Mechanical Degradation and Failure Analysis of Different Glass/Basalt Hybrid Composite Configuration in Simulated Marine Condition

Abstract

:1. Introduction

| Advantages | Disadvantages | Ref. |

|---|---|---|

| They offer a cost-cutting solution to manufacturers. | The final hybrid composite might be slightly less durable depending on the hybrid materials used. | [23] |

| Improved high thermal and electrical conductivity than the constituent material. | Reduced thermal and electrical conductivity than the constituent material. | [24] |

| Natural fiber reinforced hybrid composites are environmentally friendly and sustainable. | Addition of natural fibers can reduce the overall strength of the hybrid composite. | [25] |

| Reduced moisture absorption capability than the constituent fibers, | Can increase the moisture absorption properties of the original materials. | [26] |

2. Materials and Methods

2.1. Materials Properties

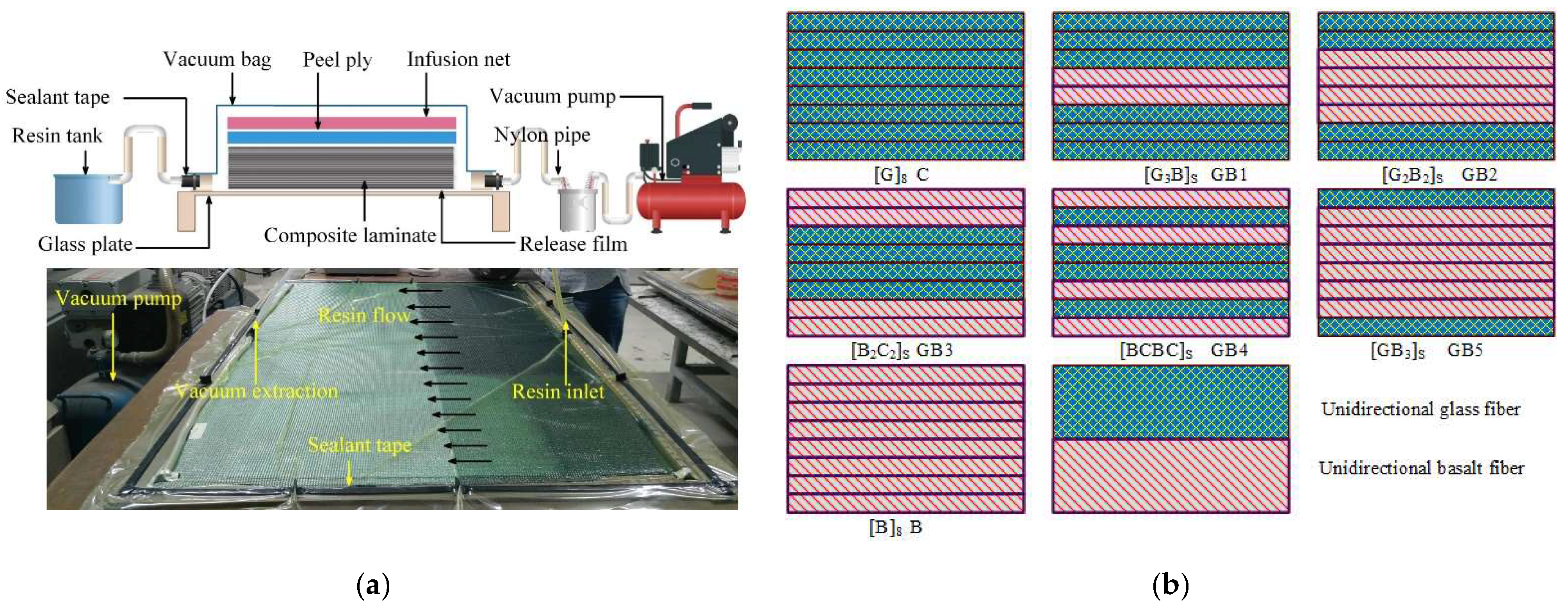

2.2. Composite Fabrication

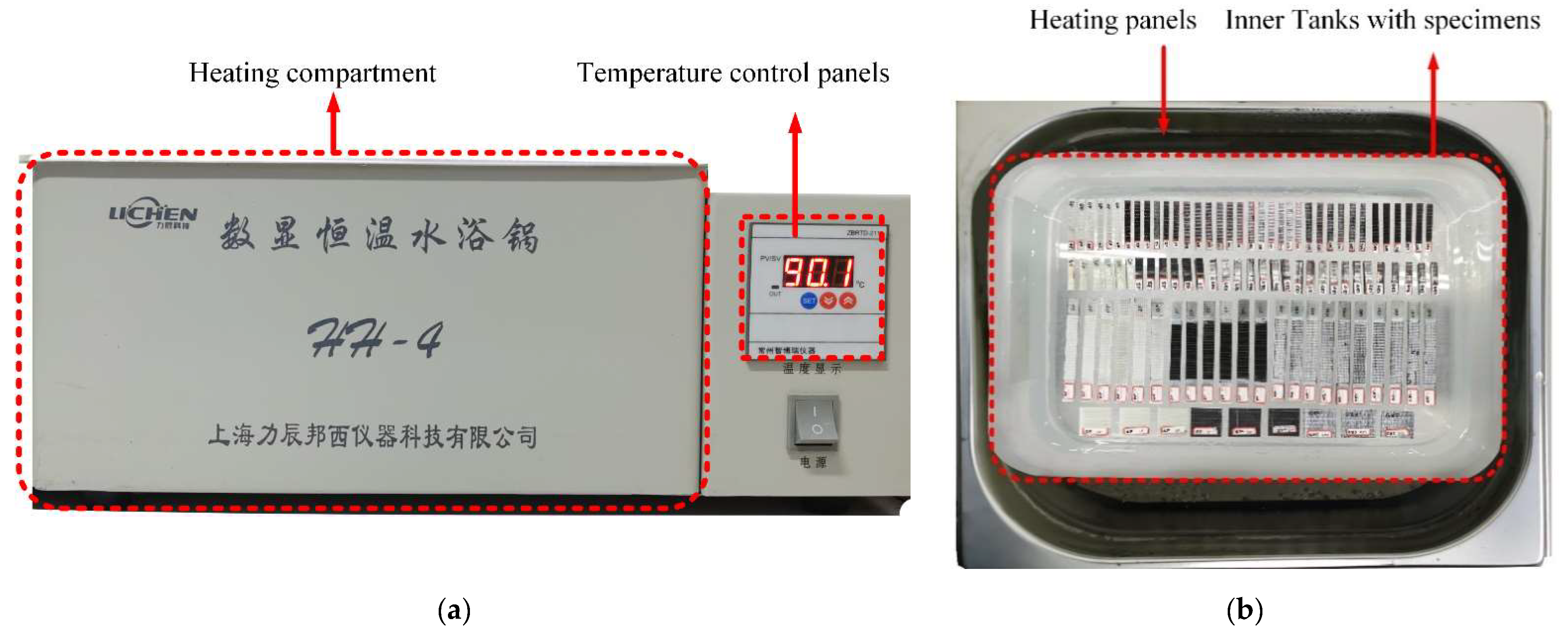

2.3. Ageing Process

2.4. Mechanical Tests

2.4.1. Tensile Test

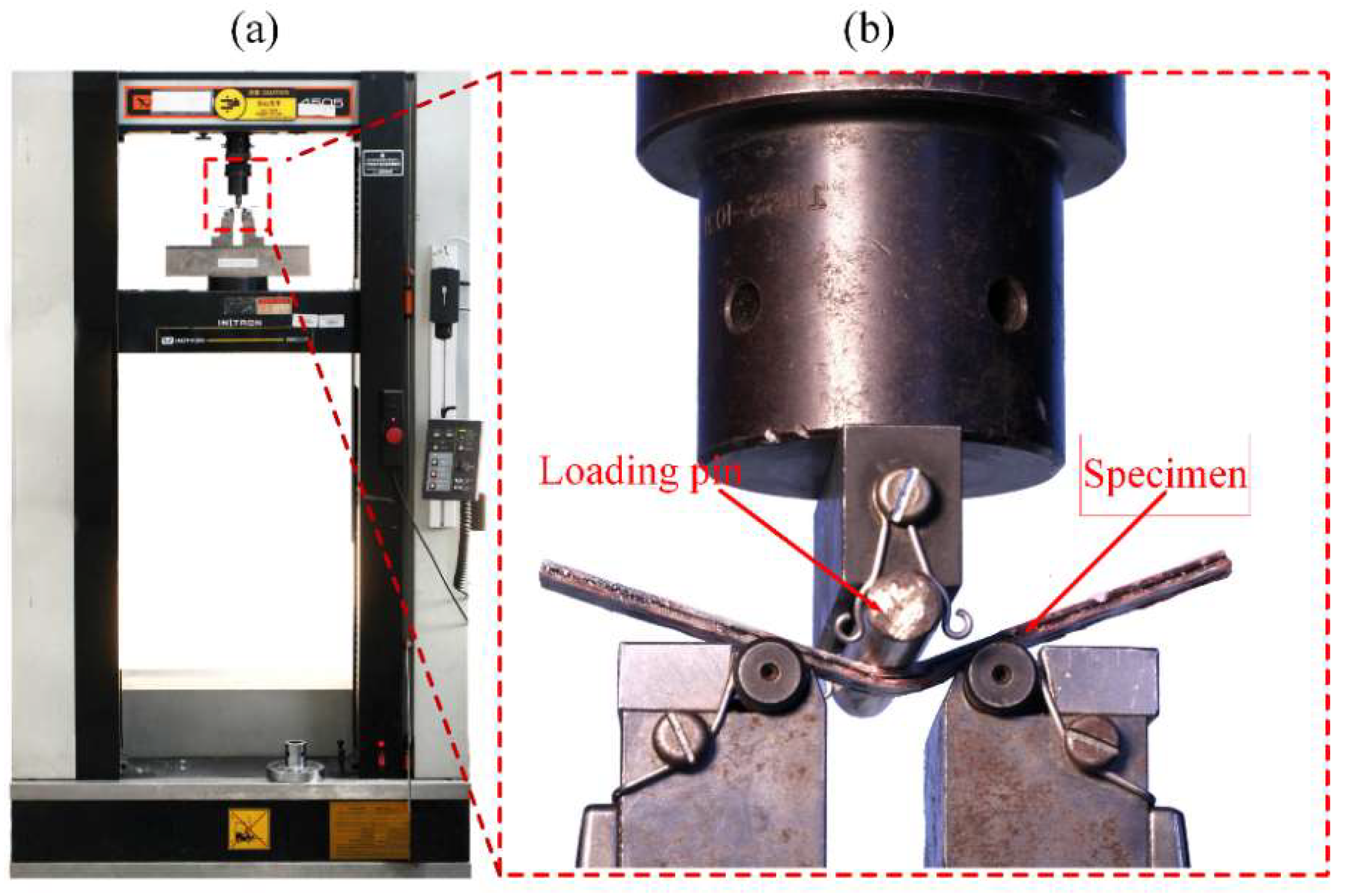

2.4.2. Flexural Test

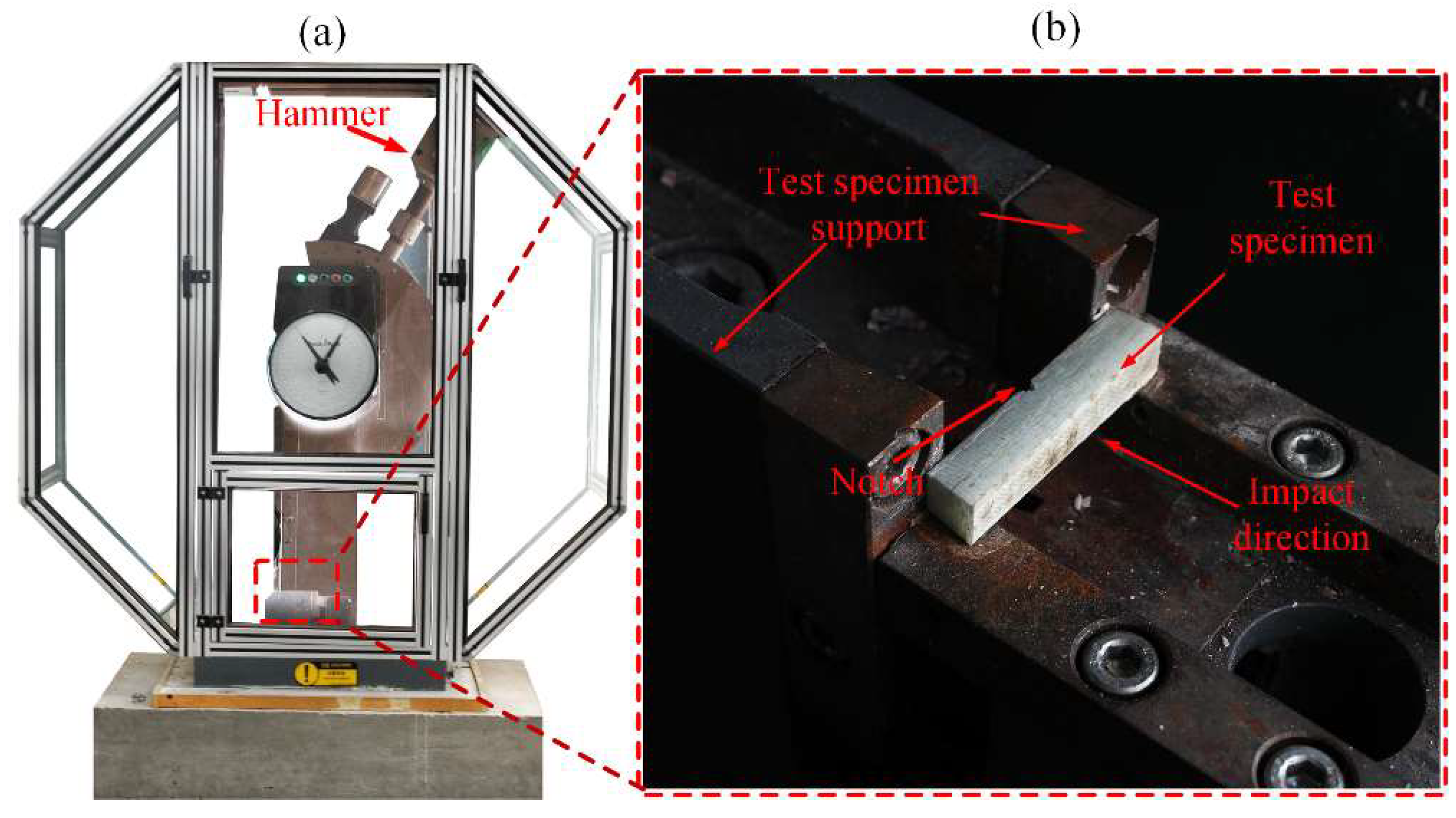

2.4.3. Impact Test

2.5. Damage Analysis

3. Results and Discussion

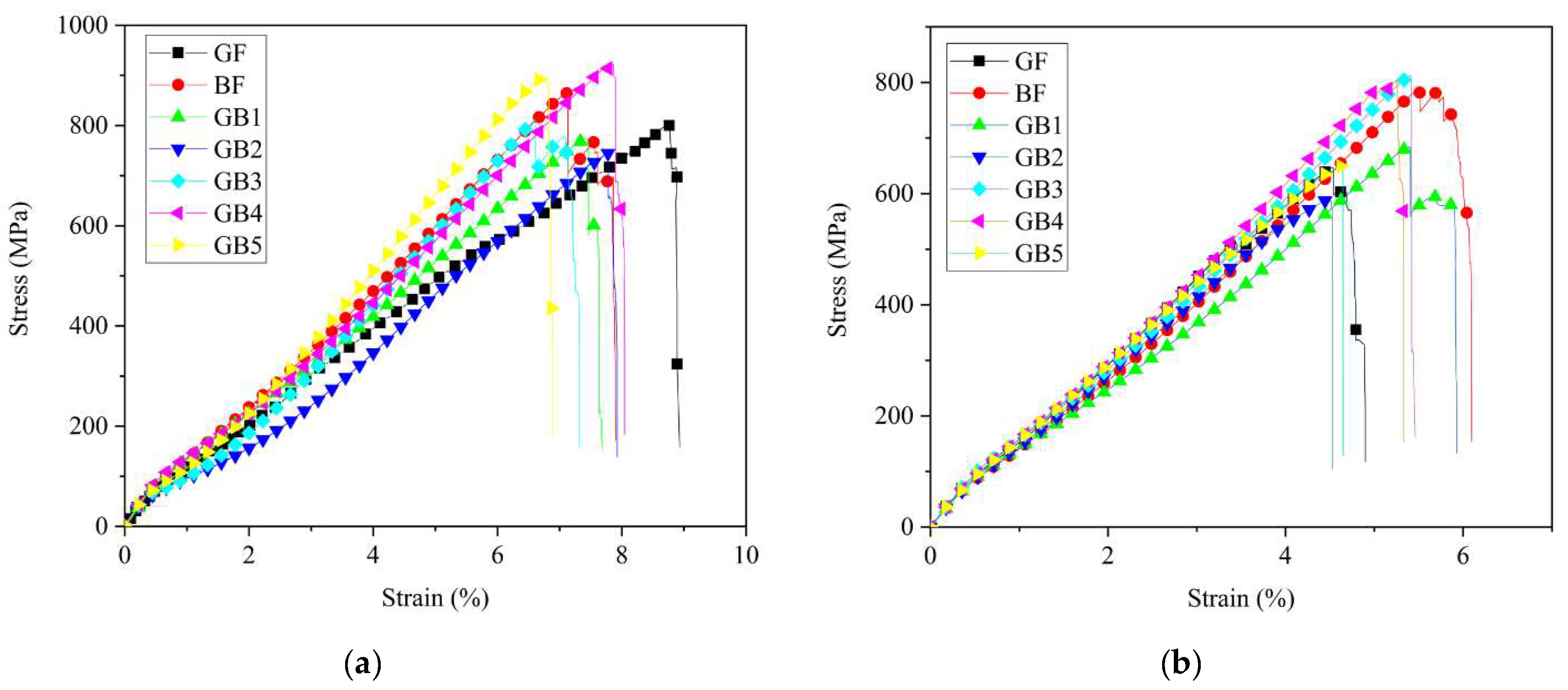

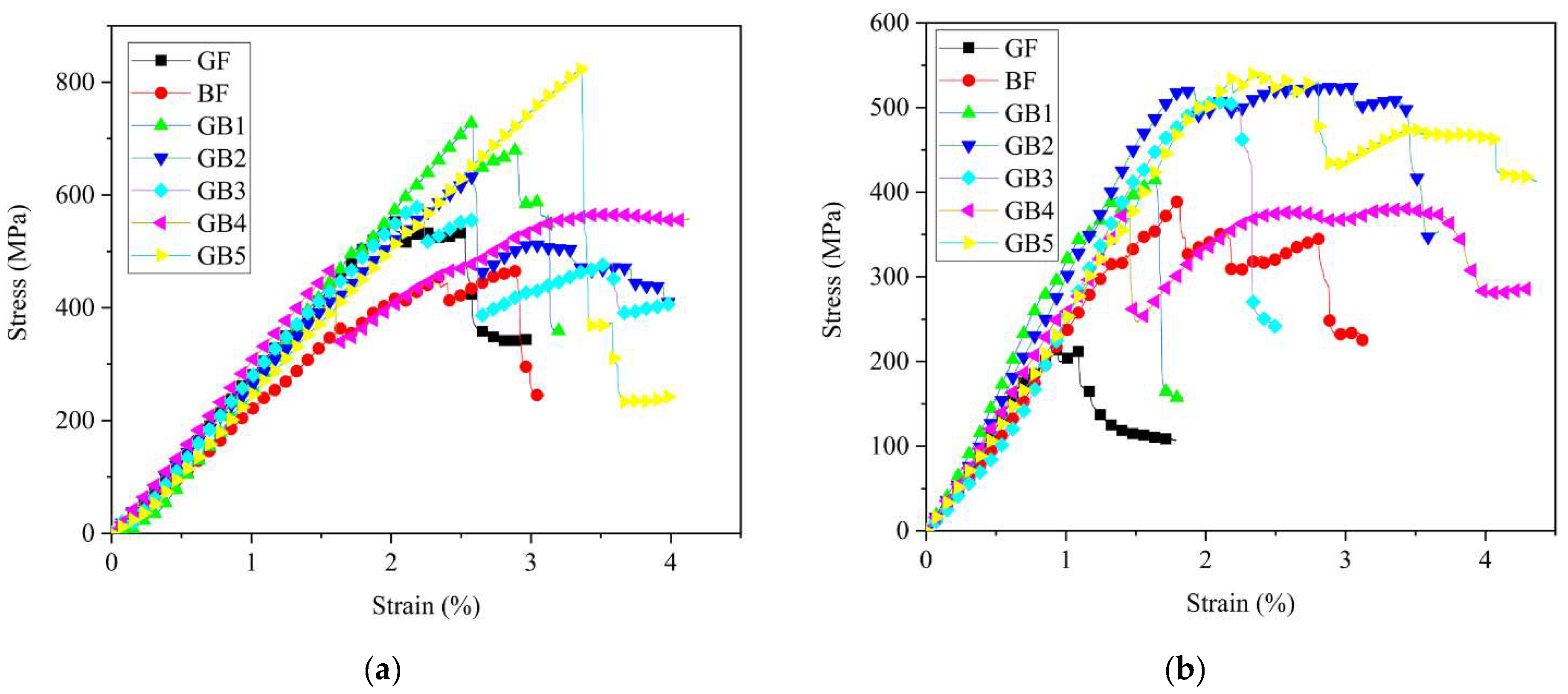

3.1. Tensile Properties of Dry and Seawater Aged Laminates

