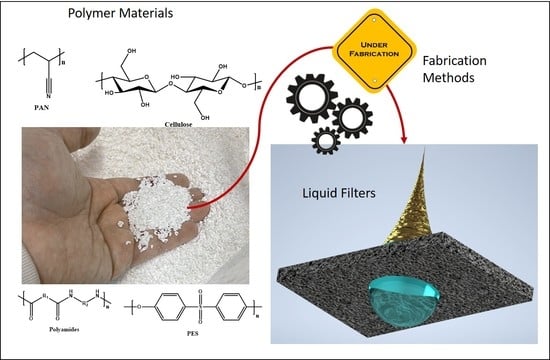

Polymeric Materials and Microfabrication Techniques for Liquid Filtration Membranes

Abstract

:1. Introduction

2. Microfabrication Techniques

2.1. Phase Inversion

2.2. Electrospinning

2.3. Interfacial Polymerization and Thin Film Composites

2.4. Stretching

2.5. Templating, Ablation, Photolithography, Etching and Self-Assembly

3. Polymer Materials

3.1. Polyethersulfone and Polysulfone

3.2. Polyacrylonitrile

3.3. Cellulose and Chitin Derivatives

3.4. Polyvinylalcohol

3.5. Polyvinylidene Fluoride

4. Membrane Modification for Antifouling and Specificity

4.1. Addition of Antifouling Properties

4.2. Addition of Selective Filtration Properties

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liquid Filtration Market, Markets and Markets: 2019; Report Number: CH 6693.

- Samatya, S.; Kabay, N.; Yüksel, Ü.; Arda, M.; Yüksel, M. Removal of nitrate from aqueous solution by nitrate selective ion exchange resins. React. Funct. Polym. 2006, 66, 1206. [Google Scholar] [CrossRef]

- Qin, L.; Vervuurt, S.J.N.; Elmes, R.B.P.; Berry, S.N.; Proschogo, N.; Jolliffe, K.A. Extraction and transport of sulfate using macrocyclic squaramide receptors. Chem. Sci. 2020, 11, 201. [Google Scholar] [CrossRef]

- Kim, S.; Nham, J.; Jeong, Y.S.; Lee, C.S.; Ha, S.H.; Park, H.B.; Lee, Y. Biomimetic Selective Ion Transport through Graphene Oxide Membranes Functionalized with Ion Recognizing Peptides. J. Chem. Mater. 2015, 27, 1255. [Google Scholar] [CrossRef]

- Coskun, H.; Aljabour, A.; De Luna, P.; Farka, D.; Greunz, T.; Stifter, D.; Kus, M.; Zheng, X.; Liu, M.; Hassel, A.W.; et al. Biofunctionalized conductive polymers enable efficient CO2 electroreduction. Sci. Adv. 2017, 3, e1700686. [Google Scholar] [CrossRef]

- Gao, H.; Zhang, B.; Tong, X.; Chen, Y. Monovalent-anion selective and antifouling polyelectrolytes multilayer anion exchange membrane for reverse electrodialysis. J. Membr. Sci. 2018, 567, 68. [Google Scholar] [CrossRef]

- Kerr-Phillips, T.E.; Aydemir, N.; Chan, E.W.C.; Barker, D.; Malmström, J.; Plesse, C.; Travas-Sejdic, J. Conducting electrospun fibres with polyanionic grafts as highly selective, label-free, electrochemical biosensor with a low detection limit for non-Hodgkin lymphoma gene. Biosens. Bioelectron. 2018, 100, 549. [Google Scholar] [CrossRef] [PubMed]

- Wu, K.; Yang, W.; Jiao, Y.; Zhou, C.J. A surface molecularly imprinted electrospun polyethersulfone (PES) fiber mat for selective removal of bilirubin. Mater. Chem. B 2017, 5, 5763. [Google Scholar] [CrossRef] [PubMed]

- Angelakis, A.; Mays, L. Evolution of Water Supply Through the Millennia; IWA Publishing: London, UK, 2014. [Google Scholar]

- Glater, J. The early history of reverse osmosis membrane development. Desalination 1998, 117, 297. [Google Scholar] [CrossRef]

- Yu, B.; Sun, J.; Zhao, K.; Ma, F.; Sun, L.; Shao, J.; Tian, J.; Hu, C. Mitigating membrane fouling by coupling coagulation and the electrokinetic effect in a novel electrocoagulation membrane cathode reactor. Water Res. 2022, 217, 118378. [Google Scholar] [CrossRef]

- Zhao, G.; Chen, W.N. Design of poly(vinylidene fluoride)-g-p(hydroxyethyl methacrylate-co-N-isopropylacrylamide) membrane via surface modification for enhanced fouling resistance and release property. Appl. Surf. Sci. 2017, 398, 103. [Google Scholar] [CrossRef]

- Wagner, V.E.; Koberstein, J.T.; Bryers, J.D. Protein and bacterial fouling characteristics of peptide and antibody decorated surfaces of PEG-poly(acrylic acid) co-polymers. Biomaterials 2004, 25, 2247. [Google Scholar] [CrossRef] [PubMed]

- Sun, H.; Zhang, Y.; Sadam, H.; Ma, J.; Bai, Y.; Shen, X.; Kim, J.; Shao, L. Novel mussel-inspired zwitterionic hydrophilic polymer to boost membrane water-treatment performance. J. Membr. Sci. 2019, 582, 1. [Google Scholar] [CrossRef]

- Yang, W.; Sundaram, H.S.; Ella, J.; He, N.; Jiang, S. Low-fouling electrospun PLLA films modified with zwitterionic poly(sulfobetaine methacrylate)-catechol conjugates. Acta Biomater. 2016, 40, 92. [Google Scholar] [CrossRef] [PubMed]

- Purkait, M.K.; Sinha, M.K.; Mondal, P.; Singh, R. Chapter 1-Introduction to Membranes. Interface Sci. Technol. 2018, 25, 1. [Google Scholar]

- Rana, D.; Matsuura, T.; Mohd, A.K.; Ismail, A.F. Reverse Osmosis Membrane. In Handbook of Membrane Separations; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Ng, Z.C.; Lau, W.J.; Matsuura, T.; Ismail, A.F. Thin film nanocomposite RO membranes: Review on fabrication techniques and impacts of nanofiller characteristics on membrane properties. Chem. Eng. Res. Des. 2021, 165, 81. [Google Scholar] [CrossRef]

- Van de Voorde, B.; Bueken, B.; Denayer, J.; De Vos, D. Adsorptive separation on metal–organic frameworks in the liquid phase. Chem. Soc. Rev. 2014, 43, 5766. [Google Scholar] [CrossRef]

- Voigt, I.; Adler, J.Ö.; Weyd, M.; Kriegel, R. Ceramic Filters and Membranes. In Ceramics Science and Technology; Wiley Online Library: Hoboken, NJ, USA, 2013. [Google Scholar]

