Soft Conductive Hydrogel-Based Electronic Skin for Robot Finger Grasping Manipulation

Abstract

1. Introduction

- (1)

- RES is designed with a simultaneous strain and pressure tactile sensing ability based on the soft conductive hydrogel. The soft conductive hydrogel is synthetized with several polymers through a sol–gel process for guaranteeing the overall softness of RES. RES is designed for finger gesture detection and grasping manipulation. RES with a strain and pressure sensor on the substrate is compatible with the robot finger, which would expand the application abilities of the robot finger in human–machine interaction (HMI) areas.

- (2)

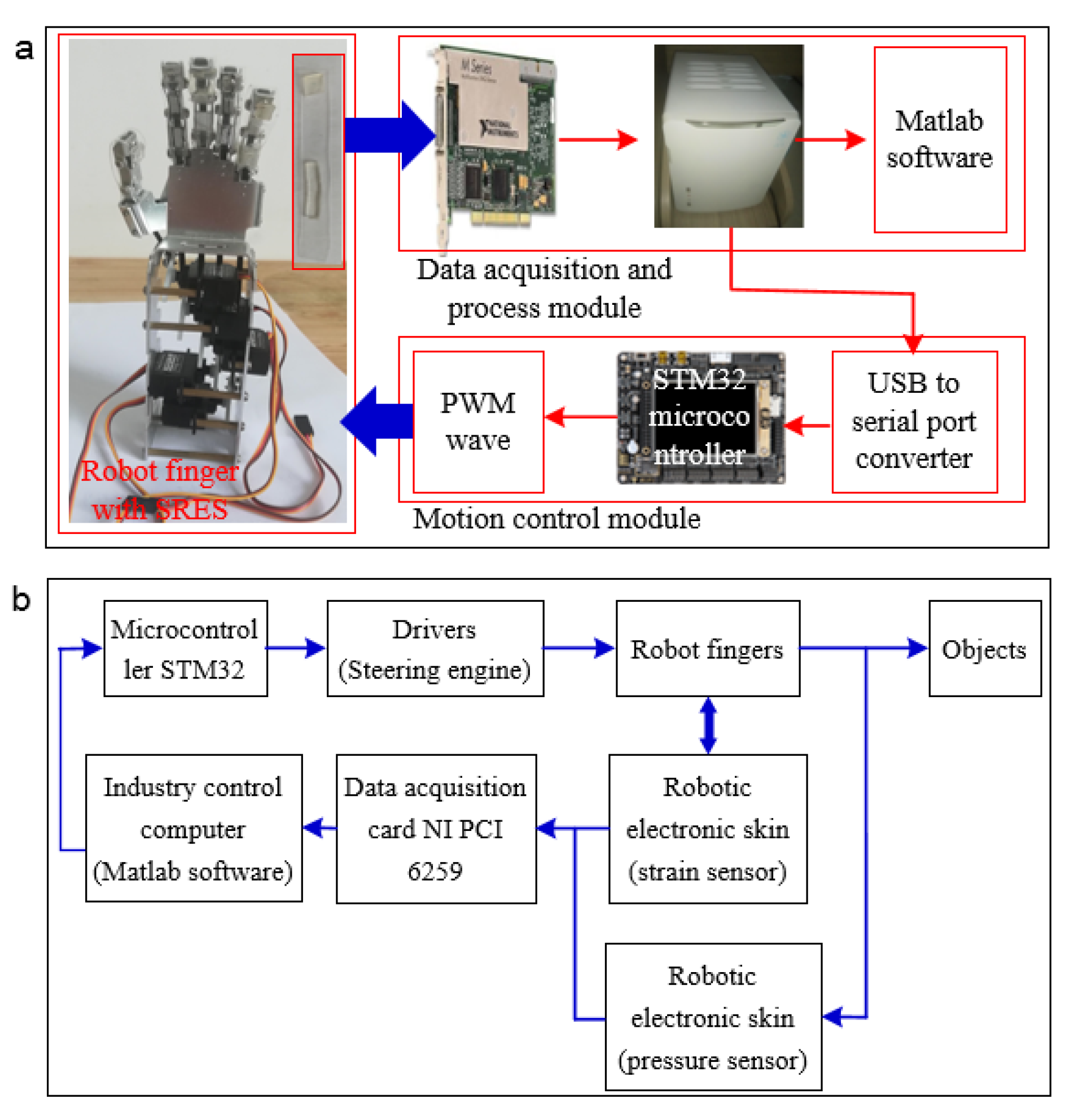

- A negative force feedback is applied to RES for improving the grasping capability of the robot finger. RES is adhered onto the robot finger for bending strain and touching pressure recording during the manipulation of the robot finger. The negative force feedback control method is built for grasping manipulation of the robot finger integrated with RES, which would provide a self-adaptive control method to determine whether the objects are grasped successfully or not.

