Mechanical Properties of Macromolecular Separators for Lithium-Ion Batteries Based on Nanoindentation Experiment

Abstract

:1. Introduction

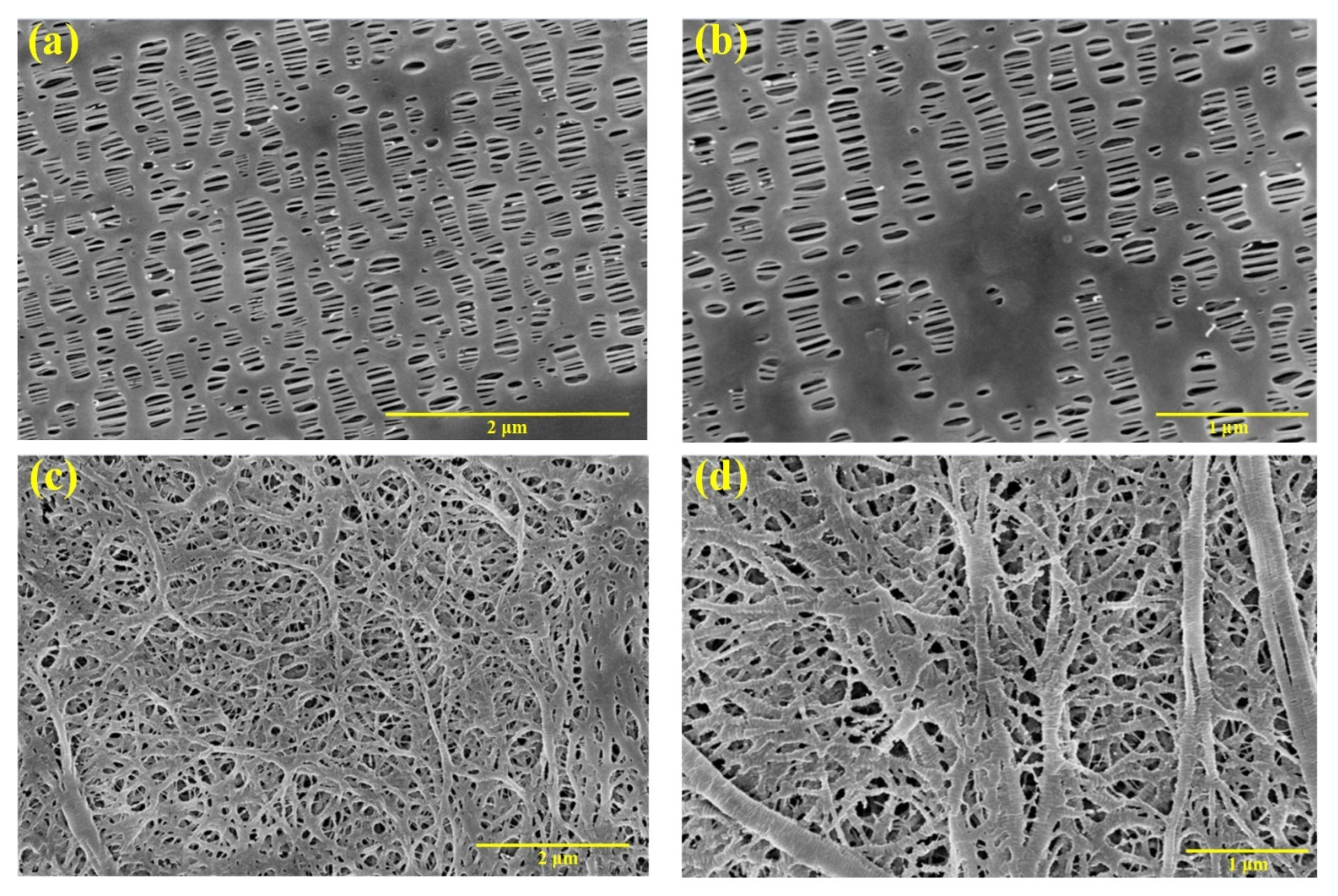

2. Materials and Methods

3. Results and Discussion

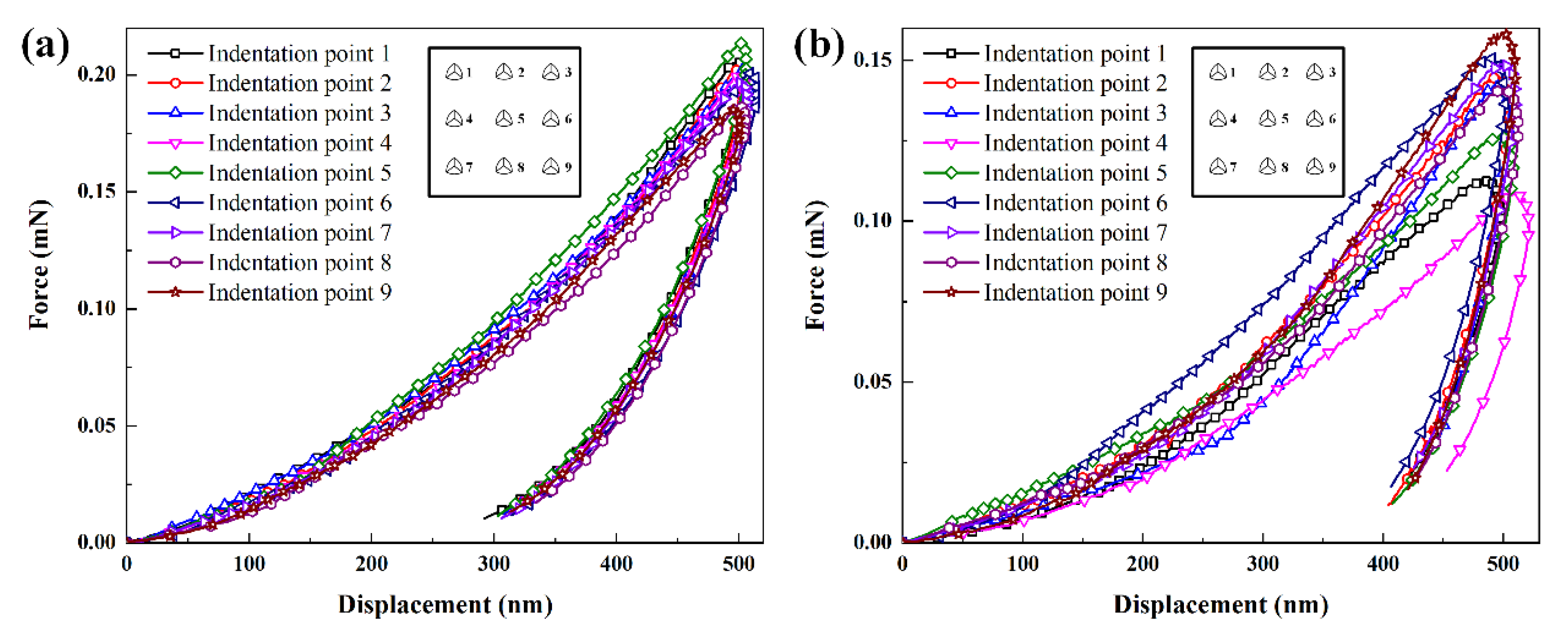

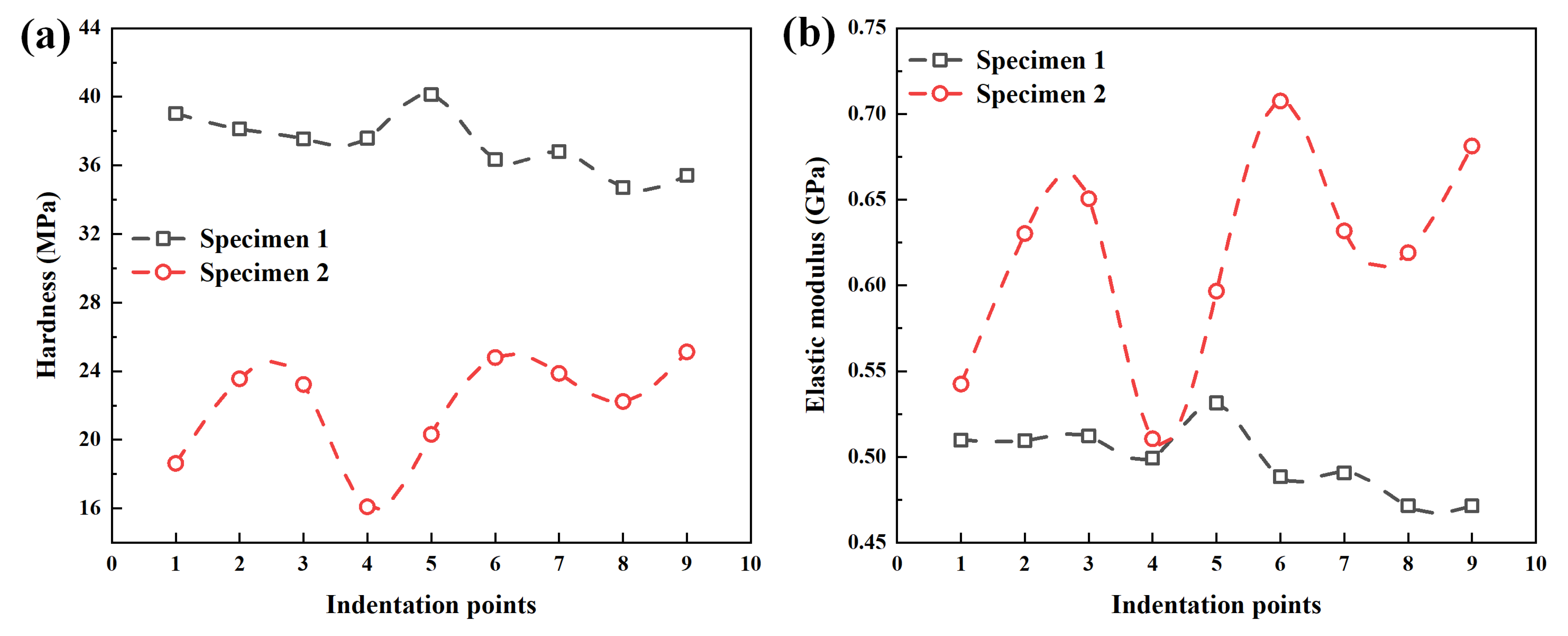

3.1. Nanoindentation Experiment Results

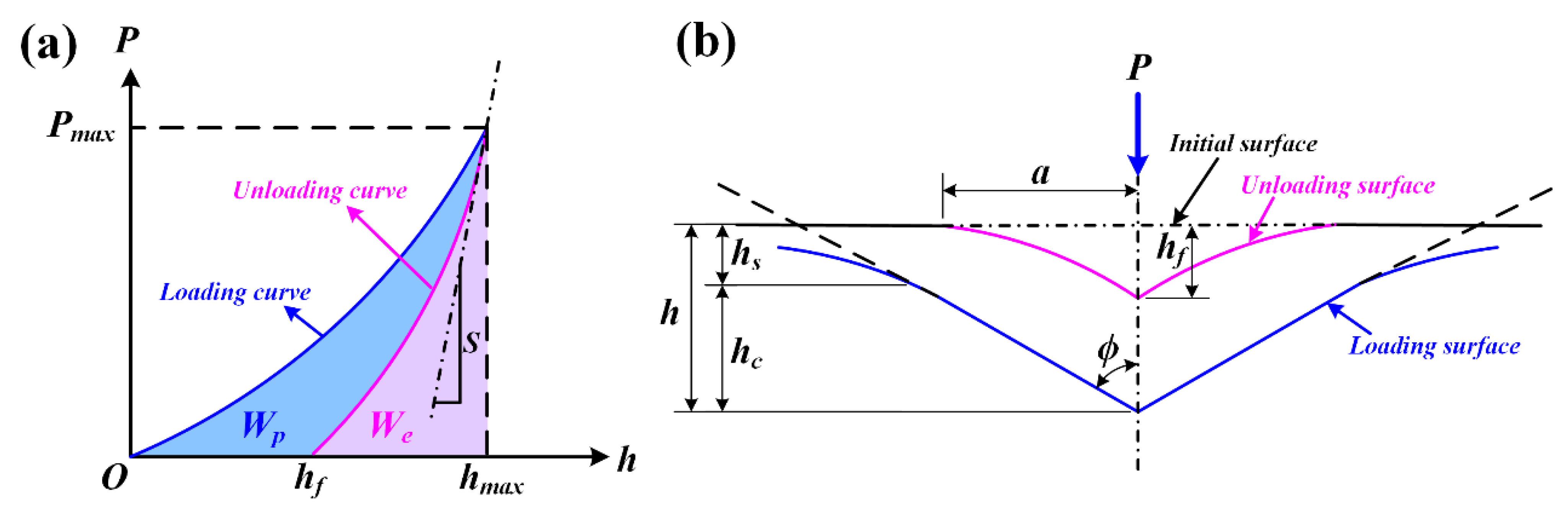

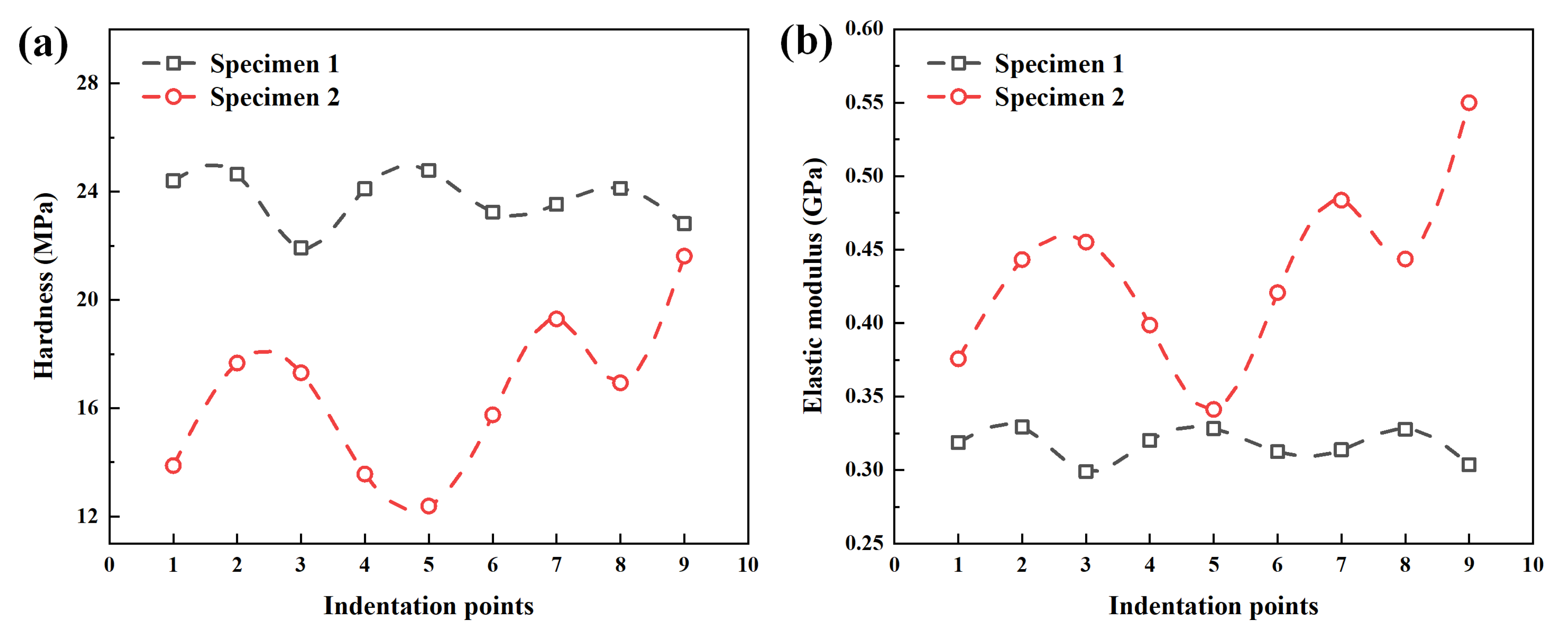

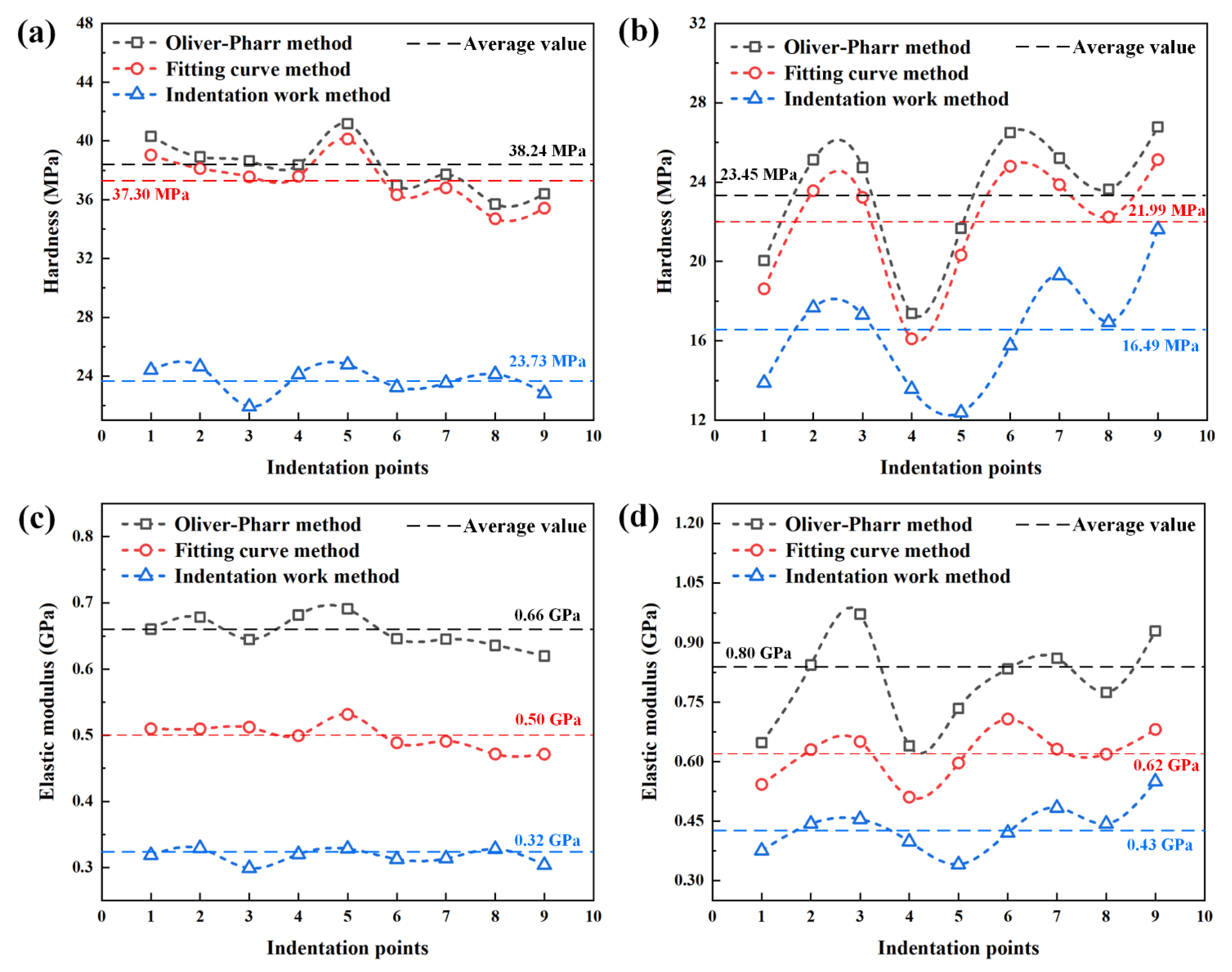

3.2. Mechanical Parameters Based on the Oliver–Pharr Method

3.3. Mechanical Parameters Based on the Indentation Work Method