- Hassan, M.F.; Sabri, M.A.; Fazal, H.; Hafeez, A.; Shezad, N.; Hussain, M. Recent trends in activated carbon fibers production from various precursors and applications—A comparative review. J. Anal. Appl. Pyrolysis 2020, 145, 104715. [Google Scholar] [CrossRef]

- Hołda, A.K.; Vankelecom, I.F.J. Understanding and guiding the phase inversion process for synthesis of solvent resistant nanofiltration membranes. J. Appl. Polym. Sci. 2015, 132, 42130. [Google Scholar] [CrossRef]

- Buonomenna, M.G. Design Next Generation Membranes or Rethink the “Old” Asymmetric Membranes? Symmetry 2020, 12, 270. [Google Scholar] [CrossRef]

- Abdullah, N.; Rahman, M.A.; Dzarfan Othman, M.H.; Jaafar, J.; Ismail, A.F. Chapter 2-Membranes and Membrane Processes: Fundamentals. In Current Trends and Future Developments on (Bio-) Membranes; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Zhao, Y.; Qian, Y.; Zhu, B.; Xu, Y. Modification of porous poly(vinylidene fluoride) membrane using amphiphilic polymers with different structures in phase inversion process. J. Membr. Sci. 2008, 310, 567. [Google Scholar] [CrossRef]

- Kannan, B.; Cha, H.; Hosie, I.C. Electrospinning—Commercial Applications, Challenges and Opportunities. In Nano-Size Polymers: Preparation, Properties, Applications; Springer International Publishing: Cham, Switzerland, 2016. [Google Scholar]

- Doshi, J.; Reneker, D.H.J. Electrospinning process and applications of electrospun fibers. Electrostatics 1995, 35, 151. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, R.; Ma, H.; Hsiao, B.S.; Chu, B. High-flux microfiltration filters based on electrospun polyvinylalcohol nanofibrous membranes. Polymer 2013, 54, 548. [Google Scholar] [CrossRef]

- Wang, Z.; Crandall, C.; Sahadevan, R.; Menkhaus, T.J.; Fong, H. Microfiltration performance of electrospun nanofiber membranes with varied fiber diameters and different membrane porosities and thicknesses. Polymer 2017, 114, 64. [Google Scholar] [CrossRef]

- Yoon, K.; Kim, K.; Wang, X.; Fang, D.; Hsiao, B.S.; Chu, B. High flux ultrafiltration membranes based on electrospun nanofibrous PAN scaffolds and chitosan coating. Polymer 2006, 47, 2434. [Google Scholar] [CrossRef]

- Qin, X.; Wang, S. Filtration properties of electrospinning nanofibers. J. Appl. Polym. Sci. 2006, 102, 1285. [Google Scholar] [CrossRef]

- Chan, E.W.C.; Baek, P.; Barker, D.; Travas-Sejdic, J. Highly functionalisable polythiophene phenylenes. Polym. Chem. 2015, 6, 7618. [Google Scholar] [CrossRef]

- El-Shazly, A.; Rezk, M.Y.; Gameel, K.M.; Allam, N.K. Electrospun Lead-Free All-Inorganic Double Perovskite Nanofibers for Photovoltaic and Optoelectronic Applications. ACS Appl. Nano Mater. 2019, 2, 7085. [Google Scholar] [CrossRef]

- Yoon, K.; Hsiao, B.S.; Chu, B. Formation of functional polyethersulfone electrospun membrane for water purification by mixed solvent and oxidation processes. Polymer 2009, 50, 2893. [Google Scholar] [CrossRef]

- Yue, B.; Zhang, B.; You, J.; Li, Y.; Li, L.; Li, J. “Lotus-effect” tape: Imparting superhydrophobicity to solid materials with an electrospun Janus composite mat. RSC Adv. 2016, 6, 17215. [Google Scholar] [CrossRef]

- Stanishevsky, A.V.; Wetuski, J.D.; Yockell-Lelièvre, H. Crystallization and stability of electrospun ribbon- and cylinder-shaped tungsten oxide nanofibers. Ceram. Int. 2016, 42, 388. [Google Scholar] [CrossRef]

- Fallahi, A.; Mandla, S.; Kerr-Phillip, T.; Seo, J.; Rodrigues, R.O.; Jodat, Y.A.; Samanipour, R.; Hussain, M.A.; Lee, C.K.; Bae, H.; et al. Flexible and Stretchable PEDOT-Embedded Hybrid Substrates for Bioengineering and Sensory Applications. ChemNanoMat 2019, 5, 729. [Google Scholar] [CrossRef]

- Duan, G.; Liu, S.; Jiang, S.; Hou, H. High-performance polyamide-imide films and electrospun aligned nanofibers from an amide-containing diamine. J. Mater. Sci. 2019, 54, 6719. [Google Scholar] [CrossRef]

- Gluais, M.; Clouet, J.; Fusellier, M.; Decante, C.; Moraru, C.; Dutilleul, M.; Veziers, J.; Lesoeur, J.; Dumas, D.; Abadie, J.; et al. In vitro and in vivo evaluation of an electrospun-aligned microfibrous implant for Annulus fibrosus repair. Biomaterials 2019, 205, 81. [Google Scholar] [CrossRef] [PubMed]

- Aussawasathien, D.; Teerawattananon, C.; Vongachariya, A. Separation of micron to sub-micron particles from water: Electrospun nylon-6 nanofibrous membranes as pre-filters. J. Membr. Sci. 2008, 315, 11. [Google Scholar] [CrossRef]

- Wang, X.; Fang, D.; Yoon, K.; Hsiao, B.S.; Chu, B. High performance ultrafiltration composite membranes based on poly(vinyl alcohol) hydrogel coating on crosslinked nanofibrous poly(vinyl alcohol) scaffold. J. Membr. Sci. 2006, 278, 261. [Google Scholar] [CrossRef]

- Kerr-Phillips, T.; Woehling, V.; Agniel, R.; Nguyen, G.T.M.; Vidal, F.; Kilmartin, P.; Plesse, C.; Travas-Sejdic, J. Electrospun rubber fibre mats with electrochemically controllable pore sizes. J. Mater. Chem. B 2015, 3, 4249. [Google Scholar] [CrossRef]

- Homaeigohar, S.S.; Buhr, K.; Ebert, K. Polyethersulfone electrospun nanofibrous composite membrane for liquid filtration. J. Membr. Sci. 2010, 365, 68. [Google Scholar] [CrossRef]

- Grey, C.P.; Newton, S.T.; Bowlin, G.L.; Haas, T.W.; Simpson, D.G. Gradient fiber electrospinning of layered scaffolds using controlled transitions in fiber diameter. Biomaterials 2013, 34, 4993. [Google Scholar] [CrossRef] [PubMed]

- Im, J.S.; Park, S.; Kim, T.J.; Kim, Y.H.; Lee, Y. The study of controlling pore size on electrospun carbon nanofibers for hydrogen adsorption. J. Colloid Interface Sci. 2008, 318, 42. [Google Scholar] [CrossRef]

