Bearing Capacity of Reinforced Concrete Beams with Initial Cracks Reinforced with Polymer Composite Materials

Abstract

:1. Introduction

- (1)

- Testing prototypes with initial inclined cracks of various widths, obtained at three shear spans equal to (1.5; 2.0; 2.5) and tested after reinforcement with three-sided stirrups at already indicated distances from the support axis to the point of application of concentrated loads.

- (2)

- Obtaining new data on the strength of inclined sections of beams reinforced with external reinforcement under the above variable factors.

- (3)

- Determining the degree of influence of the type of composite stirrups, the scheme of their location, as well as the size of the cut span on the strength of the inclined sections of the prototypes.

- (4)

- Evaluating the effectiveness of composite stirrups at different widths of inclined cracks, both when varying the shear span at the stage of formation of initial cracks, and the final test after strengthening the inclined sections.

- (5)

- Analyzing of the obtained experimental data and evaluate the existing method for calculating beams reinforced with composite materials.

- (6)

- Developing proposals for improving the regulatory framework for the calculation of bending reinforced concrete elements reinforced with composite materials based on carbon fiber under the action of transverse forces.

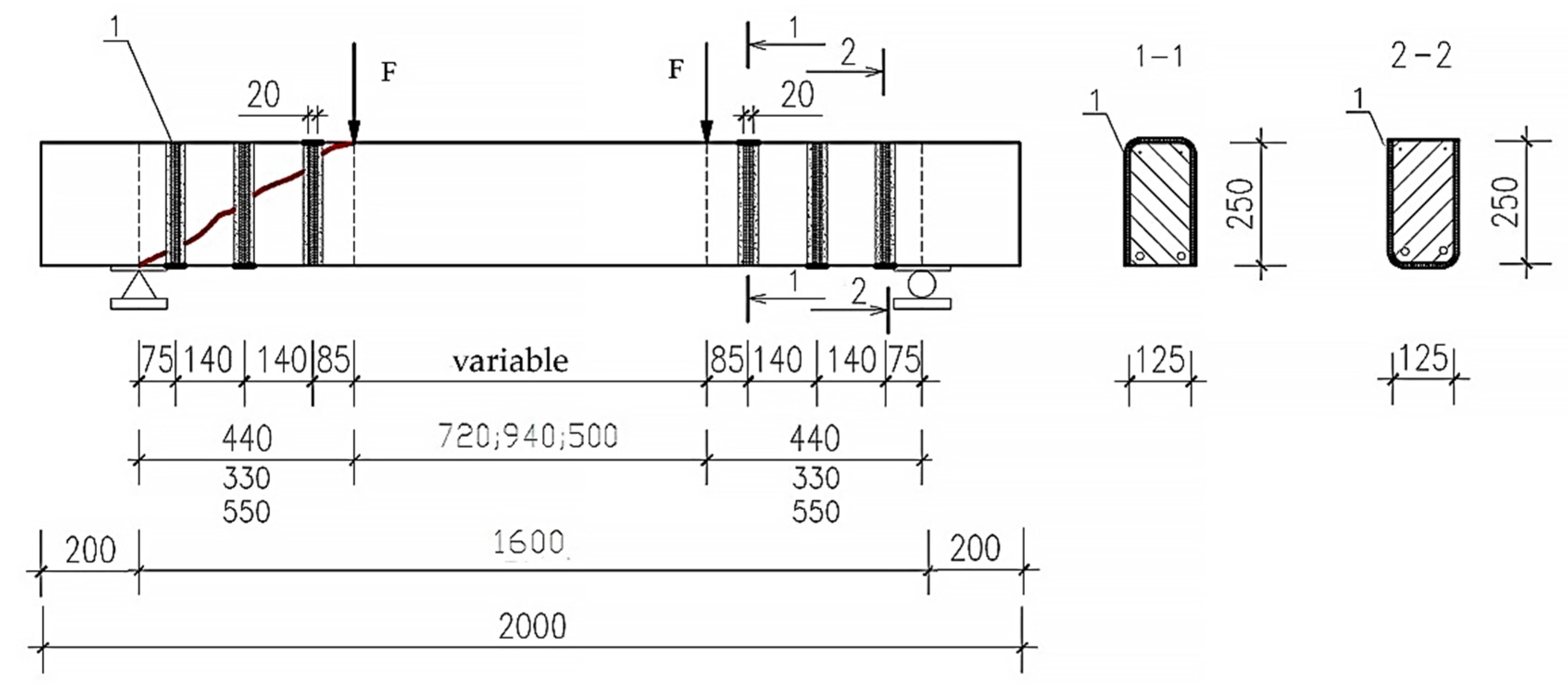

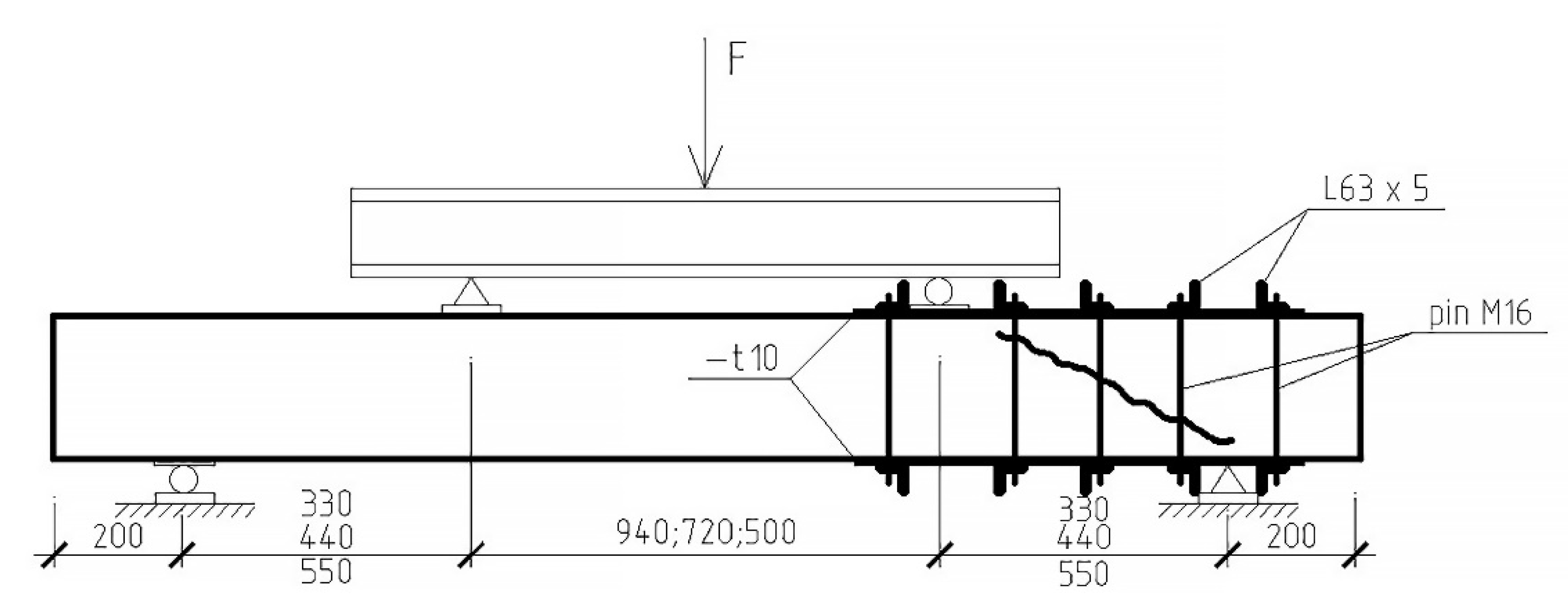

2. Materials and Methods

3. Results and Discussion

3.1. Influence of Shear Span and Type of Composite Stirrups

3.2. Accounting for the Influence of Opening Width of Initial Oblique Cracks

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Guo, X.; Cui, H.; Wang, Y.; Chen, Z. Fatigue Life Prediction of CFRP-Strengthened RC Beams with Flexural Crack under Hygrothermal Environments. Materials 2022, 15, 4681. [Google Scholar] [CrossRef] [PubMed]

