.D. The impact of lubricant film thickness and ball bearings failures. Lubricants 2019, 7, 48. [Google Scholar] [CrossRef] [Green Version]

- Sánchez Pérez, J.F.; Moreno, J.A.; Alhama, F. Numerical simulation of high-temperature oxidation of lubricants using the network method. Chem. Eng. Commun. 2015, 202, 982–991. [Google Scholar] [CrossRef]

- Zhu, J.; Yoon, J.M.; He, D.; Qu, Y.; Bechhoefer, E. Lubrication oil condition monitoring and remaining useful life prediction with particle filtering. Int. J. Progn. Health Manag. 2013, 4, 124–138. [Google Scholar] [CrossRef]

- Zhao, S.; Tie, L.; Guo, Z.; Li, J. Water deteriorates lubricating oils: Removal of water in lubricating oils using a robust superhydrophobic membrane. Nanoscale 2020, 12, 11703–11710. [Google Scholar] [CrossRef] [PubMed]

- Amarnath, M.; Kankar, P.K. Failure analysis of a grease-lubricated cylindrical roller bearing. Procedia Technol. 2014, 14, 59–66. [Google Scholar]

- Needelman, W.M.; Barris, M.A.; LaVallee, G.L. Contamination control for wind turbine gearboxes. Power Eng. 2009, 113, 112–115. [Google Scholar]

- Sari, M.R.; Ville, F.; Haiahem, A.; Flamand, L. Effect of lubricant contamination on friction and wear in an EHL sliding contact. Mechanics 2010, 82, 43–49. [Google Scholar]

- Salomonsson, L.; Stang, G.; Zhmud, B. Oil/thickener interactions and rheology of lubricating greases. Tribol. Trans. 2007, 50, 302–309. [Google Scholar] [CrossRef]

- Ramadan, M.A. Friction and wear of sand-contaminated lubricated sliding. Friction 2018, 6, 457–463. [Google Scholar] [CrossRef] [Green Version]

- Philip, M.; Li, W. Wind turbine lubrication. In Synthetics, Mineral Oils, and Bio-Based Lubricants, 3rd ed.; Philip, M., Ed.; CRC Press Publishing: Boca Raton, FL, USA, 2020; Chapter 3; pp. 787–800. [Google Scholar]

- Dutta, S. Positive outlook for wind turbine lubricants. Tribol. Lubr. Technol. 2017, 73, 16. [Google Scholar]

- Greaves, M. Pressure viscosity coefficients and traction properties of synthetic lubricants for wind turbine gear systems. Lubr. Sci. 2012, 24, 75–83. [Google Scholar] [CrossRef]

- McGuire, N. Lubrication challenges in the wind turbine industry. Tribol. Lubr. Technol. 2019, 75, 34–43. [Google Scholar]

- Cheng, F.; Qu, L.; Qiao, W.; Hao, L. Enhanced particle filtering for bearing remaining useful life prediction of wind turbine drivetrain gearboxes. IEEE Trans. Ind. Electron. 2018, 66, 4738–4748. [Google Scholar] [CrossRef]

- Ruellan, A.; Stadler, K.; Jelita Rydel, J.; Ryan, H. The influence of lubricant formulation on early thrust and radial bearing damage associated with white etching cracks. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2021, 235, 1047–1059. [Google Scholar] [CrossRef]

- Singh, D.K.; Kurien, J.; Villayamore, A. Study and analysis of wind turbine gearbox lubrication failure and its mitigation process. Mater. Today Proc. 2021, 44, 3976–3983. [Google Scholar] [CrossRef]

- The Importance of Lubrication in the Production of Wind Energy. Available online: https://www.dropsa.com/ (accessed on 20 March 2022).

- Yakout, M.; Nassef, M.G.A.; Backar, S. Effect of clearances in rolling element bearings on their dynamic performance, quality and operating life. J. Mech. Sci. Technol. 2019, 33, 2037–2042. [Google Scholar] [CrossRef]

- Ren, G.; Zhang, P.; Ye, X.; Li, W.; Fan, X.; Zhu, M. Comparative study on corrosion resistance and lubrication function of lithium complex grease and polyurea grease. Friction 2021, 9, 75–91. [Google Scholar] [CrossRef] [Green Version]

- Bell, T.E. Selecting the best grease for rolling element bearings. Tribol. Lubr. Technol. 2014, 70, 28. [Google Scholar]

- Stachowiak, G.W. How tribology has been helping us to advance and to survive. Friction 2017, 5, 233–247. [Google Scholar] [CrossRef] [Green Version]

- Williams, T.; Ribadeneira, X.; Billington, S.; Kurfess, T. Rolling element bearing diagnostics in run-to-failure lifetime testing. Mech. Syst. Signal Process. 2001, 15, 979–993. [Google Scholar] [CrossRef]

- Cheng, R.C.; Chen, K.S. Ball bearing multiple failure diagnosis using feature-selected autoencoder model. Int. J. Adv. Manuf. Technol. 2022, 120, 4803–4819. [Google Scholar] [CrossRef]

- Du, Y.; Duan, C.; Wu, T. Replacement scheme for lubricating oil based on Bayesian control chart. IEEE Trans. Instrum. Meas. 2020, 70, 1–10. [Google Scholar] [CrossRef]

- Sequeira, C.; Pacheco, A.; Galego, P.; Gorbeña, E. Analysis of the efficiency of wind turbine gearboxes using the temperature variable. Renew. Energy. 2019, 135, 465–472. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.; Wang, S.; Liu, J. Life-cycle green-house gas emissions of onshore and offshore wind turbines. J. Clean. Prod. 2019, 210, 804–810. [Google Scholar] [CrossRef]

- Fernandes, C.M.; Blazquez, L.; Sanesteban, J.; Martins, R.C.; Seabra, J.H. Energy efficiency tests in a full scale wind turbine gearbox. Tribol. Int. 2016, 101, 375–382. [Google Scholar] [CrossRef]

- Greco, A.; Sheng, S.; Keller, J.; Erdemir, A. Material wear and fatigue in wind turbine systems. Wear 2013, 302, 1583–1591. [Google Scholar] [CrossRef]

- Lugt, P.M. A review on grease lubrication in rolling bearings. Tribol. Trans. 2009, 52, 470–480. [Google Scholar] [CrossRef]

- Yang, W.; Tavner, P.J.; Crabtree, C.J.; Feng, Y.; Qiu, Y. Wind turbine condition monitoring: Technical and commercial challenges. Wind Energy 2014, 17, 673–693. [Google Scholar] [CrossRef] [Green Version]

- Sun, L.; Li, J.; Hu, B.; Zhou, X. Study on the properties of a heterocyclic derivative as a grease additive. Pet. Process. Petrochem. 2012, 43, 55–58. [Google Scholar]

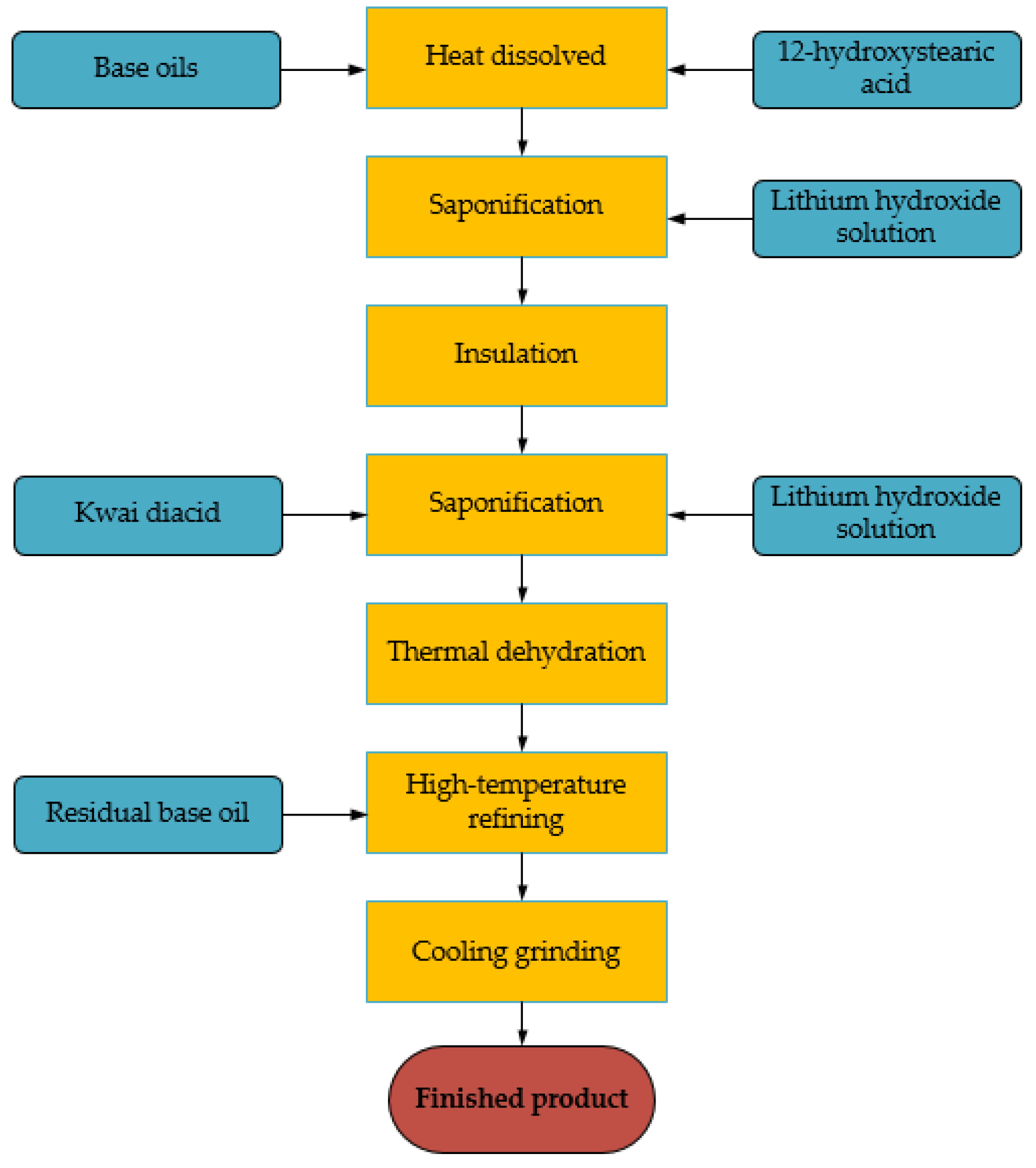

- Xia, Y.; Liu, L. Preparation and tribological properties of a wind power bearing grease. Pet. Process. Petrochem. 2018, 49, 66–71. Available online: http://www.sylzyhg.com (accessed on 10 April 2022).

- Mutyala, K.C.; Doll, G.L.; Wen, J.; Sumant, A.V. Superlubricity in rolling/sliding contacts. Appl. Phys. Lett. 2019, 115, 103103. [Google Scholar] [CrossRef]

- Ng, K.P.; Liew, K.W.; Lim, E. Role of eco-friendly bio-based graphene-oil nanofluids on friction reduction for wind turbine application. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Sapporo, Japan, 26–28 August 2021; p. 012012. [Google Scholar]

- Greases for Main Shaft Bearings. Available online: https://www.skf.com/ (accessed on 24 March 2022).

