1. Introduction

Composite materials represent the technological leading edge in terms of structural optimization for all major industrial domains, as a consequence of rigorous demands for better strength and mass properties. Although the manufacturing costs are slightly higher than those of traditional metal alloys [

1], the benefits are without a doubt worth the financial effort thanks to their major advantages. Automotive engineering [

2], marine structures [

3], infrastructure works [

4] and more recently the additive manufacturing industry [

5] are all playing a part in developing improved composite materials, to meet the demands of increasingly challenging tasks. The aircraft manufacturing industry is undoubtedly one of the major investors in composite development. Over the past years, composite components found their way into nearly every corner of an aircraft, starting with small components, such as bulkheads or stringers [

6], and ending with massive fuselage parts [

7]. One important aspect is the manufacturing processes diversification, which occurred over the past decades [

8], opening the market for middle range manufacturers, thus making composite materials an affordable solution for a broader range of customers. Even more delicate structures that are considered critical for aircraft safety, such as wings [

9] or compressor blades [

10], are now being considered for a composite conversion, due to the increasing confidence in their capabilities. A few of the many advantages that composites possess over traditional materials are the ability to tailor properties accordingly with the performance demands, an excellent strength-to-weight ratio and not the least, the chemical characteristics (resistance to corrosion and chemical resistance) [

11]. Metal aircraft components are especially considered for a composite material upgrade due to the light weight they possess and also due to certain important capabilities, such as on-site manufacturing/repairing or the lower degree of maintenance they imply [

12].

Composites are manufactured by combining two or more materials with exceptional properties, which also possess a high degree of compatibility. In order to prove their worthiness to fulfill difficult tasks, composites have to undergo a series of experimental tests, depending on the load type and direction. Tensile or compression testing, shear testing, bending or fatigue testing are only a few examples of the investigations that must be covered in order to obtain a complete set of mechanical characteristics [

13]. The macro-scale tensile testing effects on carbon fiber-reinforced plastics have been intensely studied during the last decade [

14,

15], with the inconvenience of allowing only the assessment of the overall material deformation. In order to have a more precise understanding of the large-scale effects, it is imperative to observe deformations that occur on the smallest scale possible, in this case being a single ply of a laminated composite. The microscale fracture mechanics also constitutes a frequently approached subject [

16], shedding light on the failure emergence and propagation.

Digital image correlation is an optical technique, which was developed in the middle 1970s, that has recently recaptured the interest of scientists involved in mechanical applications research [

17,

18]. One of the major advantages of this procedure is that it does not imply any direct contact with the object being studied, thus eliminating the necessity of additional equipment, such as strain gages or extensometers, and yet providing a full range of mechanical characteristics: displacements, strains and vibrations [

19]. The transverse contraction coefficient, also known as Poisson ratio, is a key elastic constant used for characterizing the mechanical properties of composite materials that can be determined through digital image correlation, which is further needed in the fulfillment of finite element numerical simulations [

20]. Nowadays, finite element analyses (FEA) represent the most common method for designing and evaluating the performances of a composite structure [

21]. Commercial FEA products have been developed in order to allow a broader range of simulations, which faithfully characterize the specific character of composite materials. Some of the most widespread software programs include: Ansys with the Composite PrepPost analysis (ACP), NX Nastran, Abaqus or Solidworks, which can simulate basically all the major composite categories, such as laminates, foam cores and honeycombs [

22].

Carbon fiber reinforced plastics represent an intensely studied category of composite materials, with both tensile [

23,

24] and flexural [

25,

26] performance evaluation being at the heart of their characterization. The lack of similar information regarding the linkage between the mesoscopic effects of single-ply CFRP compared to the macroscale mechanical characteristics evaluation was the main reason for addressing this subject.

