Bio-Based Composites for Light Automotive Parts: Statistical Analysis of Mechanical Properties; Effect of Matrix and Alkali Treatment in Sisal Fibers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

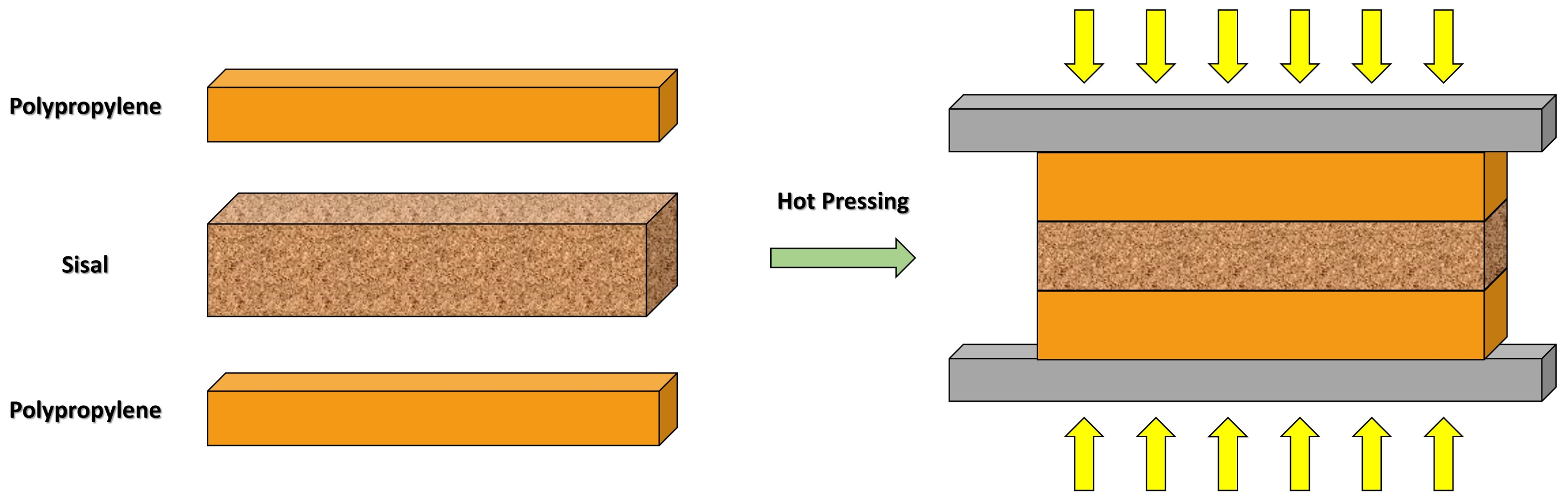

2.2. Alkali Treatment of Sisal and Bio-Based Composites Processing

2.3. Characterization

2.3.1. Fourier Transform Infrared Spectroscopy (FTIR)

2.3.2. X-ray Diffraction (XRD)

2.3.3. Water Absorption

2.3.4. Density Measurements

2.3.5. Shore-D Hardness

2.3.6. Izod Impact Test

2.3.7. Statistical Analysis

3. Results and Discussion

3.1. Fourier Transform Infrared Spectroscopy (FTIR)

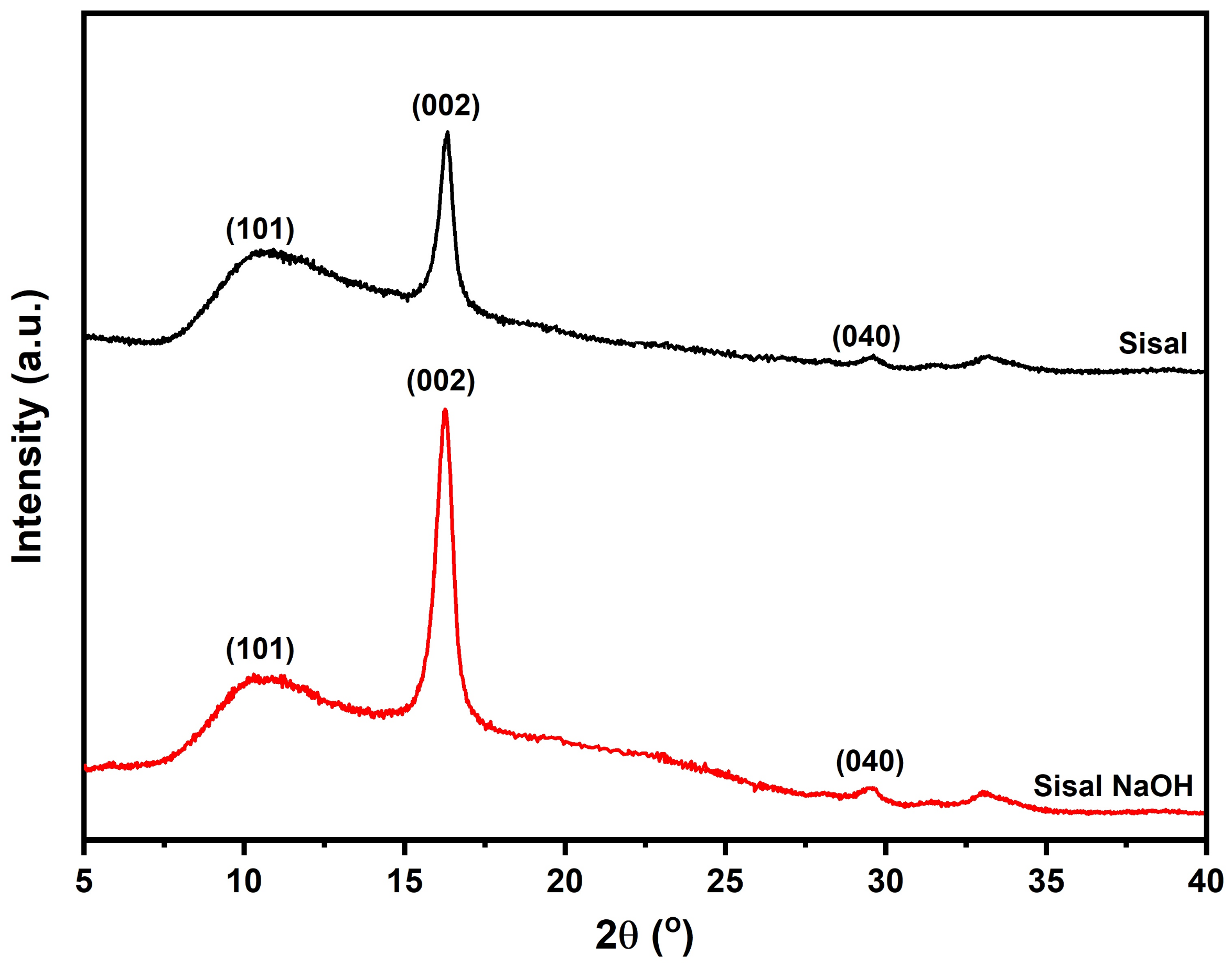

3.2. X-ray Diffraction (XRD)

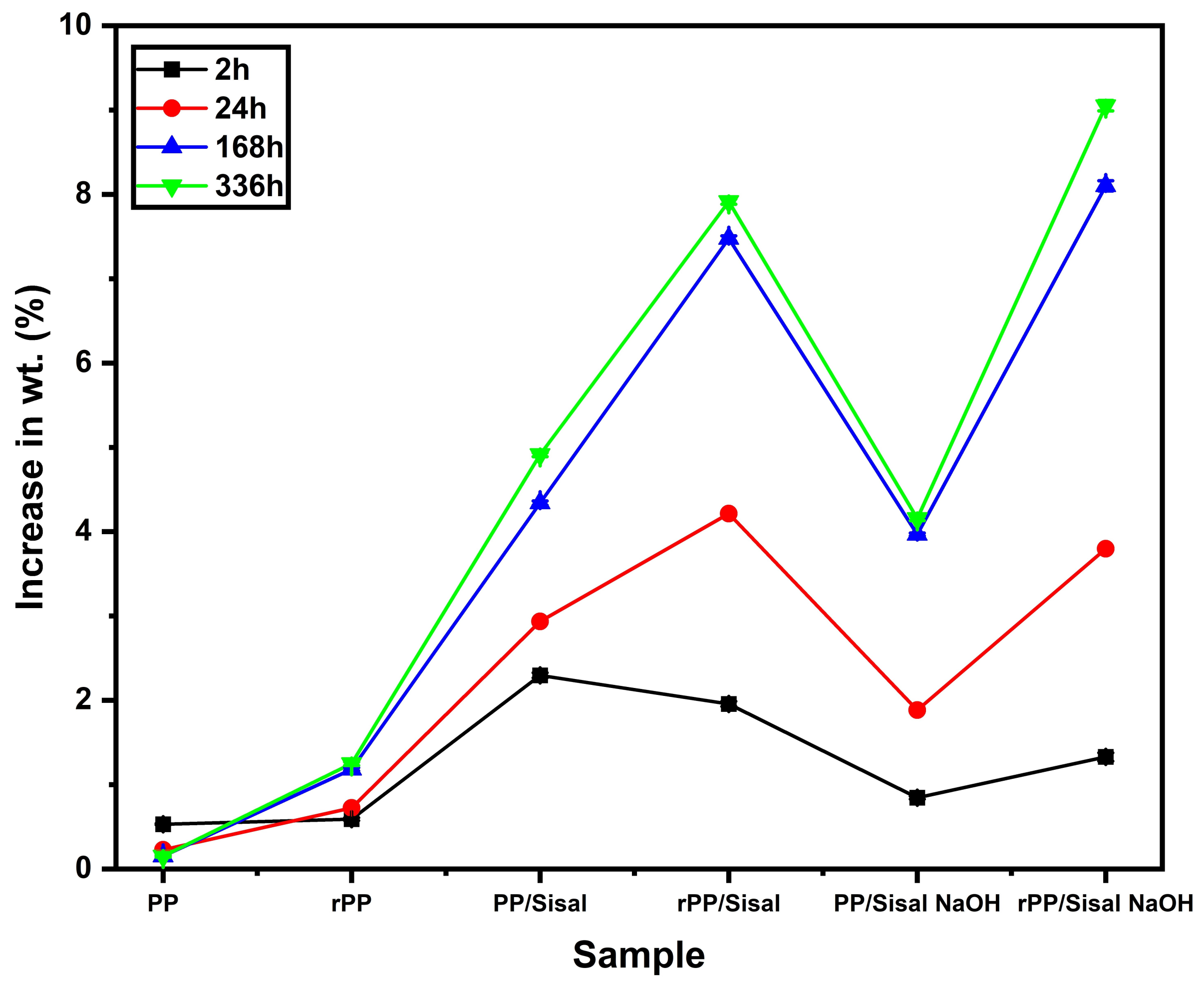

3.3. Water Absorption

3.4. Density, Hardness and Impact Strenght

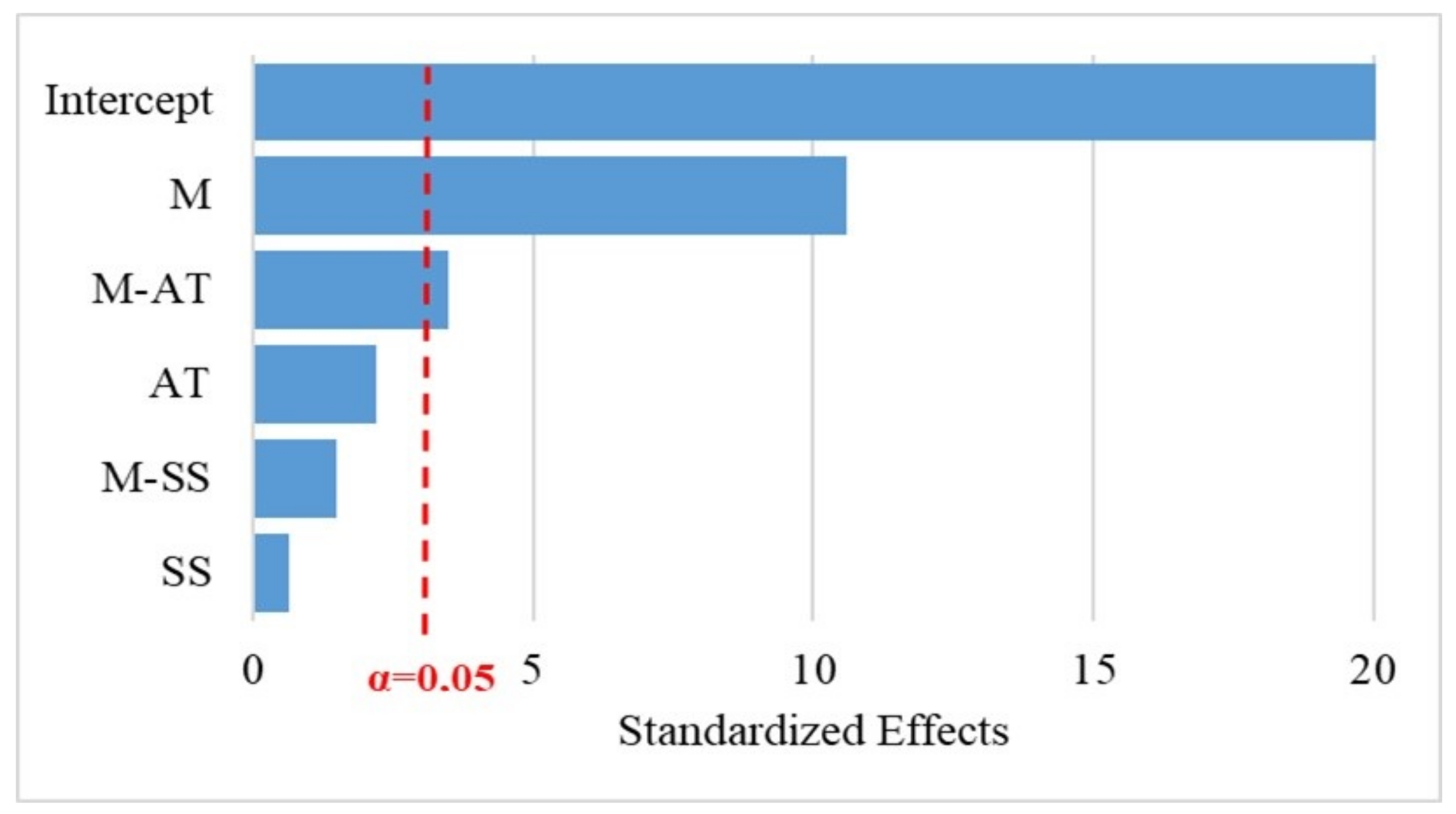

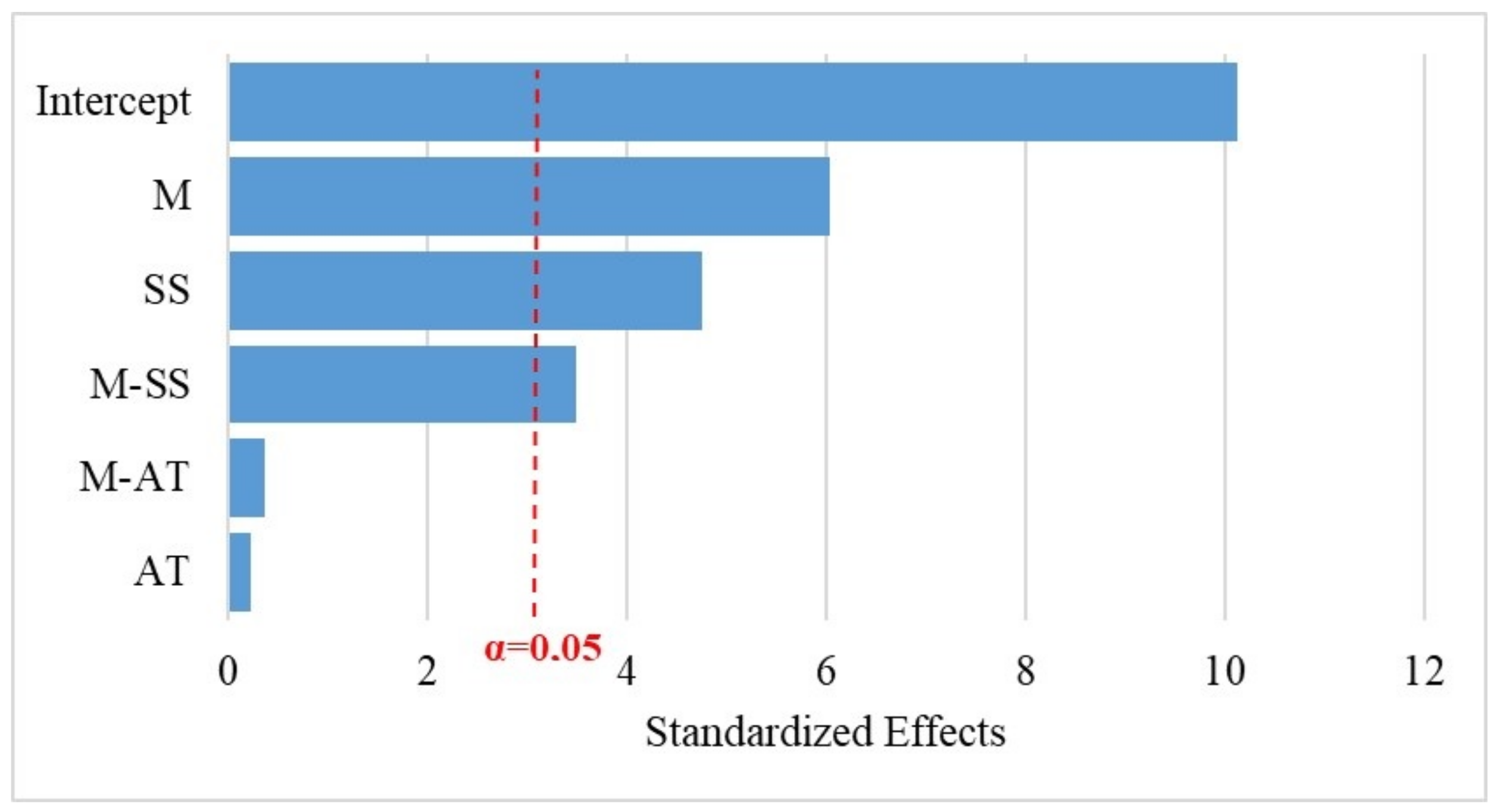

3.5. Statistical Analysis

4. Summary and Conclusions

- The FTIR analysis indicated that the alkali treatment removed most of the amorphous materials, such as hemicellulose, and lignin from the surface of the sisal fibers.

- X-ray diffraction analysis of the sisal showed that the alkali treatment promoted a significant increase in its crystallinity, in which the crystallinity index increased from 44.76% to 73.18%, corroborating the FTIR analyses.

