Effects of Polypropylene Fibers on the Frost Resistance of Natural Sand Concrete and Machine-Made Sand Concrete

Abstract

1. Introduction

2. Materials and Methods

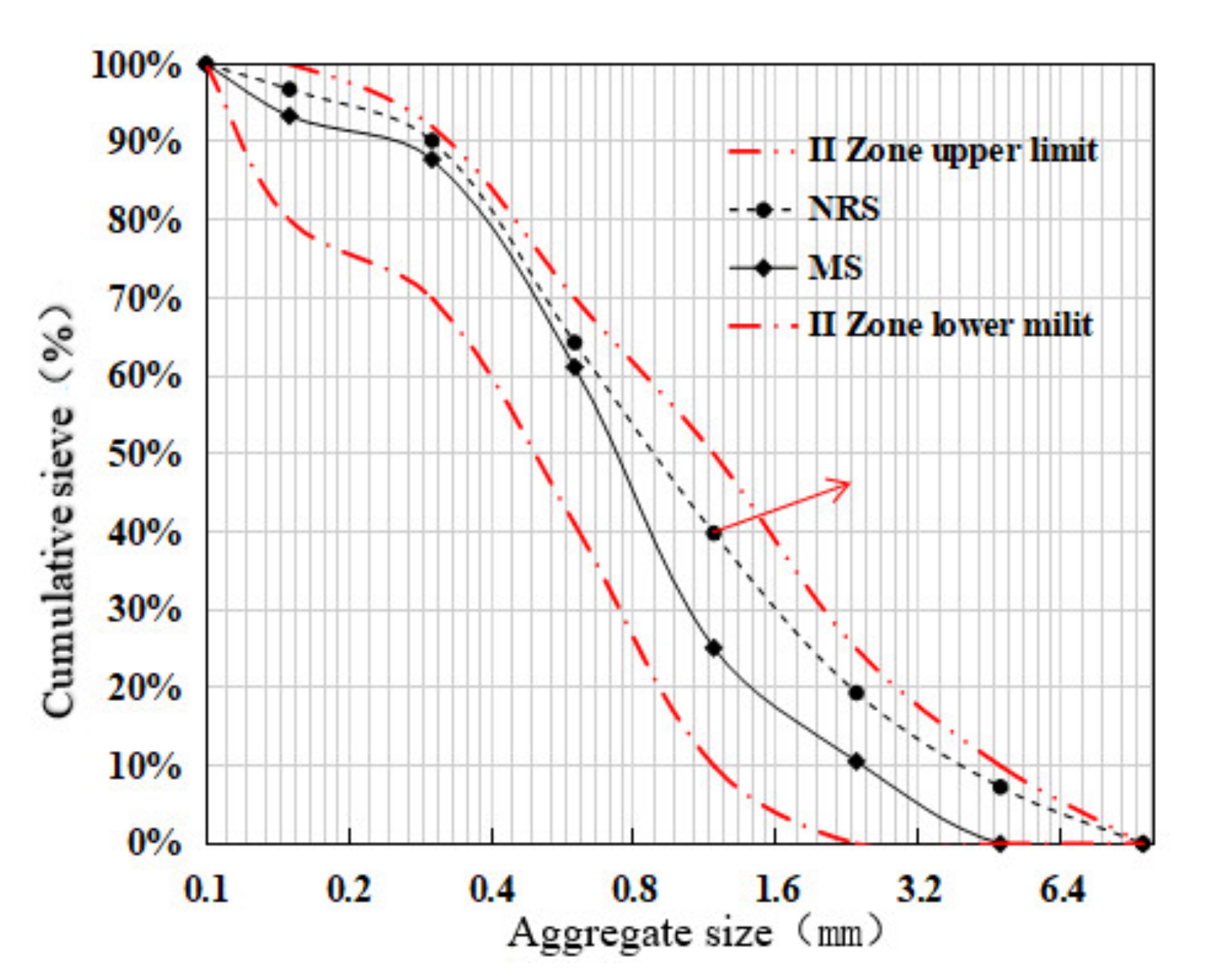

2.1. Raw Materials and Mix Ratio

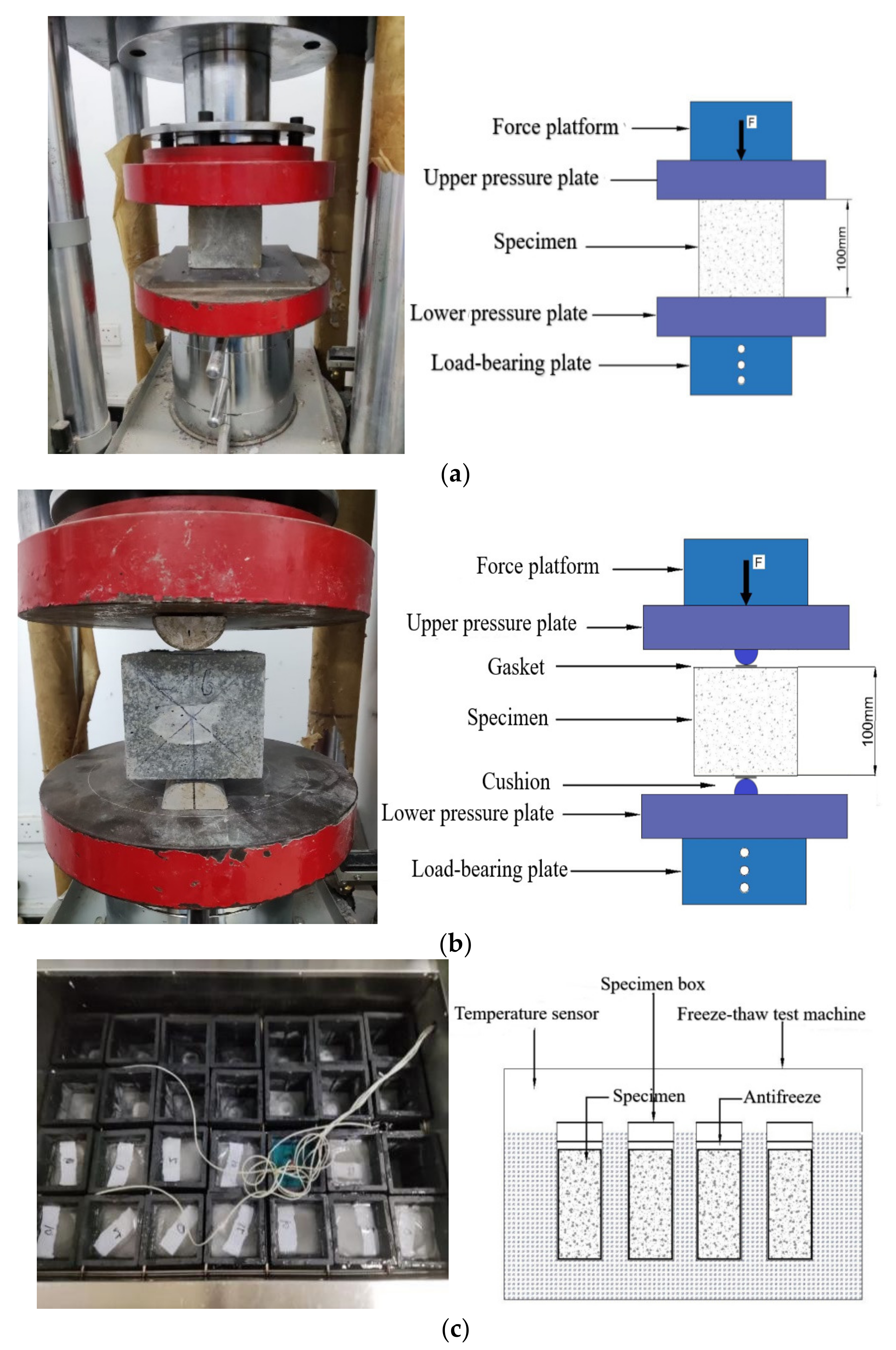

2.2. Test Equipment and Test Methods

3. Test Results and Discussion

3.1. Strength Analysis after Freeze–Thaw Cycle

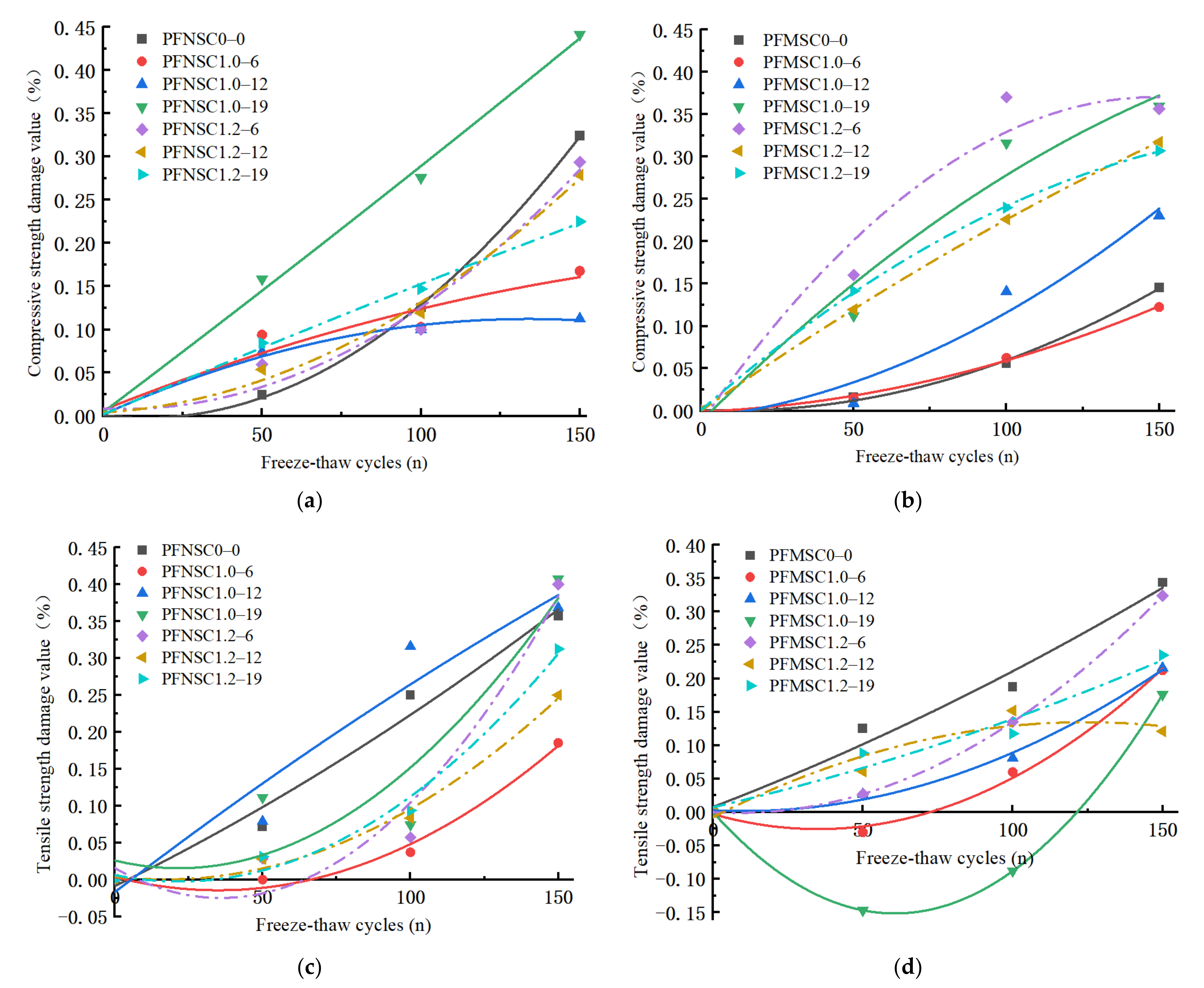

3.2. Freeze–Thaw Injury of PFNSC and PFMSC under Strength Evaluation Index

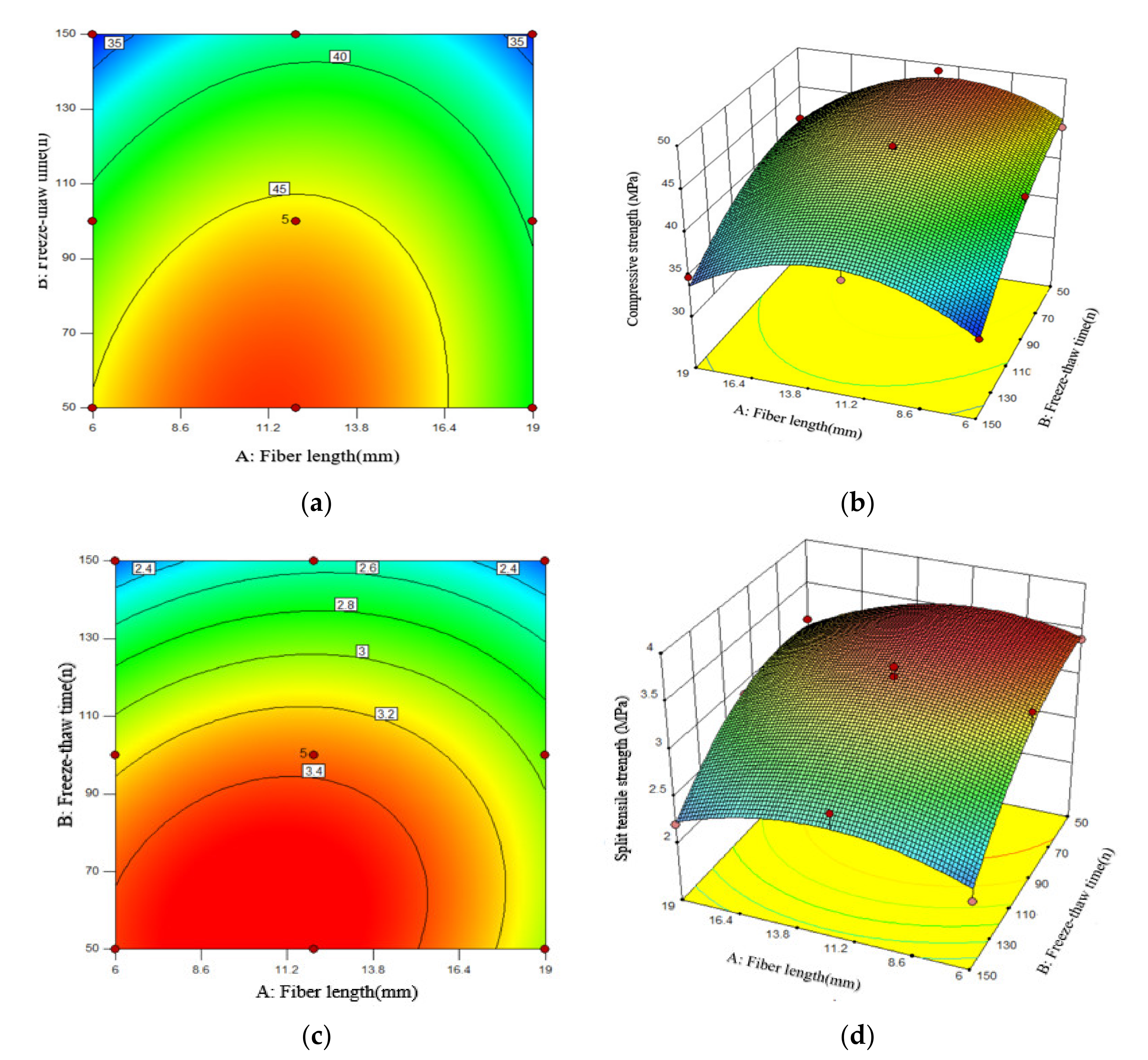

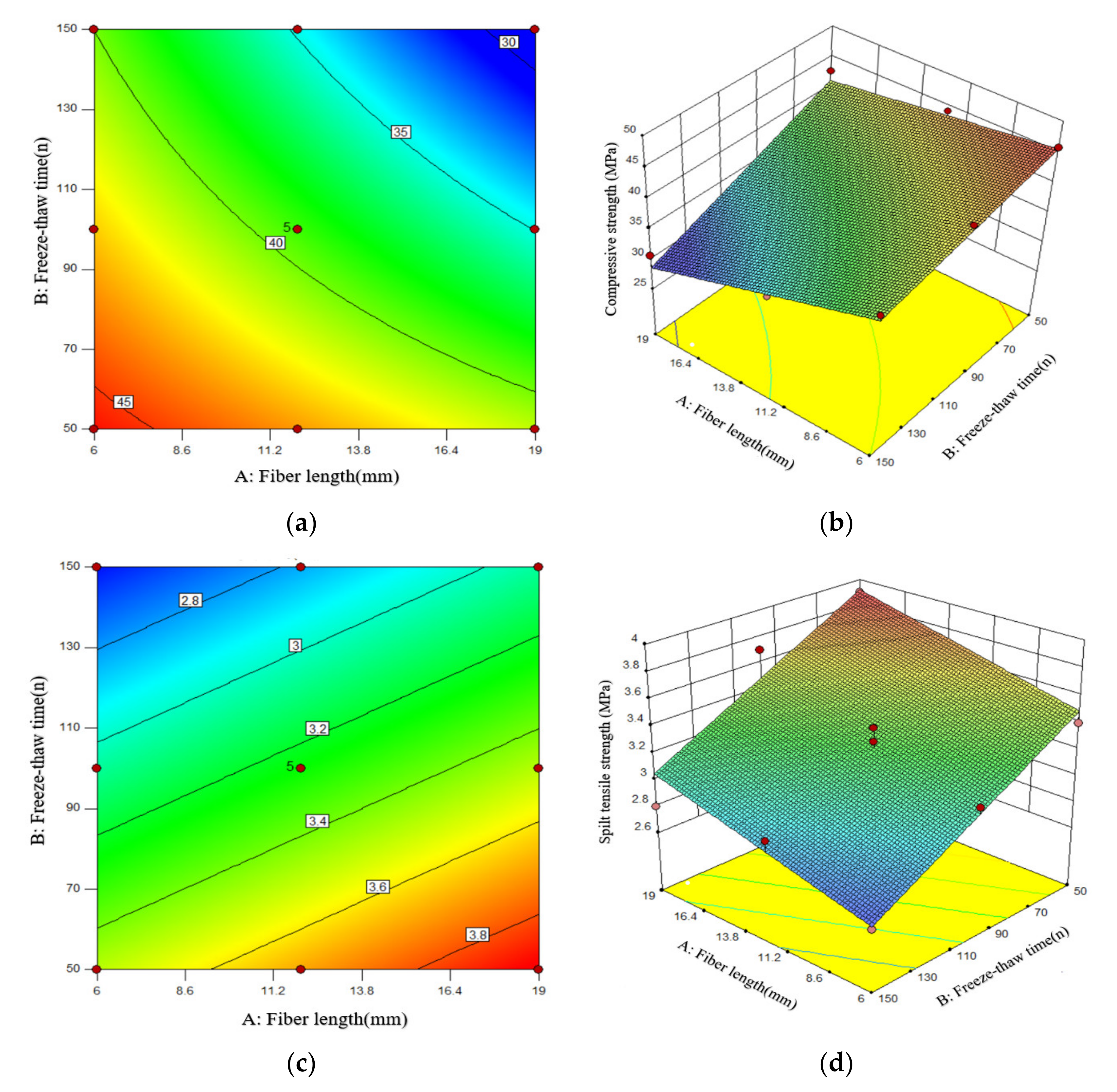

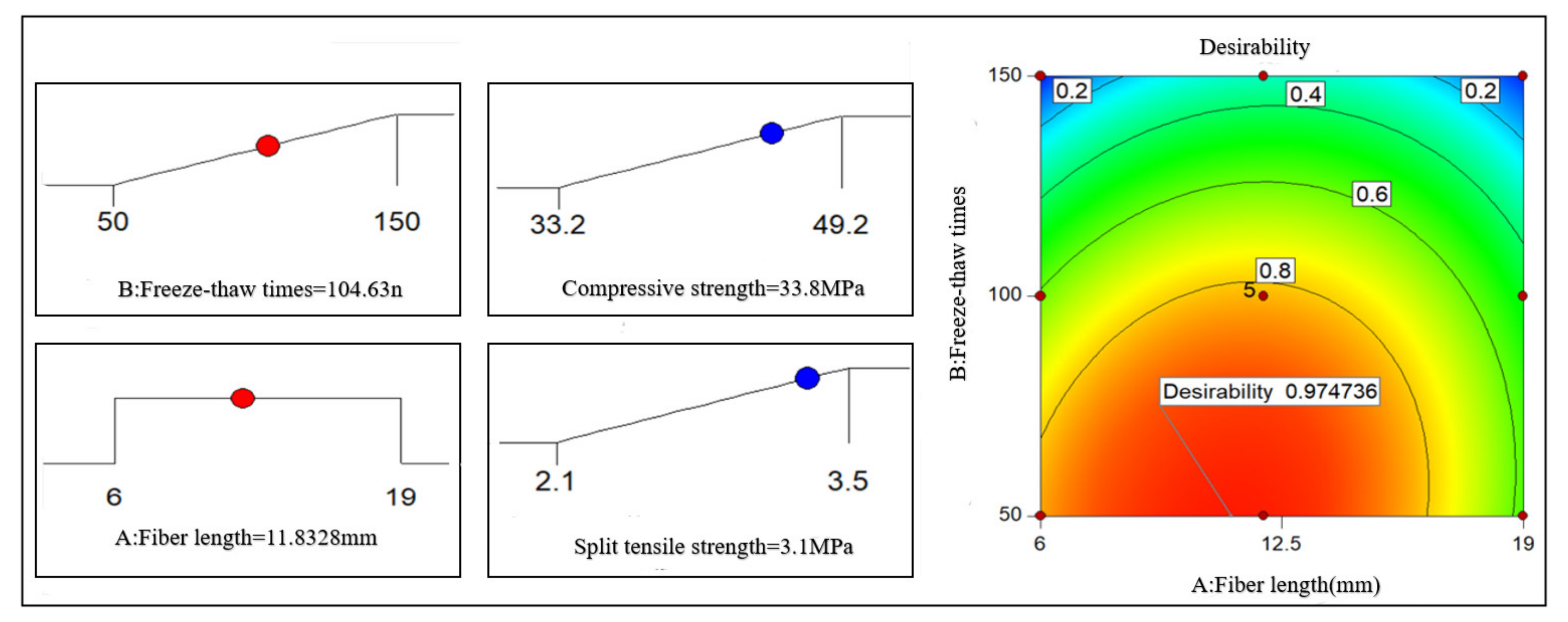

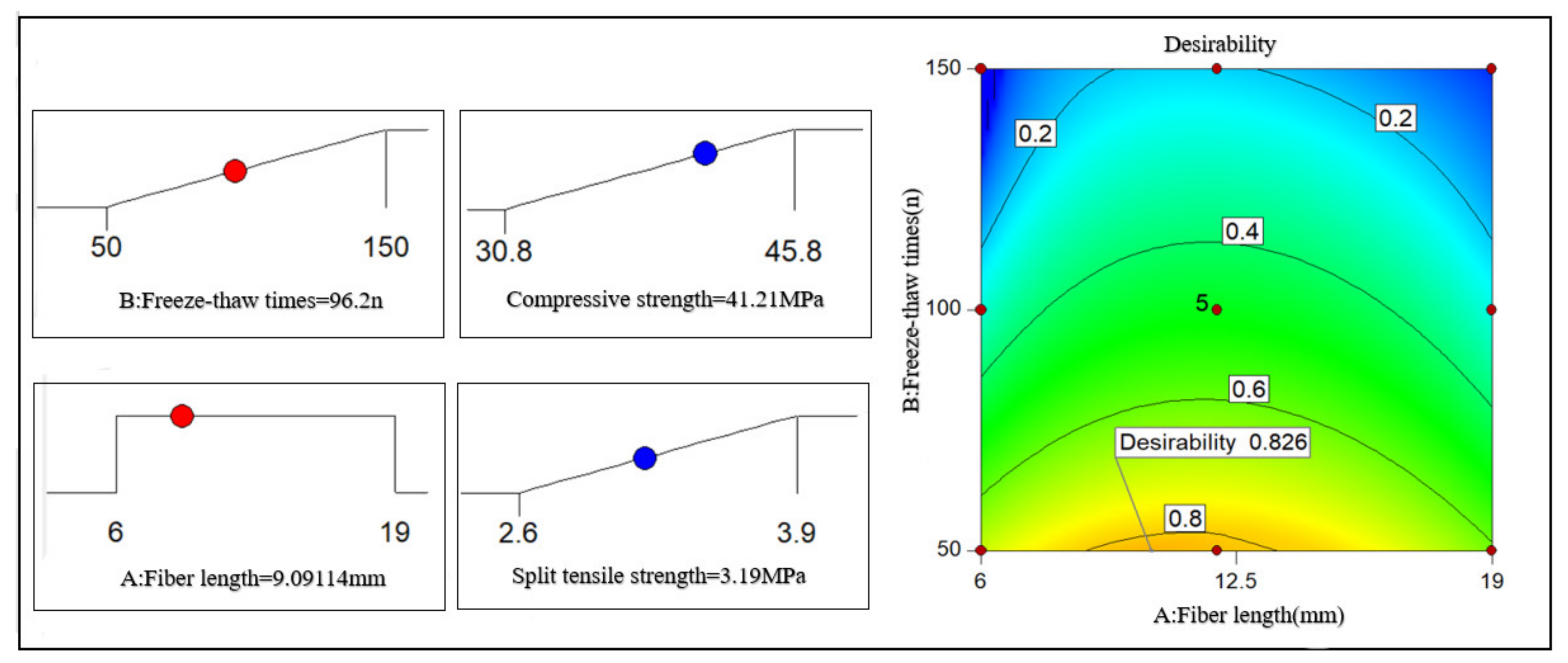

4. Model of the Composite Factor RSM Intensity

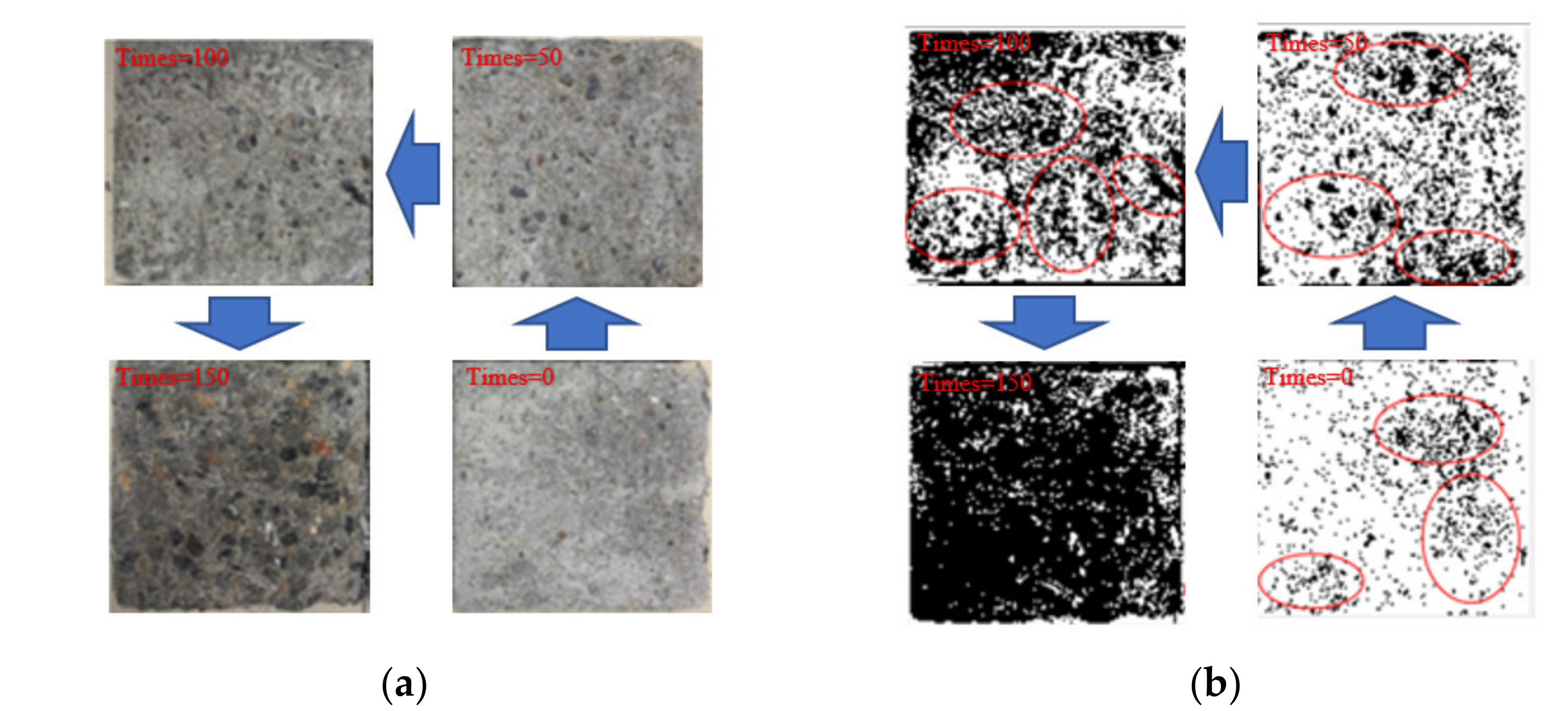

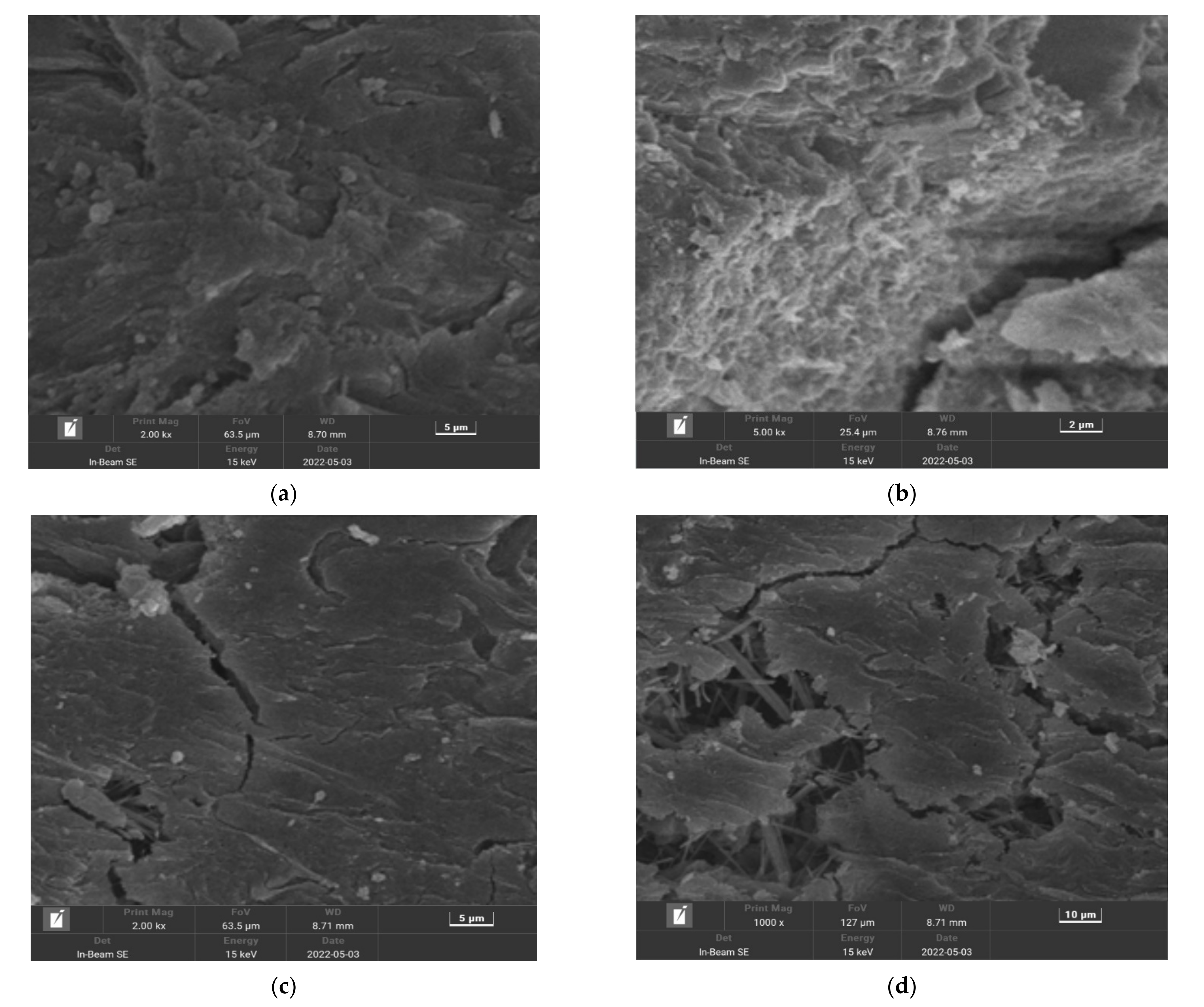

5. Micromorphology Analysis

6. Conclusions

