Effects of Fiber Volume Fraction and Length on the Mechanical Properties of Milled Glass Fiber/Polyurea Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Composites

2.3. Tests

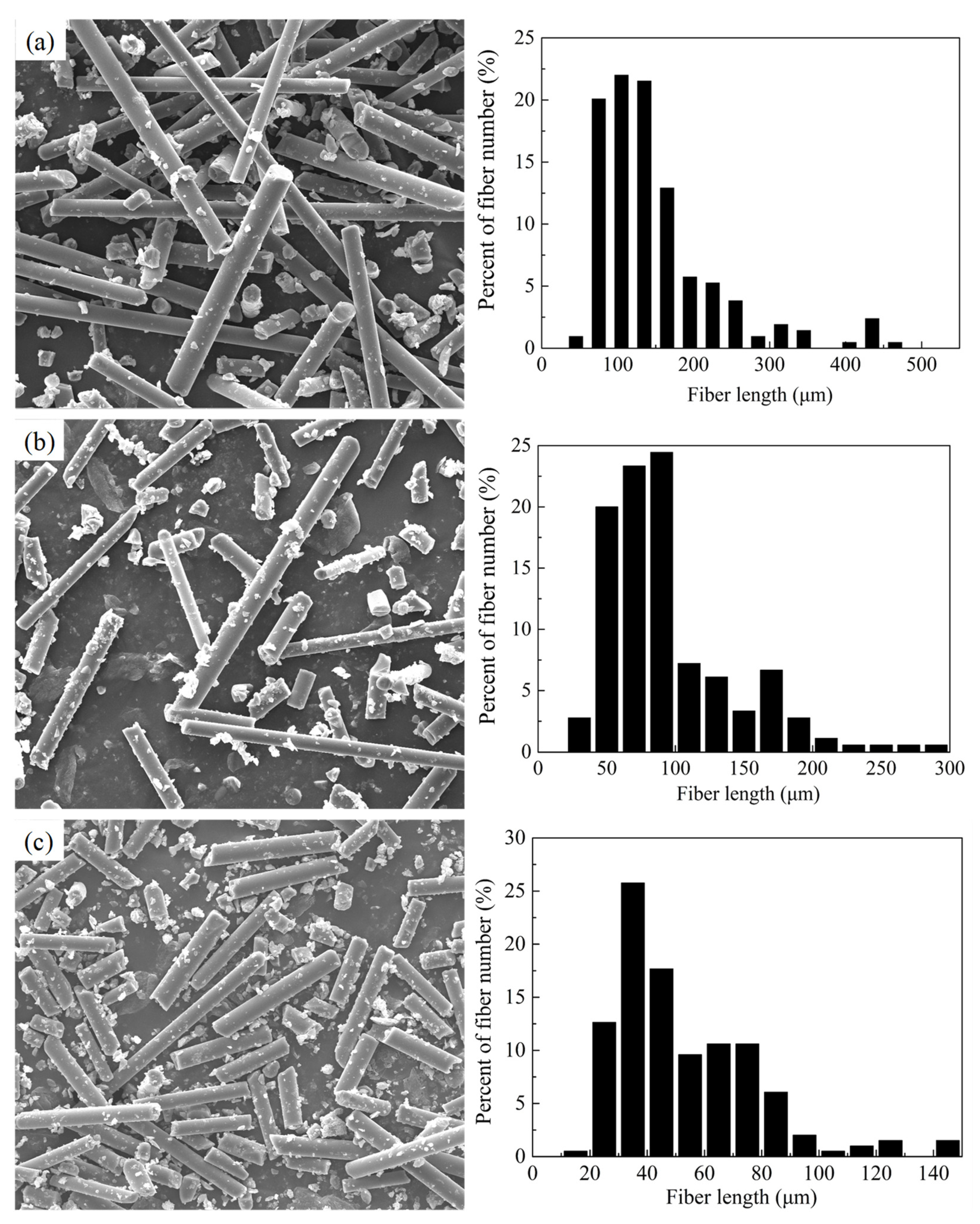

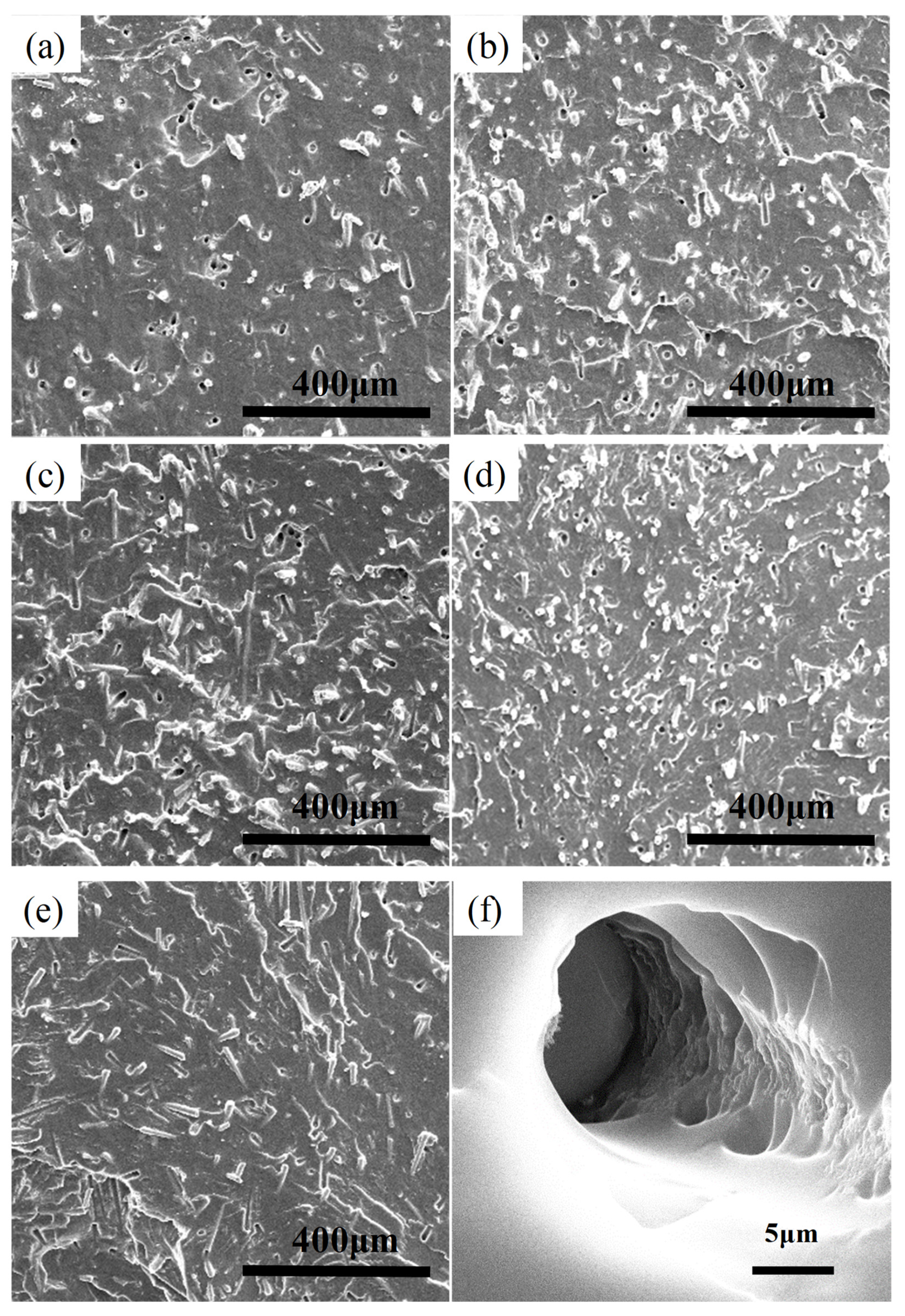

2.3.1. Scanning Electron Microscopy (SEM)

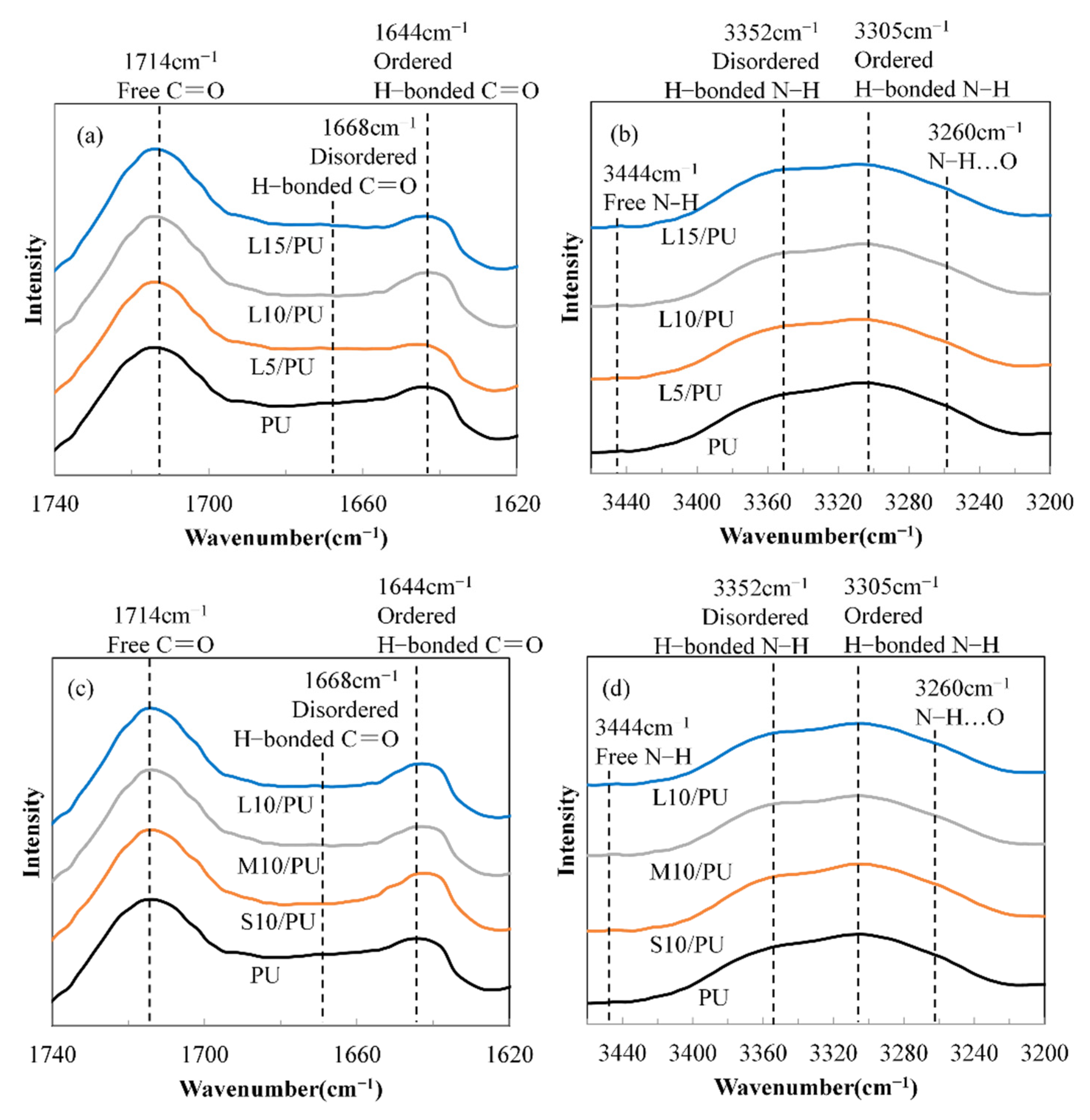

2.3.2. Fourier Transform Infrared (FTIR) Spectroscopy

2.3.3. Compression Tests

2.3.4. Characterization of Dynamic Mechanical Properties

3. Results and Discussion

3.1. Microstructure

3.2. Hydrogen Bonding

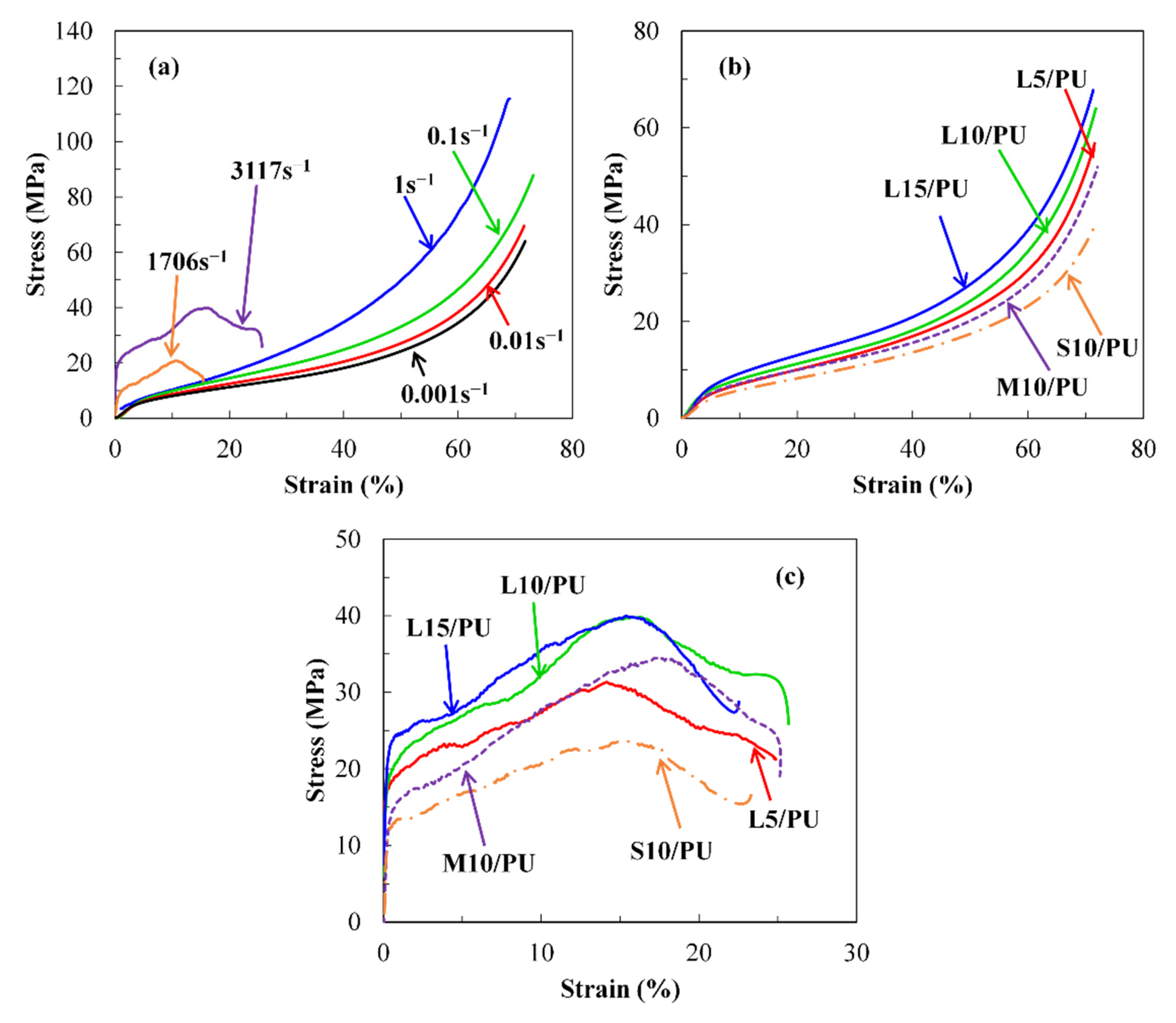

3.3. Compression Testing: Rate Dependence of Stress–Strain Behavior

3.3.1. Stress–Strain Relationship

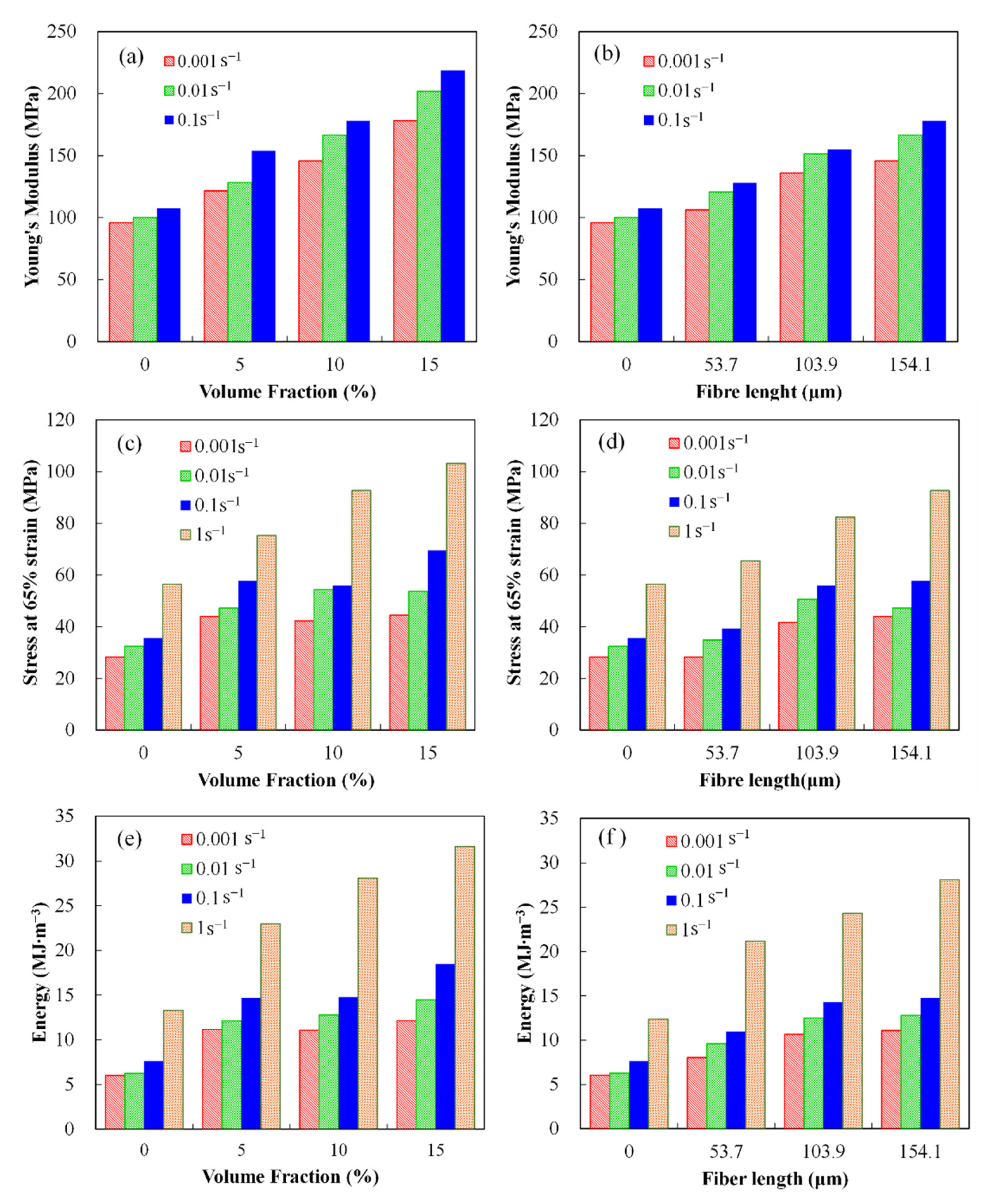

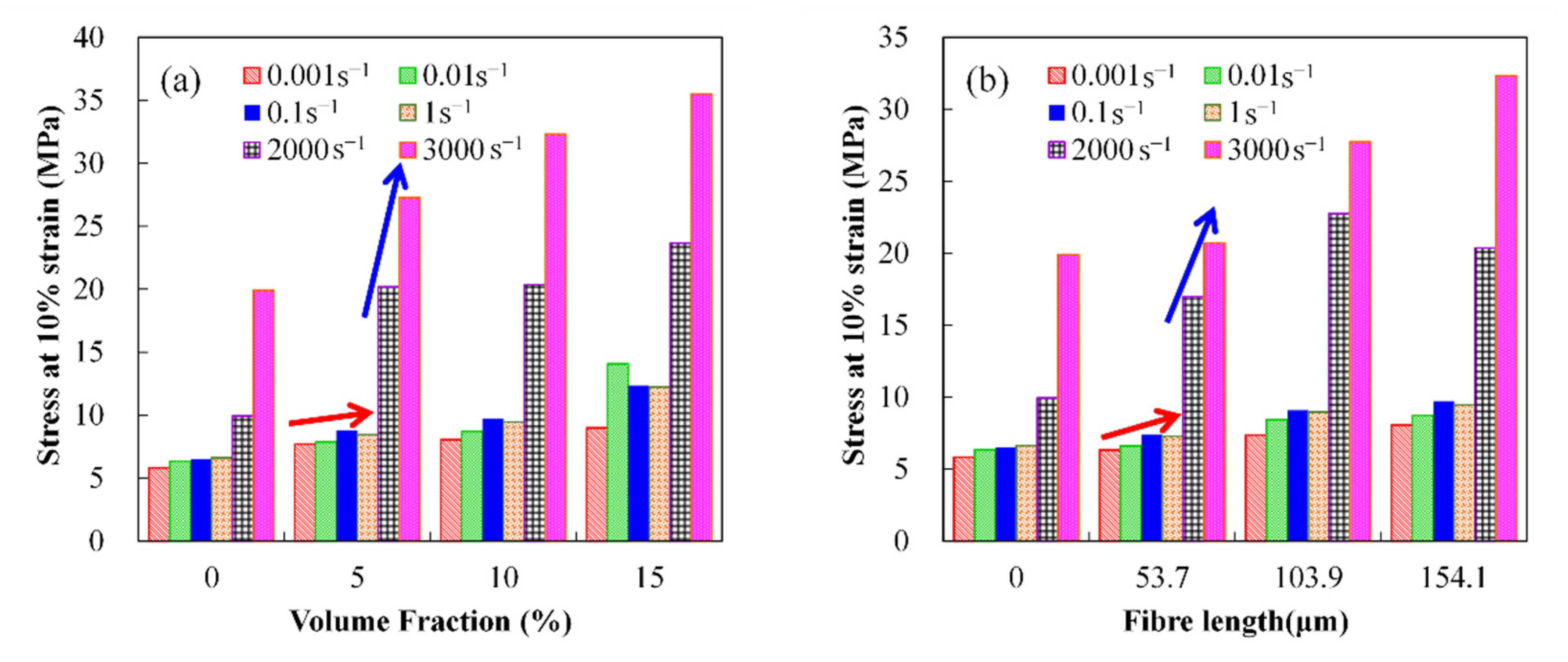

3.3.2. Compressive Mechanical Properties

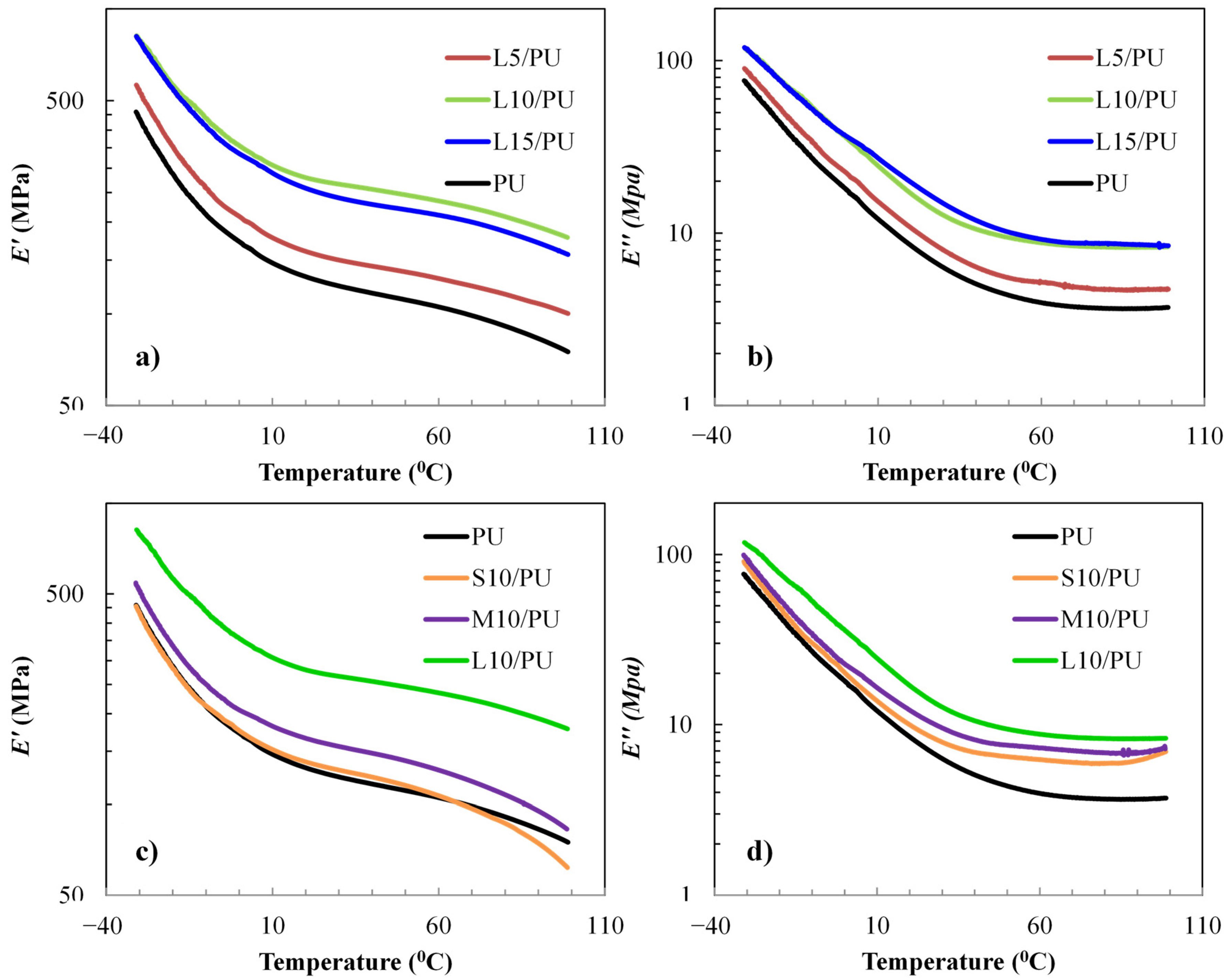

