Effect of Stacking Sequence on Long-Term Creep Performance of Pultruded GFRP Composites

Abstract

:1. Introduction

2. Material and Methods

2.1. Fabrication Process and Material Properties

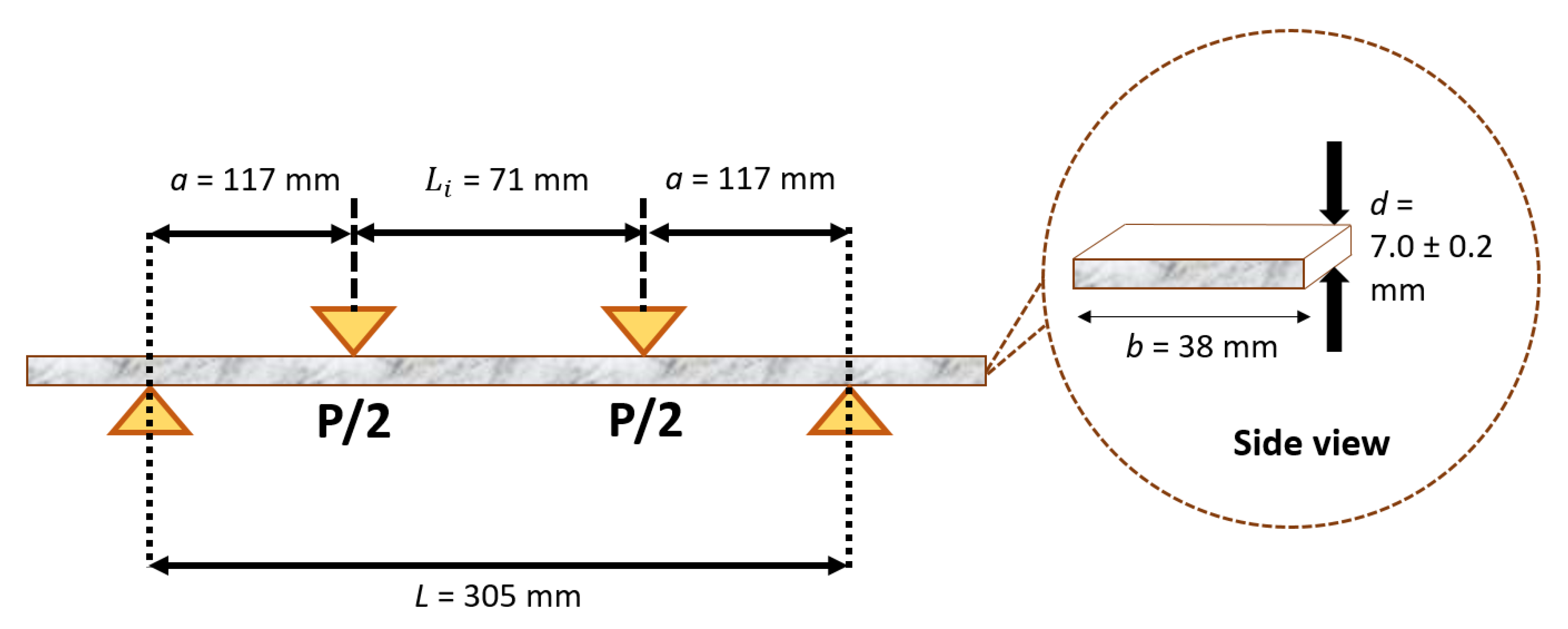

2.2. Quasi-Static Flexural Test

2.3. Flexural Creep Test

2.4. Numerical Analysis: Findley Model and Creep Elastic Modulus

3. Results and Discussion

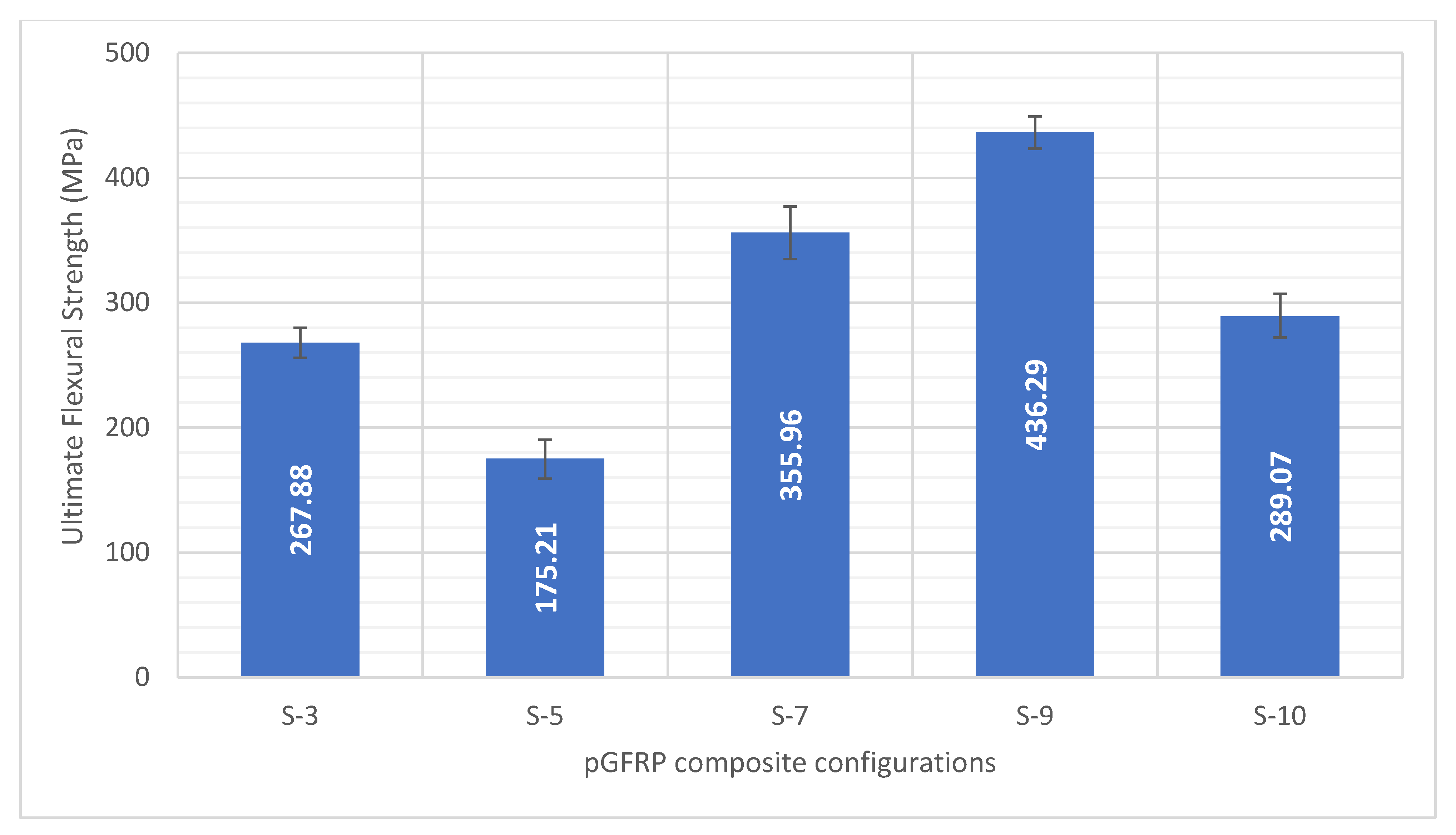

3.1. Ultimate Flexural Strength

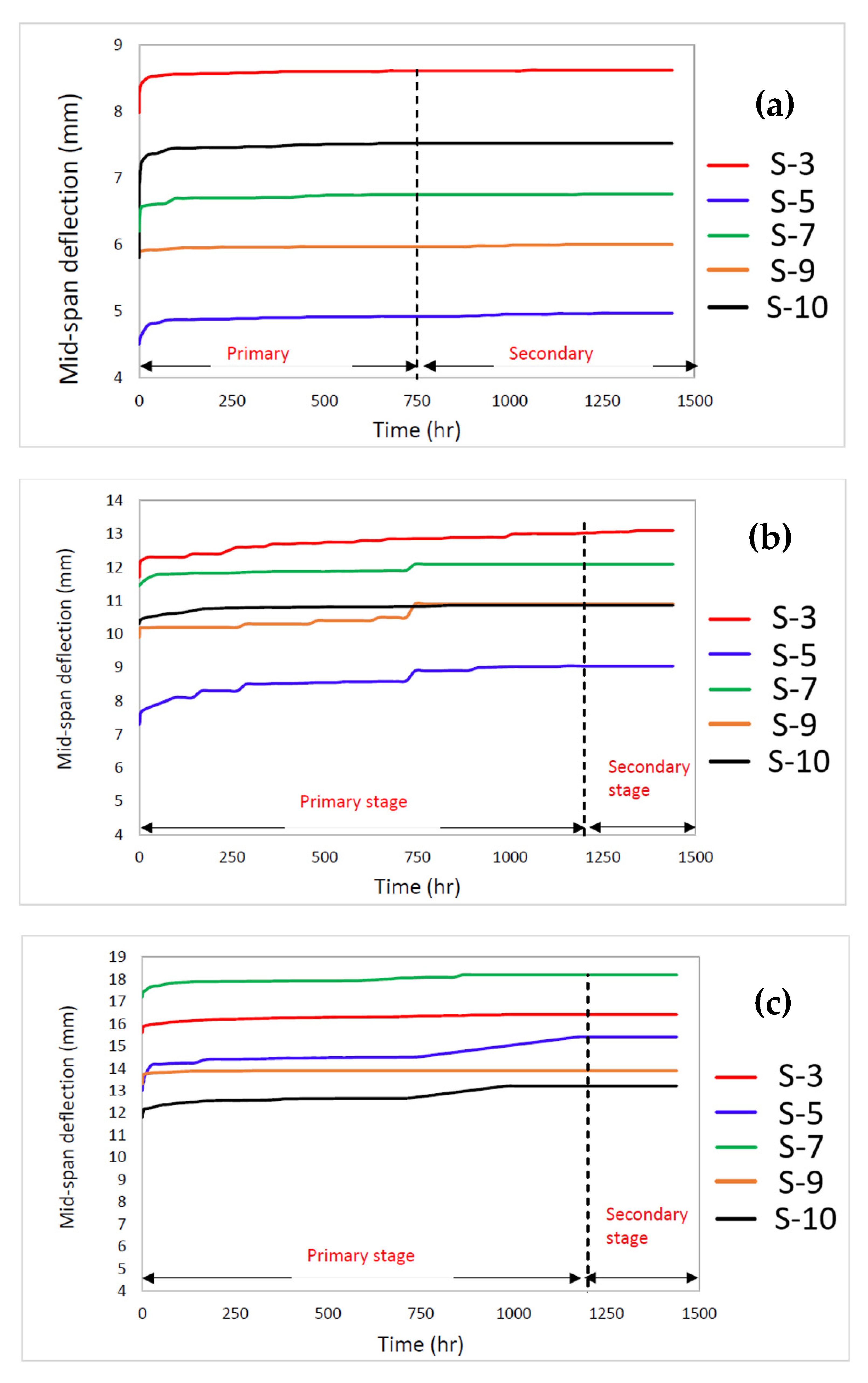

3.2. Flexural Creep Properties

3.3. Creep Analysis Using Findley’s Power Law Model

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, X.; Li, N.; Peng, Z.; Liao, J.; Wang, Q. Potential distribution computation and structure optimization for composite cross-arms in 750 kV AC transmission line. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 1660–1669. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Syamsir, A.; Supian, A.B.M.; Usman, F.; Ilyas, R.A.; Nurazzi, N.M.; Norrrahim, M.N.F.; Razman, M.R.; Zakaria, S.Z.S.; Sharma, S.; et al. Sugar Palm Fibre-Reinforced Polymer Composites: Influence of Chemical Treatments on Its Mechanical Properties. Materials 2022, 15, 3852. [Google Scholar] [CrossRef] [PubMed]