- Before the freeze–thaw cycle, the overall compressive strength of PFNSC increased with the increase in PPF volume content and length, and the overall PFMSC showed a decreasing trend with the increase in PPF volume content and length. The compressive strength is the best when the content of PPF is 1.2%, and the compressive strength of PFMSC is the best when the length of PPF is 9 mm and the volume content of PFMSC is 1.0%. The overall trend is an increase, and the splitting tensile strength is the best when the PPF length is 12 mm and the volume content is 1%.

- With the increase in the number of freeze–thaw cycles, the exposed area of the internal aggregate of PFMSC gradually increased. After 50, 100, and 150 cycles, the average mass damage was 0.32%, 1.85%, and 4.5%, respectively. Mechanical properties and durability performance gradually deteriorated.

- The mechanical properties and antifreeze properties of PFNSC and PFMSC were comprehensively evaluated with the strength value damage variable as the index, which could better reflect the evolution law of freeze–thaw damage. When the volume content of PPF is 1.0% and the length is 6 mm and 12 mm, the compressive strength damage of the PFMSC specimen is lower; when the volume content of PPF is 1.0% and the length is 6 mm, the splitting tensile strength damage of the PFMSC specimen is higher. The strength damage of the PFMSC specimens is generally lower than that of the PFNSC specimens, and when the PPF length is the same, the volume content of 1% can better reduce the strength damage. According to the prediction results of PFNSC and PFMSC, the antifreeze performances of PFNSC and PFMSC are similar. This shows that polypropylene fibers have similar effects on PFNSC and PFMSC. It also shows that it is feasible to replace natural sand concrete with 100% artificial sand in practical engineering.

