Antibacterial Films Made of Bacterial Cellulose

Abstract

:1. Introduction

2. Materials and Methods

2.1. Bacterial Cellulose (BC) and Cellulose from Plant Preparation

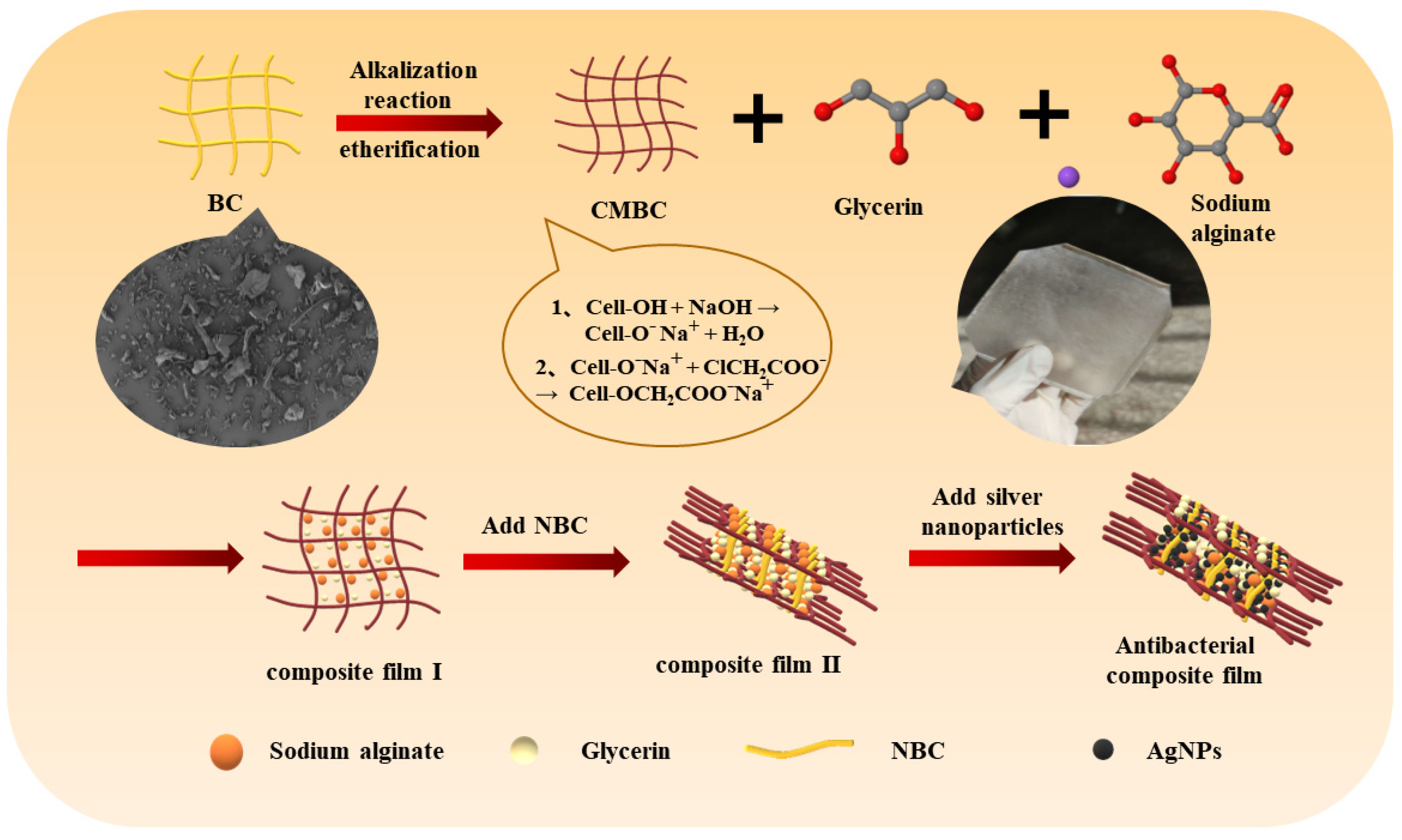

2.2. Carboxymethyl Cellulose Bacterial Cellulose (CMBC) and CMC Preparation

2.3. Characterizations of BC and CMBC

2.4. Preparation of CMBC and CMC Composite Films

2.5. Antimicrobial Testing of CMBC Composite Films

2.6. Tensile Properties, Opacity, Viscosity, and Water Vapor Permeability of Carboxymethyl Bacterial Cellulose Antibacterial Composite Film