2. Materials and Methods

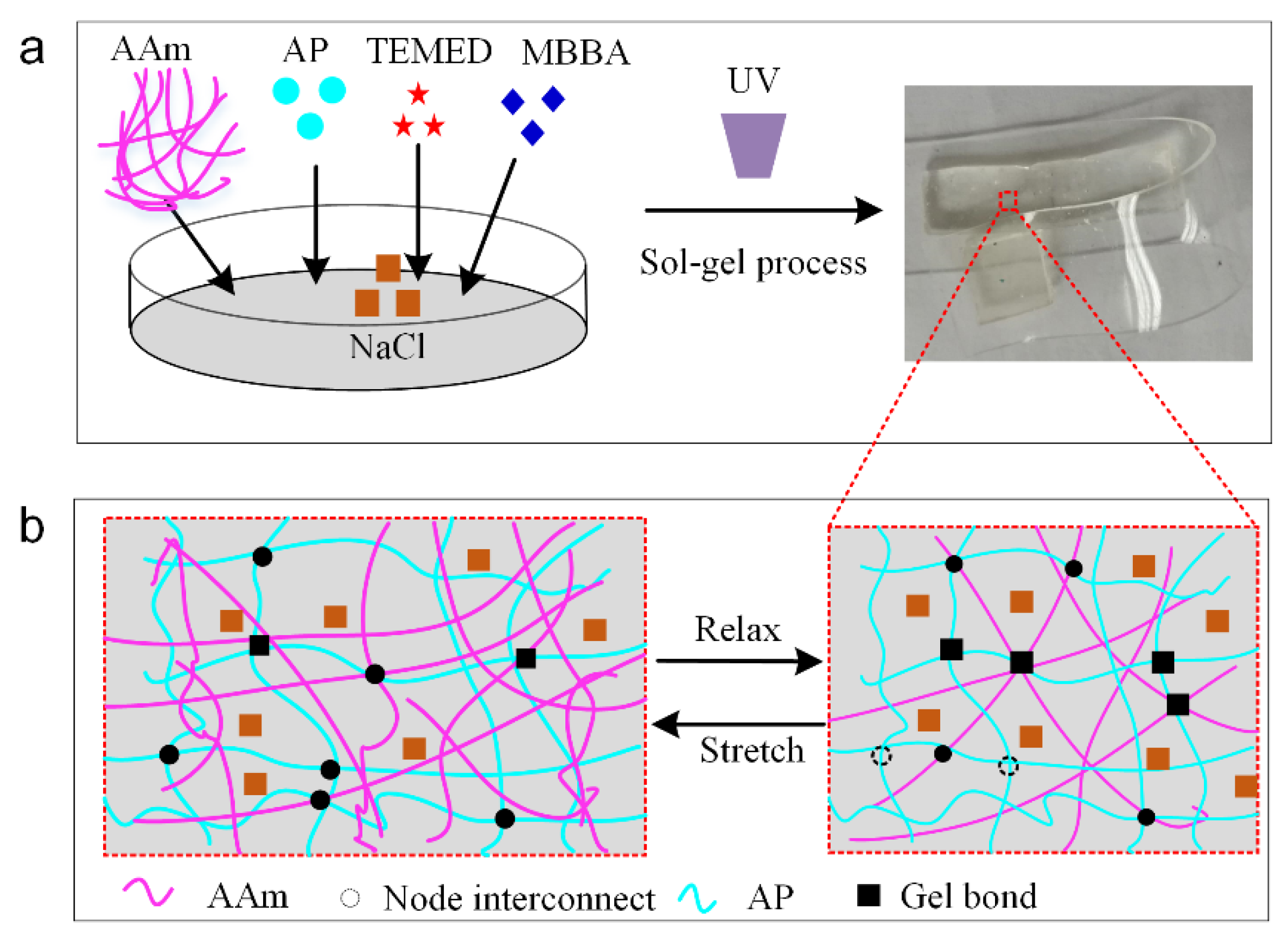

2.1. Design of RES

2.2. Material Selection and Fabrication Process

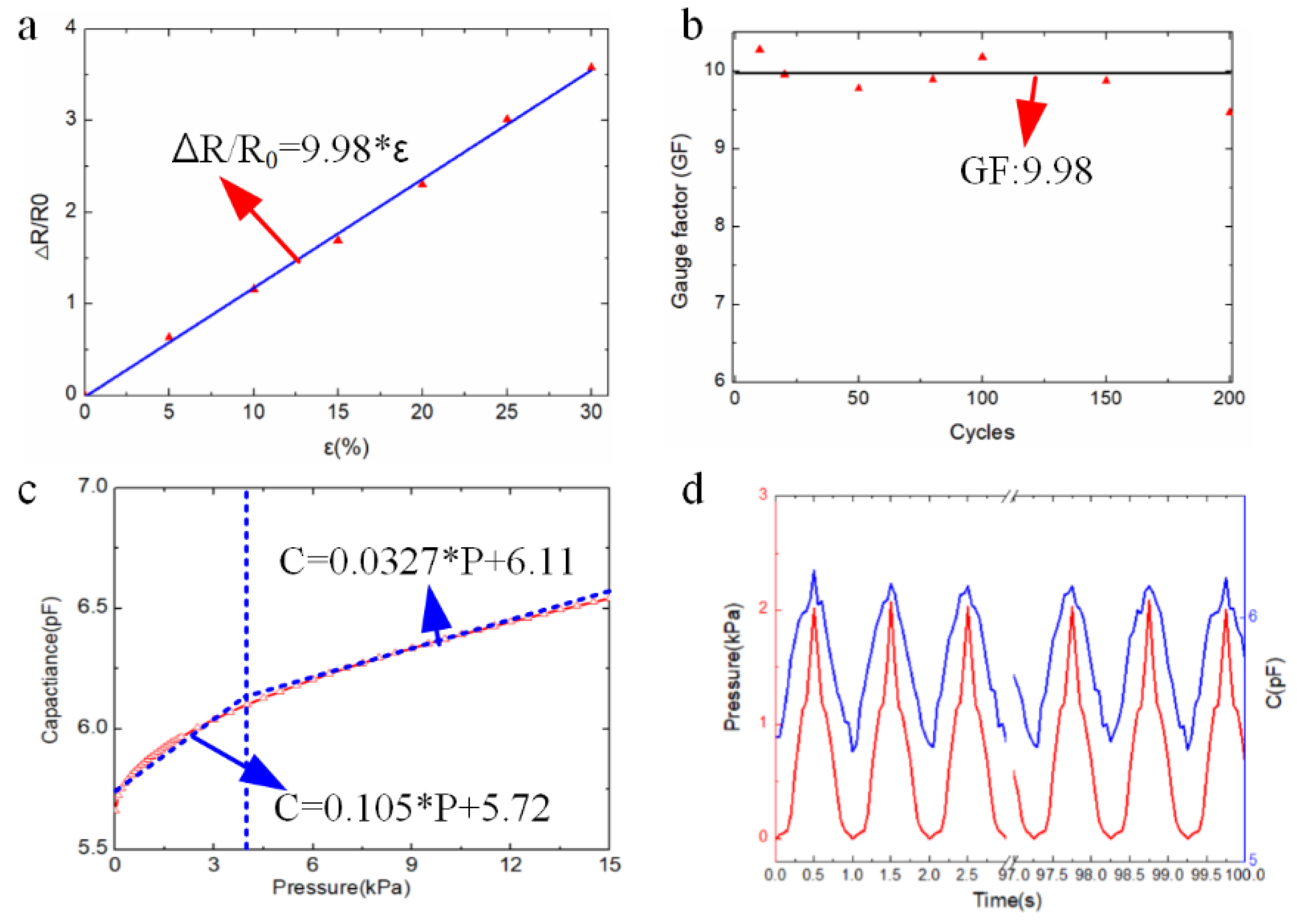

2.3. Electrical Performance

3. Result and Discussions

3.1. Finger Gesture Detection

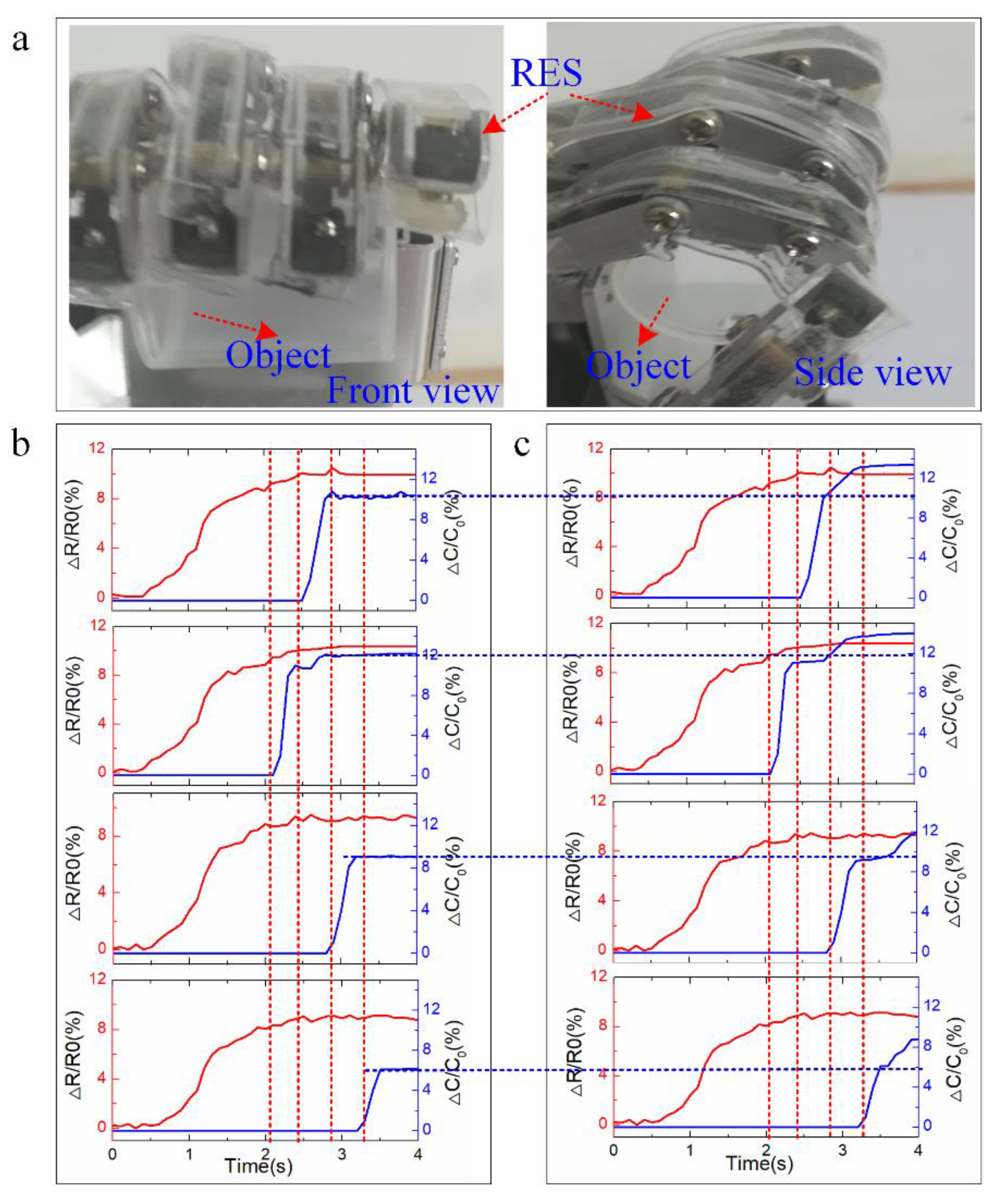

3.2. Grasping Experiments

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gopalai, A.A.; Senanayake, S.M.N.A.A. A Wearable Real-Time Intelligent Posture Corrective System Using Vibrotactile Feedback. IEEE/ASME Trans. Mechatron. 2011, 16, 827–834. [Google Scholar] [CrossRef]

- Carta, R.; Jourand, P.; Hermans, B.; Thoné, J.; Brosteaux, D.; Vervust, T.; Bossuyt, F.; Axisa, F.; Vanfleteren, J.; Puers, R. Design