- The density of the materials ranged from 0.89 to 0.95 g·cm−3, showing the possibility of using these bio-based composites in light automotive parts.

- The rPP and rPP composites had lower hardness than those of virgin PP.

- Water absorption tests revealed that the composites with the rPP matrix showed higher liquid absorption, due to the lack of sisal–matrix interaction and the hydrophilic character of the fiber, besides the presence of the fibers that had hydrophilic behavior. All groups except PP presented the highest liquid absorption in the 168 h test.

- The composites with the PP matrix displayed higher-impact strength values than the composites with the rPP matrix, corroborating the results of water absorption and hardness.

- Statistical analysis revealed that the type of bio-based composite matrix was the most significant variable. The regression model and the Pareto diagrams showed that the alkali treatment was a significant factor for the hardness of rPP and PP composites, and that the addition of a sisal layer was relevant to improve the impact resistance of the composites. For the fabrication of internal components of automobiles, the matrix of virgin PP and the alkali treatment of the fiber are indicated.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Taghipour, A.; Akkalatham, W.; Eaknarajindawat, N.; Stefanakis, A.I. The impact of government policies and steel recycling companies’ performance on sustainable management in a circular economy. Resour. Policy 2022, 77, 102663. [Google Scholar] [CrossRef]

- Rodrigues, I.; Mata, T.A.; Martins, A.A. Environmental analysis of a bio-based coating material for automobile interiors. J. Clean. Prod. 2022, 367, 133011. [Google Scholar] [CrossRef]

- Chandgude, S.; Salunkhe, S. In state of art: Mechanical behavior of natural fiber-based hybrid polymeric composites for application of automobile components. Polym. Compos. 2021, 42, 2678–2703. [Google Scholar] [CrossRef]

- Ganesarajan, D.; Simon, L.; Tamrakar, S.; Kiziltas, A.; Mielewski, D.; Behabtu, N.; Lenges, C. Hybrid composites with engineered polysaccharides for automotive lightweight. Compos. Part C Open Access 2022, 7, 100222. [Google Scholar] [CrossRef]

- Kuroda, S.; Mizutani, A.; Ito, H. Effect of talc size on surface roughness and glossiness of polypropylene injection molding application to automotive plastics. Polym. Eng. Sci. 2020, 60, 132–139. [Google Scholar] [CrossRef]

- Palanikumar, K.; AshokGandhi, R.; Raghunath, B.; Jayaseelan, V. Role of Calcium Carbonate (CaCO3) in improving wear resistance of Polypropylene (PP) components used in automobiles. Mater. Today Proc. 2019, 16, 1363–1371. [Google Scholar] [CrossRef]

