Gas Dynamics Processes above the Polymers Surface under Irradiation with Broadband High-Brightness Radiation in the Vacuum Ultraviolet Spectrum Region

Abstract

:1. Introduction

2. Experimental Methods

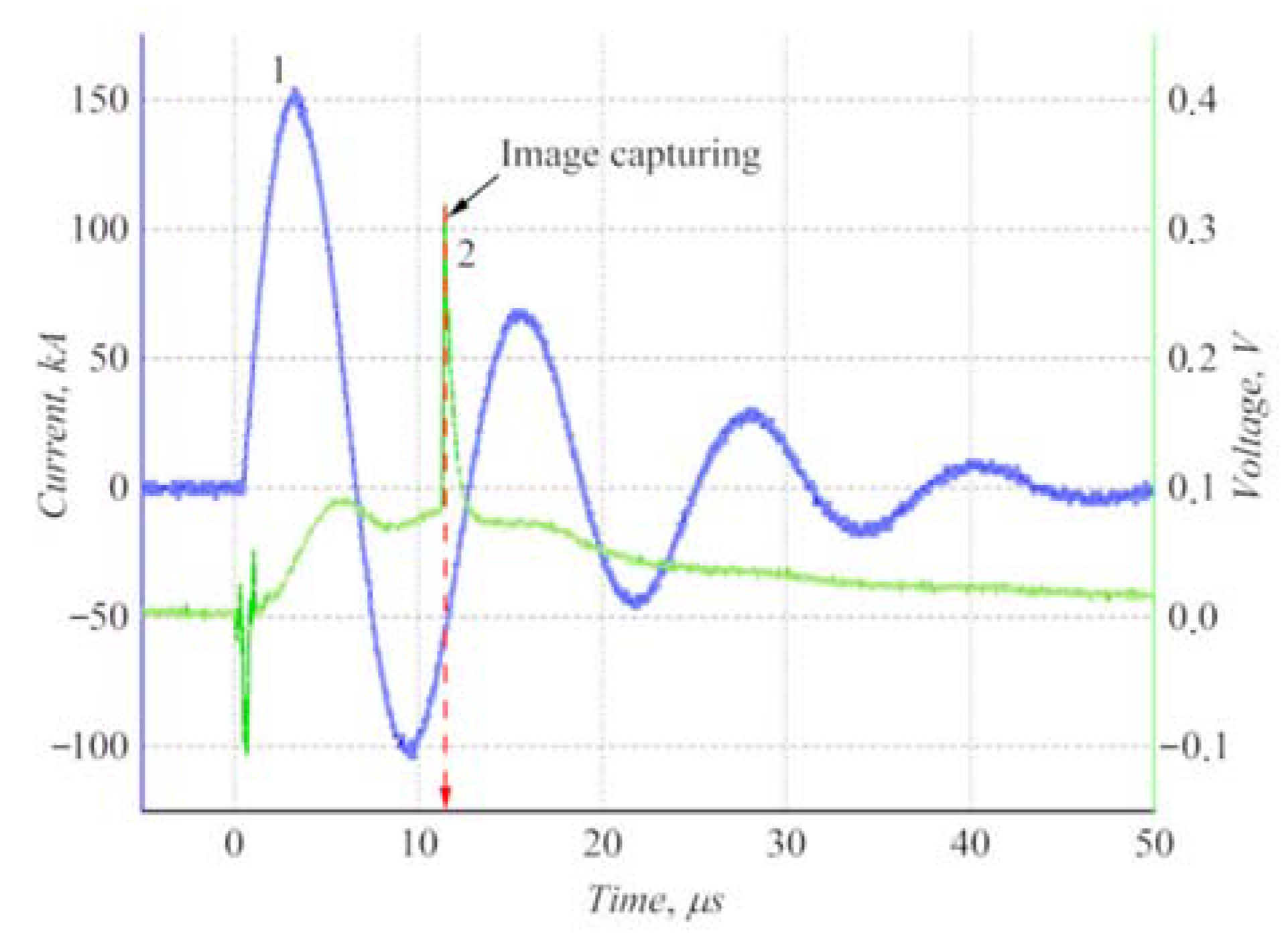

2.1. Key Features of Used Plasma Radiation Source and its Operation Process

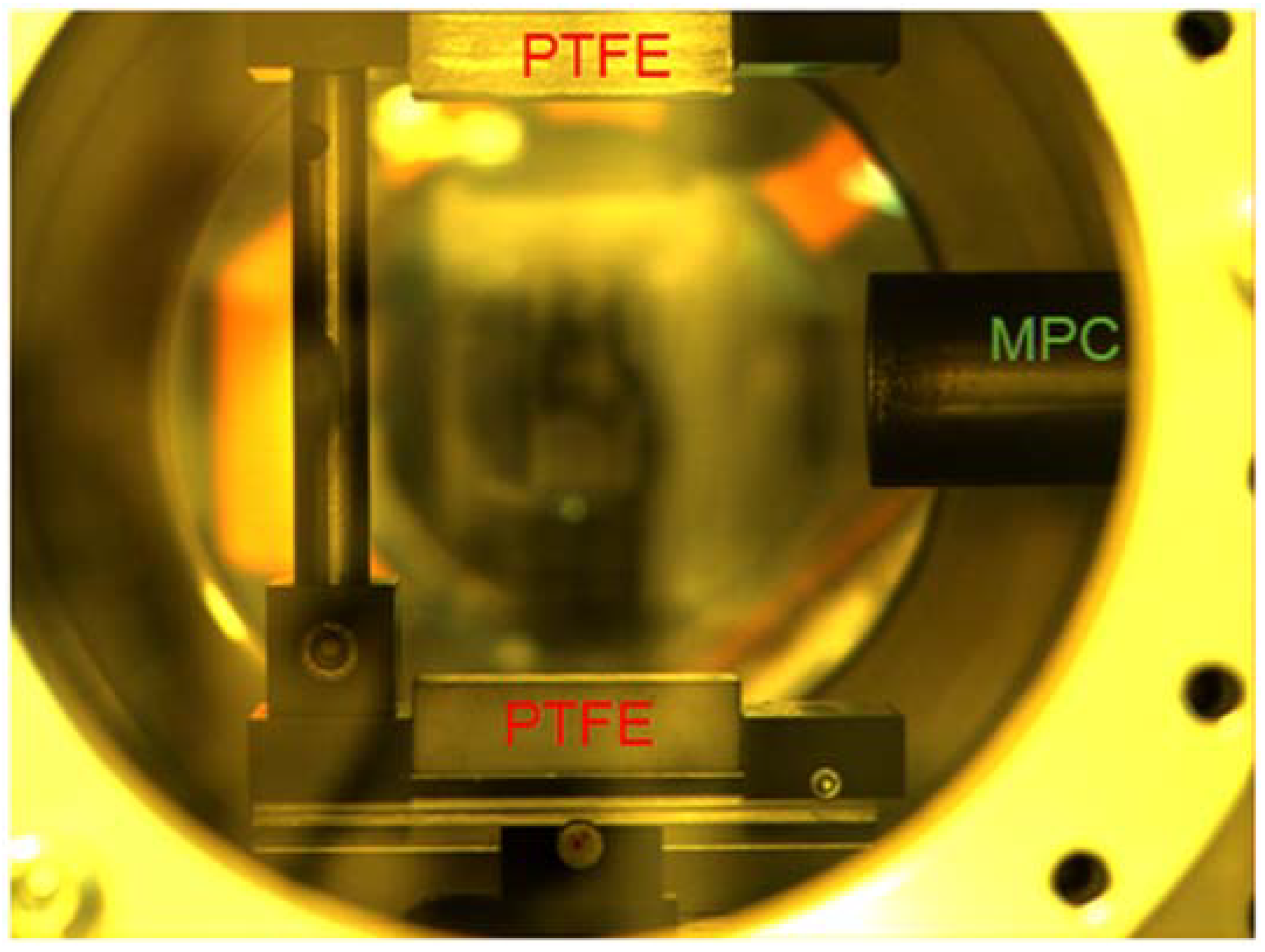

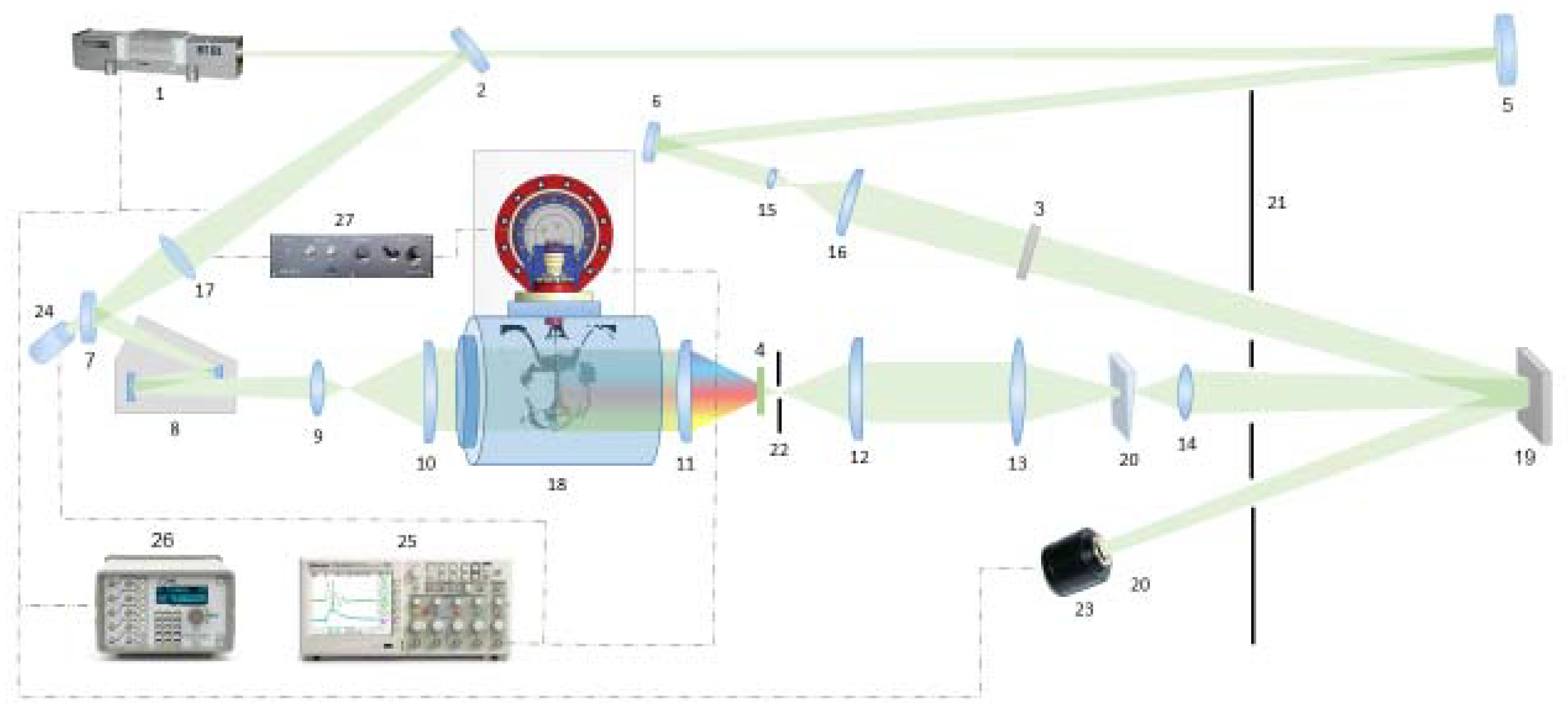

2.2. Experimental Set up

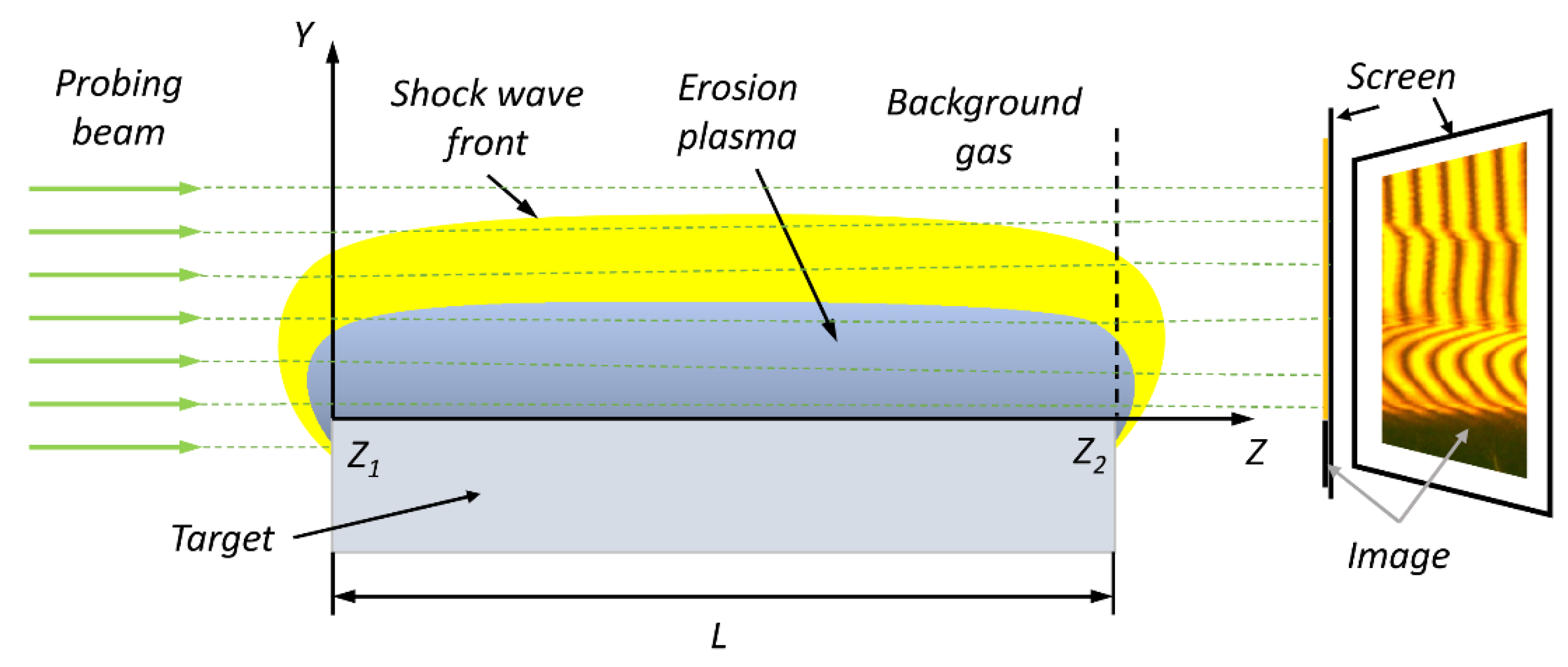

2.3. Laser Diagnostics Techniques

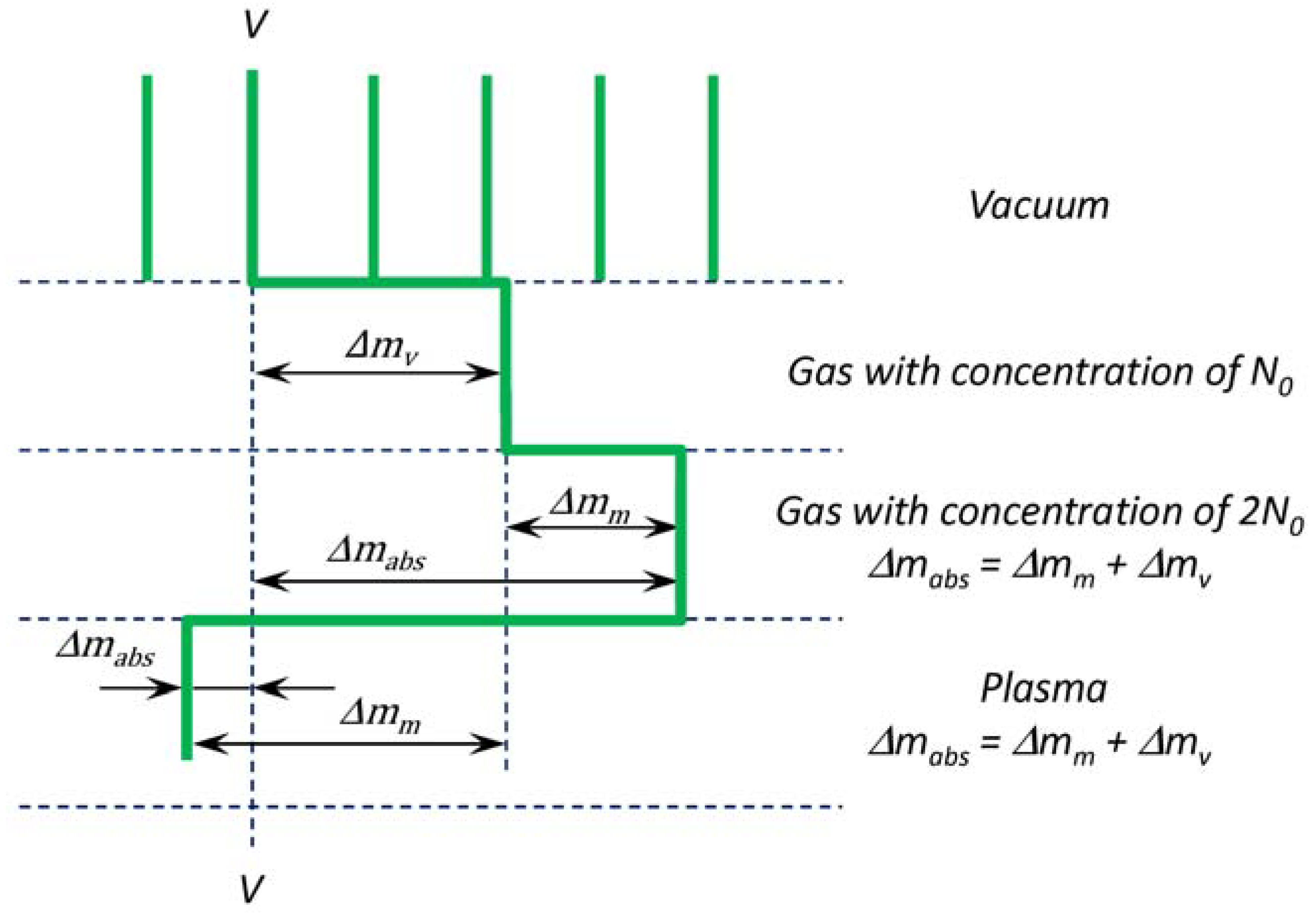

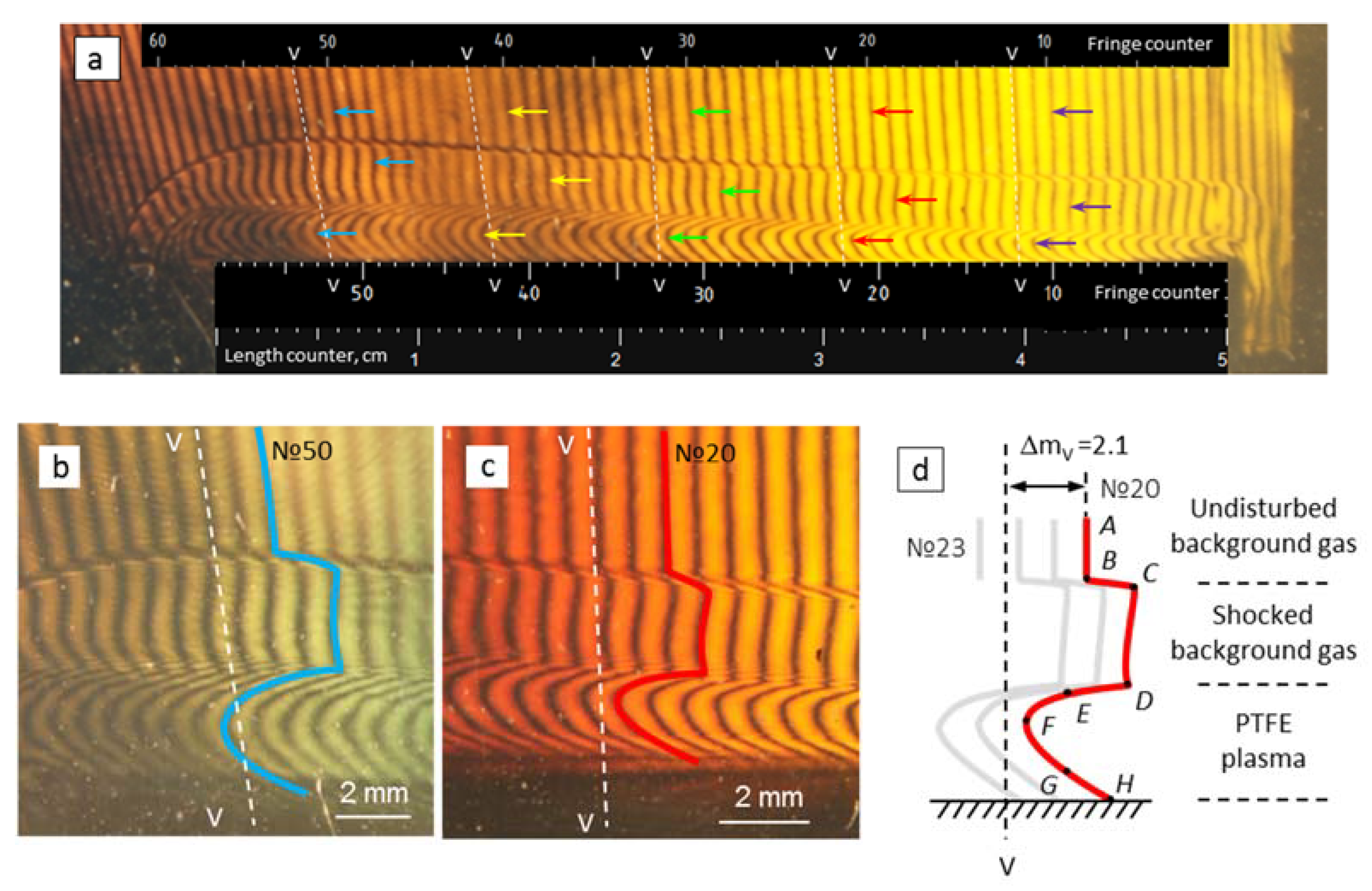

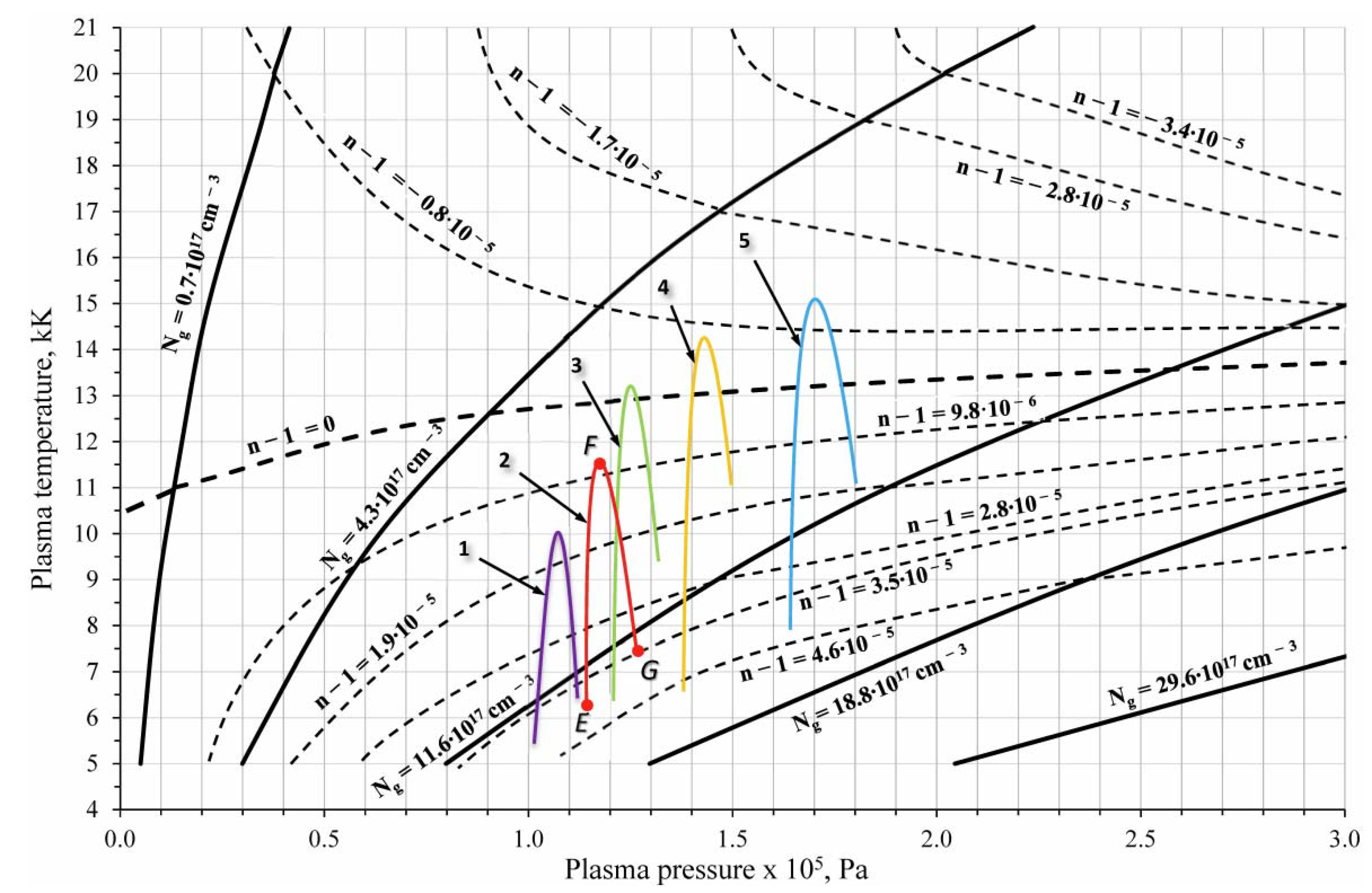

2.4. To Analysis of Holograms