- Naser, M.Z.; Hawileh, R.A.; Abdalla, J.A. Fiber-reinforced polymer composites in strengthening reinforced concrete structures: A critical review. Eng. Struct. 2019, 198, 109542. [Google Scholar] [CrossRef]

- Zhang, Q.; Wu, J.; Gao, L.; Liu, T.; Zhong, W.; Sui, G.; Zheng, G.; Fang, W.; Yang, X. Dispersion stability of functionalized MWCNT in the epoxy-amine system and its effects on mechanical and interfacial properties of carbon fiber composites. Mater. Des. 2016, 94, 392–402. [Google Scholar] [CrossRef]

- Genedy, M.; Daghash, S.; Soliman, E.; Reda Taha, M.M. Improving fatigue performance of GFRP composite using Carbon Nanotubes. Fibers 2015, 3, 13–29. [Google Scholar] [CrossRef]

- Zhao, J.; Mei, K.; Wu, J. Long-term mechanical properties of FRP tendon–anchor systems—A review. Constr. Build. Mater. 2020, 230, 117017. [Google Scholar] [CrossRef]

- Bedon, C.; Louter, C. Structural glass beams with embedded GFRP, CFRP or steel reinforcement rods: Comparative experimental, analytical and numerical investigations. J. Build. Eng. 2019, 22, 227–241. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Syamsir, A.; Zahari, N.M.; Supian, A.B.M.; Ishak, M.R.; Sapuan, S.M.; Sharma, S.; Rashedi, A.; Razman, M.R.; Zakaria, S.Z.S.; et al. Product Development of Natural Fibre-Composites for Various Applications: Design for Sustainability. Polymers 2022, 14, 920. [Google Scholar] [CrossRef]

