Preparation and Characterisation of Wood Polymer Composites Using Sustainable Raw Materials

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

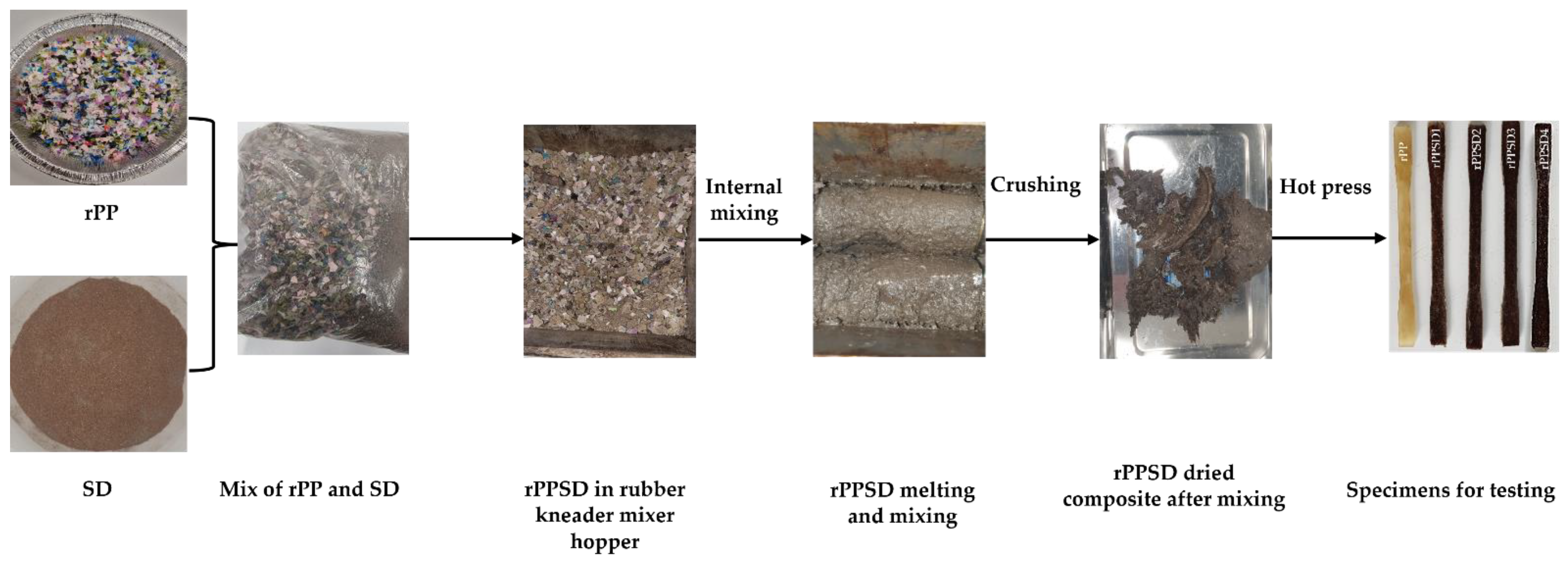

2.2. Preparation of Sawdust-Reinforced Recycled Polypropylene (rPPSD) Composites

2.2.1. Cleaning of the Recycled Polypropylene (rPP)

2.2.2. Cleaning of Sawdust (SD)

2.2.3. Preparation of rPPSD Composites

2.3. Morphology

2.4. Thermal Analysis

2.4.1. Thermogravimetric Analysis (TGA)

2.4.2. Differential Scanning Calorimeter (DSC) Analysis