3.4. Dynamic Mechanical Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, R.; Huang, W.; Lyu, P.; Yan, S.; Wang, X.; Ju, J. Polyurea for Blast and Impact Protection: A Review. Polymers 2022, 14, 2670. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Ren, H.; Wu, X.; Cai, C. Blast response of polymer-retrofitted masonry unit walls. Compos. Part B Eng. 2017, 128, 174–181. [Google Scholar] [CrossRef]

- Acharya, P.; Ebrahimian, H.; Moustafa, M.A. Behavior Study of Commercial Polyurea under Monotonic, Rate Dependent, Cyclic, and Fatigue Tensile Loading for Potential Structural Applications. Polymers 2022, 14, 1878. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.; Guo, B.; Chen, P.; Su, J.; Arab, A.; Ding, G.; Yan, G.; Jiang, H.; Guo, F. Investigating ballistic resistance of CFRP/polyurea composite plates subjected to ballistic impact. Thin-Walled Struct. 2021, 166, 108111. [Google Scholar] [CrossRef]

- Zhou, H.; Attard, T.L.; Dhiradhamvit, K.; Wang, Y.; Erdman, D. Crashworthiness characteristics of a carbon fiber reinforced dual-phase epoxy–polyurea hybrid matrix composite. Compos. Part B Eng. 2015, 71, 17–27. [Google Scholar] [CrossRef] [Green Version]

- Qiao, J.; Wu, Y.; Li, L. Effect of filler content on the stress relaxation behavior of fly ash/polyurea composites. Polym. Test. 2020, 81, 106168. [Google Scholar] [CrossRef]

- Santana, J.S.; Cardoso, E.S.; Triboni, E.R.; Politi, M.J. Polyureas Versatile Polymers for New Academic and Technological Applications. Polymers 2021, 13, 4393. [Google Scholar] [CrossRef]

- Hou, H.; Chen, C.; Cheng, Y.; Zhang, P.; Tian, X.; Liu, T.; Wang, J. Effect of structural configuration on air blast resistance of polyurea-coated composite steel plates: Experimental studies. Mater. Des. 2019, 182, 108049. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, Z.; Zhao, P.; Zhang, L.; Jin, X.; Xu, Y. Experimental investigation on ballistic resistance of polyurea coated steel plates subjected to fragment impact. Thin-Walled Struct. 2019, 144, 106342. [Google Scholar] [CrossRef]

- Harikumar, R.; Devaraju, A. Exploration of mechanical properties of polyurea coated mild steel plate and aluminium plate sandwich composites. In Proceedings of the International Conference on Materials Engineering and Characterization (IC-MECH), Adhi Coll Engn & Technol, Chennai, India, 8–10 May 2019; pp. 1144–1148. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Z.; Zhao, T.; Cao, X.; Jiang, Y.; Xiao, D.; Fang, D. An experimental study on dynamic response of polyurea coated metal plates under intense underwater impulsive loading. Int. J. Impact Eng. 2019, 133, 103361. [Google Scholar] [CrossRef]

- Chen, Y.-S.; Wang, B.; Zhang, B.; Zheng, Q.; Zhou, J.-N.; Jin, F.-N.; Fan, H.-L. Polyurea coating for foamed concrete panel: An efficient way to resist explosion. Def. Technol. 2020, 16, 136–149. [Google Scholar] [CrossRef]

- Ji, L.; Wang, P.; Cai, Y.; Shang, W.; Zu, X. Blast Resistance of 240 mm Building Wall Coated with Polyurea Elastomer. Materials 2022, 15, 850. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, P.; Jin, F.; He, H.; Zhou, Y.; Chen, H.; Zhou, J.; Wang, B.; Fan, H. Blast responses of polyurea-coated concrete arches. Arch. Civ. Mech. Eng. 2021, 21, 30. [Google Scholar] [CrossRef]

- Chang, C.-P.; Shih, C.-H.; You, J.-L.; Youh, M.-J.; Liu, Y.-M.; Ger, M.-D. Preparation and Ballistic Performance of a Multi-Layer Armor System Composed of Kevlar/Polyurea Composites and Shear Thickening Fluid (STF)-Filled Paper Honeycomb Panels. Polymers 2021, 13, 3080. [Google Scholar] [CrossRef]

- LeBlanc, J.; Gardner, N.; Shukla, A. Effect of polyurea coatings on the response of curved E-Glass/Vinyl ester composite panels to underwater explosive loading. Compos. Part B Eng. 2013, 44, 565–574. [Google Scholar] [CrossRef]

- Sazhenkov, N.A.; Semenov, S.V.; Voronov, L.V.; Kurakin, A.D.; Nikhamkin, M.S.; Stergiou, T.; Baxevanakis, K.P.; Roy, A.; Silberschmidt, V.V. Polyurea-coated glass-fibre-reinforced laminate under high-speed impact: Experimental study. In Proceedings of the 1st European-Structural-Integrity-Society (ESIS) Virtual European Conference on Fracture (ECF), Electr Network, Online, 29 June–1 July 2020; pp. 1572–1578. [Google Scholar]