- Yadav, R.; Tirumali, M.; Wang, X.; Naebe, M.; Kandasubramanian, B. Polymer composite for antistatic application in aerospace. Def. Technol. 2020, 16, 107–118. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Syamsir, A.; Nurazzi, N.M.; Sabaruddin, F.A.; Shazleen, S.S.; Norrrahim, M.N.F.; Rafidah, M.; Ilyas, R.A.; Rashid, M.Z.A.; et al. Mechanical properties of oil palm fibre-reinforced polymer composites: A review. J. Mater. Res. Technol. 2022, 17, 33–65. [Google Scholar] [CrossRef]

- Hosseini, S.M.; Mostofinejad, D.; Saljoughian, A.; Nader Tehrani, B. Seismic Retrofit of Square RC Short Columns with Shear-Flexural Failure Mode via CFRP Composites Using Different Confinement Techniques. J. Compos. Constr. 2020, 24, 04020029. [Google Scholar] [CrossRef]

- Aslani, F.; Gunawardena, Y.; Dehghani, A. Behaviour of concrete filled glass fibre-reinforced polymer tubes under static and flexural fatigue loading. Constr. Build. Mater. 2019, 212, 57–76. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Rafidah, M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Ilyas, R.A.; Razman, M.R. Integration of TRIZ, Morphological Chart and ANP method for development of FRP composite portable fire extinguisher. Polym. Compos. 2020, 41, 2917–2932. [Google Scholar] [CrossRef]

- Zhu, J.; Lopez, M.M. Performance of a lightweight GFRP composite bridge deck in positive and negative bending regions. Compos. Struct. 2014, 113, 108–117. [Google Scholar] [CrossRef]

- Nadhirah, A.; Mohamad, D.; Zainoodin, M.; Nabihah, S.; Mubin, N.; Itam, Z.; Mansor, H.; Kamal, N.M.; Muda, Z.C.; Nasional, U.T.; et al. Properties of fiberglass crossarm in transmission tower-a review. Int. J. Appl. Eng. Res. 2017, 12, 15228–15233. [Google Scholar]

- Asyraf, M.R.M.; Ishak, M.R.; Norrrahim, M.N.F.; Amir, A.L.; Nurazzi, N.M.; Ilyas, R.A.; Asrofi, M.; Rafidah, M.; Razman, M.R. Potential of Flax Fiber Reinforced Biopolymer Composites for Cross-Arm Application in Transmission Tower: A Review. Fibers Polym. 2022, 23, 853–877. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Rafidah, M.; Ebadi, S.; Azrina, A.; Razman, M.R. Mechanical properties of sugar palm lignocellulosic fibre reinforced polymer composites: A review. Cellulose 2022, 29, 6493–6516. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Rafidah, M.; Azrina, A.; Razman, M.R. Dynamic mechanical behaviour of kenaf cellulosic fibre biocomposites: A comprehensive review on chemical treatments. Cellulose 2021, 28, 2675–2695. [Google Scholar] [CrossRef]

- Ascione, L.; Berardi, V.P.; Giordano, A.; Spadea, S. Buckling failure modes of FRP thin-walled beams. Compos. Part B Eng. 2013, 47, 357–364. [Google Scholar] [CrossRef]

- Xin, H.; Liu, Y.; Mosallam, A.S.; He, J.; Du, A. Evaluation on material behaviors of pultruded glass fiber reinforced polymer (GFRP) laminates. Compos. Struct. 2017, 182, 283–300. [Google Scholar] [CrossRef]

- Alhayek, A.; Syamsir, A.; Supian, A.B.M.; Usman, F.; Asyraf, M.R.M.; Atiqah, M.A. Flexural Creep Behaviour of Pultruded GFRP Composites Cross-Arm: A Comparative Study on the Effects of Stacking Sequence. Polymers 2022, 14, 1330. [Google Scholar] [CrossRef] [PubMed]

- Syamsir, A.; Nadhirah, A.; Mohamad, D.; Beddu, S.; Asyraf, M.R.M.; Itam, Z.; Anggraini, V. Performance Analysis of Full Assembly Glass Fiber-Reinforced Polymer Composite Cross-Arm in Transmission Tower. Polymers 2022, 14, 1563. [Google Scholar] [CrossRef] [PubMed]

- Selvaraj, M.; Kulkarni, S.; Babu, R.R. Analysis and experimental testing of a built-up composite cross arm in a transmission line tower for mechanical performance. Compos. Struct. 2013, 96, 1–7. [Google Scholar] [CrossRef]

- Qi, Y.; Fang, H.; Shi, H.; Liu, W.; Bai, Y. Bending performance of GFRP-wood sandwich beams with lattice-web reinforcement in flatwise and sidewise directions. Constr. Build. Mater. 2017, 156, 532–545. [Google Scholar] [CrossRef]

- Colombo, C.; Vergani, L. Optimization of filament winding parameters for the design of a composite pipe. Compos. Part B Eng. 2018, 148, 207–216. [Google Scholar] [CrossRef]

- Kumawat, H. Use of graphene-based composite pipe materials for transportation of oil and gas. In Proceedings of the ASME India Oil and Gas Pipeline Conference, New Delhi, India, 17–18 April 2015. [Google Scholar] [CrossRef]

- Shen, F.C. A filament-wound structure technology overview. Mater. Chem. Phys. 1995, 42, 96–100. [Google Scholar] [CrossRef]

- Rawi, I.M.; Rahman, M.S.A.; Ab Kadir, M.Z.A.; Izadi, M. Wood and fiberglass crossarm performance against lightning strikes on transmission towers. In Proceedings of the International Conference on Power Systems Transient (IPST), Seoul, Korea, 26–29 June 2017; pp. 1–6. [Google Scholar]

- Rawi, I.M.; Ab Kadir, M.Z.A. Investigation on the 132 kV overhead lines lightning-related flashovers in Malaysia. In Proceedings of the International Symposium on Lightning Protection, XIII SIPDA, Balneario Camboriu, Brazil, 28 September–2 October 2015; pp. 239–243. [Google Scholar]

- Peesapati, V.; Zachariades, C.; Li, Q.; Rowland, S.M.; Cotton, I.; Allison, F.; Chambers, D. 3D electric field computation of a composite cross-arm. In Proceedings of the IEEE International Symposium on Electrical Insulation, San Juan, Puerto Rico, 10–13 June 2012; Densley, J., Ed.; IEEE: San Juan, Puerto Rico, 2012; pp. 464–468. [Google Scholar]

- Abd Rahman, M.S.; Ab Kadir, M.Z.A.; Ab-Rahman, M.S.; Osman, M.; Mohd Nor, S.F.; Mohd Zainuddin, N. Effects of a Crossarm Brace Application on a 275 kV Fiberglass-Reinforced Polymer Crossarm Subjected to a Lightning Impulse. Energies 2020, 13, 6248. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N. Conceptual design of multi-operation outdoor flexural creep test rig using hybrid concurrent engineering approach. J. Mater. Res. Technol. 2020, 9, 2357–2368. [Google Scholar] [CrossRef]