2.5. Tensile Testing

2.6. Flexural Testing

2.7. Hardness

2.8. Creep Analysis

2.9. Soil Burial Degradation

2.10. Water Absorption

2.11. Water Contact Angle

2.12. Statistical Analyses

3. Results and Discussion

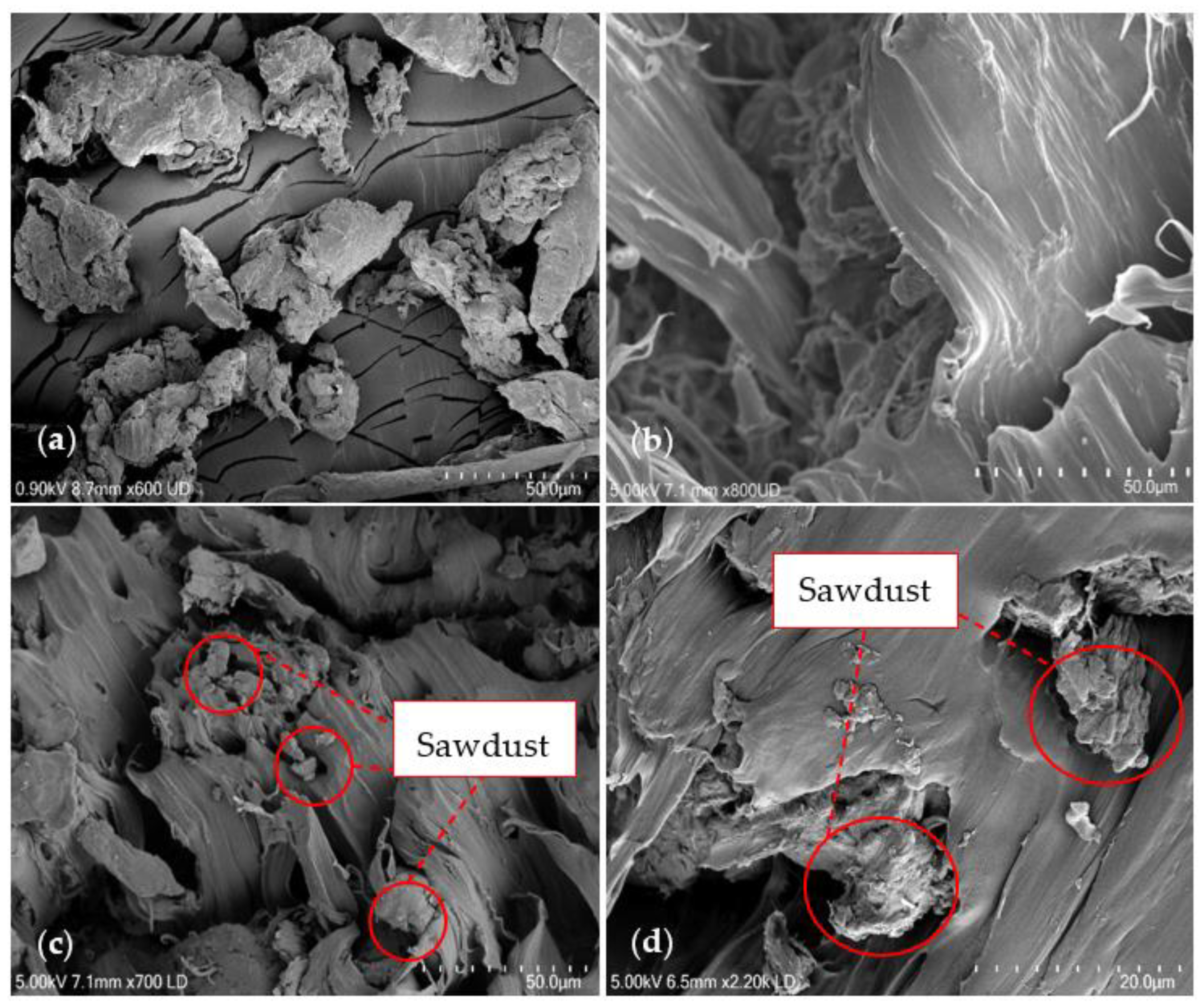

3.1. Morphology

3.2. Thermal Properties

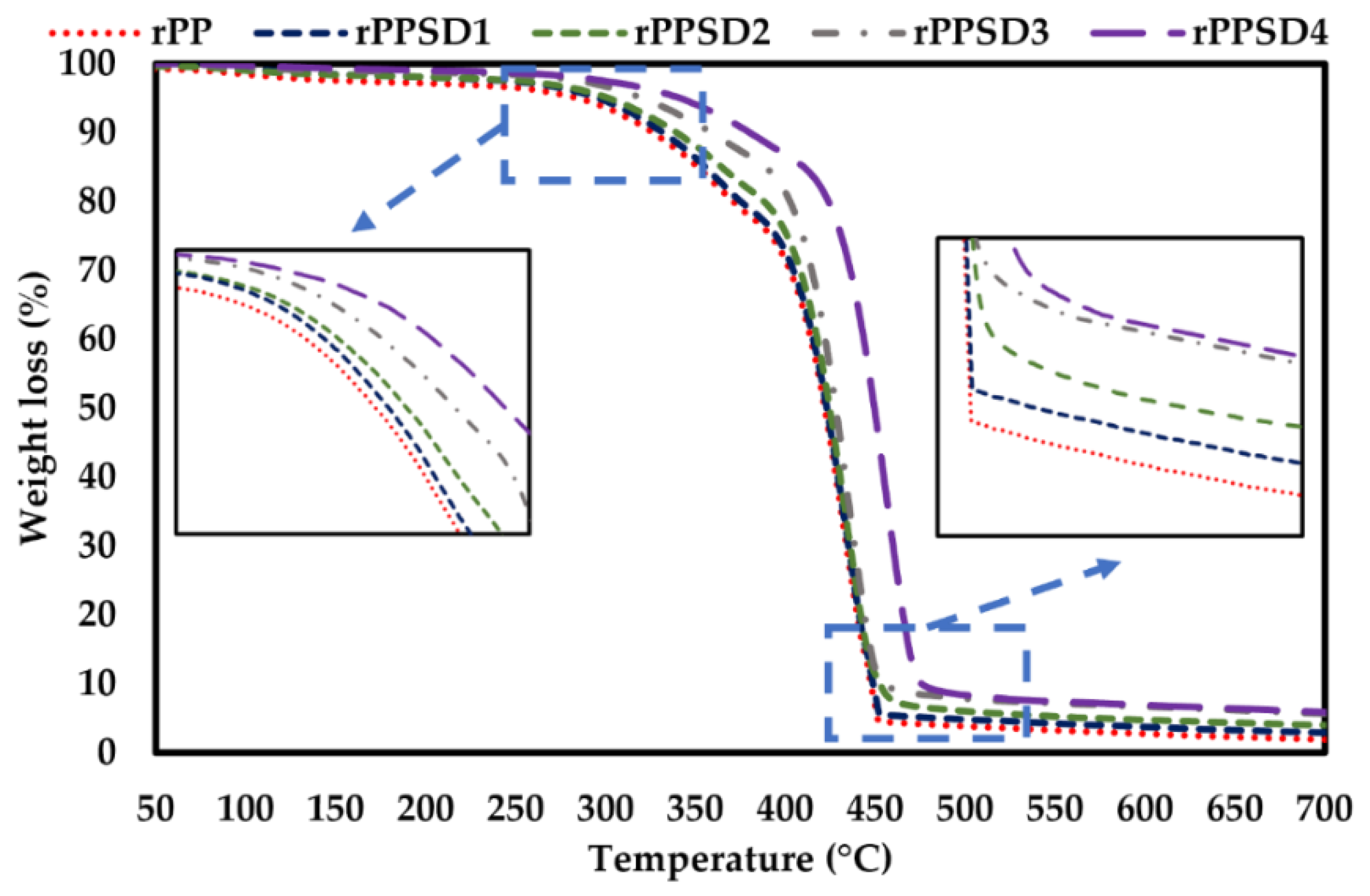

3.2.1. Thermogravimetric Analysis (TGA)

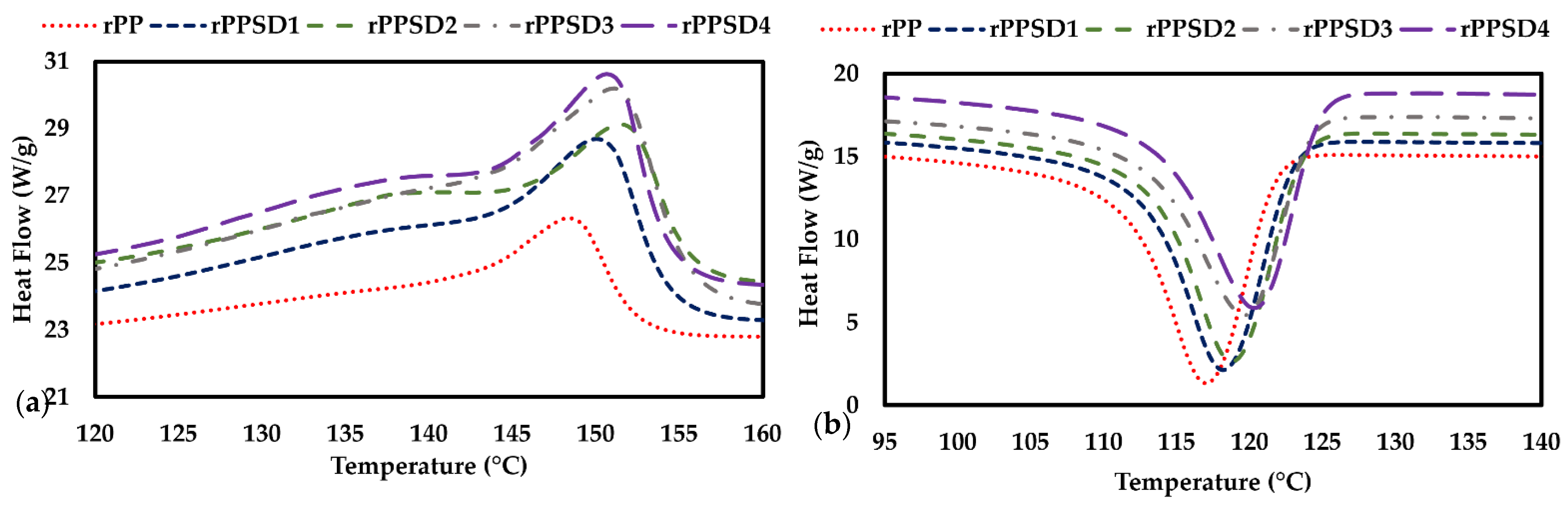

3.2.2. Differential Scanning Calorimetric Analysis (DSC)