- Gao, Y.; Wang, J.; Wang, Q. Development and application of grease for wind turbine main shaft bearings. Lubricants 2018, 33, 35–40. [Google Scholar]

- Johnson, M. Lubricant application: Grease volumes and frequencies. Tribol. Lubr. Technol. 2009, 2, 1–7. [Google Scholar]

- Gao, Y. Development of wind turbine pitch bearing grease. Synthe. Lubr. 2020, 47, 1–5. [Google Scholar]

- Schwack, F.; Bader, N.; Leckner, J.; Demaille, C.; Poll, G. A study of grease lubricants under wind turbine pitch bearing conditions. Wear 2020, 454–455, 203335. [Google Scholar] [CrossRef]

- Sun, J.; Ou, H.; Du, L.; Zhang, X.; Wu, R. Analysis of the influence of phosphorus-containing additive lubricating oil on the wear of fan gearbox. Mech. Elec. Eng. Tec. 2021, 50, 281–283. [Google Scholar]

- Saidi, M.Z.; El Moujahid, C.; Pasc, A.; Canilho, N.; Delgado-Sanchez, C.; Celzard, A.; Fierro, V.; Kouitat-Njiwa, R.; Chafik, T. Enhanced tribological properties of wind turbine engine oil formulated with flower-shaped MoS2 nano-additives. Colloids Surfaces A Physicochem. Eng. Asp. 2021, 620, 1–10. [Google Scholar] [CrossRef]

- Iglesias, P.; McNabb, K.B. Improving wear performance of wind turbine gearboxes using ionic liquids as additives of lubricants. In Proceedings of the VIII Iberian Conference on Tribology Conference Proceedings, Cartagena, Spanish, 18–19 June 2015; pp. 23–30. [Google Scholar]

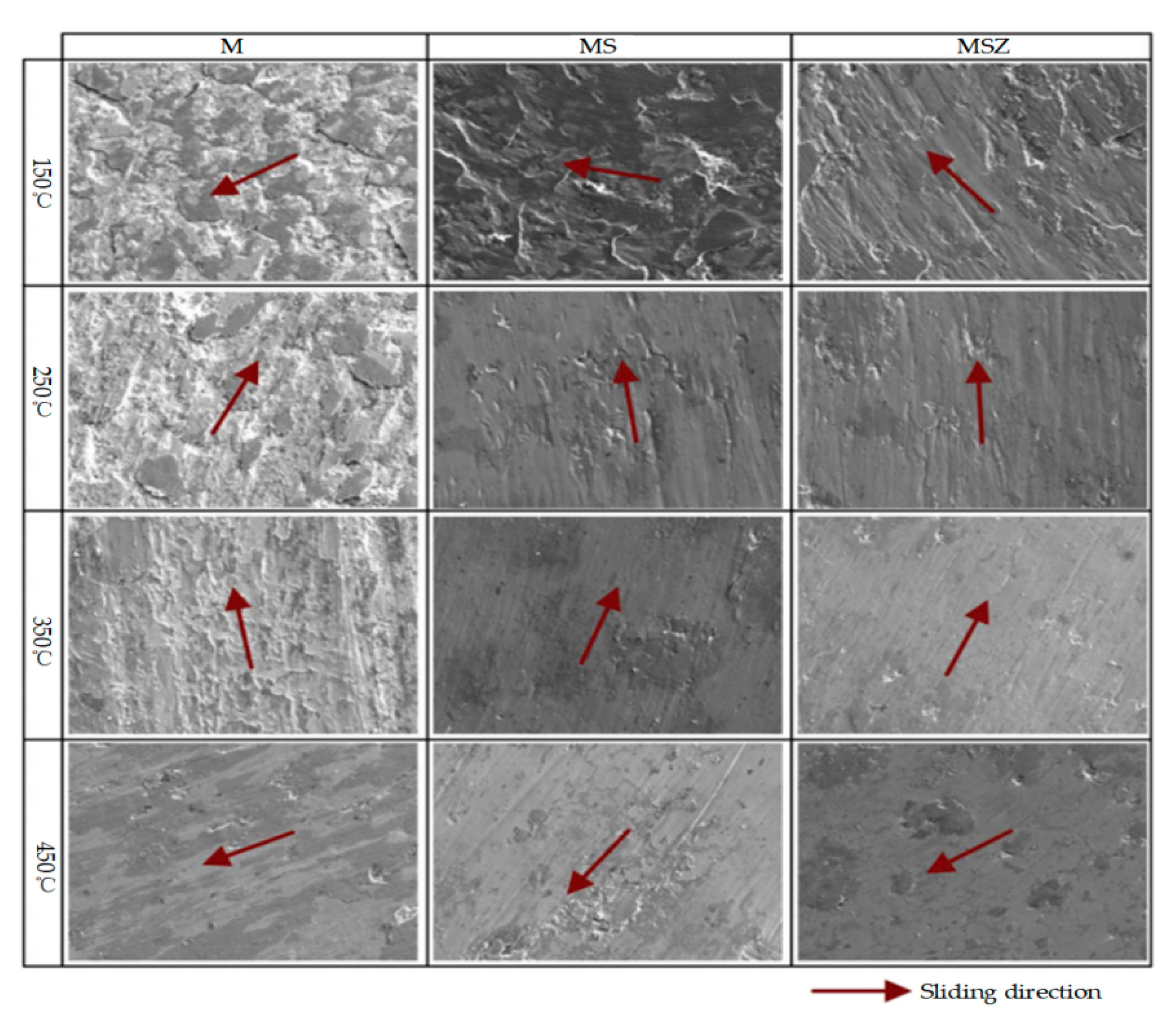

- Ali, M.K.A.; Xianjun, H. M50 matrix sintered with nanoscale solid lubricants shows enhanced self-lubricating properties under dry sliding at different temperatures. Tribol. Lett. 2019, 67, 1–16. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Yu, J.; Sathyamurthy, R.; Tawfik, M.M.; Shanmugan, S.; Essa, F.A. Improving the tribological properties of AISI M50 steel using Sns/Zno solid lubricants. J. Alloys Compd. 2020, 821, 153494. [Google Scholar] [CrossRef]

- Essa, F.A.; Zhang, Q.; Huang, X.; Ali, M.K.A.; Elagouz, A.; Abdelkareem, M.A. Effects of ZnO and MoS2 solid lubricants on mechanical and tribological properties of M50-steel-based composites at high temperatures: Experimental and simulation study. Tribol. Lett. 2017, 65, 1–29. [Google Scholar] [CrossRef]

- Ali, M.K.A.; Xianjun, H.; Mai, L.; Qingping, C.; Turkson, R.F.; Bicheng, C. Improving the tribological characteristics of piston ring assembly in automotive engines using Al2O3 and TiO2 nanomaterials as nano-lubricant additives. Tribol. Int. 2016, 103, 540–554. [Google Scholar] [CrossRef]

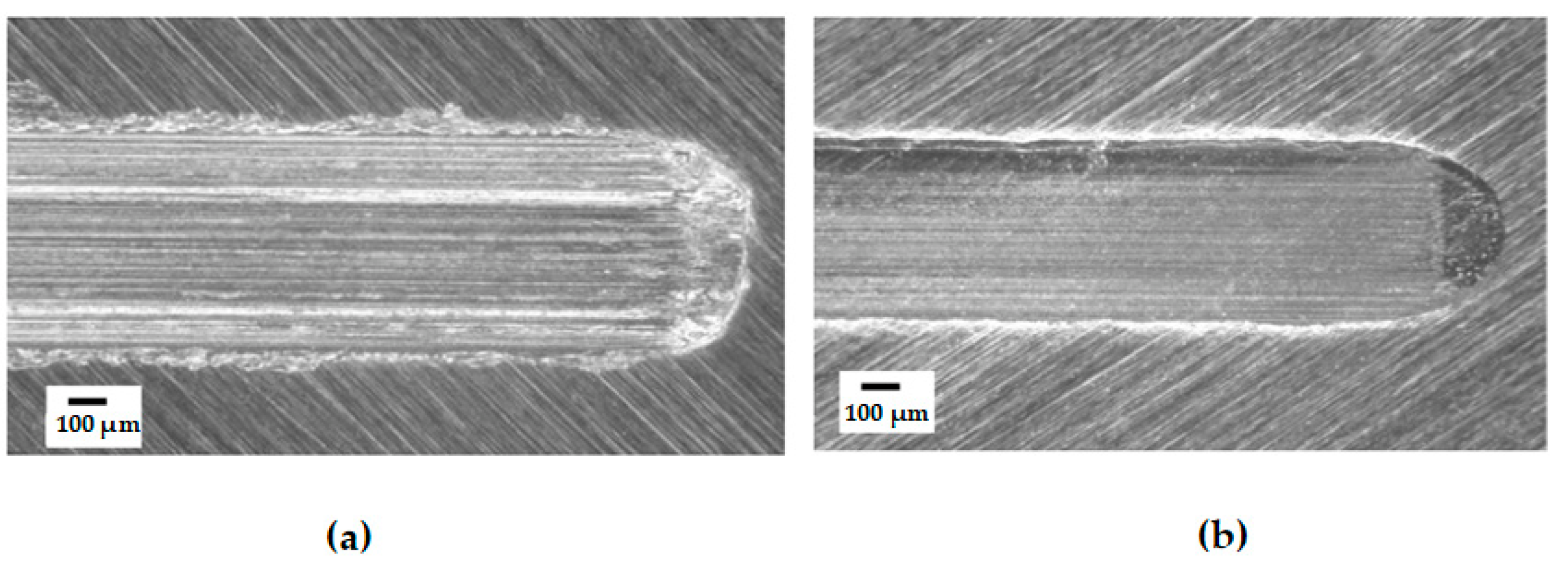

- Li, R.; Wang, L.; Li, X.; Liu, Y.; Zhang, X. Effect of wind power grease on friction and wear characteristics of bearing steel surface. Hot Work. Tec. 2021, 50, 49–53. [Google Scholar]

- Haque, T.; Korres, S.; Carey, J.T.; Jacobs, P.W.; Loos, J.; Franke, J. Lubricant effects on white etching cracking failures in thrust bearing rig tests. Tribol. Trans. 2018, 61, 979–990. [Google Scholar] [CrossRef]

- Li, X.; Li, R.; Wang, L.; Hu, Z.; Zhang, X. Grease monitoring and bearing wear analysis in wind power applications. Hot Work. Tec. 2021, 50, 68–72. [Google Scholar]

- Feng, M.; Chen, C.; Wang, S. Reasons and countermeasures for the deterioration of gear oil in wind farms. China New Technol. New Prod. 2021, 1, 40–42. Available online: https://www.cnki.net (accessed on 27 March 2022).

- Feng, Y.; Qiu, Y.; Crabtree, C.J.; Long, H.; Tavner, P.J. Monitoring wind turbine gearboxes. Wind Energy 2013, 16, 728–740. [Google Scholar] [CrossRef]

- Ahmed, N.S.; Nassar, A.M. Lubrication and lubricants. Tribol Fundam. Adv. 2013, 2, 55–76. [Google Scholar]

- McMillan, D.; Ault, G.W. Quantification of condition monitoring benefit for offshore wind turbines. Wind. Eng. 2007, 31, 267–285. [Google Scholar] [CrossRef]

- Patil, P.P.; Kumar, A. Dynamic structural and thermal characteristics analysis of oil-lubricated multi-speed transmission gearbox: Variation of load, rotational speed and convection heat transfer. Iran. J. Sci. Technol. Trans. Mech. Eng. 2017, 41, 281–291. [Google Scholar] [CrossRef]

- Serrato, R.; Maru, M.M.; Padovese, L.R. Effect of lubricant viscosity grade on mechanical vibration of roller bearings. Tribol. Int. 2007, 40, 1270–1275. [Google Scholar] [CrossRef]

- Cann, P.M.E.; Lubrecht, A.A. Bearing performance limits with grease lubrication: The interaction of bearing design, operating conditions and grease properties. J. Phys. D Appl. Phys. 2007, 40, 5446. [Google Scholar] [CrossRef]

- The Importance of Correct Bearing Lubrication. Available online: https://auburnbearing.com/ (accessed on 10 April 2022).