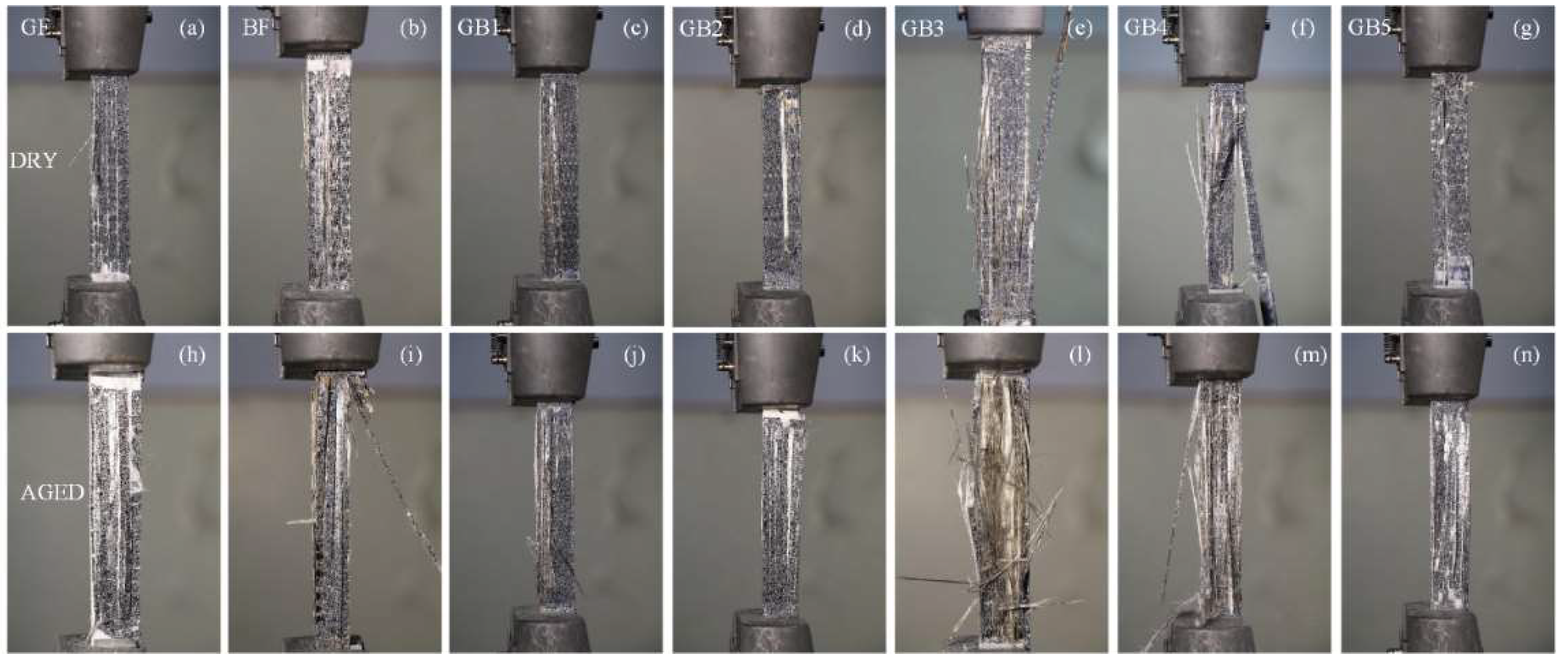

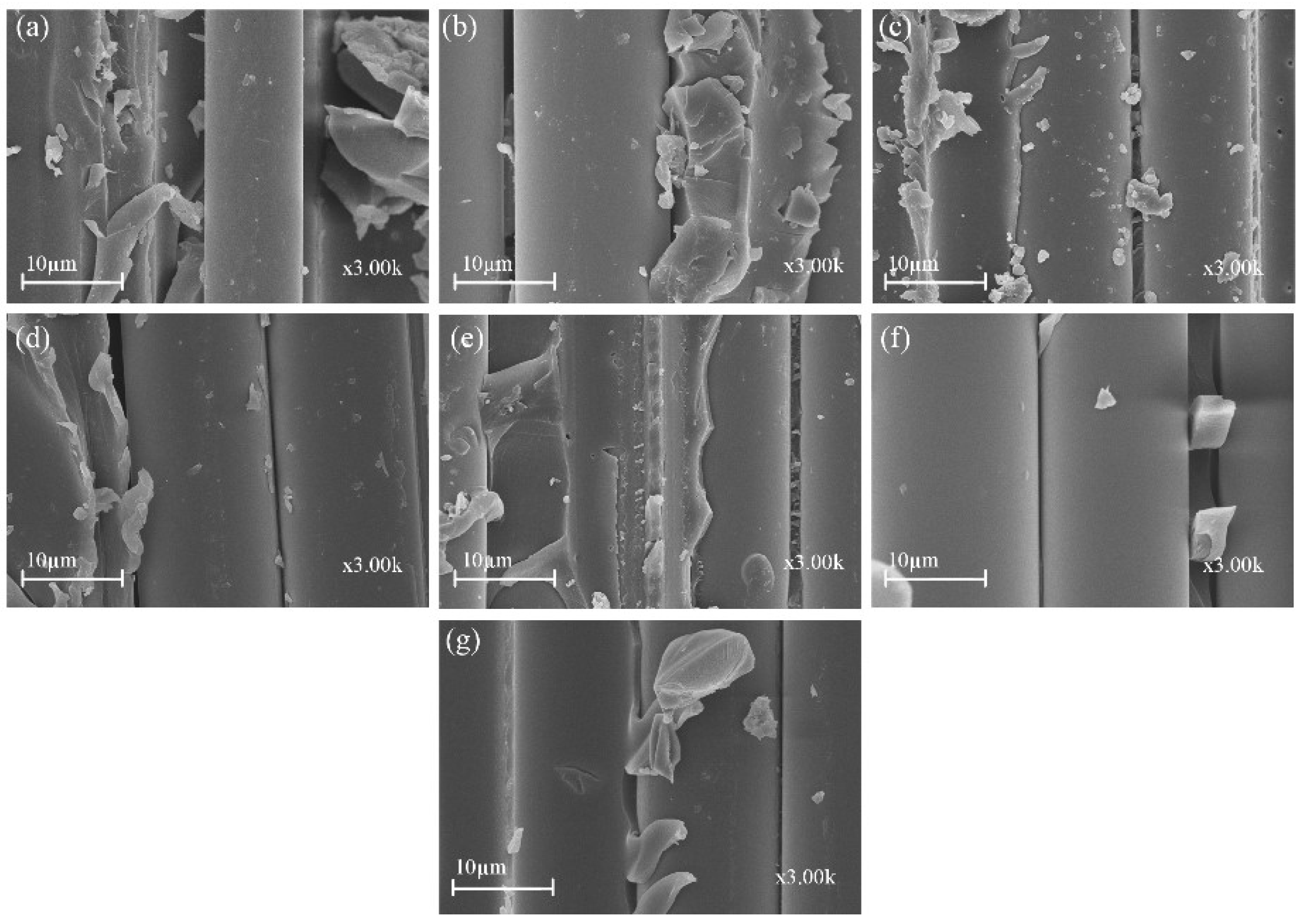

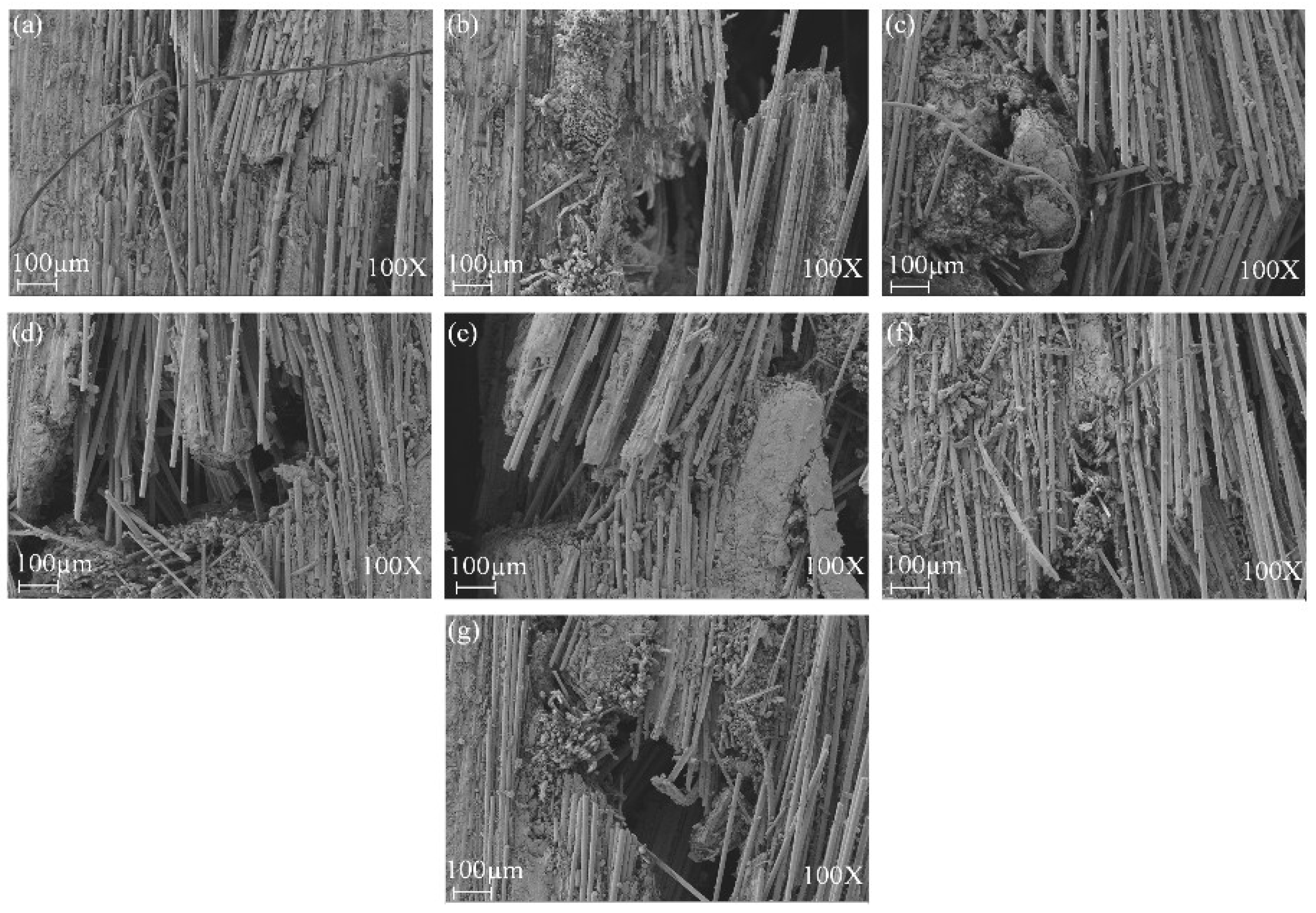

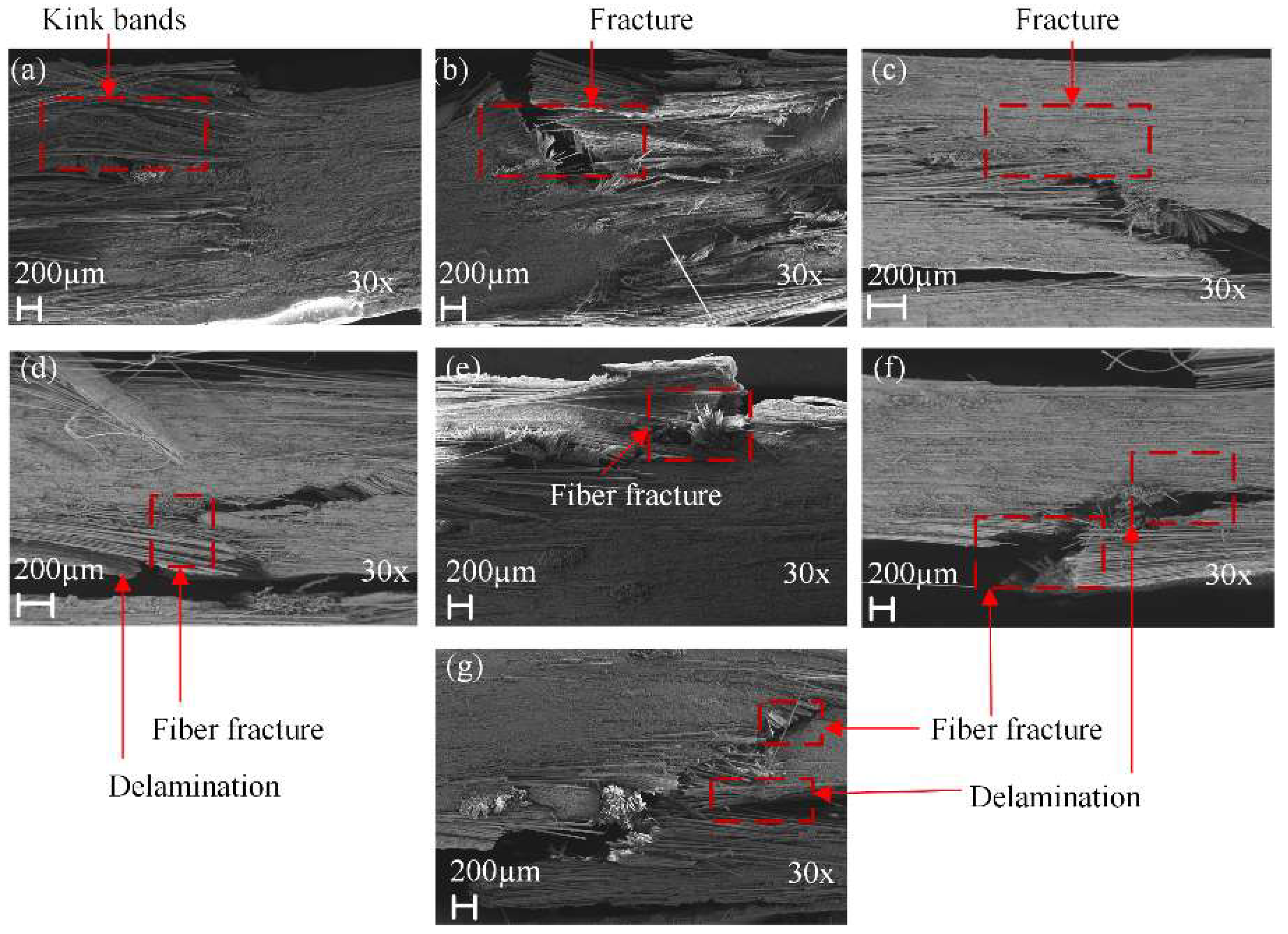

Tensile Failure Analysis

3.2. Impact Properties of Dry and Seawater Aged Laminates

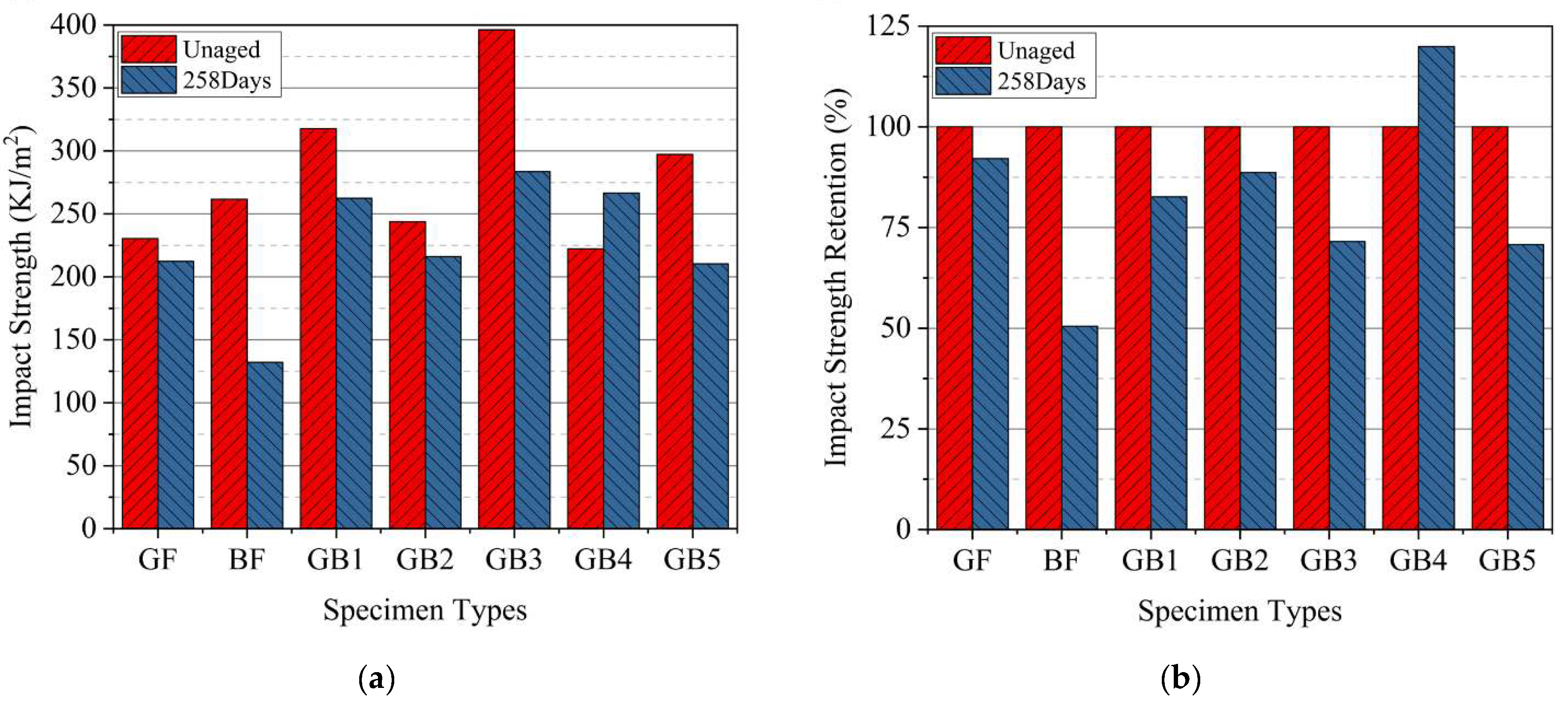

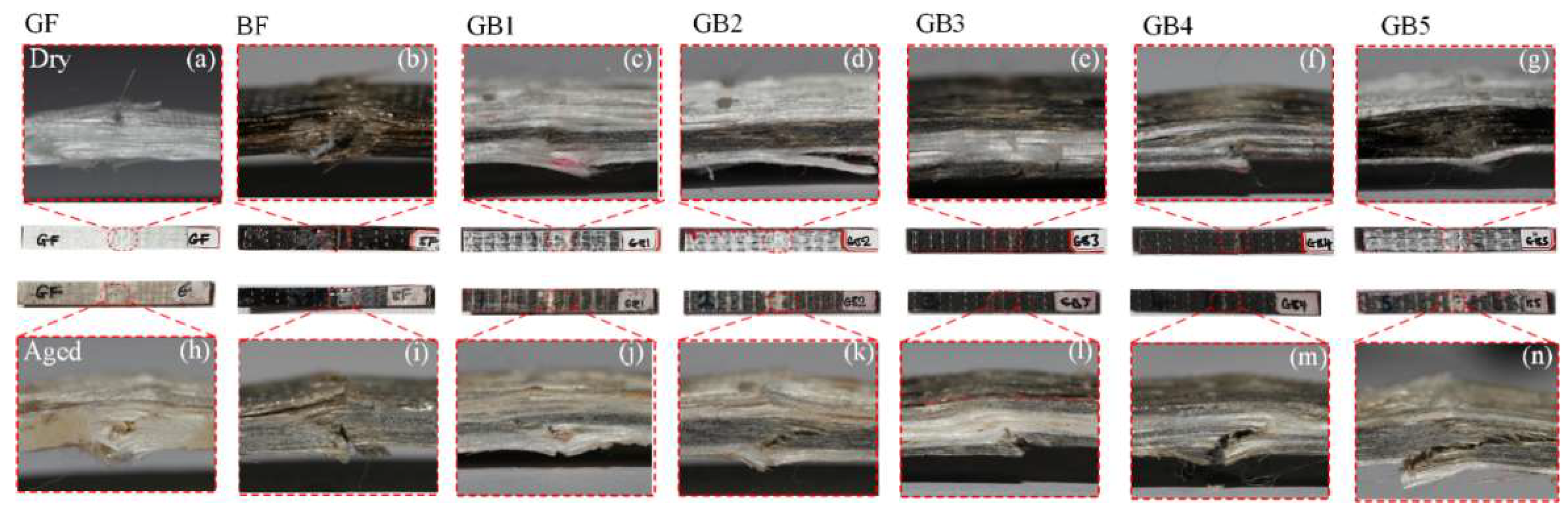

Impact Failure Analysis

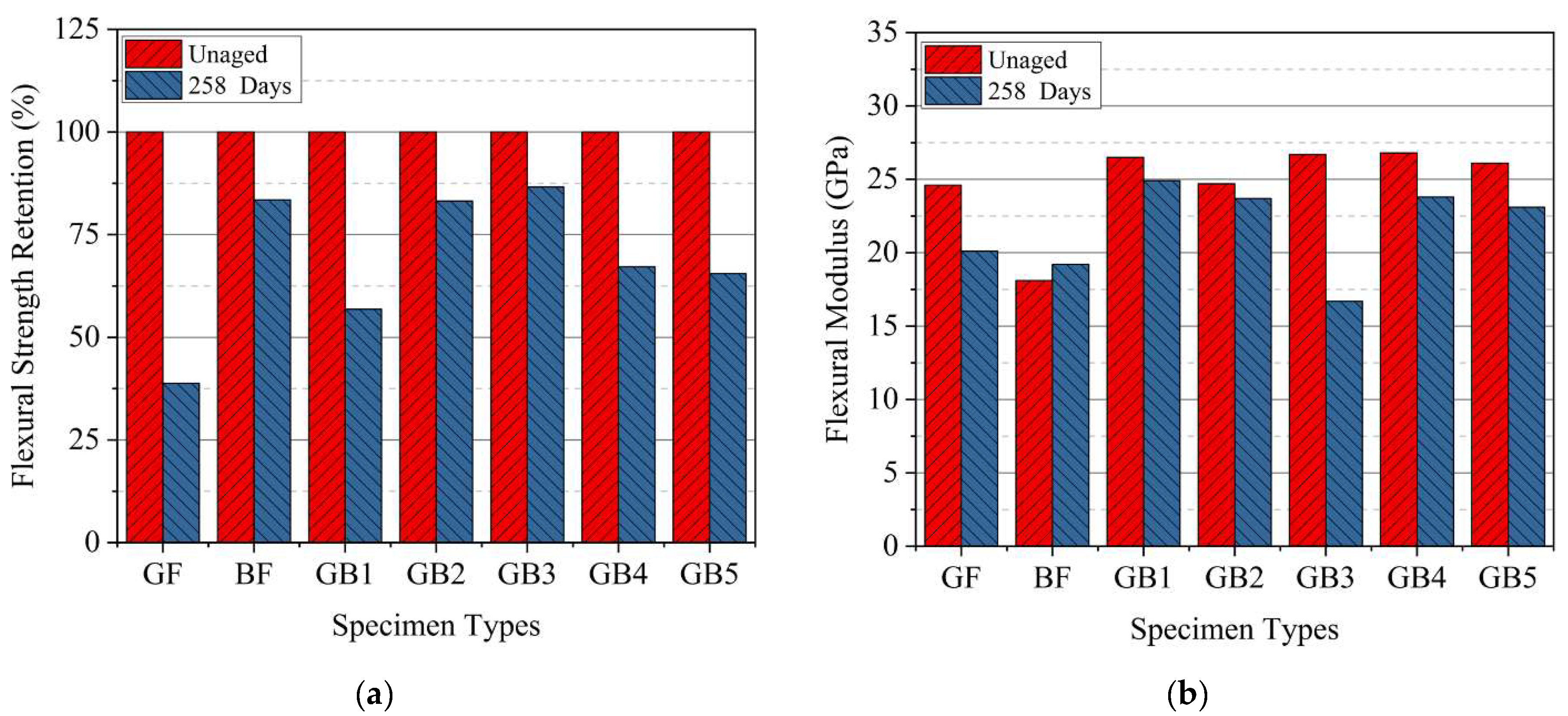

3.3. Flexural Properties of Dry and Seawater Aged Laminates