3.4. Mechanical Parameters Based on the Fitting Curve Method

3.5. Comparison among Three Theoretical Methods

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Separators | No. | Fitting Exponential n | Final Indentation Depth hf (nm) | Maximum Indentation Depth hmax (nm) | Maximum Force pm (mn) | Contact Depth hc (nm) | Ratio hf/hm |

|---|---|---|---|---|---|---|---|

| PP/PE/PP | 1-1 | 1.58 | 292.38 | 503.84 | 0.21 | 428.43 | 0.58 |

| 1-2 | 1.58 | 308.67 | 504.04 | 0.20 | 431.90 | 0.61 | |

| 1-3 | 1.49 | 307.95 | 509.38 | 0.20 | 434.24 | 0.60 | |

| 1-4 | 1.62 | 313.19 | 505.02 | 0.20 | 434.74 | 0.62 | |

| 1-5 | 1.57 | 303.31 | 506.41 | 0.21 | 432.19 | 0.60 | |

| 1-6 | 1.61 | 314.43 | 514.63 | 0.20 | 441.55 | 0.61 | |

| 1-7 | 1.63 | 306.20 | 506.41 | 0.20 | 433.46 | 0.60 | |

| 1-8 | 1.65 | 334.32 | 505.59 | 0.19 | 435.14 | 0.66 | |

| 1-9 | 1.64 | 313.76 | 501.06 | 0.19 | 428.21 | 0.63 | |

| PE | 2-1 | 1.74 | 419.79 | 498.03 | 0.11 | 461.04 | 0.84 |

| 2-2 | 1.73 | 404.69 | 505.43 | 0.15 | 469.05 | 0.80 | |

| 2-3 | 2.31 | 446.05 | 505.59 | 0.14 | 473.64 | 0.88 | |

| 2-4 | 1.75 | 453.14 | 521.74 | 0.11 | 487.40 | 0.87 | |

| 2-5 | 1.44 | 407.92 | 508.47 | 0.13 | 471.92 | 0.80 | |