- Bediwy, A.; Mahmoud, K.; El-Salakawy, E. Effect of Longitudinal Reinforcement Ratio on the Behaviour of Deep Beams Reinforced with GFRP Headed-End Bars. Lect. Notes Civil Eng. 2023, 241, 67–73. [Google Scholar] [CrossRef]

- Abdallah, A.; El-Salakawy, E. Effect of Concrete Strength on GFRP-RC Circular Columns Under Simulated Seismic Loading. Lect. Notes Civ. Eng. 2023, 241, 127–133. [Google Scholar] [CrossRef]

- Mayhoub, O.A.; Abadel, A.A.; Alharbi, Y.R.; Nehdi, M.L.; de Azevedo, A.R.G.; Kohail, M. Effect of Polymers on Behavior of Ultra-High-Strength Concrete. Polymers 2022, 14, 2585. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Liu, W.; Xu, W.; Ji, Y. Durability Investigation on CFRP Strengthened Cementitious Materials in Cold Region. Polymers 2022, 14, 2190. [Google Scholar] [CrossRef] [PubMed]

- MohamedSalih, M.M.; Yousif, A.R. Effect of type, amount and configuration of reinforcement in HSC box-girders reinforced with BFRP bars and steel stirrups under torsion-shear-bending. Ain Shams Eng. J. 2022, 13, 101787. [Google Scholar] [CrossRef]

- Mailyan, D.R.; Polskoy, P.P.; Mervat, H.; Kurgin, K.V. About the question of deformability flexural elements of heavy concrete with the location carbon fiber and composite reinforcement in two rows. Eng. J. Don 2013, 4, 2094. Available online: http://www.ivdon.ru/en/magazine/archive/n4y2013/2094 (accessed on 16 August 2022).

- Khishmakh, M.; Mailyan, D.R.; Polskoy, P.P.; Blagoz, A.M. Strength and deformability of bending elements made of heavy concrete, reinforced with glass-plastic and steel reinforcement. New Technol. 2012, 4, 147–152. Available online: https://elibrary.ru/download/elibrary_19116118_93785531.pdf (accessed on 16 August 2022).

- Polskoy, P.P.; Khishmakh, M.; Mikhub, A. On the possibility of using round carbon fiber rods as working reinforcement for bending elements. Sci. Rev. 2012, 6, 211–213. Available online: http://www.sced.ru/ru/index.php?option=com_content&view=article&id=178:6-2012&catid=23&Itemid=156&limitstart=7 (accessed on 16 August 2022).

- Polskoy, P.P.; Mailyan, D.R. Influence of steel and composite reinforcement on the width of normal cracks. Eng. J. Don 2013, 2, 1675. Available online: https://ivdon.ru/ru/magazine/archive/n2y2013/1675 (accessed on 16 August 2022).

- Polskoy, P.P.; Mailyan, D.R.; Dedukh, D.A.; Georgiev, S.V. Design of reinforced concrete beams in case of change of cross section of composite strengthening reinforcement. Glob. J. Pure Appl. Math. 2016, 12, 1767–1786. Available online: https://ripublication.com/gjpam16/gjpamv12n2_50.pdf (accessed on 16 August 2022).

