Effect of Thermal Oxygen Aging Mode on Rheological Properties and Compatibility of Lignin-Modified Asphalt Binder by Dynamic Shear Rheometer

Abstract

:1. Introduction

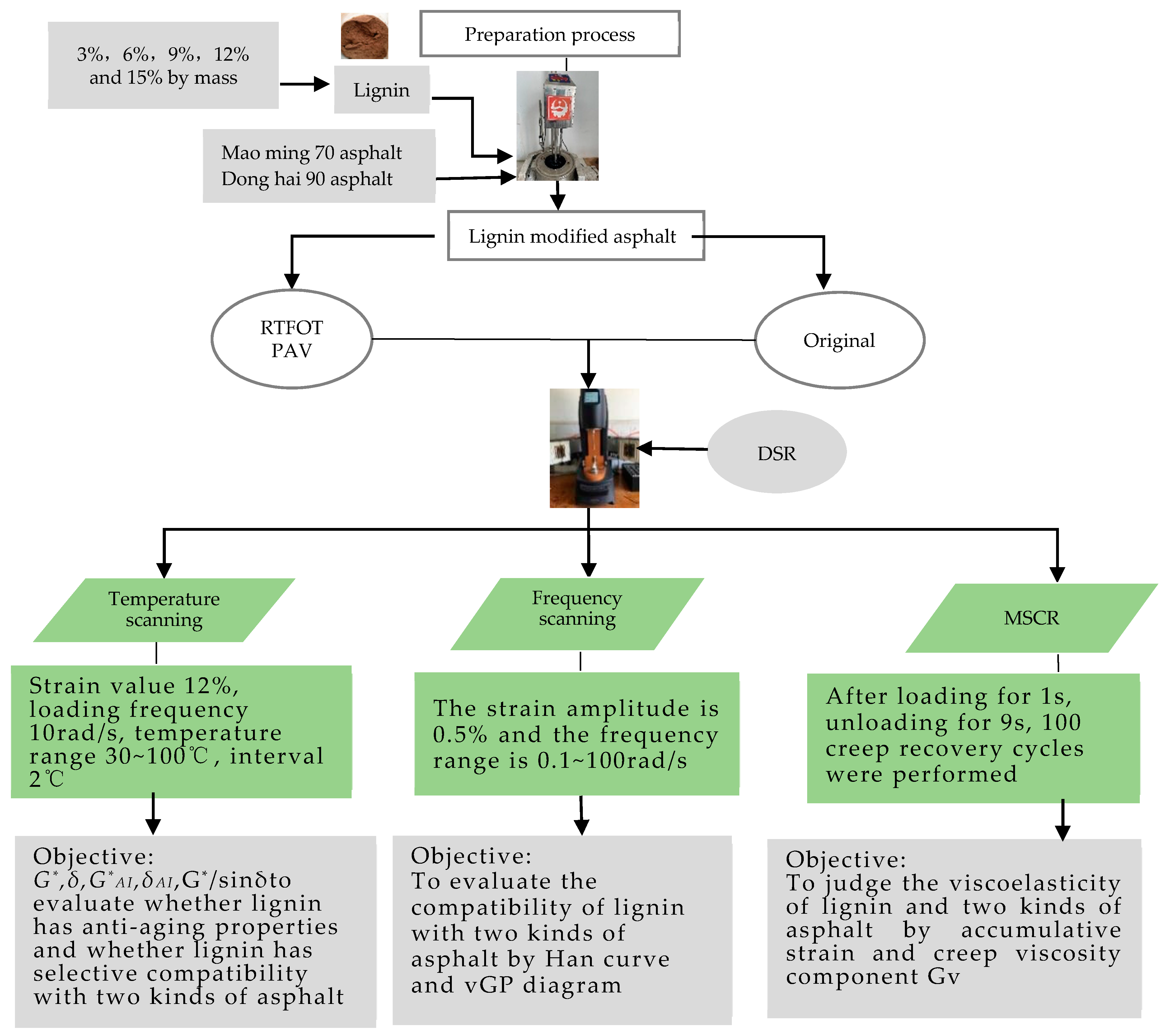

2. Materials and Methods

2.1. Raw Materials

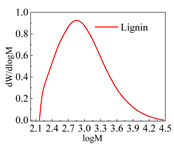

2.1.1. Lignin

2.1.2. Based Asphalt

2.2. Preparation of Lignin-Modified Asphalt

2.3. Preparation of Aged Samples

2.4. Test Design and Evaluation Index

2.4.1. Temperature Scanning and Frequency Sweep Test

2.4.2. Aging Index Evaluation

2.4.3. Repeat Creep Test

3. Results and Discussion Results

3.1. Analysis of Rheological Properties of Lignin-Modified Asphalt

3.2. Analysis of PG Classification of Lignin-Modified Asphalt

3.3. Complex Shear Modulus Aging Index of Lignin-Modified Asphalt

