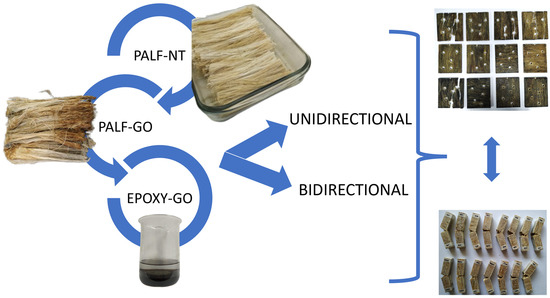

3.1. Izod Tests

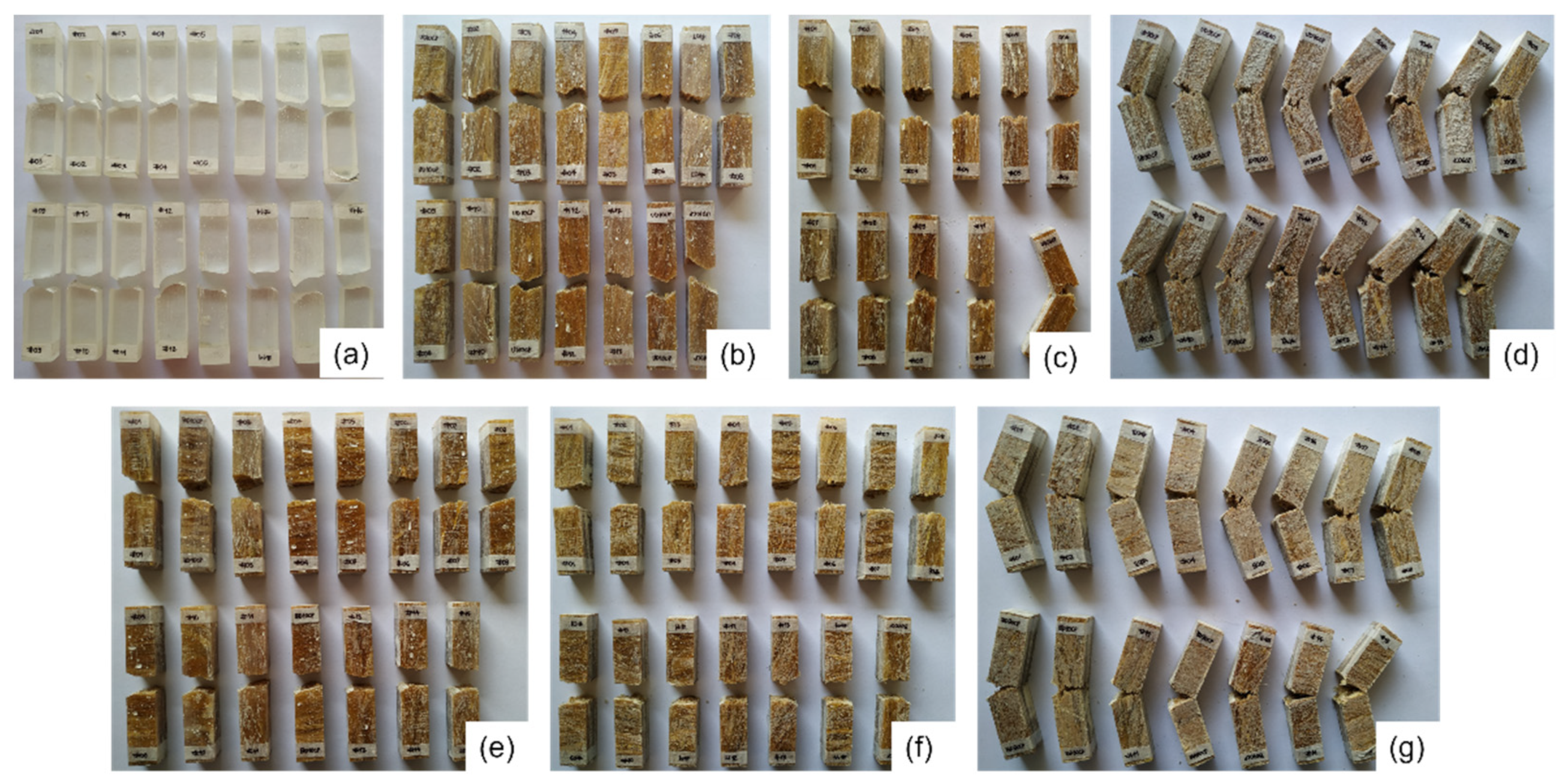

The samples after the Izod impact test are shown in

Figure 3, in which all composites underwent complete rupture, except for the group containing 30 vol.% of fibers and for one sample of the group with 20 vol.% unidirectional PALF-epoxy.