- Jannat Alipour, H.; Aminnejad, S.; Jazaeri, M. Decreasing the right of way of transmission lines by using towers with polymer insulation arms. In Proceedings of the 2007 International Conference on Power Engineering, Energy and Electrical Drives, Setubal, Portugal, 12–14 April 2007; pp. 571–576. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Ilyas, R.A. Woods and composites cantilever beam: A comprehensive review of experimental and numerical creep methodologies. J. Mater. Res. Technol. 2020, 9, 6759–6776. [Google Scholar] [CrossRef]

- Bakar, M.S.A.; Mohamad, D.; Ishak, Z.A.M.; Yusof, Z.M.; Salwi, N. Durability control of moisture degradation in GFRP cross arm transmission line towers. AIP Conf. Proc. 2018, 2031, 020027. [Google Scholar]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N. Conceptual design of creep testing rig for full-scale cross arm using TRIZ-Morphological chart-analytic network process technique. J. Mater. Res. Technol. 2019, 8, 5647–5658. [Google Scholar] [CrossRef]

- Larsson, J. Evaluation of Current Methods for Creep Analysis and Impression Creep Testing of Power Plant Steels. Master Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2012. [Google Scholar]

- Xu, B.X.; Yue, Z.F.; Eggeler, G. A numerical procedure for retrieving material creep properties from bending creep tests. Acta Mater. 2007, 55, 6275–6283. [Google Scholar] [CrossRef]

- Jorik, S.; Lion, A.; Johlitz, M. Design of the novel tensile creep experimental setup, characterisation and description of the long-term creep performance of polycarbonate. Polym. Test. 2019, 75, 151–158. [Google Scholar] [CrossRef]

- Kumar, A.; Sharma, K.; Dixit, A.R. A review on the mechanical properties of polymer composites reinforced by carbon nanotubes and graphene. Carbon Lett. 2021, 31, 149–165. [Google Scholar] [CrossRef]

- Jawaid, M.; Khalil, H.P.S.A.; Bakar, A.A.; Khanam, P.N. Chemical resistance, void content and tensile properties of oil palm/jute fibre reinforced polymer hybrid composites. Mater. Des. 2011, 32, 1014–1019. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Ilyas, R.A.; Rafidah, M.; Razman, M.R. Evaluation of design and simulation of creep test rig for full-scale cross arm structure. Adv. Civ. Eng. 2020, 2020, 6980918. [Google Scholar] [CrossRef]

- Fiore, V.; Di Bella, G.; Valenza, A. The effect of alkaline treatment on mechanical properties of kenaf fibers and their epoxy composites. Compos. Part B Eng. 2015, 68, 14–21. [Google Scholar] [CrossRef]

- Muhi, R.J.; Najim, F.; de Moura, M.F.S.F. The effect of hybridization on the GFRP behavior under high velocity impact. Compos. Part B Eng. 2009, 40, 798–803. [Google Scholar] [CrossRef]

- Randjbaran, E.; Zahari, R.; Abdul Jalil, N.A.; Abang Abdul Majid, D.L. Hybrid composite laminates reinforced with Kevlar/carbon/glass woven fabrics for ballistic impact testing. Sci. World J. 2014, 2014, 413753. [Google Scholar] [CrossRef]

- Patel, P.; Chokshi, S. A Review of Fabrication Methods and Stacking Sequence Arrangements of Fiber for Composite. Int. J. Curr. Eng. Sci. Res. 2018, 5, 13–20. [Google Scholar]

- Ashraf, W.; Nawab, Y.; Umair, M.; Shaker, K.; Karahan, M. Investigation of mechanical behavior of woven/knitted hybrid composites. J. Text. Inst. 2017, 108, 1510–1517. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Kam, K.K.C.; Joshi, S.C. Mechanical and vibration response of insulated hybrid composites. J. Ind. Text. 2018, 47, 1887–1907. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Norrrahim, M.N.F.; Nurazzi, N.M.; Shazleen, S.S.; Ilyas, R.A.; Rafidah, M.; Razman, M.R. Recent advances of thermal properties of sugar palm lignocellulosic fibre reinforced polymer composites. Int. J. Biol. Macromol. 2021, 193, 1587–1599. [Google Scholar] [CrossRef] [PubMed]

- Asyraf, M.Z.; Suriani, M.J.; Ruzaidi, C.M.; Khalina, A.; Ilyas, R.A.; Asyraf, M.R.M.; Syamsir, A.; Azmi, A.; Mohamed, A. Development of Natural Fibre-Reinforced Polymer Composites Ballistic Helmet Using Concurrent Engineering Approach: A Brief Review. Sustainability 2022, 14, 7092. [Google Scholar] [CrossRef]

- Marsyahyo, E.; Jamasri; Rochardjo, H.S.B. Soekrisno Preliminary investigation on bulletproof panels made from ramie fiber reinforced composites for NIJ Level II, IIA, and IV. J. Ind. Text. 2009, 39, 13–26. [Google Scholar] [CrossRef]

- Karahan, M. Comparison of Ballistic Performance and Energy Absorption Capabilities of Woven and Unidirectional Aramid Fabrics. Text. Res. J. 2008, 78, 718–730. [Google Scholar] [CrossRef]

- Ma, P.; Jin, L.; Wu, L. Experimental and numerical comparisons of ballistic impact behaviors between 3D angle-interlock woven fabric and its reinforced composite. J. Ind. Text. 2019, 48, 1044–1058. [Google Scholar] [CrossRef]

- Mohamad, D.; Syamsir, A.; Sa’don, S.N.; Zahari, N.M.; Seman, S.A.H.A.; Razali, M.F.; Abas, A.; Ng, F.C. Stacking sequence effects on performance of composite laminate structure subjected to multi-axial quasi-static loading stacking sequence. IOP Conf. Ser. Mater. Sci. Eng. 2019, 530, 012030. [Google Scholar] [CrossRef]

- Supian, A.B.M.; Sapuan, S.M.; Zuhri, M.Y.M.; Zainudin, E.S.; Ya, H.H.; Hisham, H.N. Effect of winding orientation on energy absorption and failure modes of filament wound kenaf/glass fibre reinforced epoxy hybrid composite tubes under intermediate-velocity impact (IVI) load. J. Mater. Res. Technol. 2021, 10, 1–14. [Google Scholar] [CrossRef]

- Guades, E.; Aravinthan, T. Residual properties of square FRP composite tubes subjected to repeated axial impact. Compos. Struct. 2013, 95, 354–365. [Google Scholar] [CrossRef]

- Abu Bakar, M.S.; Salit, M.S.; Mohamad Yusoff, M.Z.; Zainudin, E.S.; Ya, H.H. The crashworthiness performance of stacking sequence on filament wound hybrid composite energy absorption tube subjected to quasi-static compression load. J. Mater. Res. Technol. 2020, 9, 654–666. [Google Scholar] [CrossRef]

- Xiao, Y.; Hu, Y.; Zhang, J.; Song, C.; Liu, Z.; Yu, J. Dynamic bending responses of CFRP thin-walled square beams filled with aluminum honeycomb. Thin-Walled Struct. 2018, 132, 494–503. [Google Scholar] [CrossRef]