and implementation of advanced systems in a flexible-stretchable technology for biomedical applications. Sens. Actuators A Phys. 2009, 156, 79–87. [Google Scholar] [CrossRef]

- Zhang, C.; Liu, S.; Huang, X.; Guo, W.; Li, Y.; Wu, H. A stretchable dual-mode sensor array for multifunctional robotic electronic skin. Nano Energy 2019, 62, 164–170. [Google Scholar] [CrossRef]

- Kim, J.; Lee, M.; Shim, H.J.; Ghaffari, R.; Cho, H.R.; Son, D.; Jung, Y.H.; Soh, M.; Choi, C.; Jung, S.; et al. Stretchable silicon nanoribbon electronics for skin prosthesis. Nat. Commun. 2014, 5, 5747. [Google Scholar] [CrossRef]

- Westerveld, A.J.; Schouten, A.C.; Veltink, P.H.; Van, d.K.H. Selectivity and resolution of surface electrical stimulation for grasp and release. IEEE Trans. Neural Syst. Rehabil. Eng. Publ. IEEE Eng. Med. Biol. Soc. 2012, 20, 94–101. [Google Scholar] [CrossRef]

- Lu, Z.; Gao, X.; Yu, H. GTac: A Biomimetic Tactile Sensor with Skin-Like Heterogeneous Force Feedback for Robots. IEEE Sens. J. 2022, 22, 14491–14500. [Google Scholar] [CrossRef]

- Ferre, M.; Galiana, I.; Wirz, R.; Tuttle, N. Haptic Device for Capturing and Simulating Hand Manipulation Rehabilitation. IEEE/ASME Trans. Mechatron. 2011, 16, 808–815. [Google Scholar] [CrossRef]

- Chen, W.; Wu, S.; Zhou, T.; Xiong, C. On the biological mechanics and energetics of the hip joint muscle–tendon system assisted by passive hip exoskeleton. Bioinspiration Biomim. 2018, 14, 016012. [Google Scholar] [CrossRef]

- Huang, Y.; Dong, W.; Zhu, C.; Xiao, L. Electromechanical Design of Self-Similar Inspired Surface Electrodes for Human-Machine Interaction. Complexity 2018, 2018, 3016343. [Google Scholar] [CrossRef]

- Wang, F. Soft Tactile Sensors for Human-Machine Interaction; Springer: Singapore, 2015. [Google Scholar]

- Lee, J.W.; Xu, R.; Lee, S.; Jang, K.-I.; Yang, Y.; Banks, A.; Yu, K.J.; Kim, J.; Xu, S.; Ma, S.; et al. Soft, thin skin-mounted power management systems and their use in wireless thermography. Proc. Natl. Acad. Sci. USA 2016, 113, 6131–6136. [Google Scholar] [CrossRef]