- Pavliňák, D.; Hnilica, J.; Quade, A.; Schäfer, J.; Alberti, M.; Kudrle, V. Functionalisation and pore size control of electrospun PA6 nanofibres using a microwave jet plasma. Polym. Degrad. Stab. 2014, 108, 48. [Google Scholar] [CrossRef]

- Ma, H.; Hsiao, B.S.; Chu, B. Thin-film nanofibrous composite membranes containing cellulose or chitin barrier layers fabricated by ionic liquids. Polymer 2011, 52, 2594. [Google Scholar] [CrossRef]

- Yung, L.; Ma, H.; Wang, X.; Yoon, K.; Wang, R.; Hsiao, B.S.; Chu, B. Fabrication of thin-film nanofibrous composite membranes by interfacial polymerization using ionic liquids as additives. J. Membr. Sci. 2010, 365, 52. [Google Scholar] [CrossRef]

- Ma, H.; Burger, C.; Hsiao, B.S.; Chu, B. Fabrication and characterization of cellulose nanofiber based thin-film nanofibrous composite membranes. J. Membr. Sci. 2014, 454, 272. [Google Scholar] [CrossRef]

- Yoon, K.; Hsiao, B.S.; Chu, B. High flux ultrafiltration nanofibrous membranes based on polyacrylonitrile electrospun scaffolds and crosslinked polyvinyl alcohol coating. J. Membr. Sci. 2009, 338, 145. [Google Scholar] [CrossRef]

- Lalia, B.S.; Kochkodan, V.; Hashaikeh, R.; Hilal, N. A review on membrane fabrication: Structure, properties and performance relationship. Desalination 2013, 326, 77. [Google Scholar] [CrossRef]

- Sarada, T.; Sawyer, L.C.; Ostler, M.I. Three dimensional structure of celgard® microporous membranes. J. Membr. Sci. 1983, 15, 97. [Google Scholar] [CrossRef]

- Tabatabaei, S.H.; Carreau, P.J.; Ajji, A. Microporous membranes obtained from PP/HDPE multilayer films by stretching. J. Membr. Sci. 2009, 345, 148. [Google Scholar] [CrossRef]

- Holdich, R.; Kosvintsev, S.; Cumming, I.; Zhdanov, S. Pore design and engineering for filters and membranes. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2006, 364, 161. [Google Scholar] [CrossRef]

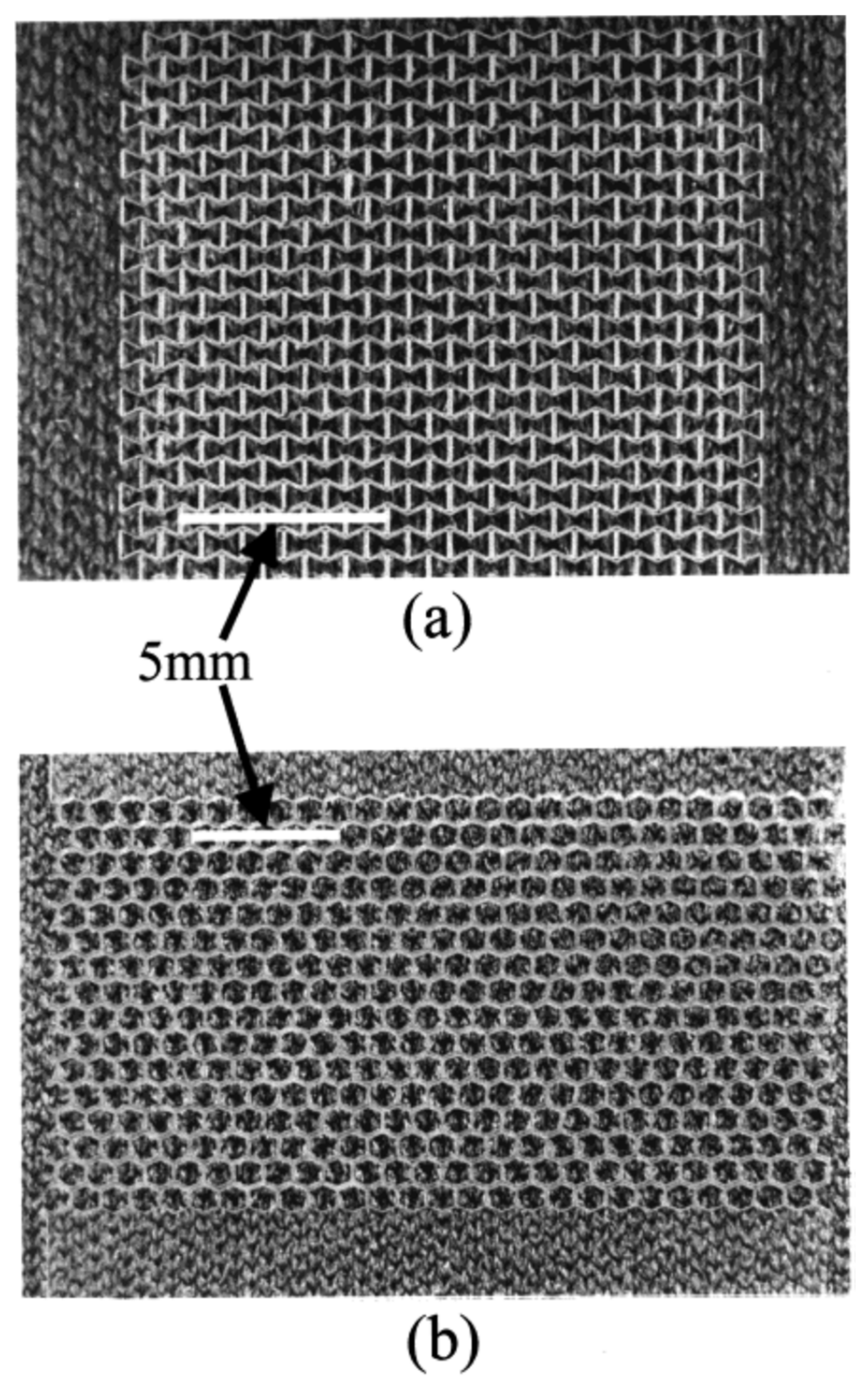

- Alderson, A.; Rasburn, J.; Ameer-Beg, S.; Mullarkey, P.G.; Perrie, W.; Evans, K.E. An Auxetic Filter: A Tuneable Filter Displaying Enhanced Size Selectivity or Defouling Properties. Ind. Eng. Chem. Res. 2000, 39, 654. [Google Scholar] [CrossRef]

- Fan, F.; Wang, L.; Jiang, W.; Chen, B.; Liu, H. A novel polyethylene microfiltration membrane with highly permeable ordered ‘wine bottle’ shaped through-pore structure fabricated via imprint and thermal field induction. J. Phys. D 2016, 49, 125501. [Google Scholar] [CrossRef]