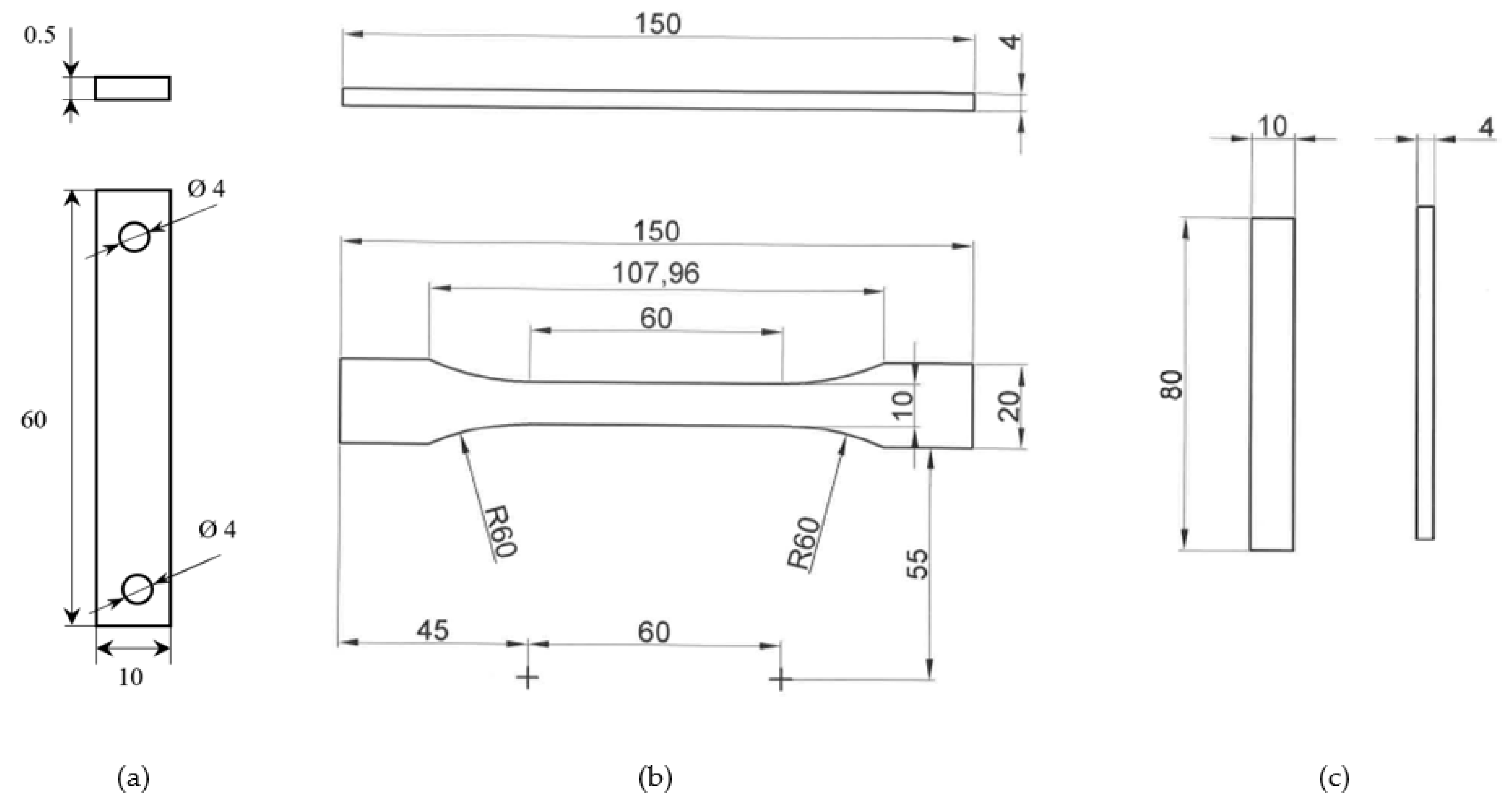

The main testing procedures covered in the current article are tensile and three-point bending testing, all realized with the aid of the Q400 D.I.C. system from Dantec Dynamics and the INSTRON 8801 servo hydraulic testing system. The objective of the experimental study is to determine the mechanical characteristics of a single-ply CFRP and to assess the relationship with the multi-ply CFRP made of the same material, which will constitute the basis for manufacturing a helicopter tail rotor blade. This shall be realized by examining the correlation between the visible small-scale effects, the displacement and strain position in connection with weave characteristics, and then transposed on the multi-ply composite, which will constitute the skin of the blade. The aerodynamic pressure loading on the tail rotor blade has been validated in previous studies [

27]; the tensile pull being caused by the centrifugal forces acting exterior to the rotation axis. Other materials and structural configurations of interest towards developing a composite helicopter blade have also been studied in previous articles [

28].

3. Results

3.1. Tensile Performance Analysis of the Single-Ply CFRP Specimens

The single-ply material was subjected to tensile loading with the purpose of assessing its orthotropic behavior with respect to the material axes and to determine its main mechanical characteristics: tensile strength, Young’s modulus and Poisson ratio. Material failure was not the purpose of the tension tests and thus was not achieved during the trials, due to the limited tensile force capability of the testing device. The maximum force applied on each specimen is positioned in the range of 493 N up to 602 N. The mean values obtained for the tensile specimens cut along the warp and weft direction are presented in

Table 2.