- The optimal performances of PFNSC and PFMSC are predicted by the RSM strength composite model. PFNSC can maintain a good antifreeze performance within 105 cycles of freezing and thawing. When the volume content of PPF is 1.2% and the length is 11.82 mm, the freezing performance is optimal, the compressive strength value is 33.8 MPa, and the split tensile strength value is 3.1 MPa. PFMSC can maintain a good antifreeze performance within 96 freeze–thaw cycles. When the volume content of PPF is 1.2% and the length is 9.1 mm, the antifreeze performance of the specimen reaches its maximum, its maximum tensile strength value is 45.8 MPa, and the split tensile strength value is 3.2 MPa.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Detwiler, R.J.; Dalgleish, B.J.; Williamson, R.B. Assessing the durability of concrete in freezing and thawing. ACI Mater. J. 1989, 86, 29–35. [Google Scholar] [CrossRef]

- Alireza, F. Compressive behavior of concrete under environmental effects. In Compressive Strength of Concrete; IntechOpen: London, UK, 2020. [Google Scholar] [CrossRef]

- Alireza, F. Temperature and humidity effects on behavior of grouts. Adv. Concr. Constr. 2017, 5, 659–669. [Google Scholar] [CrossRef]

- Navid, C.; Alireza, F.; Nima, P. Nano silica and metakaolin effects on the behavior of concrete containing rubber crumbs. Civil Eng. 2020, 1, 17. [Google Scholar] [CrossRef]

- Niu, D.T.; Yang, D.Z.; Luo, D. Durability assessment method of existing concrete structures. Build. Struct. 2021, 51, 115–121. [Google Scholar]

- Soroushia, P.; Nagi, M.; Okwuegbu, A. Freeze-thaw durability of Lightweight carbon fiber reinforced cement composites. ACI Mater. J. 1992, 89, 491–494. [Google Scholar]

- Mandal, S.; Chakarborty, S.; Gupta, A. Some studies on durability of recycled aggregate concrete. Indian Concr. J. 2002, 76, 385–388. [Google Scholar]

