Modelling and Simulation of MuCell®: The Effect of Key Processing Parameters on Cell Size and Weight Reduction

Abstract

:1. Introduction

2. MuCell® Simulation

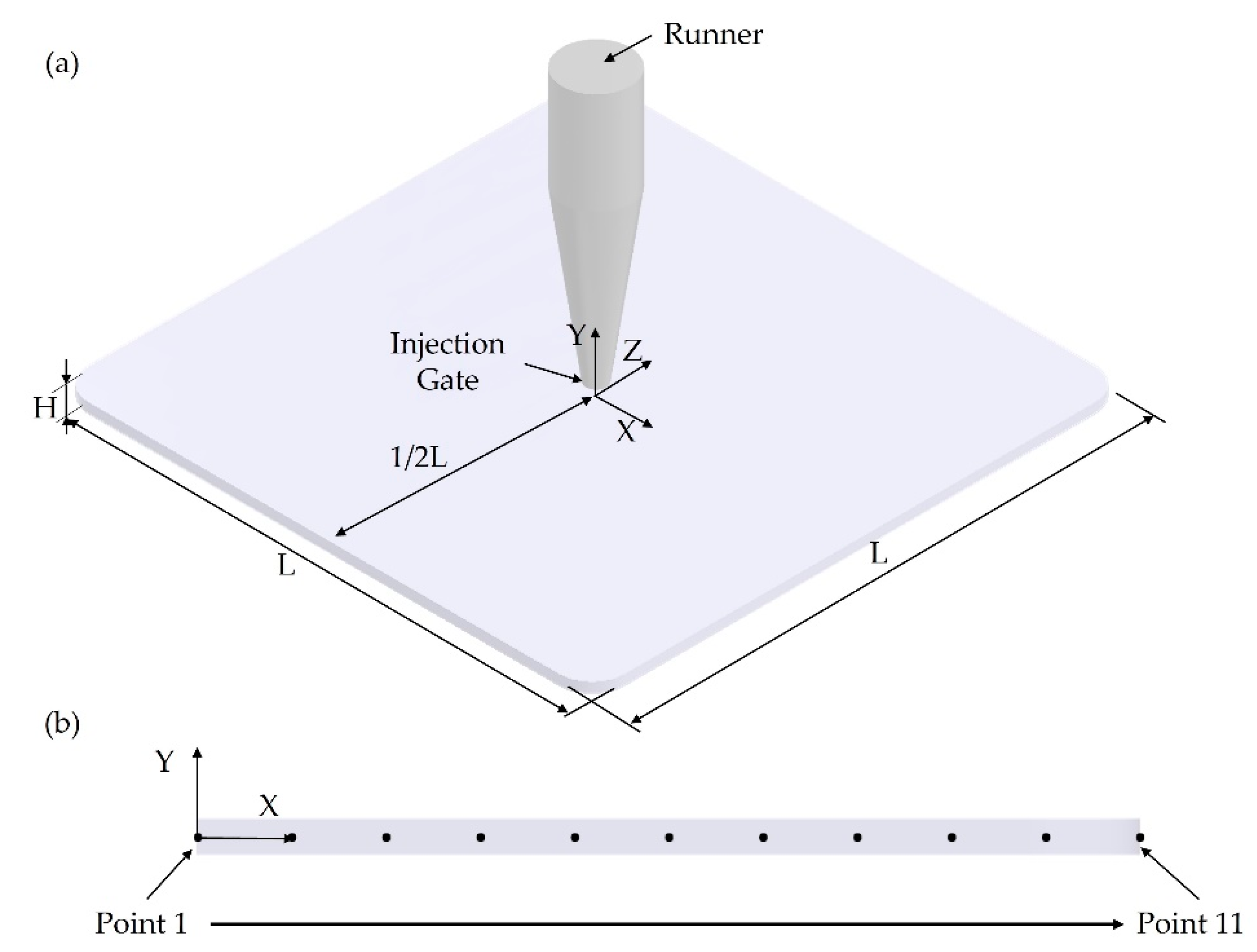

2.1. Part Design and Materials

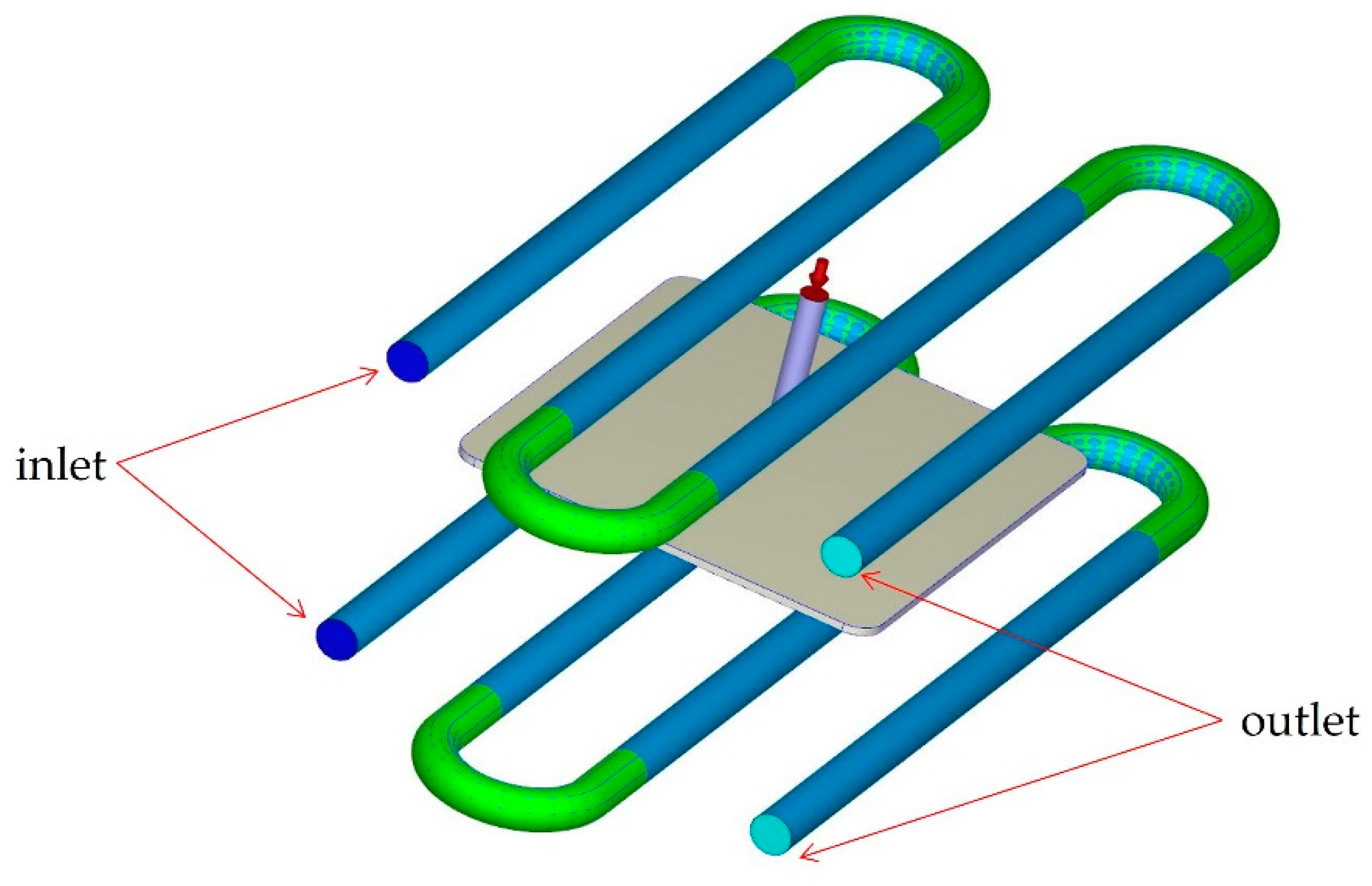