- Bicchi, A.; Kumar, V. Robotic grasping and contact: A review. In Proceedings of the 2000 ICRA. Millennium Conference. IEEE International Conference on Robotics and Automation. Symposia Proceedings (Cat. No.00CH37065), San Francisco, CA, USA, 24–28 April 2000; Volume 1, pp. 348–353. [Google Scholar]

- Ge, G.; Zhang, Y.; Shao, J.; Wang, W.; Si, W.; Huang, W.; Dong, X. Stretchable, Transparent, and Self-Patterned Hydrogel-Based Pressure Sensor for Human Motions Detection. Adv. Funct. Mater. 2018, 28, 1802576. [Google Scholar] [CrossRef]

- Won, S.M.; Song, E.; Zhao, J.; Li, J.; Rivnay, J.; Rogers, J.A. Recent Advances in Materials, Devices, and Systems for Neural Interfaces. Adv. Mater. 2018, 30, e1800534. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Ruan, X.; Xing, C.; Zhao, H.; Luo, M.; Chen, Y.; Hong, W.; Guo, X. Highly sensitive and flexible three-dimensional force tactile sensor based on inverted pyramidal structure. Smart Mater. Struct. 2022, 31, 095013. [Google Scholar] [CrossRef]

- Jin, Y.; Yang, T.; Ju, S.; Zhang, H.; Choi, T.-Y.; Neogi, A. Thermally Tunable Dynamic and Static Elastic Properties of Hydrogel Due to Volumetric Phase Transition. Polymers 2020, 12, 1462. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Shao, C.; Meng, L. Strain Rate-Dependent Viscoelasticity and Fracture Mechanics of Cellulose Nanofibril Composite Hydrogels. Langmuir 2019, 35, 10542–10550. [Google Scholar] [CrossRef]

- Zhou, Y.; Wan, C.; Yang, Y.; Yang, H.; Wang, S.; Dai, Z.; Ji, K.; Jiang, H.; Chen, X.; Long, Y. Highly Stretchable, Elastic, and Ionic Conductive Hydrogel for Artificial Soft Electronics. Adv. Funct. Mater. 2019, 29, 1806220. [Google Scholar] [CrossRef]

- Del Agua, I.; Mantione, D.; Ismailov, U.; Sanchez-Sanchez, A.; Aranburu, N.; Malliaras, G.G.; Mecerreyes, D.; Ismailova, E. DVS-Crosslinked PEDOT:PSS Free-Standing and Textile Electrodes toward Wearable Health Monitoring. Adv. Mater. Technol. 2018, 3, 1700322. [Google Scholar] [CrossRef]

- Xu, D.; Michel, S.; McKay, T.; O’Brien, B.; Gisby, T.; Anderson, I. Sensing frequency design for capacitance feedback of dielectric elastomers. Sens. Actuators A Phys. 2015, 232, 195–201. [Google Scholar] [CrossRef]

- Maiolino, P.; Galantini, F.; Mastrogiovanni, F.; Gallone, G.; Cannata, G.; Carpi, F. Soft dielectrics for capacitive sensing in robot skins: Performance of different elastomer types. Sens. Actuators A Phys. 2015, 226, 37–47. [Google Scholar] [CrossRef]

- Meli, L.; Pacchierotti, C.; Prattichizzo, D. Sensory Subtraction in Robot-Assisted Surgery: Fingertip Skin Deformation Feedback to Ensure Safety and Improve Transparency in Bimanual Haptic Interaction. IEEE Trans. Biomed. Eng. 2014, 61, 1318–1327. [Google Scholar] [CrossRef]

- Huang, Y.; Cai, X.; Kan, W.; Qiu, S.; Guo, X.; Liu, C.; Liu, P. A flexible dual-mode proximity sensor based on cooperative sensing for robot skin applications. Rev. Sci. Instrum. 2017, 88, 085005. [Google Scholar] [CrossRef] [PubMed]

- You, X.; He, J.; Nan, N.; Sun, X.; Qi, K.; Zhou, Y.; Shao, W.; Liu, F.; Cui, S. Stretchable capacitive fabric electronic skin woven by electrospun nanofiber coated yarns for detecting tactile and multimodal mechanical stimuli. J. Mater. Chem. C 2018, 6, 12981–12991. [Google Scholar] [CrossRef]