Flexural Failure Analysis

4. Conclusions

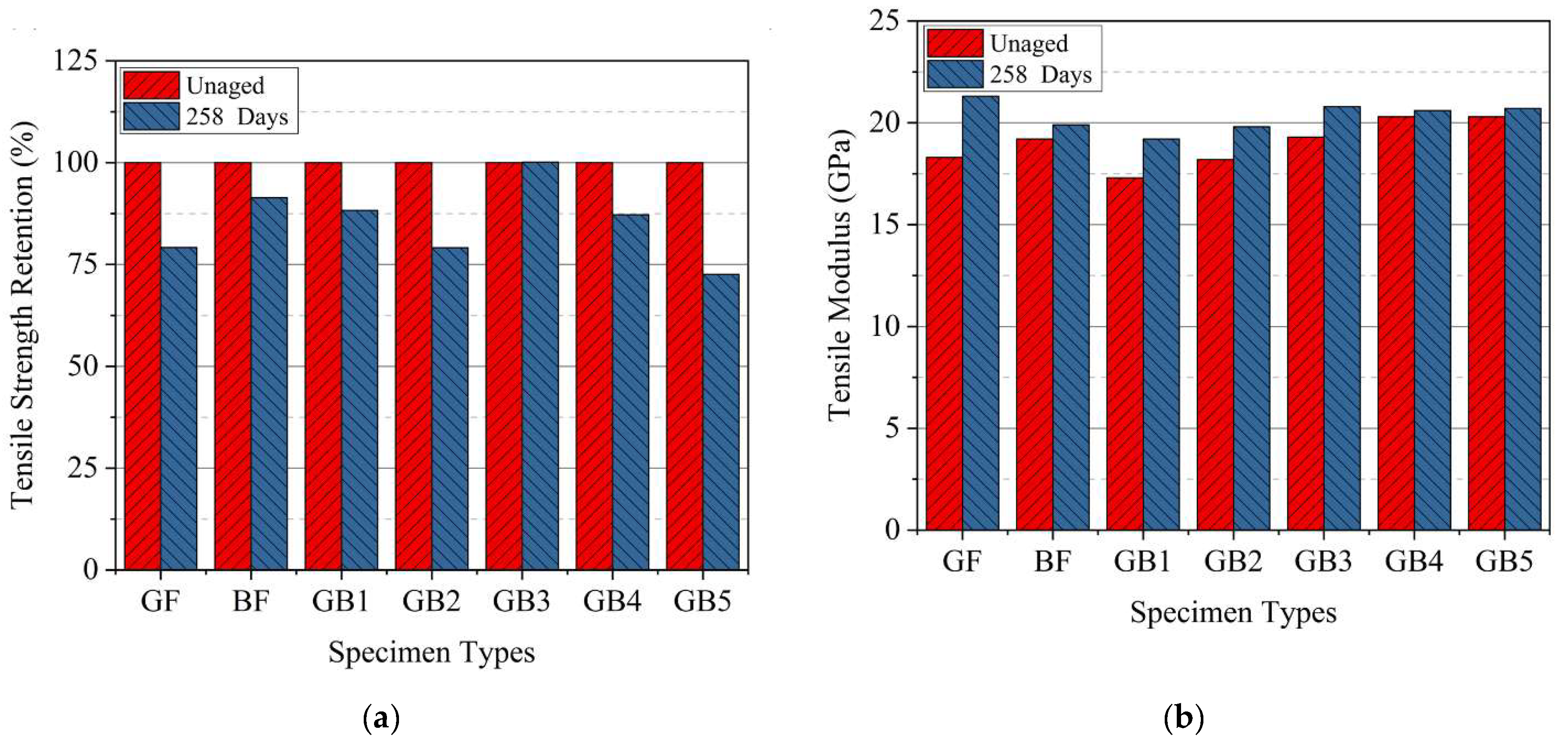

- The tensile strength of alternately sequenced hybrid composite (GB4) was the highest in dry condition with 13% strength increase over G composite and 6.63% improvement over B composite. The tensile strength, however, decreased by 13% when aged in seawater, which was an improvement over plain G composite but not B composite. The tensile modulus increased in comparison to both plain composites in dry condition, and, besides, there was an increase among all hybrid composites after ageing. Overall, although GB4 composite possessed the highest tensile strength among the specimens, GB3 retained the highest strength after ageing due its basalt fiber exterior plies. This outcome gives GB3 an edge over GB4 for use in marine application. However, for regular non-marine applications, where strength improvement is paramount, the opposite is true.

