Factors Affecting Mechanical Properties of Reinforced Bioplastics: A Review

Abstract

:1. Introduction of Bioplastics

2. Types of Bioplastics and Process of Moulding Different Types of Bioplastics

3. Mechanical Properties of Different Types of Bioplastics

3.1. Tensile Properties

3.2. Flexural Properties

3.3. Impact Properties

3.4. Hardness

4. Reinforcement Materials for Bioplastics

4.1. Inorganic Filler

4.2. Lignocellulosic Materials

4.3. Bacterial Cellulose

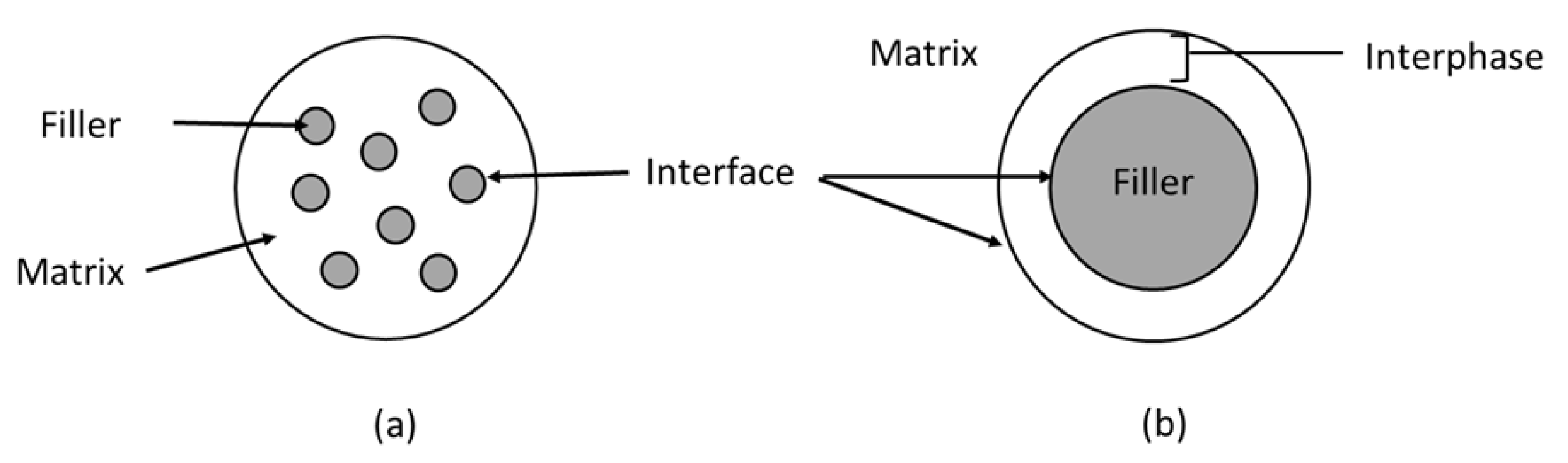

5. Mechanical Properties of Reinforced Bioplastics

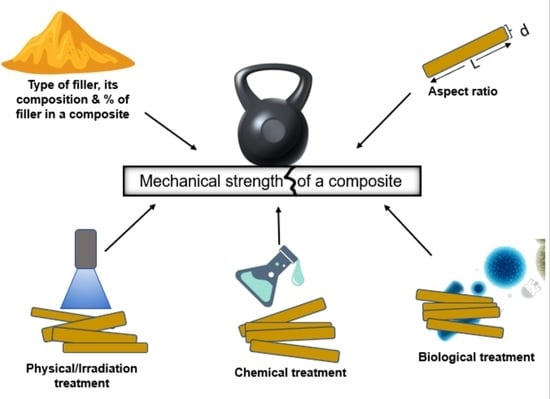

6. Factors Affecting the Mechanical Properties of Reinforced Bioplastics

6.1. Types of Fillers

6.2. Aspect Ratio

6.3. Percentage of Filler

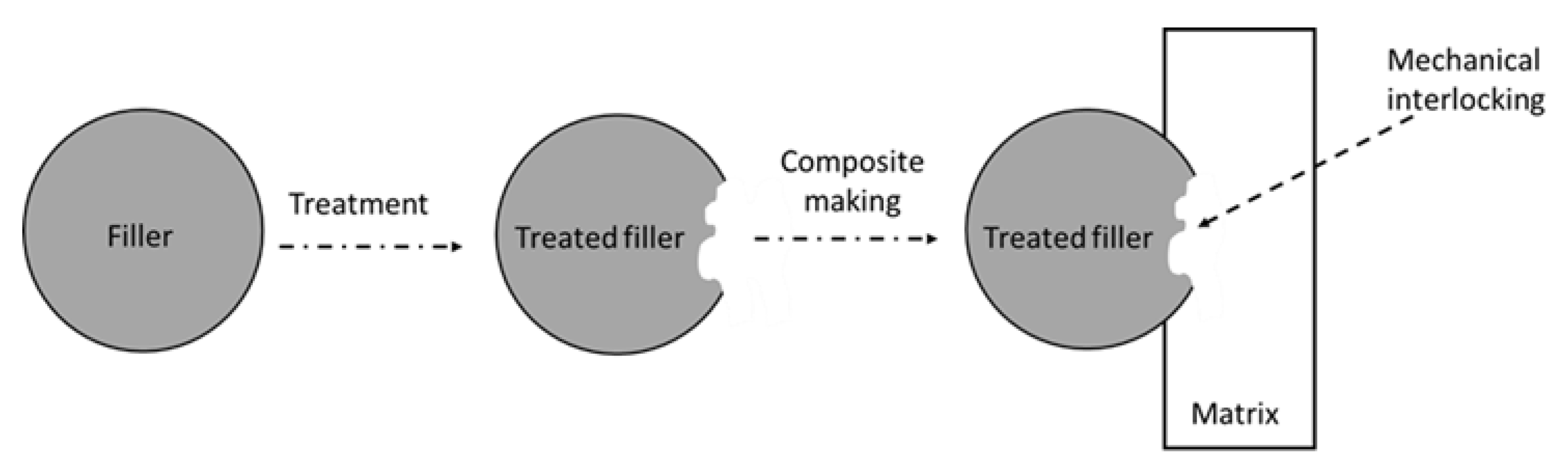

6.4. Types of Treatment for Reinforcement Materials

6.4.1. Physical Treatment

6.4.2. Chemical Treatment

6.4.3. Biological Treatment

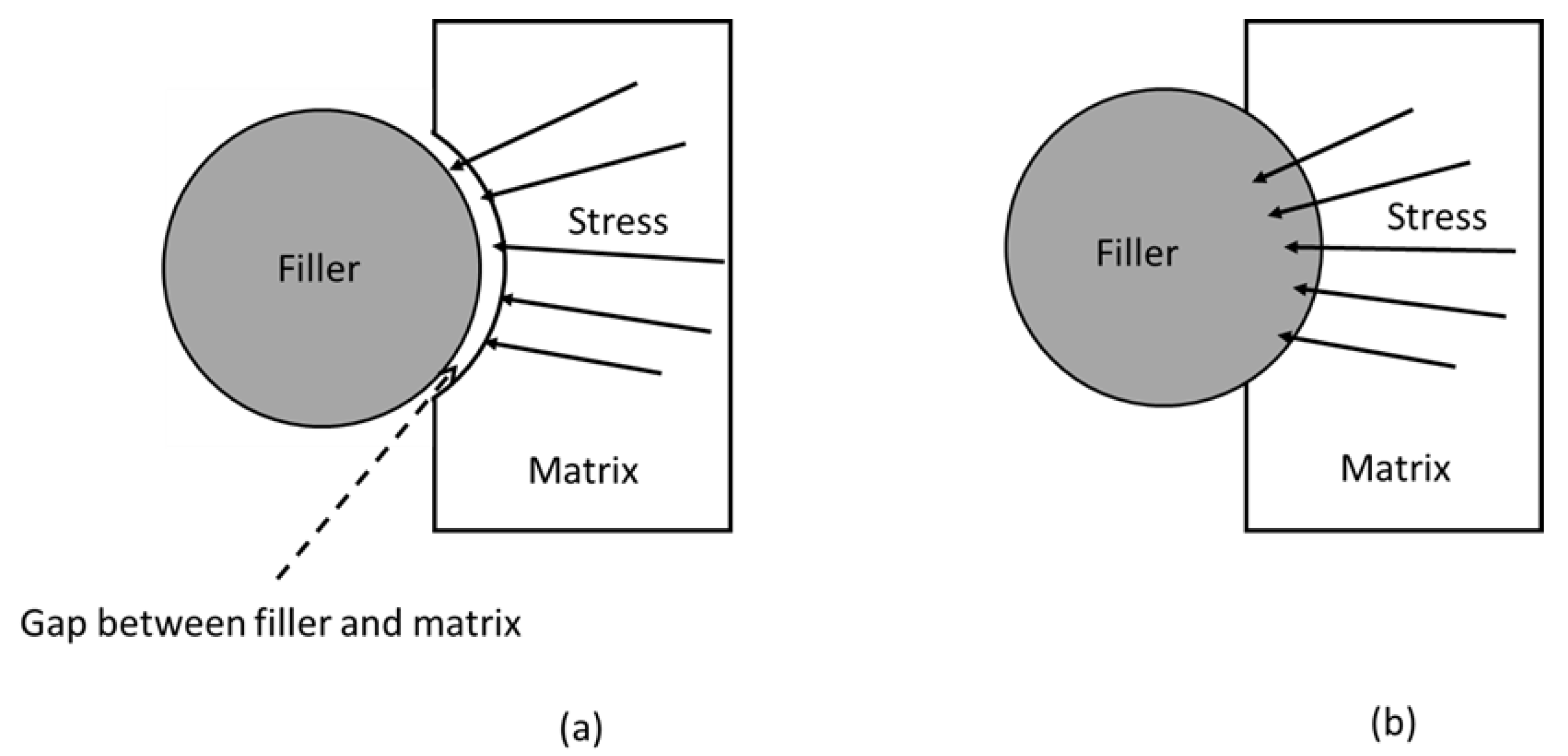

7. Effect of Filler Treatment on the Mechanical Properties

7.1. Physical Treatment

7.2. Chemical Treatment

7.3. Biological Treatment

8. Advantages and Disadvantages of Reinforced Bioplastics and Its Treatment

9. Applications of Reinforced Bioplastics

10. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Garrison, T.F.; Murawski, A.; Quirino, R.L. Bio-Based Polymers with Potential for Biodegradability. Polymers 2016, 8, 262. [Google Scholar] [CrossRef] [PubMed]

- Pudełko, A.; Postawa, P.; Stachowiak, T.; Malińska, K.; Dróżdż, D. Waste Derived Biochar as an Alternative Filler in Biocomposites-Mechanical, Thermal and Morphological Properties of Biochar Added Biocomposites. J. Clean. Prod. 2021, 278, 123850. [Google Scholar] [CrossRef]