Figure 4 shows the graph with the averages and standard deviations of these values related to the variation of the Izod impact resistance.

According to the results presented, it is possible to verify a relationship between the increase in the PALF volume fraction and the Izod impact energy. With the change from 10% to 30 vol.% of fiber, the energy absorbed after impact increases significantly, around 579% for unidirectional composites and 497% for bidirectional composites. Rahman et al. [

54] also reported an increase in the impact strength with the addition of fiber content, however a drop of 19.30% was observed at further volume fractions, i.e., 60 vol.%.

This observed increase was expected due to the epoxy’s fragile behavior, in which the impact generated crack on unreinforced specimens propagates without restrictions until a complete fracture occurs. However, in the case of fiber-reinforced epoxy, the initial crack has its propagation blocked, leading to the migration of cracks to the fiber/matrix interface. Consequently, reinforced samples were not fully ruptured and bent after hammer impact due to the flexibility of the fibers [

55]. This partial failure behavior indicates high tenacity imparted by the PALF reinforcement on the composites and implies a higher amount of energy absorbed if total failure was observed [

27].

The PALF play a vital role in the impact resistance of composites since they interact with the formation and propagation of cracks in the matrix and function as a stress transfer medium [

54]. It is worth noting that the standard deviation presented is due to the heterogeneous nature of any NLF, resulting in substantial dispersion of their reinforced composites’ properties [

56]. Cellulose, hemicellulose, and lignin are the main constituents of NLFs, such as PALF, and their proportion in the fiber depends on the age, source of the fiber, and the extraction conditions used to obtain the fibers [

35]. Hemicellulose usually acts as a filler between cellulose, contributing little to the stiffness and strength of fibers. In a different manner, lignin acts as a glue in the fiber structure, stiffening the cell wall and influencing the flexibility of the fibers. In high-cellulose content fibers, such as PALF (i.e., 80%), cracks propagate through the cell interface, causing intercellular fracture without the removal of microfibrils. In contrast, in fibers with lower cellulose content cracks propagate through the cells and result in intracellular fracture with microfibrillar pullout [

35].

ANOVA analysis was performed to verify the reliability of the results. However, those referring to partially ruptured specimens should not be considered and consequently not used statistically, according to item 5.8 of ASTM D256 [

53].

In fact, the statistical test indicated that the calculated F (31.13) > critical F (2.58), rejecting the hypothesis that the means are equal with a confidence level of 95%. Therefore, changing the volumetric fraction of PALF in epoxy matrix composites influences the Izod impact energy. In addition, the Tukey test was applied to compare means to verify which group presents the best results in terms of Izod impact energy.

Table 2 shows the Tukey analysis results, in which the absolute mean difference (ADM) between the groups are shown, with the values above the honestly significant difference (HSD) highlighted in bold to indicate the difference.

The ADM values may be either positive or negative, based on the direction of which the significant change was achieved, i.e., increase or decrease in the mean values compared to the reference.

Based on these results, uni- and bidirectional composites reinforced with 20 vol.% PALF presented the best performances and the most significant difference in terms of the value of Izod impact energy.

In order to compare the results found with those found in the literature,

Table 3 presents Izod impact energy values for polymeric composites with different NLFs. In this table, one can see that the values for the 30 vol.% PALF-reinforced epoxy composites have considerable variation between the various papers.

3.2. Ballistic Tests

Regarding the ballistic test result, the samples perforated after the test are shown in

Figure 5.

Table 4 presents the values referring to the averages of absorbed energy (Equation (1)) and limit velocity (Equation (2)).