- Polskoy, P.P. Strength of flexible compressed elements when changing the options of composite reinforcement and application of the load. Mater. Sci. Forum 2018, 931, 315–320. [Google Scholar] [CrossRef]

- Shilov, A.A.; Polskoy, P.P.; Mailyan, D.R.; Shilov, P.A. Initial crack effect on the strength of oblique cross sections of reinforced concrete beams strengthened with carbon fiber. E3S Web Conf. 2019, 110, 01053. [Google Scholar] [CrossRef]

- Polskoy, P.P.; Shilov, A.A.; Mailyan, D.R. The Cut Span Effect on the Beams Inclined Sections Strength Reinforced with External Composite Reinforcement. Mater. Sci. Forum 2020, 974, 633–637. Available online: https://www.scientific.net/MSF.974.633 (accessed on 16 August 2022). [CrossRef]

- ACI 440.2R-08; Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures. American Concrete Institute: Farmington Hills, MI, USA, 2008; p. 76.

- Eurocode 2: Design of Concrete Structures—Part 1-1. In General Rules and Rules for Buildings; European Commitiee for Standardization: Brussels, Belgium, 2004; p. 229.

- GB 50608-2010; Technical Code for Infrastructure Application of FRP Composites. (In Chinese). Ministry of Housing and Urban-Rural Development of P. R. China: Beijing, China, 2010.

- Lu, C.; Cai, Q.; Xu, K.; Sha, X.; Yan, Y. Comparison of flexural behaviors between plain and steel-fiber-reinforced concrete beams with hybrid GFRP and steel bars. Structures 2022, 43, 1–11. [Google Scholar] [CrossRef]

- Lanning, A.; Hain, A.; Zaghi, A.E.; Saiidi, M.S. Experimental study on hybrid concrete-filled fiber reinforced polymer tube (HCFFTs) columns under simulated seismic loading. Eng. Struct. 2022, 264, 114478. [Google Scholar] [CrossRef]

- Abed, M.A.; Anagreh, A.; Tošić, N.; Alkhabbaz, O.; Alshwaiki, M.E.; Černý, R. Structural Performance of Lightweight Aggregate Concrete Reinforced by Glass or Basalt Fiber Reinforced Polymer Bars. Polymers 2022, 14, 2142. [Google Scholar] [CrossRef]

- Hosseini, S.M.; Yekrangnia, M.; Oskouei, A.V. Effect of spiral transverse bars on structural behavior of concrete shear walls reinforced with GFRP bars. J. Build. Eng. 2022, 55, 104706. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M.; Mailyan, L.R.; Meskhi, B.; Efremenko, I.; Varavka, V.; Beskopylny, N.; Dotsenko, N. Modeling and Experimental Verification of the Performance of Polymer Composite Reinforcing Bars of Different Types in Concrete of Different Density. Polymers 2022, 14, 1756. [Google Scholar] [CrossRef]

- Stel’makh, S.A.; Shcherban, E.M.; Beskopylny, A.; Mailyan, L.R.; Meskhi, B.; Dotsenko, N. Enchainment of the Coefficient of Structural Quality of Elements in Compression and Bending by Combined Reinforcement of Concrete with Polymer Composite Bars and Dispersed Fiber. Polymers 2021, 13, 4347. [Google Scholar] [CrossRef]

- Li, J.; Liu, H.; Guo, Q.; Dai, G.; Zhou, J.; Xie, P. Low-Cycle Reverse Loading Tests of the Continuous Basalt Fiber-Reinforced Polymer Column Filled with Concrete. Appl. Sci. 2022, 12, 6359. [Google Scholar] [CrossRef]

- Pereira, M.; Gaspar, F.; Serrão, D.; Mateus, A.; Silva, M. Carbon Fiber-Reinforced Polymer (CFRP) Composites for Strengthening and Repair of Reinforced Concrete. Mater. Proc. 2022, 8, 99. [Google Scholar] [CrossRef]

- Wang, H.-P.; Ni, Y.-Q.; Dai, J.-G.; Yuan, M.-D. Interfacial debonding detection of strengthened steel structures by using smart CFRP-FBG composites. Smart Mater. Struct. 2019, 28, 115001. [Google Scholar] [CrossRef]