3. Results and Discussion

3.1. Characteristics or Multi-Feature Exploration of BC and CMBC

3.1.1. DS of CMBC and CMC

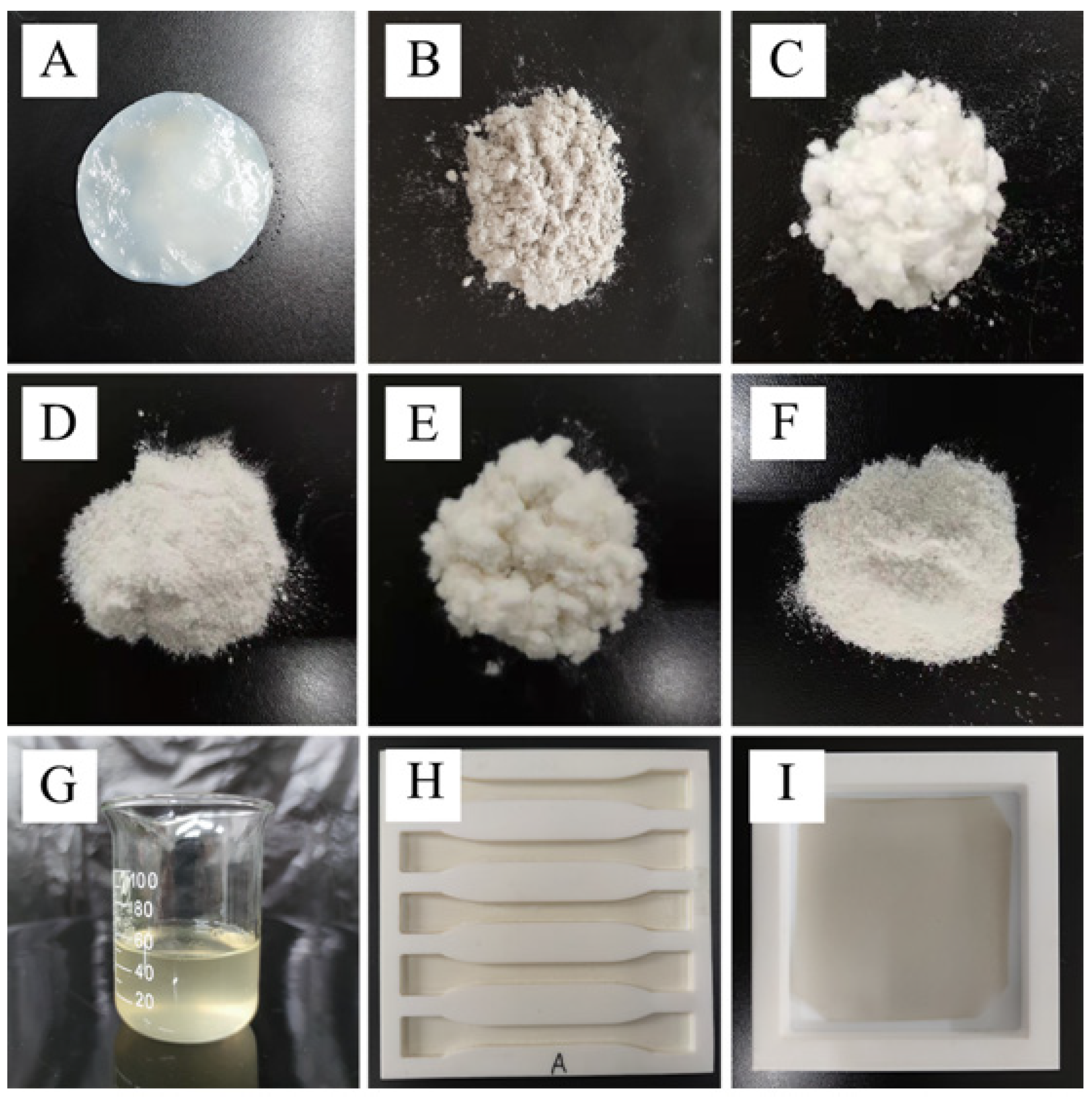

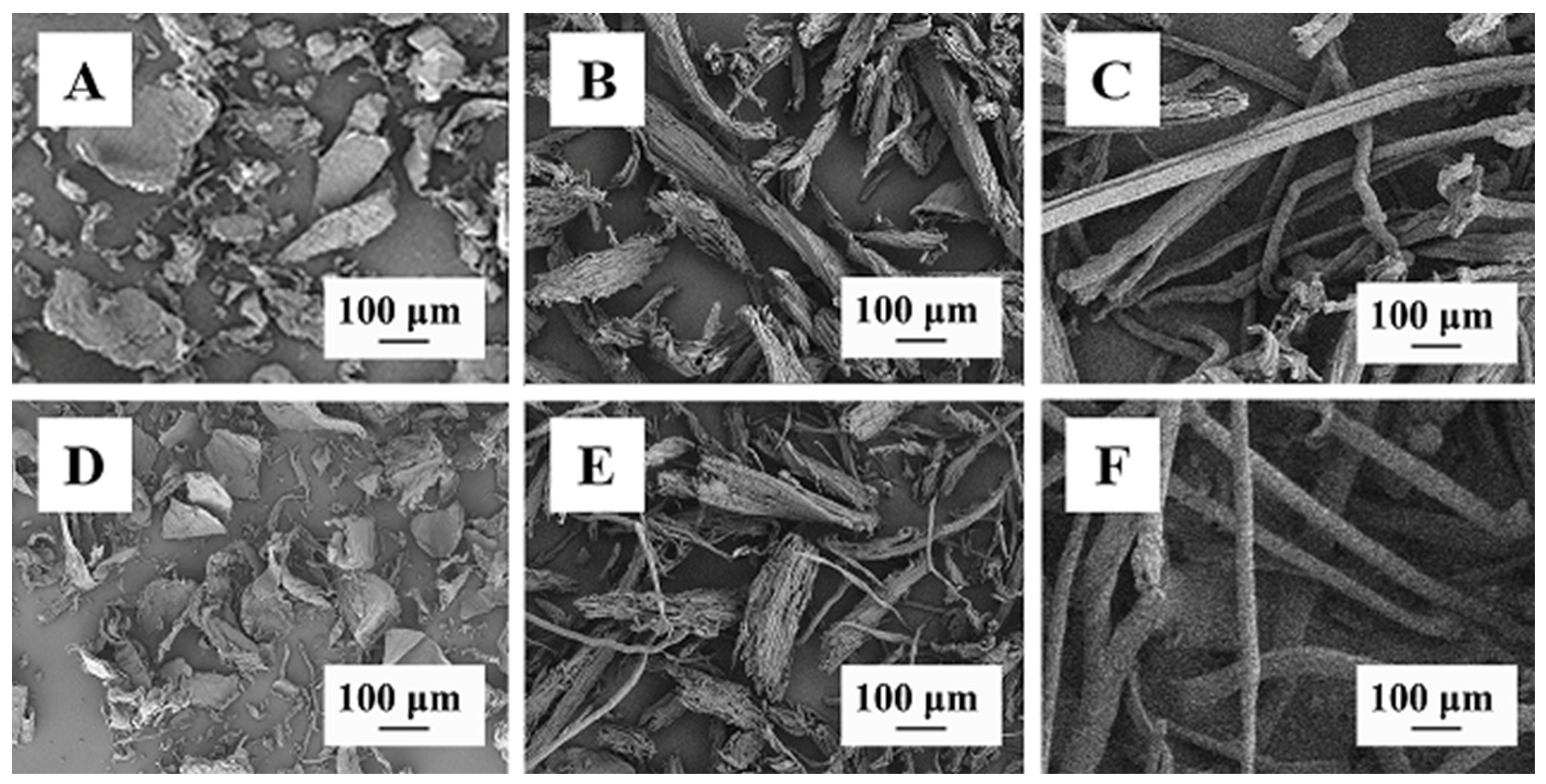

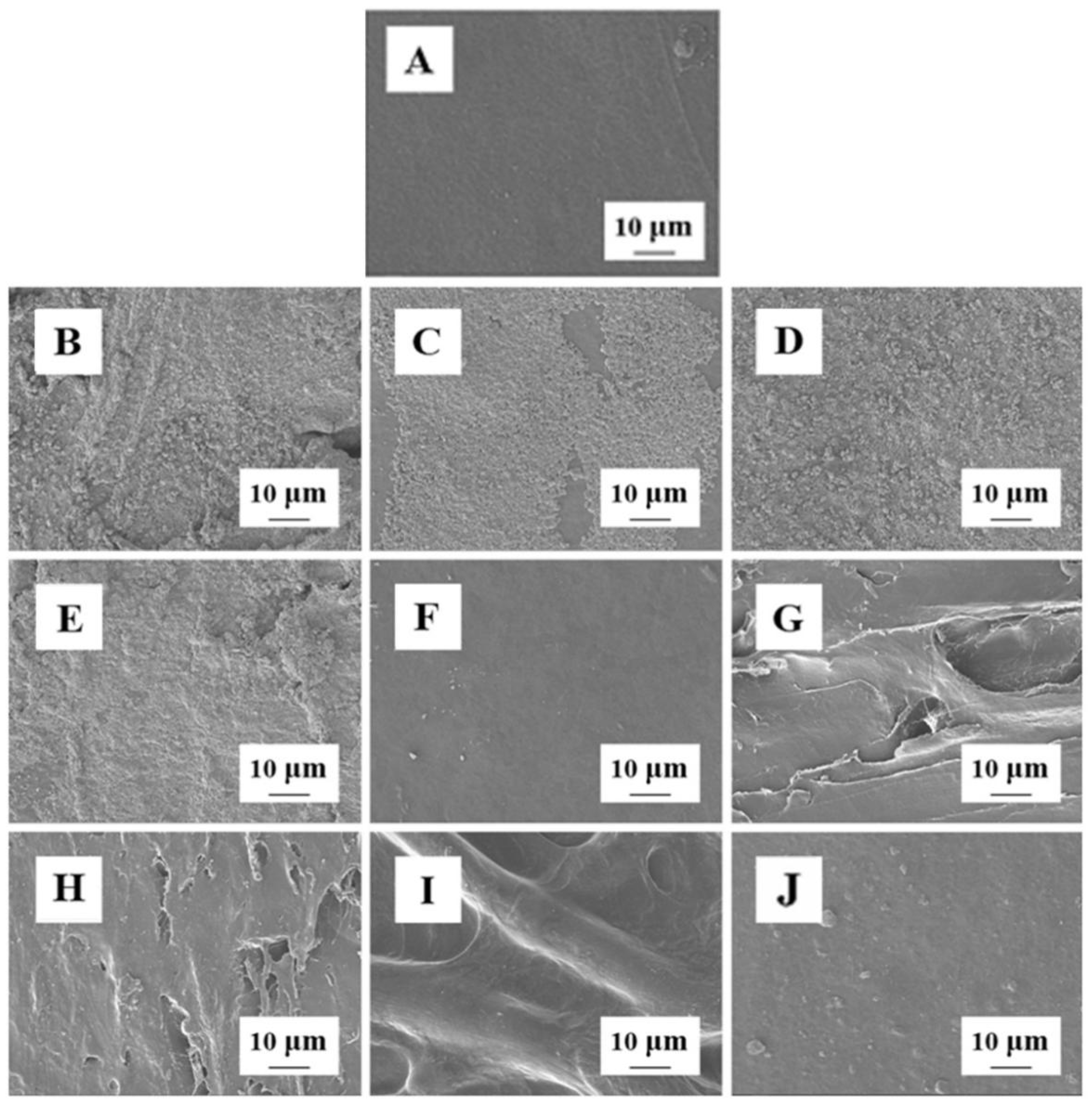

3.1.2. Micro-Structure of BC, Cellulose, CMBC, and CMC

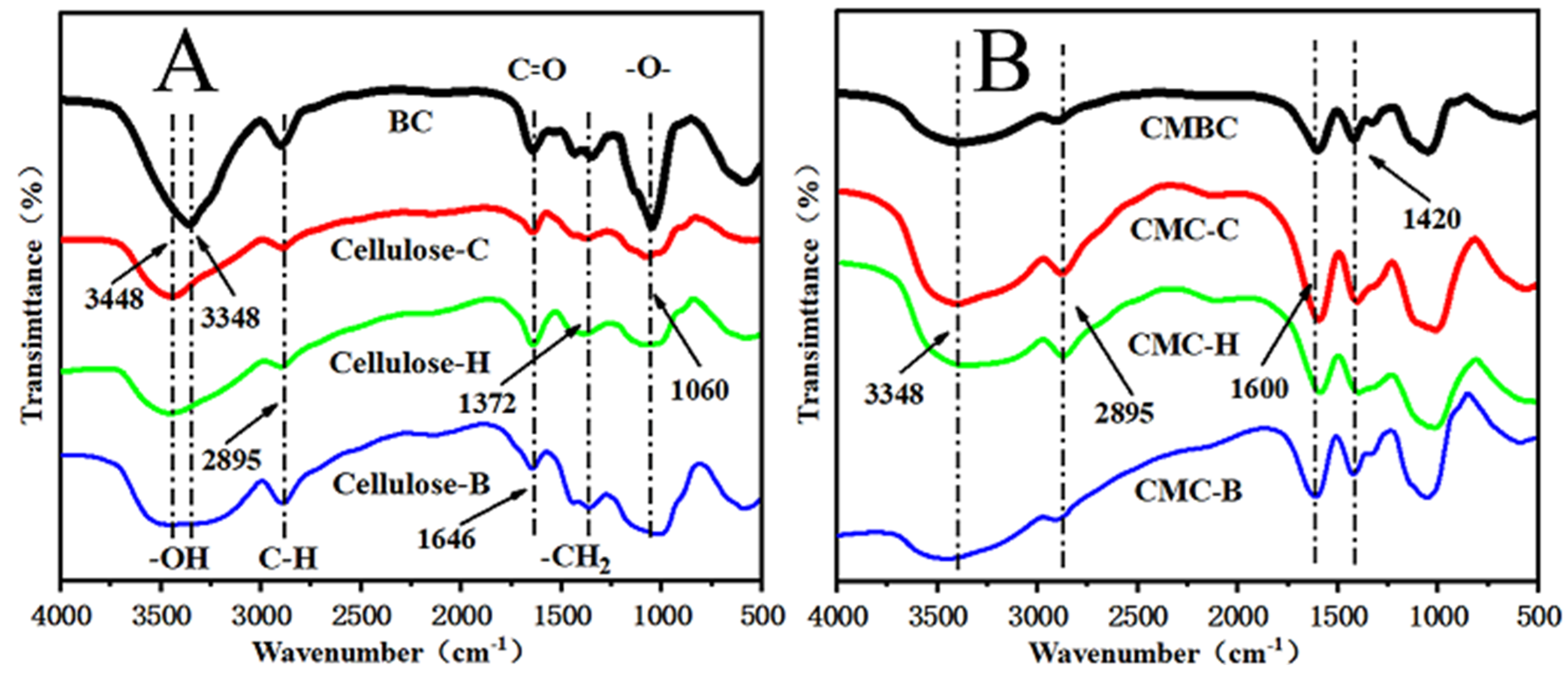

3.1.3. FTIR Spectrum of BC, Cellulose, CMBC, and CMC

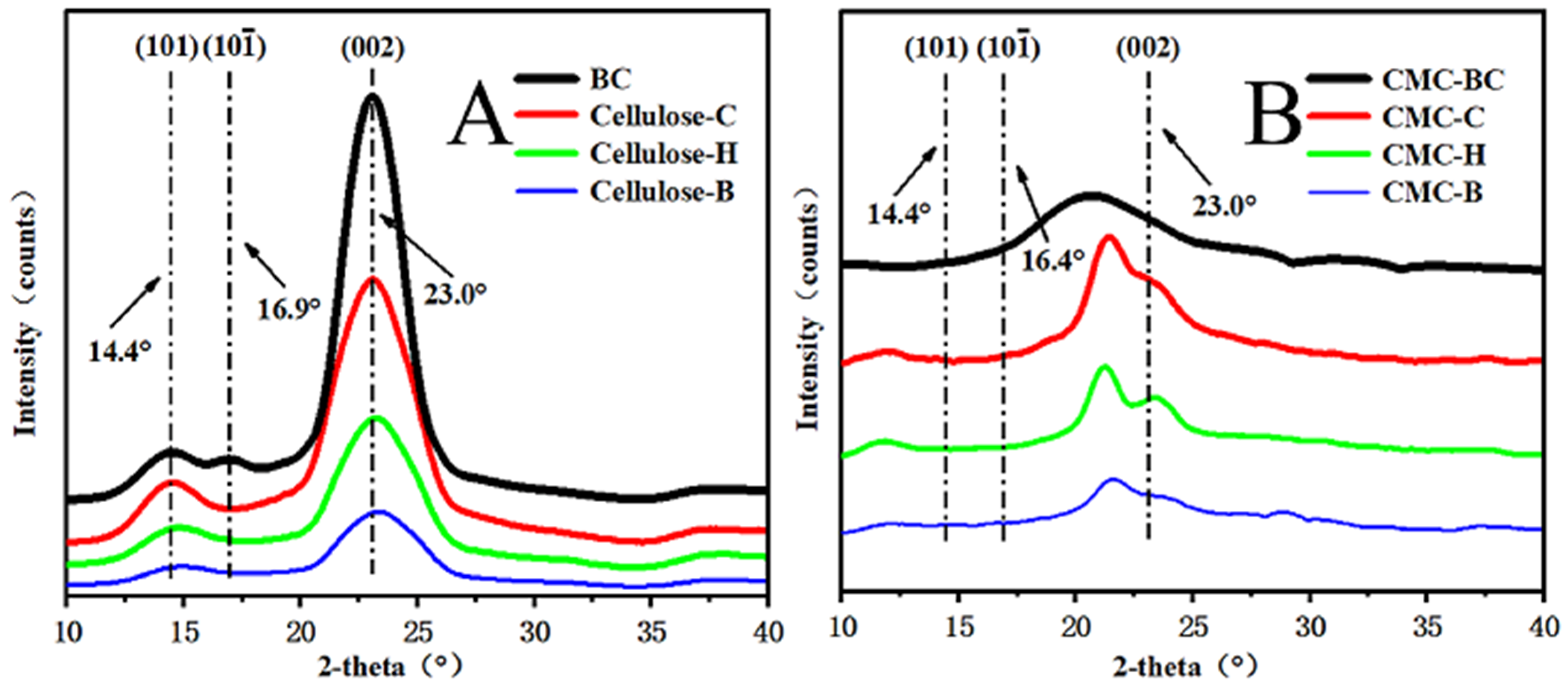

3.1.4. XRD Analysis of BC, CMBC, and CMC

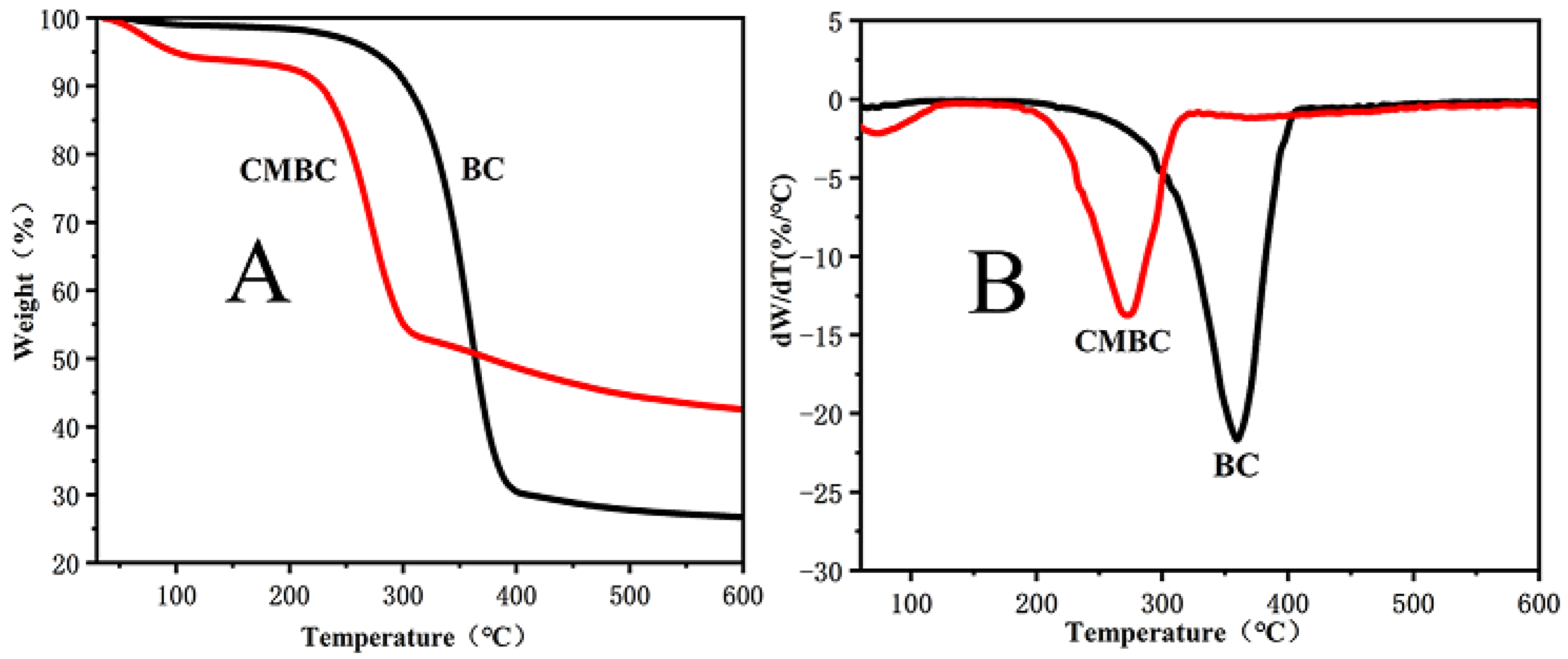