3.4. Creep and Recovery Behavior of Lignin-Modified Asphalt

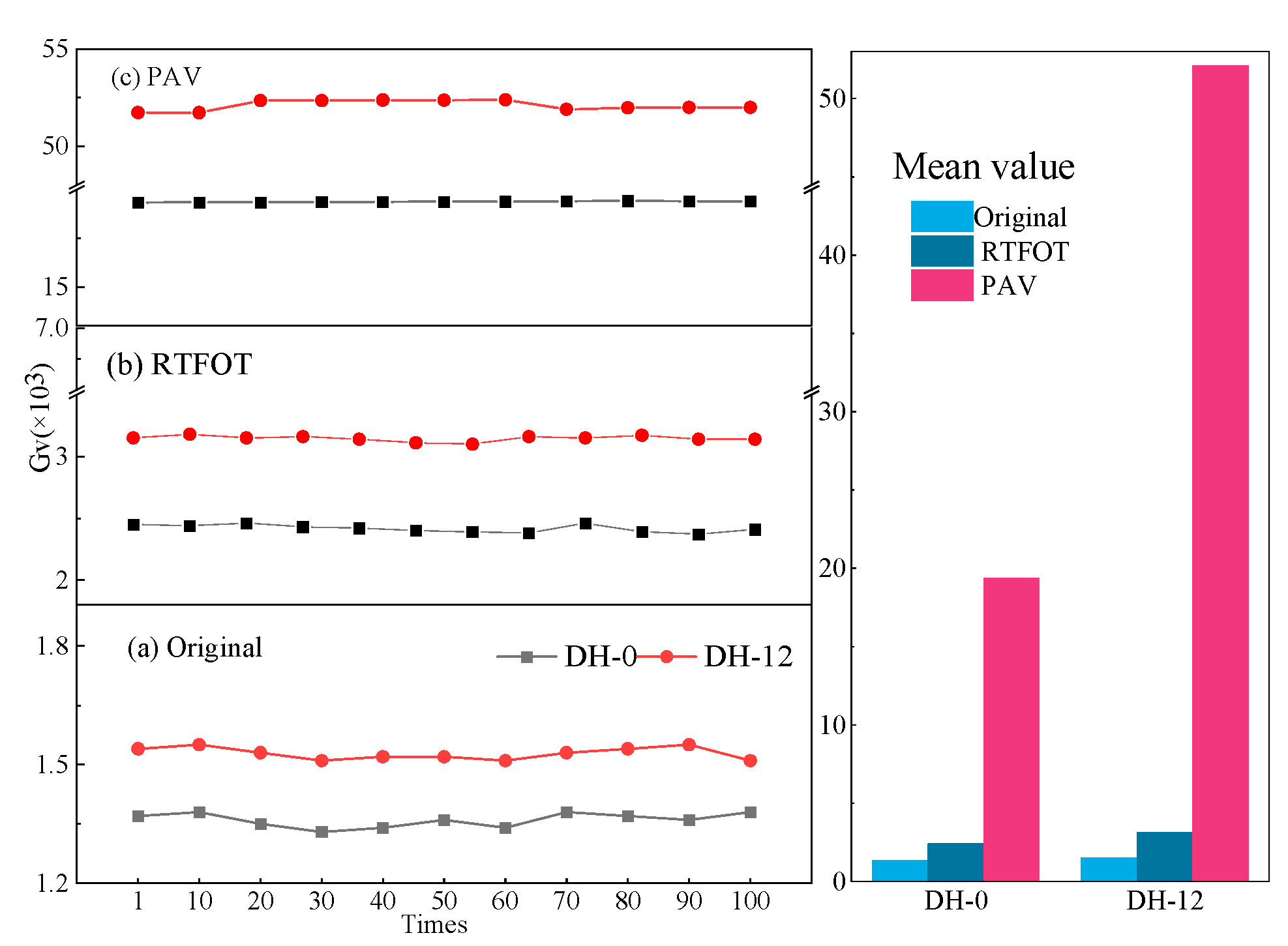

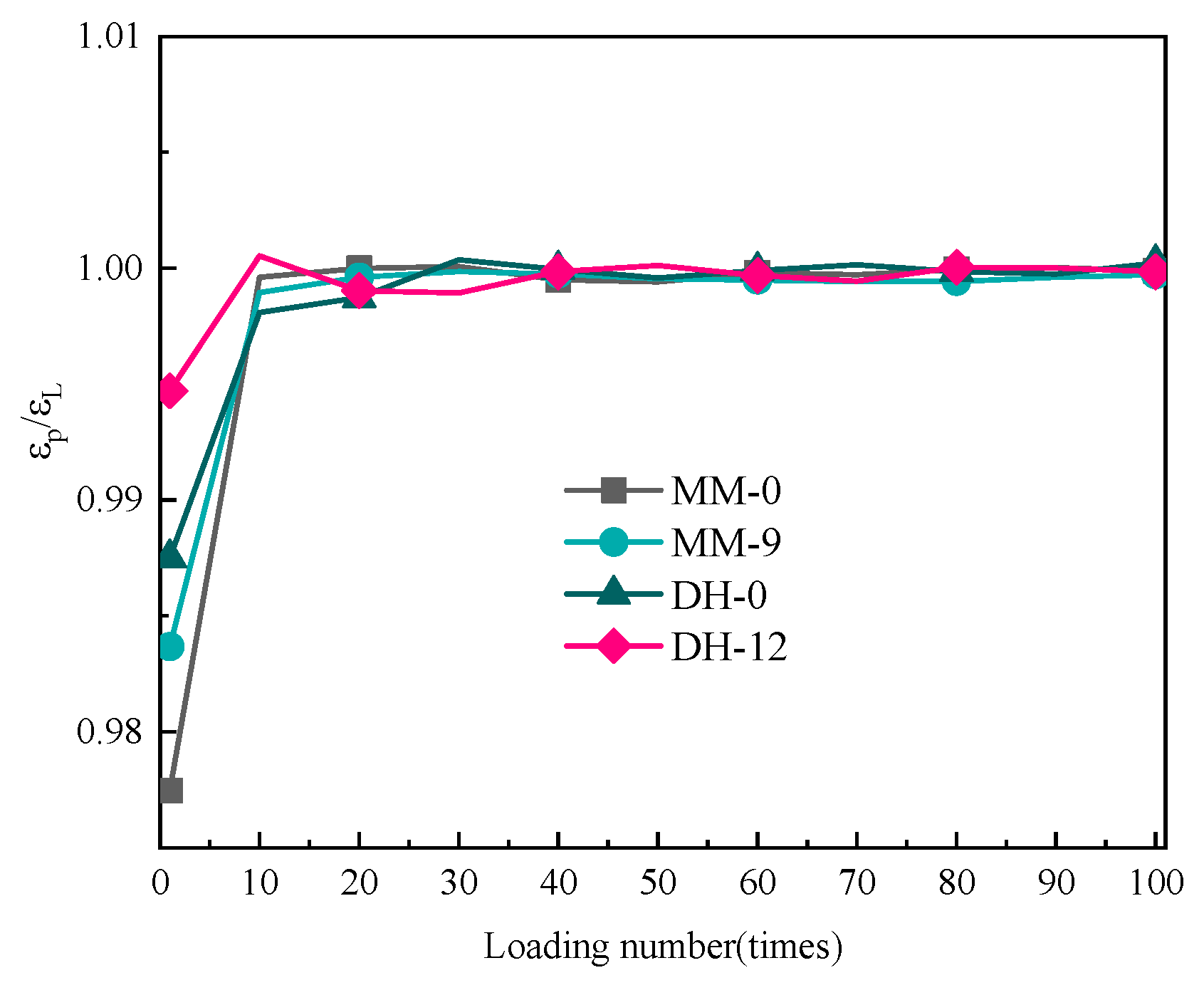

3.4.1. Creep Test Viscous Component

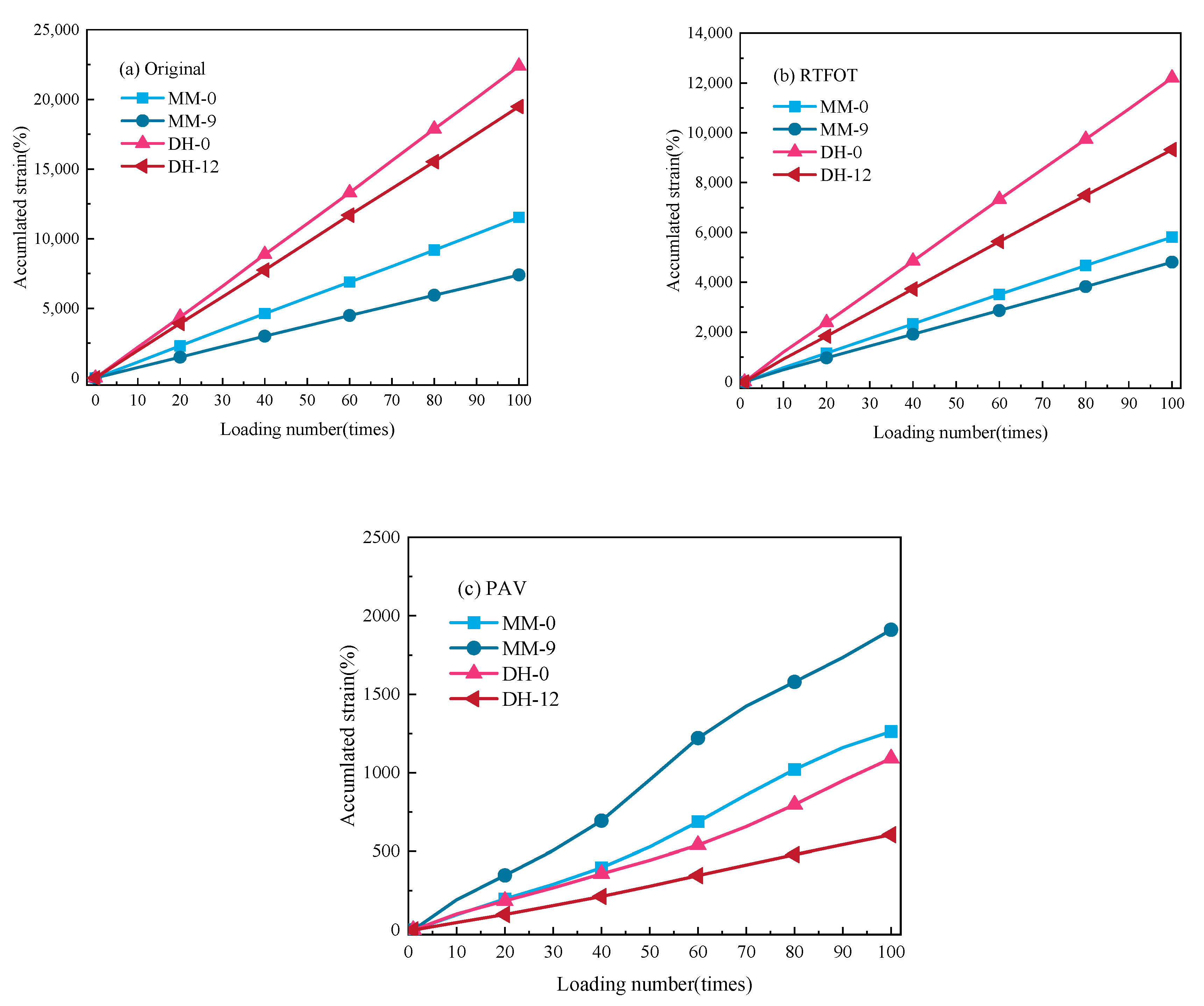

3.4.2. Accumulated Strain

3.5. Compatibility Analysis of Lignin and Asphalt

4. Conclusions

- (1)

- The addition of lignin had a significant effect on the high-temperature resistance of asphalt, but the degree of improvement in the high-temperature performance of the two matrix asphalts was not the same. The results indicated that there was a compatibility problem with lignin in improving the performance of matrix asphalt.

- (2)

