Effect of Aggregate Size on the Axial Compressive Behavior of FRP-Confined Coral Aggregate Concrete

Abstract

:1. Introduction

2. Experimental Program

2.1. Design and Preparation of the Specimens

2.2. Material Properties

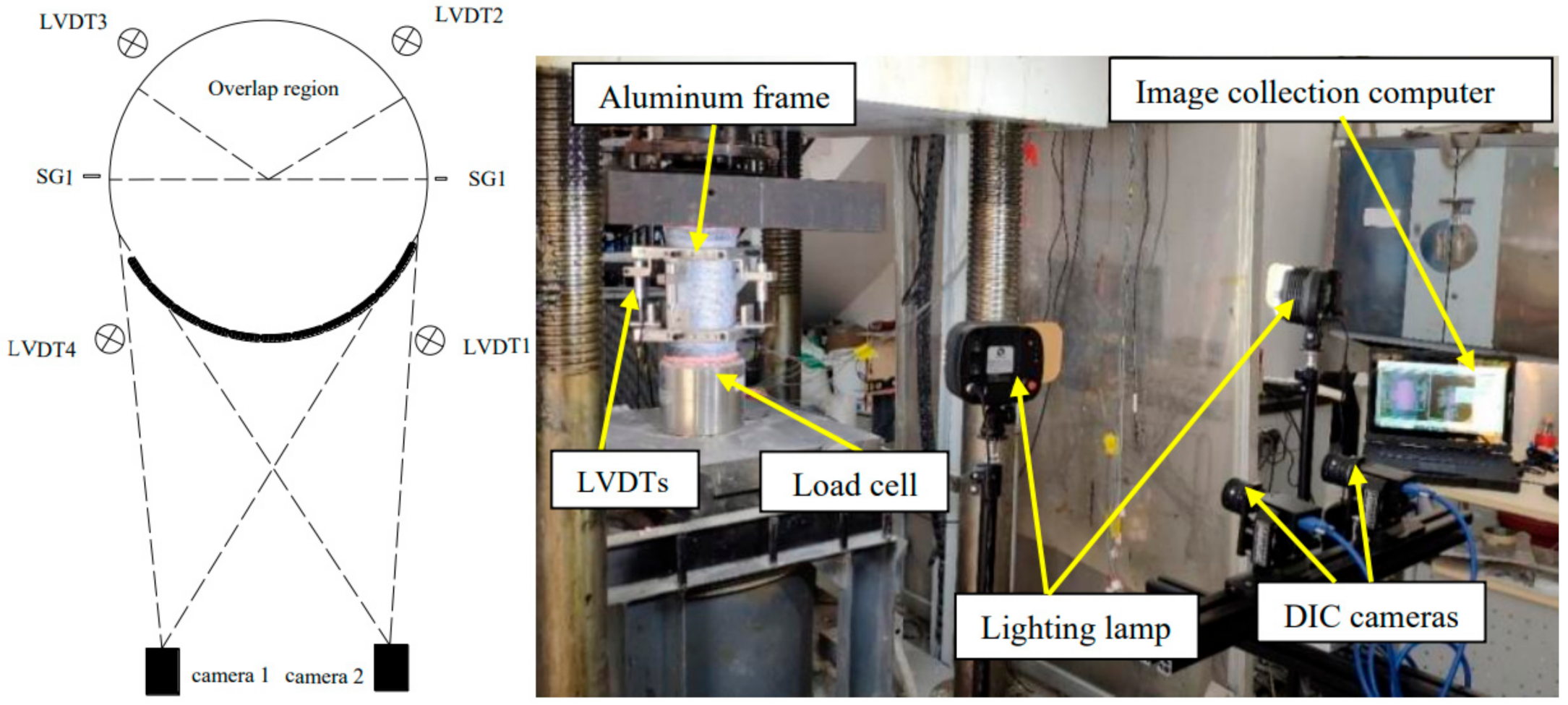

2.3. Testing and Instrumentation

3. Experimental Results and Discussions

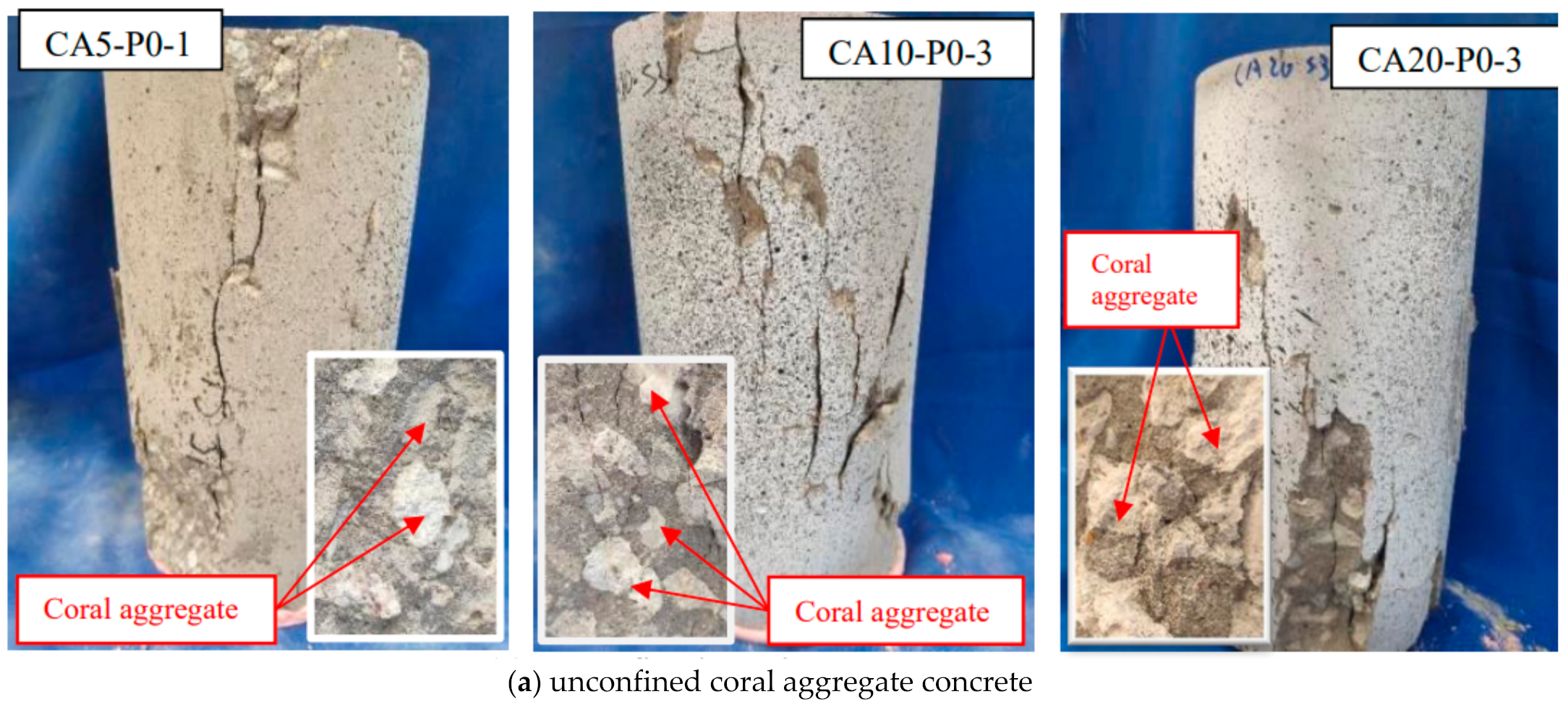

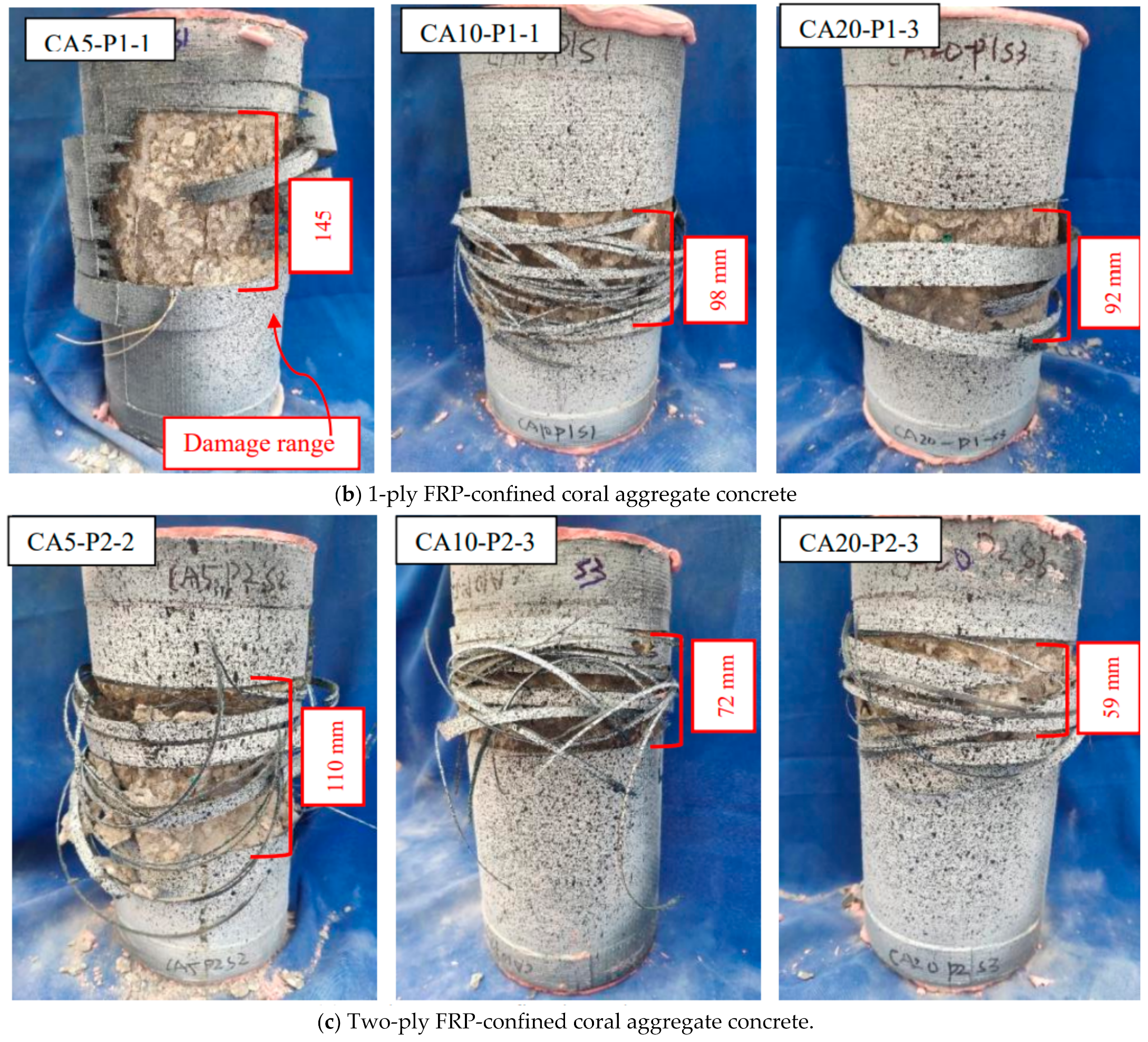

3.1. Failure Modes