It is important to emphasize that the residual velocity test was performed in the subsonic region, with velocities below 300 m/s, using a pressure rifle and a 45 caliber projectile [

60]. The shock wave appears in the supersonic region and is not perceived in the subsonic regime [

61]. Considering that, the classical field theory can be applied in order to convert the absorbed energies, based on the projectile’s mass. This physical theory portrays the interaction of systems made up of particles and fields, having as basic entities a set of space and time functions taken by the field equations [

62,

63]. In practical terms, the field is the velocity difference in magnitude while the particle is the projectile. Furthermore, this requires invariance in actions and equations of motion for a general solution containing an arbitrary scalar function of space–time coordinates [

63,

64,

65].

In this context, the energy absorbed by a body follows a quadratic regime with a small variation in the parabolic representation of velocity (x-axis) versus energy (y-axis), with good tolerance. By considering the same projectile, it is possible to obtain the same energy value between two velocities in any region of the parabola. Thus, to compare the absorbed energy data reported in the literature regarding different projectiles, it becomes possible to convert the energies absorbed by the respective masses by dividing them. From that assumption, the absorbed energy of the present work was estimated considering the data presented in the NIJ 01.01.04 standard [

40] on the calibers and their respective masses, as shown in

Table 5.

Table 6 illustrates the data found in the literature.

Comparatively, considering the values of absorbed energy achieved for the different groups of composites in the present study, the 30BD-PNT/EGO group, which reached the highest

Eabs value, was superior to the epoxy—PALF (30 vol.%) and polyester—curaua fiber (20 vol.%) composites corresponding to level III, and to aramid fabric, corresponding to level II. Considering the percentage of absorbed energy, the results found are adequate, since higher percentages mean higher kinetic energy dissipation through mechanisms, such as the delamination between layers, elastic deformation of the composite, shear of the layers, tension at rupture of the fibers, and brittle fracture of the epoxy matrix [

19,

20].

Thus, regarding the NIJ [

40] classification of protection systems as levels I, II, and III, it is unfeasible to compare the present results with the literature data since none of the studies assessed level IIIA ammunition, which provides significant protection against firearms. In addition, it is worth mentioning that, in terms of the MAS performance, the energy absorption capacity of an individual component does not display the combined performance as a function of the synergistic effect. It indicates, however, the suitability for ballistic use [

27].

For the ballistic tests, ANOVA was performed on the data to verify the reliability of the results. Tukey’s test was necessary given that the critical F (1.72) is smaller than the calculated F (2.22), thus rejecting the null hypothesis, for which the mean values are equal. Of the 190 combinations, 7 were significantly different. These are presented in

Table 7, which refers to the ADM as higher than the reference value found by the test.

Thus, the treatment that most influenced the energy absorption of the composites was the one related to the addition of GO in the epoxy matrix (PNT/EGO). It is important to note that the composites with higher reinforcement percentages retain their physical integrity, unlike the 10UD and 10HD PNT/ENT groups and the 20UD composite plates, which fragmented after the shots. This fragmentation may be associated with the relative fragility of the epoxy matrix [

5]. The 20UD plates of the PGO/ENT, PNT/EGO, and PGO/EGO groups were also fragmented, corroborating the influence of the bidirectional layers on the physical integrity of the composites, followed by the fiber volume. The fragmentation of the 30UD-PNT/EGO plate was an unexpected behavior, given the higher volumetric fraction and the coating with GO. Other studies report that an increase in fiber-epoxy interfacial adhesion is associated with GO functionalization, which in turn influences the physical integrity of the plates, a condition necessary for personal protective vests [

10,

46].

One of the analyses carried out in the study by Sundaram et al. [

68] was the influence of fiber orientation on composite performance. They indicated that the bidirectional configuration provided better results due to the bending flexibility along the direction of bullet penetration, which was the reason for the higher absorption of the projectile kinetic energy compared to other fiber configurations. A similar observation was made in the works by Kumrungsie et al. [

69]. The study described a computer simulation of the ballistic impact in polymeric composites with a bidirectional fiber arrangement and showed that the bidirectional plate absorbs more energy, resulting in a lower residual velocity of the penetrated projectile. However, despite the energy absorbed per area being relatively large, Dimeski et al. [

51] drew attention to the disadvantage of crossing points in this arrangement. In the unidirectional orientation of the fibers, due to the lack of crossing points, that is, due to the inferior extension of the reflective impact wave. In fact, the ballistic impact wave is transmitted to a larger composite area, thus being able to present a superior performance.