- Ibrahim, N.I.; Shahar, F.S.; Sultan, M.T.H.; Shah, A.U.M.; Safri, S.N.A.; Mat Yazik, M.H. Overview of Bioplastic Introduction and Its Applications in Product Packaging. Coatings 2021, 11, 1423. [Google Scholar] [CrossRef]

- Burrola-Núñez, H.; Herrera-Franco, P.J.; Rodríguez-Félix, D.E.; Soto-Valdez, H.; Madera-Santana, T.J. Surface Modification and Performance of Jute Fibers as Reinforcement on Polymer Matrix: An Overview. J. Nat. Fibers 2019, 16, 944–960. [Google Scholar] [CrossRef]

- Latif, R.; Wakeel, S.; Khan, N.Z.; Noor Siddiquee, A.; Lal Verma, S.; Akhtar Khan, Z. Surface Treatments of Plant Fibers and Their Effects on Mechanical Properties of Fiber-Reinforced Composites: A Review. J. Reinf. Plast. Compos. 2018, 38, 15–30. [Google Scholar] [CrossRef]

- Sanivada, U.K.; Mármol, G.; Brito, F.P.; Fangueiro, R. PLA Composites Reinforced with Flax and Jute Fibers—A Review of Recent Trends, Processing Parameters and Mechanical Properties. Polymers 2020, 12, 2373. [Google Scholar] [CrossRef]

- Shahzad, A. 11-Mechanical Properties of Lignocellulosic Fiber Composites. In Lignocellulosic Fibre and Biomass-Based Composite Materials; Jawaid, M., Md Tahir, P., Saba, N., Eds.; Woodhead Publishing: Sawston, UK, 2017; pp. 193–223. ISBN 978-0-08-100959-8. [Google Scholar]

- Hubbe, M.A.; Lavoine, N.; Lucia, L.A.; Dou, C. Formulating Bioplastic Composites for Biodegradability, Recycling, and Performance: A Review. BioResources 2020, 16, 2021–2083. [Google Scholar] [CrossRef]

- Narancic, T.; Cerrone, F.; Beagan, N.; O’Connor, K.E. Recent Advances in Bioplastics: Application and Biodegradation. Polymers 2020, 12, 920. [Google Scholar] [CrossRef]

- Coppola, G.; Gaudio, M.T.; Lopresto, C.G.; Calabro, V.; Curcio, S.; Chakraborty, S. Bioplastic from Renewable Biomass: A Facile Solution for a Greener Environment. Earth Syst. Environ. 2021, 5, 231–251. [Google Scholar] [CrossRef]