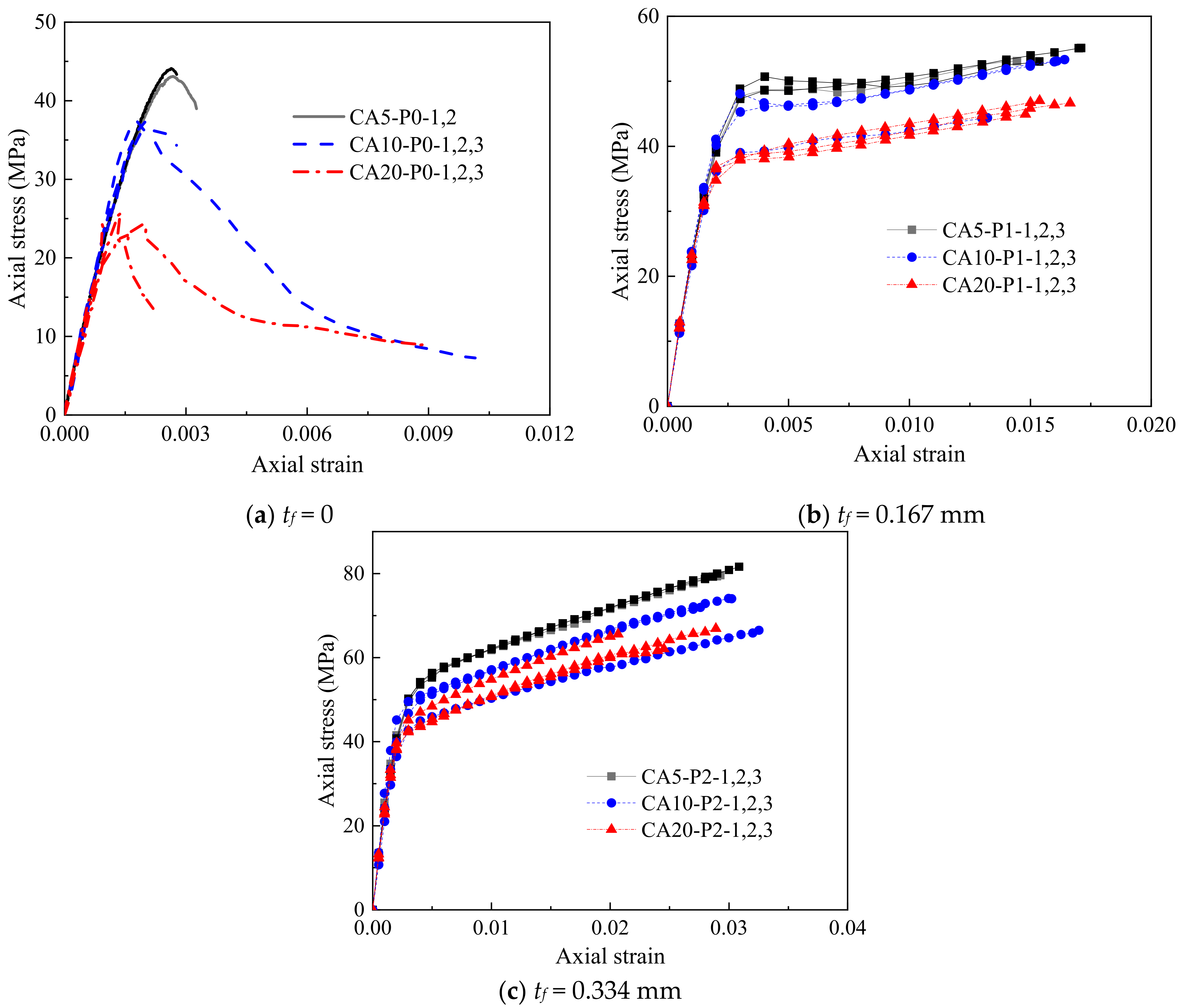

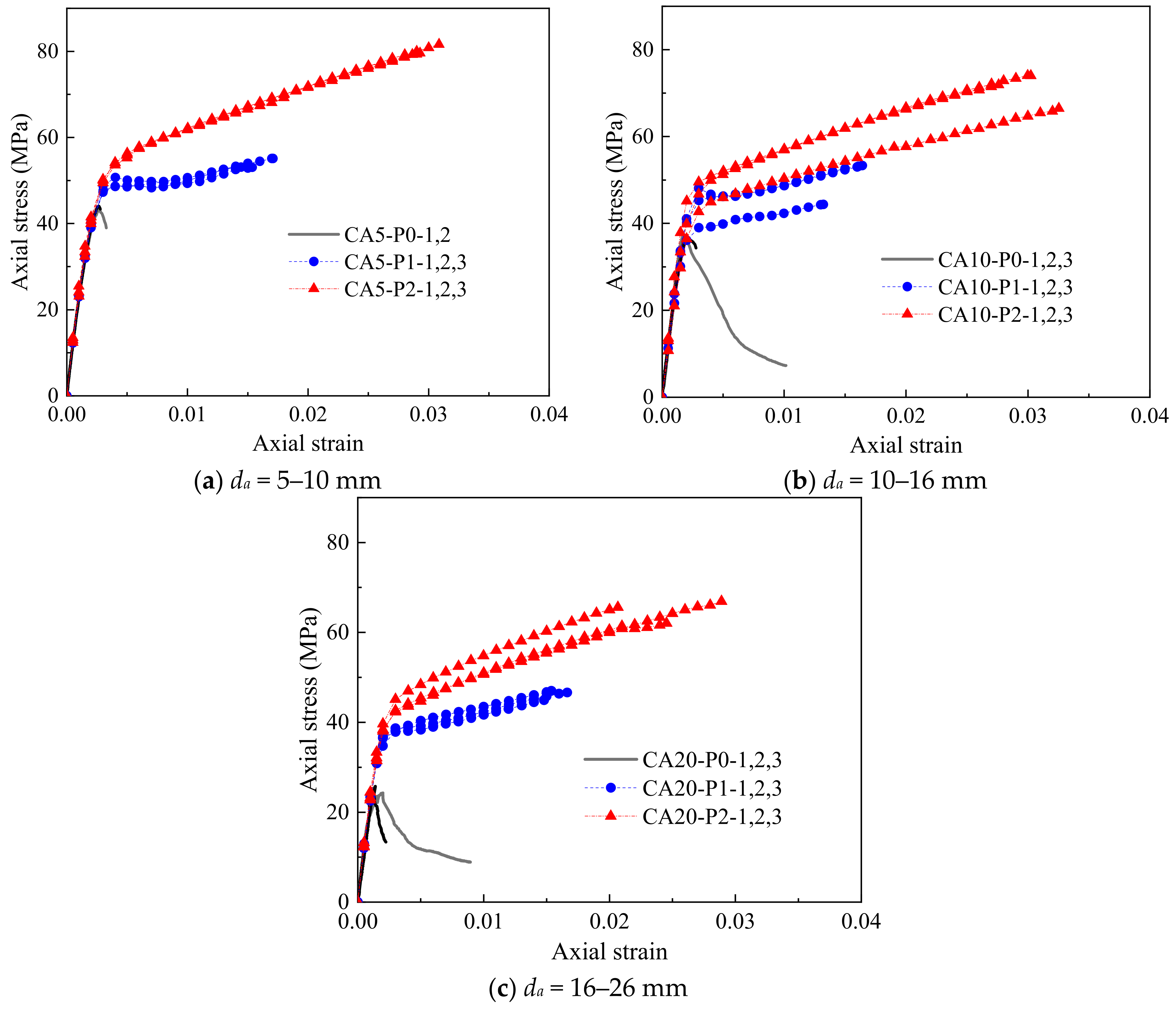

3.2. Stress–Strain Behavior

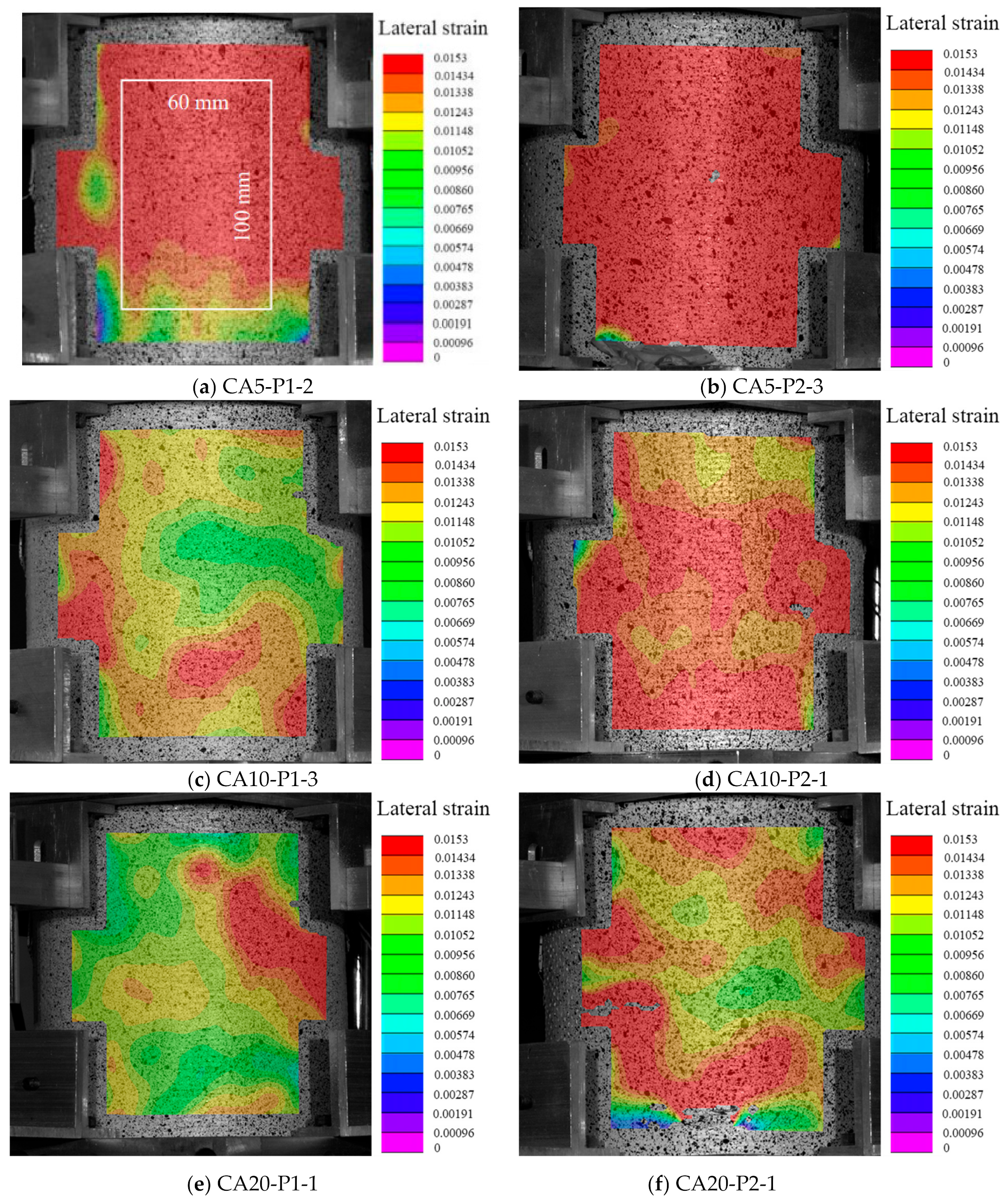

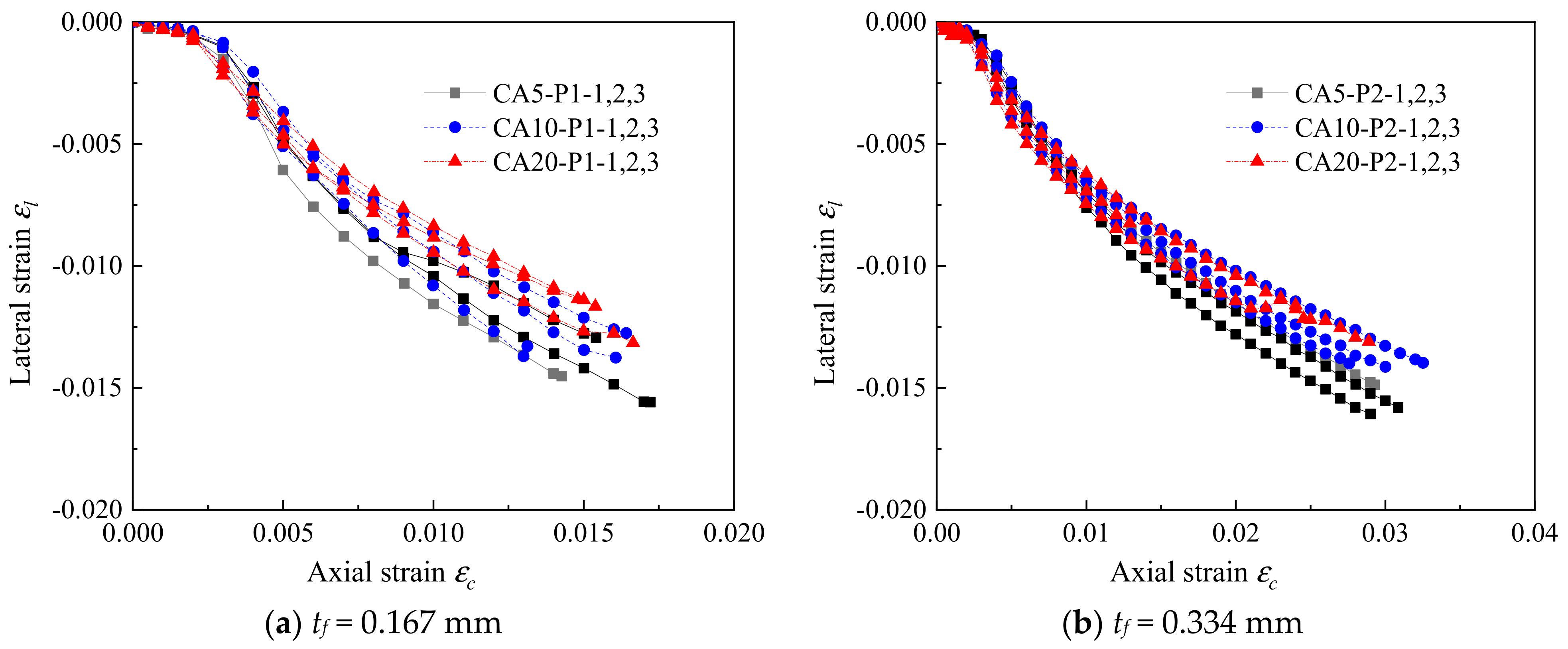

3.3. Lateral Strain Distribution

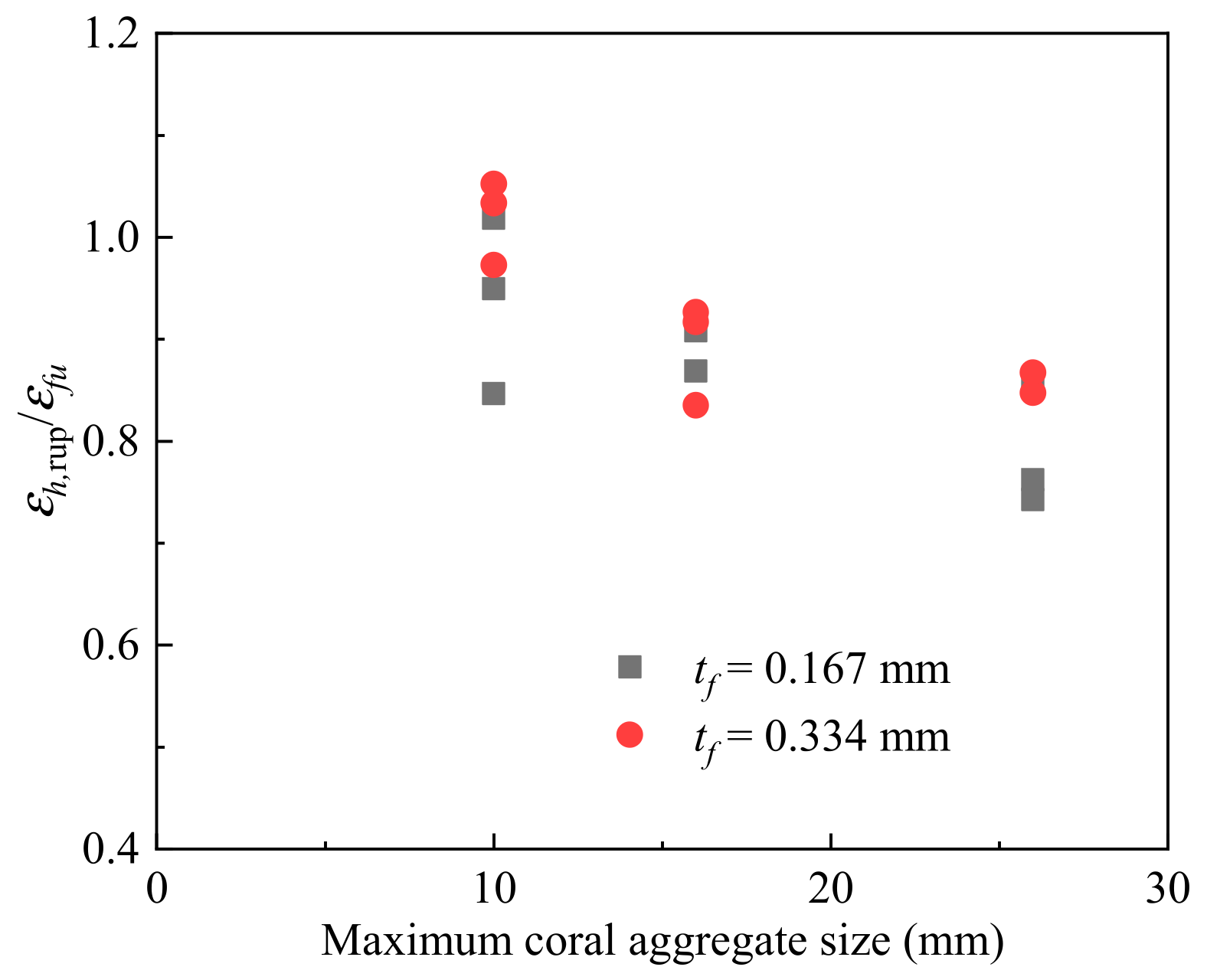

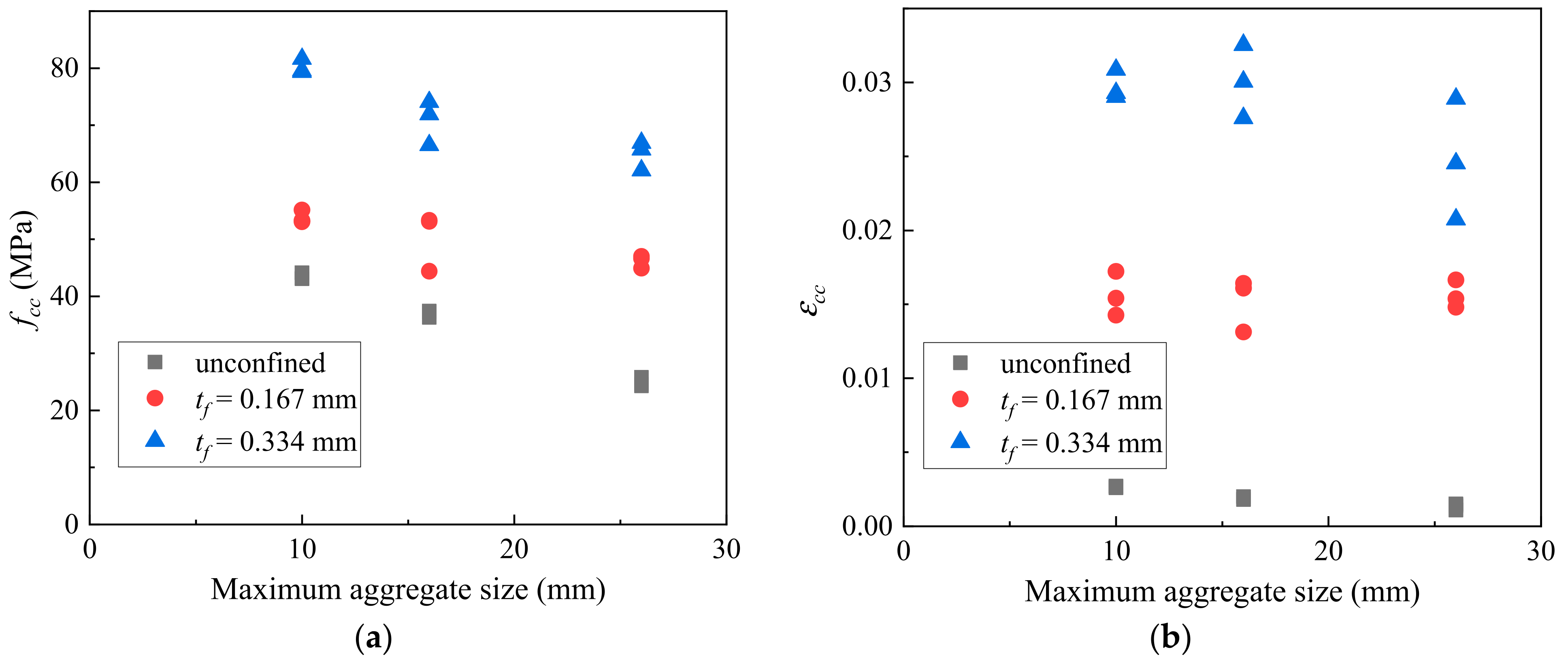

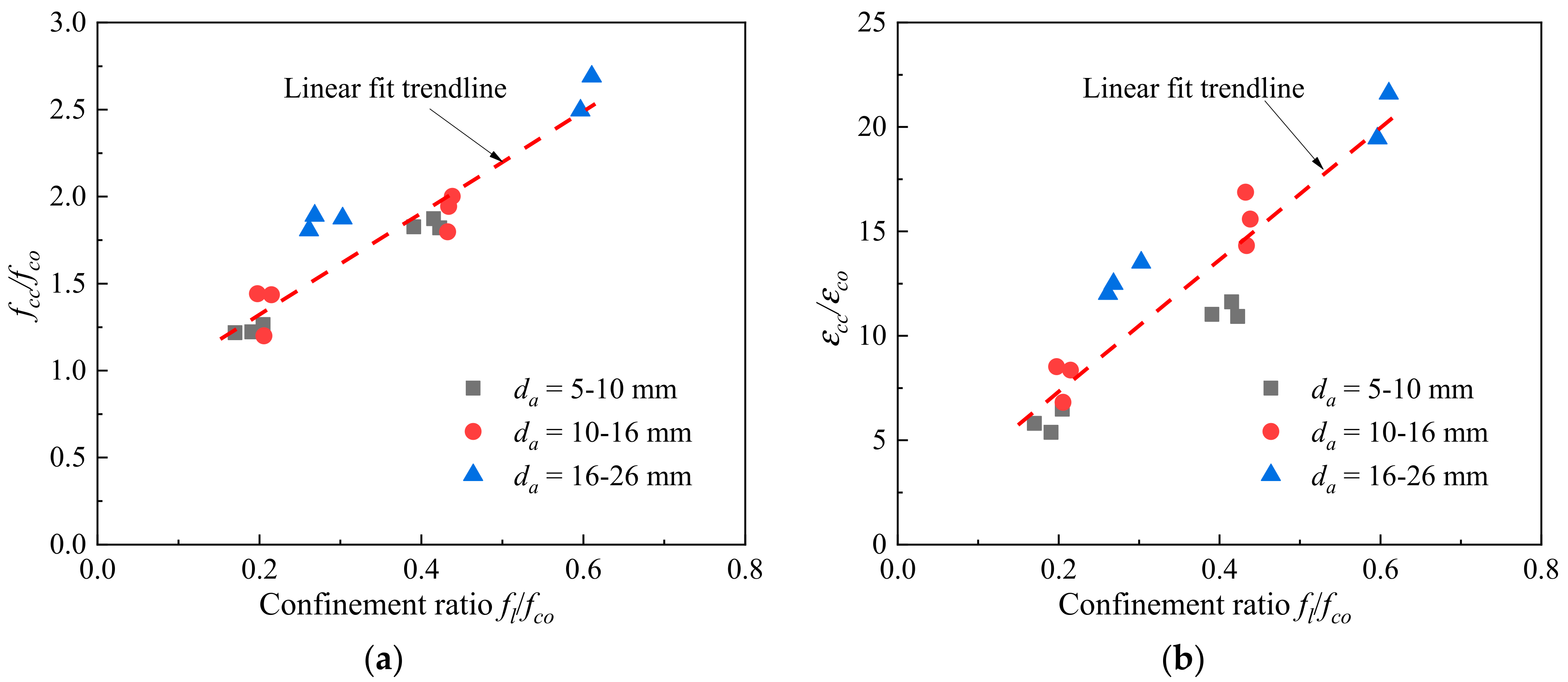

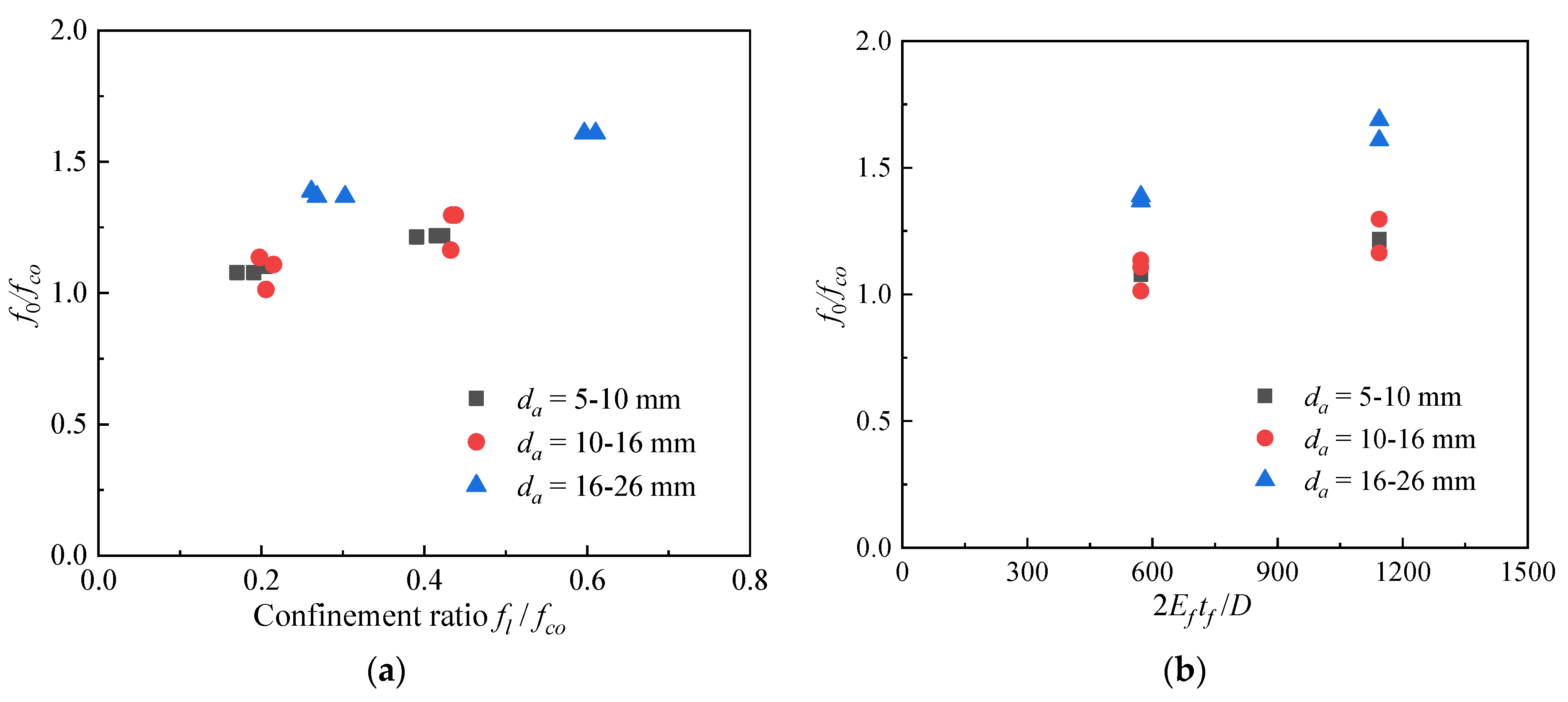

3.4. The Ultimate Condition

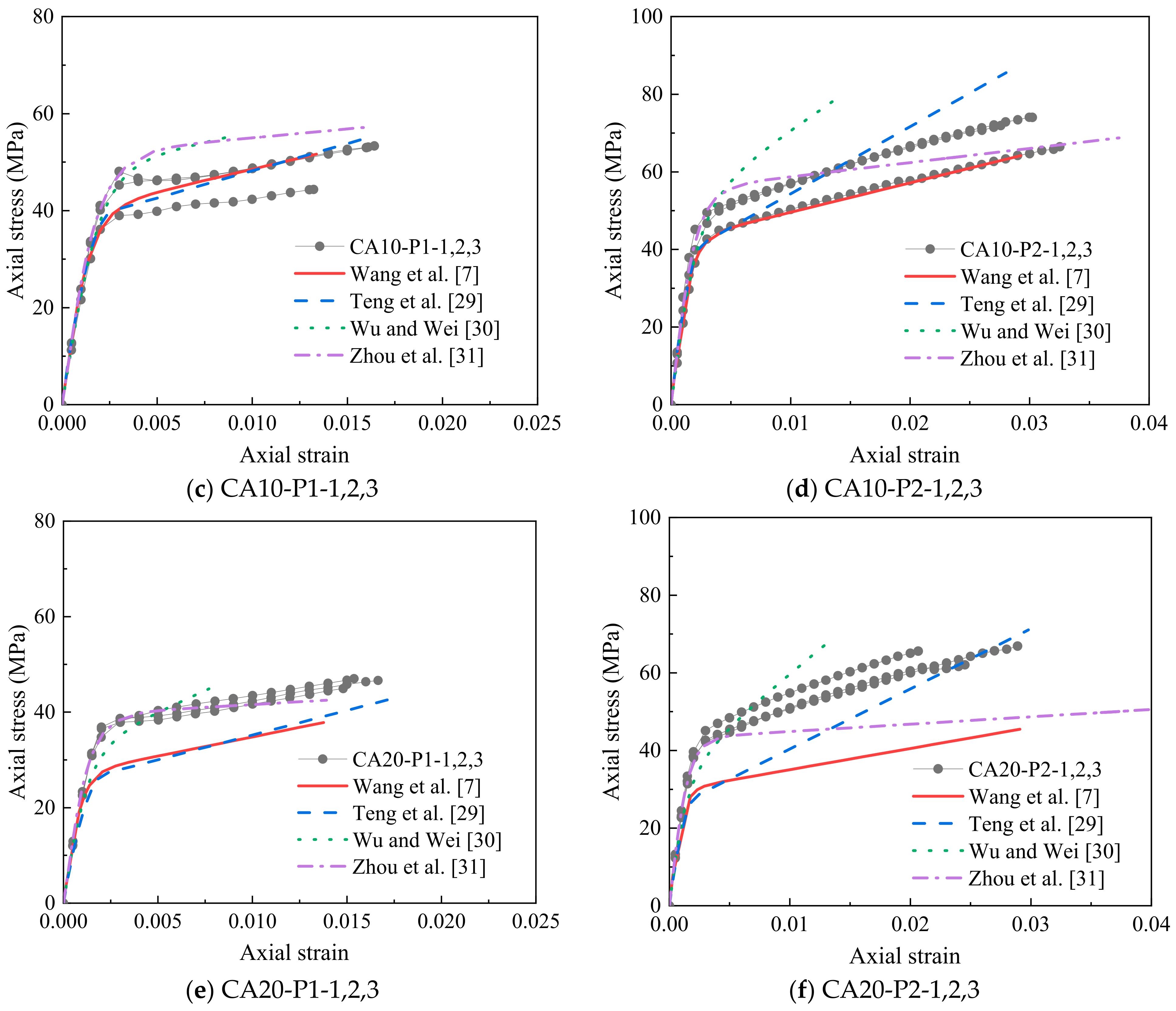