- The results of the repeated creep and recovery test indicated that lignin-modified asphalt and base asphalt showed the same behavior, and lignin did not increase the elastic recovery rate of modified polymer binders such as SBS. However, the addition of lignin increased the viscosity resistance of the asphalt binder, which significantly reduced the cumulative strain of the lignin-modified asphalt, and this was also the fundamental reason for improving the high-temperature stability of matrix asphalt.

- (3)

- After long-term aging, the cumulative strain of lignin-modified asphalt was higher than that of base asphalt, and the long-term aging performance was significantly improved. This was owing to the probable depolymerization and molecular weight reduction of lignin during long-term aging.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, X.P.; Ma, Y.F. Research on performance of crumb rubber modified asphalt. New Chem. Mater. 2010, 38, 118–120. [Google Scholar]

- Ouyang, C.; Wang, S.; Zhang, Y.; Zhang, Y. Improving the aging resistance of asphalt by addition of Zinc dialkyldithiophosphate. Fuel 2006, 85, 1060–1066. [Google Scholar] [CrossRef]

- Tian, W.M. On aging performance analysis of SBS modified asphalt. Shanxi Archit. 2012, 38, 139–141. [Google Scholar]

- Zhang, Q.C.; Wang, Y.; Xiong, L. Study on anti ultraviolet aging ability of nano TiO2 modified asphalt. Roads Mot. 2011, 27, 88–91. [Google Scholar]

- Qian, X.O. Study on improving adhesion between Asphalt and acid stone in Qinghai area by anti-spalling agent. Highway 2011, 56, 141–146. [Google Scholar]

- Yadykova, A.Y.; Ilyin, S.O. Rheological and adhesive properties of nanocomposite bitumen binders based on hydrophilic or hydrophobic silica and modified with bio-oil. Constr. Build. Mater. 2022, 342, 127946. [Google Scholar] [CrossRef]

- Ilyin, S.O.; Arinina, M.P.; Mamulat, Y.S.; Malkin, A.Y.; Kulichikhin, V.G. Rheological properties of road bitumens modified with polymer and solid nanosized additives. Colloid J. 2014, 76, 425–434. [Google Scholar] [CrossRef]

- Zhang, W.; Zou, L.; Wang, Y.; Liu, J.; Yang, C.; Di, J.; Hu, H.; Yang, Z. Influence of High Viscosity Petroleum Resin (HV-PR) on the Intermediate and High Temperature Performances of Styrene–Butadiene–Styrene Block Copolymer (SBS) Modified Bitumen. Arab. J. Sci. Eng. 2022, 12, 1–13. [Google Scholar] [CrossRef]