- Reichert, C.L.; Bugnicourt, E.; Coltelli, M.B.; Cinelli, P.; Lazzeri, A.; Canesi, I.; Braca, F.; Martínez, B.M.; Alonso, R.; Agostinis, L.; et al. Bio-Based Packaging: Materials, Modifications, Industrial Applications and Sustainability. Polymers 2020, 12, 1558. [Google Scholar] [CrossRef]

- Nielsen, C.; Rahman, A.; Rehman, A.U.; Walsh, M.K.; Miller, C.D. Food Waste Conversion to Microbial Polyhydroxyalkanoates. Microb. Biotechnol. 2017, 10, 1338–1352. [Google Scholar] [CrossRef] [PubMed]

- Luyt, A.S.; Malik, S.S. 16-Can Biodegradable Plastics Solve Plastic Solid Waste Accumulation? In Plastics to Energy; Al-Salem, S.M., Ed.; William Andrew Publishing: Norwich, NY, USA, 2019; pp. 403–423. ISBN 978-0-12-813140-4. [Google Scholar]

- Loureiro, N.C.; Esteves, J.L.; Viana, J.C.; Ghosh, S. Mechanical Characterization of Polyhydroxyalkanoate and Poly(Lactic Acid) Blends. J. Thermoplast. Compos. Mater. 2013, 28, 195–213. [Google Scholar] [CrossRef]

- Obruca, S.; Petrik, S.; Benesova, P.; Svoboda, Z.; Eremka, L.; Marova, I. Utilization of Oil Extracted from Spent Coffee Grounds for Sustainable Production of Polyhydroxyalkanoates. Appl. Microbiol. Biotechnol. 2014, 98, 5883–5890. [Google Scholar] [CrossRef] [PubMed]

- Obruca, S.; Benesova, P.; Kucera, D.; Petrik, S.; Marova, I. Biotechnological Conversion of Spent Coffee Grounds into Polyhydroxyalkanoates and Carotenoids. New Biotechnol. 2015, 32, 569–574. [Google Scholar] [CrossRef]

- Stavroula, K.; Simos, M.; Katherine-Joanne, H. Polyhydroxyalkanoates (PHAs) from Household Food Waste: Research Over the Last Decade. Int. J. Biotechnol. Bioeng. 2020, 6, 26–36. [Google Scholar]

- Jiang, T.; Duan, Q.; Zhu, J.; Liu, H.; Yu, L. Starch-Based Biodegradable Materials: Challenges and Opportunities. Adv. Ind. Eng. Polym. Res. 2020, 3, 8–18. [Google Scholar] [CrossRef]

- Collazo-Bigliardi, S.; Ortega-Toro, R.; Boix, A.C. Reinforcement of Thermoplastic Starch Films with Cellulose Fibres Obtained from Rice and Coffee Husks. J. Renew. Mater. 2018, 6, 599–610. [Google Scholar] [CrossRef]

- Sisti, L.; Celli, A.; Totaro, G.; Cinelli, P.; Signori, F.; Lazzeri, A.; Bikaki, M.; Corvini, P.; Ferri, M.; Tassoni, A.; et al. Monomers, Materials and Energy from Coffee By-Products: A Review. Sustainability 2021, 13, 6921. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef]

- Cui, X.; Gu, G.; Li, C.; Liu, N.; Gong, Y.; Liu, B. Synthesis and Properties of Biomass Eugenol-Functionalized Isotactic Poly(1-Butene)s. Polymer 2020, 202, 122739. [Google Scholar] [CrossRef]

- Su, S.; Kopitzky, R.; Tolga, S.; Kabasci, S. Polylactide (PLA) and Its Blends with Poly(Butylene Succinate) (PBS): A Brief Review. Polymers 2019, 11, 1193. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Aydemir, D.; Gardner, D.J. Biopolymer Blends of Polyhydroxybutyrate and Polylactic Acid Reinforced with Cellulose Nanofibrils. Carbohydr. Polym. 2020, 116867. [Google Scholar] [CrossRef] [PubMed]

- Omar, L.; Zambrano-robledo, P.; Reyes-osorio, L.A.; Garza, C. Mechanical Characterisation of a Bamboo Fibre/Polylactic Acid Composite Produced by Fused Deposition Modelling. J. Reinf. Plast. Compos. 2020, 39, 932–944. [Google Scholar] [CrossRef]

- Pickering, K.L.; Efendy, M.G.A.; Le, T.M. A Review of Recent Developments in Natural Fibre Composites and Their Mechanical Performance. Compos. Part Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Zwawi, M. A Review on Natural Fiber Bio-Composites, Surface Modifications and Applications. Molecules 2021, 26, 404. [Google Scholar] [CrossRef] [PubMed]

- Sandhu, S.S.; Singh, R. Comparative Analysis of Polymer Matrix Composites Processed by Injection and Compression Molding. Int. J. Emerg. Technol. Innov. Res. 2018, 5, 790–810. [Google Scholar]

- Sapuan, S.M. Chapter 3-Composite Materials. In Composite Materials; Sapuan, S.M., Ed.; Butterworth-Heinemann: Boston, MA, USA, 2017; pp. 57–93. ISBN 978-0-12-802507-9. [Google Scholar]

- Shubhra, Q.T.H.; Alam, A.K.M.M.; Quaiyyum, M.A. Mechanical Properties of Polypropylene Composites: A Review. J. Thermoplast. Compos. Mater. 2013, 26, 362–391. [Google Scholar] [CrossRef]

- Rajak, D.K.; Wagh, P.H.; Linul, E. Manufacturing Technologies of Carbon/Glass Fiber-Reinforced Polymer Composites and Their Properties: A Review. Polymers 2021, 13, 3721. [Google Scholar] [CrossRef]

- Balla, V.K.; Kate, K.H.; Satyavolu, J.; Singh, P.; Tadimeti, J.G.D. Additive Manufacturing of Natural Fiber Reinforced Polymer Composites: Processing and Prospects. Compos. Part B Eng. 2019, 174, 106956. [Google Scholar] [CrossRef]

- Advani, S.G. 2.2 Role of Process Models in Composites Manufacturing. Compr. Compos. Mater. II 2018, 24–41. [Google Scholar] [CrossRef]

- Gallos, A.; Paës, G.; Allais, F.; Beaugrand, J. Lignocellulosic Fibers: A Critical Review of the Extrusion Process for Enhancement of the Properties of Natural Fiber Composites. RSC Adv. 2017, 7, 34638–34654. [Google Scholar] [CrossRef]

- Jamshidian, M.; Tehrany, E.A.; Imran, M.; Jacquot, M.; Desobry, S. Poly-Lactic Acid: Production, Applications, Nanocomposites, and Release Studies. Compr. Rev. Food Sci. Food Saf. 2010, 9, 552–571. [Google Scholar] [CrossRef] [PubMed]