- Cann, P.M.; Webster, M.N.; Doner, J.P.; Cann, P.M.; Webster, M.N.; Doner, J.P.; Wikstrom, V.; Lugt, P. Grease degradation in R0F bearing tests. Tribol. Trans. 2007, 50, 187–197. [Google Scholar] [CrossRef]

- Scherge, M. The running-in of lubricated metal-metal contacts—A review on ultra-low wear systems. Lubricants 2018, 6, 54. [Google Scholar] [CrossRef] [Green Version]

- Yan, K.; Dong, L.; Zheng, J.; Li, B.; Wang, D.; Sun, Y. Flow performance analysis of different air supply methods for high speed and low friction ball bearing. Tribol. Int. 2018, 121, 94–107. [Google Scholar] [CrossRef]

- Gerdun, V.; Sedmak, T.; Šinkovec, V.; Kovše, I.; Cene, B. Failures of bearings and axles in railway freight wagons. Eng. Fail. Anal. 2007, 14, 884–894. [Google Scholar] [CrossRef]

- Malla, C.; Panigrahi, I. Review of condition monitoring of rolling element bearing using vibration analysis and other techniques. J. Vib. Eng. Technol. 2019, 7, 407–414. [Google Scholar] [CrossRef]

- Yan, B.; Dong, L.; Yan, K.; Chen, F.; Zhu, Y.; Wang, D. Effects of oil-air lubrication methods on the internal fluid flow and heat dissipation of high-speed ball bearings. Mech. Syst. Signal Process. 2021, 151, 107409. [Google Scholar] [CrossRef]

- Li, X.; Li, J.; Dong, G. Bioinspired topological surface for directional oil lubrication. ACS Appl. Mater. Interfaces 2020, 12, 5113–5119. [Google Scholar] [CrossRef] [PubMed]

- Varenberg, M.; Kligerman, Y.; Halperin, G.; Nakad, S.; Kasem, H. Assessing workability of greased bearings after long-term storage. Friction 2019, 7, 489–496. [Google Scholar] [CrossRef] [Green Version]

- Yao, L.; Shangguan, L.; Zhao, M.; Liu, D.; Wang, C. Development of a grease-lubricated pump station in alpine environment. J. NCWU Univ. 2015, 36, 70–73. Available online: https://kns.cnki.net/kns8/defaultresult/index (accessed on 15 April 2022).

- Wang, Y.; Li, D.; Zhang, X.; Sun, W.; Sun, Z. Analysis of the lubrication state of wind power main bearings based on elastohydrodynamic theory. Lubr. Eng. 2016, 41, 65–70. [Google Scholar]

- Johnson, K.L. One hundred years of Hertz contact. Proc. Inst. Mech. Eng. 1982, 196, 363–378. [Google Scholar] [CrossRef]

- Gu, K. Analysis of Mechanical Properties and Lubrication Performance of Rolling Bearings. Master’s Thesis, East China Jiaotong University, Nanchang, China, 2019. Available online: https://d.wanfangdata.com.cn/thesis (accessed on 13 April 2022).

- Peng, Q.; Fu, C.; Mao, W. Fault analysis and improvement of wind turbine bearing lubrication system. J. Hunan. Ins. Eng. 2020, 30, 34–40. [Google Scholar]

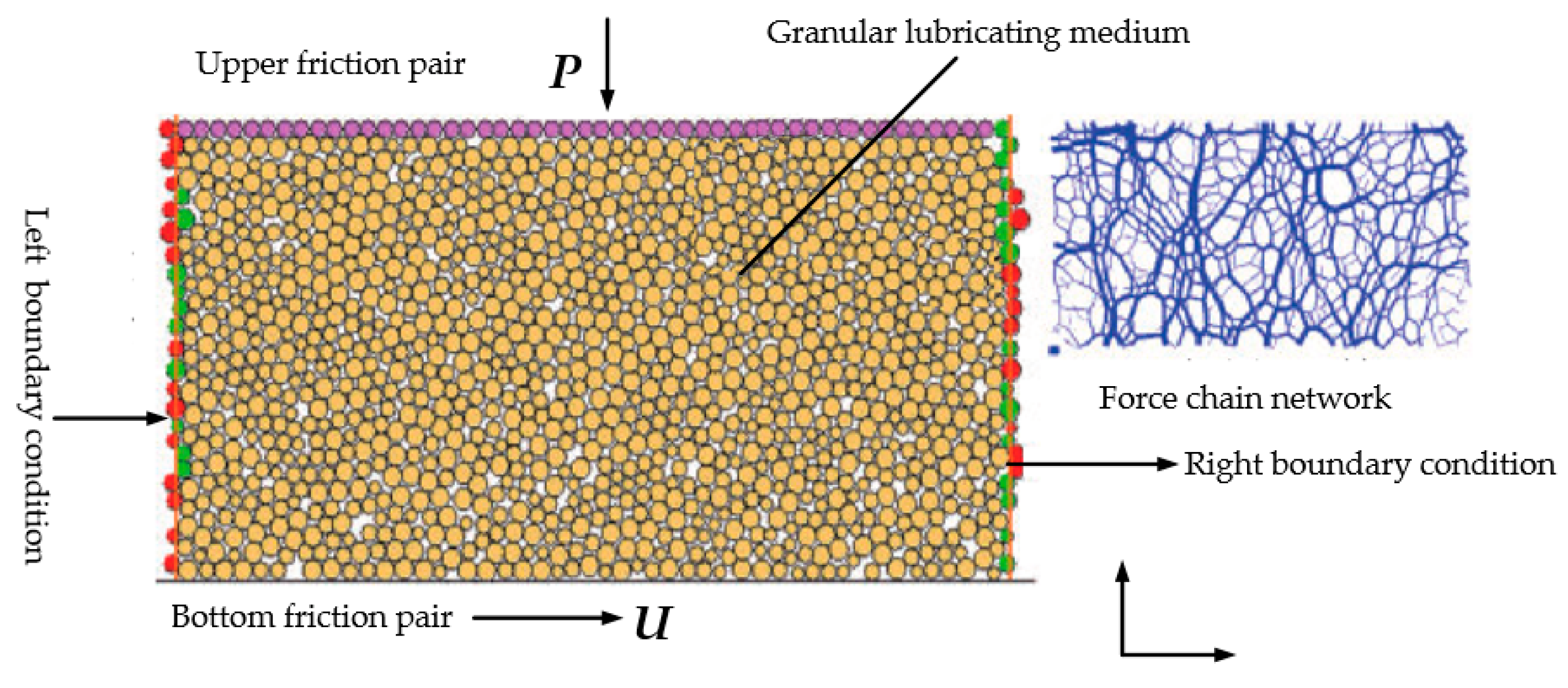

- Meng, F.; Liu, H.; Hua, S. Mechanical mechanism of the effect of interparticle friction on particle flow lubrication. Eng. Mech. 2021, 38, 221–229. Available online: https://navi.cnki.net/knavi/journals/GCLX/detail (accessed on 19 April 2022).

- Westerberg, L.G.; Farré-Lladós, J.; Li, J.; Höglund, E.; Casals-Terré, J. Grease flow in an elbow channel. Tribol. Lett. 2015, 57, 1–13. [Google Scholar] [CrossRef]

- Liu, J.; Ni, H.; Xu, Z.; Pan, G. A simulation analysis for lubricating characteristics of an oil-jet lubricated ball bearing. Simul. Model. Pract. Theory. 2021, 113, 102371. [Google Scholar] [CrossRef]

- Li, K.; Liu, Y.; Liu, J.; Chen, W. Study on the performance of a designed annular piezoelectric microjet for active lubrication of space bearing. IEEE Trans. Ind. Electron. 2021, 69, 2728–2736. [Google Scholar] [CrossRef]

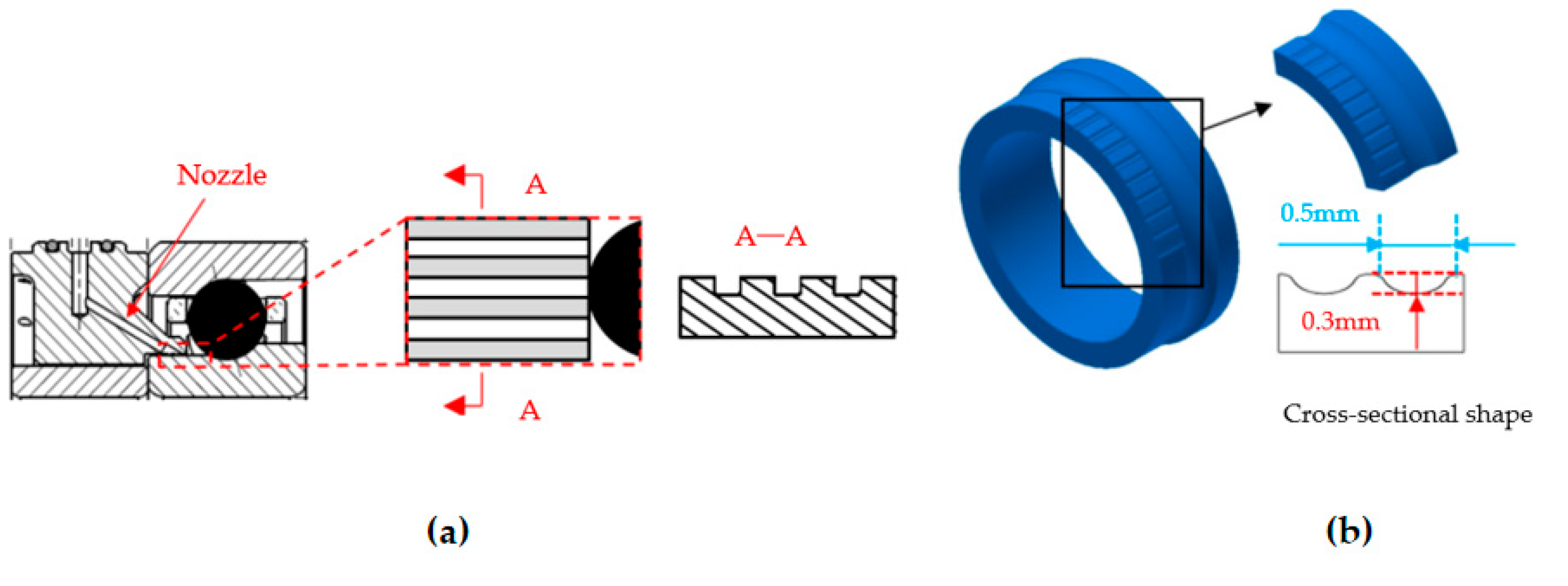

- Farré-Lladós, J.; Westerberg, L.G.; Casals-Terré, J. New method for lubricating wind turbine pitch gears using embedded micro-nozzles. J. Mech. Sci. Technol. 2017, 31, 797–806. [Google Scholar] [CrossRef] [Green Version]