In the present study, the functionalization of GO in the resin resulted in a 19.54% increase in absorbed energy. Comparing the untreated group (30BD-PNT/ENT) with the groups of the same fiber configuration and volume, varying only the treatment with GO, i.e., 30BD-PGO/ENT and 30BD-PGO/EGO, there was a decrease of 11%, 39% and 1.11%, respectively. In terms of the 30BD-PNT/EGO group, there was an increase of 36.19%.

Pereira et al. [

44] studied the ballistic performance of composites, adding 0.5 wt.% of GO to the epoxy matrix reinforced with 30 vol.% of ramie fabric, reporting that the ballistic tests showed an increase in absorption energy, which was related to the presence of GO in the epoxy matrix. In the study by Silva et al. [

65], the ballistic test was performed on the aramid fabric with and without GO treatment. The coating with GO showed a significant improvement in the absorbed energy of up to 50% when compared to the uncoated aramid fabric, due to the higher friction between the fibers. Therefore, GO functionalization in composites promotes an enhancement in energy absorption as a result of the interfacial interactions.

Despite the variability of the composite’s properties with the introduction of an NLF, literature suggests that when PALF and other natural fiber-reinforced composite plates are applied in an MAS they effectively stop bullet penetration and meet the NIJ back-face signature (BFS) depth criterion [

16,

31], offering protection in personal bullet proof vests.