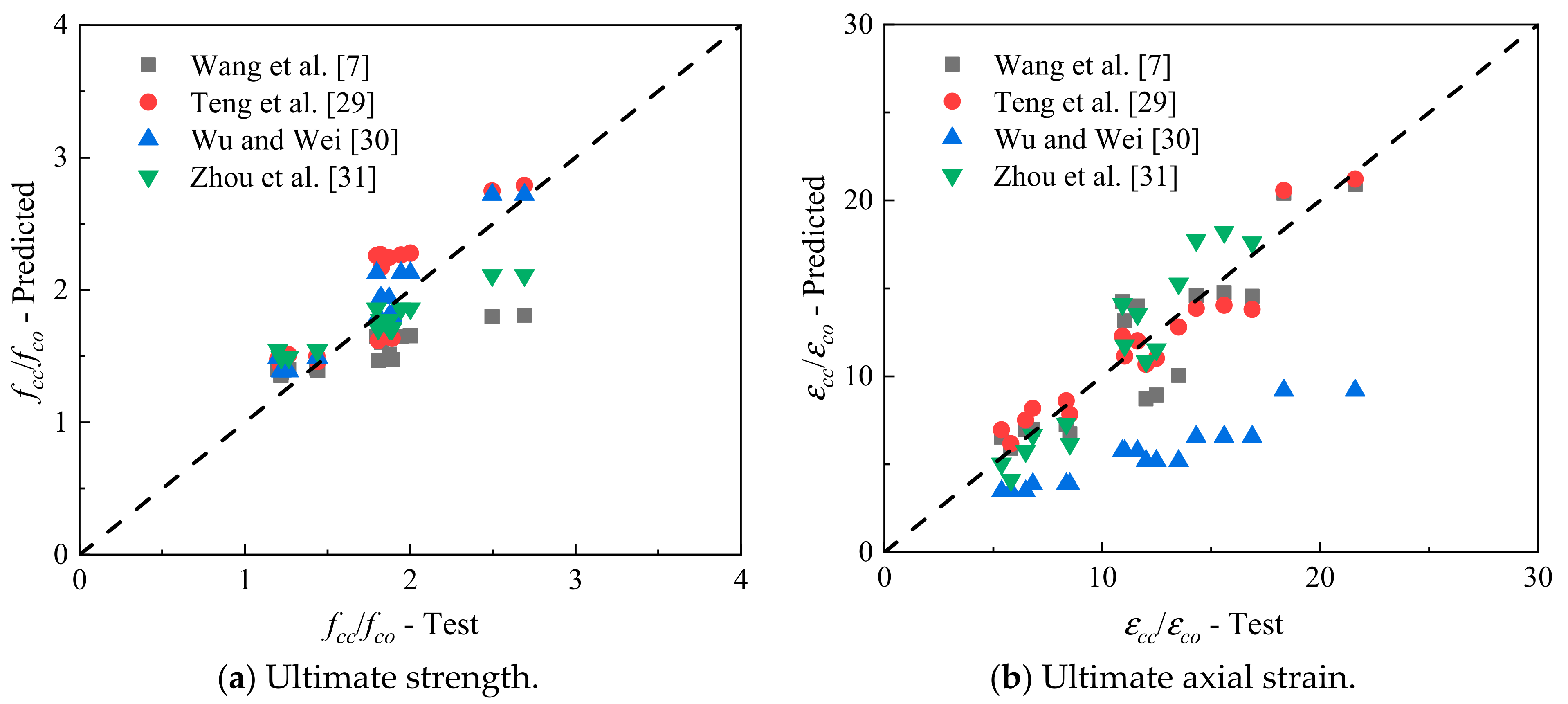

4. Comparisons of the Available Stress–Strain Models

5. Performance of the Modified Stress–Strain Model

6. Practical Implications of the Present Study

7. Conclusions

- (1)

- Owing to the low strength of the coral aggregate, the failure mode was rather brittle for the unconfined CAC. The aggregate size had a pronounced influence on the mechanical properties of the CAC. The larger the size of the coral aggregate was, the lower the strength and the smaller the ultimate axial strain of the CAC. Under the same mixture proportions, when the coral aggregate size increased from 5–10 mm to 16–26 mm, a 43.9% and 51.9% reduction of the stress and the ultimate strain were observed, respectively.

- (2)

- The strength and ductility of CAC could be enhanced significantly by using external FRP confinement. The coral aggregate size had a pronounced effect on the dilation property of the CAC. The CAC with a smaller aggregate size dilated more uniformly than the CAC with the same FRP thickness but a larger aggregate size, suggesting a higher FRP confinement efficiency. When the coral aggregate size decreased from 16–26 mm to 5–10 mm, the average values of the εh,rup/εfu improved by 19.0% and 18.9%, respectively, for the columns confined by one and two-ply FRP jackets.

- (3)

- The ultimate axial stress of the FRP-confined CAC was inversely proportional to the coral aggregate size. When the coral aggregate size increased from 5–10 mm to 16–26 mm, the average peak stress decreased by 42.9%, 14.2%, and 19.1%, respectively, for the columns without confinement, confined by one-, and two-ply FRP jackets. However, the coral aggregate size had little influence on the strength and ultimate axial strain enhancements as the confinement ratio increased.