3.3. Tensile Properties

3.4. Flexural Properties

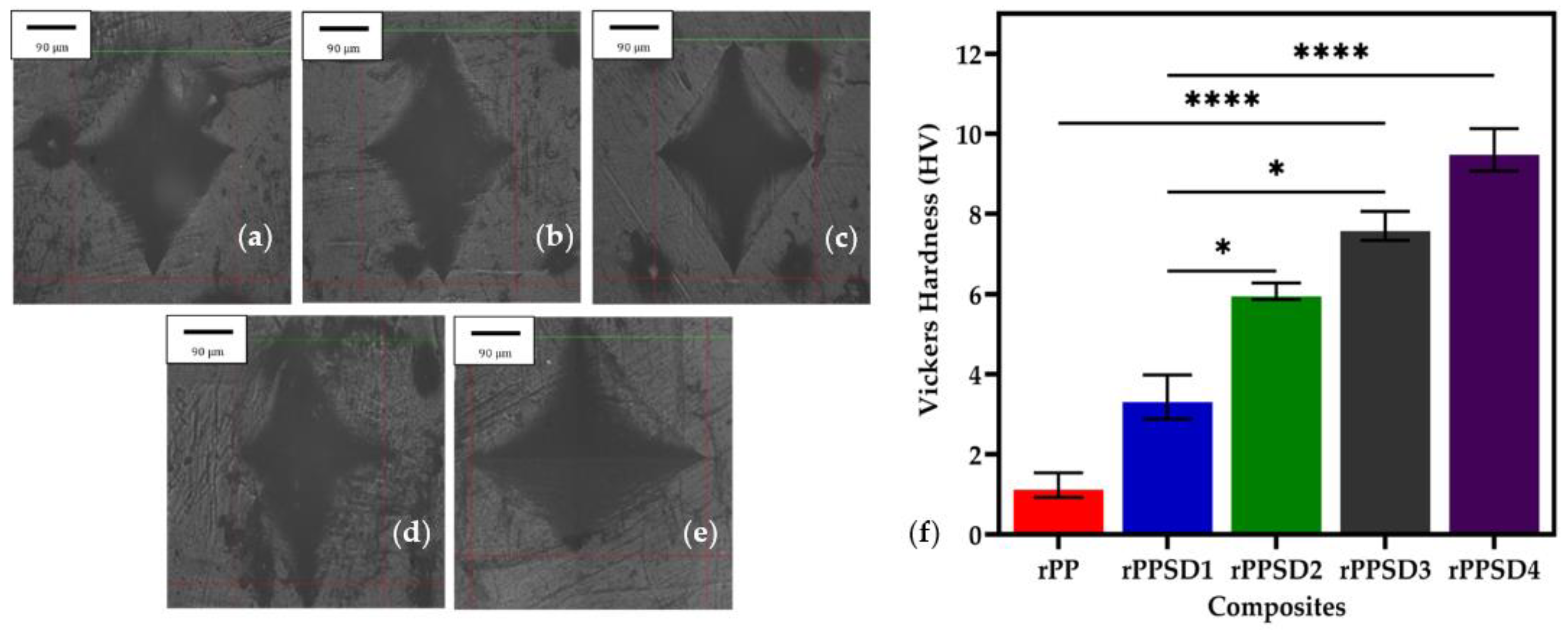

3.5. Hardness

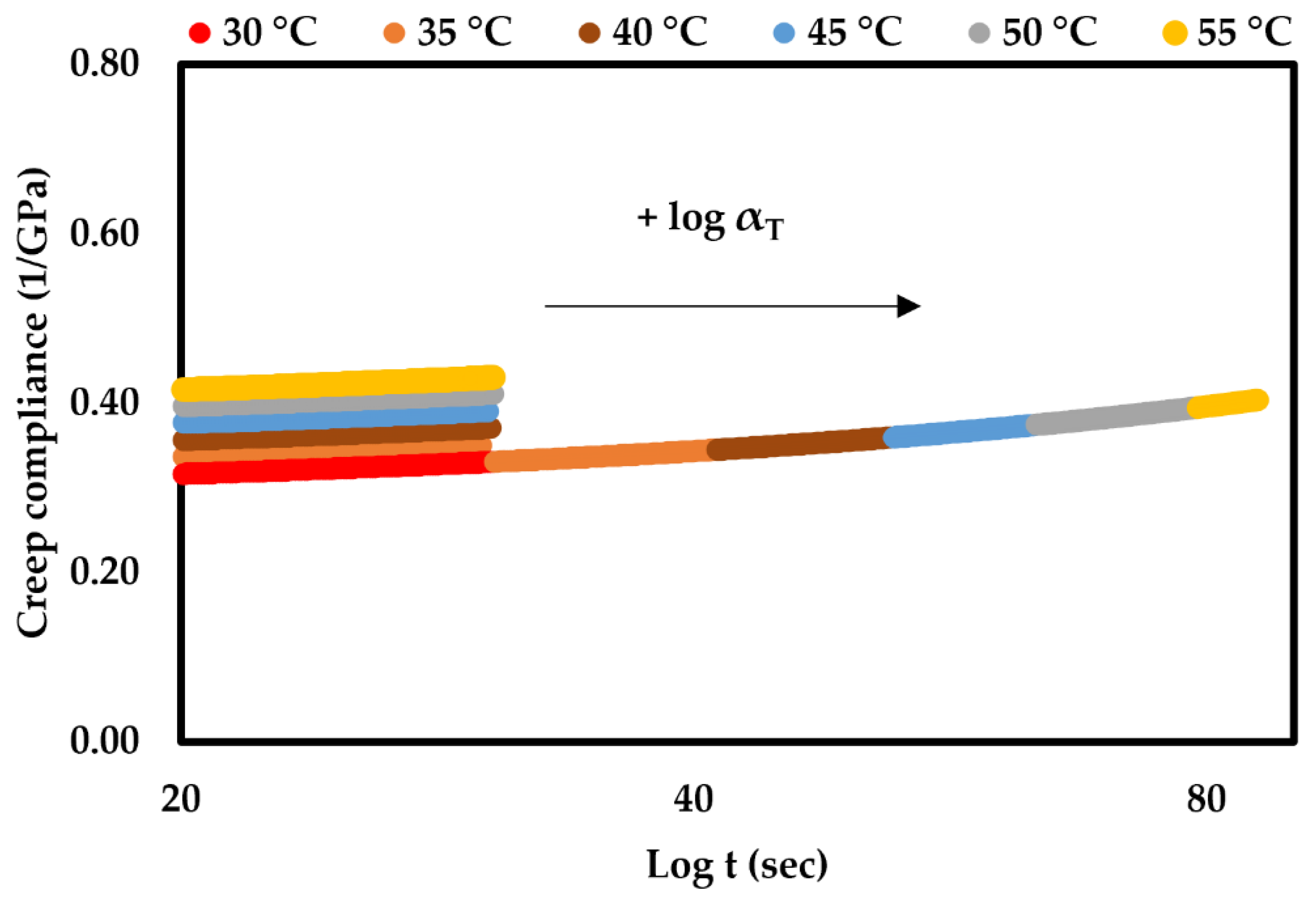

3.6. Creep Analysis

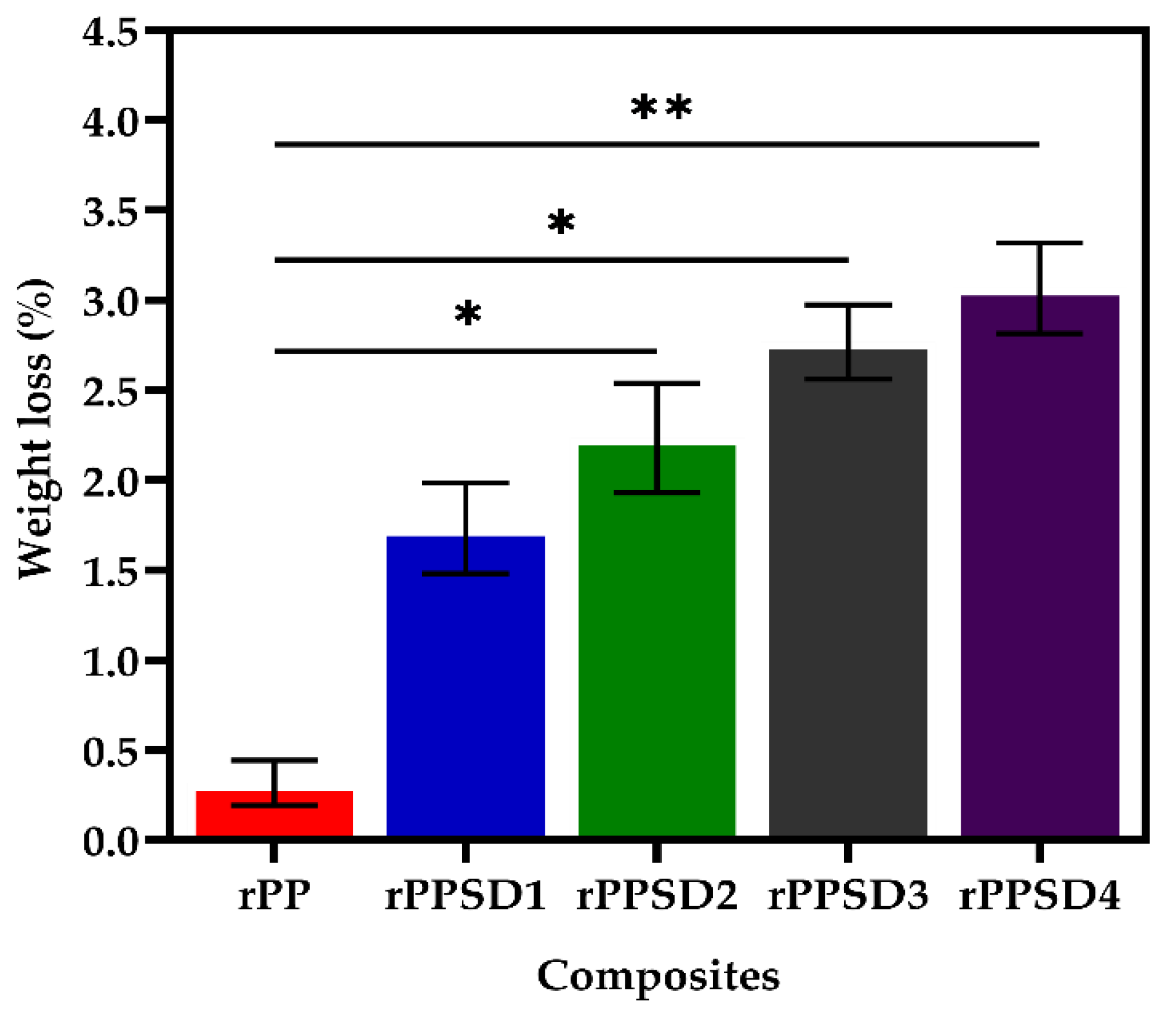

3.7. Soil Burial Degradation

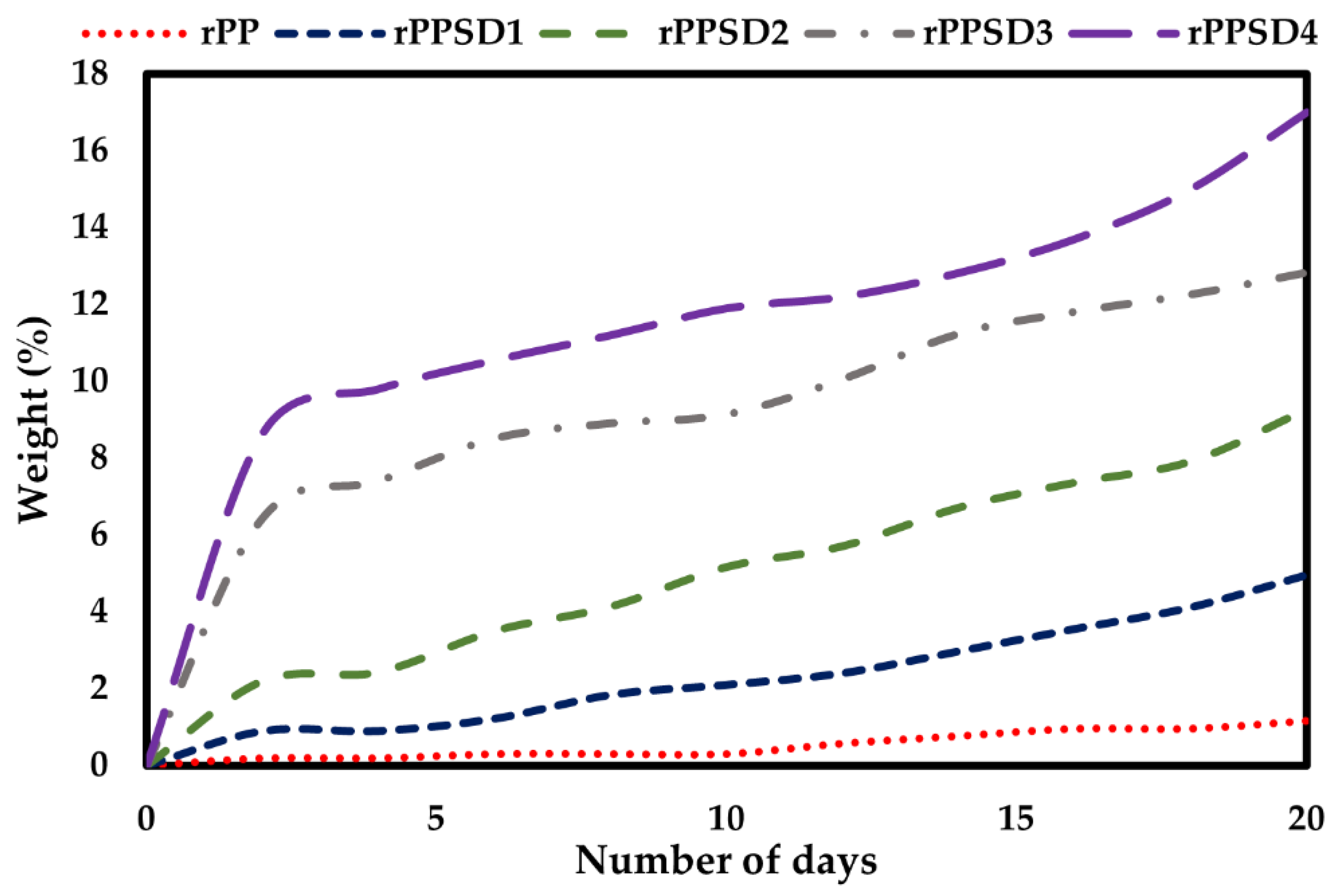

3.8. Water Absorption

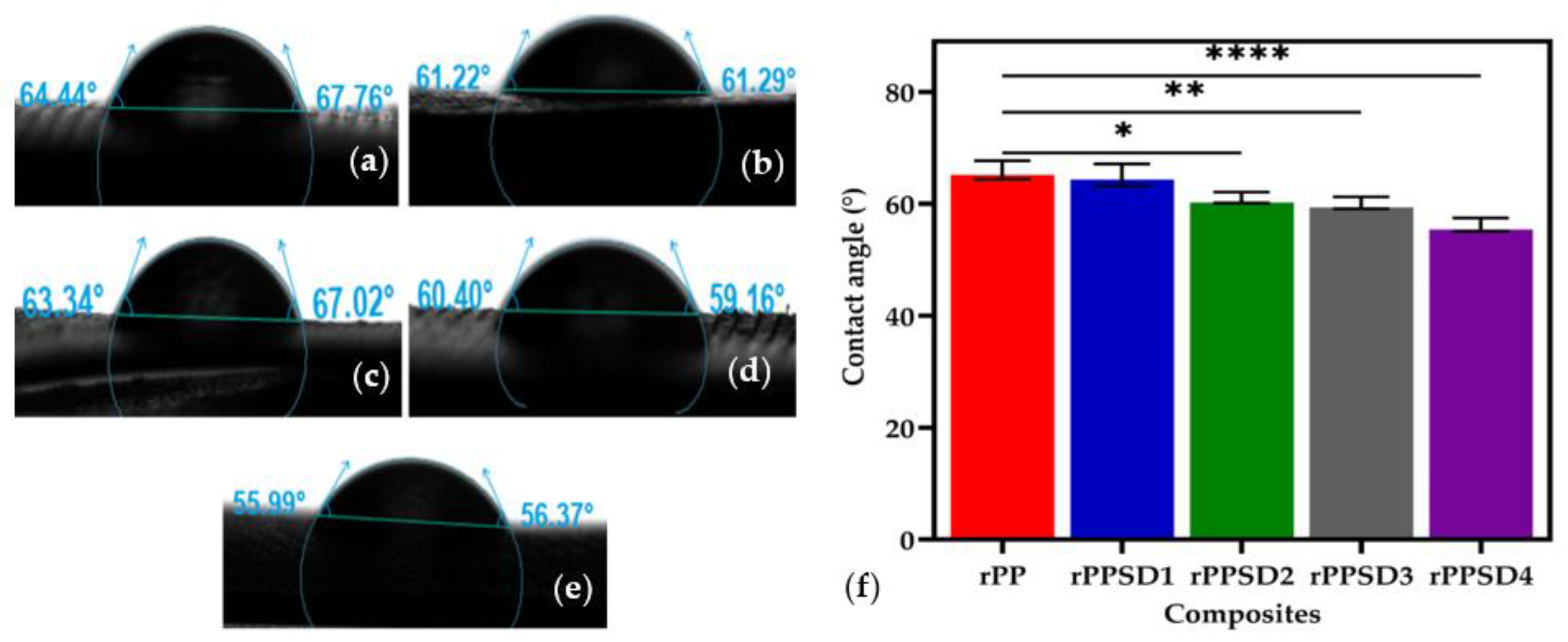

3.9. Water Contact Angle

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chand, N.; Fahim, M. Wood-reinforced polymer composites. In Tribology of Natural Fiber Polymer Composites; Elsevier: Amsterdam, The Netherlands, 2021; pp. 177–191. [Google Scholar]

- Kakarla, A.B.; Nukala, S.G.; Kong, I. Biodegradable materials. In Materials for Lightweight Constructions; CRC Press: Boca Raton, FL, USA, 2022; pp. 161–190. [Google Scholar]

- Lette, M.J.; Ly, E.B.; Ndiaye, D.; Takasaki, A.; Okabe, T. Evaluation of Sawdust and Rice Husks as Fillers for Phenolic Resin Based Wood-Polymer Composites. Open J. Compos. Mater. 2018, 8, 124–137. [Google Scholar] [CrossRef] [Green Version]