3.3. SEM Analysis

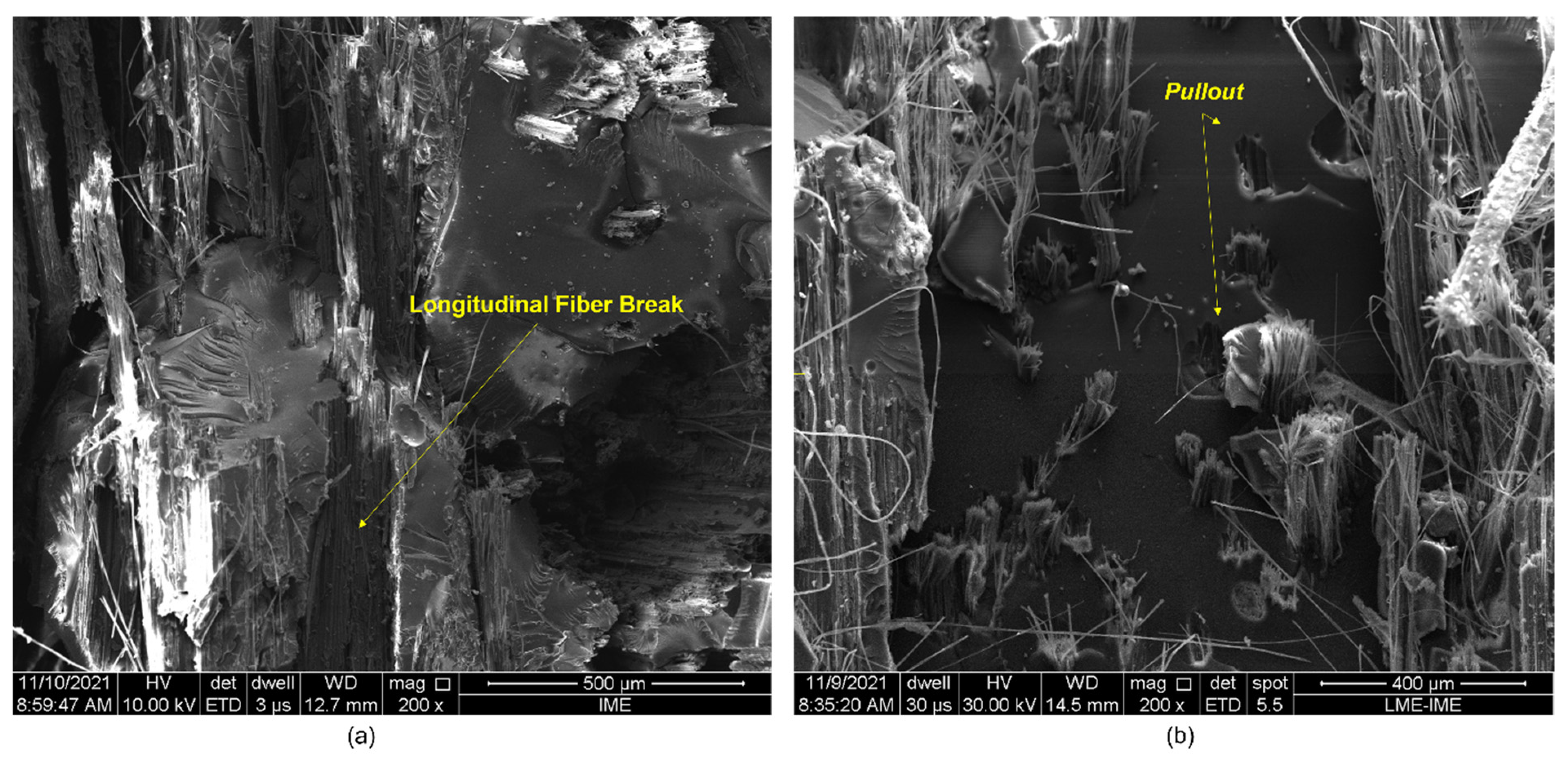

SEM analysis was performed on the samples after ballistic impact to verify the active failure mechanisms and better understand the energy dissipation.

Figure 6 and

Figure 7 show the untreated composites’ fracture surfaces, depicting the fibers and the matrix. The samples containing 10 vol.% of fibers, i.e., with the lowest percentage of reinforcement, show the fragile behavior of the epoxy matrix, with evidence of river marks and smooth and flat surfaces (

Figure 6). Regarding the fibers, transversal (

Figure 6a and

Figure 7a) and longitudinal (

Figure 7a) ruptures, as well as pullout (

Figure 7b) were observed.