- Panaitescu, I.; Koch, T.; Archodoulaki, V.M. Accelerated aging of a glass fiber/polyurethane composite for automotive applications. Polym. Test. 2019, 74, 245–256. [Google Scholar] [CrossRef]

- Agarwal, J.; Sahoo, S.; Mohanty, S.; Nayak, S.K. Progress of novel techniques for lightweight automobile applications through innovative eco-friendly composite materials: A review. J. Thermoplast. Compos. Mater. 2020, 33, 978–1013. [Google Scholar] [CrossRef]

- Dhas, J.E.R.; Arun, M. A review on development of hybrid composites for aerospace applications. Mater. Today Proc. 2022, 64, 267–273. [Google Scholar] [CrossRef]

- Ali, N.; Hoque, M.E. Bionanocomposites in the Automotive and Aerospace Applications. In Polymer Based Bio-Nanocomposites; Springer: Singapore, 2022; pp. 237–253. [Google Scholar]

- Bhadra, D.; Dhar, N.R. Selection of the natural fiber for sustainable applications in aerospace cabin interior using fuzzy MCDM model. Materialia 2022, 21, 101270. [Google Scholar] [CrossRef]

- Boumaaza, M.; Belaadi, A.; Bourchak, M. Systematic Review on Reinforcing Mortars with Natural Fibers: Challenges of Environment-Friendly Option. J. Nat. Fibers 2022, 1–25. [Google Scholar] [CrossRef]