3. Results and Discussion

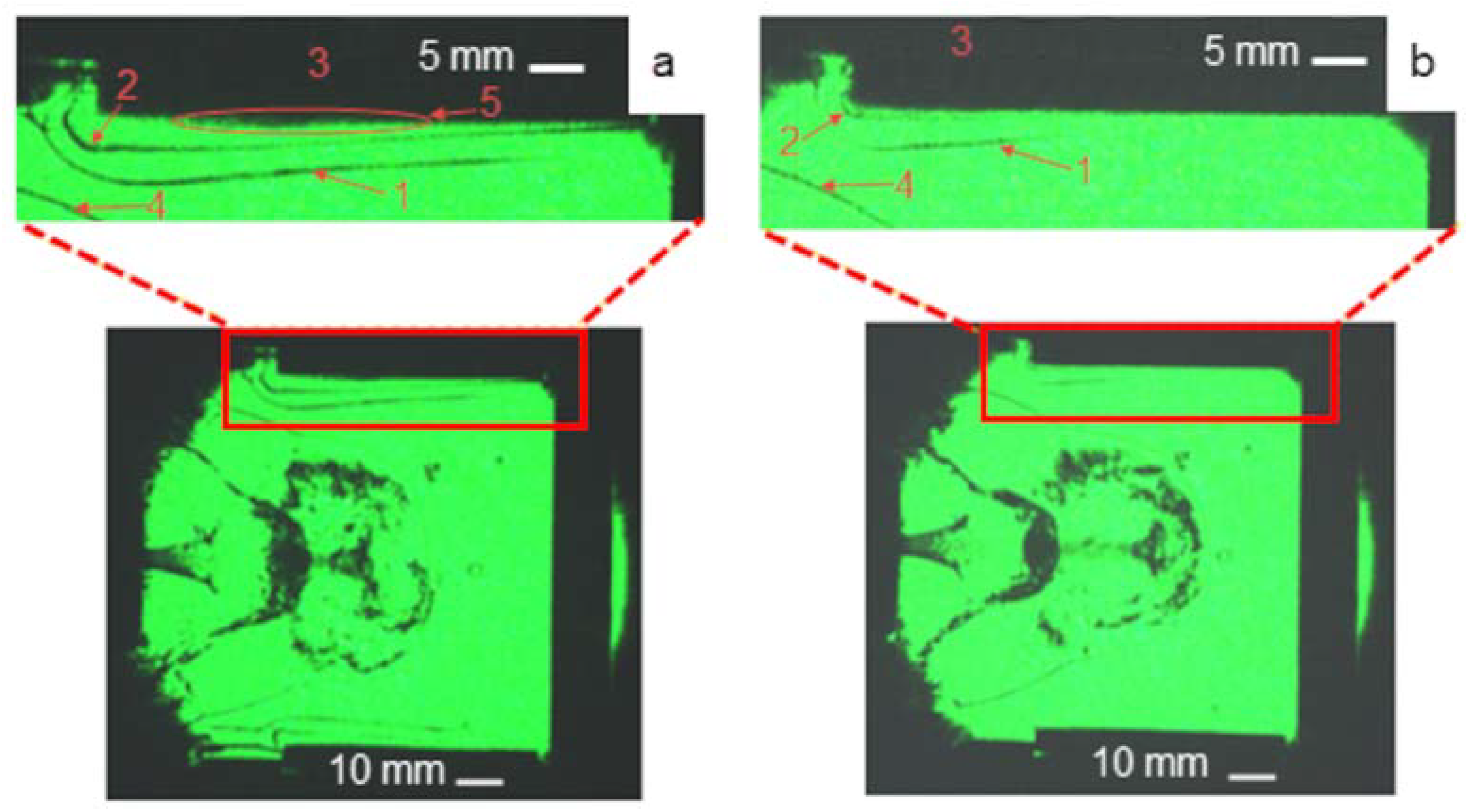

3.1. Experimental Data on Gas-Dynamic Response from PTFE Surface

3.2. Interpretation of Gas Flow Structures with Interferograms

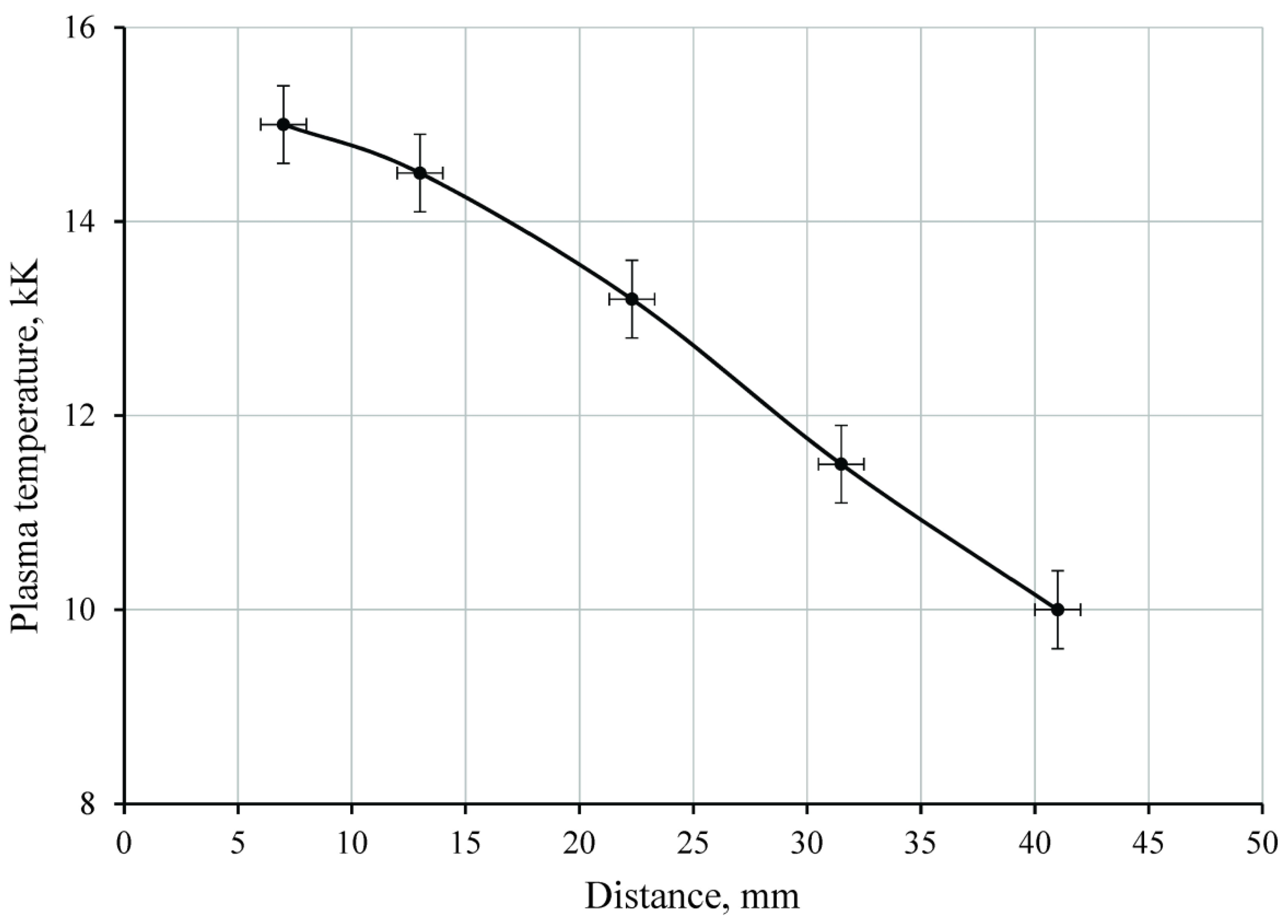

3.3. Thermodynamic Parameters of Plasma above PTFE Surface

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Popov, G.A.; Antropov, N.N. Ablative PPT. New quality, new perspectives. Acta Astronaut. 2006, 59, 175–180. [Google Scholar] [CrossRef]

- Huang, T.; Wu, Z.; Sun, G.; Liu, X.; Ling, W.Y.L. Study and modelling of propellant ablation in coaxial ablative pulsed plasma thrusters. Acta Astronaut. 2020, 173, 69–75. [Google Scholar] [CrossRef]