- Mohamad, D.; Syamsir, A.; Beddu, S.; Kamal, N.L.M.; Zainoodin, M.M.; Razali, M.F.; Abas, A.; Seman, S.A.H.A.; Ng, F.C. Effect of laminate properties on the failure of cross arm structure under multi-axial load. IOP Conf. Ser. Mater. Sci. Eng. 2019, 530, 012029. [Google Scholar] [CrossRef]

- Mohamad, D.; Syamsir, A.; Itam, Z.; Bakar, H.A.; Abas, A.; Ng, F.C.; Razali, M.F.; Seman, S.A.H.A. Numerical Simulation on the Statics Deformation Study of Composite Cross Arms of Different Materials and Configurations. IOP Conf. Ser. Mater. Sci. Eng. 2019, 530, 012028. [Google Scholar] [CrossRef]

- Heckadka, S.S.; Nayak, S.Y.; Narang, K.; Vardhan Pant, K. Chopped Strand/Plain Weave E-Glass as Reinforcement in Vacuum Bagged Epoxy Composites. J. Mater. 2015, 2015, 957043. [Google Scholar] [CrossRef]

- Acharya, S.K.; Dalbehera, S. Study on mechanical properties of natural fiber reinforced woven jute-glass hybrid epoxy composites. Adv. Polym. Sci. Technol. 2014, 4, 1–6. [Google Scholar]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Rafidah, M.; Ilyas, R.A.; Razman, M.R. Potential application of green composites for cross arm component in transmission tower: A brief review. Int. J. Polym. Sci. 2020, 2020, 8878300. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Syamsir, A.; Amir, A.L.; Nurazzi, N.M.; Norrrahim, M.N.F.; Asrofi, M.; Rafidah, M.; Ilyas, R.A.; Rashid, M.Z.A.; et al. Filament-wound glass-fibre reinforced polymer composites: Potential applications for cross arm structure in transmission towers. Polym. Bull. 2022. [Google Scholar] [CrossRef]

- Loni, S.; Stefanou, I.; Valvo, P.S. Experimental study on the creep behaviour of GFRP pultruded beams. In AIMETA 2013–XXI Congresso Nazionale dell’Associazione Italiana di Meccanica Teorica e Applicata; Edizioni Libreria Cortina: Turin, Italy, 2013. [Google Scholar]

- Yang, J.L.; Zhang, Z.; Schlarb, A.K.; Friedrich, K. On the characterization of tensile creep resistance of polyamide 66 nanocomposites. Part II: Modeling and prediction of long-term performance. Polymer 2006, 47, 6745–6758. [Google Scholar] [CrossRef]

- Du, Y.; Yan, N.; Kortschot, M.T. An experimental study of creep behavior of lightweight natural fiber-reinforced polymer composite/honeycomb core sandwich panels. Compos. Struct. 2013, 106, 160–166. [Google Scholar] [CrossRef]

- Findley, W.N.; Davis, F.A. Creep and Relaxation of Nonlinear Viscoelastic Materials; Courier Corporation: North Chelmsford, MA, USA, 2013. [Google Scholar]

- Sayahi, M.; Sghaier, S.; Belhadjsalah, H. Finite element analysis of ball burnishing process: Comparisons between numerical results and experiments. Int. J. Adv. Manuf. Technol. 2013, 67, 1665–1673. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, W.; Zhai, Z.J.; Chen, Q.Y. Evaluation of various turbulence models in predicting airflow and turbulence in enclosed environments by CFD: Part 2—comparison with experimental data from literature. HVAC R Res. 2007, 13, 871–886. [Google Scholar] [CrossRef]

- Kelkar, A.D.; Tate, J.S.; Chaphalkar, P. Performance evaluation of VARTM manufactured textile composites for the aerospace and defense applications. Mater. Sci. Eng. B Solid-State Mater. Adv. Technol. 2006, 132, 126–128. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N.; Jayaraman, K. Flax fibre and its composites—A review. Compos. Part B Eng. 2014, 56, 296–317. [Google Scholar] [CrossRef]

- Hashim, M.K.R.; Majid, M.S.A.; Jamir, M.R.M.; Kasim, F.H.; Sultan, M.T.H. The effect of stacking sequence and ply orientation on the mechanical properties of pineapple leaf fibre (Palf)/carbon hybrid laminate composites. Polymers 2021, 13, 455. [Google Scholar] [CrossRef]

- Bai, Y.; Zhang, J.; Shen, H. Residual compressive load-carrying capacity of cross-laminated timber walls after exposed to one-side fire. J. Build. Eng. 2021, 34, 101931. [Google Scholar] [CrossRef]

- Fotouhi, M.; Jalalvand, M.; Wisnom, M.R. High performance quasi-isotropic thin-ply carbon/glass hybrid composites with pseudo-ductile behaviour in all fibre orientations. Compos. Sci. Technol. 2017, 152, 101–110. [Google Scholar] [CrossRef]

- Bandaru, A.K.; Vetiyatil, L.; Ahmad, S. The effect of hybridization on the ballistic impact behavior of hybrid composite armors. Compos. Part B Eng. 2015, 76, 300–319. [Google Scholar] [CrossRef]

- Kasiviswanathan, S.; Santhanam, K.; Kumaravel, A. Evaluation of mechanical properties of natural hybrid fibers, reinforced polyester composite materials. Carbon-Sci. Technol. 2015, 7, 43–49. [Google Scholar]

- Berardi, V.P.; Perrella, M.; Feo, L.; Cricrì, G. Creep behavior of GFRP laminates and their phases: Experimental investigation and analytical modeling. Compos. Part B Eng. 2017, 122, 136–144. [Google Scholar] [CrossRef]

- Scott, D.W.; Zureick, A.-H. Compression creep of a pultruded E-glass/vinylester composite. Compos. Sci. Technol. 1998, 58, 1361–1369. [Google Scholar] [CrossRef]

- Johari, A.N.; Ishak, M.R.; Leman, Z.; Yusoff, M.Z.M.; Asyraf, M.R.M. Influence of CaCO3 in pultruded glass fiber/unsaturated polyester resin composite on flexural creep behavior using conventional and time-temperature superposition principle methods. Polimery 2020, 65, 792–800. [Google Scholar] [CrossRef]

- Stochioiu, C.; Chettah, A.; Piezel, B.; Fontaine, S.; Gheorghiu, H.M. Study of the time varying properties of flax fiber reinforced composites. AIP Conf. Proc. 2018, 1932, 030041. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, D.; Lu, W.; Khan, M.U.; Xu, H.; Yi, W.; Lei, H.; Huo, E.; Qian, M.; Zhao, Y.; et al. Production of high-density polyethylene biocomposites from rice husk biochar: Effects of varying pyrolysis temperature. Sci. Total Environ. 2020, 738, 139910. [Google Scholar] [CrossRef]

- Cardoso, D.C.T.; Harries, K.A. A viscoelastic model for time-dependent behavior of pultruded GFRP. Constr. Build. Mater. 2019, 208, 63–74. [Google Scholar] [CrossRef]

- D’Antino, T.; Pisani, M.A. Long-term behavior of GFRP reinforcing bars. Compos. Struct. 2019, 227, 111283. [Google Scholar] [CrossRef]