- de Lima, T.E.; de Azevedo, A.R.; Marvila, M.T.; Candido, V.S.; Fediuk, R.; Monteiro, S.N. Potential of Using Amazon Natural Fibers to Reinforce Cementitious Composites: A Review. Polymers 2022, 14, 647. [Google Scholar] [CrossRef] [PubMed]

- Pereira, A.C.; Monteiro, S.N.; Simonassi, N.T.; Vieira, C.M.F.; Lima, A.M.; Costa, U.O.; Pinheiro, W.A.; Oliveira, M.S.; da Silva Figueiredo, A.B.H. Enhancement of impact toughness using graphene oxide in epoxy composite reinforced with ramie fabric. Compos. Struct. 2022, 282, 115023. [Google Scholar] [CrossRef]

- Nayak, S.Y.; Sultan, M.T.H.; Shenoy, S.B.; Kini, C.R.; Samant, R.; Shah, A.U.M.; Amuthakkannan, P. Potential of natural fibers in composites for ballistic applications—A review. J. Nat. Fibers 2022, 19, 1648–1658. [Google Scholar] [CrossRef]

- Alves, C.; Silva, A.; Reis, L.; Freitas, M.; Rodrigues, L.; Alves, D. Ecodesign of automotive components making use of natural jute fiber composites. J. Clean. Prod. 2010, 18, 313–327. [Google Scholar] [CrossRef]

- Khalfallah, M.; Abbès, B.; Abbès, F.; Guo, Y.; Marcel, V.; Duval, A.; Vanfleteren, F.; Rousseau, F. Innovative flax tapes reinforced Acrodur biocomposites: A new alternative for automotive applications. Mater. Des. 2014, 64, 116–126. [Google Scholar] [CrossRef]

- Nachippan, N.M.; Alphonse, M.; Raja, V.B.; Shasidhar, S.; Teja, G.V.; Reddy, R.H. Experimental investigation of hemp fiber hybrid composite material for automotive application. Mater. Today Proc. 2021, 44, 3666–3672. [Google Scholar] [CrossRef]

- Wu, Y.; Cai, L.; Mei, C.; Lam, S.S.; Sonne, C.; Shi, S.Q.; Xia, C. Development and evaluation of zinc oxide-blended kenaf fiber biocomposite for automotive applications. Mater. Today Commun. 2020, 24, 101008. [Google Scholar] [CrossRef]

- Mahesh, A.; Rudresh, B.; Reddappa, H. Potential of natural fibers in the modification of mechanical behavior of polypropylene hybrid composites. Mater. Today Proc. 2022, 54, 131–136. [Google Scholar] [CrossRef]

- Nascimento, H.; Granzotto, D.; Radovanovic, E.; Fávaro, S. Obtention and characterization of polypropylene composites reinforced with new natural fibers from Yucca aloifolia L. Compos. Part B Eng. 2021, 227, 109414. [Google Scholar] [CrossRef]

- Nasri, K.; Toubal, L.; Loranger, É.; Koffi, D. Influence of UV irradiation on mechanical properties and drop-weight impact performance of polypropylene biocomposites reinforced with short flax and pine fibers. Compos. Part C Open Access 2022, 9, 100296. [Google Scholar] [CrossRef]

- Tiwari, Y.M.; Sarangi, S.K. Characterization of raw and alkali treated cellulosic Grewia Flavescens natural fiber. Int. J. Biol. Macromol. 2022, 209, 1933–1942. [Google Scholar] [CrossRef] [PubMed]

- Nayak, S.; Khuntia, S.K.; Mohanty, S.D.; Mohapatra, J.; Mall, T.K. An experimental study of physical, mechanical and morphological properties of alkali treated moringa/areca based natural fiber hybrid composites. J. Nat. Fibers 2022, 19, 630–641. [Google Scholar] [CrossRef]

- Goda, K.; Sreekala, M.; Gomes, A.; Kaji, T.; Ohgi, J. Improvement of plant based natural fibers for toughening green composites—Effect of load application during mercerization of ramie fibers. Compos. Part A Appl. Sci. Manuf. 2006, 37, 2213–2220. [Google Scholar] [CrossRef]

- Kabir, M.; Wang, H.; Lau, K.; Cardona, F. Chemical treatments on plant-based natural fibre reinforced polymer composites: An overview. Compos. Part B Eng. 2012, 43, 2883–2892. [Google Scholar] [CrossRef]

- Khalid, M.Y.; Al Rashid, A.; Arif, Z.U.; Ahmed, W.; Arshad, H.; Zaidi, A.A. Natural fiber reinforced composites: Sustainable materials for emerging applications. Results Eng. 2021, 11, 100263. [Google Scholar] [CrossRef]

- Joseph, K.; Tolêdo Filho, R.D.; James, B.; Thomas, S.; Carvalho, L.H.d. A review on sisal fiber reinforced polymer composites. Rev. Bras. Eng. Agríc. Ambient. 1999, 3, 367–379. [Google Scholar] [CrossRef]

- Mishra, S.; Mohanty, A.K.; Drzal, L.T.; Misra, M.; Hinrichsen, G. A review on pineapple leaf fibers, sisal fibers and their biocomposites. Macromol. Mater. Eng. 2004, 289, 955–974. [Google Scholar] [CrossRef]

- Senthilkumar, K.; Saba, N.; Rajini, N.; Chandrasekar, M.; Jawaid, M.; Siengchin, S.; Alotman, O.Y. Mechanical properties evaluation of sisal fibre reinforced polymer composites: A review. Constr. Build. Mater. 2018, 174, 713–729. [Google Scholar] [CrossRef]

- Veerasimman, A.; Shanmugam, V.; Rajendran, S.; Johnson, D.J.; Subbiah, A.; Koilpichai, J.; Marimuthu, U. Thermal properties of natural fiber sisal based hybrid composites—A brief review. J. Nat. Fibers 2021, 1–11. [Google Scholar] [CrossRef]

- Liu, Y.; Guo, L.; Wang, W.; Sun, Y.; Wang, H. Modifying wood veneer with silane coupling agent for decorating wood fiber/high-density polyethylene composite. Constr. Build. Mater. 2019, 224, 691–699. [Google Scholar] [CrossRef]

- Segal, L.; Creely, J.J.; Martin, A., Jr.; Conrad, C. An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text. Res. J. 1959, 29, 786–794. [Google Scholar] [CrossRef]

- ASTM D570; Standard Test Method for Water Absorption of Plastics. American Society For Testing Materials: West Conshohocken, PA, USA, 2010.