- Shesan, O.J.; Stephen, A.C.; Chioma, A.G.; Neerish, R.; Rotimi, S.E. Improving the Mechanical Properties of Natural Fiber Composites for Structural and Biomedical Applications. In Renewable and Sustainable Composites; Agwuncha, C.S., Ed.; IntechOpen: Rijeka, Croatia, 2019; ISBN 978-1-78984-216-6. [Google Scholar]

- Sadasivuni, K.K.; Saha, P.; Adhikari, J.; Deshmukh, K.; Ahamed, M.B.; Cabibihan, J.J. Recent Advances in Mechanical Properties of Biopolymer Composites: A Review. Polym. Compos. 2019, 41, 32–59. [Google Scholar] [CrossRef]

- Long, S.; Zhong, L.; Lin, X.; Chang, X.; Wu, F.; Wu, R.; Xie, F. Preparation of Formyl Cellulose and Its Enhancement Effect on the Mechanical and Barrier Properties of Polylactic Acid Films. Int. J. Biol. Macromol. 2021, 172, 82–92. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.; Chen, Z.; Smith, L.M.; Hong, G.; Song, W.; Zhang, S. Polypyrrole-Modified Bamboo Fiber/Polylactic Acid with Enhanced Mechanical, the Antistatic Properties and Thermal Stability. Ind. Crops Prod. 2021, 162, 113227. [Google Scholar] [CrossRef]

- García-García, D.; Carbonell, A.; Samper, M.D.; García-Sanoguera, D.; Balart, R. Green Composites Based on Polypropylene Matrix and Hydrophobized Spend Coffee Ground (SCG) Powder. Compos. Part B Eng. 2015, 78, 256–265. [Google Scholar] [CrossRef]

- Moon, R.J.; Martini, A.; Nairn, J.; Simonsen, J.; Youngblood, J. Cellulose Nanomaterials Review: Structure, Properties and Nanocomposites. Chem. Soc. Rev. 2011, 40, 3941–3994. [Google Scholar] [CrossRef]

- Vishnu Vardhini, K.J.; Murugan, R.; Surjit, R. Effect of Alkali and Enzymatic Treatments of Banana Fibre on Properties of Banana/Polypropylene Composites. J. Ind. Text. 2018, 47, 1849–1864. [Google Scholar] [CrossRef]

- Aaliya, B.; Sunooj, K.V.; Lackner, M. Biopolymer Composites: A Review. Int. J. Biobased Plast. 2021, 3, 40–84. [Google Scholar] [CrossRef]

- Youssef, A.M.; Hasanin, M.S.; Abd El-Aziz, M.E.; Darwesh, O.M. Green, Economic, and Partially Biodegradable Wood Plastic Composites via Enzymatic Surface Modification of Lignocellulosic Fibers. Heliyon 2019, 5, e01332. [Google Scholar] [CrossRef]

- Chaari, R.; Khlif, M.; Mallek, H.; Bradai, C.; Lacoste, C.; Belguith, H.; Tounsi, H.; Dony, P. Enzymatic Treatments Effect on the Poly (Butylene Succinate)/Date Palm Fibers Properties for Bio-Composite Applications. Ind. Crops Prod. 2020, 148, 112270. [Google Scholar] [CrossRef]

- Kenned, J.J.; Sankaranarayanasamy, K.; Kumar, C.S. Chemical, Biological, and Nanoclay Treatments for Natural Plant Fiber-Reinforced Polymer Composites: A Review. Polym. Polym. Compos. 2021, 29, 1011–1038. [Google Scholar] [CrossRef]

- Hemanth, R.; Sekar, M.; Suresha, B. Effects of Fibers and Fillers on Mechanical Properties of Thermoplastic Composites. Indian J. Adv. Chem. Sci. 2014, 2, 28–35. [Google Scholar]

- Sathishkumar, T.P.; Naveen, J.; Satheeshkumar, S. Hybrid Fiber Reinforced Polymer Composites-A Review. J. Reinf. Plast. Compos. 2014, 33, 454–471. [Google Scholar] [CrossRef]

- Liu, W.; Ma, J.; Yao, X.; Fang, R. Inorganic Fibers for Biomedical Engineering Applications. In Materials for Biomedical Engineering: Bioactive Materials, Properties, and Applications; Grumezescu, V., Grumezescu, A.M., Eds.; Elsevier: Oxford, UK, 2019; pp. 1–32. [Google Scholar] [CrossRef]

- Ishikawa, T.; Oda, H. Heat-Resistant Inorganic Fibers. In Advances in High Temperature Ceramic Matrix Compo sites and Materials for Sustainable Development; Ceramic Transactions, Volume CCLXIII; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2017; pp. 7–18. ISBN 978-1-119-40727-0. [Google Scholar]

- Chihaoui, B.; Serra-Parareda, F.; Tarrés, Q.; Espinach, F.X.; Boufi, S.; Delgado-Aguilar, M. Effect of the Fiber Treatment on the Stiffness of Date Palm Fiber Reinforced PP Composites: Macro and Micromechanical Evaluation of the Young’s Modulus. Polymers 2020, 12, 1693. [Google Scholar] [CrossRef]

- Kahl, C.; Gemmeke, N.; Bagnucki, J.; Heim, H.P. Investigations on Fiber–Matrix Properties of Heat-Treated and UV-Treated Regenerated Cellulose Fibers. Compos. Part Appl. Sci. Manuf. 2022, 152, 106669. [Google Scholar] [CrossRef]

- Moustafa, H.; Guizani, C.; Dufresne, A. Sustainable Biodegradable Coffee Grounds Filler and Its Effect on the Hydrophobicity, Mechanical and Thermal Properties of Biodegradable PBAT Composites. J. Appl. Polym. Sci. 2016, 134. [Google Scholar] [CrossRef]

- Sun, S.; Sun, S.; Cao, X.; Sun, R. The Role of Pretreatment in Improving the Enzymatic Hydrolysis of Lignocellulosic Materials. Bioresour. Technol. 2016, 199, 49–58. [Google Scholar] [CrossRef]

- Saha, P.; Chowdhury, S.; Roy, D.; Adhikari, B.; Kim, J.K.; Thomas, S. A Brief Review on the Chemical Modifications of Lignocellulosic Fibers for Durable Engineering Composites. Polym. Bull. 2016, 73, 587–620. [Google Scholar] [CrossRef]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Chemical Treatments on Plant-Based Natural Fibre Reinforced Polymer Composites: An Overview. Compos. Part B 2012, 43, 2883–2892. [Google Scholar] [CrossRef]