- Ji, Z.P.; Zhu, H.; Liu, H.C.; Liu, N.; Chen, T. The Design and Characterization of a Flexible Tactile Sensing Array for Robot Skin. Sensors 2016, 16, 2001. [Google Scholar] [CrossRef]

- Wang, Y.; Gregory, C.; Minor, M.A. Improving Mechanical Properties of Molded Silicone Rubber for Soft Robotics Through Fabric Compositing. Soft Robot. 2018, 5, 272–290. [Google Scholar] [CrossRef] [PubMed]

- Ho, V.A.; Makikawa, M.; Hirai, S. Flexible Fabric Sensor Toward a Humanoid Robot’s Skin: Fabrication, Characterization, and Perceptions. IEEE Sens. J. 2013, 13, 4065–4080. [Google Scholar] [CrossRef]

- Sierrapérez, J.; Torresarredondo, M.A.; Alvarezmontoya, J. Damage detection methodology under variable load conditions based on strain field pattern recognition using FBGs, nonlinear principal component analysis, and clustering techniques. Smart Mater. Struct. 2017, 27, 015002. [Google Scholar] [CrossRef]

- Gupta, H.P.; Chudgar, H.S.; Mukherjee, S.; Dutta, T.; Sharma, K. A Continuous Hand Gestures Recognition Technique for Human-Machine Interaction Using Accelerometer and Gyroscope Sensors. IEEE Sens. J. 2016, 16, 6425–6432. [Google Scholar] [CrossRef]

- Zhu, H.-W.; Gao, H.-L.; Zhao, H.-Y.; Ge, J.; Hu, B.-C.; Huang, J.; Yu, S.-H. Printable elastic silver nanowire-based conductor for washable electronic textiles. Nano Res. 2020, 13, 2879–2884. [Google Scholar] [CrossRef]

- Lin, S.; Yuk, H.; Zhang, T.; Parada, G.A.; Koo, H.W.; Yu, C.; Zhao, X. Stretchable Hydrogel Electronics and Devices. Adv. Mater. 2016, 28, 4497–4505. [Google Scholar] [CrossRef]

- Dong, W.; Yao, D.; Yang, L. Soft Bimodal Sensor Array Based on Conductive Hydrogel for Driving Status Monitoring. Sensors 2020, 20, 1641. [Google Scholar] [CrossRef]

- Sun, J.-Y.; Zhao, X.; Illeperuma, W.R.K.; Chaudhuri, O.; Oh, K.H.; Mooney, D.J.; Vlassak, J.J.; Suo, Z. Highly stretchable and tough hydrogels. Nature 2012, 489, 133–136. [Google Scholar] [CrossRef] [PubMed]

- Keplinger, C.; Sun, J.Y.; Foo, C.C.; Rothemund, P.; Whitesides, G.M.; Suo, Z. Stretchable, transparent, ionic conductors. Science 2013, 341, 984–987. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, X.; Zhang, F.; Dong, W. Soft Conductive Hydrogel-Based Electronic Skin for Robot Finger Grasping Manipulation. Polymers 2022, 14, 3930. https://doi.org/10.3390/polym14193930

Cheng X, Zhang F, Dong W. Soft Conductive Hydrogel-Based Electronic Skin for Robot Finger Grasping Manipulation. Polymers. 2022; 14(19):3930. https://doi.org/10.3390/polym14193930

Chicago/Turabian StyleCheng, Xiao, Fan Zhang, and Wentao Dong. 2022. "Soft Conductive Hydrogel-Based Electronic Skin for Robot Finger Grasping Manipulation" Polymers 14, no. 19: 3930. https://doi.org/10.3390/polym14193930

APA StyleCheng, X., Zhang, F., & Dong, W. (2022). Soft Conductive Hydrogel-Based Electronic Skin for Robot Finger Grasping Manipulation. Polymers, 14(19), 3930. https://doi.org/10.3390/polym14193930