- Metha, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties and Materials, 3rd ed.; McGraw-Hill: New York, NY, USA, 2006; pp. 121–209. [Google Scholar]

- Liu, D.; Wang, L.; Wang, Z.D.; Fang, J. Exploration on the durability test method of ultra–lightweight concrete. Concrete 2022, 7, 151–154. [Google Scholar] [CrossRef]

- Wei, J.; Wu, X.H.; Zhao, X.L. A model for concrete durability degradation in freeze-thawing cycles. Acta Mech. Solida Sin. 2003, 16, 353–358. [Google Scholar]

- Niu, D.T.; Jian, L.; Bai, M. Experimental analysis is on the frost-resistance of steel fiber reinforced concrete. J. Civ. Archit. Environ. Eng. 2012, 34, 80–84. [Google Scholar]

- Yao, W. Property of fiber reinforced concrete at low temperature and its damage mechanism under freezing-thawing cycles. J. Glaciol. Geocryol. 2005, 27, 545–549. [Google Scholar]

- Mansouri, I.; Shahheidari, F.S.; Hashemi, S.M.; Farzampour, A. Investigation of steel fiber effects on concrete abrasion resistance. Adv. Concr. Constr. 2020, 9, 367–374. [Google Scholar]

- Fouad, T.; Shad, M.; Issam, K.; Husam, H. Material Properties of Synthetic Fiber–Reinforced Concrete under Freeze-Thaw Conditions. J. Mater. Civ. Eng. 2018, 9, 30. [Google Scholar]

- Andreikiv, O.E.; Dolinska, I.Y.; Raiter, O.K. Computational Model for the Evaluation of the Service Life of Fiber-Reinforced Concrete Structures Under Long-Term Static Loading. Mater. Sci. 2020, 56, 291–300. [Google Scholar] [CrossRef]

- Bhogone, M.V.; Subramaniam, K.V. Early-Age Tensile Constitutive Relationships for Steel and Polypropylene Fiber Reinforced Concrete. Eng. Fract. Mech. 2021, 244, 107556. [Google Scholar] [CrossRef]

- Bindiganavilev, B. Polymer and steel fiber-rein-forced cementitious composites under impact loading—Part 1: Bondslip response. ACI Mater. J. 2001, 98, 10–16. [Google Scholar]

- Seung, H.P.; Dong, J.K.; GumSung, R.; Kyung, T.K. Tensile behavior of UItra High Performance Hybrid Fiber Reinforced Concrete. Front. Mater. 2012, 34, 172–184. [Google Scholar] [CrossRef]

- de Sá, F.R.G.; de Silva, F.A.; Cardoso, D.C.T. Tensile and flexural performance of concrete members reinforced with polypropylene fibers and GFRP bars. Compos. Struct. 2020, 253, 112784. [Google Scholar] [CrossRef]

- Luo, H.L.; Yang, D.Y.; Zhou, X.Y.; Shan, C.C.; Liu, X.; Zhao, F.Z. The mechanical properties of reinforced concrete with different length ratio polypropylene fiber. Compos. Mater. J. 2019, 36, 1935–1948. [Google Scholar]

- Fu, Q.; Niu, D.; Li, D. Impact characterization and modelling of basalt-polypropylene fibre-reinforced concrete containing mineral admixtures. Cem. Concr. Compos. 2018, 93, 246–259. [Google Scholar] [CrossRef]

- Shen, D.J.; Liu, X.Z.; Zeng, X. Effect of polypropylene plastic fibers length on cracking resistance of high performance concrete at early age. Constr. Build. Mater. 2020, 244, 117874. [Google Scholar] [CrossRef]

- Zoran, J.G.; Gordana, A.T.C.; Nenad, S.R.; Iva, M.D. Abrasion resistance of concrete micro-reinforced with polypro-pylene fibers. Constr. Build. Mater. 2012, 27, 305–312. [Google Scholar] [CrossRef]

- Rouhollah, R.; Mohammad, Z.; Khaled, S. An investigation into influence of physical and chemical surface modification of macro-polypropylene fibers on properties of cementitious composites. Constr. Build. Mater. 2020, 244, 118340. [Google Scholar]

- Latifi, M.R.; Biricik, Ö.; Mardani, A.A. Effect of the addition of polypropylene fiber on concrete properties. J. Adhes. Sci. Technol. 2022, 36, 345–369. [Google Scholar] [CrossRef]

- Cheng, H.Q.; Gao, D.Y. Experimental study on freeze-thaw damage of polypropylene fiber concrete. J. Southeast Univ. 2010, 40, 197–200. [Google Scholar]

- Chen, L.Z.; Zhang, G.T.; Huang, W.M. The injury research of fiber rein forced concrete under freeze-thaw cycles. Sci. Technol. Eng. 2015, 15, 145–150. [Google Scholar]

- Salehi, P.; Dabbagh, H.; Ashengroph, M. Effects of microbial strains on the mechanical and durability properties of lightweight concrete reinforced with polypropylene fiber. Constr. Build. Mater. 2022, 322, 126519. [Google Scholar] [CrossRef]

- Liu, B.; Zhang, X.T.; Ying, R.J.; Gao, Y. Review of polypropylene fiber concrete research. Cem. Concr. Prod. 2021, 1, 5–6. [Google Scholar]

- Mundra, S.; Sindhi, P.R.; Chandwani, V. Crushed rock sand an economical and ecological alternative to natural sand to optimize concrete mi. Perspect. Sci. 2016, 8, 345–347. [Google Scholar] [CrossRef]

- Shen, W.; Liu, Y.; Cao, L.; Huo, X.; Yang, Y.Z.; Zhou, C.; He, P.; Lu, Z. Mixing design and microstructure of ultra high strength concrete with manufactured sand. Constr. Build. Mater. 2017, 143, 312–321. [Google Scholar] [CrossRef]

- Qin, Y.; Luo, J.; Chen, Z.; Mei, G.; Yan, L.E. Measuring the albedo of limited-extent targets without the aid of known-albedo masks. Sol. Energy 2018, 171, 971–976. [Google Scholar] [CrossRef]

- Bonavetti, V.; Donza, H.; Menendez, G. Limestone filler cement in low wle concrete: A rational use of energy. Cem. Concr. Res. 2003, 33, 865–871. [Google Scholar] [CrossRef]

- Bonavetti, V.L.; Rahhal, V.F.; Irassar, E.F. Studies on the carboaluminate formation in limestone filler-blended cements. Cem. Concr. Res. 2001, 31, 853–859. [Google Scholar] [CrossRef]

- Anne, M.P.; Geert, D.S. Cement hydration in the presence of high filler contents. Cem. Concr. Res. 2005, 35, 2290–2299. [Google Scholar]

- Ding, X.X.; Li, C.Y.; Xu, Y.Y. Experimental study on long-term compressive strength of concrete with manufactured sand. Constr. Build. Mater. 2016, 108, 67–73. [Google Scholar] [CrossRef]

- Wang, j.; Li, B.X.; Yang, J.B. Effects of stone powder content and steel fiber length on the properties of manufactured sand ultra-high performance concrete. Acta Silicate 2020, 39, 2120–2126. [Google Scholar] [CrossRef]

- Zhang, H.R.; Ji, T.; Zeng, X.P. Mechanical behavior of ultra-high performance concrete (UHPC) using recycled fine aggregate cured under different conditions and the mechanism based on integrated microstructural parameters. Constr. Build. Mater. 2018, 192, 489–507. [Google Scholar] [CrossRef]