2.2. Cooling System

2.3. Processing Conditions and Nucleation Model

2.4. Mathematical Models for MuCell® Simulation

3. Simulation Results

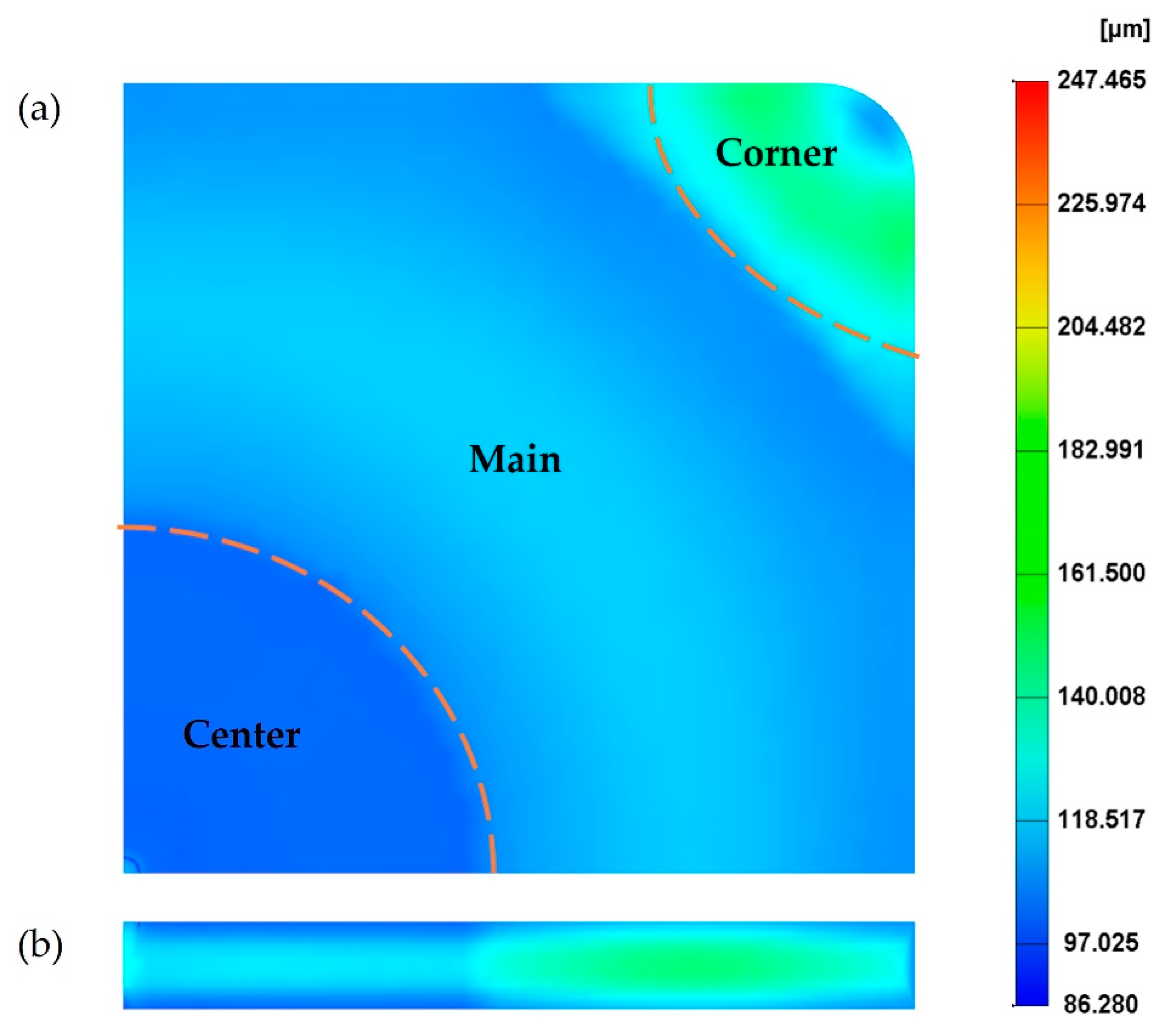

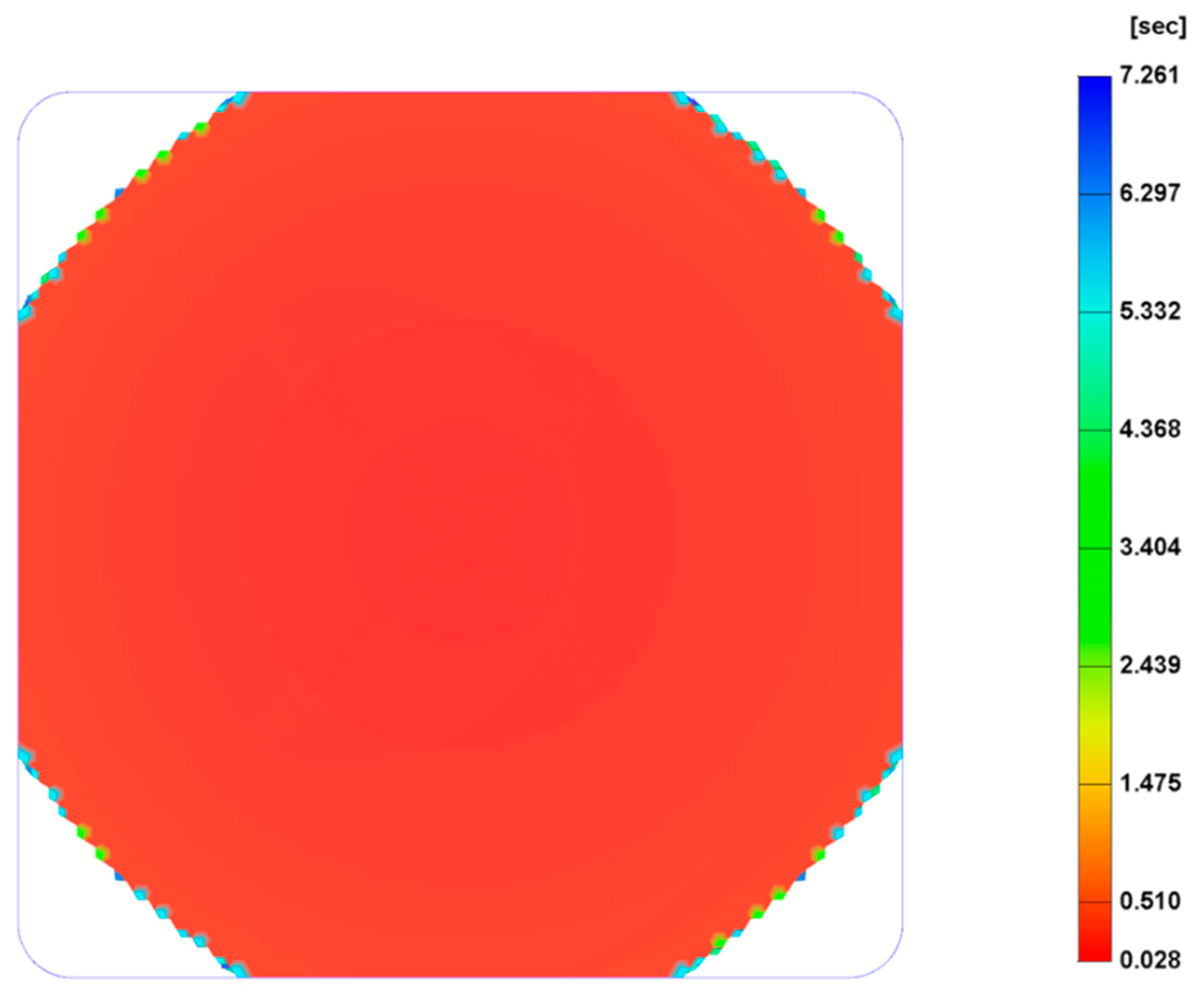

3.1. Reference Case