- Zykova, A.K.; Pantyukhov, P.V.; Mastalygina, E.E.; Chaverri-Ramos, C.; Nikolaeva, S.G.; Saavedra-Arias, J.J.; Popov, A.A.; Wortman, S.E.; Poletto, M. Biocomposites of Low-Density Polyethylene Plus Wood Flour or Flax Straw: Biodegradation Kinetics across Three Environments. Polymers 2021, 13, 2138. [Google Scholar] [CrossRef] [PubMed]

- Pokhrel, G.; Gardner, D.J.; Han, Y. Properties of Wood–Plastic Composites Manufactured from Two Different Wood Feedstocks: Wood Flour and Wood Pellets. Polymers 2021, 13, 2769. [Google Scholar] [CrossRef] [PubMed]

- Espert, A.; Vilaplana, F.; Karlsson, S. Comparison of water absorption in natural cellulosic fibres from wood and one-year crops in polypropylene composites and its influence on their mechanical properties. Compos. Part A Appl. Sci. Manuf. 2004, 35, 1267–1276. [Google Scholar] [CrossRef]

- Shubhra, Q.T.; Alam, A.; Quaiyyum, M. Mechanical properties of polypropylene composites. J. Thermoplast. Compos. Mater. 2013, 26, 362–391. [Google Scholar] [CrossRef]

- Ramesh, M.; Rajeshkumar, L.; Sasikala, G.; Balaji, D.; Saravanakumar, A.; Bhuvaneswari, V.; Bhoopathi, R. A Critical Review on Wood-Based Polymer Composites: Processing, Properties, and Prospects. Polymers 2022, 14, 589. [Google Scholar] [CrossRef]

- Katsiroumpas, K.; Carels, P.; Masoumi, H.; Salkauskis, J. Lightweight Floating Floor Innovations in Gym/Sports Applications. Int.-Noise Noise-Con. Congr. Conf. Proc. 2018, 258, 1075–1084. [Google Scholar]

- Mo, X.; Zhang, X.; Fang, L.; Zhang, Y. Research Progress of Wood-Based Panels Made of Thermoplastics as Wood Adhesives. Polymers 2021, 14, 98. [Google Scholar] [CrossRef]

- Rahman, K.S.; Islam, M.N.; Rahman, M.M.; Hannan, M.O.; Dungani, R.; Khalil, H.P.S.A. Flat-pressed wood plastic composites from sawdust and recycled polyethylene terephthalate (PET): Physical and mechanical properties. Springerplus 2013, 2, 629. [Google Scholar] [CrossRef] [Green Version]

- Gill, Y.Q.; Abid, U.; Irfan, M.S.; Saeed, F.; Shakoor, A.; Firdaus, A. Fabrication, Characterization, and Machining of Polypropylene/Wood Flour Composites. Arab. J. Sci. Eng. 2021, 47, 5973–5983. [Google Scholar] [CrossRef]

- Diouf, P.M.; Thiandoume, C.; Abdulrahman, S.T.; Ndour, O.; Jibin, K.P.; Maria, H.J.; Thomas, S.; Tidjani, A. Mechanical and rheological properties of recycled high-density polyethylene and ronier palm leaf fiber based biocomposites. J. Appl. Polym. Sci. 2022, 139, 51713. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Zuhri, M.Y.M.; Aisyah, H.A.; Asyraf, M.R.M.; Hassan, S.A.; Zainudin, E.S.; Sapuan, S.M.; Sharma, S.; Bangar, S.P.; Jumaidin, R.; et al. Natural Fiber-Reinforced Polylactic Acid, Polylactic Acid Blends and Their Composites for Advanced Applications. Polymers 2022, 14, 202. [Google Scholar] [CrossRef] [PubMed]

- Mirowski, J.; Oliwa, R.; Oleksy, M.; Tomaszewska, J.; Ryszkowska, J.; Budzik, G. Poly(vinyl chloride) Composites with Raspberry Pomace Filler. Polymers 2021, 13, 1079. [Google Scholar] [CrossRef] [PubMed]

- Mirski, R.; Dukarska, D.; Walkiewicz, J.; Derkowski, A. Waste Wood Particles from Primary Wood Processing as a Filler of Insulation PUR Foams. Materials 2021, 14, 4781. [Google Scholar] [CrossRef]

- Ares, A.; Bouza, R.; Pardo, S.G.; Abad, M.J.; Barral, L. Rheological, Mechanical and Thermal Behaviour of Wood Polymer Composites Based on Recycled Polypropylene. J. Polym. Environ. 2010, 18, 318–325. [Google Scholar] [CrossRef]

- Sanvezzo, P.B.; Branciforti, M.C. Recycling of industrial waste based on jute fiber-polypropylene: Manufacture of sustainable fiber-reinforced polymer composites and their characterization before and after accelerated aging. Ind. Crops Prod. 2021, 168, 113568. [Google Scholar] [CrossRef]

- Ferreira, E.D.S.B.; Luna, C.B.B.; Araújo, E.M.; Siqueira, D.D.; Wellen, R.M.R. Polypropylene/wood powder composites: Evaluation of PP viscosity in thermal, mechanical, thermomechanical, and morphological characters. J. Thermoplast. Compos. Mater. 2022, 35, 71–92. [Google Scholar] [CrossRef]

- Venkatesh, G.S.; Deb, A.; Karmarkar, A.; Gurumoorthy, B. Eco-Friendly Wood Polymer Composites for Sustainable Design Applications. In CIRP Design 2012; Springer: London, UK, 2013; pp. 399–408. [Google Scholar]

- Kumar, R.; Ul Haq, M.I.; Raina, A.; Anand, A. Industrial applications of natural fibre-reinforced polymer composites–challenges and opportunities. Int. J. Sustain. Eng. 2019, 12, 212–220. [Google Scholar] [CrossRef]

- Khan, M.Z.R.; Srivastava, S.K.; Gupta, M.K. A state-of-the-art review on particulate wood polymer composites: Processing, properties and applications. Polym. Test. 2020, 89, 106721. [Google Scholar] [CrossRef]

- Jubinville, D.; Esmizadeh, E.; Tzoganakis, C.; Mekonnen, T. Thermo-mechanical recycling of polypropylene for the facile and scalable fabrication of highly loaded wood plastic composites. Compos. Part B Eng. 2021, 219, 108873. [Google Scholar] [CrossRef]

- Moreno, D.D.P.; de Camargo, R.V.; dos Santos Luiz, D.; Branco, L.T.P.; Grillo, C.C.; Saron, C. Composites of Recycled Polypropylene from Cotton Swab Waste with Pyrolyzed Rice Husk. J. Polym. Environ. 2021, 29, 350–362. [Google Scholar] [CrossRef]

- Burgada, F.; Fages, E.; Quiles-Carrillo, L.; Lascano, D.; Ivorra-Martinez, J.; Arrieta, M.P.; Fenollar, O. Upgrading Recycled Polypropylene from Textile Wastes in Wood Plastic Composites with Short Hemp Fiber. Polymers 2021, 13, 1248. [Google Scholar] [CrossRef] [PubMed]

- Englund, K.; Villechevrolle, V. Flexure and water sorption properties of wood thermoplastic composites made with polymer blends. J. Appl. Polym. Sci. 2011, 120, 1034–1039. [Google Scholar] [CrossRef]

- Butylina, S.; Martikka, O.; Kärki, T. Comparison of water absorption and mechanical properties of wood–plastic composites made from polypropylene and polylactic acid. Wood Mater. Sci. Eng. 2010, 5, 220–228. [Google Scholar] [CrossRef]

- Tamrakar, S.; Lopez-Anido, R.A. Water absorption of wood polypropylene composite sheet piles and its influence on mechanical properties. Constr. Build. Mater. 2011, 25, 3977–3988. [Google Scholar] [CrossRef]

- van den Oever, M.; Molenveld, K. Creep deflection of Wood Polymer Composite profiles at demanding conditions. Case Stud. Constr. Mater. 2019, 10, e00224. [Google Scholar] [CrossRef]

- Tamrakar, S.; Lopez-Anido, R.A.; Kiziltas, A.; Gardner, D.J. Time and temperature dependent response of a wood–polypropylene composite. Compos. Part A Appl. Sci. Manuf. 2011, 42, 834–842. [Google Scholar] [CrossRef]

- Kajaks, J.; Kalnins, K.; Matvejs, J. Mechanical and rheological properties of wood plastic composites based on polypropylene and birch plywood sanding dust. IOP Conf. Ser. Mater. Sci. Eng. 2019, 500, 012001. [Google Scholar] [CrossRef]