- Pyo, S.; Kim, H.; Lee, B.Y. Effects of coarser fine aggregate on tensile properties of ultra high performance concrete. Cem. Concr. Compos. 2017, 84, 28–35. [Google Scholar] [CrossRef]

- Zhang, J.F.; Li, D.; Wang, Y.H. Toward intelligent construction: Prediction of mechanical properties of manufactured-sand concrete using tree-based models. J. Clean. Prod. 2020, 258, 120665. [Google Scholar] [CrossRef]

- Bonavetti, V.L.; Irassar, E.F. The Effect of Stone Dust Content in Sand. Cem. Concr. Res. 1994, 24, 580–590. [Google Scholar] [CrossRef]

- Donza, H.; Carera, O.; Irassar, E.F. High-strength concrete with different fine aggregate. Cem. Concr. Res. 2002, 32, 1755–1761. [Google Scholar] [CrossRef]

- Zeghichi, L.; Benghazi, Z.; Baali, L. The Effect of the Kind of Sands and Additions on the Mechanical Behaviour of SCC. Phys. Procedia 2014, 55, 485–492. [Google Scholar] [CrossRef]

- Keisuke, M.; Koji, Y.; Kazushi, Y. Structure and fracture toughness of thin-wall polypropylene moulded at different injection speeds. Thin-Walled Struct. 2018, 125, 12–20. [Google Scholar] [CrossRef]

- Thanasak, W.; Antoine, E. Naaman Unrestrained early age shrinkage of concrete with polypropylene, PVA, and carbon fibers. Mater. Struct. 2007, 40, 289–300. [Google Scholar] [CrossRef]

- Zhao, Y.R.; Liu, F.F.; Wang, L.; Guo, Z.L. Study on compressive strength model of single-sided frozen concrete based on pore structure. J. Build. Mater. 2020, 23, 432. [Google Scholar] [CrossRef]

- Ramalingam, K.; Murugesan, R. Study on fiber reinforced concrete using manufactured sand as fine aggregate and domestic waste plastics as fibres. J. Struct. Eng. 2014, 40, 521–527. [Google Scholar] [CrossRef][Green Version]

- Pu, C.Z.; Cao, P.; Zhang, C.Y.; Zhang, Q.C. Variable parameter nonlinear creep damage model considering aging damage degradation. Eng. Mech. 2017, 34, 17–27. [Google Scholar]

- Dong, W.; Shen, X.D.; Xue, H.J. Research on the freeze-thaw cyclic test and damage model of Aeolian sand lightweight aggregate concrete. Constr. Build. Mater. 2016, 123, 792–799. [Google Scholar] [CrossRef]

- ACI Committee 544. Measurement of Properties of Fiber Reinforced Concrete. ACI Mater. J. 1998, 85, 83–93. [Google Scholar] [CrossRef]

- Raymond, H.M. Response Surface Methodology-Current Status and Future Directions. J. Qual. Technol. 1999, 31, 30–44. [Google Scholar] [CrossRef]

- Li, Y.L.; Guo, H.Y.; Zhou, H.; Li, Y.; Chen, J.H. Damage characteristics and constitutive model of concrete under uniaxial compression after Freeze-Thaw damage. Constr. Build. Mater. 2022, 345, 128171. [Google Scholar] [CrossRef]

- Kim, R.; Min, J.Y.; Ahn, E.; Choi, H. Assessment of degradation index in freeze-thaw damaged concrete using multi-channel contactless ultrasound. Constr. Build. Mater. 2022, 349, 128815. [Google Scholar] [CrossRef]

- Ma, W.L.; Xu, Z.G.; Qin, Y.; Cao, C.; Wang, Y.X.; Zhou, H. Experimental investigation of nonlinear flow characteristics in cracked polypropylene fibre-reinforced concrete. Mater. Struct. 2021, 54, 215. [Google Scholar] [CrossRef]

- Hill, W.J.; Hunter, W.G. A Review of Response Surface Methodology: A Literature Review. Technometrics 1966, 8, 571–590. [Google Scholar] [CrossRef]

- Mead, R.; Pike, D.J. A Review of Response Surface Methodology from A Biometrics Viewpoint. Biometrics 1975, 31, 803–851. [Google Scholar] [CrossRef]

- Fang, S.E.; Perera, R. Damage identification by response surface based model updating using D-optimal design. Mech. Syst. Signal Process. 2011, 25, 717–733. [Google Scholar] [CrossRef]

- Zong, Z.H.; Sun, J.L.; Xu, L.Q. Design and study of structural health monitoring system of Xiabaishi bridge. J. China Railw. Soc. 2009, 31, 65–71. [Google Scholar]

- Liu, Y.W.; Moses, F. A sequential response surface method and its application in the reliability analysis of aircraft structural systems. Struct. Saf. 1994, 16, 39–46. [Google Scholar] [CrossRef]

- Strzelecki, P. Determination of fatigue life for low probability of failure for different stress levels using 3-parameter Weibull distribution. Int. J. Fatigue 2021, 145, 106080. [Google Scholar] [CrossRef]

- Siamardi, K.; Shabani, S. Evaluation the effect of micro-synthetic fiber on mechanical and freeze-thaw behavior of non-air-entrained roller compacted concrete pavement using response surface methodology. Constr. Build. Mater. 2021, 295, 123628. [Google Scholar] [CrossRef]

- Ai, Y.; Zhu, S.P.; Liao, D.; Correia, J.A.F.O.; Souto, C.; De Jesus, A.M.P.; Keshtegar, B. Probabilistic modeling of fatigue life distribution and size effect of components with random defects. Int. J. Fatigue 2019, 126, 165–173. [Google Scholar]

| Type | Density (g/cm3) | Elastic Modulus (MPa) | Break Strength (MPa) | Elongation at Break (%) | Melting Point (°C) | Ignite (°C) | Acid and AlkaliResistance |

|---|---|---|---|---|---|---|---|

| Fascicular | 0.91 | >4500 | 450 | 255± | 165–175 | 590 | Better |

| NO. | Polypropylene Fiber | Material Dosage (kg/m3) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Volume Dosage (%) | Length (mm) | Cement | Flash | Natural River Sand | Mechanism Sand | Coarse Aggregate | Water | Water Reducer | |

| PFNSC0–0 | 0 | 0 | 398 | 80 | 763 | 0 | 920 | 200 | 4.71 |

| PFNSC1.0–b | 1.0 | 6/12/19 | 398 | 80 | 763 | 0 | 920 | 200 | 4.71 |

| PFNSC1.2–b | 1.2 | 6/12/19 | 398 | 80 | 763 | 0 | 920 | 200 | 4.71 |

| PFMSC0–0 | 0 | 0 | 398 | 80 | 0 | 763 | 920 | 200 | 4.71 |

| PFMSC1.0–b | 1.0 | 6/12/19 | 398 | 80 | 0 | 763 | 920 | 200 | 4.71 |

| PFMSC1.2–b | 1.2 | 6/12/19 | 398 | 80 | 0 | 763 | 920 | 200 | 4.71 |

| NO. | 0 Freeze–Thaw Cycles | 50 Freeze–Thaw Cycles | 100 Freeze–Thaw Cycles | 150 Freeze–Thaw Cycles | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Strength (MPa) | Mass (kg) | Strength (MPa) | Mass (kg) | Strength (MPa) | Mass (kg) | Strength (MPa) | Mass (kg) | |||||

| Compression | Tensile | Compression | Tensile | Compression | Tensile | Compression | Tensile | |||||