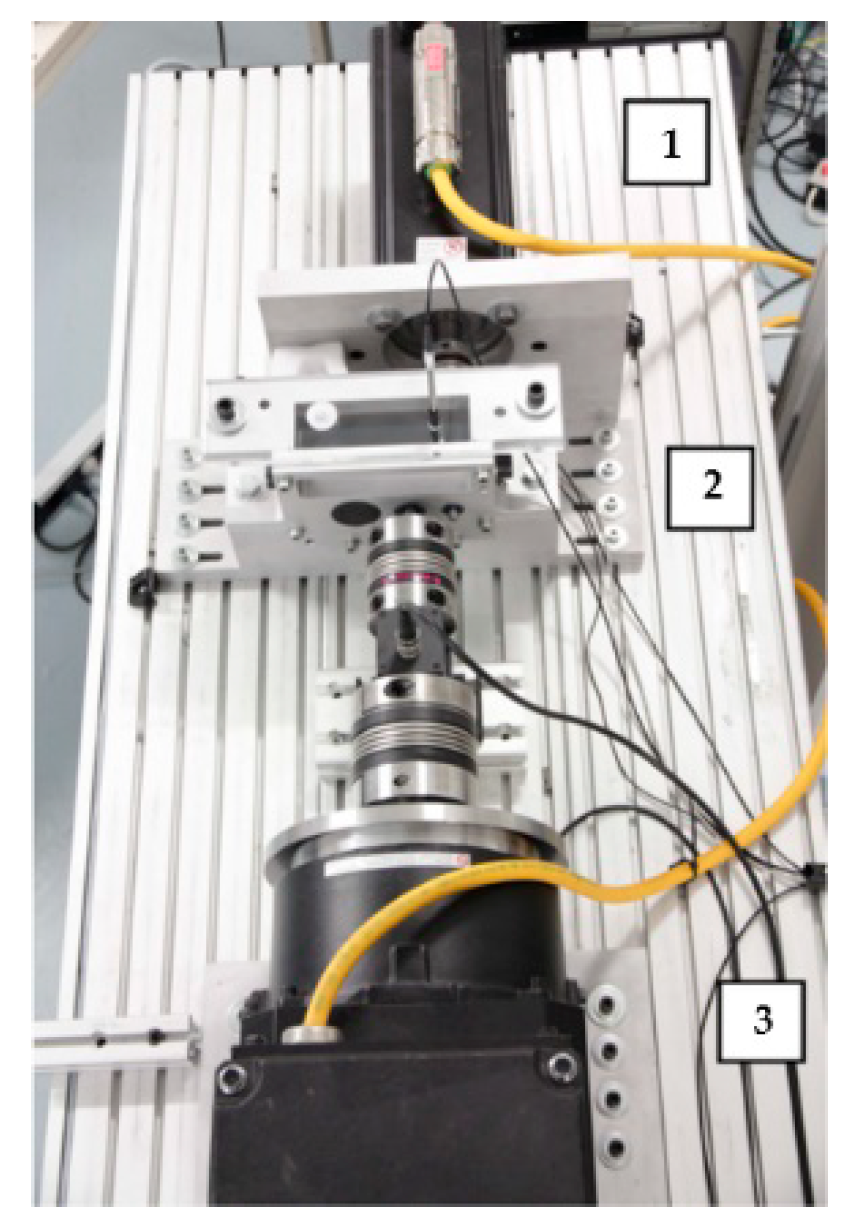

- Oliveira, M.V.M.; Cunha, B.Z.; Daniel, G.B. A model-based technique to identify lubrication condition of hydrodynamic bearings using the rotor vibrational response. Tribol. Int. 2021, 160, 1–10. [Google Scholar] [CrossRef]

- Ge, L.; Yan, K.; Wang, C.; Zhu, Y.; Hong, J. A novel method for bearing lubrication enhancement via the inner ring groove structure. In Journal of Physics: Conference Series, Guilin, China, 15–17 January 2021; IOP Publishing: Bristol, UK, 2021; pp. 1742–1820. [Google Scholar]

- Erill, D.G.I. Method for Dynamically Lubricating a Wind Turbine Pitch Blade Bearing. U.S. Patent 8480362, 9 July 2013. [Google Scholar]

- Xiaopin, Y.; Haitao, W.; Yang, Z.; Zhiying, Z. The research on the dynamic lubricating control system of wind turbine’s main bearings. In Proceedings of the 2016 IEEE International Conference on Power and Renewable Energy, Shanghai, China, 21–23 October 2016; pp. 83–86. [Google Scholar]

- Fischer, K.; Besnard, F.; Bertling, L. Reliability-centered maintenance for wind turbines based on statistical analysis and practical experience. IEEE Trans. Energy Convers. 2011, 27, 184–195. [Google Scholar] [CrossRef] [Green Version]

- Boyde, S. Green lubricants. Environmental benefits and impacts of lubrication. Green Chem. 2002, 4, 293–307. [Google Scholar] [CrossRef]

- Wandel, S.; Bader, N.; Schwack, F.; Glodowski, J.; Lehnhardt, B.; Poll, G. Starvation and relubrication mechanisms in grease lubricated oscillating bearings. Tribol. Int. 2022, 165, 107276. [Google Scholar] [CrossRef]

- Li, X.; Guo, F.; Poll, G.; Fei, Y.; Yang, P. Grease film evolution in rolling elastohydrodynamic lubrication contacts. Friction 2021, 9, 179–190. [Google Scholar] [CrossRef]

- Lubrication Basics and Condition Inspection. Available online: https://www.cbmconnect.com/ (accessed on 25 March 2022).

- Maru, M.M.; Castillo, R.S.; Padovese, L.R. Study of solid contamination in ball bearings through vibration and wear analyses. Tribol. Int. 2007, 40, 433–440. [Google Scholar] [CrossRef]

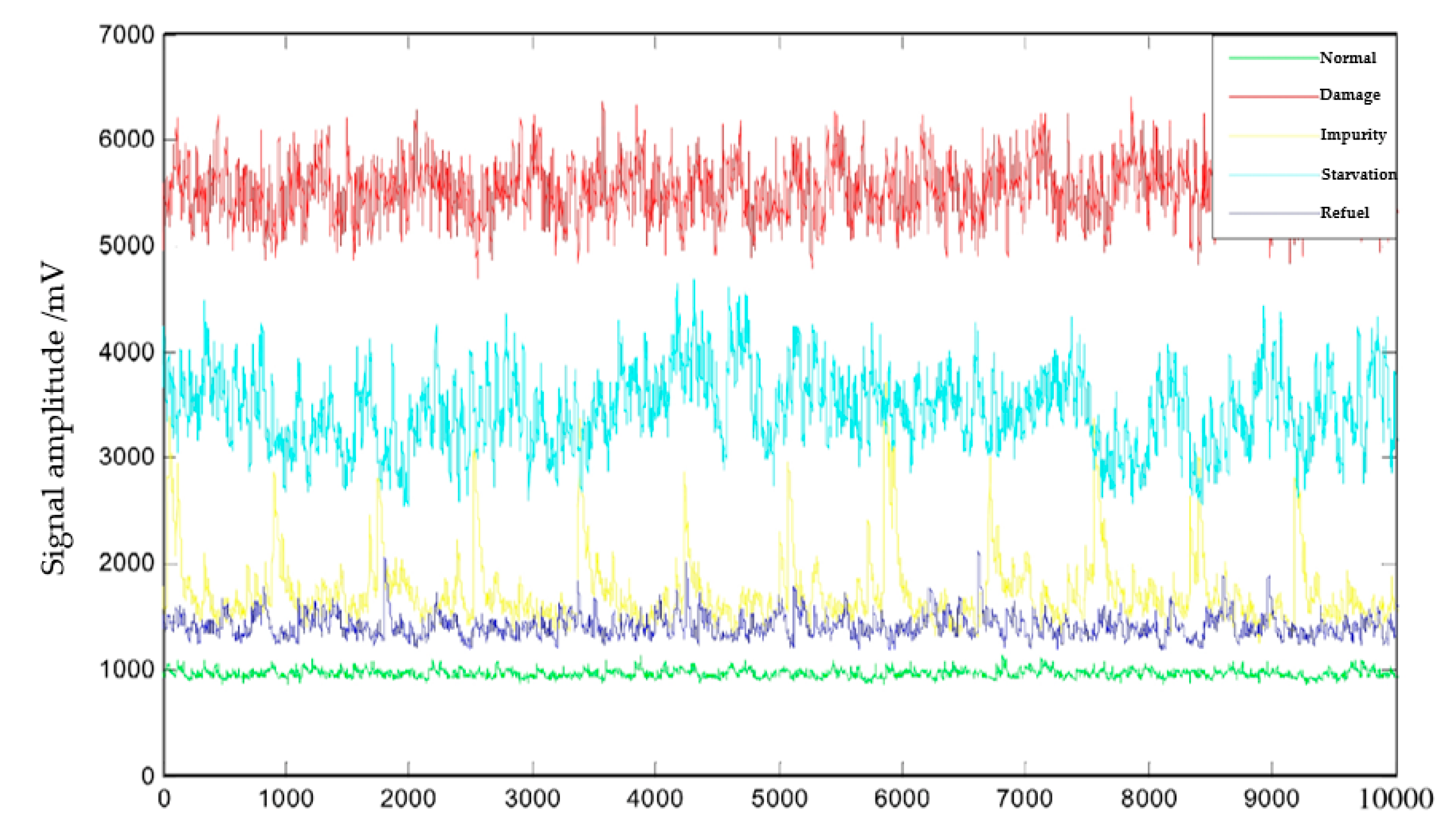

- Su, L.; Li, C.; Li, X.; Zhang, Y. Research on the monitoring of bearing lubrication status based on ultrasonic signal. J. Yanshan Univ. 2013, 37, 442–447. Available online: http://xuebao.ysu.edu.cn (accessed on 6 May 2022).

- Zakani, B.; Salem, H.; Entezami, S.; Sedaghat, A.; Grecov, D. Effect of particle concentration on lubrication performance of cellulose nanocrystalline (CNC) water-based lubricants: Mixed lubrication regime. Cellulose 2022, 29, 3963–3984. [Google Scholar] [CrossRef]

- Chao, X.; Zhang, P.; Wang, H.; Li, Y.; Lv, C. Ultrasonic echo waveshape features extraction based on qpso-matching pursuit for online wear debris discrimination. Mech. Syst. Signal Process. 2015, 60, 301–315. [Google Scholar]

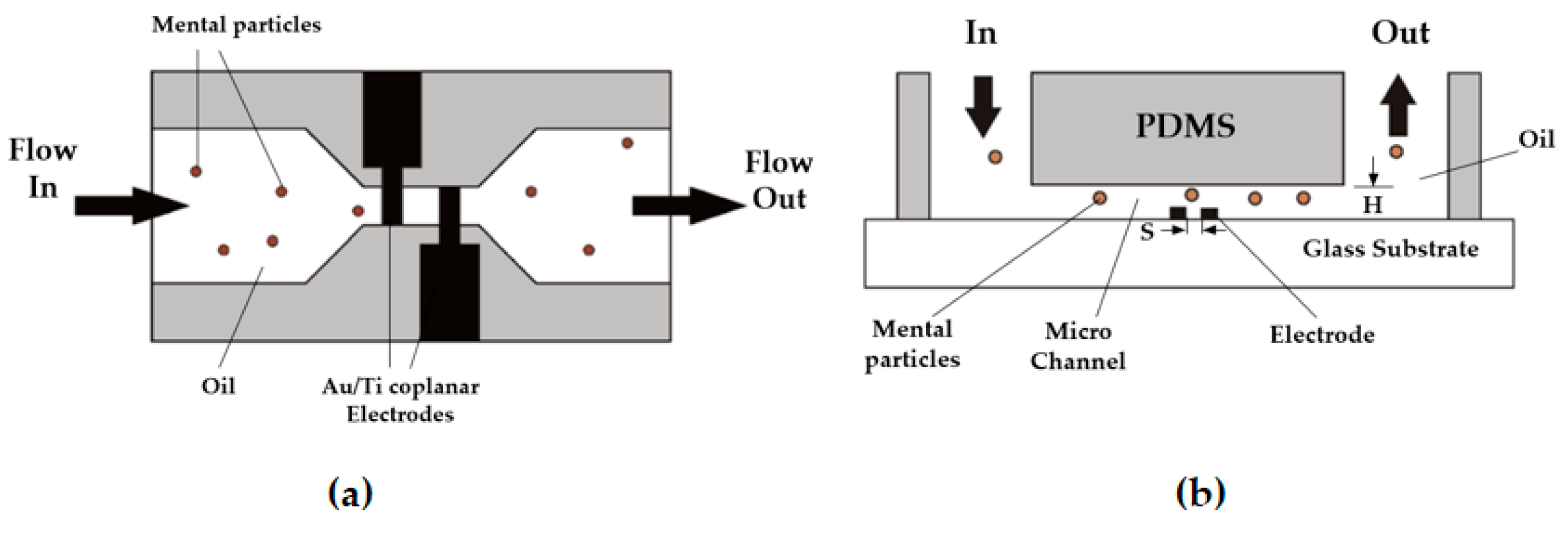

- Zhu, X.; Zhong, C.; Zhe, J. Lubricating oil conditioning sensors for online machine health monitoring–A review. Tribol. Int. 2017, 109, 473–484. [Google Scholar] [CrossRef] [Green Version]