3.1.5. The Pyrolysis Characteristics of BC and CMBC

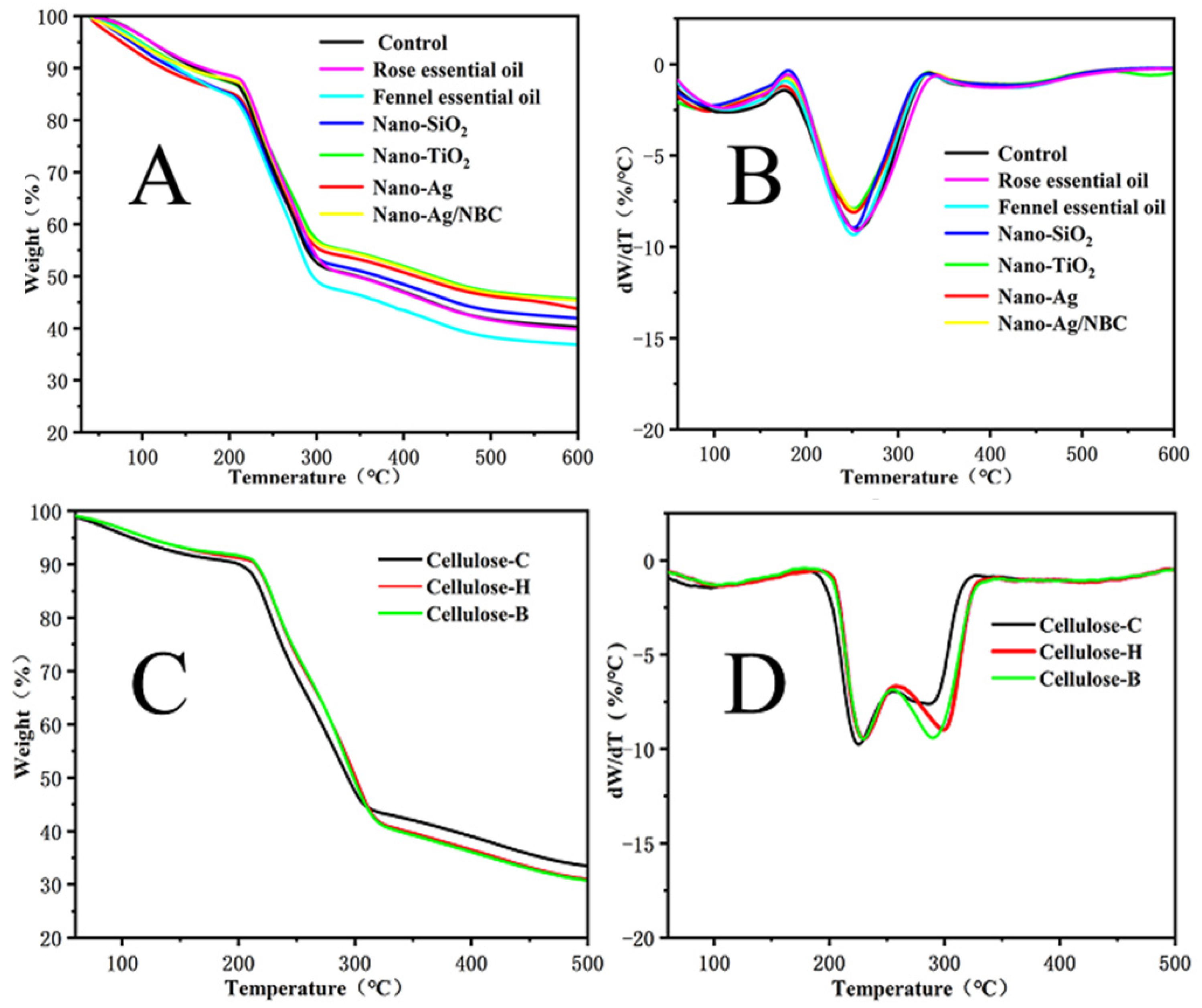

3.2. Antibacterial, Microstructure, and Pyrolysis Characteristics Properties of Composite Films

3.3. Mechanical and Physical Properties of CMB Composite Films

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lee, J.; Deng, F.; Yeomans, W.; Allen, A.; Gross, R.; Kaplan, D. Direct incorporation of glucosamine and N-acetylglucosamine into exopolymers by Gluconacetobacter xylinus (=Acetobacter xylinum) ATCC 