- Wang, H.-P.; Chen, H.; Chen, C.; Zhang, H.-Y.; Jiang, H.; Song, T.; Feng, S.-Y. The Structural Performance of CFRP Composite Plates Assembled with Fiber Bragg Grating Sensors. Symmetry 2021, 13, 1631. [Google Scholar] [CrossRef]

- Madan, C.S.; Panchapakesan, K.; Anil Reddy, P.V.; Joanna, P.S.; Rooby, J.; Gurupatham, B.G.A.; Roy, K. Influence on the Flexural Behaviour of High-Volume Fly-Ash-Based Concrete Slab Reinforced with Sustainable Glass-Fibre-Reinforced Polymer Sheets. J. Compos. Sci. 2022, 6, 169. [Google Scholar] [CrossRef]

- Meskhi, B.; Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M.; Mailyan, L.R.; Beskopylny, N.; Dotsenko, N. Theoretical and Experimental Substantiation of the Efficiency of Combined-Reinforced Glass Fiber Polymer Composite Concrete Elements in Bending. Polymers 2022, 14, 2324. [Google Scholar] [CrossRef]

- Younis, A.; El-Sherif, H.; Ebead, U. Shear strength of recycled-aggregate concrete beams with glass-FRP stirrups. Compos. Part C Open Access 2022, 8, 100257. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M.; Mailyan, L.R.; Meskhi, B. Nano modifying additive micro silica influence on integral and differential characteristics of vibrocentrifuged concrete. J. Build. Eng. 2022, 51, 104235. [Google Scholar] [CrossRef]

- Gao, J.; Xu, P.; Fan, L.; Terrasi, G.P. Study on Bond-Slip Behavior between Seawater Sea-Sand Concrete and Carbon Fiber-Reinforced Polymer (CFRP) Bars with Different Surface Shapes. Polymers 2022, 14, 2689. [Google Scholar] [CrossRef]

- Li, W.; Tang, S.; Huang, X.; Liu, W.; Yang, X.; Shi, T. Carbon fiber-reinforced polymer mesh fabric as shear reinforcement in reinforced concrete beams. J. Build. Eng. 2022, 53, 104433. [Google Scholar] [CrossRef]

- Preinstorfer, P.; Huber, T.; Reichenbach, S.; Lees, J.M.; Kromoser, B. Parametric Design Studies of Mass-Related Global Warming Potential and Construction Costs of FRP-Reinforced Concrete Infrastructure. Polymers 2022, 14, 2383. [Google Scholar] [CrossRef] [PubMed]

- Beskopylny, A.; Kadomtseva, E.; Strelnikov, G. Numerical study of the stress-strain state of reinforced plate on an elastic foundation by the Bubnov-Galerkin method. IOP Conf. Ser. Earth Environ. Sci. 2017, 90, 012017. [Google Scholar] [CrossRef]

- Madan, C.S.; Munuswamy, S.; Joanna, P.S.; Gurupatham, B.G.A.; Roy, K. Comparison of the Flexural Behavior of High-Volume Fly AshBased Concrete Slab Reinforced with GFRP Bars and Steel Bars. J. Compos. Sci. 2022, 6, 157. [Google Scholar] [CrossRef]

- Shen, J.; Huang, Z.; Song, X.; Yao, Y. Deformation performance analysis of concrete shear wall with CFRP grids based on the modified uniaxial shear-flexural model. J. Build. Eng. 2022, 54, 104621. [Google Scholar] [CrossRef]

- Smirnova, O.; Kazanskaya, L.; Koplík, J.; Tan, H.; Gu, X. Concrete Based on Clinker-Free Cement: Selecting the Functional Unit for Environmental Assessment. Sustainability 2021, 13, 135. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Kadomtseva, E.E.; Strelnikov, G.P.; Berdnik, Y.A. Stress-strain state of reinforced bimodulus beam on an elastic foundation. IOP Conf. Ser. Earth Environ. Sci. 2017, 90, 012064. [Google Scholar] [CrossRef]