- Nwamba, M.C.; Sun, F.; Mukasekuru, M.R.; Song, G.; Harindintwali, J.D.; Boyi, S.A.; Sun, H. Trends and Hassles in the Microbial Production of Lactic Acid from Lignocellulosic Biomass. Environ. Technol. Innov. 2021, 21, 101337. [Google Scholar] [CrossRef]

- Ahmad, R.; Hamid, R.; Osman, S.A. Physical and Chemical Modifications of Plant Fibres for Reinforcement in Cementitious Composites. Adv. Civ. Eng. 2019, 2019, 5185806. [Google Scholar] [CrossRef]

- Nanni, A.; Cancelli, U.; Montevecchi, G.; Masino, F.; Messori, M.; Antonelli, A. Functionalization and Use of Grape Stalks as Poly(Butylene Succinate) (PBS) Reinforcing Fillers. Waste Manag. 2021, 126, 538–548. [Google Scholar] [CrossRef] [PubMed]

- Azeredo, H.M.C.; Barud, H.; Farinas, C.S.; Vasconcellos, V.M.; Claro, A.M. Bacterial Cellulose as a Raw Material for Food and Food Packaging Applications. Front. Sustain. Food Syst. 2019, 3, 7. [Google Scholar] [CrossRef]

- Swingler, S.; Gupta, A.; Gibson, H.; Kowalczuk, M.; Heaselgrave, W.; Radecka, I. Recent Advances and Applications of Bacterial Cellulose in Biomedicine. Polymers 2021, 13, 412. [Google Scholar] [CrossRef]

- Wang, B.; Lin, F.; Li, X.; Ji, X.; Liu, S.; Han, X.; Yuan, Z.; Luo, J. Transcrystallization of Isotactic Polypropylene/Bacterial Cellulose Hamburger Composite. Polymers 2019, 11, 508. [Google Scholar] [CrossRef]

- Wang, B.; Yang, D.; Zhang, H.; Huang, C.; Xiong, L.; Luo, J.; Chen, X. Preparation of Esterified Bacterial Cellulose for Improved Mechanical Properties and the Microstructure of Isotactic Polypropylene/Bacterial Cellulose Composites. Polymers 2016, 8, 129. [Google Scholar] [CrossRef]

- Mohammed, L.; Ansari, M.N.M.; Pua, G.; Jawaid, M.; Islam, M.S. A Review on Natural Fiber Reinforced Polymer Composite and Its Applications. Int. J. Polym. Sci. 2015, 2015, 243947. [Google Scholar] [CrossRef]

- Nasir, M.; Hashim, R.; Sulaiman, O.; Nordin, N.A.; Lamaming, J.; Asim, M. Laccase, an Emerging Tool to Fabricate Green Composites: A Review. BioResources 2015, 10, 6262–6284. [Google Scholar] [CrossRef]

- Rozman, H.D.; Tay, G.S.; Abubakar, A.; Kumar, R.N. Tensile Properties of Oil Palm Empty Fruit Bunch–Polyurethane Composites. Eur. Polym. J. 2001, 37, 1759–1765. [Google Scholar] [CrossRef]

- Jiménez, A.M.; Espinach, F.X.; Delgado-Aguilar, M.; Reixach, R.; Quintana, G.; Fullana-i-Palmer, P.; Mutjè, P. Starch-Based Biopolymer Reinforced with High Yield Fibers from Sugarcane Bagasse as a Technical and Environmentally Friendly Alternative to High Density Polyethylene. BioResources 2016, 11, 9856–9868. [Google Scholar] [CrossRef]

- Totaro, G.; Sisti, L.; Fiorini, M.; Lancellotti, I.; Andreola, F.N.; Saccani, A. Formulation of Green Particulate Composites from PLA and PBS Matrix and Wastes Deriving from the Coffee Production. J. Polym. Environ. 2019, 27, 1488–1496. [Google Scholar] [CrossRef]

- Baek, B.S.; Park, J.W.; Lee, B.H.; Kim, H.J. Development and Application of Green Composites: Using Coffee Ground and Bamboo Flour. J. Polym. Environ. 2013, 21, 702–709. [Google Scholar] [CrossRef]

- Kumar, A.; Tumu, V.R. Physicochemical Properties of the Electron Beam Irradiated Bamboo Powder and Its Bio-Composites with PLA. Compos. Part B Eng. 2019, 175, 107098. [Google Scholar] [CrossRef]

- George, M.; Mussone, P.G.; Alemaskin, K.; Chae, M.; Wolodko, J.; Bressler, D.C. Enzymatically Treated Natural Fibres as Reinforcing Agents for Biocomposite Material: Mechanical, Thermal, and Moisture Absorption Characterization. J. Mater. Sci. 2015, 51, 2677–2686. [Google Scholar] [CrossRef]

- Lule, Z.C.; Kim, J. Properties of Economical and Eco-Friendly Polybutylene Adipate Terephthalate Composites Loaded with Surface Treated Coffee Husk. Compos. Part Appl. Sci. Manuf. 2021, 140, 106154. [Google Scholar] [CrossRef]

- de Farias, J.G.G.; Cavalcante, R.C.; Canabarro, B.R.; Viana, H.M.; Scholz, S.; Simão, R.A. Surface Lignin Removal on Coir Fibers by Plasma Treatment for Improved Adhesion in Thermoplastic Starch Composites. Carbohydr. Polym. 2017, 165, 429–436. [Google Scholar] [CrossRef]

- Murthy, P.S.; Madhava Naidu, M. Sustainable Management of Coffee Industry By-Products and Value Addition-A Review. Resour. Conserv. Recycl. 2012, 66, 45–58. [Google Scholar] [CrossRef]

- Jia, W.; Gong, R.H.; Hogg, P.J. Poly (Lactic Acid) Fibre Reinforced Biodegradable Composites. Compos. Part B Eng. 2014, 62, 104–112. [Google Scholar] [CrossRef]

- Karaduman, Y.; Gokcan, D.; Onal, L. Effect of Enzymatic Pretreatment on the Mechanical Properties of Jute Fiber-Reinforced Polyester Composites. J. Compos. Mater. 2012, 47, 1293–1302. [Google Scholar] [CrossRef]

- Sahu, G.; Rajput, M.S.; Mahapatra, S.P. Polylactic Acid Nanocomposites for Biomedical Applications: Effects of Calcium Phosphate, and Magnesium Phosphate Nanoparticles Concentration. Plast. Rubber Compos. 2021, 50, 228–240. [Google Scholar] [CrossRef]

- Ragoubi, M.; George, B.; Molina, S.; Bienaimé, D.; Merlin, A.; Hiver, J.M.; Dahoun, A. Effect of Corona Discharge Treatment on Mechanical and Thermal Properties of Composites Based on Miscanthus Fibres and Polylactic Acid or Polypropylene Matrix. Compos. Part Appl. Sci. Manuf. 2012, 43, 675–685. [Google Scholar] [CrossRef]