- Tajvidi, M.; Falk, R.H.; Hermanson, J.C. Time-temperature superposition principle applied to a kenaf-fiber/high- density polyethylene composite. J. Appl. Polym. Sci. 2005, 97, 1995–2004. [Google Scholar] [CrossRef]

- Jauhari, N.; Mishra, R.; Thakur, H. Natural Fibre Reinforced Composite Laminates—A Review. Mater. Today Proc. 2015, 2, 2868–2877. [Google Scholar] [CrossRef]

- Palani, P.K.; Nanda, M. Analysis of Mechanical Properties of Chopped Strand Mat E-Glass Fiber Epoxy Resin Nanoclay Composites. Int. J. Eng. Sci. 2013, 2, 185–189. [Google Scholar]

- Shibata, S.; Cao, Y.; Fukumoto, I. Press forming of short natural fiber-reinforced biodegradable resin: Effects of fiber volume and length on flexural properties. Polym. Test. 2005, 24, 1005–1011. [Google Scholar] [CrossRef]

- Cordin, M.; Bechtold, T.; Pham, T. Effect of fibre orientation on the mechanical properties of polypropylene–lyocell composites. Cellulose 2018, 25, 7197–7210. [Google Scholar] [CrossRef]

- Liu, Q.; Hughes, M. The fracture behaviour and toughness of woven flax fibre reinforced epoxy composites. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1644–1652. [Google Scholar] [CrossRef]

- Riccio, A.; Di Felice, G.; Saputo, S.; Scaramuzzino, F. Stacking sequence effects on damage onset in composite laminate subjected to low velocity impact. Procedia Eng. 2014, 88, 222–229. [Google Scholar] [CrossRef]

- Amaro, A.M.; Reis, P.N.B.; de Moura, M.; Santos, J.B. Influence of the specimen thickness on low velocity impact behavior of composites. J. Polym. Eng. 2012, 32. [Google Scholar] [CrossRef]

- Reis, P.N.B.; Neto, M.A.; Amaro, A.M. Effect of the extreme conditions on the tensile impact strength of GFRP composites. Compos. Struct. 2018, 188, 48–54. [Google Scholar] [CrossRef]

- Morioka, K.; Tomita, Y. Effect of lay-up sequences on mechanical properties and fracture behavior of CFRP laminate composites. Mater. Charact. 2000, 45, 125–136. [Google Scholar] [CrossRef]

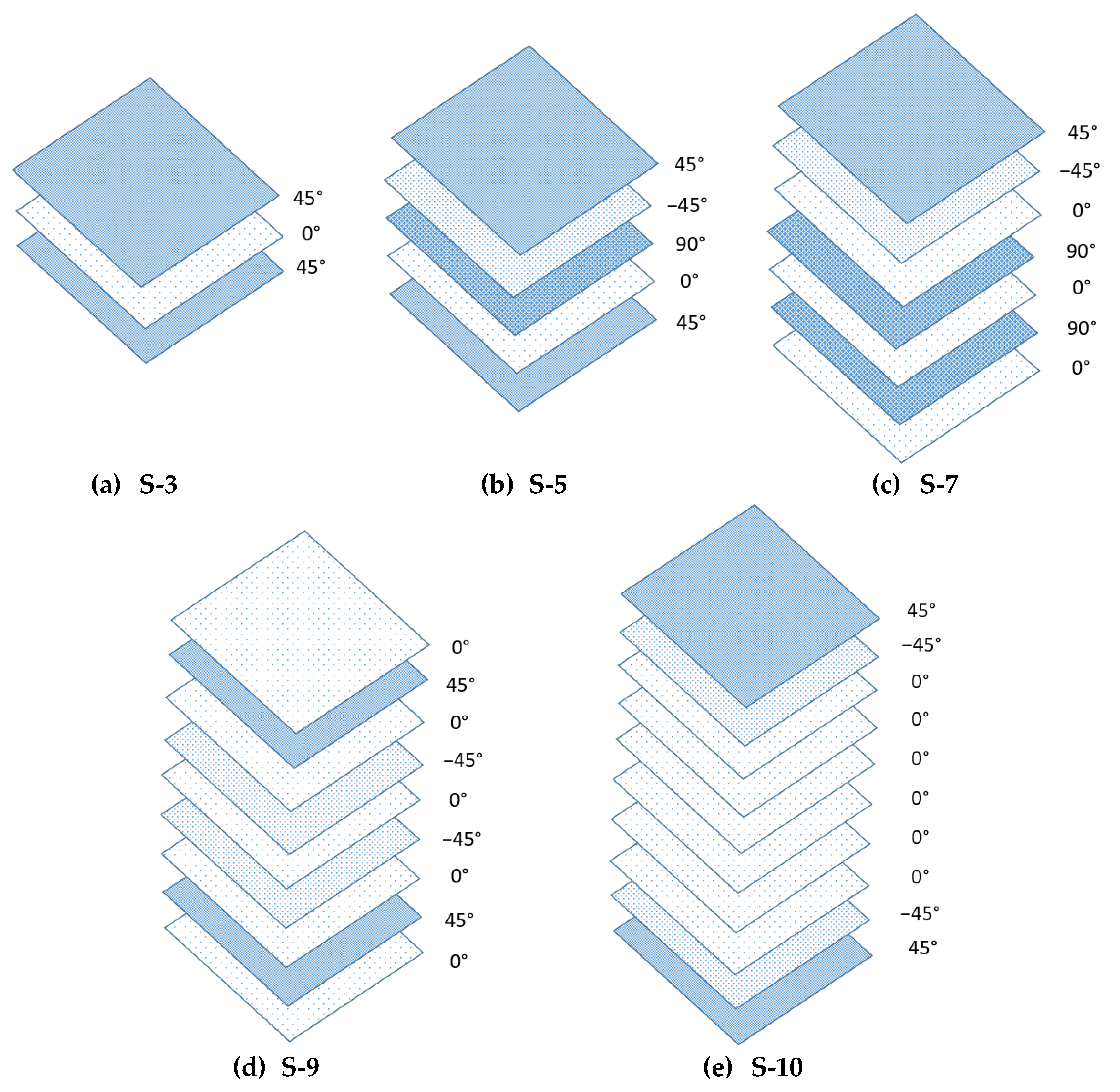

| No. | Configuration | Number of Layer | Layering Sequence |

|---|---|---|---|

| 1. | S-3 | 3 | 45°/0°/45° |

| 2. | S-5 | 5 | 45°/−45°/90°/0°/45° |

| 3. | S-7 | 7 | 45°/−45°/0°/90°/0°/90°/0° |

| 4. | S-9 | 9 | 0°/45°/0°/−45°/0°/−45°/0°/45°/0° |

| 5. | S-10 | 10 | 45°/−45°/0°/0°/0°/0°/0°/0°/−45°/45° |

| No. | Configuration | Fibre Mass (%) | Resin Mass (%) |

|---|---|---|---|

| 1. | S-3 | 64.11 | 35.89 |

| 2. | S-5 | 64.67 | 35.33 |

| 3. | S-7 | 72.77 | 27.33 |

| 4. | S-9 | 78.04 | 21.96 |

| 5. | S-10 | 74.17 | 25.83 |

| pGFRP Composite Configurations | Sample | Maximum Flexural Load (N) | Average Maximum Flexural Load (N) | Standard Deviation | Percentage Error (%) | Ultimate Flexural Strength (MPa) |