10245: Production of chitosan-cellulose and chitin-cellulose exopolymers. Appl. Environ. Microbiol. 2001, 67, 3970–3975. [Google Scholar] [CrossRef] [PubMed]

- Hong, F.; Guo, X.; Zhang, S.; Han, S.; Yang, G.; Jönsson, L. Bacterial cellulose production from cotton-based waste textiles: Enzymatic saccharification enhanced by ionic liquid pretreatment. Bioresour. Technol. 2012, 104, 503–508. [Google Scholar] [CrossRef]

- Shao, W.; Wu, J.; Liu, H.; Ye, S.; Jiang, L.; Liu, X. Novel bioactive surface functionalization of bacterial cellulose film. Carbohydr. Polym. 2017, 178, 270–276. [Google Scholar] [CrossRef] [PubMed]

- Pivec, T.; Hribernik, S.; Kolar, M.; Kleinschek, K. Environmentally friendly procedure for in-situ coating of regenerated cellulose fibres with silver nanoparticles. Carbohydr. Polym. 2017, 163, 92–100. [Google Scholar] [CrossRef] [PubMed]

- Yin, N.; Du, R.; Zhao, F.; Han, Y.; Zhou, Z. Characterization of antibacterial bacterial cellulose composite films modified with chitosan or chitooligosaccharide. Carbohydr. Polym. 2020, 229, 115520. [Google Scholar] [CrossRef]

- Wirongrong, T.; Lisa, J.; Sasitorn, W. Effect of Carboxymethyl Cellulose Concentration on Physical Properties of Biodegradable Cassava Starch-Based Films. Chem. Cent. J. 2011, 5, 6–14. [Google Scholar]

- Ruan, C.; Zhang, Y.; Sun, Y. Effect of Sodium Alginate and Carboxymethyl cellulose Edible Coating with Epigallocatechin Gallate on Quality and Shelf Life of Fresh Pork. Int. J. Biol. Macromol. 2019, 141, 178–184. [Google Scholar] [CrossRef]