- Gibeop, N.; Lee, D.W.; Prasad, C.V.; Toru, F.; Kim, B.S.; Song, J.I. Effect of Plasma Treatment on Mechanical Properties of Jute Fiber/Poly (Lactic Acid) Biodegradable Composites. Adv. Compos. Mater. 2013, 22, 389–399. [Google Scholar] [CrossRef]

- De Prez, J.; Van Vuure, A.W.; Ivens, J.; Aerts, G.; Van de Voorde, I. Enzymatic Treatment of Flax for Use in Composites. Biotechnol. Rep. 2018, 20, e00294. [Google Scholar] [CrossRef]

- Loureiro, N.C.; Esteves, J.L.; Viana, J.C.; Ghosh, S. Development of Polyhydroxyalkanoates/Poly(Lactic Acid) Composites Reinforced with Cellulosic Fibers. Compos. Part B Eng. 2014, 60, 603–611. [Google Scholar] [CrossRef]

- Ravindran, R.; Jaiswal, A.K. A Comprehensive Review on Pre-Treatment Strategy for Lignocellulosic Food Industry Waste: Challenges and Opportunities. Bioresour. Technol. 2016, 199, 92–102. [Google Scholar] [CrossRef]

- Saritha, M.; Arora, A. Lata Biological Pretreatment of Lignocellulosic Substrates for Enhanced Delignification and Enzymatic Digestibility. Indian J. Microbiol. 2012, 52, 122–130. [Google Scholar] [CrossRef]

- Bozaci, E.; Sever, K.; Sarikanat, M.; Seki, Y.; Demir, A.; Ozdogan, E.; Tavman, I. Effects of the Atmospheric Plasma Treatments on Surface and Mechanical Properties of Flax Fiber and Adhesion between Fiber-Matrix for Composite Materials. Compos. Part B Eng. 2013, 45, 565–572. [Google Scholar] [CrossRef]

- Ricciardi, M.R.; Papa, I.; Coppola, G.; Lopresto, V.; Sansone, L.; Antonucci, V. Effect of Plasma Treatment on the Impact Behavior of Epoxy/Basalt Fiber-Reinforced Composites: A Preliminary Study. Polymers 2021, 13, 1293. [Google Scholar] [CrossRef]

- Amirou, S.; Zerizer, A.; Haddadou, I.; Merlin, A. Effects of Corona Discharge Treatment on the Mechanical Properties of Biocomposites from Polylactic Acid and Algerian Date Palm Fibres. Sci. Res. Essays 2013, 8, 946–952. [Google Scholar] [CrossRef]

- Lee, C.H.; Khalina, A.; Lee, S.H. Importance of Interfacial Adhesion Condition on Characterization of Plant-Fiber-Reinforced Polymer Composites: A Review. Polymers 2021, 13, 438. [Google Scholar] [CrossRef] [PubMed]

- Boonsuk, P.; Sukolrat, A.; Bourkaew, S.; Kaewtatip, K.; Chantarak, S.; Kelarakis, A.; Chaibundit, C. Structure-Properties Relationships in Alkaline Treated Rice Husk Reinforced Thermoplastic Cassava Starch Biocomposites. Int. J. Biol. Macromol. 2021, 167, 130–140. [Google Scholar] [CrossRef] [PubMed]

- Werchefani, M.; Lacoste, C.; Belguith, H.; Gargouri, A.; Bradai, C. Effect of Chemical and Enzymatic Treatments of Alfa Fibers on Polylactic Acid Bio-Composites Properties. J. Compos. Mater. 2020, 54, 4959–4967. [Google Scholar] [CrossRef]

- Essabir, H.; Raji, M.; Laaziz, S.A.; Rodrique, D.; Bouhfid, R.; Qaiss, A. el kacem Thermo-Mechanical Performances of Polypropylene Biocomposites Based on Untreated, Treated and Compatibilized Spent Coffee Grounds. Compos. Part B Eng. 2018, 149, 1–11. [Google Scholar] [CrossRef]

- Geremew, A.; De Winne, P.; Demissie, T.A.; De Backer, H. Treatment of Natural Fiber for Application in Concrete Pavement. Adv. Civ. Eng. 2021, 2021. [Google Scholar] [CrossRef]

- Khoshnava, S.M.; Rostami, R.; Ismai, M.; Valipour, A. The Using Fungi Treatment as Green and Environmentally Process for Surface Modification of Natural Fibres. Appl. Mech. Mater. 2014, 554, 116–122. [Google Scholar] [CrossRef]

- Jayasekara, S.; Ratnayake, R. Microbial Cellulases: An Overview and Applications. In Cellulose; IntechOpen: London, UK, 2019. [Google Scholar]

- Pickering, K.L.; Li, Y.; Farrell, R.L.; Lay, M. Interfacial Modification of Hemp Fiber Reinforced Composites Using Fungal and Alkali Treatment. J. Biobased Mater. Bioenergy 2007, 1, 109–117. [Google Scholar] [CrossRef]

- Sindhu, R.; Binod, P.; Pandey, A. Biological Pretreatment of Lignocellulosic Biomass-An Overview. Bioresour. Technol. 2016, 199, 76–82. [Google Scholar] [CrossRef]

- Dong, A.; Fan, X.; Wang, Q.; Yu, Y.; Cavaco-Paulo, A. Enzymatic Treatments to Improve Mechanical Properties and Surface Hydrophobicity of Jute Fiber Membranes. BioResources 2016, 11, 3289–3302. [Google Scholar] [CrossRef]

- Bendourou, F.E.; Suresh, G.; Laadila, M.A.; Kumar, P.; Rouissi, T.; Dhillon, G.S.; Zied, K.; Brar, S.K.; Galvez, R. Feasibility of the Use of Different Types of Enzymatically Treated Cellulosic Fibres for Polylactic Acid (PLA) Recycling. Waste Manag. 2021, 121, 237–247. [Google Scholar] [CrossRef]

- Fitch-Vargas, P.R.; Camacho-Hernández, I.L.; Martínez-Bustos, F.; Islas-Rubio, A.R.; Carrillo-Cañedo, K.I.; Calderón-Castro, A.; Jacobo-Valenzuela, N.; Carrillo-López, A.; Delgado-Nieblas, C.I.; Aguilar-Palazuelos, E. Mechanical, Physical and Microstructural Properties of Acetylated Starch-Based Biocomposites Reinforced with Acetylated Sugarcane Fiber. Carbohydr. Polym. 2019, 219, 378–386. [Google Scholar] [CrossRef] [PubMed]

- Siqueira, D.D.; Luna, C.B.B.; Ferreira, E.S.B.; Araújo, E.M.; Wellen, R.M.R. Tailored PCL/Macaíba Fiber to Reach Sustainable Biocomposites. J. Mater. Res. Technol. 2020, 9, 9691–9708. [Google Scholar] [CrossRef]