- Phipps, C.R.; Loktionov, E.Y.; Bonnal, C.; Boyer, S.A.E.; Sharaborova, E.; Tahan, G. Is laser space propulsion practical?: Review. Appl. Opt. 2021, 60, H1–H11. [Google Scholar] [CrossRef]

- O’Reilly, D.; Herdrich, G.; Kavanagh, D.F. Electric Methods for Small Satellites: A Review. Aerospace 2021, 8, 22. [Google Scholar] [CrossRef]

- Lemmer, K. Propulsion for CubeSats. Acta Astronaut. 2017, 134, 231–243. [Google Scholar] [CrossRef]

- Bostick, W.H. Experimental Study of Ionized Metter Projected Across a Magnetic Field. Phys. Rev. 1956, 104, 292–299. [Google Scholar] [CrossRef]

- Artsimovich, L.; Lukianov, S.; Podgornyi, I.; Chuvatin, S. Electrodynamic Acceleration of Plasma Bunches. J. Exp. Theor. Phys. 1958, 6, 1–5. [Google Scholar]

- Kantrowitz, A. Propulsion to orbit by ground-based lasers. J. Aeronaut. Astronaut. Aviat. Ser. 1972, 10, 74–76. [Google Scholar]

- Bityurin, N.; Luk’yanchuk, B.S.; Hong, M.H.; Chong, T.C. Models for Laser Ablation of Polymers. Chem. Rev. 2003, 103, 519–552. [Google Scholar] [CrossRef]

- Urech, L.; Lippert, T. Photoablation of Polymer Materials. In Photochemistry and Photophysics of Polymer Materials; Allen, N.S., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2010; pp. 541–568. [Google Scholar] [CrossRef]