- Liang, H.; Cao, X.; Zhang, W.; Lin, H.; Zhou, F.; Chen, L.; Yu, S. Robust and Highly Efficient Free-Standing Carbonaceous Nanofiber Membranes for Water Purification. Adv. Funct. Mater. 2011, 21, 3851. [Google Scholar] [CrossRef]

- Ross, C.A.; Berggren, K.K.; Cheng, J.Y.; Jung, Y.S.; Chang, J. Three-Dimensional Nanofabrication by Block Copolymer Self-Assembly. Adv. Mater. 2014, 26, 4386. [Google Scholar] [CrossRef] [PubMed]

- Phillip, W.A.; O’Neill, B.; Rodwogin, M.; Hillmyer, M.A.; Cussler, E.L. Self-Assembled Block Copolymer Thin Films as Water Filtration Membranes. ACS Appl. Mater. Interfaces 2010, 2, 847. [Google Scholar] [CrossRef] [PubMed]

- Shin, S.; Lim, J.; Gu, M.; Yu, C.; Hong, M.; Char, K.; Choi, T. Dimensionally controlled water-dispersible amplifying fluorescent polymer nanoparticles for selective detection of charge-neutral analytes. Polym. Chem. 2017, 8, 7507. [Google Scholar] [CrossRef]

- Yuan, Y.; Li, J.; Liu, Y.; Chen, T.; Lin, J. Layer-by-layer self-assembly of aramid nanofibers on nonwoven fabric for liquid filtration. Polym. Compos. 2018, 39, 2411. [Google Scholar] [CrossRef]

- Del Barrio, J.; Sánchez-Somolinos, C. Light to Shape the Future: From Photolithography to 4D Printing. Adv. Opt. Mater. 2019, 7, 1900598. [Google Scholar] [CrossRef]

- Wang, Z.; Ma, H.; Hsiao, B.S.; Chu, B. Nanofibrous ultrafiltration membranes containing cross-linked poly(ethylene glycol) and cellulose nanofiber composite barrier layer. Polymer 2014, 55, 366. [Google Scholar] [CrossRef]

- Huang, Z.; Liu, J.; Liu, Y.; Xu, Y.; Li, R.; Hong, H.; Shen, L.; Lin, H.; Liao, B. Enhanced permeability and antifouling performance of polyether sulfone (PES) membrane via elevating magnetic Ni@MXene nanoparticles to upper layer in phase inversion process. J. Membr. Sci. 2021, 623, 119080. [Google Scholar] [CrossRef]

- Xue, J.; Wu, T.; Dai, Y.; Xia, Y. Electrospinning and Electrospun Nanofibers: Methods, Materials, and Applications. Chem. Rev. 2019, 119, 5298. [Google Scholar] [CrossRef] [PubMed]

- Vandezande, P.; Li, X.; Gevers, L.E.M.; Vankelecom, I.F.J. High throughput study of phase inversion parameters for polyimide-based SRNF membranes. J. Membr. Sci. 2009, 330, 307. [Google Scholar] [CrossRef]

- Vatanpour, V.; Madaeni, S.S.; Moradian, R.; Zinadini, S.; Astinchap, B. Fabrication and characterization of novel antifouling nanofiltration membrane prepared from oxidized multiwalled carbon nanotube/polyethersulfone nanocomposite. J. Membr. Sci. 2011, 375, 284. [Google Scholar] [CrossRef]

- Li, Z.; Zabihi, O.; Wang, J.; Li, Q.; Wang, J.; Lei, W.; Naebe, M. Hydrophilic PAN based carbon nanofibres with improved graphitic structure and enhanced mechanical performance using ethylenediamine functionalized graphene. RSC Adv. 2017, 7, 2621. [Google Scholar] [CrossRef]

- Xiang, T.; Yue, W.; Wang, R.; Liang, S.; Sun, S.; Zhao, C. Surface hydrophilic modification of polyethersulfone membranes by surface-initiated ATRP with enhanced blood compatibility. Colloids Surf. B Biointerfaces 2013, 110, 15. [Google Scholar] [CrossRef]

- Polyethersulphone (PES)-Supplier Data by Goodfellow. Available online: https://www.azom.com/article.aspx?ArticleID=1953 (accessed on 20 September 2022).

- Overview of Materials for Polyethersulfone (PES). Available online: https://www.matweb.com/search/datasheet.aspx?matguid=6be926d8eb0842abbfb80b5658ade95a (accessed on 20 September 2022).

- Casciola, M.; Donnadio, A.; Pica, M. 3.7 Basic Aspects in Proton-Conducting Membranes for Fuel Cells. In Comprehensive Membrane Science and Engineering, 2nd ed.; Elsevier: Oxford, UK, 2017. [Google Scholar]

- Huang, Y.; Young, R.J. Effect of fibre microstructure upon the modulus of PAN- and pitch-based carbon fibres. Carbon 1995, 33, 97. [Google Scholar] [CrossRef]

- Carraher, C.E. Carraher’s Polymer Chemistry; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Krentsel, L.B.; Kudryavtsev, Y.V.; Rebrov, A.I.; Litmanovich, A.D.; Platé, N.A. Acidic Hydrolysis of Polyacrylonitrile: Effect of Neighboring Groups. Macromolecules 2001, 34, 5607. [Google Scholar] [CrossRef]

- Litmanovich, A.D.; Platé, N.A. Alkaline hydrolysis of polyacrylonitrile. On the reaction mechanism. Macromol. Chem. Phys. 2000, 201, 2176. [Google Scholar] [CrossRef]

- Sukitpaneenit, P.; Chung, T.J. Molecular elucidation of morphology and mechanical properties of PVDF hollow fiber membranes from aspects of phase inversion, crystallization and rheology. Membr. Sci. 2009, 340, 192. [Google Scholar] [CrossRef]

- Overview of Materials for Polyvinylidinefluoride (PVDF), Molded/Extruded. Available online: https://www.matweb.com/search/DataSheet.aspx?MatGUID=a011f8ccf4b448a19246773a32085094 (accessed on 15 September 2022).