- Lule, Z.C.; Kim, J. Compatibilization Effect of Silanized SiC Particles on Polybutylene Adipate Terephthalate/Polycarbonate Blends. Mater. Chem. Phys. 2021, 258, 123879. [Google Scholar] [CrossRef]

- Tanjung, F.A.; Arifin, Y.; Husseinsyah, S. Enzymatic Degradation of Coconut Shell Powder–Reinforced Polylactic Acid Biocomposites. J. Thermoplast. Compos. Mater. 2018, 33, 800–816. [Google Scholar] [CrossRef]

- Zhuo, G.; Zhang, X.; Jin, X.; Wang, M.; Yang, X.; Li, S. Effect of Different Enzymatic Treatment on Mechanical, Water Absorption and Thermal Properties of Bamboo Fibers Reinforced Poly(Hydroxybutyrate-Co-Valerate) Biocomposites. J. Polym. Environ. 2020, 28, 2377–2385. [Google Scholar] [CrossRef]

- Thakur, K.; Kalia, S. Enzymatic Modification of Ramie Fibers and Its Influence on the Performance of Ramie-Poly(Butylene Succinate) Biocomposites. Int. J. Plast. Technol. 2017, 21, 209–226. [Google Scholar] [CrossRef]

- Jha, K.; Kataria, R.; Verma, J.; Pradhan, S. Potential Biodegradable Matrices and Fiber Treatment for Green Composites: A Review. AIMS Mater. Sci. 2019, 6, 119–138. [Google Scholar] [CrossRef]

- Wang, B.; Mao, S.; Lin, F.; Zhang, M.; Zhao, Y.; Zheng, X.; Wang, H.; Luo, J. Interfacial Compatibility on the Crystal Transformation of Isotactic Poly (1-Butene)/Herb Residue Composite. Polymers 2021, 13, 1654. [Google Scholar] [CrossRef]

- Wang, B.; Lin, F.; Zhao, Y.; Li, X.; Liu, Y.; Li, J.; Han, X.-J.; Liu, S.; Ji, X.; Luo, J.; et al. Isotactic Polybutene-1/Bamboo Powder Composites with Excellent Properties at Initial Stage of Molding. Polymers 2019, 11, 1981. [Google Scholar] [CrossRef]

- Thyavihalli Girijappa, Y.G.; Mavinkere Rangappa, S.; Parameswaranpillai, J.; Siengchin, S. Natural Fibers as Sustainable and Renewable Resource for Development of Eco-Friendly Composites: A Comprehensive Review. Front. Mater. 2019, 6, 226. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites Reinforced with Natural Fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Zhao, X.; Cornish, K.; Vodovotz, Y. Narrowing the Gap for Bioplastic Use in Food Packaging: An Update. Environ. Sci. Technol. 2020, 54, 4712–4732. [Google Scholar] [CrossRef] [PubMed]

- Zarrinbakhsh, N.; Wang, T.; Rodriguez-Uribe, A.; Misra, M.; Mohanty, A.K. Characterization of Wastes and Coproducts from the Coffee Industry for Composite Material Production. BioResources 2016, 11, 7637–7653. [Google Scholar] [CrossRef]

- Chen, G.-Q. Introduction of Bacterial Plastics PHA, PLA, PBS, PE, PTT, and PPP. In Plastics from Bacteria; Chen, G.G.-Q., Ed.; Microbiology Monographs; Springer: Berlin/Heidelberg, Germany, 2010; Volume 14, pp. 1–16. ISBN 978-3-642-03286-8. [Google Scholar]

- Jin, L.S.; Salimi, M.N.; Kamal, S.Z. Optimization of Pretreatment and Enzymatic Hydrolysis of Spent Coffee Ground for the Production of Fermentable Sugar. IOP Conf. Ser. Mater. Sci. Eng. 2020, 743, 012030. [Google Scholar] [CrossRef]

- Kalia, S.; Vashistha, S. Surface Modification of Sisal Fibers (Agave Sisalana) Using Bacterial Cellulase and Methyl Methacrylate. J. Polym. Environ. 2012, 20, 142–151. [Google Scholar] [CrossRef]

- Kopparthy, S.D.S.; Netravali, A.N. Review: Green Composites for Structural Applications. Compos. Part C Open Access 2021, 6. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Harussani, M.M.; Aisyah, H.A.; Ilyas, R.A.; Norrrahim, M.N.F.; Khalina, A.; Abdullah, N. Treatments of Natural Fiber as Reinforcement in Polymer Composites—a Short Review. Funct. Compos. Struct. 2021, 3, 024002. [Google Scholar] [CrossRef]

- Burgos, N.; Armentano, I.; Fortunati, E.; Dominici, F.; Luzi, F.; Fiori, S.; Cristofaro, F.; Visai, L.; Jiménez, A.; Kenny, J.M. Functional Properties of Plasticized Bio-Based Poly(Lactic Acid)_Poly(Hydroxybutyrate) (PLA_PHB) Films for Active Food Packaging. Food Bioprocess Technol. 2017, 10, 770–780. [Google Scholar] [CrossRef]

- Luzi, F.; Fortunati, E.; Jiménez, A.; Puglia, D.; Pezzolla, D.; Gigliotti, G.; Kenny, J.M.; Chiralt, A.; Torre, L. Production and Characterization of PLA_PBS Biodegradable Blends Reinforced with Cellulose Nanocrystals Extracted from Hemp Fibres. Ind. Crops Prod. Prod. 2016, 93, 276–289. [Google Scholar] [CrossRef]

- Papadopoulou, E.L.; Paul, U.C.; Tran, T.N.; Suarato, G.; Ceseracciu, L.; Marras, S.; D’arcy, R.; Athanassiou, A. Sustainable Active Food Packaging from Poly(Lactic Acid) and Cocoa Bean Shells. ACS Appl. Mater. Interfaces 2019, 11, 31317–31327. [Google Scholar] [CrossRef]