- Smirnova, O.M.; Menéndez Pidal de Navascués, I.; Mikhailevskii, V.R.; Kolosov, O.I.; Skolota, N.S. Sound-Absorbing Composites with Rubber Crumb from Used Tires. Appl. Sci. 2021, 11, 7347. [Google Scholar] [CrossRef]

- Cao, X.; Ren, Y.-C.; Zhang, L.; Jin, L.-Z.; Qian, K. Flexural behavior of ultra-high-performance concrete beams with various types of rebar. Compos. Struct. 2022, 292, 115674. [Google Scholar] [CrossRef]

- Yang, S.; Liu, C.; Sun, Z.; Xu, M.; Feng, Y. Effects of resin pre-coating treatment and fibre reinforcement on adhesive bonding between CFRP sheet and concrete. Compos. Struct. 2022, 292, 115610. [Google Scholar] [CrossRef]

- Wagner, J.; Würgau, C.; Schumann, A.; Schütze, E.; Ehlig, D.; Nietner, L.; Curbach, M. Strengthening of Reinforced Concrete Structures with Carbon Reinforced Concrete—Possibilities and Challenges. CivilEng 2022, 3, 24. [Google Scholar] [CrossRef]

| Test Stage | Shear Span during Initial Crack Formation a, cm | Code of Beams during Initial Crack Formation | Ordinal Number of Specimens after Reinforcement | Shear Force at:, kN | Horizontal Projection Incl. Cracks “C”, cm | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Crack Formation Qcr | Max. Crack Opening Q | Formation | Max. Crack Opening | After Unloading. | ||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| Samples reinforced with three-way U-stirrups | ||||||||||

| I stage | a1B | 14 | 25.0 | 37.5 | 0.02 | 0.68/0.60 | 0.48/0.40 | 32.0 | ||

| a2B | 16 | 301.3 | 20.0 | 32.5 | 0.08 | 0.70/0.60 | 0.48/0.40 | 25.0 | ||

| a3B | 10 | 30.0 | 52.5 | 0.02 | 0.64/0.70 | 0.40/0.48 | 31.0 | |||

| a4Б | 12 | 362.3 | 30.0 | 45.0 | 0.08 | 0.75/0.7 | 0.45/0.30 | 29.0 | ||

| a5B | 18 | 25.0 | 35.0 | 0.10 | 0.80/0.63 | 0.48/0.30 | 30.0 | |||

| a6B | 20 | 259.4 | 20.0 | 32.5 | 0.07 | 0.85/0.50 | 0.45/0.20 | 29.0 | ||

| b1B | 30 | 30.0 | 40.0 | 0.08 | 0.60/0.40 | 0.30/0.20 | 25.0 | |||

| b2B | 32 | 342.5 | 25.0 | 35.0 | 0.06 | 0.75/0.30 | 0.50/0.20 | 27.0 | ||

| b3B | 22 | 35.0 | 49.0 | 0.06 | 0.60/0.75 | 0.40/0.45 | 28.0 | |||

| b4B | 24 | 373.8 | 35.0 | 40.0 | 0.085 | 0.80/0.70 | 0.45/0.55 | 24.0 | ||

| b5B | 26 | 25.0 | 45.0 | 0.07 | 0.85/0.60 | 0.65/0.40 | 21.0 | |||

| b6B | 28 | 391.5 | 35.0 | 60.0 | 0.06 | 0.66/0.60 | 0.40/0.45 | 25.5 | ||

| c2B | 38 | 35.0 | 62.5 | 0.10 | 0.60/0.70 | 0.25/0.38 | 13.5 | |||

| c1B | 40 | 383.0 | 37.5 | 85.0 | 0.08 | 0.70/0.54 | 0.35/0.20 | 16.0 | ||

| c3B | 34 | 35.0 | 67.5 | 0.08 | 0.64/0.56 | 0.40/0.30 | 12.5 | |||

| c4B | 36 | 335.2 | 35.0 | 77.5 | 0.09 | 0.70/0.40 | 0.30/0.12 | 15.0 | ||

| c5B | 42 | 40.0 | 80.0 | 0.06 | 0.90/0.40 | 0.50/0.10 | 13.0 | |||

| c6B | 44 | 311.8 | 35.0 | 70.0 | 0.04 | 1.0/0.50 | 0.50/0.40 | 12.0 | ||

| Shear Span at: | N of Samples | Experimental Values: | ||||||

|---|---|---|---|---|---|---|---|---|

| Forming Inclined Cracks | Testing Etalon or Enhanced Samples | Concrete Strength | Shear Force | |||||