- Phipps, C.R. Laser Ablation Propulsion and Its Applications in Space. In Advances in the Application of Lasers in Materials Science; Ossi, P.M., Ed.; Springer: Cham, Switzerland, 2018; pp. 217–246. [Google Scholar] [CrossRef]

- Skurat, V. Vacuum ultraviolet photochemistry of polymers. Nucl. Instrum. Methods Phys. Res. B 2003, 208, 27–34. [Google Scholar] [CrossRef]

- Zhang, J.; Bi, R.; Jiang, S.; Wen, Z.; Luo, C.; Yao, J.; Liu, G.; Chen, C.; Wang, M. Laser Ablation Mechanism and Performance of Carbon Fiber-Reinforced Poly Aryl Ether Ketone (PAEK) Composites. Polymers 2022, 14, 2676. [Google Scholar] [CrossRef]

- Zaplotnik, R.; Vesel, A. Effect of VUV Radiation on Surface Modification of Polystyrene Exposed to Atmospheric Pressure Plasma Jet. Polymers 2020, 12, 1136. [Google Scholar] [CrossRef] [PubMed]

- Cherkashina, N.I.; Pavlenko, V.I.; Noskov, A.V.; Shkaplerov, A.N.; Kuritsyn, A.A.; Gorodov, A.I. Changes in surface properties of PI/WO2 coatings after vacuum ultraviolet irradiation. J. Photochem. Photobiol. 2021, 405, 112970. [Google Scholar] [CrossRef]

- Chen, J.; Ding, N.; Li, Z.; Wang, W. Organic polymer materials in the space environment. Prog. Aerosp. Sci. 2016, 83, 37–56. [Google Scholar] [CrossRef]

- Popović, D.; Mozetič, M.; Vesel, A.; Primc, G.; Zaplotnik, R. Review on vacuum ultraviolet generation in low-pressure plasmas. Plasma Processes Polym. 2021, 18, 2100061. [Google Scholar] [CrossRef]

- Lippert, T. Interaction of Photons with Polymers: From Surface Modification to Ablation. Plasma Processes Polym. 2005, 2, 525–546. [Google Scholar] [CrossRef]

- Telekh, V.D.; Pavlov, A.V.; Kirillov, D.V.; Vorob’ev, E.V.; Turyanskiy, A.G.; Senkov, V.M.; Tsygankov, P.A.; Parada-Becerra, F.F.; Vesnin, V.R.; Skriabin, A.S. Experimental Study of Irradiation of Thin Oxide and Mo/Si Multilayers by High Brightness Broadband VUV/UV Radiation and Their Degradation. Coatings 2022, 12, 290. [Google Scholar] [CrossRef]