- Mahdiyar, S.; Seyed, J.; Amirhossein, S. Carboxymethyl Cellulose Film Modification through Surface Photo-Crosslinking and Chemical Crosslinking for Food Packaging Applications. Food Hydrocoll. 2016, 61, 378–389. [Google Scholar]

- Esteghlal, S.; Mehrdad, N.; Seyed, M. Physical and Mechanical Properties of Gelatin-CMC Composite Films under the Influence of Electrostatic Interactions. Int. J. Biol. Macromol. 2018, 114, 1–9. [Google Scholar] [CrossRef]

- Li, H.; Shi, H.; He, Y. Preparation and Characterization of Carboxymethyl Cellulose-Based Composite Films Reinforced by Cellulose Nanocrystals Derived from Pea Hull Waste for Food Packaging Applications. Int. J. Biol. Macromol. 2020, 164, 4104–4112. [Google Scholar] [CrossRef]

- Han, Y.; Wang, L. Sodium alginate/carboxymethyl cellulose films containing pyrogallic acid: Physical and antibacterial properties. J. Sci. Food Agric. 2017, 97, 1295–1301. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Han, W.; Zhu, Y. Anti-oxidative and antibacterial self-healing edible polyelectrolyte multilayer film in fresh-cut fruits. J. Nanosci. Nanotechnol. 2018, 18, 2592–2600. [Google Scholar] [CrossRef] [PubMed]

- Tang, Z.; Yang, M.; Qiang, M.; Li, X.; Morrell, J.J.; Yao, Y.; Su, Y. Preparation of cellulose nanoparticles from foliage by bio-Enzyme methods. Materials 2021, 14, 4557. [Google Scholar] [CrossRef] [PubMed]

- Nandi, N.; Gayen, K.; Ghosh, S. Amphiphilic peptide-based supramolecular, noncytotoxic, stimuli-responsive hydrogels with antibacterial activity. Biomacromolecules 2017, 18, 3621–3629. [Google Scholar] [CrossRef] [PubMed]

- Han, J.; Floros, J.D. Casting antimicrobial packaging films and measuring their physical properties and antimicrobial activity. J. Plast. Film Sheeting 1997, 13, 287–298. [Google Scholar] [CrossRef]

- Talja, R.A.; Helén, H.; Roos, Y.H.; Jouppila, K. Effect of type and content of binary polyol mixtures on physical and mechanical properties of starch-based edible films. Carbohydr. Polym. 2008, 71, 269–276. [Google Scholar] [CrossRef]

- Yang, M.; Hadi, P.; Yin, X. Antifouling nanocellulose films: How subtle adjustment of surface charge lead to self-cleaning property. J. Membr. Sci. 2021, 618, 118739. [Google Scholar] [CrossRef]

- Yao, Y.; Sun, Z.; Li, X.; Tang, Z.; Li, X.; Morrell, J.J.; Liu, Y.; Li, C.; Luo, Z. Effects of raw material source on the properties of CMC composite films. Polymers 2022, 14, 32. [Google Scholar] [CrossRef]

- Rachtanapun, P.; Jantrawut, P.; Klunklin, W. Carboxymethyl bacterial cellulose from nata de coco: Effects of NaOH. Polymers 2021, 13, 348. [Google Scholar] [CrossRef]

- Rachtanapun, P.; Rattanapanone, N. Synthesis and characterization of carboxymethyl cellulose powder and films from Mimosa pigra. J. Appl. Polym. Sci. 2011, 122, 3218–3226. [Google Scholar] [CrossRef]

- Bourmaud, A.; Siniscalco, D.; Foucat, L. Evolution of flax cell wall ultrastructure and mechanical properties during the retting step. Carbohydr. Polym. 2017, 206, 48–56. [Google Scholar] [CrossRef] [PubMed]

- Ulusoy, S.; Boşgelmez-Tinaz, G.; Seçilmiş-Canbay, H. Tocopherol, carotene, phenolic contents and antibacterial properties of rose essential oil, hydrosol and absolute. Curr. Microbiol. 2009, 59, 88–95. [Google Scholar] [CrossRef] [PubMed]

- Durán, N.; Durán, M.; De Jesus, M.B.; Seabra, A.B.; Fávaro, W.J.; Nakazato, G. Silver nanoparticles: A new view on mechanistic aspects on antimicrobial activity. Nanomedicine 2016, 12, 789–799. [Google Scholar] [CrossRef] [PubMed]

- Chien, C.S.; Lin, C.J.; Ko, C.J. Antibacterial activity of silver nanoparticles (AgNPs) confined to mesostructured silica against methicillin-resistant Staphylococcus aureus (MRSA). J. Alloys Compd. 2018, 747, 1–7. [Google Scholar] [CrossRef]

- Jose Ruben, M.; Jose Luis, E.; Alejandra, C. The bactericidal effect of silver nanoparticles. Nanotechnology 2005, 16, 2346–2353. [Google Scholar]

- Ullah, N.; Li, D.; Xiao, D. Photo-irradiation based biosynthesis of silver nanoparticles by using an ever green shrub and its antibacterial study. Dig. J. Nanomater. Biostruct. 2015, 10, 95–105. [Google Scholar]

- Yang, Y.; Lu, K.; Wang, P.; Ho, Y.; Tsai, M.L.; Mi, F. Development of bacterial cellulose/chitin multi-nanofibers based smart films containing natural active microspheres and nanoparticles formed in situ. Carbohydr. Polym. 2020, 228, 115370. [Google Scholar] [CrossRef]