- The flexural strength of GB5 hybrid composite was the highest in dry condition with 48.9% strength increase over G laminate and 76.35% improvement over B specimen. After ageing, the flexural strength decreased by 34%, which represented an improvement over the plain G specimen but not B specimen. The flexural modulus improved compared to plain composite in dry condition; however, there was a decrease among all hybrid composites after ageing. GB5 composite possessed the highest flexural strength. Meanwhile, similar to the tensile test result, GB3 laminate still maintained the highest residual strength in flexure after ageing.

- The impact strength of dry GB4 composite was the highest at 395.32 kJ/m2. Other hybrid architecture, like GB1 and GB5, had higher impact strength than both plain laminates, hence having potential use in certain applications. Unlike the tensile and flexural properties, impact strength retention had an opposite trend. G laminate retained a higher impact strength than B laminate after ageing while GB4 had the highest residual impact strength after seawater ageing.

- Damage analysis from the different hybrid configurations showed more progressive failure than for the plain laminates. The different fiber sequencing provided a toughening effect by preventing quick propagation of cracks through the composites. In seawater ageing hybrid laminate with basalt exterior plies was more effective in retaining its tensile and flexural properties due to the chemical stability of basalt fibers.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Amuthakkannan, P.; Manikandan, V.; Uthayakumar, M. Mechanical properties of basalt and glass fiber reinforced polymer hybrid composites. J. Adv. Microsc. Res. 2014, 9, 44–49. [Google Scholar] [CrossRef]

- Abd El-baky, M.A.; Attia, M.A.; Kamel, M. Flexural fatigue and failure probability analysis of polypropylene-glass hybrid fibres reinforced epoxy composite laminates. Plast. Rubber. Compos. 2018, 47, 47–64. [Google Scholar] [CrossRef]

- Abd El-Baky, M.A.; Attia, M.A. Flexural fatigue performance of hybrid composite laminates based on E-glass and polypropylene fibers. J. Thermoplast. Compos Mater. 2019, 32, 228–247. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Zhang, Z.Y.; Guthrie, R.; MacMullen, J.; Bennett, N. Development of flax/carbon fibre hybrid composites for enhanced properties. Carbohydr. Polym. 2013, 96, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Ebrahimnezhad-Khaljiri, H.; Eslami-Farsani, R.; Akbarzadeh, E. Effect of interlayer hybridization of carbon, Kevlar, and glass fibers with oxidized polyacrylonitrile fibers on the mechanical behaviors of hybrid composites. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2020, 234, 1823–1835. [Google Scholar] [CrossRef]

- Saidane, E.H.; Scida, D.; Assarar, M.; Sabhi, H.; Ayad, R. Hybridisation effect on diffusion kinetic and tensile mechanical behaviour of epoxy based flax–glass composites. Compos. Part A Appl. Sci. Manuf. 2016, 87, 153–160. [Google Scholar] [CrossRef]

- Ebrahimnezhad-Khaljiri, H.; Eslami-Farsani, R. The effect of hybridization on thermal and mechanical properties of glass/oxidized PAN fibers-polymer composites. Fibers. Polym. 2015, 16, 2445–2450. [Google Scholar] [CrossRef]

- Shahzad, A. Impact and fatigue properties of hemp–glass fiber hybrid biocomposites. J. Reinf. Plast. Compos. 2011, 30, 1389–1398. [Google Scholar] [CrossRef]

- Javaid, U.; Ling, C.; Cardiff, P. Mechanical performance of carbon-glass hybrid composite joints in quasi-static tension and tension-tension fatigue. Eng. Fail. Anal. 2020, 116, 104730. [Google Scholar] [CrossRef]

- Jagannatha, T.D.; Harish, G. Mechanical properties of carbon/glass fiber reinforced epoxy hybrid polymer composites. Int. J. Mech. Eng. Robot. Res. 2015, 4, 131–137. [Google Scholar] [CrossRef]

- Tsai, Y.I.; Bosze, E.J.; Barjasteh, E.; Nutt, S.R. Influence of hygrothermal environment on thermal and mechanical properties of carbon fiber/fiberglass hybrid composites. Compos. Sci. Technol. 2009, 69, 432–437. [Google Scholar] [CrossRef]

- Malatyński, T.; Duda, S.; Babiarczuk, B.; Warycha, J.; Zielonka, P.; Lesiuk, G. Flexural and compressive residual strength of composite bars subjected to harsh environments. Eng. Fail. Anal. 2022, 133, 105958. [Google Scholar] [CrossRef]

- Amini, M.; Gazik, R.A.; Honarvar, F.; Montazeri, A. Analysis of failure mechanisms of degraded hybrid glass-carbon composites in acidic medium: Insights from acoustic emission analysis. Eng. Fail. Anal. 2022, 134, 106082. [Google Scholar] [CrossRef]

- Liu, Q.; Shaw, M.T.; Parnas, R.S.; McDonnell, A. Investigation of basalt fiber composite mechanical properties for applications in transportation. Polym. Compos. 2005, 27, 41–48. [Google Scholar] [CrossRef]

- Liu, Q.; Shaw, M.T.; Parnas, R.S.; McDonnell, A. Investigation of basalt fiber composite aging behavior for applications in transportation. Polym. Compos. 2006, 27, 475–483. [Google Scholar] [CrossRef]

- Wei, B.; Cao, H.; Song, S. Degradation of basalt fibre and glass fibre/epoxy resin composites in seawater. Corros. Sci. 2011, 53, 426–431. [Google Scholar] [CrossRef]

- Dong, C.; Davies, I.J. Optimal design for the flexural behaviour of glass and carbon fibre reinforced polymer hybrid composites. Mater. Des. 2012, 37, 450–457. [Google Scholar] [CrossRef]

- Dong, C.; Ranaweera-Jayawardena, H.A.; Davies, I.J. Flexural properties of hybrid composites reinforced by S-2 glass and T700S carbon fibres. Compos. Part B Eng. 2012, 43, 573–581. [Google Scholar] [CrossRef]

- Fiore, V.; Di Bella, G.; Valenza, A. Glass–basalt/epoxy hybrid composites for marine applications. Mater. Des. 2011, 32, 2091–2099. [Google Scholar] [CrossRef]

- Fotouhi, M.; Jalalvand, M.; Wisnom, M.R. High performance quasi-isotropic thin-ply carbon/glass hybrid composites with pseudo-ductile behaviour in all fibre orientations. Compos. Sci. Technol. 2017, 152, 101–110. [Google Scholar] [CrossRef]

- Wei, B.; Cao, H.; Song, S. Tensile behavior contrast of basalt and glass fibers after chemical treatment. Mater. Des. 2010, 31, 4244–4250. [Google Scholar] [CrossRef]

- Černý, M.; Glogar, P.; Sucharda, Z.; Chlup, Z.; Kotek, J. Partially pyrolyzed composites with basalt fibres–Mechanical properties at laboratory and elevated temperatures. Compos. Part. A Appl. Sci. Manuf. 2009, 40, 1650–1659. [Google Scholar] [CrossRef]

- Usca, Ü.A.; Şap, S.; Uzun, M.; Giasin, K.; Pimenov, D.Y. Evaluation of Mechanical and Tribological Aspect of Self-Lubricating Cu-6Gr Composites Reinforced with SiC–WC Hybrid Particles. Nanomaterials 2022, 12, 2154. [Google Scholar] [CrossRef]