- (4)

- None of the existing models can capture the stress–strain behavior of FRP-confined CAC well. A modified stress–strain model is subsequently suggested for FRP-confined CAC with the careful consideration of the models of the ultimate condition as well as the model of the stress at the transition segment (the value of f0). The modified model provided a reasonable prediction of the stress–strain curve of the FRP-confined CAC.

- (5)

- A smaller coral aggregate size is more desirable for the property enhancement of both unconfined and confined CAC. Since the tailoring of the size of coral aggregate is easily available, the research findings of the present study are conducive to further promoting the low-carbon sustainable application of coral aggregate in remote island construction.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, Z.L.; Chen, T.Y.; Qu, Z.M. A feasibility study of application of coral reef sand concrete. Ocean. Eng. 1991, 9, 67–80. [Google Scholar]

- Cheng, S.; Wu, Z.; Wu, Q.; Chen, X.; Tu, Y. Mitigation on the shrinkage properties of ultra-high strength concrete via using porous coral sand and shrinkage reducing agent. J. Build. Eng. 2022, 57, 104861. [Google Scholar] [CrossRef]

- Arumugam, R.A.; Ramamurthy, K. Study of compressive strength characteristics of coral aggregate concrete. Mag. Concr. Res. 1996, 48, 141–148. [Google Scholar] [CrossRef]

- Nishida, T.; Otsuki, N.; Onitsuka, R.; Wanchai, Y.; Yokokura, J. Study on strength and permeability of concrete using low quality coarse aggregates from Circum-Pacific region. Doboku Gakkai Ronbunshu 2003, 746, 103–114. [Google Scholar] [CrossRef]

- Zhou, W.; Feng, P.; Yang, J.Q. Advances in coral aggregate concrete and its combination with FRP: A state-of-the-art review. Adv. Struct. Eng. 2020, 24, 1161–1181. [Google Scholar] [CrossRef]

- Da, B.; Yu, H.; Ma, H.; Tan, Y.; Mi, R.; Dou, X. Experimental investigation of whole stress-strain curves of coral concrete. Constr. Build. Mater. 2016, 122, 81–89. [Google Scholar] [CrossRef]

- Wang, J.; Feng, P.; Hao, T.; Yue, Q. Axial compressive behavior of seawater coral aggregate concrete-filled FRP tubes. Constr. Build. Mater. 2017, 147, 272–285. [Google Scholar] [CrossRef]

- Zhou, W.; Feng, P.; Lin, H. Constitutive relations of coral aggregate concrete under uniaxial and triaxial compression. Constr. Build. Mater. 2020, 251, 118957. [Google Scholar] [CrossRef]

- Ma, L.; Li, Z.; Liu, J.; Duan, L.; Wu, J. Mechanical properties of coral concrete subjected to uniaxial dynamic compression. Constr. Build. Mater. 2018, 199, 244–255. [Google Scholar] [CrossRef]

- Niu, D.; Zhang, L.; Fu, Q.; Wen, B.; Luo, D. Critical conditions and life prediction of reinforcement corrosion in coral aggregate concrete. Constr. Build. Mater. 2019, 238, 117685. [Google Scholar] [CrossRef]

- Rao, L.; Yue, Q.; Huang, B.; Liu, X. Axial compressive performance of novel square coral concrete-filled duplex stainless steel tubes. J. Build. Eng. 2022, 49, 104068. [Google Scholar] [CrossRef]

- Benmokrane, B.; Ali, A.H.; Mohamed, H. Microstructural characterization and durability of GFRP reinforcing bars exposed to concrete environment and saline solution. In Proceedings of the International Workshop on Seawater Sea-Sand Concrete (SSC) Structures Reinforced with FRP Composites, Hong Kong, China, 13 December 2016. [Google Scholar]

- Nishizaki, I.; Sasaki, I.; Sakuraba, H. Long-term exposure performance of FRP composites in marine environments. In Proceedings of the International Workshop on Seawater Sea-Sand Concrete (SSC) Structures Reinforced with FRP Composites, Hong Kong, China, 13 December 2016. [Google Scholar]

- Teng, J.G.; Chen, J.F.; Yu, T. FRP-Strengthened RC Structures; John Wiley & Sons: Hoboken, NJ, USA, 2022. [Google Scholar]

- Ying, J.; Huang, Y.; Qin, L.; Gao, X.; Wang, Z. Axial compressive behavior of GFRP tube confined seawater coral aggregate concrete reinforced with epoxy-coated bars. Compos. Struct. 2021, 266, 113807. [Google Scholar] [CrossRef]

- Zhang, T.; Niu, D.; Rong, C. GFRP-confined coral aggregate concrete cylinders: The experimental and theoretical analysis. Constr. Build. Mater. 2019, 218, 206–213. [Google Scholar] [CrossRef]

- Li, Y.T.; Zhou, L.; Zhang, Y.; Cui, J.W.; Shao, J. Study on Long-Term Performance of Concrete Based on Seawater, Sea Sand and Coral Sand. Adv. Mater. Res. 2013, 706–708, 512–515. [Google Scholar] [CrossRef]

- Xiao, J.; Qiang, C.; Nanni, A.; Zhang, K. Use of sea-sand and seawater in concrete construction: Current status and future opportunities. Constr. Build. Mater. 2017, 155, 1101–1111. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, S.; Niu, D.; Su, L.; Luo, D. Strength and chloride ion distribution brought by aggregate of basalt fiber reinforced coral aggregate concrete. Constr. Build. Mater. 2019, 234, 117390. [Google Scholar] [CrossRef]

- Woode, A.; Amoah, D.K.; Aguba, I.A.; Ballow, P. The effect of maximum coarse aggregate on the compressive strength of concrete produced in Ghana. Civil Environ. Res. 2015, 7, 7–12. [Google Scholar]

- Jin, L.; Yu, W.; Li, D.; Du, X. Numerical and theoretical investigation on the size effect of concrete compressive strength considering the maximum aggregate size. Int. J. Mech. Sci. 2021, 192, 106130. [Google Scholar] [CrossRef]

- Tumidajski, P.J.; Gong, B. Effect of coarse aggregate size on strength and workability of concrete. Can. J. Civ. Eng. 2006, 33, 206–213. [Google Scholar] [CrossRef]

- Jiang, C.; Wu, Y.-F.; Jiang, J.-F. Effect of aggregate size on stress-strain behavior of concrete confined by fiber composites. Compos. Struct. 2017, 168, 851–862. [Google Scholar] [CrossRef]

- Tijani, I.; Wu, Y.-F.; Lim, C. Aggregate size effects and general static loading response on mechanical behavior of passively confined concrete. Constr. Build. Mater. 2019, 205, 61–72. [Google Scholar] [CrossRef]

- GB/T 14685-2011; Pebble and Crushed Stone for Construction. Standards Press of China: Beijing, China, 2011.

- ASTM D3039/D3039M-17; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. American Society for Testing and Materials (ASTM) International: West Conshohocken, PA, USA, 2017.

- Jiang, C.; Yuan, F.; Wu, Y.-F.; Zhao, X.-M. Effect of Interfacial Bond on Plastic Hinge Length of FRP-Confined RC Columns. J. Compos. Constr. 2019, 23, 04019007. [Google Scholar] [CrossRef]

- Li, P.; Zhou, Y.; Yang, T.; Yang, Q.; Xing, F. Axial compressive behavior of seawater sea-sand recycled aggregate concrete-filled double-skin non-corrosive tubular columns with square cross-section. Thin-Walled Struct. 2021, 167, 108213. [Google Scholar] [CrossRef]

- Teng, J.G.; Jiang, T.; Lam, L.; Luo, Y.Z. Refinement of a Design-Oriented Stress–Strain Model for FRP-Confined Concrete. J. Compos. Constr. 2009, 13, 269–278. [Google Scholar] [CrossRef]

- Wu, Y.-F.; Wei, Y. General Stress-Strain Model for Steel- and FRP-Confined Concrete. J. Compos. Constr. 2015, 19, 04014069. [Google Scholar] [CrossRef]

- Zhou, Y.; Liu, X.; Xing, F.; Cui, H.; Sui, L. Axial compressive behavior of FRP-confined lightweight aggregate concrete: An experimental study and stress-strain relation model. Constr. Build. Mater. 2016, 119, 1–15. [Google Scholar] [CrossRef]