- Gulitah, V.; Chiang Liew, K.; Liew, K.C. Effect of Plastic Content Ratio on the Mechanical Properties of Wood-Plastic Composite (WPC) Made from Three Different Recycled Plastic and Acacia Fibres. Trans. Sci. Technol. 2018, 5, 184–189. [Google Scholar]

- Khalid, M.Y.; Arif, Z.U.; Ahmed, W.; Arshad, H. Recent trends in recycling and reusing techniques of different plastic polymers and their composite materials. Sustain. Mater. Technol. 2022, 31, e00382. [Google Scholar] [CrossRef]

- Sormunen, P.; Deviatkin, I.; Horttanainen, M.; Kärki, T. An evaluation of thermoplastic composite fillers derived from construction and demolition waste based on their economic and environmental characteristics. J. Clean. Prod. 2021, 280, 125198. [Google Scholar] [CrossRef]

- Liikanen, M.; Grönman, K.; Deviatkin, I.; Havukainen, J.; Hyvärinen, M.; Kärki, T.; Varis, J.; Soukka, R.; Horttanainen, M. Construction and demolition waste as a raw material for wood polymer composites–Assessment of environmental impacts. J. Clean. Prod. 2019, 225, 716–727. [Google Scholar] [CrossRef]

- Medupin, R. Mechanical Properties of Wood Waste Reinforced Polymer Matrix Composites. Am. Chem. Sci. J. 2013, 3, 507–513. [Google Scholar] [CrossRef]

- Jiang, T.; Zeng, G.; Hu, C. Fabrication of highly filled wood plastic composite pallets with extrusion-compression molding technique. Polym. Compos. 2020, 41, 2724–2731. [Google Scholar] [CrossRef]

- Sormunen, P.; Kärki, T. Compression Molded Thermoplastic Composites Entirely Made of Recycled Materials. Sustainability 2019, 11, 631. [Google Scholar] [CrossRef] [Green Version]

- Mathew, A.P.; Oksman, K.; Sain, M. The effect of morphology and chemical characteristics of cellulose reinforcements on the crystallinity of polylactic acid. J. Appl. Polym. Sci. 2006, 101, 300–310. [Google Scholar] [CrossRef]

- Ndiaye, D.; Diop, B.; Thiandoume, C.; Fall, P.; Farota, A.; Tidjani, A. Morphology and Thermo Mechanical Properties of Wood/Polypropylene Composites. In Polypropylene; IntechOpen: London, UK, 2012; pp. 415–428. ISBN 978-953-51-0636-4. [Google Scholar]

- Monasse, B.; Haudin, J.M. Growth transition and morphology change in polypropylene. Colloid Polym. Sci. 1985, 263, 822–831. [Google Scholar] [CrossRef]

- Okonkwo, E.G.; Anabaraonye, C.N.; Daniel-Mkpume, C.C.; Egoigwe, S.V.; Okeke, P.E.; Whyte, F.G.; Okoani, A.O. Mechanical and thermomechanical properties of clay-Bambara nut shell polyester bio-composite. Int. J. Adv. Manuf. Technol. 2020, 108, 2483–2496. [Google Scholar] [CrossRef]

- Yang, T.-C.; Chien, Y.-C.; Wu, T.-L.; Hung, K.-C.; Wu, J.-H. Effects of Heat-Treated Wood Particles on the Physico-Mechanical Properties and Extended Creep Behavior of Wood/Recycled-HDPE Composites Using the Time–Temperature Superposition Principle. Materials 2017, 10, 365. [Google Scholar] [CrossRef] [Green Version]

- Hung, K.-C.; Wu, T.-L.; Chen, Y.-L.; Wu, J.-H. Assessing the effect of wood acetylation on mechanical properties and extended creep behavior of wood/recycled-polypropylene composites. Constr. Build. Mater. 2016, 108, 139–145. [Google Scholar] [CrossRef]

- Kale, G.; Auras, R.; Singh, S.P.; Narayan, R. Biodegradability of polylactide bottles in real and simulated composting conditions. Polym. Test. 2007, 26, 1049–1061. [Google Scholar] [CrossRef]

- Yang, F.; Long, H.; Xie, B.; Zhou, W.; Luo, Y.; Zhang, C.; Dong, X. Mechanical and biodegradation properties of bamboo fiber-reinforced starch/polypropylene biodegradable composites. J. Appl. Polym. Sci. 2020, 137, 48694. [Google Scholar] [CrossRef]

- Kufel, A.; Kuciel, S. Hybrid Composites Based on Polypropylene with Basalt/Hazelnut Shell Fillers: The Influence of Temperature, Thermal Aging, and Water Absorption on Mechanical Properties. Polymers 2019, 12, 18. [Google Scholar] [CrossRef] [Green Version]

- Sdrobiş, A.; Darie, R.N.; Totolin, M.; Cazacu, G.; Vasile, C. Low density polyethylene composites containing cellulose pulp fibers. Compos. Part B Eng. 2012, 43, 1873–1880. [Google Scholar] [CrossRef]

- Wang, P.; Liang, C.; Wu, B.; Huang, N.; Li, J. Protection of copper corrosion by modification of dodecanethiol self-assembled monolayers prepared in aqueous micellar solution. Electrochim. Acta 2010, 55, 878–883. [Google Scholar] [CrossRef]

- Li, Y.-F.; Liu, Y.-X.; Wang, X.-M.; Wu, Q.-L.; Yu, H.-P.; Li, J. Wood-polymer composites prepared by the in situ polymerization of monomers within wood. J. Appl. Polym. Sci. 2011, 119, 3207–3216. [Google Scholar] [CrossRef]

- Nukala, S.G.; Kong, I.; Kakarla, A.B.; Kong, W.; Kong, W. Development of Wood Polymer Composites from Recycled Wood and Plastic Waste: Thermal and Mechanical Properties. J. Compos. Sci. 2022, 6, 194. [Google Scholar] [CrossRef]

- Kakarla, A.B.; Kong, I.; Kong, C.; Irving, H. Extrusion-Based Bioprinted Boron Nitride Nanotubes Reinforced Alginate Scaffolds: Mechanical, Printability and Cell Viability Evaluation. Polymers 2022, 14, 486. [Google Scholar] [CrossRef]

- Borysiuk, P.; Wilkowski, J.; Krajewski, K.; Auriga, R.; Skomorucha, A.; Auriga, A. Selected Properties of Flat Pressed Wood-Polymer Composites for High Humidity Conditions. BioResources 2020, 15, 5141–5155. [Google Scholar] [CrossRef]

- Renner, K.; Móczó, J.; Pukánszky, B. Deformation and failure of PP composites reinforced with lignocellulosic fibers: Effect of inherent strength of the particles. Compos. Sci. Technol. 2009, 69, 1653–1659. [Google Scholar] [CrossRef]

- Chun, S.-J.; Lee, S.-Y. Thermal Stability of Polypropylene-Based Wood Plastic Composites by the Addition of Ammonium Polyphosphate. J. Korean Wood Sci. Technol. 2014, 42, 682–690. [Google Scholar] [CrossRef] [Green Version]

- Guo, Y.; Zhu, S.; Chen, Y.; Li, D. Thermal Properties of Wood-Plastic Composites with Different Compositions. Materials 2019, 12, 881. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, H.; Yan, R.; Chen, H.; Lee, D.H.; Zheng, C. Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 2007, 86, 1781–1788. [Google Scholar] [CrossRef]

- Chun, K.S.; Husseinsyah, S.; Azizi, F.N. Characterization and Properties of Recycled Polypropylene/Coconut Shell Powder Composites: Effect of Sodium Dodecyl Sulfate Modification. Polym. Plast. Technol. Eng. 2013, 52, 287–294. [Google Scholar] [CrossRef]

- Zander, N.E.; Park, J.H.; Boelter, Z.R.; Gillan, M.A. Recycled Cellulose Polypropylene Composite Feedstocks for Material Extrusion Additive Manufacturing. ACS Omega 2019, 4, 13879–13888. [Google Scholar] [CrossRef] [Green Version]

- Jeske, H.; Schirp, A.; Cornelius, F. Development of a thermogravimetric analysis (TGA) method for quantitative analysis of wood flour and polypropylene in wood plastic composites (WPC). Thermochim. Acta 2012, 543, 165–171. [Google Scholar] [CrossRef]