- Poddar, S.; Tandon, N. Detection of particle contamination in journal bearing using acoustic emission and vibration monitoring techniques. Tribol. Int. 2019, 134, 154–164. [Google Scholar] [CrossRef]

- Mijares Tobias, J.A. Detection of Lubrication Starvation in Ball Bearings by Means of Lateral and Torsional Vibrations. Ph.D. Thesis, Texas A & M University, College Station, TX, USA, 2018. [Google Scholar]

- Nicholas, G.; Clarke, B.P.; Dwyer-Joyce, R.S. Detection of lubrication state in a field operational wind turbine gearbox bearing using ultrasonic reflectometry. Lubricants 2021, 9, 6–28. [Google Scholar] [CrossRef]

- Sheriff, K.A.I.; Hariharan, V.; Kannan, T. Analysis of solid contamination in ball bearing through acoustic emission signals. Arch. Met. Mater. 2017, 62, 1871–1874. [Google Scholar] [CrossRef] [Green Version]

- Tandon, N.; Choudhury, A. A review of vibration and acoustic measurement methods for the detection of defects in rolling element bearings. Tribol. Int. 1999, 32, 469–480. [Google Scholar] [CrossRef]

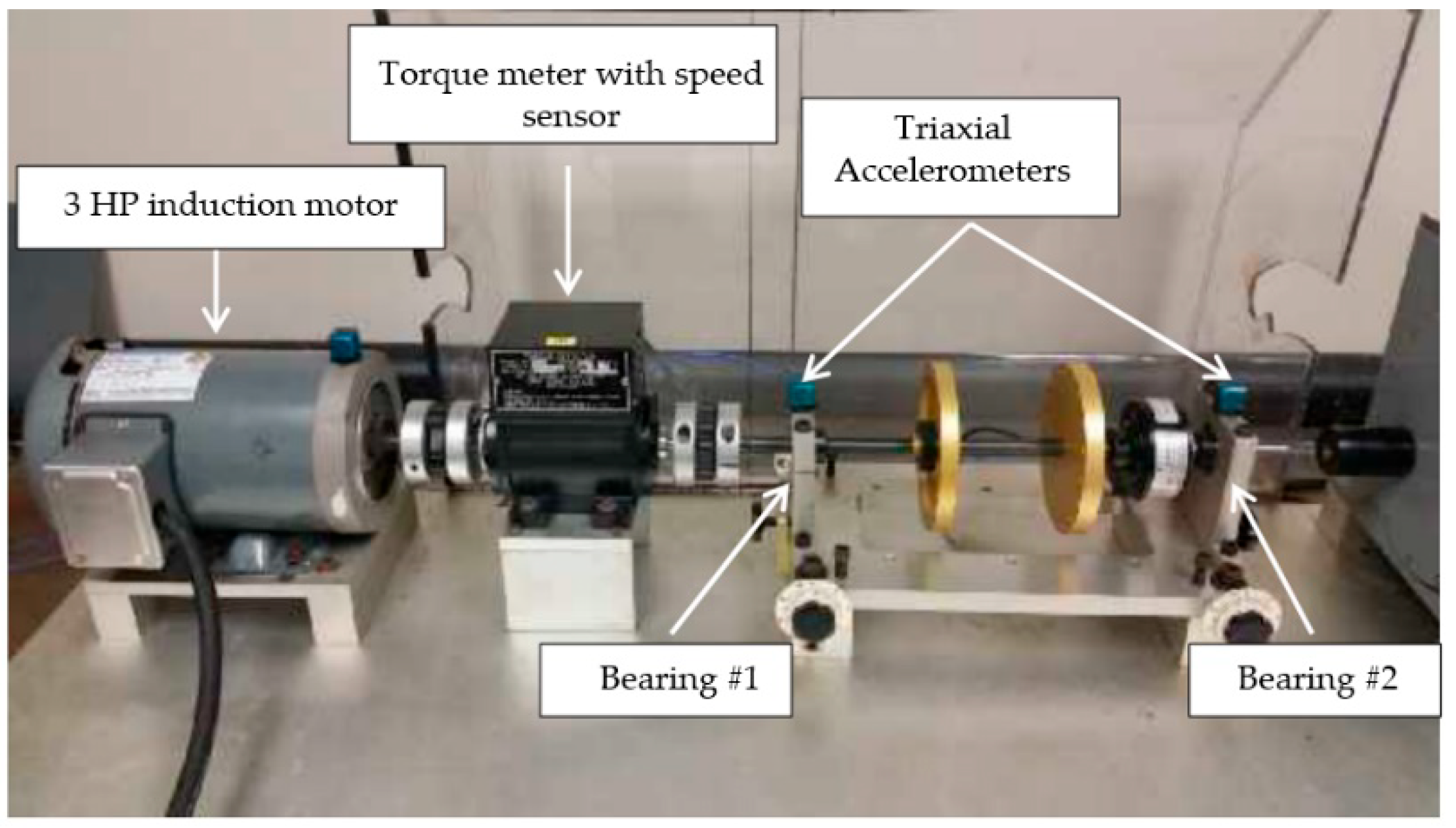

- Gómez, M.J.; Marklund, P.; Strombergsson, D.; Castejón, C.; García-Prada, J.C. Analysis of vibration signals of drivetrain failures in wind turbines for condition monitoring. Exp Tech. 2021, 45, 1–12. [Google Scholar] [CrossRef]

- Miettinen, J.; Andersson, P. Acoustic emission of rolling bearings lubricated with contaminated grease. Tribol. Int. 2000, 33, 777–787. [Google Scholar] [CrossRef]

- Chmelar, J.; Petr, K.; Mossoczy, P.; Dynybyl, V. Experimental study of lubrication film monitoring in a roller bearing by utilization of surface acoustic waves. Tribol. Int. 2020, 141, 105908. [Google Scholar]

- Nabhan, A.; Ghazaly, N.; Samy, A.; Mousa, M.O. Bearing fault detection techniques-a review. Turk. J. Eng. Sci. Technol. 2015, 3, 1–18. [Google Scholar]

- He, Y.; Zhang, X.; Friswell, M.I. Defect diagnosis for rolling element bearings using acoustic emission. J. Vib. Acoustics. 2009, 131, 1–18. [Google Scholar]

- Ünlü, B.S.; Durmuş, H.; Meriç, C. Determination of tribological properties at CuSn10 alloy journal bearings by experimental and means of artificial neural networks method. Ind. Lubr. Tribol. 2012, 64, 258–264. [Google Scholar] [CrossRef]

- Moder, J.; Bergmann, P.; Grün, F. Lubrication regime classification of hydrodynamic journal bearings by machine learning using torque data. Lubricants 2018, 6, 108. [Google Scholar]

- Zavos, A.; Katsaros, K.P.; Nikolakopoulos, P.G. Optimum selection of coated piston rings and thrust bearings in mixed lubrication for different lubricants using machine learning. Coatings 2022, 12, 704. [Google Scholar] [CrossRef]

- Katsaros, K.P.; Nikolakopoulos, P.G. On the tilting-pad thrust bearings hydrodynamic lubrication under combined numerical and machine learning techniques. Lubr. Sci. 2021, 33, 153–170. [Google Scholar] [CrossRef]

- Márton, L.; van der Linden, F. Temperature dependent friction estimation: Application to lubricant health monitoring. Mechatronics 2012, 22, 1078–1084. [Google Scholar] [CrossRef]

- Murali, S.; Xia, X.; Jagtiani, A.V.; Carletta, J.; Zhe, J. Capacitive coulter counting: Detection of metal wear particles in lubricant using a microfluidic device. Smart Mater. Struct. 2009, 18, 037001. [Google Scholar] [CrossRef]

- Dittes, N.; Sjödahl, M.; Pettersson, A.; Lang, D. Corrosion sensor for water-contaminated grease. Tribol. Trans. 2020, 63, 891–896. [Google Scholar] [CrossRef]

- Schaeffler Grease Condition Monitoring Sensor. Available online: https://medias.schaeffler.cn/en/monitor (accessed on 28 March 2022).

- Velayi, E.; Norouzbeigi, R. A mesh membrane coated with dual-scale superhydrophobic nano zinc oxide: Efficient oil-water separation. Surf. Coat. Technol. 2020, 385, 125394. [Google Scholar] [CrossRef]

- Hong, S.H. Literature review of machine condition monitoring with oil sensors-Types of sensors and their functions. Tribol. Lubr. 2020, 36, 297–306. [Google Scholar]

- Clough, A.E. Measuring the water content of synthetic lubricants with polymer-coated sensors. Anal. Chim. Acta. 1995, 315, 15–26. [Google Scholar] [CrossRef]

- Balde, M.; Vena, A.; Sorli, B. Fabrication of porous anodic aluminium oxide layers on paper for humidity sensors. Sens. Actuators B Chem. 2015, 220, 829–839. [Google Scholar] [CrossRef]

- Raadnui, S.; Kleesuwan, S. Low-cost condition monitoring sensor for used oil analysis. Wear 2005, 259, 1502–1506. [Google Scholar] [CrossRef]

- Prashad, H. Investigation of damaged rolling-element bearings and deterioration of lubricants under the influence of electric fields. Wear 1994, 176, 151–161. [Google Scholar] [CrossRef]

- Karluk, A.A.; Ekim, S.D.; Baytekin, B.; Baytekin, H.T. Online lubricant degradation monitoring using contact charging of polymers. Appl. Surf. Sci. 2022, 584, 152593. [Google Scholar] [CrossRef]

- Maruyama, T.; Maeda, M.; Nakano, K. Lubrication condition monitoring of practical ball bearings by electrical impedance method. Tribol. Online. 2019, 14, 327–338. [Google Scholar] [CrossRef] [Green Version]

- El-Thalji, I.; Jantunen, E. A summary of fault modelling and predictive health monitoring of rolling element bearings. Mech. Syst. Signal Process. 2015, 60, 252–272. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, D.; Zhang, F.; Liu, Y.; Chen, B.; Wang, Z.L.; Pan, J.; Larsson, R.; Shi, Y. Real-time and online lubricating oil condition monitoring enabled by triboelectric nanogenerator. ACS Nano 2021, 15, 11869–11879. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Zhang, L. A review of failure modes, condition monitoring and fault diagnosis methods for large-scale wind turbine bearings. Measurement 2020, 149, 107002. [Google Scholar] [CrossRef]

- Liu, W.Y.; Tang, B.P.; Han, J.G.; Lu, X.N.; Hu, N.N.; He, Z.Z. The structure healthy condition monitoring and fault diagnosis methods in wind turbines: A review. Renew. Sustain. Energy Rev. 2015, 44, 466–472. [Google Scholar] [CrossRef]