|---|---|---|---|---|---|---|

| S-3 | Sample 1 | 1697.38 | 1694 | 24 | 1.42 | 267.88 |

| Sample 2 | 1724.78 | |||||

| Sample 3 | 1704.73 | |||||

| S-5 | Sample 1 | 1152.99 | 1108 | 31 | 2.94 | 175.21 |

| Sample 2 | 1051.14 | |||||

| Sample 3 | 1091.80 | |||||

| S-7 | Sample 1 | 2250.65 | 2251 | 42 | 1.07 | 355.96 |

| Sample 2 | 2251.88 | |||||

| Sample 3 | 2281.96 | |||||

| S-9 | Sample 1 | 2799.12 | 2759 | 26 | 0.94 | 436.29 |

| Sample 2 | 2765.66 | |||||

| Sample 3 | 2783.42 | |||||

| S-10 | Sample 1 | 1789.24 | 1828 | 37 | 2.02 | 289.07 |

| Sample 2 | 1820.41 | |||||

| Sample 3 | 1868.92 |

| Sequence | Ultimate Flexural load (N) | Load Level | Applied Load (N) |

|---|---|---|---|

| S-3 | 1694 | 12% | 203.28 |

| 24% | 406.56 | ||

| 37% | 626.78 | ||

| S-5 | 1108 | 12% | 132.96 |

| 24% | 256.92 | ||

| 37% | 409.96 | ||

| S-7 | 2251 | 12% | 270.12 |

| 24% | 540.24 | ||

| 37% | 832.87 | ||

| S-9 | 2759 | 12% | 331.08 |

| 24% | 662.16 | ||

| 37% | 1020.83 | ||

| S-10 | 1694 | 12% | 203.28 |

| 24% | 406.56 | ||

| 37% | 626.78 |

| Samples | Load (%) | n | Average n | m | Average m |

|---|---|---|---|---|---|

| S-3 | 12 | 0.0954 | 0.1769 | 0.0097 | 0.00743 |

| 24 | 0.2315 | 0.0071 | |||

| 37 | 0.2038 | 0.0055 | |||

| S-5 | 12 | 0.3000 | 0.3070 | 0.0020 | 0.00567 |

| 24 | 0.3424 | 0.0051 | |||

| 37 | 0.2786 | 0.0099 | |||

| S-7 | 12 | 0.1290 | 0.2694 | 0.0088 | 0.00553 |

| 24 | 0.4340 | 0.0012 | |||

| 37 | 0.2452 | 0.0066 | |||

| S-9 | 12 | 0.149 | 0.1317 | 0.0019 | 0.00737 |

| 24 | 0.1803 | 0.0071 | |||

| 37 | 0.0658 | 0.0131 | |||

| S-10 | 12 | 0.0582 | 0.1920 | 0.0464 | 0.01953 |

| 24 | 0.2843 | 0.0031 | |||

| 37 | 0.2335 | 0.0091 |

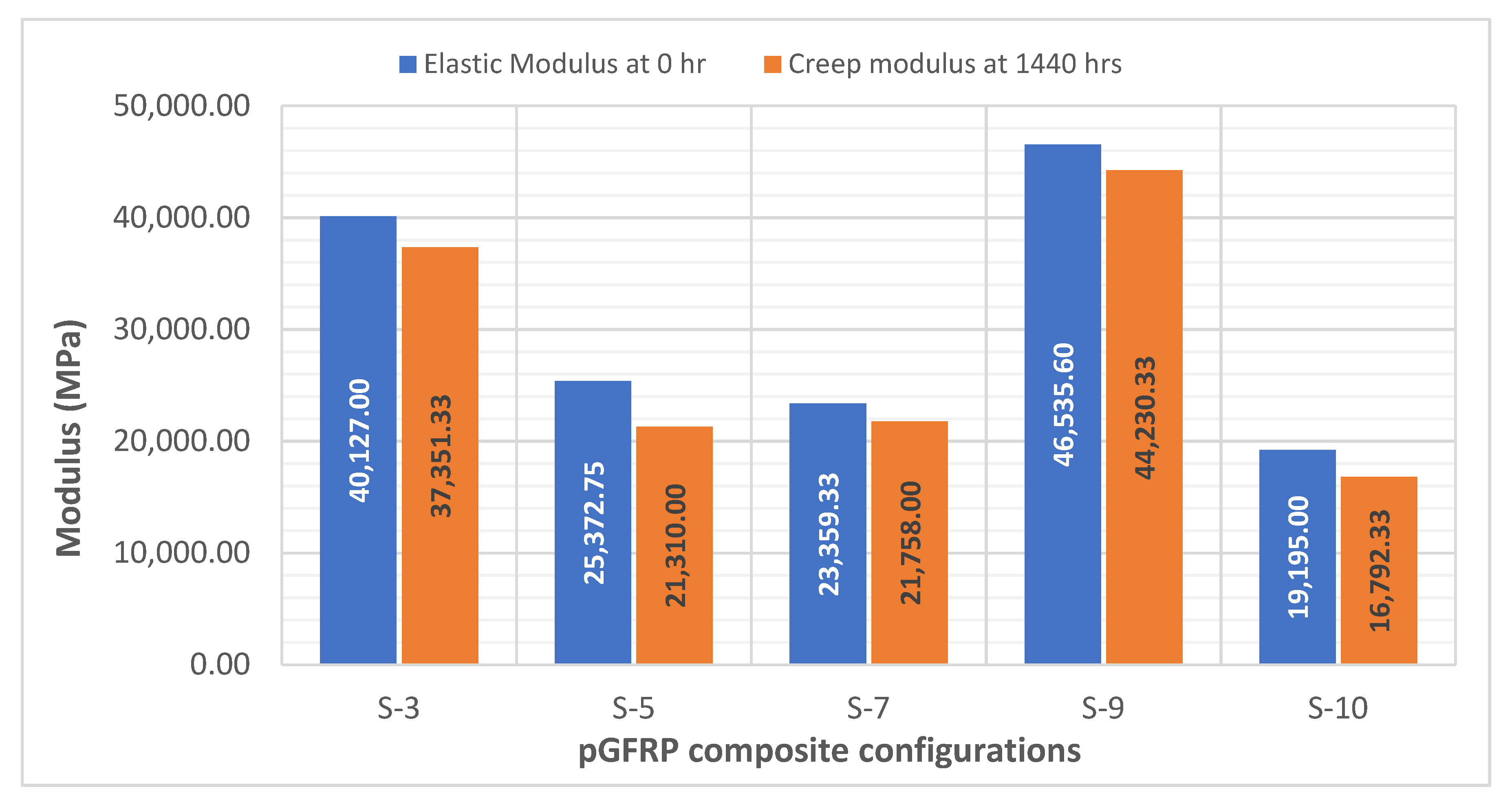

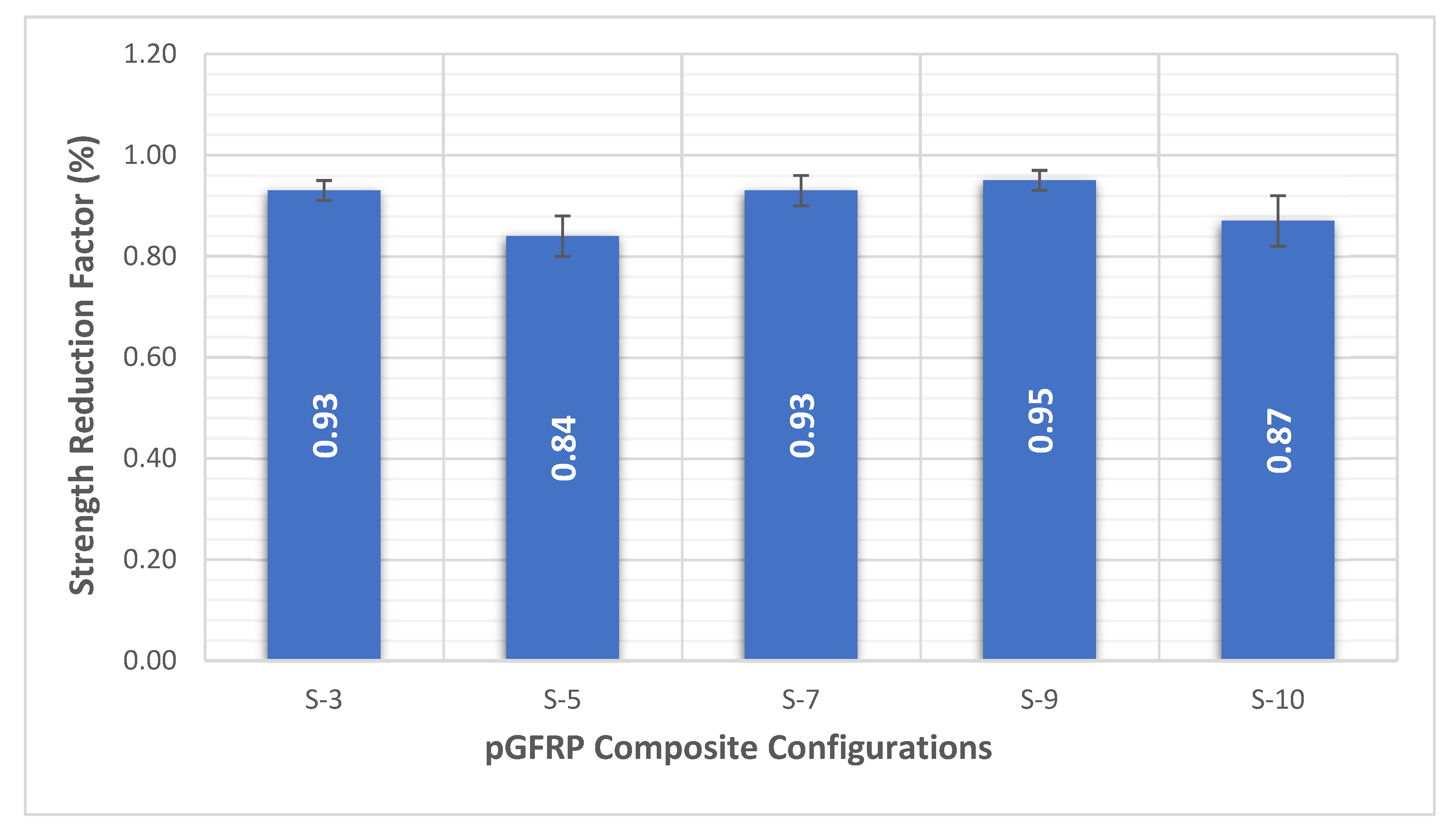

| Configurations | Load Level (%) | Instantaneous Deflection, ε (mm) | Elastic Modulus, E0 (MPa) | Creep Modulus at 1440 Hrs, Et (MPa) | Strength Reduction Factor, |