- Kamrukov, A.S.; Kozlov, N.P.; Protasov, Y.S.; Shashkovskii, S.G. Bright thermal VUV sources based on plasmodynamic discharges in gases. High Temp. 1989, 27, 141–155. [Google Scholar]

- Protasov, Y.S.; Protasov, Y.Y.; Telekh, V.D.; Shchepanyuk, T.S. Plasmadynamic light sources of high spectral brightness and shock waves generators. In Enciclopedia of Low Temperature Plasma; Yanus-K: Moscow, Russia, 2014; Volume IX-4, pp. 383–436. [Google Scholar]

- Shelkovenko, T.A.; Tilikin, I.N.; Bolkhovitinov, E.A.; Kologrivova, A.A.; Mingaleev, A.R.; Romanova, V.M.; Zorin, V.B.; Rupasov, A.A.; Pikuz, S.A. A Study of the Ultraviolet Radiation of Hybrid X-Pinches. Plasma Phys. Rep. 2020, 46, 10–19. [Google Scholar] [CrossRef]

- Kozlov, N.P.; Protasov, Y.S. On the mechanism of a plasma focus formation in an ablation type magnetoplasma compressor. Phys. Lett. A 1978, 67, 191–193. [Google Scholar] [CrossRef]

- Kamrukov, A.S.; Kashnikov, G.N.; Kozlov, N.P.; Kuznetsov, S.G.; Opekan, A.G.; Orlov, V.K.; Protasov, Y.S.; Yakimenko, A.N. High-power quartz plasmadynamic source of short-wavelength and vacuum ultraviolet radiation with a brightness temperature ~40 kK. Sov. J. Quantum Electron. 1984, 14, 1094–1099. [Google Scholar] [CrossRef]

- Couprie, M.E. New generation of light sources: Present and future. J. Electron Spectrosc. Relat. Phenom. 2014, 196, 3–13. [Google Scholar] [CrossRef]

- Pavlov, A.V.; Protasov, Y.Y.; Telekh, V.D.; Shchepanuk, T.S. Laser holographic interferometry of short ultraviolet radiation with high power density interaction with condensed matters. Sci. Vis. 2019, 11, 111–125. [Google Scholar] [CrossRef]

- Settles, G.S. Schlieren and Shadowgraph Techniques; Springer: Berlin/Heidelberg, Germany, 2001. [Google Scholar]

- Kreis, T. Handbook of Holographic Interferometry: Optical and Digital Methods; WILEY-VCH Verlag GmbH & Co.: Weinheim, Germany, 2005. [Google Scholar] [CrossRef]

- Ostrovskaya, G.V. Holographic diagnostics of the plasma: A review. Tech. Phys. 2008, 53, 1103–1128. [Google Scholar] [CrossRef]

- Ostrovsky, Y.I.; Butusov, M.M.; Ostrovskaya, G.V. Interferometry by Holography; Springer: Berlin, Germany, 1980. [Google Scholar] [CrossRef]

- Schwerdtfeger, P.; Nagle, J.K. Table of static dipole polarizabilities of the neutral elements in the periodic table. Mol. Phys. 2018, 117, 1200–1225. [Google Scholar] [CrossRef] [Green Version]

- Huddlestone, R.H.; Leonard, S.L. Plasma Diagnostic Techniques; Academic Press: New York, NY, USA, 1965. [Google Scholar]

- Boiko, Y.V.; Grishin, Y.M.; Kamrukov, A.S.; Kozlov, N.P.; Protasov, Y.S.; Chuvashev, S.N. Thermodynamic and Optical Properties of Ionized Gases at Temperatures up to 100 eV; Hemisphere Publishing Corp.: New York, NY, USA, 1990. [Google Scholar]

- Zeldovich, Y.B.; Raizer, Y.P. Physics of Shock Waves and High-Temperature Hydrodynamic Phenomena; Dover Publications: New York, NY, USA, 2002. [Google Scholar]

- Braginskii, S.I. Theory of the Development of a Spark Channel. J. Exp. Theor. Phys. 1958, 7, 1068–1074. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pavlov, A.; Shchepanyuk, T.; Skriabin, A.; Telekh, V. Gas Dynamics Processes above the Polymers Surface under Irradiation with Broadband High-Brightness Radiation in the Vacuum Ultraviolet Spectrum Region. Polymers 2022, 14, 3940. https://doi.org/10.3390/polym14193940

Pavlov A, Shchepanyuk T, Skriabin A, Telekh V. Gas Dynamics Processes above the Polymers Surface under Irradiation with Broadband High-Brightness Radiation in the Vacuum Ultraviolet Spectrum Region. Polymers. 2022; 14(19):3940. https://doi.org/10.3390/polym14193940

Chicago/Turabian StylePavlov, Aleksei, Tadeush Shchepanyuk, Andrei Skriabin, and Victor Telekh. 2022. "Gas Dynamics Processes above the Polymers Surface under Irradiation with Broadband High-Brightness Radiation in the Vacuum Ultraviolet Spectrum Region" Polymers 14, no. 19: 3940. https://doi.org/10.3390/polym14193940

APA StylePavlov, A., Shchepanyuk, T., Skriabin, A., & Telekh, V. (2022). Gas Dynamics Processes above the Polymers Surface under Irradiation with Broadband High-Brightness Radiation in the Vacuum Ultraviolet Spectrum Region. Polymers, 14(19), 3940. https://doi.org/10.3390/polym14193940