- Moustafa, H.; Guizani, C.; Dupont, C.; Martin, V.; Jeguirim, M.; Dufresne, A. Utilization of Torrefied Coffee Grounds as Reinforcing Agent to Produce High-Quality Biodegradable PBAT Composites for Food Packaging Applications. ACS Sustain. Chem. Eng. 2017, 5, 1906–1916. [Google Scholar] [CrossRef]

| Treatment Type | Method | Filler | Matrix | Fabrication Method | Mechanical Performance | References |

|---|---|---|---|---|---|---|

| Plasma treatment | Jute fibre | PLA | Injection moulding | Plasma polymerised jute fibre composites exhibited an increment in tensile strength, Young’s modulus, and flexural strength up to 28, 17, and 20%, respectively. The IFSS of plasma polymerised jute fibre composites exhibited a significant increase of 90% more than untreated fibre, with a value of 6.84 MPa. | [79] | |

| Physical treatment | Plasma treatment | Coir fibre | TPS | Compression moulding | Oxygen plasma with stronger etching was more influential in all conditions compared to air plasma, with the composite’s tensile strength and elastic modulus increased by up to 300% and 2000%, respectively. | [73] |

| Corona treatment | Miscanthus fibre | PLA | Extrusion- compression moulding | Lower fibre content (20% and 30%) increased Young’s modulus more than the greater fibre content (40%). | [78] | |

| Corona treatment | Date palm fibre | PLA | Extrusion- compression moulding | Significant improvement in tensile strength and Young’s modulus with 30% reinforcement of treated palm fibres in PLA, achieving the highest elastic modulus compared to untreated reinforcements and the PLA matrix. | [86] | |

| Electron beam irradiation | Bamboo powder | PLA | Injection moulding | The PLA/EBP5/ES 5phr composite demonstrated a 12% increase in notched impact strength over pure PLA. | [70] | |

| Chemical treatment | NaOH alkali treatment | Alfa fibre | PLA | Injection moulding | The tensile strength and Young’s modulus of the composite were strengthened by 17% and 45%, respectively, when 20 wt% NaOH-treated alfa fibres were included. | [89] |

| NaOH alkali treatment | Rice husk | TPS | Compression moulding | The composites developed from alkaline-treated RH at a 20 wt% concentration gave the highest tensile strength by a factor of 220%. | [88] | |

| Acetylation | Sugarcane fibre | TPS | Extrusion | The addition of AcSF to the composite mixture increased the product’s tensile strength while decreasing its water affinity. | [98] | |

| Acetylation and silanisation | Grape stalk powder | PBS | Injection moulding | Treated biocomposites showed better tensile properties than the control polymer. Acetylated GS powder gave the maximum improvement in Young’s modulus from 616 MPa to 732 MPa. | [59] | |

| Maleic anhydride, NaOH alkali, and salinisation | Palm fibre (Macaíba) | PCL | Injection moulding | PCL composites with 15% and 20% MA treated MF showed the highest elastic modulus among all the samples. MA treatment presented the best mechanical performance, whereas NaOH treatment resulted in the worst. | [99] | |

| Silanisation | Coffee husk | PBAT | Melt extrusion | The addition of 40 wt% silane-treated CH increased the composite’s mechanical properties (tensile strength, Young’s modulus, and elongation at break) as compared to the 40 wt% untreated CH-reinforced PBAT composite. | [72] | |

| Silanisation | Silicon carbide | PBAT/PC | Solution casting and melt extrusion | The PBAT/PC composite with T-SiC showed a substantial enhancement in tensile strength and Young’s modulus, with a reasonable drop in ductility. | [100] | |

| Maleic acid and silanisation | Coconut shell powder | PLA | Compression moulding | The treated composite’s tensile strength and Young’s modulus increased after the CS surface-treated with maleic acid and 3-APE coupling agent but had lower elongation at break. | [101] | |

| NaOH alkali treatment | Jute fibre | PLA | Injection moulding | Jute fibres treated with 5% NaOH concentration have good interaction with the PLA matrix, resulting in an improvement in tensile strength. | [79] | |

| Biological treatment | Xylanase and pectinase enzymatic treatments | Alfa fibre | PLA | Injection moulding | The tensile strength of PLA/xylanase and PLA/pectinase composite samples is increased by ≈22% and ≈27%, respectively, when compared to that of unmodified samples. | [89] |

| Xylanase and pectinase enzymatic treatments | Date palm fibre | PBS | Injection moulding | The combined action of two enzymes (xylanase and pectinase) gave the highest tensile modulus of reinforced composites (1600 MPa). | [45] | |

| Pectinase, laccase, and cellulase enzymatic treatments | Bamboo fibre | PHBV | Injection moulding | The values of tensile strength, impact strength, flexural strength, and flexural modulus were greatest for pectinase-treated bamboo fibre/PHBV composite. | [102] | |

| Cellulase enzymatic treatment | Ramie fibre | PBS | Compression moulding | The tensile and flexural strength of treated fibre reinforced biocomposites increased as the fibre concentration increased (0.5% to 1%). | [103] |

| Property/Natural Fibre | Bagasse | Bamboo | Cotton | Coir | Jute | Ramie | Oil Palm |

|---|---|---|---|---|---|---|---|

| Density (g/cm3) | 1.25 | 0.6–1.1 | 1.5–1.6 | 1.2–1.5 | 1.3–1.5 | 1.5 | 0.7–1.55 |

| Tensile strength (MPa) | 222–290 | 140–800 | 287–800 | 140–180 | 200–773 | 400–938 | 248 |

| Young’s modulus (GPa) | 17 | 11–17 | 5.5–13 | 4–6 | 10–55 | 61.4–128 | 3.2 |

| Elongation at break (%) | 1.1 | 1.4 | 7–8 | 30 | 1.5–1.8 | 3.6–3.8 | 25 |

| Property/Polymer | PLA | PHA | PBS | PP | PET | PS |

|---|---|---|---|---|---|---|

| Density (g/cm3) | 1.24 | 1.25 | 1.26 | 0.91 | 1.3–1.4 | 1.05 |

| Tensile strength (MPa) | 37–66 | 20–40 | 30–35 | 15–27 | 55–79 | 24–60 |

| Flexural modulus (MPa) | 2392–4930 | 1280–3668 | - | 850–1050 | 1000–2300 | 2100–3000 |

| Young’s modulus (GPa) | 2.7 | 2.95 | 0.27 | 0.95–1.77 | 2–4 | 3.4 |

| Elongation at break (%) | 0.5–9.2 | 1.4–5.5 | 8–13 | 100–600 | 15–165 | 1.6–2.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boey, J.Y.; Lee, C.K.; Tay, G.S. Factors Affecting Mechanical Properties of Reinforced Bioplastics: A Review. Polymers 2022, 14, 3737. https://doi.org/10.3390/polym14183737

Boey JY, Lee CK, Tay GS. Factors Affecting Mechanical Properties of Reinforced Bioplastics: A Review. Polymers. 2022; 14(18):3737. https://doi.org/10.3390/polym14183737

Chicago/Turabian StyleBoey, Jet Yin, Chee Keong Lee, and Guan Seng Tay. 2022. "Factors Affecting Mechanical Properties of Reinforced Bioplastics: A Review" Polymers 14, no. 18: 3737. https://doi.org/10.3390/polym14183737

APA StyleBoey, J. Y., Lee, C. K., & Tay, G. S. (2022). Factors Affecting Mechanical Properties of Reinforced Bioplastics: A Review. Polymers, 14(18), 3737. https://doi.org/10.3390/polym14183737