|---|---|---|---|---|---|

| S-3 | 12 | 2.20 | 30,543.00 | 28,232.00 | 0.942 |

| 24 | 3.30 | 41,664.00 | 37,874.00 | 0.909 | |

| 37 | 4.30 | 48,174.00 | 45,948.00 | 0.954 | |

| S-5 | 12 | 1.96 | 23,064.85 | 20,544.00 | 0.891 |

| 24 | 3.34 | 28,436.11 | 22,523.00 | 0.792 | |

| 37 | 4.48 | 24,617.29 | 20,863.00 | 0.847 | |

| S-7 | 12 | 2.32 | 21,930.00 | 19,994.00 | 0.910 |

| 24 | 4.28 | 23,771.00 | 22,304.00 | 0.940 | |

| 37 | 6.44 | 24,377.00 | 22,976.00 | 0.940 | |

| S-9 | 12 | 1.96 | 39,556.02 | 38,457.00 | 0.970 |

| 24 | 3.34 | 46,588.20 | 43,179.00 | 0.930 | |

| 37 | 4.48 | 53,462.59 | 51,055.00 | 0.950 | |

| S-10 | 12 | 2.20 | 15,812.00 | 12,004.00 | 0.760 |

| 24 | 4.00 | 17,790.00 | 16,756.00 | 0.940 | |

| 37 | 4.50 | 23,983.00 | 21,617.00 | 0.900 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Asyraf, M.R.M.; Syamsir, A.; Zahari, N.M.; Supian, A.B.M.; Usman, F.; Itam, Z. Effect of Stacking Sequence on Long-Term Creep Performance of Pultruded GFRP Composites. Polymers 2022, 14, 4064. https://doi.org/10.3390/polym14194064

Asyraf MRM, Syamsir A, Zahari NM, Supian ABM, Usman F, Itam Z. Effect of Stacking Sequence on Long-Term Creep Performance of Pultruded GFRP Composites. Polymers. 2022; 14(19):4064. https://doi.org/10.3390/polym14194064

Chicago/Turabian StyleAsyraf, Muhammad Rizal Muhammad, Agusril Syamsir, Nazirul Mubin Zahari, Abu Bakar Mohd Supian, Fathoni Usman, and Zarina Itam. 2022. "Effect of Stacking Sequence on Long-Term Creep Performance of Pultruded GFRP Composites" Polymers 14, no. 19: 4064. https://doi.org/10.3390/polym14194064

APA StyleAsyraf, M. R. M., Syamsir, A., Zahari, N. M., Supian, A. B. M., Usman, F., & Itam, Z. (2022). Effect of Stacking Sequence on Long-Term Creep Performance of Pultruded GFRP Composites. Polymers, 14(19), 4064. https://doi.org/10.3390/polym14194064