- Pi, Y.H. Test Research on the Road Performance of Asphalt Mixtures with Bonifibers and SBS Modified. J. Transp. Eng. Inf. 2008, 6, 56–60. [Google Scholar] [CrossRef]

- Cheng, Z.S. Demand for Oil Will Exceed Supply After 2007; China Petroleum & Chemical Corporation: Beijing, China, 2005; p. 53. [Google Scholar]

- Wen, J.L.; Chen, T.Y.; Sun, R.C. Research progress on separation and structural analysis of lignin in lignocellulosic biomass. J. For. Eng. 2017, 2, 76–84. [Google Scholar] [CrossRef]

- Ren, L.F.; He, Q.Q.; Qing, T.T.; Wang, X.C. Activation of enzymatic hydrolysis lignin and used for preparation of phenol-formaldehyde Resin. New Chem. Mater. 2016, 44, 47–49. [Google Scholar]

- Ma, Z.M.; Li, S.J.; Yang, D.M. Activation of enzymatic hydrolysis lignin and used for preparation of phenol-formaldehyde resin. For. Eng. 2017, 33, 64–67. [Google Scholar]

- Pinheiro, F.G.C.; Soares, A.K.L.; Santaella, S.T. Optimization of the acetosolv extraction of lignin from sugarcane bagasse for phenolic resin production. Ind. Crops Prod. 2017, 96, 80–90. [Google Scholar] [CrossRef]

- Li, Y.; Han, Y.M.; Qin, T.F.; Chu, F.X. Research progress of lignin is synthesis of polyurethane materials. Chem. Ind. Eng. Prog. 2011, 30, 1990–1997. [Google Scholar]

- Ferdosian, F.; Yuan, Z.; Anderson, M.; Xu, C.C. Synthesis and characterization of hydrolysis lignin-based epoxy resins. Ind. Crops Prod. 2016, 91, 295–301. [Google Scholar] [CrossRef]

- Kumari, S.; Chauhan, G.S.; Monga, S.; Kaushik, A.; Ahn, J.H. New lignin-based polyurethane foam for wastewater treatment. RSC Adv. 2016, 6, 77768–77776. [Google Scholar] [CrossRef]

- Feng, P.; Chen, F.G. Application progress of lignin in epoxy resin synthesis. J. Mater. Sci. Technol. 2010, 2, 54–60. [Google Scholar] [CrossRef]

- Arshanitsa, A.; Krumina, L.; Telysheva, G.; Dizhbite, T. Exploring the application potential of incompletely soluble organosolv lignin as a macromonomer for polyurethane synthesis. Ind. Crops Prod. 2016, 92, 1–12. [Google Scholar] [CrossRef]

- Zhao, Z.; Chen, M.Q.; Wang, Y.S.; Ding, S.S.; Yang, J. Synthesis and property of epoxy resin based on degrading lignin. J. Mater. Sci. Technol. 2017, 3, 46–52. [Google Scholar] [CrossRef]

- Li, J.H.; Liu, C.Z.; Li, Q.L. Study on properties of lignin-filled polysulfide sealant. Adhesion 2017, 38, 39–42. [Google Scholar] [CrossRef]

- Luiz, F.N.; Scremin, F.R.; Werncke, E.; Basso, R.L.D.O.; Possan, E.; Bittencourt, P.R.S. Thermal evaluation by DSC and tensile strength of extrudated blends from polyethylene terephthalate and kraft lignin. Waste Biomass Valorization 2018, 6, 367–373. [Google Scholar] [CrossRef]

- Dizhbite, T.; Telysheva, G.; Jurkjane, V.; Viesturs, U. Characterization of the Radical Scavenging Activity of Lignins-Natural Antioxidants. Bioresour. Technol. 2004, 95, 309–317. [Google Scholar] [CrossRef] [PubMed]