- ASTM D792; Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement. American Society For Testing Materials: West Conshohocken, PA, USA, 2020.

- ASTM D2240; Standard Test Method for Rubber Property—Durometer Hardness. American Society For Testing Materials: West Conshohocken, PA, USA, 2021.

- ASTM D256; Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics. American Society For Testing Materials: West Conshohocken, PA, USA, 2018.

- Punyamurthy, R.; Sampathkumar, D.; Srinivasa, C.V.; Bennehalli, B. Effect of alkali treatment on water absorption of single cellulosic abaca fiber. BioResources 2012, 7, 3515–3524. [Google Scholar]

- Silva, T.T.d.; Silveira, P.H.P.M.d.; Ribeiro, M.P.; Lemos, M.F.; da Silva, A.P.; Monteiro, S.N.; Nascimento, L.F.C. Thermal and chemical characterization of kenaf fiber (Hibiscus cannabinus) reinforced epoxy matrix composites. Polymers 2021, 13, 2016. [Google Scholar] [CrossRef] [PubMed]

- Cai, M.; Takagi, H.; Nakagaito, A.N.; Katoh, M.; Ueki, T.; Waterhouse, G.I.; Li, Y. Influence of alkali treatment on internal microstructure and tensile properties of abaca fibers. Ind. Crop. Prod. 2015, 65, 27–35. [Google Scholar] [CrossRef]

- Da Silveira, P.H.P.; Ribeiro, M.P.; Silva, T.T.; Lima, A.M.; Lemos, M.F.; Oliveira, A.G.; Nascimento, L.F.C.; Gomes, A.V.; Monteiro, S.N. Effect of Alkaline Treatment and Graphene Oxide Coating on Thermal and Chemical Properties of Hemp (Cannabis sativa L.) Fibers. J. Nat. Fibers 2022, 1–14. [Google Scholar] [CrossRef]

- Boopathi, L.; Sampath, P.; Mylsamy, K. Investigation of physical, chemical and mechanical properties of raw and alkali treated Borassus fruit fiber. Compos. Part B Eng. 2012, 43, 3044–3052. [Google Scholar] [CrossRef]

- Orue, A.; Jauregi, A.; Peña-Rodriguez, C.; Labidi, J.; Eceiza, A.; Arbelaiz, A. The effect of surface modifications on sisal fiber properties and sisal/poly (lactic acid) interface adhesion. Compos. Part B Eng. 2015, 73, 132–138. [Google Scholar] [CrossRef]

- Mohan, T.; Kanny, K. Chemical treatment of sisal fiber using alkali and clay method. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1989–1998. [Google Scholar] [CrossRef]

- Eyupoglu, S. Characterization of new cellulosic fibers obtained from zingiber officinale. J. Nat. Fibers 2022, 19, 1287–1296. [Google Scholar] [CrossRef]

- Laifa, F.; Rokbi, M.; Amroune, S.; Zaoui, M.; Seki, Y. Investigation of mechanical, physicochemical, and thermal properties of new fiber from Silybum marianum bark fiber. J. Compos. Mater. 2022, 56, 2227–2238. [Google Scholar] [CrossRef]

- Njoku, C.E.; Omotoyinbo, J.A.; Alaneme, K.K.; Daramola, M.O. Characterization of Urena lobata fibers after alkaline treatment for use in polymer composites. J. Nat. Fibers 2022, 19, 485–496. [Google Scholar] [CrossRef]

- Seisa, K.; Chinnasamy, V.; Ude, A.U. Surface Treatments of Natural Fibres in Fibre Reinforced Composites: A Review. Fibres Text. East. Eur. 2022, 151, 82–89. [Google Scholar] [CrossRef]

- Ariawan, D.; Sunardi; Akbar, H.I. Adhesion Energy and Roughness Observation on Alkali Treated Natural Fiber as Composites Reinforcement. In Proceedings of the Conference on Broad Exposure to Science and Technology 2021 (BEST 2021), Serang, Indonesia, 31 August 2021; pp. 464–469.

- Prithiviraj, M.; Muralikannan, R. Investigation of optimal alkali-treated perotis indica plant fibers on physical, chemical, and morphological properties. J. Nat. Fibers 2022, 19, 2730–2743. [Google Scholar] [CrossRef]

- Manivel, S.; Pannirselvam, N.; Gopinath, R.; Sathishkumar, T. Influence of Alkali Treatment on Physicochemical, Thermal and Mechanical Properties of Hibiscus Vitifolius Fibers. J. Nat. Fibers 2022, 1–14. [Google Scholar] [CrossRef]

- Da Cunha, J.d.S.C.; Nascimento, L.F.C.; da Luz, F.S.; Monteiro, S.N.; Lemos, M.F.; da Silva, C.G.; Simonassi, N.T. Physical and Mechanical Characterization of Titica Vine (Heteropsis flexuosa) Incorporated Epoxy Matrix Composites. Polymers 2021, 13, 4079. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Cho, D. Effects of Alkali-Treatment and Feeding Route of Henequen Fiber on the Heat Deflection Temperature, Mechanical, and Impact Properties of Novel Henequen Fiber/Polyamide 6 Composites. J. Compos. Sci. 2022, 6, 89. [Google Scholar] [CrossRef]