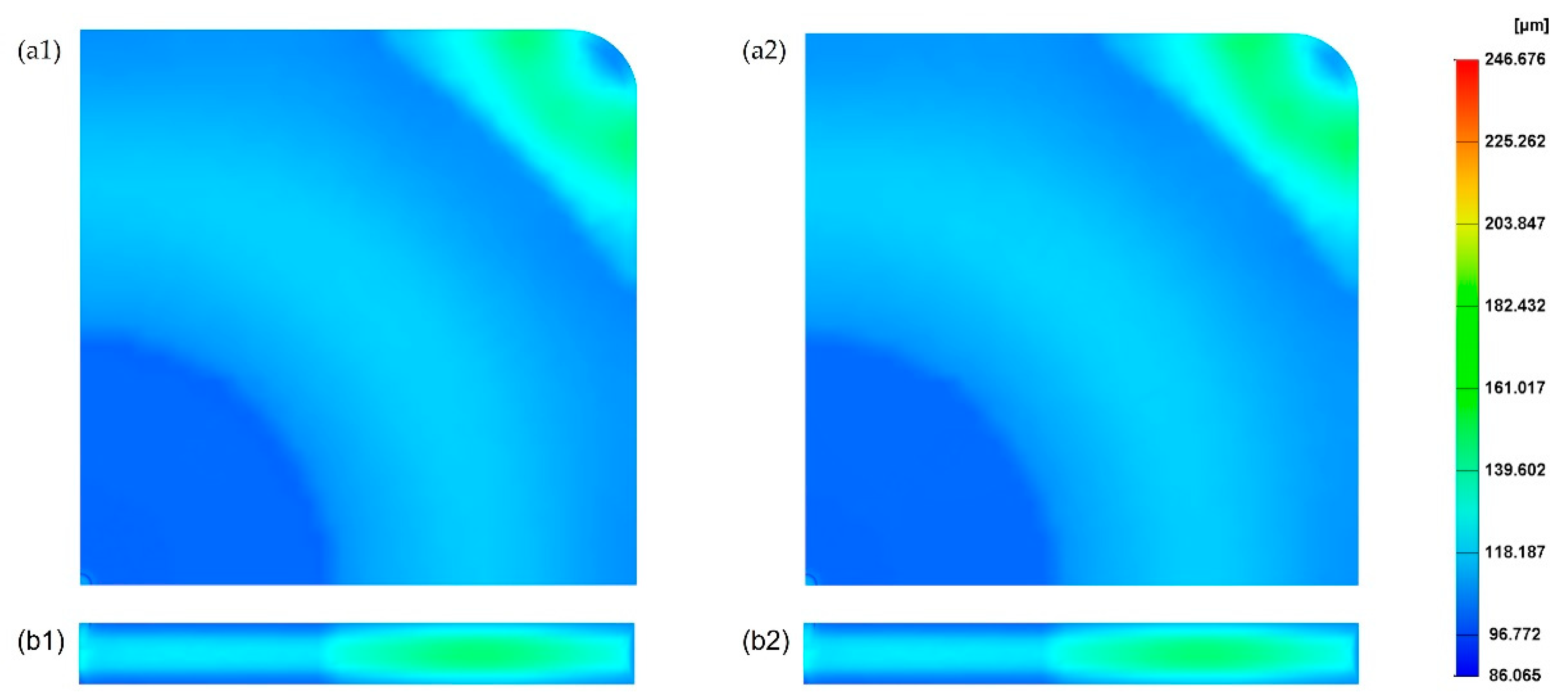

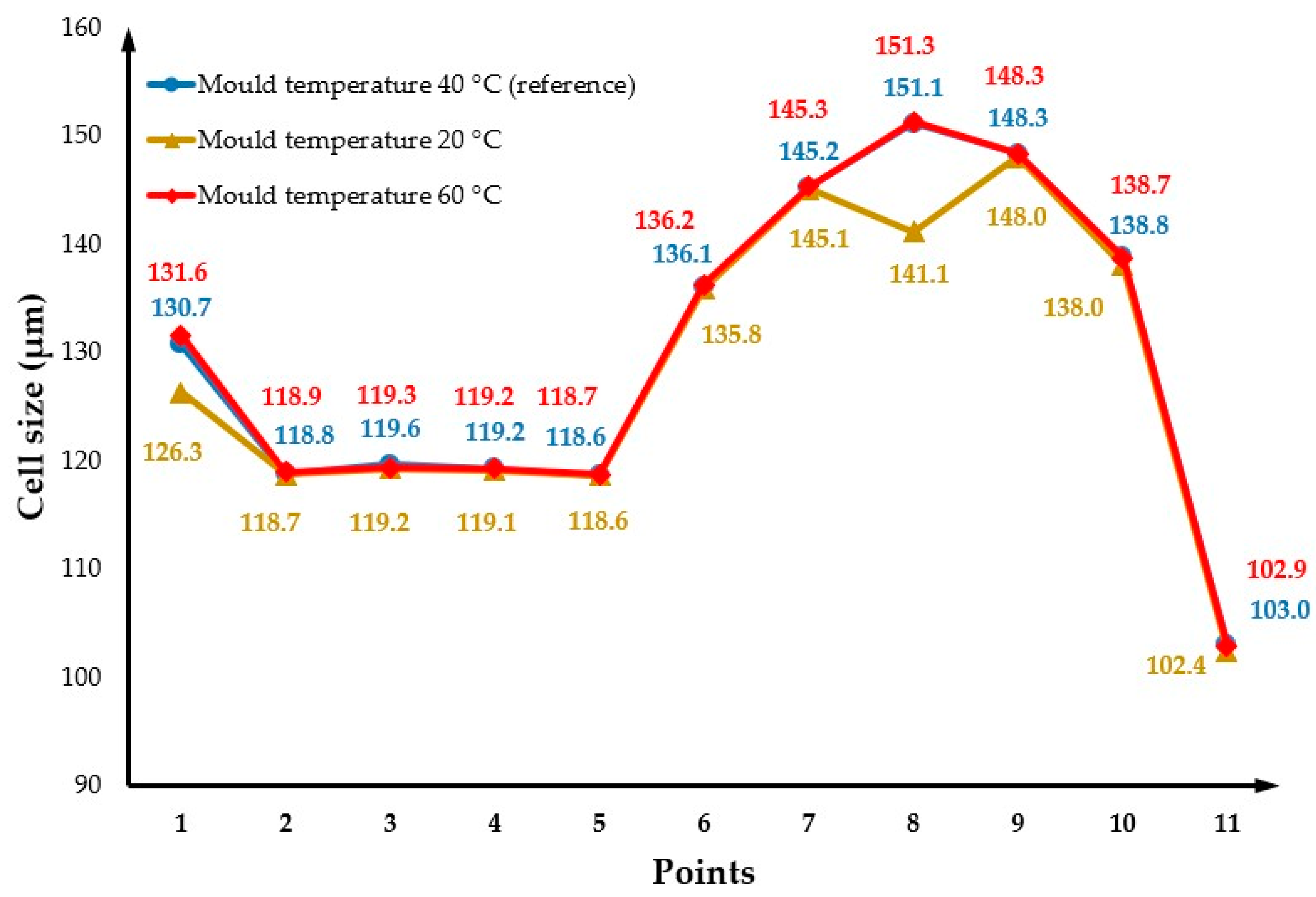

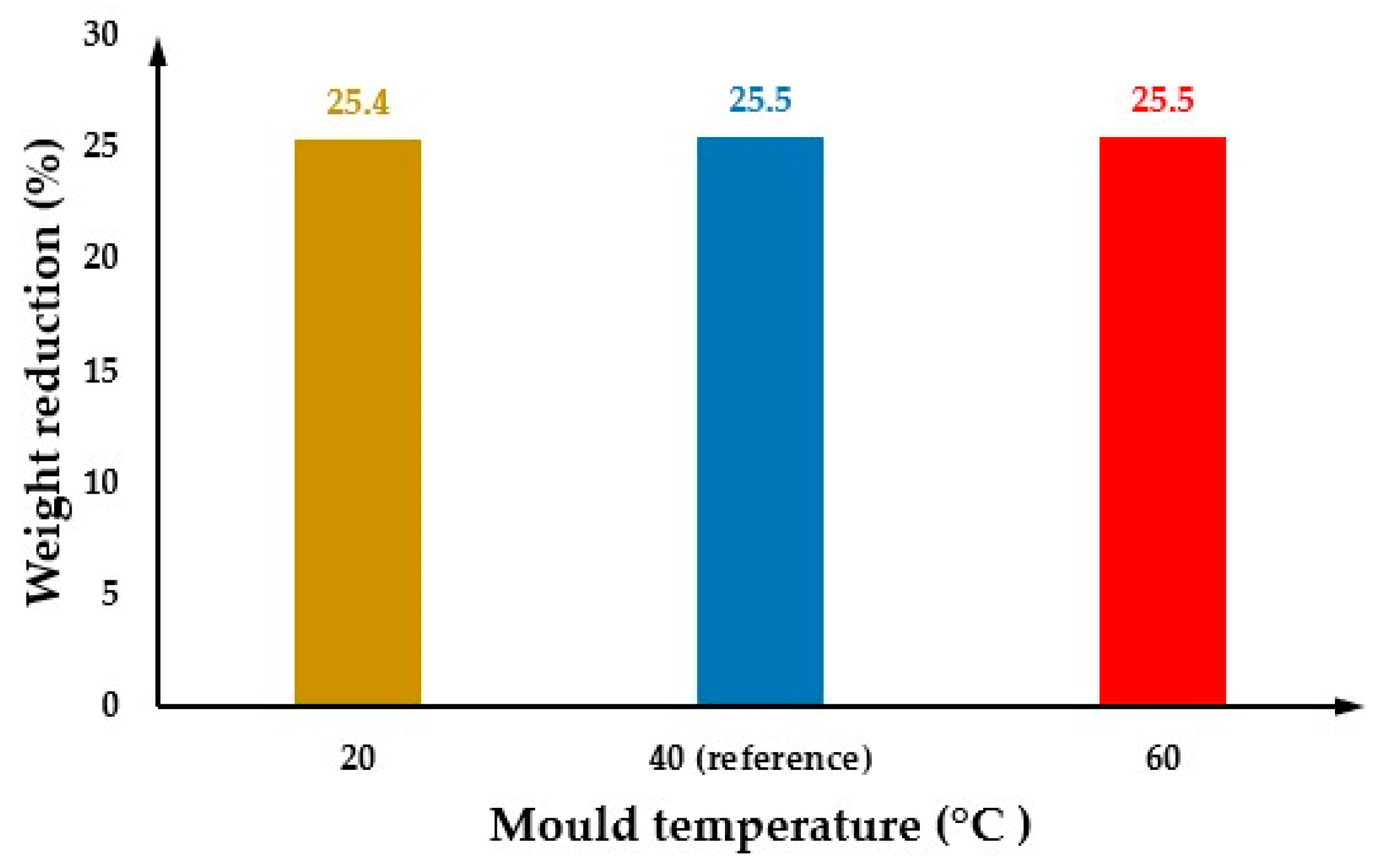