- Jain, N.; Singh, V.K.; Chauhan, S. A review on mechanical and water absorption properties of polyvinyl alcohol based composites/films. J. Mech. Behav. Mater. 2017, 26, 213. [Google Scholar] [CrossRef]

- Freire, T.F.; Quinaz, T.; Fertuzinhos, A.; Quyền, N.T.; de Moura, M.F.S.M.; Martins, M.; Zille, A.; Dourado, N. Thermal, Mechanical and Chemical Analysis of Poly(vinyl alcohol) Multifilament and Braided Yarns. Polymers 2021, 13, 3644. [Google Scholar] [CrossRef]

- Iwamoto, S.; Kai, W.; Isogai, A.; Iwata, T. Elastic Modulus of Single Cellulose Microfibrils from Tunicate Measured by Atomic Force Microscopy. Biomacromolecules 2009, 10, 2571. [Google Scholar] [CrossRef]

- Kubát, J.; Pattyranie, C. Transition in Cellulose in the Vicinity of −30 °C. Nature 1967, 215, 390. [Google Scholar] [CrossRef]

- Greene, J.P. 3-Microstructures of Polymers. In Automotive Plastics and Composites; William Andrew Publishing: Oxford, UK, 2021. [Google Scholar]

- McIntee, O.M.; Welch, B.C.; Greenberg, A.R.; George, S.M.; Bright, V.M. Elastic modulus of polyamide thin films formed by molecular layer deposition. Polymer 2022, 255, 125167. [Google Scholar] [CrossRef]

- Silva, L.; Tognana, S.; Salgueiro, W. Study of the water absorption and its influence on the Young’s modulus in a commercial polyamide. Polym. Test. 2013, 32, 158. [Google Scholar] [CrossRef]

- Urkiaga, A.; De Las Fuentes, L.; Acilu, M.; Uriarte, J. Membrane comparison for wine clarification by microfiltration. Desalination 2002, 148, 115. [Google Scholar] [CrossRef]

- Sivakumar, M.; Mohan, D.R.; Rangarajan, R. Studies on cellulose acetate-polysulfone ultrafiltration membranes: II. Effect of additive concentration. J. Membr. Sci. 2006, 268, 208. [Google Scholar] [CrossRef]

- Gopal, R.; Kaur, S.; Feng, C.Y.; Chan, C.; Ramakrishna, S.; Tabe, S.; Matsuura, T. Electrospun nanofibrous polysulfone membranes as pre-filters: Particulate removal. J. Membr. Sci. 2007, 289, 210. [Google Scholar] [CrossRef]

- Guillen, G.R.; Pan, Y.; Li, M.; Hoek, E.M.V. Preparation and Characterization of Membranes Formed by Nonsolvent Induced Phase Separation: A Review. Membr. Ind. Eng. Chem. Res. 2011, 50, 3798. [Google Scholar] [CrossRef]

- Li, J.; Xu, Z.; Yang, H.; Yu, L.; Liu, M. Effect of TiO2 nanoparticles on the surface morphology and performance of microporous PES membrane. Appl. Surf. Sci. 2009, 255, 4725. [Google Scholar] [CrossRef]

- Zha, S.; Yu, J.; Zhang, G.; Liu, N.; Lee, R. Polyethersulfone (PES)/cellulose acetate butyrate (CAB) composite hollow fiber membranes for BTEX separation from produced water. RSC Adv. 2015, 5, 105692. [Google Scholar] [CrossRef]

- Zhao, W.; Su, Y.; Li, C.; Shi, Q.; Ning, X.; Jiang, Z. Fabrication of antifouling polyethersulfone ultrafiltration membranes using Pluronic F127 as both surface modifier and pore-forming agent. J. Membr. Sci. 2008, 318, 405. [Google Scholar] [CrossRef]

- Musale, D.A.; Kumar, A.; Pleizier, G. Formation and characterization of poly(acrylonitrile)/Chitosan composite ultrafiltration membranes. J. Membr. Sci. 1999, 154, 163. [Google Scholar] [CrossRef]

- Patel, S.; Hota, G. Synthesis of novel surface functionalized electrospun PAN nanofibers matrix for efficient adsorption of anionic CR dye from water. J. Environ. Chem. Eng. 2018, 6, 5301. [Google Scholar] [CrossRef]

- Makaremi, M.; Lim, C.X.; Pasbakhsh, P.; Lee, S.M.; Goh, K.L.; Chang, H.; Chan, E.S. Electrospun functionalized polyacrylonitrile–chitosan Bi-layer membranes for water filtration applications. RSC Adv. 2016, 6, 53882. [Google Scholar] [CrossRef]

- Yeh, T.; Wang, Z.; Mahajan, D.; Hsiao, B.S.; Chu, B. High flux ethanol dehydration using nanofibrous membranes containing graphene oxide barrier layers. J. Mater. Chem. A 2013, 1, 12998. [Google Scholar] [CrossRef]

- Wang, Z.; Ma, H.; Chu, B.; Hsiao, B.S. Fabrication of cellulose nanofiber-based ultrafiltration membranes by spray coating approach. J. Appl. Polym. Sci. 2017, 134, 44583. [Google Scholar] [CrossRef]

- Wang, S.; Lu, A.; Zhang, L. Recent advances in regenerated cellulose materials. Prog. Polym. Sci. 2016, 53, 169. [Google Scholar] [CrossRef]

- Kutowy, O.; Sourirajan, S. Cellulose acetate ultrafiltration membranes. J. Appl. Polym. Sci. 1975, 19, 1449. [Google Scholar] [CrossRef]

- Demirci, S.; Celebioglu, A.; Uyar, T. Surface modification of electrospun cellulose acetate nanofibers via RAFT polymerization for DNA adsorption. Carbohydr. Polym. 2014, 113, 200. [Google Scholar] [CrossRef]

- Lan, T.; Shao, Z.; Gu, M.; Zhou, Z.; Wang, Y.; Wang, W.; Wang, F.; Wang, J. Electrospun nanofibrous cellulose diacetate nitrate membrane for protein separation. J. Membr. Sci. 2015, 489, 204. [Google Scholar] [CrossRef]

- Ma, H.; Burger, C.; Hsiao, B.S.; Chu, B. Ultrafine Polysaccharide Nanofibrous Membranes for Water Purification. Biomacromolecules 2011, 12, 970. [Google Scholar] [CrossRef]

- Tang, Z.; Wei, J.; Yung, L.; Ji, B.; Ma, H.; Qiu, C.; Yoon, K.; Wan, F.; Fang, D.; Hsiao, B.S.; et al. UV-cured poly(vinyl alcohol) ultrafiltration nanofibrous membrane based on electrospun nanofiber scaffolds. J. Membr. Sci. 2009, 328, 1. [Google Scholar] [CrossRef]

- Jahan, Z.; Niazi, M.B.K.; Gregersen, Ø.W. Mechanical, thermal and swelling properties of cellulose nanocrystals/PVA nanocomposites membranes. J. Ind. Eng. Chem. 2018, 57, 113. [Google Scholar] [CrossRef]

- Cheng, C.L.; Wan, C.C.; Wang, Y.Y. Microporous PVdF-HFP based gel polymer electrolytes reinforced by PEGDMA network. Electrochem. Commun. 2004, 6, 531. [Google Scholar] [CrossRef]

- Hsu, C.; Liu, R.; Hsu, C.; Kuo, P. High thermal and electrochemical stability of PVDF-graft-PAN copolymer hybrid PEO membrane for safety reinforced lithium-ion battery. RSC Adv. 2016, 6, 18082. [Google Scholar] [CrossRef]