- El Oudiani, A.; Ben Sghaier, R.; Chaabouni, Y.; Msahli, S.; Sakli, F. Physico-chemical and mechanical characterization of alkali-treated Agave americana L. fiber. J. Text. Inst. 2012, 103, 349–355. [Google Scholar] [CrossRef]

- Tri Phuong, N.; Gilbert, V.; Chuong, B. Preparation of recycled polypropylene/organophilic modified layered silicates nanocomposites part I: The recycling process of polypropylene and the mechanical properties of recycled polypropylene/organoclay nanocomposites. J. Reinf. Plast. Compos. 2008, 27, 1983–2000. [Google Scholar] [CrossRef]

- Serranti, S.; Luciani, V.; Bonifazi, G.; Hu, B.; Rem, P.C. An innovative recycling process to obtain pure polyethylene and polypropylene from household waste. Waste Manag. 2015, 35, 12–20. [Google Scholar] [CrossRef]

- Lima, A.M.; Santos, M.C.C.; Bastos, D.C.; Líbano, E.V.D.G.; da Costa Pereira, P.S. Compósitos à base de Polipropileno/Bagaço de cana-de-açúcar: Influência do processamento/Polypropylene/Sugarcane Bagasse Composites: Influence of processing. Braz. J. Dev. 2021, 7, 110053–110065. [Google Scholar] [CrossRef]

- Maddah, H.A. Polypropylene as a promising plastic: A review. Am. J. Polym. Sci. 2016, 6, 1–11. [Google Scholar]

- Li, Y.; Hu, C.; Yu, Y. Interfacial studies of sisal fiber reinforced high density polyethylene (HDPE) composites. Compos. Part A Appl. Sci. Manuf. 2008, 39, 570–578. [Google Scholar] [CrossRef]

- Gerardo, C.F.; França, S.C.A.; Santos, S.F.; Bastos, D.C. A study of recycled high-density polyethylene with mica addition: Influence of mica particle size on wetting behavior, morphological, physical, and chemical properties. Int. J. Dev. Res. 2020, 10, 37223–37228. [Google Scholar]

- Chagas, G.N.; Barros, M.M.; de Leão, A.G.; da Conceição Ribeiro, R.C.; Bastos, D.C. Compósito sustentável de polipropileno pós-consumo e resíduo de rocha ornamental. Braz. J. Dev. 2021, 7, 22298–22309. [Google Scholar] [CrossRef]

- Ye, K.Q.; Hamada, M. Critical values of the Lenth method for unreplicated factorial designs. J. Qual. Technol. 2000, 32, 57–66. [Google Scholar] [CrossRef]

| Absorption Band (cm−1) | Functional Group | Fiber Component |

|---|---|---|

| 3296 | O - H stretching | Cellulose |

| 2914 | C - H stretching | Cellulose |

| 2796 | C - H stretching | Hemicellulose and Lignin |

| 2357 | C = C stretching | Wax |

| 1737 | C = O stretching | Hemicellulose and Lignin |

| 1642 | OH bending | Lignin |

| 1346 | C = O stretching | Hemicellulose |

| 1028 | C - OH stretching | Lignin and Cellulose |

| Increase in wt. (%) | ||||

|---|---|---|---|---|

| Sample | Immersion Time | |||

| 2 h | 24 h | 168 h | 336 h | |

| PP | 0.531 ± 0.008 | 0.227 ± 0.008 | 0.152 ± 0.009 | 0.152 ± 0.008 |

| rPP | 0.592 ± 0.017 | 0.723 ± 0.017 | 1.183 ± 0.018 | 1.249 ± 0.018 |

| PP/Sisal | 2.297 ± 0.031 | 2.935 ± 0.028 | 4.339 ± 0.025 | 4.914 ± 0.028 |

| rPP/Sisal | 1.958 ± 0.031 | 4.214 ± 0.031 | 7.477 ± 0.032 | 7.914 ± 0.031 |

| PP/Sisal NaOH | 0.847 ± 0.017 | 1.885 ± 0.019 | 3.966 ± 0.017 | 4.156 ± 0.019 |

| rPP/Sisal NaOH | 1.329 ± 0.050 | 3.797 ± 0.057 | 8.101 ± 0.060 | 9.051 ± 0.057 |