Based on the previously displayed results, the mean value of Young’s modulus for the warp cut specimens is 24,352.338 MPa on the proportionality portion of the stress–strain curve (σ-ε), with a coefficient of variation of 17%, whilst Poisson ratio has a mean value of 0.351 with a variation of approximately 12%. On account of the inconsistent variation of the U2 tensile specimen, this value was not taken into account in determining the mean values previously presented. The maximum real deformation for the warp cut test specimens has a value of approximately 0.46%.

The mean value of the elastic modulus for the weft cut specimens is 23585.489 MPa on the linear elastic region, with a coefficient of variation of 22.25%, while the transverse contraction ratio has a mean value of 0.3495. The B1 tensile sample was not considered in determining the mean values, due to unusual mechanical behavior displayed during the experiments. The maximum real deformation for the weft cut test specimens has a value of approximately 0.44%.

The force–displacements evolution for the single-ply test specimens can be classified as predominantly nonlinear, with certain segments of linear elasticity, where the mechanical characteristics could be determined. This is mostly due to the reduced capability of the traction device and the high material strength, specific for CFRP, which makes it difficult to assess the complete stress–strain curve evolution. The linear elastic variations of stress–strain curves for the single-ply tensile test specimens are presented in

Figure 6.

Figure 6a exhibits a similar evolution for all of the five warp cut specimens, with the exception of the U

2 sample, which has a smaller linear section compared to the other four. For this reason, it has been excluded from the mean values determination but was presented graphically for comparison purposes.

The stress–strain evolution posted in

Figure 6b is relatively similar in terms of size and shape for all of the five specimens, but with a slight scatter in terms of strain values. The B

2 specimen is characterized by a steady linear elastic evolution closely after the tensile force was applied, while for the B

1 and B

5 test, specimens have a nonlinear behavior during the first few frames, until proper material tension is obtained. These differences are most probably caused by the aluminum reinforcement bonds placed at both ends of the specimens, and the necessary time period for the composite ply to fully take over the applied force. Nonetheless, all of the previously displayed specimens have a similar evolution. It can be stated that the slope of the stress–strain curve for the specimens cut on the warp direction is slightly greater than that of the weft cut specimens, being thus a little stiffer when loaded in this direction, according to the experimental results.

In order to assess the microscopic mechanical behavior of the specimens, certain captions have been presented in the figures below from the image processing software of the digital image correlation system.

Figure 7 and

Figure 8 exhibit frames from the tensile testing process when the fabric components are placed under visible tension, corresponding to 180 s from the tensile test commencement.

The displacements presented in

Figure 7a are with rigid body movement removed (RMBR), in order to better perceive the motion of the carbon fiber filaments.

Figure 7b exhibits the manner in which the weft of the carbon fabric is stressed during tensile testing. The fabric weft, which runs across the length of the specimen, is placed under tensile tension (displayed in red), while the warp filaments remain in a more relaxed posture. The obtained visual effect for all of the tested specimens is that of two alternative diagonal patterns. This effect is also present in the specimens presented in

Figure 8 the warp filaments being, this time, placed on the tensile direction. A mirror effect can be visualized in comparison with the weft cut specimens, with the presence of a similar diagonally shaped pattern specific for the twill 2/2 weave. The noncolored points from the previous images signify the nodes, which could not be traced by the software when analyzing the caption frames in order to detect the filament motion. In other words, the displacement in the Z direction of the specimen illustrates the tendency of the weave to pull the material towards the horizontal symmetry axis, generating a stiffening effect.

The strain characteristics of the specimens reveal a similar mechanical behavior. It is observable in

Figure 8 that the maximum strain values occur on the fibers being placed on the tensile direction, revealing a diagonal strain pattern, similarly with the manner in which the fibers are intertwined on the right side of the figure. Small matrix cracks occurred during the testing procedure for the specimens, which surpassed the 85 MPa tensile strength of the epoxy resin, but they were not visually identifiable under the microscope lens. Overall, the high resistance of matrix made the tensile test very accessible for the material. At an approximate 100 MPa maximum measured tensile stress, the carbon fiber was 44 times below the maximum stress capacity specified by the manufacturer.

3.2. Tensile Performance Analysis of the Multi-Ply CFRP Specimens

The experimental tests were realized in accordance with the ASTM D3039 standard, the tensile specimens being stretched to the point of failure. The stress–strain dependence of the five multi-ply specimens is graphically presented in

Figure 9.