3.2. The Effect of Changing the Mould Temperature

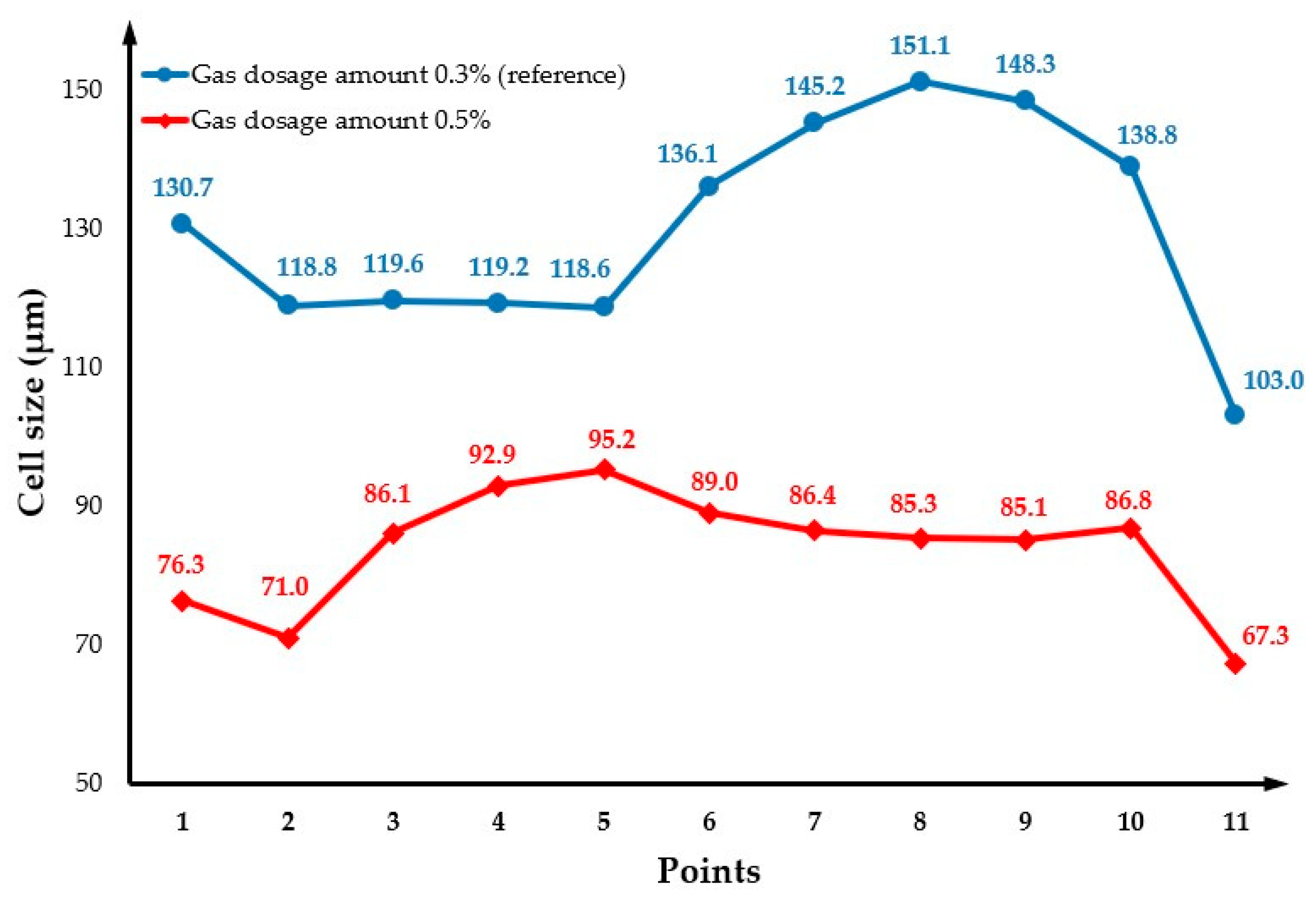

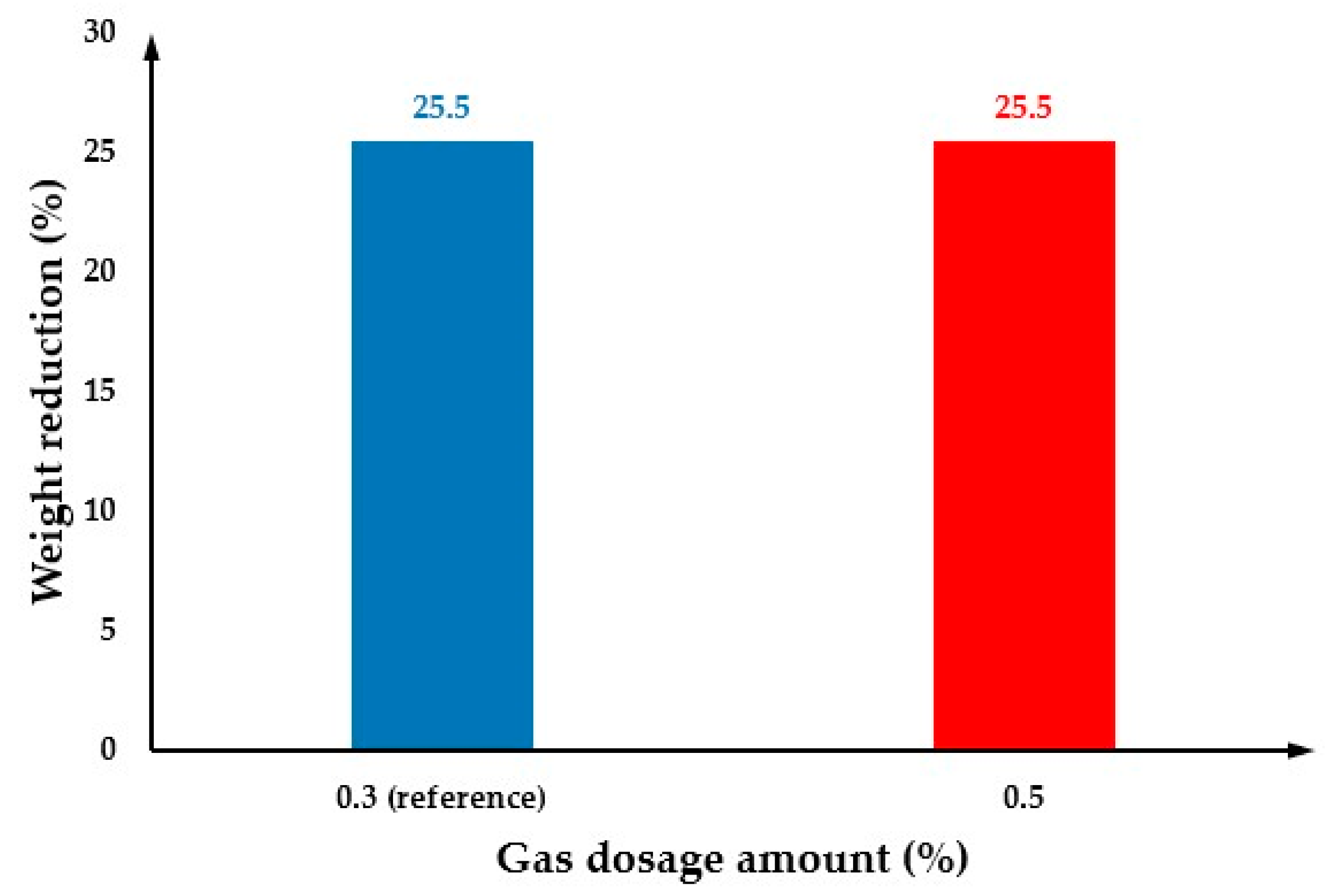