| Compressive, MPa/Tensile Rbt, MPa | In Polymer reinforcement Qf, kN | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| Etalon samples | ||||||||

| - | (series a) | 1 | 28.5/2.24 | 74.1 | -/12.59 | -/- | -/- | 79.55 |

| 2 | 85.0 | -/- | -/- | |||||

| 3 | 90.0 | -/- | -/- | 92.125 | ||||

| 4 | 94.25 | -/- | -/- | |||||

| - | (series b) | 5 | 28.0/2.22 | 81.3 | -/13.35 | -/- | -/- | 77.9 |

| 6 | 74.5 | -/- | -/- | |||||

| - | (series c) | 7 | 27.0/2.18 | 112.0 | -/12.22 | -/- | -/- | 102.75 |

| 8 | 93.5 | -/- | -/- | |||||

| Samples reinforced with U-stirrups | ||||||||

| 2h0 (a) | (series a) | 9 | 28.2/2.23 | 113.6 | 101.01/12.59 | 101.46/114.05 | 21.93 | 32.4 |

| 10 | 95.0 | 82.41/12.59 | 82.78/95.4 | 3.28 | ||||

| 11 | 134.5 | 121.91/12.59 | 122.46/135.5 | 42.93 | ||||

| 2h0 (a) | 12 | 28.2/2.23 | 120.0 | 107.41/12.59 | 107.89/120.48 | 28.36 | 15.8 | |

(series b) | 13 | 23.5/2.01 | 101.3 | 87.95/13.35 | 97.14/110.49 | 32.59 | 28.15 | |

| 14 | 93.5 | 80.15/13.35 | 88.52/101.87 | 23.97 | ||||

| 15 | 93.25 | 79.9/13.35 | 88.25/101.6 | 23.7 | ||||

| 16 | 90.0 | 76.63/13.35 | 84.65/98.0 | 20.1 | 22.0 | |||

(series c) | 17 | 20.2/1.83 | 105.0 | 92.78/12.22 | 110.5/122.7 | 19.99 | 18.2 | |

| 18 | 95.5 | 83.28/12.22 | 99.2/111.4 | 8.65 | ||||

| 19 | 102.0 | 89.78/12.22 | 106.95/119.2 | 16.45 | ||||

| 20 | 90.0 | 77.78/12.22 | 92.65/104.9 | 2.15 | 5.4 | |||

| 2.5h0 (b) | (series a) | 21 | 29.9/2.27 | 115.0 | 102.41/12.59 | 101.05/113.65 | 21.52 | 21.0 |

| 22 | 115.0 | 102.41/12.59 | 101.05/113.65 | 21.52 | ||||

| 23 | 114.0 | 101.41/12.59 | 100.06/112.66 | 20.53 | ||||

| 24 | 108.0 | 95.41/12.59 | 94.15/106.74 | 14.6 | 18.1 | |||

(series b) | 25 | 26.1/2.13 | 109.45 | 96.1/13.35 | 100.16/113.5 | 35.6 | 34.3 | |