- Ullah, N.; Yasin, S.; Abro, Z. Mechanically robust and antimicrobial cotton fibers loaded with silver nanoparticles: Synthesized via Chinese holly plant leaves. Int. J. Text. Sci. 2014, 3, 1–5. [Google Scholar]

- Alain, B.; Hom, N.D.; Anouck, H. Exploring the potential of waste leaf sheath date palm fibres for composite reinforcement through a structural and mechanical analysis. Compos. Part A 2017, 103, 292–303. [Google Scholar]

- Phothisarattana, D.; Wongphan, P.; Promhuad, K. Biodegradable Poly (Butylene Adipate-Co-Terephthalate) and Thermoplastic Starch-Blended TiO2 Nanocomposite Blown Films as Functional Active Packaging of Fresh Fruit. Polymers 2021, 13, 4192. [Google Scholar] [CrossRef]

- Wongphan, P.; Khowthong, M.; Supatrawiporn, T. Novel edible starch films incorporating papain for meat tenderization. Food Packag. Shelf Life 2022, 31, 100787. [Google Scholar] [CrossRef]

| Sample | CMBC | C-CMC | H-CMC | B-CMC |

|---|---|---|---|---|

| Degree of Substitution | 0.81 | 0.64 | 0.64 | 0.65 |

| (0.02) | (0.01) | (0.09) | (0.05) |

| Cellulose | Additive | E. coli (mm) | S. aureus (mm) | Residual Material (%) | Peak Temperature (°C) | |

|---|---|---|---|---|---|---|

| BC | Control | 0 | 0 | 40.3 | 250 | - |

| Rose essential oil | 6.26 (0.02) | 6.36 (0.02) | 40.3 | 250 | - | |

| Fennel essential oil | 6.04 (0.02) | 6.13 (0.01) | 36.8 | 250 | - | |

| Nano-SiO2 | 0 | 0 | 42.0 | 250 | - | |

| Nano-TiO2 | 7.42 (0.01) | 7.75 (0.04) | 45.5 | 250 | - | |

| Nano-Ag | 9.04 (0.11) | 9.41 (0.06) | 43.8 | 250 | - | |

| Cellulose-C | Nano-Ag | 7.33 (0.32) | 7.56 (0.15) | 33.3 | 210 | 300 |

| Cellulose-H | Nano-Ag | 7.71 (0.16) | 7.81 (0.04) | 30.4 | 210 | 300 |

| Cellulose-B | Nano-Ag | 6.76 (0.04) | 6.70 (0.06) | 30.4 | 210 | 300 |

| BC | Nano-Ag/NBC | 13.1 (0.50) | 15.0 (0.50) | 45.5 | 250 | - |

| Additive | Tensile Strength (MPa) | Elongation at Break (%) | Opacity (A/mm) | The Kinematic Viscosity (mm2/s) | Water Vapor Permeability (g·cm/(cm2·s·Pa)) |

|---|---|---|---|---|---|

| Control | 28.8 | 19.1 | 8.60 | 277.6 | 0.12 |

| (2.23) | (2.26) | (1.11) | (2.95) | (0.02) | |

| Rose essential oil | 26.4 | 6.16 | 9.60 | 264.5 | 0.16 |

| (2.69) | (0.91) | (0.67) | (2.31) | (0.04) | |

| Fennel essential oil | 25.2 | 7.36 | 8.71 | 243.6 | 0.09 |

| (3.74) | (1.30) | (1.26) | (3.01) | (0.01) | |

| Nano-SiO2 | 34.4 | 8.81 | 17.1 | 237.5 | 0.11 |

| (3.21) | (2.55) | (1.65) | (3.54) | (0.01) | |

| Nano-TiO2 | 35.1 | 8.53 | 12.3 | 209.6 | 0.12 |

| (3.21) | (0.94) | (2.13) | (2.65) | (0.02) | |

| Nano-Ag | 33.3 | 9.36 | 9.07 | 215.7 | 0.12 |

| (3.04) | (1.07) | (1.29) | (3.00) | (0.03) | |

| Nano-Ag/NBC | 40.8 | 4.41 | 7.20 | 184.1 | 0.07 |

| (4.41) | (0.39) | (0.58) | (5.25) | (0.01) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Z.; Li, X.; Tang, Z.; Li, X.; Morrell, J.J.; Beaugrand, J.; Yao, Y.; Zheng, Q. Antibacterial Films Made of Bacterial Cellulose. Polymers 2022, 14, 3306. https://doi.org/10.3390/polym14163306

Sun Z, Li X, Tang Z, Li X, Morrell JJ, Beaugrand J, Yao Y, Zheng Q. Antibacterial Films Made of Bacterial Cellulose. Polymers. 2022; 14(16):3306. https://doi.org/10.3390/polym14163306

Chicago/Turabian StyleSun, Zhenbing, Xiaoping Li, Zhengjie Tang, Xiaobao Li, Jeffrey J. Morrell, Johnny Beaugrand, Yao Yao, and Qingzhuang Zheng. 2022. "Antibacterial Films Made of Bacterial Cellulose" Polymers 14, no. 16: 3306. https://doi.org/10.3390/polym14163306

APA StyleSun, Z., Li, X., Tang, Z., Li, X., Morrell, J. J., Beaugrand, J., Yao, Y., & Zheng, Q. (2022). Antibacterial Films Made of Bacterial Cellulose. Polymers, 14(16), 3306. https://doi.org/10.3390/polym14163306