| 2-6 | 1.53 | 406.72 | 501.84 | 0.15 | 463.16 | 0.81 | |

| 2-7 | 1.86 | 425.45 | 510.10 | 0.15 | 473.60 | 0.83 | |

| 2-8 | 1.76 | 428.09 | 512.95 | 0.14 | 475.00 | 0.83 | |

| 2-9 | 1.93 | 421.01 | 510.26 | 0.16 | 474.36 | 0.83 |

| Separators | No. | Absolute Work Ws (pJ) | Total Work wt (pj) | Elastic Work we (pj) | Energy Constant ve | HOP (MPa) | HF (MPa) | HI (MPa) | EOP (GPa) | EF (GPa) | EI (GPa) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| PP/PE/PP | 1-1 | 103.54 | 40.15 | 15.37 | 6.74 | 40.30 | 39.04 | 24.41 | 0.66 | 0.51 | 0.32 |

| 1-2 | 101.92 | 39.00 | 14.59 | 6.99 | 38.91 | 38.12 | 24.64 | 0.68 | 0.51 | 0.33 | |

| 1-3 | 103.10 | 41.41 | 15.18 | 6.79 | 38.64 | 37.56 | 21.92 | 0.64 | 0.51 | 0.30 | |

| 1-4 | 100.90 | 38.73 | 14.58 | 6.92 | 38.36 | 37.59 | 24.11 | 0.68 | 0.50 | 0.32 | |

| 1-5 | 108.22 | 42.25 | 15.95 | 6.78 | 41.17 | 40.13 | 24.78 | 0.69 | 0.53 | 0.33 | |

| 1-6 | 103.39 | 39.77 | 14.79 | 6.99 | 36.98 | 36.33 | 23.24 | 0.65 | 0.49 | 0.31 | |

| 1-7 | 99.66 | 38.32 | 14.37 | 6.94 | 37.72 | 36.81 | 23.53 | 0.65 | 0.49 | 0.31 | |

| 1-8 | 94.44 | 35.00 | 12.88 | 7.33 | 35.70 | 34.71 | 24.12 | 0.64 | 0.47 | 0.33 | |

| 1-9 | 92.95 | 35.6 | 13.38 | 6.95 | 36.40 | 35.43 | 22.82 | 0.62 | 0.47 | 0.30 | |