- Thakur, V.K.; Thakur, M.K. Recent advances in green hydrogels from lignin: A review. Int. J. Biol. Macromol. 2015, 72, 834–847. [Google Scholar] [CrossRef]

- Yu, H.; Zhu, Z.; Zhang, Z.; Yu, J.; Oeser, M.; Wang, D. Recycling waste packaging tape into bituminous mixtures towards enhanced mechanical properties and environmental benefits. J. Clean. Prod. 2019, 229, 22–31. [Google Scholar] [CrossRef]

- Sun, Q.N.; Qin, T.F.; Li, G.Y. Progress on activation and application to wood adhesives of lignin. Polym. Bull. 2008, 9, 55–60. [Google Scholar]

- Wu, W.J.; Wang, T.; Wu, J.T. Impact of Lignin on Aging Property of Modified Asphalt. Pap. Sci. Technol. 2018, 37, 19–24. [Google Scholar]

- Gao, J.; Wang, H.; Liu, C.; Ge, D.; You, Z.; Yu, M. High-temperature rheological behavior and fatigue performance of lignin modified asphalt binder. Constr. Build. Mater. 2020, 230, 117063. [Google Scholar] [CrossRef]

- Batista, K.B.; Padilha, R.P.L.; Castro, T.O.; Silva, C.F.S.C.; Araújo, M.F.A.S.; Leite, L.F.M.; Pasa, V.M.D.; Lins, V.F.C. High-temperature, low-temperature and weathering aging performance of lignin modified asphalt binders. Ind. Crops Prod. 2018, 111, 107–116. [Google Scholar] [CrossRef]

- Xu, G.; Wang, H.; Zhu, H. Rheological properties and anti-aging performance of asphalt binder modified with wood lignin. Constr. Build. Mater. 2017, 151, 801–808. [Google Scholar] [CrossRef]

- Zhang, H.L.; Duan, H.H.; Tang, J.C. Effects of Different Anti-stripping Agents on Physical, Rheological and Aging Properties of Asphalt. J. Highw. Transp. Res. Dev. 2021, 38, 1–9. [Google Scholar] [CrossRef]

- Lin, J.T.; Pan, L. High Temperature Performance Evaluation of Asphalt Based on MSCR Test and Burgers Model Analysis. J. Highw. Transp. Res. Dev. 2018, 35, 22–29. [Google Scholar] [CrossRef]

- Cheng, C.; Tao, G.X.; Wang, Q. Experimental study on performance of lignin modified asphalt at high temperatures. China For. Sci. Technol. 2019, 4, 148–154. [Google Scholar]

- Chen, P.Q.; Zhang, Y.Y.; Luo, Y.C. Discussion on Formation Mechanism of Epoxy Asphalt by Four-component Analysis. China Build. Waterproofing 2012, 10, 16–19. [Google Scholar] [CrossRef]

- Henoy, A. Refinement of the superpave specification parsmeter for performance grading of asphalt. J. Transp. Eng. 2001, 127, 357–362. [Google Scholar]

- Chen, Z.J.; Hao, P.W. High temperature performance of chemical modified asphalt based on repeated creep and recovery test. J. Jiangsu Univ. Nat. Sci. Ed. 2017, 38, 479–483. [Google Scholar]

- Peng, X.L.; Gao, D.H. Research on Elastic Recovery Performance of SBS Modified Asphalt. Guangdong Highw. Commun. 2018, 44, 1–6. [Google Scholar] [CrossRef]

- Yin, H.; Li, K. Grey Correlation Analysis of Zero Shear Viscosity and High Temperature Rheological Parameters of Asphalt. J. Build. Mater. 2020, 23, 108–113. [Google Scholar] [CrossRef]

- Cui, Y.X.; Hao, P.W. High Temperature Performance of Rubber Modified Asphalt Based on MSCR Test. Road Mach. Constr. Mech. 2019, 36, 47–51. [Google Scholar] [CrossRef]