- Wiser, R.; Rand, J.; Seel, J.; Beiter, P.; Baker, E.; Lantz, E.; Gilman, P. Expert elicitation survey predicts 37% to 49% declines in wind energy costs by 2050. Nat. Energy 2021, 6, 555–565. [Google Scholar] [CrossRef]

- Rezamand, M.; Kordestani, M.; Carriveau, R.; Ting, D.S.; Saif, M. An integrated feature-based failure prognosis method for wind turbine bearings. IEEE ASME Trans. Mechatron. 2020, 25, 1468–1478. [Google Scholar] [CrossRef]

| Basis | Category Name |

|---|---|

| Spindle to ground Position | Horizontal, vertical. |

| Generator types | Synchronous, asynchronous. |

| Loading mode | Lifting, resistance. |

| Operation mode | Constant-speed, limited-variable-speed, variable-speed. |

| Power | Micro, small, medium, large. |

| Grid connection | Grid-connected, off-grid. |

| Drive train | Gearbox speed increase, direct drive. |

| Blade number | Multi-blade, three-blade, double-blade, single-blade. |

| Bearing Type | Components Used |

|---|---|

| Cylindrical, Spherical, Tapered roller bearings | Main shaft, Gearbox |

| Cylindrical and Spherical rolling element bearings | Generator |

| Single/Double row contact ball bearings | Pitch/Yaw, Gearbox |

| Cylindrical roller bearings | Main shaft, Gearbox, Generator |

| Failure Type | Failure Modes and Characteristics | Failure Cause |

|---|---|---|

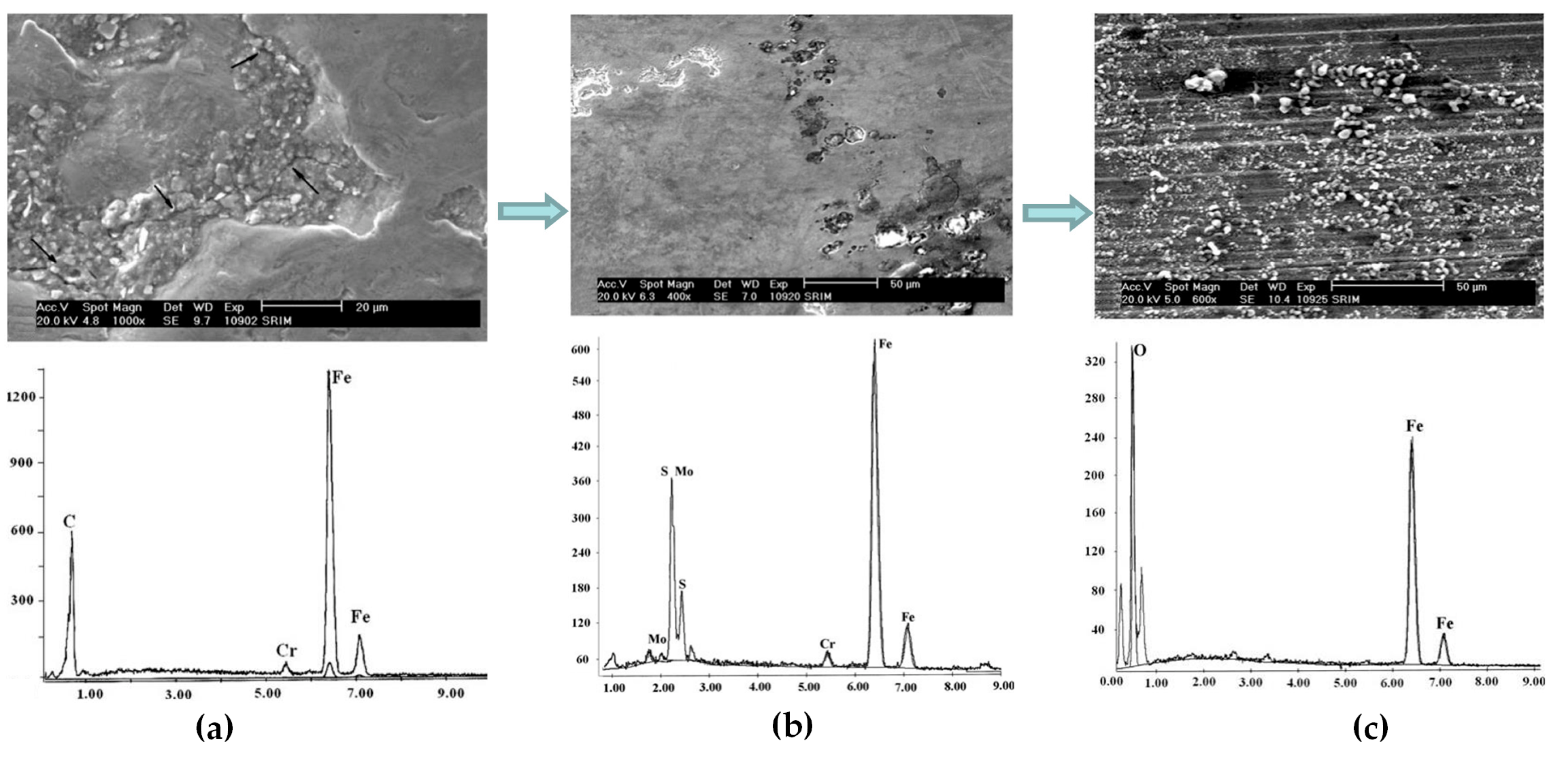

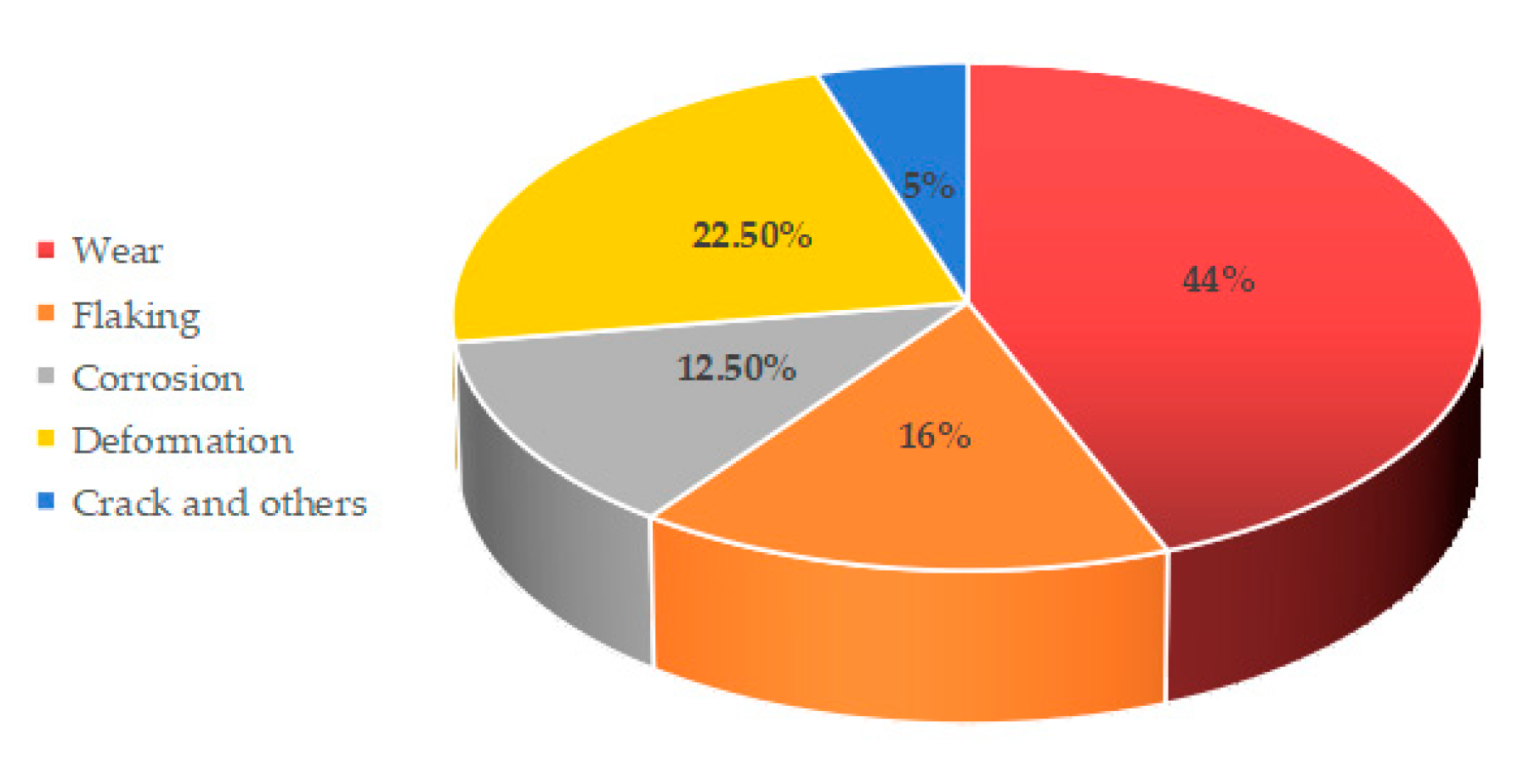

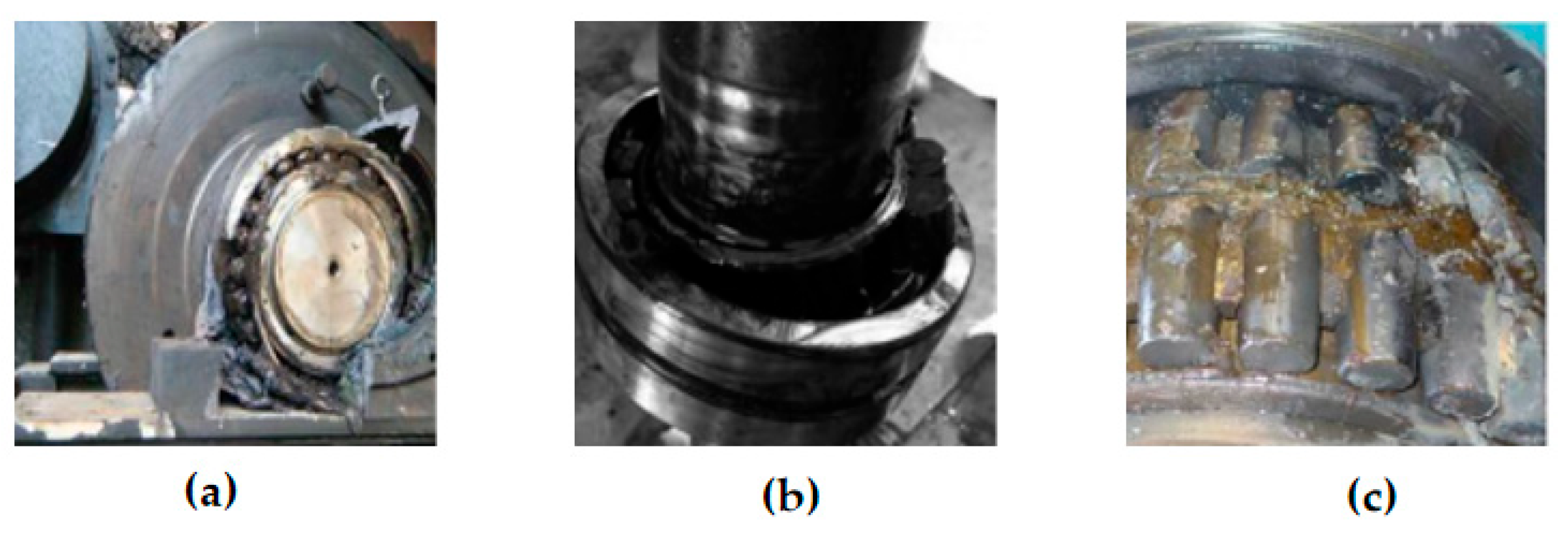

| Fatigue failure | Characteristics: as shown in Figure 4a, bearing surface appears to be peeling and other phenomena. Modes: white microstructure flaking, micropitting, and axial cracking. | Manufacture technology issues, long-term high-load operation, bearing rolling contact fatigue. |