- Lim, J.C.; Ozbakkaloglu, T. Confinement Model for FRP-Confined High-Strength Concrete. J. Compos. Constr. 2014, 18, 04013058. [Google Scholar] [CrossRef]

| Specimen ID | da (mm) | FRP Layers | fco (MPa) | eco (%) | fcc (MPa) | ecc (%) | eh,rup (%) | fl (MPa) | Ec (MPa) | E2 (MPa) | f0 (MPa) | fcc/fco | ecc/eco |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CA5-P0-1 | 5–10 | 0 | 43.1 | 0.27 | 25,206 | ||||||||

| CA5-P0-2 | 44.1 | 0.26 | 24,673 | ||||||||||

| CA5-P0-3 | - | - | - | ||||||||||

| CA10-P0-1 | 10–16 | 37.4 | 0.18 | 23,698 | |||||||||

| CA10-P0-2 | 37.3 | 0.20 | 24,230 | ||||||||||

| CA10-P0-3 | 36.3 | 0.20 | 23,210 | ||||||||||

| CA20-P0-1 | 16–26 | 24.3 | 0.15 | 25,304 | |||||||||

| CA20-P0-2 | 24.6 | 0.11 | 25,118 | ||||||||||

| CA20-P0-3 | 25.8 | 0.14 | 23,163 | ||||||||||

| CA5-P1-1 | 5–10 | 1 | 43.6 | 0.27 | 53.3 | 1.43 | 1.44 | 8.2 | 23,136 | 483 | 45.7 | 1.22 | 5.38 |

| CA5-P1-2 | 43.6 | 0.27 | 55.1 | 1.72 | 1.57 | 9.0 | 23,131 | 562 | 45.4 | 1.26 | 6.49 | ||

| CA5-P1-3 | 43.6 | 0.27 | 53.1 | 1.54 | 1.41 | 8.1 | 22,834 | 223 | 48.4 | 1.22 | 5.81 | ||

| CA5-P2-1 | 2 | 43.6 | 0.27 | 79.6 | 2.93 | 1.50 | 17.2 | 26,666 | 1025 | 50.7 | 1.83 | 11.03 | |

| CA5-P2-2 | 43.6 | 0.27 | 81.6 | 3.09 | 1.57 | 17.9 | 23,798 | 1014 | 51.3 | 1.87 | 11.62 | ||

| CA5-P2-3 | 43.6 | 0.27 | 79.3 | 2.90 | 1.58 | 18.1 | 23,403 | 1030 | 50.8 | 1.82 | 10.93 | ||

| CA10-P1-1 | 10–16 | 1 | 37.0 | 0.19 | 53.1 | 1.61 | 1.48 | 8.5 | 24,514 | 486 | 44.4 | 1.44 | 8.35 |

| CA10-P1-2 | 37.0 | 0.19 | 44.4 | 1.31 | 1.50 | 8.6 | 21,954 | 482 | 37.7 | 1.20 | 6.81 | ||

| CA10-P1-3 | 37.0 | 0.19 | 53.3 | 1.64 | 1.32 | 7.6 | 24,079 | 615 | 43.0 | 1.44 | 8.52 | ||

| CA10-P2-1 | 2 | 37.0 | 0.19 | 74.0 | 3.01 | 1.46 | 16.7 | 24,966 | 966 | 46.7 | 2.00 | 15.59 | |

| CA10-P2-2 | 37.0 | 0.19 | 71.9 | 2.76 | 1.44 | 16.5 | 27,558 | 908 | 47.8 | 1.94 | 14.32 | ||

| CA10-P2-3 | 37.0 | 0.19 | 66.5 | 3.25 | 1.41 | 16.2 | 21,193 | 758 | 42.3 | 1.80 | 16.88 | ||

| CA20-P1-1 | 16–26 | 1 | 24.9 | 0.13 | 47.0 | 1.54 | 1.12 | 6.4 | 24,470 | 748 | 35.9 | 1.89 | 12.49 |

| CA20-P1-2 | 24.9 | 0.13 | 46.6 | 1.66 | 1.35 | 7.7 | 22,521 | 622 | 36.3 | 1.88 | 13.51 | ||

| CA20-P1-3 | 24.9 | 0.13 | 44.9 | 1.48 | 1.15 | 6.6 | 22,986 | 604 | 35.7 | 1.81 | 12.01 | ||

| CA20-P2-1 | 2 | 24.9 | 0.13 | 66.9 | 2.89 | 1.38 | 15.8 | 23,123 | 939 | 40.9 | 2.69 | 21.61 | |

| CA20-P2-2 | 24.9 | 0.13 | 65.7 | 2.07 | - | - | 25,209 | 1167 | 42.6 | 2.64 | 15.50 | ||

| CA20-P2-3 | 24.9 | 0.13 | 62.1 | 2.45 | 1.30 | 14.8 | 23,955 | 988 | 40.4 | 2.50 | 18.34 |

| K+ (mg/L) | Na+ (mg/L) | Ca2+ (mg/L) | Mg2+ (mg/L) | CO32− (mg/L) | SO42− (mg/L) | Cl− (mg/L) | Br− (mg/L) |

|---|---|---|---|---|---|---|---|

| 282 | 1650 | 276 | 1080 | 72 | 2110 | 14,900 | 53 |

| Apparent Density (kg/m3) | Bulk Density (kg/m3) | Mud Content (%) | Seashells (%) | Cl– (%) | SO42– (%) | Fineness Modulus |

|---|---|---|---|---|---|---|

| 2520 | 1430 | 1.3 | 0.4 | 0.01 | 0.3 | 2.2 |

| Coral Aggregate Size (mm) | Apparent Density (kg/m3) | Saturated Water Absorption (%) | Crushing Index (%) |

|---|---|---|---|

| 5–10 | 2472 | 11.67 | - |

| 10–16 | 2371 | 11.86 | 35.46 |

| 16–26 | 2288 | 12.19 | - |

| ID | Cement (kg/m3) | Sea Water (kg/m3) | Sea Sand (kg/m3) | Coral Aggregate (kg/m3) | Superplasticizer (kg/m3) | Concrete Strength in 28 Days (MPa) |

|---|---|---|---|---|---|---|

| CA5 | 616 | 300 | 635 | 729 | 2.59 | 33.5 |

| CA10 | 616 | 300 | 635 | 729 | 1.40 | 32.9 |

| CA15 | 616 | 300 | 635 | 729 | 0.98 | 27.2 |

| CFRP | Type | Thickness tf (mm) | Ultimate Strength ffrp (Gpa) | Ultimate Strain εfu (%) | Elastic Modulus Ef (Gpa) |

|---|---|---|---|---|---|

| Manufacturer | UT70-30 | 0.167 | 3.4 | 1.48 | 230 |

| coupon tests | 3.9 | 1.53 | 257 |

| Reference | Ultimate Strength Models | AAE | Ultimate Strain Models | AAE |

|---|---|---|---|---|

| Wang at al. [7] | 0.149 | 0.149 | ||

| Teng et al. [29] | 0.148 | 0.102 | ||

| Wu and Wei [30] | 0.080 | 0.516 | ||

| Zhou at al. [31] | 0.113 | 0.239 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, P.; Huang, D.; Li, R.; Li, R.; Yuan, F. Effect of Aggregate Size on the Axial Compressive Behavior of FRP-Confined Coral Aggregate Concrete. Polymers 2022, 14, 3877. https://doi.org/10.3390/polym14183877

Li P, Huang D, Li R, Li R, Yuan F. Effect of Aggregate Size on the Axial Compressive Behavior of FRP-Confined Coral Aggregate Concrete. Polymers. 2022; 14(18):3877. https://doi.org/10.3390/polym14183877

Chicago/Turabian StyleLi, Pengda, Deqing Huang, Ruiyu Li, Rongkang Li, and Fang Yuan. 2022. "Effect of Aggregate Size on the Axial Compressive Behavior of FRP-Confined Coral Aggregate Concrete" Polymers 14, no. 18: 3877. https://doi.org/10.3390/polym14183877

APA StyleLi, P., Huang, D., Li, R., Li, R., & Yuan, F. (2022). Effect of Aggregate Size on the Axial Compressive Behavior of FRP-Confined Coral Aggregate Concrete. Polymers, 14(18), 3877. https://doi.org/10.3390/polym14183877