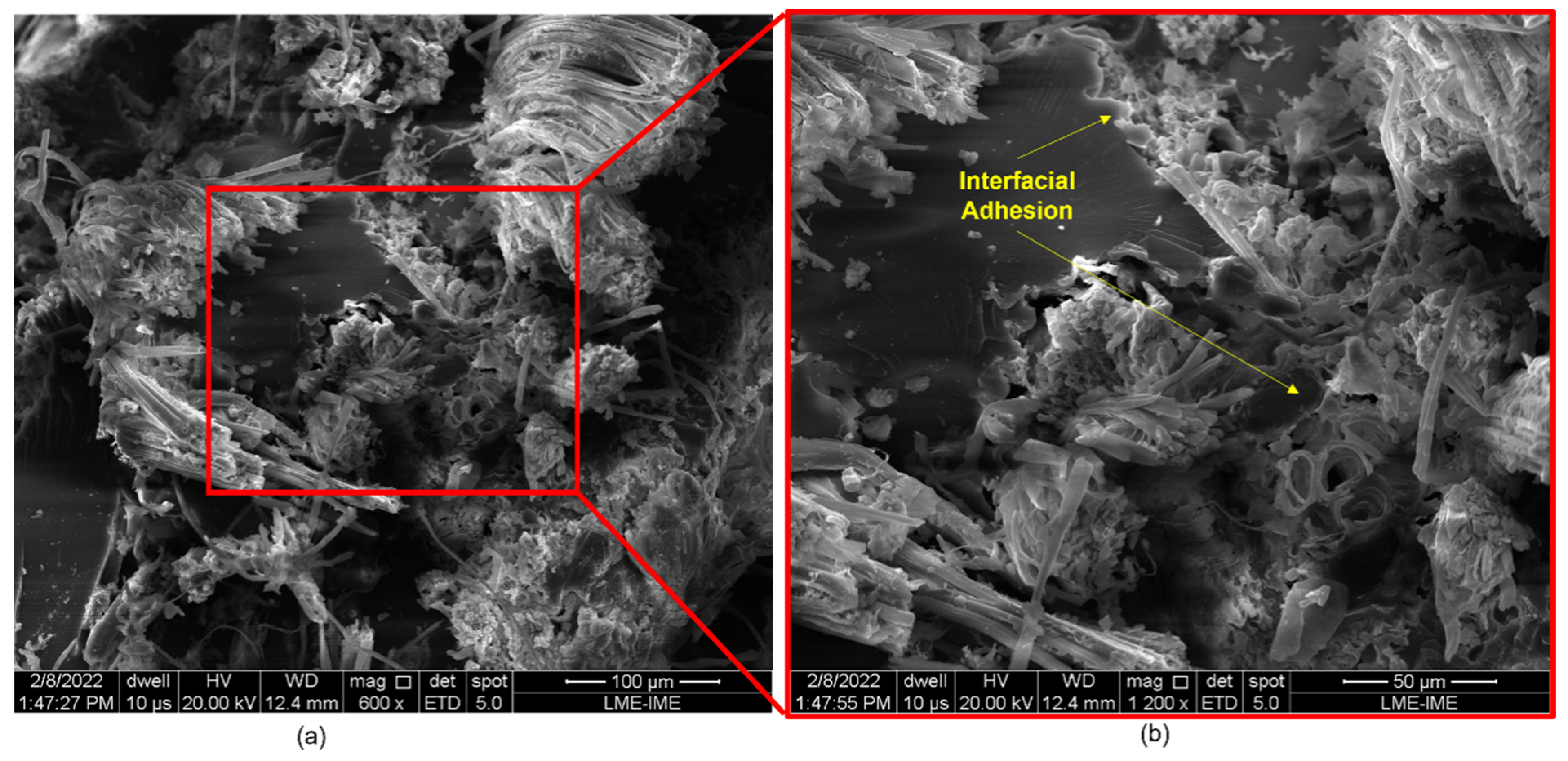

Figure 8,

Figure 9,

Figure 10,

Figure 11 and

Figure 12 show the fracture surfaces of GO functionalized composites containing 30 vol.% of PALF, that is, with the highest percentage of reinforcement of the PGO/ENT groups (

Figure 8 and

Figure 11), PNT/EGO (

Figure 9 and

Figure 10), and PGO/EGO (

Figure 12). As for the failure mechanisms, it is worth noting the fragile fracture of the non-functionalized matrix, good fiber–matrix adhesion, few pullout voids, and ruptured fibers can be seen (

Figure 8). Lumens and ruptured fiber cell walls can also be visualized in the cross-section, the surface of fibers not coated with GO (

Figure 9). In addition to the failure characteristics of the GO-functionalized epoxy, imperfections (bubbles), and defibrillation (

Figure 9 and

Figure 10), folded fiber and microfibril separation (

Figure 11) are also detected. The general appearance of the surfaces of the samples is also observed in

Figure 12a,b, in which the two characteristics of the GO are present, namely the film on the fibers (

Figure 12a) and the irregular surface of the matrix (river marks and secondary cracks, arc-shaped lines) (

Figure 12b).

Regarding the failure characteristics of the GO-functionalized epoxy, it is worth noting that it does not present an apparently smooth and flat fracture surface as in the non-functionalized epoxy. The epoxy matrix presents a similar appearance to that seen in the micrographs studied by Bortz et al. [

70] on fatigue and fracture resistance in GO/Epoxy composites. These authors emphasize that nanometer-sized particles and that fibers cannot explain crack fixation because their relative size is much smaller than the crack tip opening displacement. However, the 2D micrometric dimensions of the GO sheets are thought to be large enough to explain the observation of crack fixation (i.e., surface irregularity).

Arc-shaped lines left on fracture surfaces and secondary cracks associated with river marks are visualized in the micrographs, similar to the previously reported in the literature [

46,

70]. Bortz et al. [

70] pointed out that multiplanar characteristics on the fracture surface of the composite suggest that the GO sheets induce the deflection of the crack front propagation and that this process introduces out-of-plane loading, generating new fracture surfaces, thus increasing the strain energy required for the continuation of fracture.