- Kim, J.R.; Choi, S.W.; Jo, S.M.; Lee, W.S.; Kim, B.C. Electrospun PVdF-based fibrous polymer electrolytes for lithium ion polymer batteries. Electrochim. Acta 2004, 50, 69. [Google Scholar] [CrossRef]

- Xiang, Y.; Zheng, Y.; Liu, S.; Liu, G.; Li, Z.; Dong, W. Comparison of the sensitivity of Western blotting between PVDF and NC membranes. Sci. Rep. 2021, 11, 12022. [Google Scholar] [CrossRef] [PubMed]

- Su, C.; Shih, J.; Huang, M.; Wang, C.; Shih, W.; Liu, Y. A study of hydrophobic electrospun membrane applied in seawater desalination by membrane distillation. Fibers Polym. 2012, 13, 698. [Google Scholar] [CrossRef]

- Wang, K.Y.; Foo, S.W.; Chung, T. Mixed Matrix PVDF Hollow Fiber Membranes with Nanoscale Pores for Desalination through Direct Contact Membrane Distillation. Ind. Eng. Chem. Res. 2009, 48, 4474. [Google Scholar] [CrossRef]

- Cauda, V.; Stassi, S.; Bejtka, K.; Canavese, G. Nanoconfinement: An Effective Way to Enhance PVDF Piezoelectric Properties. ACS Appl. Mater. Interfaces 2013, 5, 6430. [Google Scholar] [CrossRef]

- Sohn, J.; Im, J.S.; Gwon, S.; Choi, J.; Shin, J.; Nho, Y. Preparation and characterization of a PVDF-HFP/PEGDMA-coated PE separator for lithium-ion polymer battery by electron beam irradiation. Radiat. Phys. Chem. 2009, 78, 505. [Google Scholar] [CrossRef]

- Liu, J.; Wang, Y.; Wang, L. Poly (3, 4-ethylenedioxythiophene) modified polyvinylidene fluoride membrane for visible photoelectrocatalysis and filtration. J. Colloid Interface Sci. 2019, 553, 220. [Google Scholar] [CrossRef]

- Li, Z.; Kang, W.; Zhao, H.; Hu, M.; Wei, N.; Qiu, J.; Cheng, B. A Novel Polyvinylidene Fluoride Tree-Like Nanofiber Membrane for Microfiltration. Nanomaterials 2016, 6, 152. [Google Scholar] [CrossRef]

- Chen, Z.; Deng, M.; Chen, Y.; He, G.; Wu, M.; Wang, J.J. Preparation and performance of cellulose acetate/polyethyleneimine blend microfiltration membranes and their applications. Membr. Sci. 2004, 235, 73. [Google Scholar] [CrossRef]

- Wang, X.; Yeh, T.; Wang, Z.; Yang, R.; Wang, R.; Ma, H.; Hsiao, B.S.; Chu, B. Nanofiltration membranes prepared by interfacial polymerization on thin-film nanofibrous composite scaffold. Polymer 2014, 55, 1358. [Google Scholar] [CrossRef]

- Wang, R.; Liu, Y.; Li, B.; Hsiao, B.S.; Chu, B. Electrospun nanofibrous membranes for high flux microfiltration. J. Membr. Sci. 2012, 392–393, 167. [Google Scholar] [CrossRef]

- Ma, H.; Hsiao, B.S.; Chu, B. Functionalized electrospun nanofibrous microfiltration membranes for removal of bacteria and viruses. J. Membr. Sci. 2014, 452, 446. [Google Scholar] [CrossRef]

- Tang, N.; Jia, Q.; Zhang, H.; Li, J.; Cao, S. Preparation and morphological characterization of narrow pore size distributed polypropylene hydrophobic membranes for vacuum membrane distillation via thermally induced phase separation. Desalination 2010, 256, 27. [Google Scholar] [CrossRef]

- Dai, J.; Liu, X.; Yang, J.; Zhang, N.; Huang, T.; Wang, Y.; Zhou, Z. Stretching induces pore formation in the β-nucleated polypropylene/graphene oxide composite. Compos. Sci. Technol. 2014, 99, 59. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, J.; Olah, A.; Baer, E. Composite nanofibrous microfiltration water filter. J. Appl. Polym. Sci. 2017, 134, 45557. [Google Scholar] [CrossRef]

- Lianchao, L.; Baoguo, W.; Huimin, T.; Tianlu, C.; Jiping, X. A novel nanofiltration membrane prepared with PAMAM and TMC by in situ interfacial polymerization on PEK-C ultrafiltration membrane. J. Membr. Sci. 2006, 269, 84. [Google Scholar] [CrossRef]

- Ameringer, T.; Ercole, F.; Tsang, K.M.; Coad, B.R.; Hou, X.; Rodda, A.; Nisbet, D.R.; Thissen, H.; Evans, R.A.; Meagher, L.; et al. Surface grafting of electrospun fibers using ATRP and RAFT for the control of biointerfacial interactions. Biointerphases 2013, 8, 16. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gualandi, C.; Vo, C.D.; Focarete, M.L.; Scandola, M.; Pollicino, A.; Di Silvestro, G.; Tirelli, N. Advantages of Surface-Initiated ATRP (SI-ATRP) for the Functionalization of Electrospun Materials. Macromol. Rapid Commun. 2013, 34, 51. [Google Scholar] [CrossRef] [PubMed]

- Ashraf, J.; Akbarinejad, A.; Hisey, C.L.; Bryant, D.T.; Wang, J.; Zhu, B.; Evans, C.W.; Williams, D.E.; Chamley, L.W.; Barker, D.; et al. Conducting Polymer-Coated Carbon Cloth Captures and Releases Extracellular Vesicles by a Rapid and Controlled Redox Process. ACS Appl. Mater. Interfaces 2022, 14, 32880. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Schon, B.S.; Travas-Sejdic, J. A Conductive Microfiltration Membrane for In Situ Fouling Detection: Proof-of-Concept Using Model Wine Solutions. Macromol. Rapid Commun. 2020, 41, 2000303. [Google Scholar] [CrossRef]

- Hackett, A.J.; Malmström, J.; Molino, P.J.; Gautrot, J.E.; Zhang, H.; Higgins, M.J.; Wallace, G.G.; Williams, D.E.; Travas-Sejdic, J. Conductive surfaces with dynamic switching in response to temperature and salt. J. Mater. Chem. B 2015, 3, 9285. [Google Scholar] [CrossRef]

- Malmström, J.; Nieuwoudt, M.K.; Strover, L.T.; Hackett, A.; Laita, O.; Brimble, M.A.; Williams, D.E.; Travas-Sejdic, J. Grafting from Poly(3,4-ethylenedioxythiophene): A Simple Route to Versatile Electrically Addressable Surfaces. Macromolecules 2013, 46, 4955. [Google Scholar] [CrossRef]