| PE | 2-1 | 56.28 | 21.7 | 4.01 | 14.03 | 20.04 | 18.62 | 13.88 | 0.65 | 0.54 | 0.38 |

| 2-2 | 73.34 | 28.00 | 5.58 | 13.14 | 25.12 | 23.56 | 17.66 | 0.84 | 0.63 | 0.44 | |

| 2-3 | 72.55 | 27.82 | 5.29 | 13.72 | 24.74 | 23.23 | 17.31 | 0.97 | 0.65 | 0.46 | |

| 2-4 | 56.66 | 20.69 | 3.52 | 16.10 | 17.37 | 16.10 | 13.56 | 0.64 | 0.51 | 0.40 | |

| 2-5 | 64.32 | 27.22 | 4.94 | 13.02 | 21.66 | 20.32 | 12.39 | 0.73 | 0.60 | 0.34 | |

| 2-6 | 75.58 | 31.35 | 5.87 | 12.88 | 26.50 | 24.80 | 15.75 | 0.83 | 0.71 | 0.42 | |

| 2-7 | 75.90 | 27.82 | 5.55 | 13.68 | 25.21 | 23.87 | 19.30 | 0.86 | 0.63 | 0.48 | |

| 2-8 | 72.43 | 27.45 | 5.24 | 13.82 | 23.64 | 22.24 | 16.94 | 0.77 | 0.62 | 0.44 | |

| 2-9 | 80.98 | 28.95 | 5.69 | 14.23 | 26.78 | 25.13 | 21.62 | 0.93 | 0.68 | 0.55 |

References

- Liu, B.H.; Yin, S.; Xu, J. Integrated computation model of lithium-ion battery subject to nail penetration. Appl. Energy 2016, 183, 278–289. [Google Scholar] [CrossRef]

- Liu, B.H.; Zhao, H.; Yu, H.L.; Li, J.; Xu, J. Multiphysics computational framework for cylindrical lithium-ion batteries under mechanical abusive loading. Electrochim. Acta 2017, 256, 172–184. [Google Scholar] [CrossRef]

- Maia, B.A.; Magalhães, N.; Cunha, E.; Braga, M.H.; Santos, R.M.; Correia, N. Designing Versatile Polymers for Lithium-Ion Battery Applications: A Review. Polymers 2022, 14, 403. [Google Scholar] [CrossRef]

- Xie, J.M.; Hao, W.Q.; Wang, F.H. Parametric study on interfacial crack propagation in solid oxide fuel cell based on electrode material. Int. J. Hydrog. Energy 2022, 47, 7975–7989. [Google Scholar] [CrossRef]

- Hao, W.Q.; Xie, J.M.; Wang, F.H. The indentation analysis triggering internal short circuit of lithium-ion pouch battery based on shape function theory. Int. J. Energy Res. 2018, 42, 3696–3703. [Google Scholar] [CrossRef]

- Hao, W.Q.; Xie, J.M.; Bo, X.Q.; Wang, F.H. Resistance exterior force property of lithium-ion pouch batteries with different positive materials. Int. J. Energy Res. 2019, 43, 4976–4986. [Google Scholar] [CrossRef]

- Huang, W.Y.; Liao, Y.H.; Li, G.J.; He, Z.H.; Luo, X.H.; Li, W.S. Investigation on polyethylene supported poly(butyl methacrylate-acrylonitrile-styrene) terpolymer based gel electrolyte reinforced by doping nano-SiO2 for high voltage lithium ion battery. Electrochim. Acta 2017, 251, 145–154. [Google Scholar] [CrossRef]

- Zhu, K.; Gao, H.; Hu, G. A flexible mesoporous Li4Ti5O12-rGO nanocomposite film as free-standing anode for high rate lithium ion batteries. J. Power Sources 2018, 375, 59–67. [Google Scholar] [CrossRef]

- Zhu, K.; Gao, H.; Hu, G.; Liu, M.; Wang, H. Scalable synthesis of hierarchical hollow Li4Ti5O12 microspheres assembled by zigzag-like nanosheets for high rate lithium-ion batteries. J. Power Sources 2017, 340, 263–272. [Google Scholar] [CrossRef]

- Xiao, X.R.; Wu, W.; Huang, X.S. A multi-scale approach for the stress analysis of polymeric separators in a lithium-ion battery. J. Power Sources 2010, 195, 7649–7660. [Google Scholar] [CrossRef]

- Sheidaei, A.; Xiao, X.R.; Huang, X.S.; Hitt, J. Mechanical behavior of a battery separator in electrolyte solutions. J. Power Sources 2011, 196, 8728–8734. [Google Scholar] [CrossRef]

- Hao, W.Q.; Xie, J.M.; Wang, F.H. Theoretical prediction for large deflection with local indentation of sandwich beam under quasi-static lateral loading. Compos. Struct. 2018, 192, 206–216. [Google Scholar] [CrossRef]

- Hao, W.Q.; Xie, J.M. Reducing diffusion-induced stress of bilayer electrode system by introducing pre-strain in lithium-ion battery. J. Electrochem. Energy Conv. Stor. 2021, 18, 020909. [Google Scholar] [CrossRef]