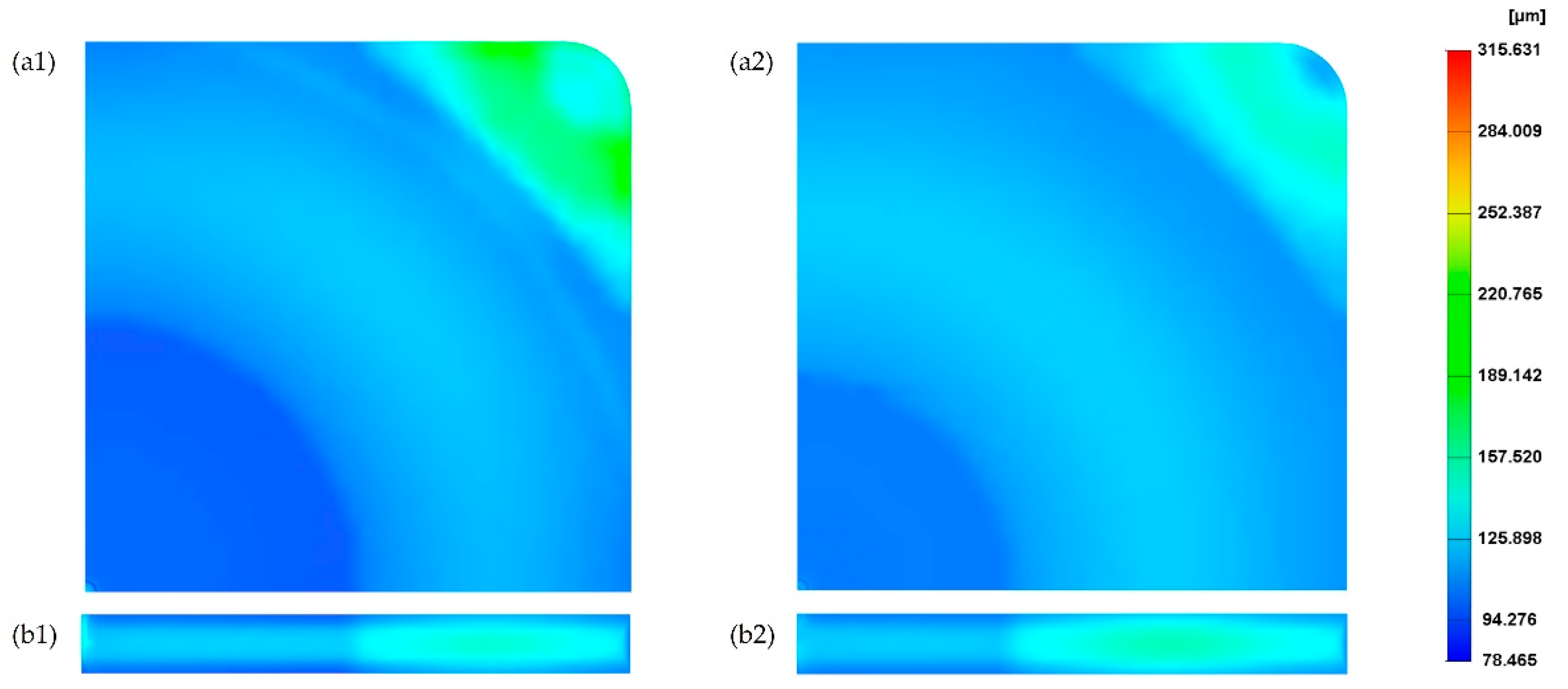

3.3. The Effect of Gas Dosage Amount

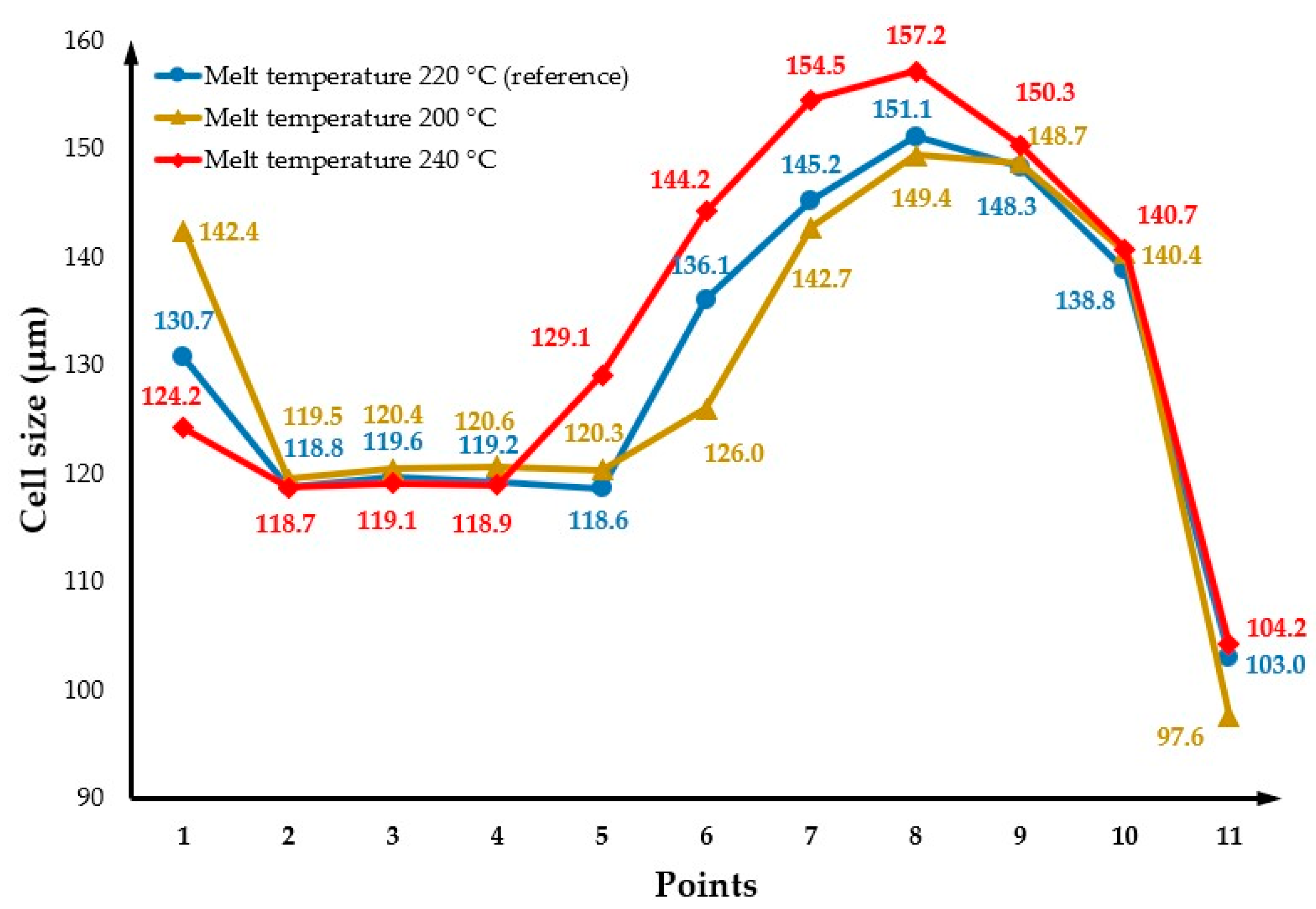