- Usca, Ü.A.; Uzun, M.; Şap, S.; Kuntoğlu, M.; Giasin, K.; Pimenov, D.Y.; Wojciechowski, S. Tool wear, surface roughness, cutting temperature and chips morphology evaluation of Al/TiN coated carbide cutting tools in milling of Cu–B–CrC based ceramic matrix composites. J. Mater. Res. Technol. 2022, 16, 1243–1259. [Google Scholar] [CrossRef]

- Safri, S.N.A.; Sultan, M.T.H.; Jawaid, M.; Jayakrishna, K. Impact behaviour of hybrid composites for structural applications: A review. Compos. Part B Eng. 2018, 133, 112–121. [Google Scholar] [CrossRef]

- Suriani, M.J.; Ilyas, R.A.; Zuhri, M.Y.M.; Khalina, A.; Sultan, M.T.H.; Sapuan, S.M.; Ruzaidi, C.M.; Nik Wan, F.; Zulkifli, F.; Harusssani, M.M.; et al. Critical review of natural fiber reinforced hybrid composites: Processing, properties, applications and cost. Polymers 2021, 13, 3514. [Google Scholar] [CrossRef]

- Eslami, S.; Honarbakhsh-Raouf, A.; Eslami, S. Effects of moisture absorption on degradation of E-glass fiber reinforced Vinyl Ester composite pipes and modelling of transient moisture diffusion using finite element analysis. Corros. Sci. 2015, 90, 168–175. [Google Scholar] [CrossRef]

- Liang, W.; Bonsu, A.O.; Lv, H.; Yang, B.; Liu, C.; Deng, J. Intumescent coating thickness effect on the post-heat mechanical properties of composites. Structures 2020, 28, 2056–2072. [Google Scholar] [CrossRef]

- Mensah, C.; Wang, Z.; Bonsu, A.O.; Liang, W. Effect of Different Bond Parameters on the Mechanical Properties of FRP and Concrete Interface. Polymers 2020, 12, 2466. [Google Scholar] [CrossRef] [PubMed]

- Pandya, K.S.; Veerraju, C.; Naik, N.K. Hybrid composites made of carbon and glass woven fabrics under quasi-static loading. Mater. Des. 2011, 32, 4094–4099. [Google Scholar] [CrossRef]

- Zhang, J.; Chaisombat, K.; He, S.; Wang, C.H. Hybrid composite laminates reinforced with glass/carbon woven fabrics for lightweight load bearing structures. Mater. Des. 2012, 36, 75–80. [Google Scholar] [CrossRef]

- Kretsis, G. A review of the tensile, compressive, flexural and shear properties of hybrid fibre-reinforced plastics. Composites 1987, 18, 13–23. [Google Scholar] [CrossRef]

- Czél, G.; Wisnom, M.R. Demonstration of pseudo-ductility in high performance glass/epoxy composites by hybridisation with thin-ply carbon prepreg. Compos. Part A Appl. Sci. Manuf. 2013, 52, 23–30. [Google Scholar] [CrossRef]

- Bonsu, A.O.; Liang, W.; Mensah, C.; Yang, B. Assessing the mechanical behavior of glass and basalt reinforced vinyl ester composite under artificial seawater environment. In Structures; Elsevier: Amsterdam, The Netherlands, 2022; Volume 38, pp. 961–978. [Google Scholar] [CrossRef]

- Khajeh, A.; Mustapha, F.; Sultan, M.T.H.; Bánhegyi, G.; Karácsony, Z.; Baranyai, V. The effect of thermooxidative aging on the durability of glass fiber-reinforced epoxy. Adv. Mater. Sci. Eng. 2015, 2015, 1–13. [Google Scholar] [CrossRef]

- Jawaid, M.; Khalil, H.P.S.A.; Bakar, A.A. Mechanical performance of oil palm empty fruit bunches/jute fibres reinforced epoxy hybrid composites. Mater. Sci. Eng. A 2010, 527, 7944–7949. [Google Scholar] [CrossRef]

- Ary Subagia, I.D.G.; Kim, Y.; Tijing, L.D.; Kim, C.S.; Shon, H.K. Effect of stacking sequence on the flexural properties of hybrid composites reinforced with carbon and basalt fibers. Compos. Part B Eng. 2014, 58, 251–258. [Google Scholar] [CrossRef]

- Bian, L.; Xiao, J.; Zeng, J.; Xing, S. Effects of seawater immersion on water absorption and mechanical properties of GFRP composites. J. Compos. Mater. 2012, 46, 3151–3162. [Google Scholar] [CrossRef]

| Material Name | Surface Mass (g/m2) | Density (g/m3) | Tensile Strength (MPa) | Elastic Modulus /GPa | Thickness /mm | Elongation (%) |

|---|---|---|---|---|---|---|

| Glass fabric | 300 | - | 1500 | 72 | 0.118 | 2.5 |

| Basalt fabric | 300 | - | ≥2000 | ≥90 | 0.115 | ≥2.0 |

| Vinyl ester | - | 1.14 | 86 | 3.2 | NA | 5–6 |

| Mechanical Properties | Specimens | ||||||

|---|---|---|---|---|---|---|---|

| GF | BF | GB1 | GB2 | GB3 | GB4 | GB5 | |

| Tensile strength/MPa | 815.79 | 864.56 | 774.47 | 744.73 | 810.94 | 921.91 | 895.92 |

| Strength retention/% | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Tensile modulus/GPa | 18.3 | 19.2 | 17.3 | 18.2 | 19.3 | 20.3 | 20.3 |

| Flexural strength/MPa | 553.08 | 467.28 | 730.44 | 632.04 | 585.72 | 567.72 | 824.04 |

| Strength retention/% | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Flexural modulus/GPa | 24.6 | 18.1 | 26.5 | 24.7 | 26.7 | 26.8 | 26.1 |

| Impact strength/KJ/m2 | 230.45 | 261.69 | 317.6 | 243.86 | 396.32 | 222.15 | 297.23 |

| Strength retention/% | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Mechanical Properties | Specimens | ||||||

|---|---|---|---|---|---|---|---|

| GF | BF | GB1 | GB2 | GB3 | GB4 | GB5 | |

| Tensile strength/MPa | 646.04 | 789.93 | 683.67 | 589.12 | 812.10 | 804.01 | 650.15 |

| Strength retention/% | 79 | 91 | 88 | 79 | 100 | 87 | 73 |

| Tensile modulus/GPa | 21.3 | 19.9 | 19.2 | 19.8 | 20.8 | 20.6 | 20.7 |

| Flexural strength/MPa | 214.68 | 390 | 415.2 | 525.96 | 507.24 | 381.6 | 539.76 |

| Strength retention/% | 39 | 83 | 57 | 83 | 87 | 67 | 66 |

| Flexural modulus/GPa | 20.1 | 19.2 | 24.9 | 23.7 | 16.7 | 23.8 | 23.1 |

| Impact strength/KJ/m2 | 212.3 | 132.11 | 262.44 | 216.17 | 283.63 | 266.46 | 210.38 |

| Strength retention/% | 92 | 51 | 83 | 89 | 72 | 120 | 71 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bonsu, A.O.; Mensah, C.; Liang, W.; Yang, B.; Ma, Y. Mechanical Degradation and Failure Analysis of Different Glass/Basalt Hybrid Composite Configuration in Simulated Marine Condition. Polymers 2022, 14, 3480. https://doi.org/10.3390/polym14173480

Bonsu AO, Mensah C, Liang W, Yang B, Ma Y. Mechanical Degradation and Failure Analysis of Different Glass/Basalt Hybrid Composite Configuration in Simulated Marine Condition. Polymers. 2022; 14(17):3480. https://doi.org/10.3390/polym14173480

Chicago/Turabian StyleBonsu, Alex Osei, Comfort Mensah, Wenyan Liang, Bin Yang, and Yunsheng Ma. 2022. "Mechanical Degradation and Failure Analysis of Different Glass/Basalt Hybrid Composite Configuration in Simulated Marine Condition" Polymers 14, no. 17: 3480. https://doi.org/10.3390/polym14173480

APA StyleBonsu, A. O., Mensah, C., Liang, W., Yang, B., & Ma, Y. (2022). Mechanical Degradation and Failure Analysis of Different Glass/Basalt Hybrid Composite Configuration in Simulated Marine Condition. Polymers, 14(17), 3480. https://doi.org/10.3390/polym14173480