- Leblanc, J.; Shukla, A. Response of polyurea-coated flat composite plates to underwater explosive loading. J. Compos. Mater. 2015, 49, 965–980. [Google Scholar] [CrossRef]

- Gauch, E.; LeBlanc, J.; Shukla, A. Near field underwater explosion response of polyurea coated composite cylinders. Compos. Struct. 2018, 202, 836–852. [Google Scholar] [CrossRef]

- Toader, G.; Rusen, E.; Teodorescu, M.; Diacon, A.; Stanescu, P.O.; Damian, C.; Rotariu, T.; Rotariu, A. New polyurea MWCNTs nanocomposite films with enhanced mechanical properties. J. Appl. Polym. Sci. 2017, 134, 45061. [Google Scholar] [CrossRef]

- Liu, Q.; Chen, P.-W.; Guo, Y.-S.; Su, J.-J.; Han, L.; Arab, A.; Yuan, J.-F. Mechanical behavior and failure mechanism of polyurea nanocomposites under quasi-static and dynamic compressive loading. Def. Technol. 2021, 17, 495–504. [Google Scholar] [CrossRef]

- Barczewski, M.; Biedrzycka, K.; Szostak, M.; Kloziński, A.; Aniśko, J.; Matykiewicz, D.; Andrzejewski, J.; Hahn, J.; Wiernicki, J. Spray-formed polyurea composites filled with basalt powder as inorganic waste filler. Plast. Rubber Compos. 2021, 50, 276–284. [Google Scholar] [CrossRef]

- Ma, L.; Liu, F.; Liu, D.; Liu, Y. Review of Strain Rate Effects of Fiber-Reinforced Polymer Composites. Polymers 2021, 13, 2839. [Google Scholar] [CrossRef]

- Geng, K.; Chai, J.; Qin, Y.; Li, X.; Duan, M.; Liang, D. Exploring the brittleness and fractal characteristics of basalt fiber reinforced concrete under impact load based on the principle of energy dissipation. Mater. Struct. 2022, 55, 78. [Google Scholar] [CrossRef]

- Song, J.-H.; Lee, E.-T.; Eun, H.-C. A Study on the Improvement of Structural Performance by Glass Fiber-Reinforced Polyurea (GFRPU) Reinforcement. Adv. Civ. Eng. 2019, 2019, 1–8. [Google Scholar] [CrossRef]

- Carey, N.L.; Myers, J.J. Discrete Fiber Reinforced Polyurea for Hazard Mitigation. In Proceedings of the 5th International Conference on FRP Composites in Civil Engineering, Beijing, China, 27–29 September 2010; pp. 81–84. [Google Scholar]

- Jia, Z.; Amirkhizi, A.V.; Nantasetphong, W.; Nemat-Nasser, S. Experimentally-based relaxation modulus of polyurea and its composites. Mech. Time-Depend. Mater 2016, 20, 155–174. [Google Scholar] [CrossRef] [Green Version]

- Nantasetphong, W.; Jia, Z.; Amirkhizi, A.V.; Nemat-Nasser, S. Dynamic properties of polyurea-milled glass composites Part I: Experimental characterization. Mech. Mater. 2016, 98, 142–153. [Google Scholar] [CrossRef]

- Nantasetphong, W.; Amirkhizi, A.V.; Jia, Z.; Nemat-Nasser, S. Dynamic properties of polyurea-milled glass composites part II: Micromechanical modeling. Mech. Mater. 2016, 98, 111–119. [Google Scholar] [CrossRef]

- Qiao, J.; Wu, G. Tensile properties of fly ash/polyurea composites. J. Mater. Sci. 2011, 46, 3935–3941. [Google Scholar] [CrossRef]

- Qiao, J.; Amirkhizi, A.V.; Schaaf, K.; Nemat-Nasser, S. Dynamic Mechanical Analysis of Fly Ash Filled Polyurea Elastomer. J. Eng. Mater. Technol. 2011, 133, 011016. [Google Scholar] [CrossRef] [Green Version]

- Unterweger, C.; Mayrhofer, T.; Piana, F.; Duchoslav, J.; Stifter, D.; Poitzsch, C.; Fürst, C. Impact of fiber length and fiber content on the mechanical properties and electrical conductivity of short carbon fiber reinforced polypropylene composites. Compos. Sci. Technol. 2020, 188, 107998. [Google Scholar] [CrossRef]

- Ganeshan, P.; Kumaran, S.S.; Raja, K.; Venkateswarlu, D. An investigation of mechanical properties of madar fiber reinforced polyester composites for various fiber length and fiber content. Mater. Res. Express 2019, 6, 015303. [Google Scholar] [CrossRef]

- Şerban, D.-A.; Weissenborn, O.; Geller, S.; Marşavina, L.; Gude, M. Evaluation of the mechanical and morphological properties of long fibre reinforced polyurethane rigid foams. Polym. Test. 2016, 49, 121–127. [Google Scholar] [CrossRef]

- Sreenivasan, V.; Ravindran, D.; Manikandan, V.; Narayanasamy, R. Mechanical properties of randomly oriented short Sansevieria cylindrica fibre/polyester composites. Mater. Des. 2011, 32, 2444–2455. [Google Scholar] [CrossRef]