The previous diagram clearly describes a bilinear mechanical behavior, in which the material starts with a linear elastic portion, which is preceded by a plastic segment of a smaller length. The mean longitudinal elastic modulus corresponding to the 0.05–0.15% specimen strain is represented by the slope of the linear elastic portion at a value of 42 GPa. This value, also known as the constant of proportionality for the region in which the stress is directly proportional to the strain, is valid up until the yield strength of the material is reached, at a value of about 448 MPa. With a standard deviation of only 4.23%, the specimens exhibit a similar mechanical behavior along the length of the tryouts. The upper elastic limit marks the passing to a linear plastic behavior. The modulus of elasticity determined for this plastic region, also known as tangent modulus, was determined for the 1.1–1.3% strain segment with a mean value of 19.457 GPa. The failure stress has a mean value of 480.57 MPa, being determined for each individual sample by dividing the applied tensile force to the cross-section area of each specimen. The failure mechanism is marked by a sudden material rupture, with no identifiable necking phenomenon. All the determined mechanical characteristics are tabularly presented in

Table 3.

The transverse contraction coefficient has a value of 0.353 and has been determined solely for the fifth tensile test specimen analyzed with the digital image correlation technique. This is due to the fact that the digital extensometer used with the INSTRON tensile testing equipment measures only the uniaxial strain and has no record of the transverse strain. The fifth specimen tensile modulus has a value of 41.525 GPa for the 0.05–0.15% strain segment, in close proximity with the median value determined for the first four tensile specimens. The tensile specimen evaluation using the digital image correlation system is presented below in

Figure 10.

The tendency of the stress to perpetuate with respect to the direction of the tensioned fibers is visible in a similar matter as with the single-ply tensile tests, the diagonal pattern being clearly visible.

All material failure occurred in the reduced section of the tensile test specimens, making them valid in terms of conformance with the tensile testing standard. The failure mechanism implied, in the first stage, the weakening of the adhesive bond between the material plies and also between the resin and the carbon fabric. The final material failure is characterized by a generalized delamination on the central section of the specimens, with local fabric ruptures, a common failure mode of carbon fiber-reinforced composites [

38]. The carbon fiber rupture occurred only as a small local effect due to the fact that the tensile stress at the breaking point was nearly ten times lower than the tensile strength declared by the manufacturer. A detailed view of the failure location can be seen in

Figure 11 for three of the five multi-ply tensile test specimens, where the failure was more visible.

3.3. Flexural Performance Analysis of the Multi-Ply CFRP Specimens

The bending tests were realized for three specimens with a rectangular section, by using the three-point bending test procedure. The results have been evaluated using the DIC method, which implied painting the specimens with black dots on a contrasting white background on the area facing the cameras, to easier identify the material movement. The bending test is generally characterized by a bending moment, which acts on the transverse section of the specimen, with a vector perpendicular to the specimen central axis. In general, the bending moment is also accompanied by a shear force. It is important to state that the three-point bending mechanism stretches the fibers located on the lower side, making the material thinner and compresses the upper side of the material, hence increasing its thickness.

Hooke’s law for linear elastic materials subjected to bending forces has the following form, for a specimen with its length in the X axis direction:

where,

E is the elasticity modulus,

ky is the curvature of the deformed mean fiber and

z is the distance from the mean fiber.

Representative sections from the bending tests have been presented in

Figure 12, where captions from the interpreting software were taken to highlight the displacements on the Y axis, perpendicular to the specimen length, with rigid body movement removed.

The ply delamination can be spotted in the previous figure due to the absence of the color scale, determined by the sudden local material deformation. The ply rupture can be observed near the application of the shear stress. The progressive movement of the central beam produces tensile stress in the lower half of the specimen and compressive stress in the upper half, both being delimited by a neutral central plane. The graphical evolution of the Y axis displacements with the force applied is depicted in

Figure 13 for the three tested specimens.

The three specimens have a similar general evolution, with a linear slope up to the maximum force applied, consisting of a mean value of 0.5966 kN. For the first two tests, the force–displacement evolution maintains a constant level after the maximum force was reached, after which the force declines and material failure occurs.

The flexural modulus of elasticity, designated with the notation E

flex, is determined for the linear elastic segment of the force–displacement curve, according with the mathematical expressions provided by the standard EN ISO 14,125 [

31], as follows:

where:

L is the distance between the base simple support, equal to 70 mm;

and

are the dimensions of the rectangular cross section.

Similarly, the flexural stress and strains are determined with the aid of the following mathematical relations:

The main flexural characteristics of the material are presented in

Table 4, calculated for each individual specimen with the equations previously presented, in accordance with the EN ISO 14,125 standard for the determination of flexural properties of fiber-reinforced plastic composites.