- Zeng, M.Z.; Hu, Y.B. Progress in preparation and application of lignin porous carbon. Chem. Ind. Eng. Prog. 2021, 40, 4573–4586. [Google Scholar] [CrossRef]

- Xu, C.; Wang, D.; Zhang, S.; Guo, E.; Luo, H.; Zhang, Z.; Yu, H. Effect of lignin modifier on engineering performance of bituminous binder and mixture. Polymers 2021, 13, 1083. [Google Scholar] [CrossRef]

- Han, C.D.; Baek, D.M.; Kim, J.K.; Ogawa, T.; Sakamoto, N.; Hashimoto, T. Effect of volume fraction on the order-disorder transition in low molecular weight polystyrene-block-polyisoprene copolymers. 1. Order-disorder transition temperature determined by rheological measurements. Macromolecules 1995, 28, 5043–5062. [Google Scholar] [CrossRef]

- Han, C.D.; Kim, J.; Kim, J.K. Determination of the order-disorder transition temperature of block copolymers. Macromolecules 1989, 22, 383–394. [Google Scholar] [CrossRef]

- Zan, X.Y.; Zhang, X.N.; Wang, D.Y. Microstructure of asphalt mastic using dynamic mechanical analysis. J. Jilin Univ. Eng. Technol. Ed. 2009, 39, 916–920. [Google Scholar]

- Wang, W.M.; Xie, X.B.; Lan, X. Phase structure analysis of nano-carbon powder–rubber powder–SBS–modified asphalt based on dynamic mechanics. Silic. Bull. 2021, 40, 2444–2453. [Google Scholar] [CrossRef]

| Figure | Main Specifications | Scope |

|---|---|---|

| PH | 7~8 |

| Appearance color | Brown powder | |

| Ash (%) | 1 | |

| Sugar content (%) | 1~3 | |

| Lignin content (%) | 85~90 | |

| Number average relative molecular weight (Mn) | 960 |

| weight-average molecular weight (Mw) | 2964 | |

| Peak molecular weight (Mp) | 1182 | |

| Dispersion coefficient (d) | 3.09 | |

| Initial decomposition temperature (°C) | 189 |

| Maximum decomposition temperature (°C) | 339.3 | |

| 700 °C Residue carbon rate (%) | 39.7 |

| Test Items | Unit | Test Result | Technical Requirement | ||

|---|---|---|---|---|---|

| Maoming 70# | Donghai 90# | 70 | 90 | ||

| Penetration (25 °C, 5 s, 100 g) | 0.1 mm | 65.4 | 86.2 | 60~80 | 80~100 |

| Softening point | °C | 46.6 | 45.7 | ≥46 | ≥45 |

| Ductility (15 °C) | cm | >150 | >150 | ≥100 | ≥100 |

| TFOT penetration ratio (25 °C) | % | 76.9 | 75.1 | ≥61 | ≥57 |

| Residual ductility (15 °C) | cm | 132.9 | 125.6 | ≥15 | ≥20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, M.; Zhao, X.; Han, X.; Du, P.; Su, Y.; Cheng, C. Effect of Thermal Oxygen Aging Mode on Rheological Properties and Compatibility of Lignin-Modified Asphalt Binder by Dynamic Shear Rheometer. Polymers 2022, 14, 3572. https://doi.org/10.3390/polym14173572

Cai M, Zhao X, Han X, Du P, Su Y, Cheng C. Effect of Thermal Oxygen Aging Mode on Rheological Properties and Compatibility of Lignin-Modified Asphalt Binder by Dynamic Shear Rheometer. Polymers. 2022; 14(17):3572. https://doi.org/10.3390/polym14173572

Chicago/Turabian StyleCai, Meng, Xun Zhao, Xuanzhen Han, Peng Du, Yi Su, and Cheng Cheng. 2022. "Effect of Thermal Oxygen Aging Mode on Rheological Properties and Compatibility of Lignin-Modified Asphalt Binder by Dynamic Shear Rheometer" Polymers 14, no. 17: 3572. https://doi.org/10.3390/polym14173572