| Wear | Characteristics: as shown in Figure 4b, bearing clearance increases and wear marks appear, which are often accompanied by abnormal vibration and noise, and the color of the bearing becomes darker. Modes: bearings are prone to adhesive wear, abrasive wear, Brinell marks, and corrosion patterns. | Bearing internal debris roller or raceway internal debris cause surface damage or lead to the appearance of chips and dents. |

| Corrosion | Characteristics: as shown in Figure 4c, rust spots and shallow pits on the outer surface of the bearings, with grey and black spots along raceways. Modes: the chemical reaction caused by the bearing surface material is divided into physical corrosion and chemical corrosion. | Physical and chemical corrosion caused by debris and water or corrosive substances in the bearings. |

| Electrico-etching | Characteristics: as shown in Figure 4d, rust on the outer surface of the bearing and on the raceways and rollers, accompanied by shallow pits and dark grooves. Modes: there is rust on the outer surface of the bearing and on the raceways and rollers. | When the axial current exists or the voltage is too high, the axial current flows through the rolling body and raceway, causing sparks and arcs, thus melting the bearing surface. |

| Plastic deformation | Characteristics: as shown in Figure 4e, the bearing appears loose, and the surface becomes twisted and deformed. Modes: Bearings material appears indentation bending and other phenomena. | Plastic deformation comes from misaligned motion, and there are two different types. The first type is on the macroscopic scale, caused by heavy or high loads with excessive accelerating loads, and occurs at the contact surface of the contact ball race. The second type is on the microscale and occurs in a small indentation in the contact surface. Misalignment of raceway edge and ball path occurs or relative motion of bearing ring and shaft. |

| Cracks and fractures | Characteristics: as shown in Figure 4f, cracks or fissures on the bearing surface. Modes: stress fracture, fatigue fracture and thermal cracking modes. | Excessive stress concentration in the tensile strength of the bearing material, high temperature caused by sliding friction and improper assembly or process problems. |

| Bearing Type | Lubricants |

|---|---|

| Main shaft bearing | Grease |

| Generator bearing | Grease |

| Pitch Bearing | Grease |

| Yaw Bearing | Grease |

| Gearbox bearing | Gear oil |

| Reference Number | Author (s), Year | Major Findings |

|---|---|---|

| [129] | Sun et al., 2012 | Synthesis of an excellent sulfur-containing heterocyclic derivative additive (RHY317). |

| [140] | Iglesias et al., 2015 | Ionic liquids are used as additives to lubricants. |

| [144] | Ali et al., 2016 | Different sizes of Al2O3 and TiO2 nanoparticles were used as lubricant additives to reduce friction. |

| [143] | Essa et al., 2017 | The use of high content of mixed solid lubricants will greatly reduce the coefficient of friction. |

| [130] | Xia et al., 2018 | A new type of wind power bearing grease (additive: T351, T323) was researched. |

| [146] | Haque et al., 2018 | Lubricants containing metal additives are prone to water contamination and cause white etch cracks (WECs). |

| [141] | Ali et al., 2019 | Solid lubricants have excellent friction reduction properties at high temperatures. |

| [131] | Mutyala et al., 2019 | Proposed combination of solid lubricant two-dimensional MoS2 with diamond-like (DLC) film. |

| [142] | Elsheikh et al., 2020 | Demonstrated that the combination of different solid nano-lubricants will have a positive effect on improving the tribological properties of bearing steel. |

| [134] | Gao et al., 2020 | Developed a grease suitable for wind turbine spindle bearings. |

| [136] | Gao et al., 2020 | Developed a new type of grease for wind turbine pitch bearings. |

| [137] | Schwack et al., 2020 | Six industrial greases with different compositions were tested for their anti-wear performance. |

| [132] | Ng et al., 2021 | Synthesis of a non-polluting and non-toxic nano-lubricant. |

| [138] | Sun et al., 2021 | L1-320 extreme pressure-anti-wear performance is better than L2-320. |

| [139] | Saidi et al., 2021 | Prepared MoS2 nano-lubricant additives. |

| [145] | Li et al., 2021 | Extreme pressure additives and solid additives can cause corrosion on the surface of the bearing steel. |

| [147] | Li et al., 2021 | Replace the lubricant for bearings whose drip point drops more than 30 °C and whose iron content exceeds 5000 ppm. |

| [148] | Feng et al., 2021 | Reprocessing of wind turbine gearbox lubricants. |

| [133] | SKF Corp. | Developed about wind power main shaft bearing LGWM series grease. |

| Lubrication Method | Advantages | Disadvantages |

|---|---|---|

| Centralized lubrication | Lubrication pump centralized pumping lubricates, high efficiency, easy maintenance and overhaul, and high precision can achieve a variety of and self-quantitative lubricate supply [163]. | The piping is complicated, the hydraulic pipe Louis leaks, the lubricant flow requirements are high, and the distributor is easily clogged causing system failure [119]. |

| Oil mist lubrication | Better sealing effect on lubricant, minimizes waste of lubricant, less lubricant required, and less impurity intrusion. | Lubricants require high-level viscosity; the conveying distance is too short and the adjustment of the oil mist volume is difficult. |

| Oil–air lubrication | No requirement for lubricant viscosity, wide range of applications; the impact to the environment is lower; controllable lubrication quantity and high lubrication efficiency and high pressure airflow can cool down and resist impurities [161]. | Need compressed air and other air sources; produce a certain amount of noise pollution; higher operational standard and total cost. |

| Oil bath lubrication | Simple lubrication structure; adequate lubrication; low operating cost. | Only suitable for low and medium-speed bearing lubrication. Oil quantity control is complicated and produces impurities, causing damage [162]. |

| Reference Number | Author (s), Year | Major Findings |

|---|---|---|

| [176] | Erill et al., 2013 | Invented a dynamic lubrication system for wind turbine pitch bearings. |

| [164] | Yao et al., 2015 | Developed a new type of lubrication pumping station. |

| [170] | Westerberg et al., 2016 | It shows that the elbow angle of the nozzle is related to the flow of grease, and the high flow rate will reduce the sliding effect. |

| [165] | Wang et al., 2016 | Theoretical analysis model of wind power bearing lubrication state was established. |

| [177] | Yang et al., 2016 | Achievement of dynamic lubrication of wind turbine main shaft bearings |

| [173] | Farré-Lladós et al., 2017 | Designed and manufactured micro-nozzles for automatic lubrication of wind turbine pitch gears. |

| [167] | Gu et al., 2019 | Structural design of rolling bearings was carried out. |

| [168] | Peng et al., 2020 | Design of automatic temperature-controlled heating device. |

| [171] | Liu et al., 2021 | A fluid–solid coupling simulation model was developed to study the effects of oil flow rate, lubricant viscosity, nozzle angle, and nozzle number on the lubrication characteristics of gearbox bearings. |

| [169] | Meng et al., 2021 | Constructed the discrete element numerical model of particle flow lubrication. |

| [172] | Li et al., 2021 | Designed a bearing lubrication device based on piezoelectric micro-jet theory. |

| [174] | Oliveira et al., 2021 | A new method for modeling and identifying the oil supply in dynamic pressure bearings is proposed. |

| [175] | Ge et al., 2021 | Proposed to add a groove structure to the non-contact area of the bearing inner ring surface. |

| Reference Number | Author (s), Year | Major Findings |

|---|---|---|

| [210] | Raadnui et al., 2005 | Developed a low-cost gate capacitive sensor. |

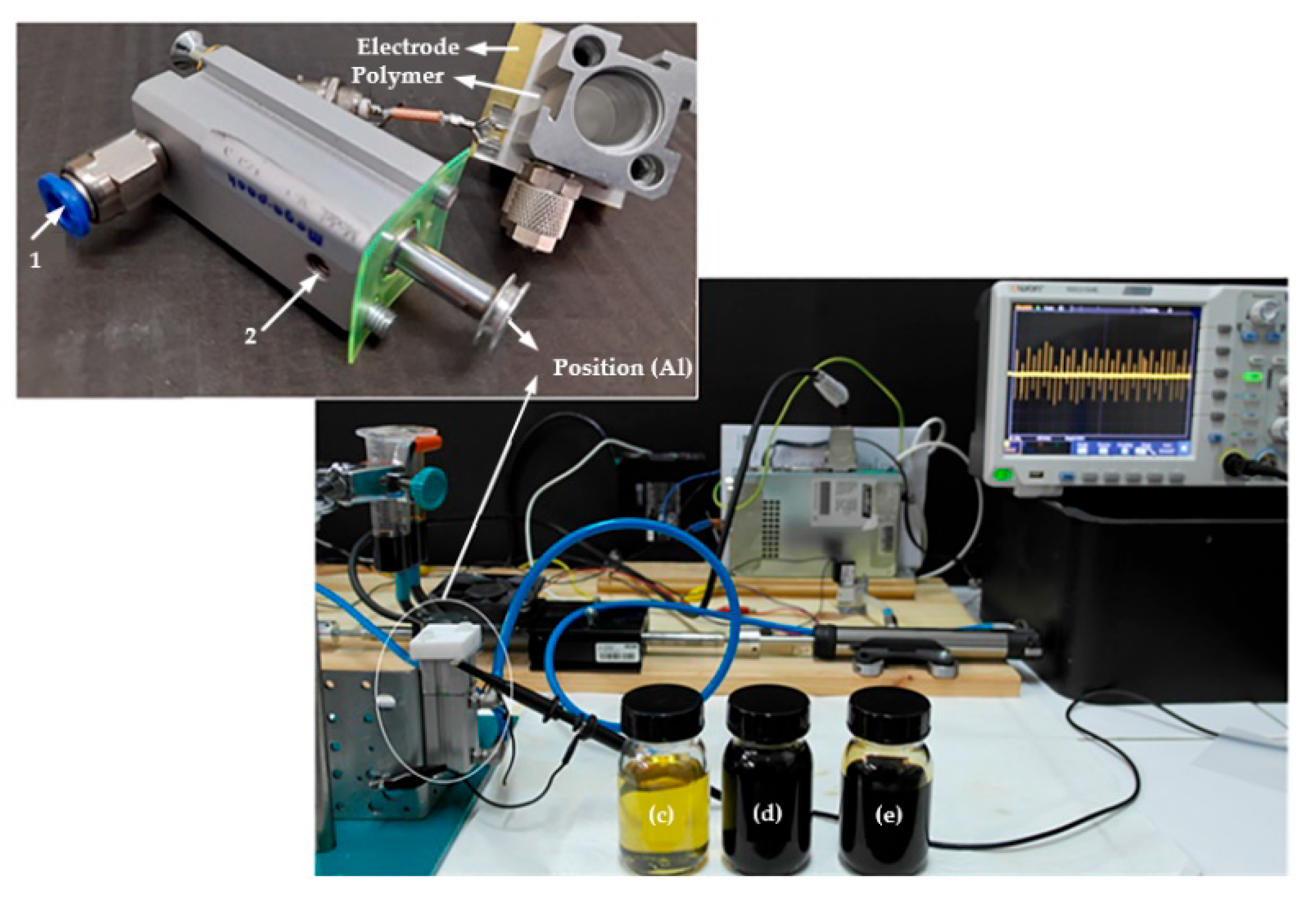

| [203] | Murali et al., 2009 | A pico-fluidic apparatus was designed for the inspection of metals particulates in low conductivity lubricants. |

| [198] | Ünlü et al., 2012 | Determined the frictional wear behavior under bearing lubrication conditions. |

| [202] | Márton et al., 2012 | Proposed an energy-balanced lubricant viscosity detection method. |

| [184] | Su et al., 2013 | Used the signal amplitude graph reflects the lubrication status of the bearing. |

| [191] | Ibrahim et al., 2017 | Used acoustic emission technology to test solid contaminants of different concentrations and particle sizes of grease. |