| Sample | Density (g·cm−3) | Shore D Hardness | Izod Impact Strength (MPa) |

|---|---|---|---|

| PP | 0.89 ± 0.02 | 63.00 ± 0.00 | 21.49 ± 0.25 |

| rPP | 0.92 ± 0.01 | 58.00 ± 0.58 | 8.48 ± 0.08 |

| PP/Sisal | 0.93 ± 0.02 | 63.33 ± 1.00 | 9.22 ± 0.02 |

| rPP/Sisal | 0.95 ± 0.01 | 59.33 ± 1.00 | 6.82 ± 0.06 |

| PP/Sisal NaOH | 0.90 ± 0.02 | 63.33 ± 1.00 | 9.14 ± 0.07 |

| rPP/Sisal NaOH | 0.93 ± 0.01 | 57.00 ± 1.00 | 5.63 ± 0.05 |

| Experiment | M | AT | SS | H | I | D |

|---|---|---|---|---|---|---|

| 1 | 1 | 0 | 0 | 63 | 0.893 | 18.614 |

| 2 | 1 | 0 | 0 | 63 | 0.875 | 17.853 |

| 3 | 1 | 0 | 0 | 63 | 0.907 | 28.025 |

| 4 | 1 | 0 | 1 | 63 | 0.955 | 9.641 |

| 5 | 1 | 0 | 1 | 64 | 0.911 | 8.788 |

| 6 | 1 | 0 | 1 | 63 | 0.934 | 9.226 |

| 7 | 1 | 15 | 1 | 63 | 0.891 | 7.911 |

| 8 | 1 | 15 | 1 | 63 | 0.921 | 8.557 |

| 9 | 1 | 15 | 1 | 64 | 0.891 | 10.956 |

| 10 | 2 | 0 | 0 | 58 | 0.932 | 10.426 |

| 11 | 2 | 0 | 0 | 58 | 0.921 | 6.620 |

| 12 | 2 | 0 | 0 | 58 | 0.923 | 8.396 |

| 13 | 2 | 0 | 1 | 60 | 0.956 | 8.004 |

| 14 | 2 | 0 | 1 | 59 | 0.957 | 5.305 |

| 15 | 2 | 0 | 1 | 59 | 0.950 | 7.150 |

| 16 | 2 | 15 | 1 | 58 | 0.931 | 6.389 |

| 17 | 2 | 15 | 1 | 57 | 0.918 | 6.228 |

| 18 | 2 | 15 | 1 | 56 | 0.932 | 4.267 |

| Source of Variation | Degree of Freedom (D.F) | Sum of Squares (SQ) | Means Squares (MQ) | F | Significance of F |

|---|---|---|---|---|---|

| Regression | 3 | 0.0076 | 0.0025 | 14.6094 | |

| Residue | 14 | 0.0024 | 0.0002 | ||

| Total | 17 | 0.0100 | |||

| Term | Coefficients | Stand. Error | Stat t | Value-p | |

| intercept | 0.8682 | 0.0107 | 80.7936 | ||

| M | 0.0269 | 0.0062 | 4.3342 | ||

| AT | −0.0020 | 0.0005 | −3.9264 | ||

| SS | 0.0353 | 0.0076 | 4.6502 | ||

| S = 0.0132 | |||||

| R-sq = 75.79% | |||||

| R-sq (adj) = 70.60% | |||||

| Source of Variation | Degree of Freedom (D.F) | Sum of Squares (SQ) | Means Squares (MQ) | F | Significance of F |

|---|---|---|---|---|---|

| Regression | 6 | 126 | 21 | 75.6 | |

| Residue | 12 | 4 | 0.3333 | ||

| Total | 18 | 130 | |||

| Term | Coefficients | Stand. Error | Stat t | Value-p | |

| Intercept | 68 | 0.7454 | 91.2316 | ||

| M | −5 | 0.4714 | −10.6066 | ||

| AT | 0.1556 | 0.0703 | 2.2136 | 0.0469 | |

| SS | −0.6667 | 1.0541 | −0.6325 | 0.5389 | |

| M-AT | −0.1556 | 0.0444 | −3.5 | 0.0044 | |

| M-SS | 1 | 0.6667 | 1.5 | 0.1595 | |

| S = 0.5775 | |||||

| R-sq = 96.92% | |||||

| R-sq (adj) = 87.31% | |||||

| Source of Variation | Degree of Freedom (D.F) | Sum of Squares (SQ) | Means Squares (MQ) | F | Significance of F |

|---|---|---|---|---|---|

| Regression | 6 | 494.8954 | 82.4826 | 14.2137 | 0.00013 |

| Residue | 12 | 83.5634 | 6,9636 | ||

| Total | 18 | 578,4588 | |||

| Term | Coefficients | Stand. Error | Stat t | Value-p | |

| intercept | 34.5137 | 3.4068 | 10.1309 | ||

| M | −13.0166 | 2.1546 | −6.0413 | ||

| AT | 0.0692 | 0.3212 | 0.2154 | 0.8330 | |

| SS | −22.8964 | 4.8179 | −4.7524 | 0.0005 | |

| M-AT | −0.0743 | 0.2031 | −0.3659 | 0.7208 | |

| M-SS | 10.6178 | 3.0471 | 3.4846 | 0.0045 | |

| S = 2.6388 | |||||

| R-sq = 85.55% | |||||

| R-sq (adj) = 71.20% | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fernandes, R.A.P.; da Silveira, P.H.P.M.; Bastos, B.C.; da Costa Pereira, P.S.; de Melo, V.A.; Monteiro, S.N.; Tapanes, N.d.L.C.O.; Bastos, D.C. Bio-Based Composites for Light Automotive Parts: Statistical Analysis of Mechanical Properties; Effect of Matrix and Alkali Treatment in Sisal Fibers. Polymers 2022, 14, 3566. https://doi.org/10.3390/polym14173566

Fernandes RAP, da Silveira PHPM, Bastos BC, da Costa Pereira PS, de Melo VA, Monteiro SN, Tapanes NdLCO, Bastos DC. Bio-Based Composites for Light Automotive Parts: Statistical Analysis of Mechanical Properties; Effect of Matrix and Alkali Treatment in Sisal Fibers. Polymers. 2022; 14(17):3566. https://doi.org/10.3390/polym14173566

Chicago/Turabian StyleFernandes, Roberta Anastacia Palermo, Pedro Henrique Poubel Mendonça da Silveira, Beatriz Cruz Bastos, Patricia Soares da Costa Pereira, Valdir Agustinho de Melo, Sergio Neves Monteiro, Neyda de La Caridad Om Tapanes, and Daniele Cruz Bastos. 2022. "Bio-Based Composites for Light Automotive Parts: Statistical Analysis of Mechanical Properties; Effect of Matrix and Alkali Treatment in Sisal Fibers" Polymers 14, no. 17: 3566. https://doi.org/10.3390/polym14173566

APA StyleFernandes, R. A. P., da Silveira, P. H. P. M., Bastos, B. C., da Costa Pereira, P. S., de Melo, V. A., Monteiro, S. N., Tapanes, N. d. L. C. O., & Bastos, D. C. (2022). Bio-Based Composites for Light Automotive Parts: Statistical Analysis of Mechanical Properties; Effect of Matrix and Alkali Treatment in Sisal Fibers. Polymers, 14(17), 3566. https://doi.org/10.3390/polym14173566