- Pei, Y.; Travas-Sejdic, J.; Williams, D.E. Reversible Electrochemical Switching of Polymer Brushes Grafted onto Conducting Polymer Films. Langmuir 2012, 28, 8072. [Google Scholar] [CrossRef]

- Kolewe, K.W.; Dobosz, K.M.; Rieger, K.A.; Chang, C.; Emrick, T.; Schiffman, J.D. Antifouling Electrospun Nanofiber Mats Functionalized with Polymer Zwitterions. ACS Appl. Mater. Interfaces 2016, 8, 27585. [Google Scholar] [CrossRef]

- Li, N.; Liu, L.; Yang, F. Highly conductive graphene/PANi-phytic acid modified cathodic filter membrane and its antifouling property in EMBR in neutral conditions. Desalination 2014, 338, 10. [Google Scholar] [CrossRef]

- Brunner, G.; Okoro, E. Reduction of Membrane Fouling by Means of an Electric Field During Ultrafiltration of Protein Solutions. Ber. Bunsenges. Phys. Chem. 1989, 93, 1026. [Google Scholar] [CrossRef]

- Ren, Q.; Liang, C. Insulator-based dielectrophoretic antifouling of nanoporous membrane for high conductive water desalination. Desalination 2020, 482, 114410. [Google Scholar] [CrossRef]

- Yan, L.; Li, Y.S.; Xiang, C.B. Preparation of poly(vinylidene fluoride)(pvdf) ultrafiltration membrane modified by nano-sized alumina (Al2O3) and its antifouling research. Polymer 2005, 46, 7701. [Google Scholar] [CrossRef]

- Zumbusch, P.V.; Kulcke, W.; Brunner, G. Use of alternating electrical fields as anti-fouling strategy in ultrafiltration of biological suspensions–Introduction of a new experimental procedure for crossflow filtration. J. Membr. Sci. 1998, 142, 75. [Google Scholar] [CrossRef]

- Moritz, C.P. 40 years Western blotting: A scientific birthday toast. J. Proteom. 2020, 212, 103575. [Google Scholar] [CrossRef]

- Burnette, W.N. “Western Blotting”: Electrophoretic transfer of proteins from sodium dodecyl sulfate-polyacrylamide gels to unmodified nitrocellulose and radiographic detection with antibody and radioiodinated protein A. Anal. Biochem. 1981, 112, 195. [Google Scholar] [CrossRef]

- Liu, X.; Wang, M.; Jia, Y. Surface-functionalized cation exchange membrane by covalent immobilization of polyelectrolyte multilayer for effective separation of mono- and multivalent cations. Sep. Sci. Technol. 2016, 51, 2823. [Google Scholar] [CrossRef]

- Wang, F.; Hickner, M.; Kim, Y.S.; Zawodzinski, T.A.; McGrath, J.E. Direct polymerization of sulfonated poly(arylene ether sulfone) random (statistical) copolymers: Candidates for new proton exchange membranes. J. Membr. Sci. 2002, 197, 231. [Google Scholar] [CrossRef]

- Qu, S.; Dilenschneider, T.; Phillip, W.A. Preparation of Chemically-Tailored Copolymer Membranes with Tunable Ion Transport Properties. ACS Appl. Mater. Interfaces 2015, 7, 19746. [Google Scholar] [CrossRef] [PubMed]

- Bai, Y.; Huang, Z.; Yu, X.; Kang, F. Graphene oxide-embedded porous carbon nanofiber webs by electrospinning for capacitive deionization. Colloids Surf. Physicochem. Eng. Asp. 2014, 444, 153. [Google Scholar] [CrossRef]

- Ma, H.; Hsiao, B.S.; Chu, B. Electrospun Nanofibrous Membrane for Heavy Metal Ion Adsorption. Curr. Org. Chem. 2013, 17, 1361. [Google Scholar] [CrossRef]

- Wang, R.; Guan, S.; Sato, A.; Wang, X.; Wang, Z.; Yang, R.; Hsiao, B.S.; Chu, B. Nanofibrous microfiltration membranes capable of removing bacteria, viruses and heavy metal ions. J. Membr. Sci. 2013, 446, 376. [Google Scholar] [CrossRef]

- Tyagi, S.; Rawtani, D.; Khatri, N.; Tharmavaram, M. Strategies for Nitrate removal from aqueous environment using Nanotechnology: A Review. J. Water Process Eng. 2018, 21, 84. [Google Scholar] [CrossRef]

- Manesiotis, P.; Riley, A.; Bollen, B.J. Polymerisable squaramide receptors for anion binding and sensing. Mater. Chem. C 2014, 2, 8990. [Google Scholar] [CrossRef]

- Papaphilippou, P.C.; Vyrides, I.; Mpekris, F.; Stylianopoulos, T.; Papatryfonos, C.A.; Theocharis, C.R.; Krasia-Christoforou, T. Evaluation of novel, cationic electrospun microfibrous membranes as adsorbents in bacteria removal. RSC Adv. 2015, 5, 67617. [Google Scholar] [CrossRef]

- Mauritz, K.A.; Moore, R.B. State of Understanding of Nafion. Chem. Rev. 2004, 104, 4535. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Cheng, T.; Zhang, X.; Zhang, W.; Liu, X. Novel composite proton exchange membrane with long-range proton transfer channels constructed by synergistic effect between acid and base functionalized graphene oxide. Polymer 2018, 149, 305. [Google Scholar] [CrossRef]

- Qin, L.; Hartley, A.; Turner, P.; Elmes, R.B.P.; Jolliffe, K.A. Macrocyclic squaramides: Anion receptors with high sulfate binding affinity and selectivity in aqueous media. Chem. Sci. 2016, 7, 4563. [Google Scholar] [CrossRef]

- Hetemi, D.; Noël, V.; Pinson, J. Grafting of Diazonium Salts on Surfaces: Application to Biosensors. Biosensors 2020, 10, 4. [Google Scholar] [CrossRef]

- Mévellec, V.; Roussel, S.; Tessier, L.; Chancolon, J.; Mayne-L’Hermite, M.; Deniau, G.; Viel, P.; Palacin, S. Grafting Polymers on Surfaces: A New Powerful and Versatile Diazonium Salt-Based One-Step Process in Aqueous Media. Chem. Mater. 2007, 19, 6323. [Google Scholar] [CrossRef]

- Allongue, P.; Delamar, M.; Desbat, B.; Fagebaume, O.; Hitmi, R.; Pinson, J.; Savéant, J. Covalent Modification of Carbon Surfaces by Aryl Radicals Generated from the Electrochemical Reduction of Diazonium Salts. J. Am. Chem. Soc. 1997, 119, 201. [Google Scholar] [CrossRef]

- Lee, L.; Ma, H.; Brooksby, P.A.; Brown, S.A.; Leroux, Y.R.; Hapiot, P.; Downard, A.J. Covalently Anchored Carboxyphenyl Monolayer via Aryldiazonium Ion Grafting: A Well-Defined Reactive Tether Layer for On-Surface Chemistry. Langmuir 2014, 30, 7104. [Google Scholar] [CrossRef] [PubMed]