- Kumaran, P.; Mohanamurugan, S.; Madhu, S.; Vijay, R.; Lenin Singaravelu, D.; Vinod, A.; Sanjay, M.R.; Siengchin, S. Investigation on thermo-mechanical characteristics of treated/untreated Portunus sanguinolentus shell powder-based jute fabrics reinforced epoxy composites. J. Ind. Text. 2019, 50, 427–459. [Google Scholar] [CrossRef]

- Adebayo, G.O.; Hassan, A.; Yahya, R.; Sarih, N.M.; Bello, K.A.; Ekebafe, L. Impact and thermal analysis of heat-treated and untreated mangrove wood/high-density polyethylene composites. Polym. Bull. 2020, 77, 3813–3829. [Google Scholar] [CrossRef]

- Kaboorani, A. Thermal Properties of Composites Made of Heat-Treated Wood and Polypropylene. J. Compos. Mater. 2009, 43, 2599–2607. [Google Scholar] [CrossRef]

- Açıkalın, K. Pyrolytic characteristics and kinetics of pistachio shell by thermogravimetric analysis. J. Therm. Anal. Calorim. 2012, 109, 227–235. [Google Scholar] [CrossRef]

- Açıkalın, K. Thermogravimetric analysis of walnut shell as pyrolysis feedstock. J. Therm. Anal. Calorim. 2011, 105, 145–150. [Google Scholar] [CrossRef]

- Chang, W.-P.; Kim, K.-J.; Gupta, R.K. Moisture Absorption Behavior of Wood/Plastic Composites Made with Ultrasound-Assisted Alkali-Treated Wood Particulates. Compos. Interfaces 2009, 16, 937–951. [Google Scholar] [CrossRef]

- Deng, H.; Skipa, T.; Zhang, R.; Lellinger, D.; Bilotti, E.; Alig, I.; Peijs, T. Effect of melting and crystallization on the conductive network in conductive polymer composites. Polymer 2009, 50, 3747–3754. [Google Scholar] [CrossRef]

- Ludueña, L.; Vázquez, A.; Alvarez, V. Effect of lignocellulosic filler type and content on the behavior of polycaprolactone based eco-composites for packaging applications. Carbohydr. Polym. 2012, 87, 411–421. [Google Scholar] [CrossRef] [PubMed]

- Atagur, M.; Seki, Y.; Pasaoglu, Y.; Sever, K.; Seki, Y.; Sarikanat, M.; Altay, L. Mechanical and thermal properties of Carpinas betulus fiber filled polypropylene composites. Polym. Compos. 2020, 41, 1925–1935. [Google Scholar] [CrossRef]

- Mattos, B.D.; Misso, A.L.; de Cademartori, P.H.G.; de Lima, E.A.; Magalhães, W.L.E.; Gatto, D.A. Properties of polypropylene composites filled with a mixture of household waste of mate-tea and wood particles. Constr. Build. Mater. 2014, 61, 60–68. [Google Scholar] [CrossRef] [Green Version]

- Ayrilmis, N.; Kaymakci, A.; Ozdemir, F. Physical, mechanical, and thermal properties of polypropylene composites filled with walnut shell flour. J. Ind. Eng. Chem. 2013, 19, 908–914. [Google Scholar] [CrossRef]

- Choudhury, A. Isothermal crystallization and mechanical behavior of ionomer treated sisal/HDPE composites. Mater. Sci. Eng. A 2008, 491, 492–500. [Google Scholar] [CrossRef]

- Lee, S.-Y.; Doh, G.-H.; Kang, I.-A. Thermal behavior of hwangto and wood flour reinforced high density polyethylene (HDPE) composites. J. Korean Wood Sci. Technol. 2006, 34, 59–66. [Google Scholar]

- Beg, M.D.H.; Pickering, K.L. Reprocessing of wood fibre reinforced polypropylene composites. Part I: Effects on physical and mechanical properties. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1091–1100. [Google Scholar] [CrossRef]

- Cui, Y.H.; Tao, J.; Noruziaan, B.; Cheung, M.; Lee, S. DSC analysis and mechanical properties of wood-plastic composites. J. Reinf. Plast. Compos. 2010, 29, 278–289. [Google Scholar] [CrossRef]

- Salazar-Cruz, B.A.; Chávez-Cinco, M.Y.; Morales-Cepeda, A.B.; Ramos-Galván, C.E.; Rivera-Armenta, J.L. Evaluation of Thermal Properties of Composites Prepared from Pistachio Shell Particles Treated Chemically and Polypropylene. Molecules 2022, 27, 426. [Google Scholar] [CrossRef] [PubMed]

- El Mechtali, F.Z.; Essabir, H.; Nekhlaoui, S.; Bensalah, M.O.; Jawaid, M.; Bouhfid, R.; Qaiss, A. Mechanical and thermal properties of polypropylene reinforced with almond shells particles: Impact of chemical treatments. J. Bionic Eng. 2015, 12, 483–494. [Google Scholar] [CrossRef]

- Ndiaye, D.; Gueye, M.; Diop, B. Characterization, Physical and Mechanical Properties of Polypropylene/Wood-Flour Composites. Arab. J. Sci. Eng. 2013, 38, 59–68. [Google Scholar] [CrossRef]

- Najafi, S.K.; Hamidinia, E.; Tajvidi, M. Mechanical properties of composites from sawdust and recycled plastics. J. Appl. Polym. Sci. 2006, 100, 3641–3645. [Google Scholar] [CrossRef]

- Ratanawilai, T.; Taneerat, K. Alternative polymeric matrices for wood-plastic composites: Effects on mechanical properties and resistance to natural weathering. Constr. Build. Mater. 2018, 172, 349–357. [Google Scholar] [CrossRef]

- Kaymakci, A.; Ayrilmis, N. Investigation of correlation between Brinell hardness and tensile strength of wood plastic composites. Compos. Part B Eng. 2014, 58, 582–585. [Google Scholar] [CrossRef]

- Kaymakci, A.; Ayrilmis, N.; Gulec, T. Surface Properties and Hardness of Polypropylene Composites Filled with Sunflower Stalk Flour. Bioresource 2012, 8, 592–602. [Google Scholar] [CrossRef]

- Kord, B. Investigation of reinforcing filler loading on the mechanical properties of wood plastic composites. World Appl. Sci. J. 2011, 13, 171–174. [Google Scholar]

- Cesarino, I.; Dias, O.; Negrão, D.; Rocha, L.; Leão, A. Deterioration of Wood Plastics Composites by the White-Rot Fungus Pycnoporus Sanguineus. J. Compos. Sci. 2019, 3, 24. [Google Scholar] [CrossRef] [Green Version]

- Kord, B. Effect of wood flour content on the hardness and water uptake of thermoplastic polymer composites. World Appl. Sci. J. 2011, 12, 1632–1634. [Google Scholar]

- Landel, R.F.; Nielsen, L.E. Mechanical Properties of Polymers and Composites; CRC Press: Boca Raton, FL, USA, 1993; ISBN 1482277433. [Google Scholar]

- Ferry, J.D. Viscoelastic Properties of Polymers; John Wiley & Sons: Hoboken, NJ, USA, 1980; ISBN 0471048941. [Google Scholar]

- Chee, S.S.; Jawaid, M.; Sultan, M.T.H.; Alothman, O.Y.; Abdullah, L.C. Accelerated weathering and soil burial effects on colour, biodegradability and thermal properties of bamboo/kenaf/epoxy hybrid composites. Polym. Test. 2019, 79, 106054. [Google Scholar] [CrossRef]

- Maran, J.P.; Sivakumar, V.; Thirugnanasambandham, K.; Sridhar, R. Degradation behavior of biocomposites based on cassava starch buried under indoor soil conditions. Carbohydr. Polym. 2014, 101, 20–28. [Google Scholar] [CrossRef] [PubMed]

- Haque, M.M.; Rejaul Haque, M.; Munshi, M.R.; Alam, S.S.; Hasan, M.; Gafur, M.A.; Rahman, F.; Firdaus, M.; Ahmod, S. Physico-mechanical properties investigation of sponge-gourd and betel nut reinforced hybrid polyester composites. Adv. Mater. Process. Technol. 2021, 7, 304–316. [Google Scholar] [CrossRef]

- Mrad, H.; Alix, S.; Migneault, S.; Koubaa, A.; Perré, P. Numerical and experimental assessment of water absorption of wood-polymer composites. Measurement 2018, 115, 197–203. [Google Scholar] [CrossRef]