- Shi, D.; Xiao, X.; Huang, X.; Kia, H. Modeling stresses in the separator of a pouch lithium-ion cell. J. Power Sources 2011, 196, 8129–8139. [Google Scholar] [CrossRef]

- Peabody, C.; Arnold, C.B. The role of mechanically induced separator creep in lithium-ion battery capacity fade. J. Power Sources 2011, 196, 8147–8153. [Google Scholar] [CrossRef]

- Cannarella, J.; Arnold, C.W. Ion transport restriction in mechanically strained separator membranes. J. Power Sources 2013, 226, 149–155. [Google Scholar] [CrossRef]

- Lam, C.K.; Chun, K.; Lau, K.T. Localized elastic modulus distribution of nanoclay/epoxy composites using nanoindentation. Compos. Struct. 2006, 75, 553–558. [Google Scholar] [CrossRef]

- Qian, H.; Kalinka, G.; Chan, K.A.; Kazarian, S.G.; Greenhalgh, E.S.; Bismarck, A.; Shaffer, M.S.P. Mapping local microstructure and mechanical performance around carbon nanotube grafted silica fibres: Methodologies for hierarchical composites. Nanoscale 2011, 3, 4759–4767. [Google Scholar] [CrossRef]

- Randall, N.X.; Vandamme, M.; Ulm, F.J. Nanoindentation analysis as a two-dimensional tool for mapping the mechanical properties of complex surfaces. J. Mater. Res. 2009, 24, 679–690. [Google Scholar] [CrossRef]

- Sanchez-Camargo, C.M.; Hor, A.; Salem, M.; Mabru, C. A robust method for mechanical characterization of heterogeneous materials by nanoindentation grid analysis. Mater. Des. 2020, 194, 108908. [Google Scholar] [CrossRef]

- Hardiman, M.; Vaughan, T.J.; McCarthy, T. A review of key developments and pertinent issues in nanoindentation testing of fibre reinforced plastic microstructures. Compos. Struct. 2017, 180, 782–798. [Google Scholar] [CrossRef]

- Stillwell, N.A.; Tabor, D. Elastic recovery of conical indentations. Proc. Roy. Soc. A Math. Phys. 1961, 78, 169–179. [Google Scholar] [CrossRef]

- Bhushan, B.; Li, X. Nanomechanical characterisation of solid surfaces and thin films. Int. Mater. Rev. 2003, 48, 125–164. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Bolshakov, A.; Pharr, G.M. Influences of pileup on the measurement of mechanical properties by load and depth sensing indentation techniques. J. Mater. Res. 1998, 13, 1049–1058. [Google Scholar] [CrossRef]

- Hardiman, M.; Vaughan, T.; McCarthy, C.T. The effect of fibre constraint in the nanoindentation of fibrous composite microstructures:a finite element investigation. Comput. Mater. Sci. 2012, 64, 162–167. [Google Scholar] [CrossRef]

- Tranchida, D.; Piccarolo, S.; Loos, J.; Alexeev, A. Mechanical characterization of polymers on a nanometer scale through nanoindentation. A study on pile-up and viscoelasticity. Macromolecules 2007, 40, 1259–1267. [Google Scholar] [CrossRef]

- Hardiman, M.; Vaughan, T.; McCarthy, C.T. The effects of pile-up, viscoelasticity and hydrostatic stress on polymer matrix nanoindentation. Polym. Test. 2016, 52, 157–166. [Google Scholar] [CrossRef]

- Lee, H.; Yanilmaz, M.; Toprakci, O.; Fu, K.; Zhang, X. A review of recent developments in membrane separators for rechargeable lithium-ion batteries. Energy. Environ. Sci. 2014, 7, 3857–3886. [Google Scholar] [CrossRef]

- Sarada, T.; Sawyer, L.C.; Ostler, M.I. Three dimensional structure of celgard® microporous membranes. J. Membr. Sci. 1983, 15, 97–113. [Google Scholar] [CrossRef]

- Celgard Product Literature. Available online: https://www.celgard.com/literature (accessed on 10 December 2017).

- Hao, W.; Kong, D.; Xie, J.; Chen, Y.; Ding, J.; Wang, F.; Xu, T. Self-polymerized dopamine nanoparticles modified separators for improving electrochemical performance and enhancing mechanical strength of lithium-ion batteries. Polymers 2020, 12, 648. [Google Scholar] [CrossRef] [PubMed]

- Hao, W.Q.; Xie, J.M.; Zhang, X.; Wang, P.; Wang, F.H. Strain rate effect and micro-buckling behavior of anisotropic macromolecular separator for lithium-ion battery. Express Polym. Lett. 2020, 14, 206–219. [Google Scholar] [CrossRef]

- Halalay, I.C.; Lukitsch, M.J. Nanoindentation testing of separators for lithium-ion batteries. J. Power Sources 2013, 238, 469–477. [Google Scholar] [CrossRef]

- ASTM E 2546-15; Standard Practice for Instrumented Indentation Testing. ASTM International: West Conshohocken, PA, USA, 2015.