| PFNSC0–0 | 40.7 | 2.8 | 2.405 | 39.7 | 2.6 | 2.402 | 35.6 | 2.1 | 2.398 | 27.5 | 1.8 | 2.381 |

| PFNSC1.0–6 | 44.7 | 2.7 | 2.379 | 40.5 | 2.7 | 2.752 | 40.1 | 2.6 | 2.362 | 37.2 | 2.2 | 2.351 |

| PFNSC1.0–12 | 47.1 | 3.8 | 2.382 | 43.6 | 3.5 | 2.375 | 42.4 | 2.6 | 2.360 | 41.8 | 2.4 | 2.347 |

| PFNSC1.0–19 | 41 | 2.7 | 2.378 | 34.5 | 2.4 | 2.374 | 29.7 | 2.5 | 2.278 | 22.9 | 1.6 | 2.252 |

| PFNSC1.2–6 | 47.7 | 3.5 | 2.382 | 44.2 | 3.4 | 2.381 | 42.3 | 3.3 | 2.326 | 33.2 | 2.1 | 2.261 |

| PFNSC1.2–12 | 52 | 3.6 | 2.318 | 49.2 | 3.5 | 2.312 | 45.8 | 3.3 | 2.281 | 37.5 | 2.7 | 2.245 |

| PFNSC1.2–19 | 44.9 | 3.2 | 2.408 | 41.1 | 3.1 | 2.389 | 38.3 | 2.9 | 2.342 | 34.8 | 2.2 | 2.294 |

| PFMSC0–0 | 50.1 | 3.2 | 2.392 | 48.1 | 2.8 | 2.384 | 49.3 | 2.6 | 2.364 | 42.8 | 2.1 | 2.310 |

| PFMSC1.0–6 | 46.5 | 3.3 | 2.333 | 45.8 | 3.4 | 2.323 | 43.6 | 3.1 | 2.317 | 40.8 | 2.6 | 2.247 |

| PFMSC1.0–12 | 44.7 | 3.7 | 2.353 | 44.3 | 3.6 | 2.347 | 38.4 | 3.4 | 2.308 | 34.4 | 2.9 | 2.120 |

| PFMSC1.0–19 | 48.1 | 3.4 | 2.391 | 42.7 | 3.9 | 2.383 | 32.9 | 3.7 | 2.293 | 30.8 | 2.8 | 2.105 |

| PFMSC1.2–6 | 44.3 | 3.7 | 2.363 | 37.2 | 3.6 | 2.348 | 27.9 | 3.2 | 2.290 | 28.5 | 2.5 | 2.278 |

| PFMSC1.2–12 | 46 | 3.3 | 2.397 | 40.5 | 3.1 | 2.394 | 35.9 | 2.8 | 2.381 | 31.4 | 2.9 | 2.294 |

| PFMSC1.2–19 | 41.7 | 3.4 | 2.316 | 35.8 | 3.1 | 2.304 | 31.7 | 3.0 | 2.282 | 28.9 | 2.6 | 2.216 |

| Variance | 3.15 | 0.34 | 0.03 | 4.18 | 0.42 | 0.10 | 6.03 | 0.42 | 0.04 | 5.65 | 0.39 | 0.08 |

| PFNSC0–0 | PFNSC1.0–6 | PFNSC1.0–12 | PFNSC1.0–19 |

| y = 2E − 5x2 − 0.0005x + 0.0011 R2 = 0.9996 | y = 3E − 6x2 + 0.0015x + 0.007 R2 = 0.9307 | y = 6E − 6x2 + 0.0016x + 0.0018 R2 = 0.9914 | y = 7E − 7x2 + 0.0028x + 0.0045 R2 = 0.9961 |

| PFNSC1.2–6 | PFNSC1.2–12 | PFNSC1.2–19 | |

| y = E − 5x2 + 0.0001x + 0.0092 R2 = 0.9663 | y = E − 5x2 + 0.0002x + 0.0041 R2 = 0.9996 | y = 7E − 7x2 + 0.0016x + 0.0019 R2 = 0.9974 | |

| PFMSC0–0 | PFMSC1.0–6 | PFMSC1.0–12 | PFMSC1.0–19 |

| y = 9E − 6x2 − 0.0005x + 0.0056 R2 = 0.9921 | y=5E − 6x2 + 0.0002x − 0.001 R2 = 0.9979 | y = 8E − 6x2 + 0.0004x + 0.0083 R2 = 0.9628 | y = 7E − 6x2 + 0.0036x + 0.0127 R2 = 0.9634 |

| PFMSC1.2–6 | PFMSC1.2–12 | PFMSC1.2–19 | |

| y = 2E − 5x2 − 0.0056x + 0.0163 R2 = 0.9597 | y = 6E − 6x2 − 0.0028x + 0.0011 R2 = 0.9999 | y = 7E − 6x2 − 0.0032x + 0.0006 R2 = 0.9986 |

| PFNSC0–0 | PFNSC1.0–6 | PFNSC1.0–12 | PFNSC1.0–19 |

| y = 4E − 6x2 + 0.002x − 0.0089 R2 = 0.9801 | y = E5 x2 − 0.001x + 0.0037 R2 = 0.9882 | y = 3E − 6x2 + 0.0031x − 0.0171 R2 = 0.939 | y = 2E − 5x2 + 0.001x + 0.0259 R2 = 0.8601 |

| PFNSC1.2–6 | PFNSC1.2–12 | PFNSC1.2–19 | |

| y = 3E − 5x2 + 0.0023x + 0.0157 R2 = 0.953 | y = E − 5x2 + 0.0005x + 0.0042 R2 = 0.9908 | y = 2E − 5x2 + 0.008x + 0.0062 R2 = 0.9869 | |

| PFMSC0–0 | PFMSC1.0–6 | PFMSC1.0–12 | PFMSC1.0–19 |

| y = 3E − 6x2 + 0.0017x + 0.0078 R2 = 0.9801 | y = 2E − 5x2 − 0.0013x − 0.003 R2 = 0.9952 | y = E − 5x2 − 0.0002x + 0.0027 R2 = 0.9947 | y = 4E − 5x2 − 0.005x R2 = 0.9999 |

| PFMSC1.2–6 | PFMSC1.2–12 | PFMSC1.2–19 | |

| y = 2E − 5x2 − 0.0003x R2 = 0.9999 | y = − 9E − 6x2 + 0.0023x − 0.0076 R2 = 0.9149 | y = 3E − 6x2 + 0.0031x − 0.0073 R2 = 0.9619 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, Y.; Long, J.; Xiong, W.; Chen, X.; Zhao, B. Effects of Polypropylene Fibers on the Frost Resistance of Natural Sand Concrete and Machine-Made Sand Concrete. Polymers 2022, 14, 4054. https://doi.org/10.3390/polym14194054

Tan Y, Long J, Xiong W, Chen X, Zhao B. Effects of Polypropylene Fibers on the Frost Resistance of Natural Sand Concrete and Machine-Made Sand Concrete. Polymers. 2022; 14(19):4054. https://doi.org/10.3390/polym14194054

Chicago/Turabian StyleTan, Yan, Junyu Long, Wei Xiong, Xingxiang Chen, and Ben Zhao. 2022. "Effects of Polypropylene Fibers on the Frost Resistance of Natural Sand Concrete and Machine-Made Sand Concrete" Polymers 14, no. 19: 4054. https://doi.org/10.3390/polym14194054

APA StyleTan, Y., Long, J., Xiong, W., Chen, X., & Zhao, B. (2022). Effects of Polypropylene Fibers on the Frost Resistance of Natural Sand Concrete and Machine-Made Sand Concrete. Polymers, 14(19), 4054. https://doi.org/10.3390/polym14194054