- Najafi, S.K.; Kiaefar, A.; Hamidina, E.; Tajvidi, M. Water Absorption Behavior of Composites from Sawdust and Recycled Plastics. J. Reinf. Plast. Compos. 2007, 26, 341–348. [Google Scholar] [CrossRef]

- Radoor, S.; Karayil, J.; Shivanna, J.M.; Siengchin, S. Water Absorption and Swelling Behaviour of Wood Plastic Composites BT–Wood Polymer Composites: Recent Advancements and Applications; Sanjay, M.R., Parameswaranpillai, J., Kumar, M.H., Siengchin, S., Eds.; Springer: Singapore, 2021; pp. 195–212. ISBN 978-981-16-1606-8. [Google Scholar]

- Sergi, C.; Tirillò, J.; Seghini, M.C.; Sarasini, F.; Fiore, V.; Scalici, T. Durability of Basalt/Hemp Hybrid Thermoplastic Composites. Polymers 2019, 11, 603. [Google Scholar] [CrossRef] [Green Version]

- Wang, W.; Guo, X.; Zhao, D.; Liu, L.; Zhang, R.; Yu, J. Water Absorption and Hygrothermal Aging Behavior of Wood-Polypropylene Composites. Polymers 2020, 12, 782. [Google Scholar] [CrossRef] [Green Version]

- Panthapulakkal, S.; Sain, M. Studies on the Water Absorption Properties of Short Hemp—Glass Fiber Hybrid Polypropylene Composites. J. Compos. Mater. 2007, 41, 1871–1883. [Google Scholar] [CrossRef]

- Dhakal, H.; Zhang, Z.; Richardson, M. Effect of water absorption on the mechanical properties of hemp fibre reinforced unsaturated polyester composites. Compos. Sci. Technol. 2007, 67, 1674–1683. [Google Scholar] [CrossRef]

- Joseph, P.; Rabello, M.S.; Mattoso, L.H.; Joseph, K.; Thomas, S. Environmental effects on the degradation behaviour of sisal fibre reinforced polypropylene composites. Compos. Sci. Technol. 2002, 62, 1357–1372. [Google Scholar] [CrossRef]

- Lin, Q.; Zhou, X.; Dai, G. Effect of hydrothermal environment on moisture absorption and mechanical properties of wood flour-filled polypropylene composites. J. Appl. Polym. Sci. 2002, 85, 2824–2832. [Google Scholar] [CrossRef]

- Mohamed, H.F.M.; Ohira, A.; Kobayashi, Y. Free Volume and Oxygen Permeability in Polymers Related to Polymer Electrolyte Fuel Cells. Mater. Sci. Forum 2008, 607, 58–60. [Google Scholar] [CrossRef]

- Ito, Y.; Mohamed, H.F.M.; Seguchi, T.; Oshima, A. Vacancy spectroscopy of radiation cross-linked and degraded polytetrafluoroethylenes. Radiat. Phys. Chem. 1996, 48, 775–779. [Google Scholar] [CrossRef]

- Mohamed, H.F.M.; Kobayashi, Y.; Kuroda, C.S.; Takimoto, N.; Ohira, A. Free volume, oxygen permeability, and uniaxial compression storage modulus of hydrated biphenol-based sulfonated poly(arylene ether sulfone). J. Memb. Sci. 2010, 360, 84–89. [Google Scholar] [CrossRef]

- Baharoğlu, M.; Nemli, G.; Sarı, B.; Bardak, S.; Ayrılmış, N. The influence of moisture content of raw material on the physical and mechanical properties, surface roughness, wettability, and formaldehyde emission of particleboard composite. Compos. Part B Eng. 2012, 43, 2448–2451. [Google Scholar] [CrossRef]

- Sarı, B.; Nemli, G.; Ayrilmis, N.; Baharoğlu, M.; Bardak, S. The Influences of Drying Temperature of Wood Particles on the Quality Properties of Particleboard Composite. Dry. Technol. 2013, 31, 17–23. [Google Scholar] [CrossRef]

- Büyüksarı, Ü.; Avci, E.; Akkılıç, H. Effect of pine cone ratio on the wettability and surface roughness of particleboard. BioResources 2014, 5, 1824–1833. [Google Scholar]

- Jaunslavietis, J.; Shulga, G.; Ozolins, J.; Neiberte, B.; Verovkins, A.; Vitolina, S.; Betkers, T. Hydrophilic-hydrophobic characteristics of wood-polymer composites filled with modified wood particles. Key Eng. Mater. 2018, 762, 176–181. [Google Scholar] [CrossRef]

- Prabhu, P.; Jayabalakrishnan, D.; Balaji, V.; Bhaskar, K.; Maridurai, T.; Prakash, V.R.A. Mechanical, tribology, dielectric, thermal conductivity, and water absorption behaviour of Caryota urens woven fibre-reinforced coconut husk biochar toughened wood-plastic composite. Biomass Convers. Biorefinery 2022. [Google Scholar] [CrossRef]

- Lazrak, C.; Kabouchi, B.; Hammi, M.; Famiri, A.; Ziani, M. Structural study of maritime pine wood and recycled high-density polyethylene (HDPEr) plastic composite using Infrared-ATR spectroscopy, X-ray diffraction, SEM and contact angle measurements. Case Stud. Constr. Mater. 2019, 10, e00227. [Google Scholar] [CrossRef]

| Sample Name | rPP (wt%) | SD (wt%) |

|---|---|---|

| rPP | 100 | 0 |

| rPPSD1 | 90 | 10 |

| rPPSD2 | 80 | 20 |

| rPPSD3 | 70 | 30 |

| rPPSD4 | 60 | 40 |

| Composites | On Set Temperature (°C) | End Set Temperature (°C) | Residual Weight (%) |

|---|---|---|---|

| rPP | 295 | 452 | 0.9 |

| rPPSD1 | 305 | 453 | 2.1 |

| rPPSD2 | 310 | 456 | 2.5 |

| rPPSD3 | 330 | 457 | 2.6 |

| rPPSD4 | 350 | 470 | 2.7 |

| Composites | Tm (°C) | Tc (°C) | ΔHm (J/g) | ΔHc (J/g) | Xc (%) |

|---|---|---|---|---|---|

| rPP | 148.6 | 117.1 | 93.7 | 95.0 | 45.6 |

| rPPSD1 | 149.9 | 118.4 | 102.6 | 105.3 | 56.5 |

| rPPSD2 | 150.8 | 119.2 | 109.8 | 105.6 | 57.7 |

| rPPSD3 | 151.5 | 120.3 | 112.3 | 110.0 | 58.5 |

| rPPSD4 | 151.6 | 120.9 | 115.6 | 110.3 | 59.8 |

| Composite | Young’s Modulus (MPa) | Ultimate Tensile Strength (MPa) |

|---|---|---|

| rPP | 3.79 ± 0.10 | 25.5 ± 0.1 |

| rPPSD1 | 4.12 ± 0.20 | 26.8 ± 0.1 |

| rPPSD2 | 5.72 ± 0.20 | 27.4 ± 0.1 |

| rPPSD3 | 5.34 ± 0.15 | 28.1 ± 0.5 |

| rPPSD4 | 6.95 ± 0.15 | 31 ± 0.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nukala, S.G.; Kong, I.; Kakarla, A.B.; Tshai, K.Y.; Kong, W. Preparation and Characterisation of Wood Polymer Composites Using Sustainable Raw Materials. Polymers 2022, 14, 3183. https://doi.org/10.3390/polym14153183

Nukala SG, Kong I, Kakarla AB, Tshai KY, Kong W. Preparation and Characterisation of Wood Polymer Composites Using Sustainable Raw Materials. Polymers. 2022; 14(15):3183. https://doi.org/10.3390/polym14153183

Chicago/Turabian StyleNukala, Satya Guha, Ing Kong, Akesh Babu Kakarla, Kim Yeow Tshai, and Win Kong. 2022. "Preparation and Characterisation of Wood Polymer Composites Using Sustainable Raw Materials" Polymers 14, no. 15: 3183. https://doi.org/10.3390/polym14153183

APA StyleNukala, S. G., Kong, I., Kakarla, A. B., Tshai, K. Y., & Kong, W. (2022). Preparation and Characterisation of Wood Polymer Composites Using Sustainable Raw Materials. Polymers, 14(15), 3183. https://doi.org/10.3390/polym14153183