The state of the specimens after failure can be observed in

Figure 14 listed below. The failure propagation is visible with the naked eye, at the location where a linear discontinuity appears on the visible painted surface, near the application point of the central force.

The main identifiable failure mode is delamination of the bonded plies near the central load application position, also accompanied by ply rupture in the case of one probe.

3.4. Finite Element Analysis of the Multi-Ply CFRP Specimens: Results Comparison

The finite element analyses were realized with the purpose of replicating the experimental conditions and results, by defining the composite material in the FEA software with the main mechanical characteristics determined in the previous subchapters. By studying the multi-ply tensile test results, we can clearly state that the material has a multilinear isotropic hardening behavior. Therefore, in order to realize an FEA simulation of the specimens, the characteristics for both the elastic and the plastic isotropic region have to be precisely defined. The linear elastic region is characterized by the slope of the stress–strain curve, meaning Young’s modulus and also Poisson’s ratio, which has been determined using the digital image correlation method. The necessary characteristics for the plastic deformation region, which must be inserted in the Ansys Workbench simulation software were determined from the engineering results, by calculating the true stress and strain values, using the equations stated below [

39]:

The plastic strain of the material is determined by subtracting the elastic strain from the total strain as depicted below:

where the elastic strain is determined using the following formula:

The simulations were performed using an explicit dynamics analysis, in order to obtain a relevant insight of the material performance. The material layup of twelve overlapping plies and the overall orientation was introduced using the Ansys ACP composite set-up. Both tensile and bending specimens resulted in an overall thickness of 3.96 cm, the equivalent of 0.33 cm per individual ply. The fiber orientation is defined by placing the warp perpendicular on the weft of each ply, the orientation remaining constant through the entire material.

The specimens were modelled as shell surfaces with quadrilateral elements, which resulted in approximately 2104 surface elements for the tensile specimen and 800 elements for the bending specimens. The surface mesh was realized using an element size of 1 mm, in order to obtain a sufficient amount of detail in the stress and strain diffusion. The element distribution on the finite element modeled specimens can be observed in

Figure 15a,b.

The tensile specimen model was fixed on one end in order to eliminate all motion, while on the other end a displacement was applied as

Figure 16b depicts. The flexural specimen on the other was simply supported on one end and provided with a null displacement on the Z axis direction at the other end, as to reproduce the practically occurring state. The displacement was applied on the central middle section of the specimen, as the mean value that occurred in the experimental tests (

Figure 16a).

The finite element analysis was realized in order to assess the resulting stress and strain, in comparison with the experimental tests. With regard to the flexural analysis, the directional deformation of the vertical direction can be seen in

Figure 17a, and the normal stress distribution on the specimen direction can be visualized in

Figure 17b.

Figure 17 also presents the finite element analysis results obtained for tensile test specimen loaded on the longitudinal direction, in the explicit dynamics analysis: the total deformation of the specimen (

Figure 17c) and equivalent von-Mises stress (

Figure 17d).

In

Table 5, a comparison between the experimental test results and finite element analysis results is presented, with respect to Young’s modulus of elasticity for the tensile test and the flexural modulus for the three-point bending test. The accuracy of the results is evaluated by determining and assessing the differences in values. The elasticity moduli for both FEA analyses was obtained as the slope of the stress–strain curve determined by the numerical software.

4. Conclusions

The paper reports the tensile and flexural mechanical properties obtained for the carbon fiber-reinforced material, in both single-ply and multi-ply test configurations. The results offer an additional contribution to the study of carbon fiber-reinforced plastics with epoxy resin matrix, creating a link between the mesoscopic and the macroscopic mechanical behavior of the material.

The single-ply experimental results lead to the conclusion that the two specimen types have similar characteristics in both weft- and warp-loading direction, with a standard deviation of only 0.5 GPa and a mean value of 23.968 GPa for the tensile modulus. The examination of the small-scale fiber loading realized with the Micro-DIC setup correlates well with the large-scale mechanical behavior, offering a better understanding of the material failure. Stress and strain properties measured with the DIC Q400 system are in range with the values obtained from the INSTRON 8801 load cell, thus being reliable and expanding the overall data set.

The ratio of the transverse strain to the axial strain is accurately determined by using the DIC method and has similar values for both single-ply and multi-ply specimens, below the value of 0.5 for isotropic material.

The elastic properties obtained for the CFRP are used to properly define the material characteristics for the numerical analysis. Tensile and flexural finite element simulations have been realized, in order to assess the equivalence between the experimental and numerical results. The reduced error of the elastic modulus for both tensile and flexural simulations implies that the FEA model is trustworthy and can be further used in developing composite structures for aeronautic purposes.