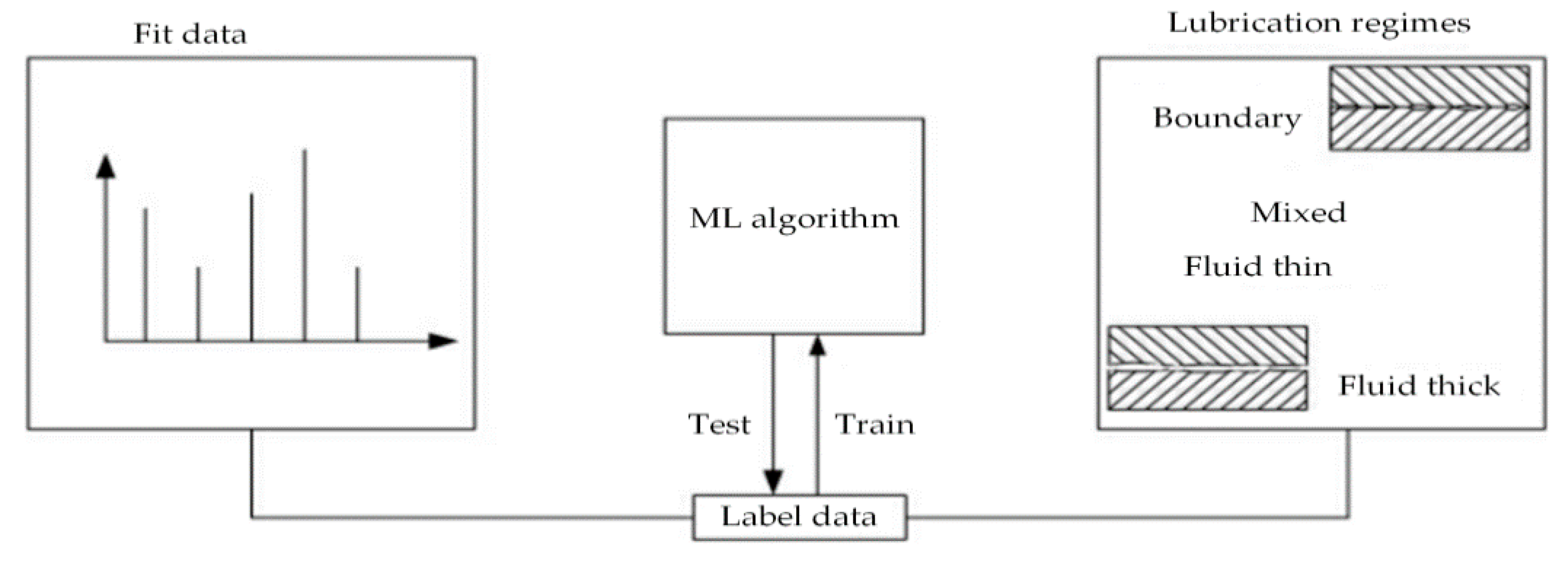

| [199] | Moder et al., 2018 | Using machine learning (ML) algorithms to predict the lubrication status of high-speed torque bearings. |

| [189] | Mijares et al., 2019 | Presented a vibration analysis method to monitor the amount of lubrication in the bearing. |

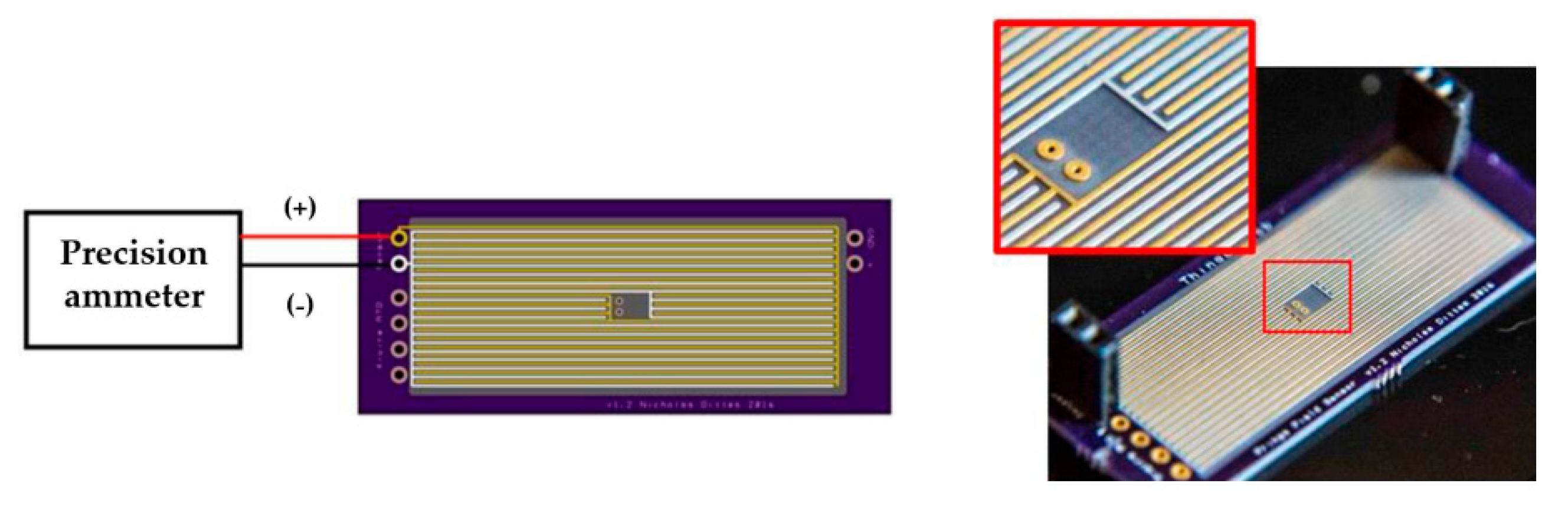

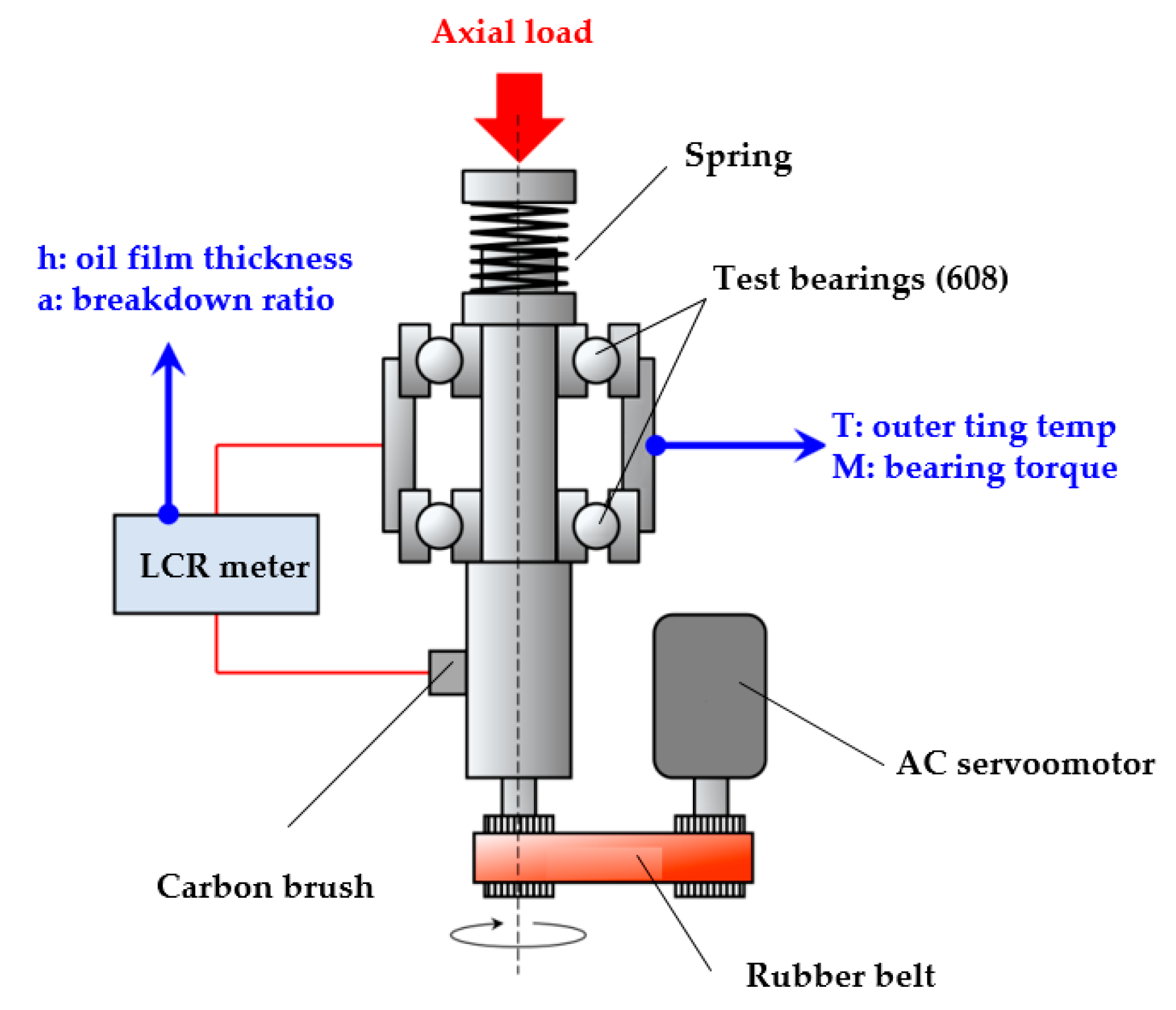

| [213] | Maruyama et al., 2019 | Developed an electrical impedance method for monitoring the lubrication status of deep groove ball bearings. |

| [204] | Dittes et al., 2020 | Developed a corrosion sensor. |

| [201] | Katsaros et al., 2021 | Combining numerical analysis and machine learning techniques. |

| [190] | Nicholas et al., 2021 | Suggested a new ultrasound reflection technique. |

| [200] | Zavos et al., 2022 | Developed an ML model based on an ordered regression algorithm to predict coating application and lubricant selection for bearing components. |

| [212] | Karluk et al., 2022 | Proposed a method for monitoring lubricant degradation based on frictional charging. |

| [205] | Schaeffler Co. | Created a device for grease condition monitoring. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, H.; Zhang, H.; Shangguan, L.; Fan, Y. Review of Tribological Failure Analysis and Lubrication Technology Research of Wind Power Bearings. Polymers 2022, 14, 3041. https://doi.org/10.3390/polym14153041

Peng H, Zhang H, Shangguan L, Fan Y. Review of Tribological Failure Analysis and Lubrication Technology Research of Wind Power Bearings. Polymers. 2022; 14(15):3041. https://doi.org/10.3390/polym14153041

Chicago/Turabian StylePeng, Han, Hai Zhang, Linjian Shangguan, and Yisa Fan. 2022. "Review of Tribological Failure Analysis and Lubrication Technology Research of Wind Power Bearings" Polymers 14, no. 15: 3041. https://doi.org/10.3390/polym14153041