- Le, X.T.; Viel, P.; Jégou, P.; Garcia, A.; Berthelot, T.; Bui, T.H.; Palacin, S. Diazonium-induced anchoring process: An application to improve the monovalent selectivity of cation exchange membranes. J. Mater. Chem. 2010, 20, 3750. [Google Scholar] [CrossRef]

| Polymer | Young’s Modulus (MPa) | Tensile Strength (MPa) | Tg (°C) | Hydropathy (Philic or Phobic) | Common Solvents | Chemical Resistance |

|---|---|---|---|---|---|---|

| PES | 25–275 [34] | 70–95 [70] | 158–228 [71] | Phobic | DMA, DMF, NMP | High [72] |

| PAN | 158,000–517,000 [73,74] | 7000 [74] | 100 [74] | Phobic | DMA, DMF, NMP | Hydrolysis yields copolymers [75,76] |

| PVDF | 2.1–8.4 [77] | 55,000 [74] | −50–−18 [78] | Phobic | DMA, DMF, NMP | High |

| PVA | 6.4–11 [41,79] | 50 [79] | 76 [80] | Philic | Water, Alcohol | High |

| Cellulose | 120,000–220,000 [81] | 800–2000 [74] | 200–250 [74,82] | Philic | Acetone, DMF | Susceptible to hydrolysis |

| Polypropylene | 900–1100 [54] | 35 [74] | −25 [83] | Phobic | Naphtha, o-xylene, petroleum ether | High |

| Polyamides | 1300–5240 [74,84] | 52–83 [74] | 42–46 [74,85] | Capable of either | DMA, DMF, NMP | Susceptible to hydrolysis |

| Polymer | Fabrication Method | Filtrant | Filtration Level | Flux (L m−2 h−1) | Ref |

|---|---|---|---|---|---|

| Cellulose Acetate-polysulfone | Phase inversion | Water, protein solution | Ultra | 14.1–42 at 414 kPa | [87] |

| Cellulose Acetate-polyethyleneimine | Phase inversion | Water, protein solution | Micro | 6–30 at 69 kPa | [115] |

| Cellulose and Chitin | Miscellaneous | Water | Ultra | 150–450 at 207 kPa | [102] |

| Polyethersulfone/cellulose acetate butyrate | Dry-jet wet spinning (phase inversion) | BTEX | Not specified | 1.45–19.48 at 690 kPa | [91] |

| Polyethersulfone/Polyamide | Electrospinning and interfacial polymerization | Water | Ultra | 12.9–75.1 at 483 kPa | [48] |

| Polyethersulfone/Cellulose/Polyamide | Electrospinning, casting and interfacial polymerization | water | Nano | 5.0 at 210 kPa | [116] |

| Polyethersulfone/TiO2 nanoparticles | Phase Inversion | Water | Micro | 3711 at 100 kPa (pressure assumed, but not specified) | [90] |

| Polyacrylonitrile | Electrospinning | Water | Micro | 1.5, pressure not specified | [117] |

| Polyacrylonitrile | Electrospinning | Water | Micro | 712 at 69 kPa | [29] |

| Polyacrylonitrile with imidazolium cation surface modification | Electrospinning | Water | Micro | 989–2185 at 15.86 kPa | [118] |

| Polyacrylonitrile/chitosan | Electrospinning and cast coating | Water | Ultra | 50–65 at 345 kPa | [30] |

| Polyacrylonitrile/chitosan/graphene oxide | Electrospinning, cast coating and spin coating | Ethanol dehydration | Ultra | 2.2 kg m−2 h−1 at unspecified pressure | [96] |

| Polyacrylonitrile/poly(ethylene glycol) and cellulose | Electrospinning, casting and photo crosslinking | Water | Ultra | 85 at 206.8 kPa | [63] |

| Polyimide | Phase Inversion | Water | Nano | 50 at 1000 kPa | [66] |

| Polypropylene | Phase Inversion | Desalination | Pore sizes of 10–600 nm | 28.92 kg m−2 h−1 at 3 kPa | [119] |

| Polypropylene/high density polyethylene | Stretching | Not Specified | 19–44 g/m2 | Not specified | [53] |

| Polypropylene/graphene oxide | Stretching | Not specified | 100 nm to 2 um pore sizes | Not specified | [120] |

| Poly(styrene-b-lactide) | Self-assembly | Water | 24 nm pore sizes | 1.15 L m−2 h−1 bar−1. | [59] |

| Nylon | Electrospinning | Water | Greater than Micro | 31 to 593 at 69 kPa | [40] |

| Poly(vinyl alcohol) | Electrospinning | Water | Micro | 11,535 at 17 kPa (Pure water flux) | [28] |

| Poly(vinyl alcohol) | Electrospinning | Water | Ultra | 101.7 at 207 kPa | [103] |

| PVDF/Synthetic PEG based triblock polymers | Phase Inversion | Water | Micro | Approximately 700 at 100 kPa | [25] |

| PVDF/HDPE | Melt-processing | Water | Micro | 24,000 at 100 kPa | [121] |

| PVDF | Phase Inversion | Not Specified | Not Specified | Not specified | [77] |

| Kevlar/PET | Layer by layer assembly | Water | Ultra | 1161 to 7585 at 1 kPa | [61] |

| Linear low-density polyethylene | Imprint and thermal filed induction (Template) | Water | Micro | 0.19 at 20 kPa | [56] |

| PEK-C/PAMAM dendrimers | Phase Inversion and interfacial polymerization | Water and cation separation | Ultra | 37.5 to 68.2 at 600 kPa | [122] |

| Carbonaceous | Te nanowire template | Water | Micro-nano | Not specified | [57] |

| Hewlett-Packard Color LaserJet Transparency film | Laser ablation | Not specified | Greater than Micro | Not specified | [55] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kerr-Phillips, T.; Schon, B.; Barker, D. Polymeric Materials and Microfabrication Techniques for Liquid Filtration Membranes. Polymers 2022, 14, 4059. https://doi.org/10.3390/polym14194059

Kerr-Phillips T, Schon B, Barker D. Polymeric Materials and Microfabrication Techniques for Liquid Filtration Membranes. Polymers. 2022; 14(19):4059. https://doi.org/10.3390/polym14194059

Chicago/Turabian StyleKerr-Phillips, Thomas, Benjamin Schon, and David Barker. 2022. "Polymeric Materials and Microfabrication Techniques for Liquid Filtration Membranes" Polymers 14, no. 19: 4059. https://doi.org/10.3390/polym14194059

APA StyleKerr-Phillips, T., Schon, B., & Barker, D. (2022). Polymeric Materials and Microfabrication Techniques for Liquid Filtration Membranes. Polymers, 14(19), 4059. https://doi.org/10.3390/polym14194059