- Castagna, A.M.; Pangon, A.; Dillon, G.P.; Runt, J. Effect of Thermal History on the Microstructure of a Poly(tetramethylene oxide)-Based Polyurea. Macromolecules 2013, 46, 6520–6527. [Google Scholar] [CrossRef]

- Pangon, A.; Dillon, G.P.; Runt, J. Influence of mixed soft segments on microphase separation of polyurea elastomers. Polymer 2014, 55, 1837–1844. [Google Scholar] [CrossRef]

- Hasnain, S.; Zulfequar, M.; Nishat, N. Adsorption properties of thermally stable and biologically active polyurea: Its synthesis and spectral aspects. Polym. Adv. Technol. 2012, 23, 1002–1010. [Google Scholar] [CrossRef]

- Seymour, R.W.; Estes, G.M.; Cooper, S.L. Infrared Studies of Segmented Polyurethan Elastomers. I. Hydrogen Bonding. Macromolecules 1970, 3, 579–583. [Google Scholar] [CrossRef]

- Tien, Y.; Wei, K. Hydrogen bonding and mechanical properties in segmented montmorillonite/polyurethane nanocomposites of different hard segment ratios. Polymer 2001, 42, 3213–3221. [Google Scholar] [CrossRef]

- Yi, J.; Boyce, M.C.; Lee, G.F.; Balizer, E. Large deformation rate-dependent stress–strain behavior of polyurea and polyurethanes. Polymer 2006, 47, 319–329. [Google Scholar] [CrossRef]

- Sarva, S.S.; Deschanel, S.; Boyce, M.C.; Chen, W. Stress–strain behavior of a polyurea and a polyurethane from low to high strain rates. Polymer 2007, 48, 2208–2213. [Google Scholar] [CrossRef]

- Roland, C.M.; Twigg, J.N.; Vu, Y.; Mott, P.H. High strain rate mechanical behavior of polyurea. Polymer 2007, 48, 574–578. [Google Scholar] [CrossRef]

- Reinecker, M.; Fuith, A.; Soprunyuk, V.; Sánchez-Ferrer, A.; Mrzel, A.; Torre, R.; Schranz, W. Influence of inorganic nanoparticles on the glass transitions of polyurea elastomers. Phys. Status Solidi A 2013, 210, 2320–2327. [Google Scholar] [CrossRef]

- Qian, X.; Yu, B.; Bao, C.; Song, L.; Wang, B.; Xing, W.; Hu, Y.; Yuen, R.K.K. Silicon nanoparticle decorated graphene composites: Preparation and their reinforcement on the fire safety and mechanical properties of polyurea. J. Mater. Chem. A 2013, 1, 9827–9836. [Google Scholar] [CrossRef]

- Rezaei, F.; Yunus, R.; Ibrahim, N.A. Effect of fiber length on thermomechanical properties of short carbon fiber reinforced polypropylene composites. Mater. Des. 2009, 30, 260–263. [Google Scholar] [CrossRef]

| R | DPS | DPM | |

|---|---|---|---|

| PU | 1.254 | 55.6% | 44.4% |

| L5/PU | 1.019 | 50.5% | 49.5% |

| L10/PU | 0.996 | 49.9% | 50.1% |

| L15/PU | 0.977 | 49.4% | 50.6% |

| S10/PU | 1.130 | 53.0% | 47.0% |

| M10/PU | 1.006 | 50.2% | 49.8% |

| −20 °C | 50 °C | |||

|---|---|---|---|---|

| E′ (MPa) | E″ (MPa) | E′ (MPa) | E″ (MPa) | |

| PU | 288.6 | 43.9 | 111.1 | 4.4 |

| L5/PU | 353.9 | 53.0 | 137.2 | 5.5 |

| L10/PU | 546.9 | 76.5 | 219.6 | 10.1 |

| L15/PU | 562.8 | 77.2 | 245.6 | 9.4 |

| S10/PU | 283.9 | 48.7 | 115.6 | 6.5 |

| M10/PU | 336.7 | 54.0 | 139.5 | 7.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiao, J.; Zhang, Q.; Wu, C.; Wu, G.; Li, L. Effects of Fiber Volume Fraction and Length on the Mechanical Properties of Milled Glass Fiber/Polyurea Composites. Polymers 2022, 14, 3080. https://doi.org/10.3390/polym14153080

Qiao J, Zhang Q, Wu C, Wu G, Li L. Effects of Fiber Volume Fraction and Length on the Mechanical Properties of Milled Glass Fiber/Polyurea Composites. Polymers. 2022; 14(15):3080. https://doi.org/10.3390/polym14153080

Chicago/Turabian StyleQiao, Jing, Quan Zhang, Chong Wu, Gaohui Wu, and Longqiu Li. 2022. "Effects of Fiber Volume Fraction and Length on the Mechanical Properties of Milled Glass Fiber/Polyurea Composites" Polymers 14, no. 15: 3080. https://doi.org/10.3390/polym14153080

APA StyleQiao, J., Zhang, Q., Wu, C., Wu, G., & Li, L. (2022). Effects of Fiber Volume Fraction and Length on the Mechanical Properties of Milled Glass Fiber/Polyurea Composites. Polymers, 14(15), 3080. https://doi.org/10.3390/polym14153080