| 26 | 102.0 | 88.65/13.35 | 92.4/105.75 | 27.85 | ||||

| 27 | 107.0 | 93.65/13.35 | 97.6/110.95 | 33.05 | ||||

| 28 | 84.0 | 70.65/13.35 | 73.64/87.0 | 9.1 | 18.5 | |||

(series c) | 29 | 26.7/2.16 | 110.0 | 97.78/12.22 | 98.7/110.9 | 8.15 | 18.5 | |

| 30 | 96.0 | 83.78/12.22 | 84.56/96.77 | −6.0 | ||||

| 31 | 130.5 | 118.28/12.22 | 119.4/131.6 | 28.85 | ||||

| 32 | 110.0 | 97.78/12.22 | 98.7/110.9 | 8.15 | 1.1 | |||

| 1.5h0 (c) | (series a) | 33 | 30.5/2.33 | 139.0 | 126.41/12.59 | 121.13/133.7 | 41.57 | 35.0 |

| 34 | 95.0 | 82.41/12.59 | 79.23/91.82 | −0.3 | ||||

| 35 | 125.0 | 112.41/12.59 | 108.06/120.65 | 28.52 | ||||

| 36 | 100.0 | 87.41/12.59 | 84.03/96.62 | 4.5 | 2.1 | |||

(series b) | 37 | 29.8/2.3 | 105.0 | 91.65/13.35 | 88.46/101.8 | 23.9 | 23.9 | |

| 38 | 84.5 | 71.15/13.35 | 68.67/82.02 | 4.12 | ||||

| 39 | 105.0 | 91.65/13.35 | 88.46/101.8 | 23.9 | ||||

| 40 | 105.0 | 91.65/13.35 | 88.46/101.8 | 23.9 | 14.0 | |||

(series c) | 41 | 24.3/2.05 | 130.0 | 117.78/12.22 | 125.25/137.47 | 34.72 | 37.4 | |

| 42 | 98.0 | 85.78/12.22 | 91.22/103.44 | 0.69 | ||||

| 43 | 135.0 | 122.78/12.22 | 130.57/142.79 | 40.0 | ||||

| 44 | 112.75 | 100.53/12.22 | 106.9/119.13 | 16.38 | 8.5 | |||

| Shear Span during the Formation of Initial Cracks | |||

|---|---|---|---|

| 1 | 2 | 3 | 4 |

| Elements reinforced with U-stirrups | |||

|  |  | |

|  |  | |

|  |  | |

| Average for series |  |  |  |

); (

); (

) and (

) and (

), which simultaneously reflect the value of the shear span during testing, the presence or absence of initial cracks, as well as options for external composite reinforcement.

), which simultaneously reflect the value of the shear span during testing, the presence or absence of initial cracks, as well as options for external composite reinforcement.| Indicators | ||||

|---|---|---|---|---|

| SP 164.1325800.2014 | Considering the Authors’ Suggestions | |||

| Elements without Initial Cracks | Elements with Initial Cracks | Elements without Initial Cracks | Elements with Initial Cracks | |

| 1.450/1.2 | 1.251/1.042 | 1.18/1.07 | 1.099 | |

| Standart deviation S | 0.157/0.131 | 0.113/0.101 | 0.122/0.103 | 0.134 |

| Variation coefficient | 0.108/0.109 | 0.090/0.096 | 0.104/0.096 | 0.122 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Polskoy, P.P.; Mailyan, D.; Beskopylny, A.N.; Meskhi, B. Bearing Capacity of Reinforced Concrete Beams with Initial Cracks Reinforced with Polymer Composite Materials. Polymers 2022, 14, 3337. https://doi.org/10.3390/polym14163337

Polskoy PP, Mailyan D, Beskopylny AN, Meskhi B. Bearing Capacity of Reinforced Concrete Beams with Initial Cracks Reinforced with Polymer Composite Materials. Polymers. 2022; 14(16):3337. https://doi.org/10.3390/polym14163337

Chicago/Turabian StylePolskoy, Petr P., Dmitry Mailyan, Alexey N. Beskopylny, and Besarion Meskhi. 2022. "Bearing Capacity of Reinforced Concrete Beams with Initial Cracks Reinforced with Polymer Composite Materials" Polymers 14, no. 16: 3337. https://doi.org/10.3390/polym14163337