- Pharr, G.M.; Bolshakov, A. Understanding nanoindentation unloading curves. J. Mater. Res. 2002, 17, 2660–2671. [Google Scholar] [CrossRef]

- Bravman, J.C.; Nix, W.D.; Barnett, D.M.; Smith, D.A. Thin Films: Stresses and Mechanical Properties V; Cambridge University Press: Cambridge, UK, 1995. [Google Scholar]

- Sneddon, N. The relation between load and penetration in the axisymmetric boussinesq problem for a punch of arbitrary profile. Int. J. Eng. Sci. 1965, 3, 47–57. [Google Scholar] [CrossRef]

- Woirgard, J.; Dargenton, J.C. An alternative method for penetration depth determination in nanoindentation measurements. J. Mater. Res. 1997, 12, 2455–2458. [Google Scholar] [CrossRef]

- Beegan, D.; Chowdhury, S.; Laugier, M.T. Work of indentation methods for determining copper film hardness. Surf. Coat. Technol. 2005, 192, 57–63. [Google Scholar] [CrossRef]

- Chollacoop, N.; Dao, M.; Suresh, S. Depth-sensing instrumented indentation with dual sharp indenters. Acta Mater. 2003, 51, 3713–3729. [Google Scholar] [CrossRef]

- Li, Y.G.; Kanouté, P.; François, M.; Chen, D.; Wang, H.W. Inverse identification of constitutive parameters with instrumented indentation test considering the normalized loading and unloading P-h curves. Int. J. Solids Struct. 2019, 156–157, 163–178. [Google Scholar] [CrossRef]

- Malzbender, J.; de With, G.; den Toonder, J. The P-h2 relationship in indentation. J. Mater. Res. 2000, 15, 1209–1212. [Google Scholar] [CrossRef]

- Tuck, J.R.; Korsunsky, A.M.; Bhat, D.G.; Bull, S.J. Indentation hardness evaluation of cathodic arc deposited thin hard coatings. Surf. Coat. Technol. 2001, 139, 63–74. [Google Scholar] [CrossRef]

- Tuck, J.R.; Korsunsky, A.M.; Davidson, R.I.; Bull, S.J.; Elliott, D.M. Modelling of the hardness of electroplated nickel coatings on copper substrates. Surf. Coat. Technol. 2000, 127, 1–8. [Google Scholar] [CrossRef]

- Tuck, J.R.; Korsunsky, A.M.; Bull, S.J.; Davidson, R.I. On the application of the work-of-indentation approach to depth-sensing indentation experiments in coated systems. Surf. Coat. Technol. 2001, 137, 217–224. [Google Scholar] [CrossRef]

| No. | Separators | Thickness (µm) | Permeability (s) | Porosity (%) | Pore Size (µm × µm) | Tensile Strength (MPa) | Puncture Strength (N) | Thermal Stability (Shrinkage) 90 °C/1 h (%) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| TD | MD | TD | MD | |||||||

| 1 | Tri-layer (PP/PE/PP) | 25 | 620 | 39 | 0.5 × 0.05 | 14.71 | 166.71 | >3.724 | 0 | <5 |

| 2 | Single-layer (PE) | 25 | 240 | 40 | 0.06 × 0.06 | 13.73 | 139.25 | >3.054 | 0 | <5 |

| Control Parameters | Data Acquisition Rate (Hz) | Maximum Linear Loading Depth (nm) | Loading Rate (nm/min) | Unloading Rate (nm/min) | Initial Contact Distance (nm) | Indenter Entrance Rate (nm/min) | Indenter Exit Rate (nm/min) | Stiffness Threshold (μN/μm) |

|---|---|---|---|---|---|---|---|---|

| Value | 10 | 500 | 1000 | 1000 | 2000 | 2500 | 2000 | 150 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hao, W.; Bo, X.; Xie, J.; Xu, T. Mechanical Properties of Macromolecular Separators for Lithium-Ion Batteries Based on Nanoindentation Experiment. Polymers 2022, 14, 3664. https://doi.org/10.3390/polym14173664

Hao W, Bo X, Xie J, Xu T. Mechanical Properties of Macromolecular Separators for Lithium-Ion Batteries Based on Nanoindentation Experiment. Polymers. 2022; 14(17):3664. https://doi.org/10.3390/polym14173664

Chicago/Turabian StyleHao, Wenqian, Xiqiao Bo, Jiamiao Xie, and Tingting Xu. 2022. "Mechanical Properties of Macromolecular Separators for Lithium-Ion Batteries Based on Nanoindentation Experiment" Polymers 14, no. 17: 3664. https://doi.org/10.3390/polym14173664

APA StyleHao, W., Bo, X., Xie, J., & Xu, T. (2022). Mechanical Properties of Macromolecular Separators for Lithium-Ion Batteries Based on Nanoindentation Experiment. Polymers, 14(17), 3664. https://doi.org/10.3390/polym14173664