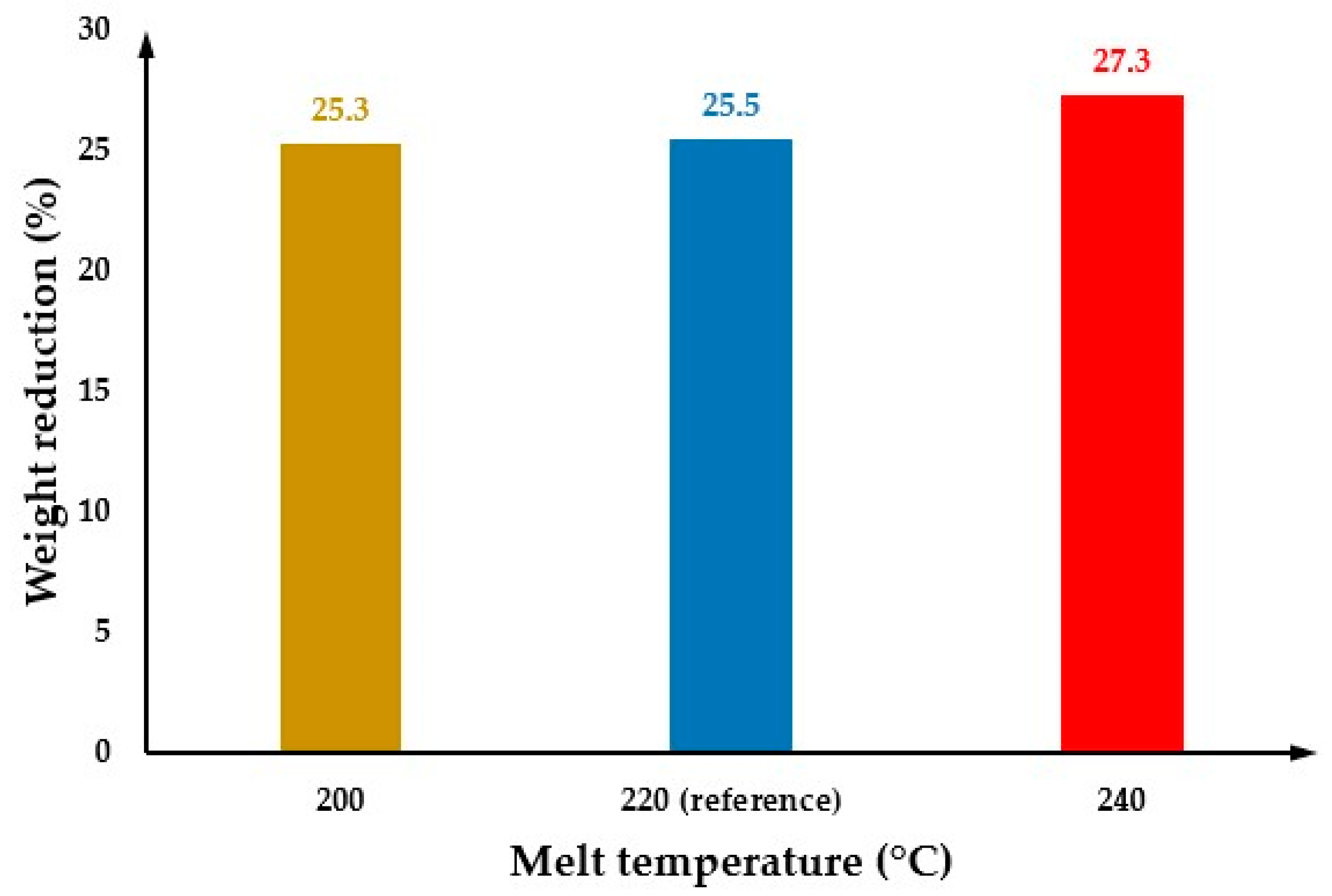

3.4. The Effect of Changing Melt Temperature

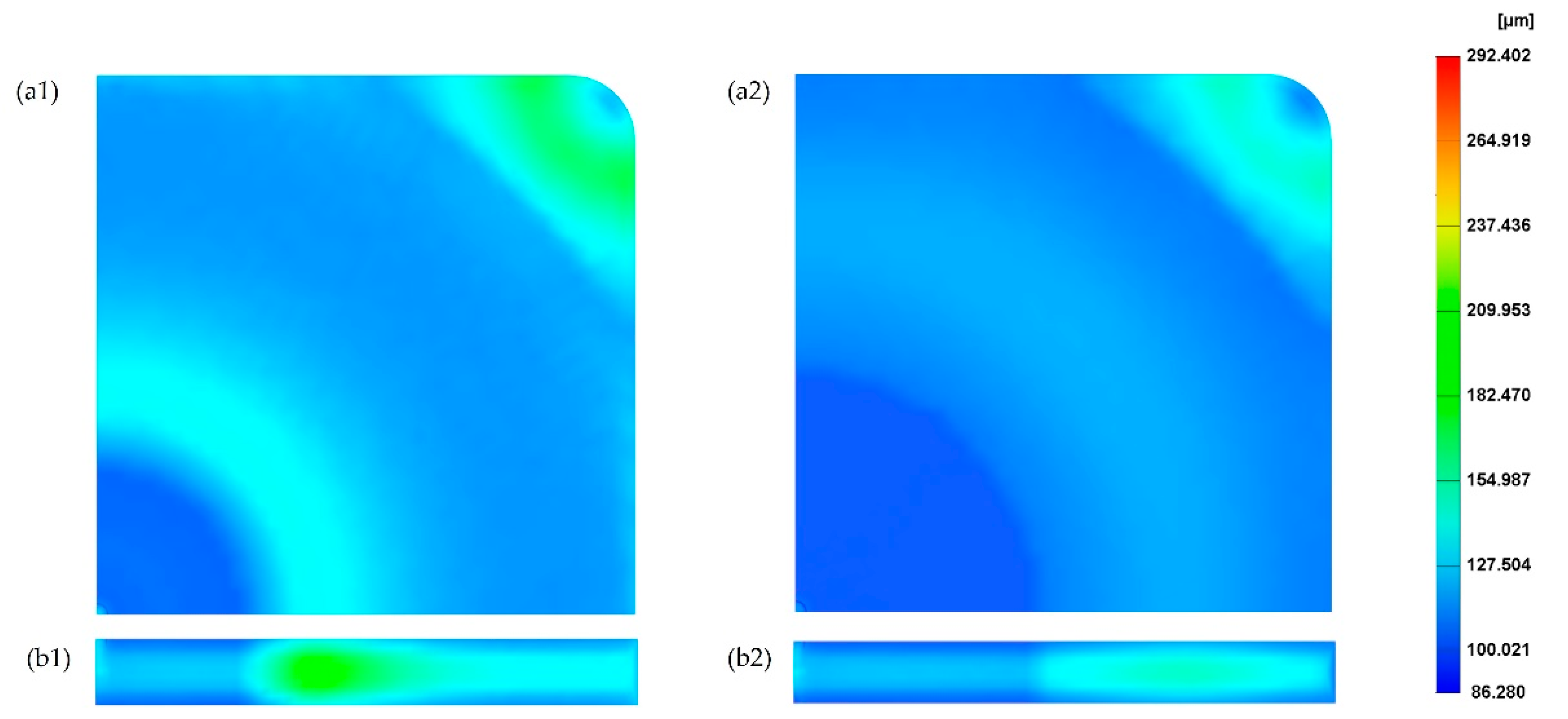

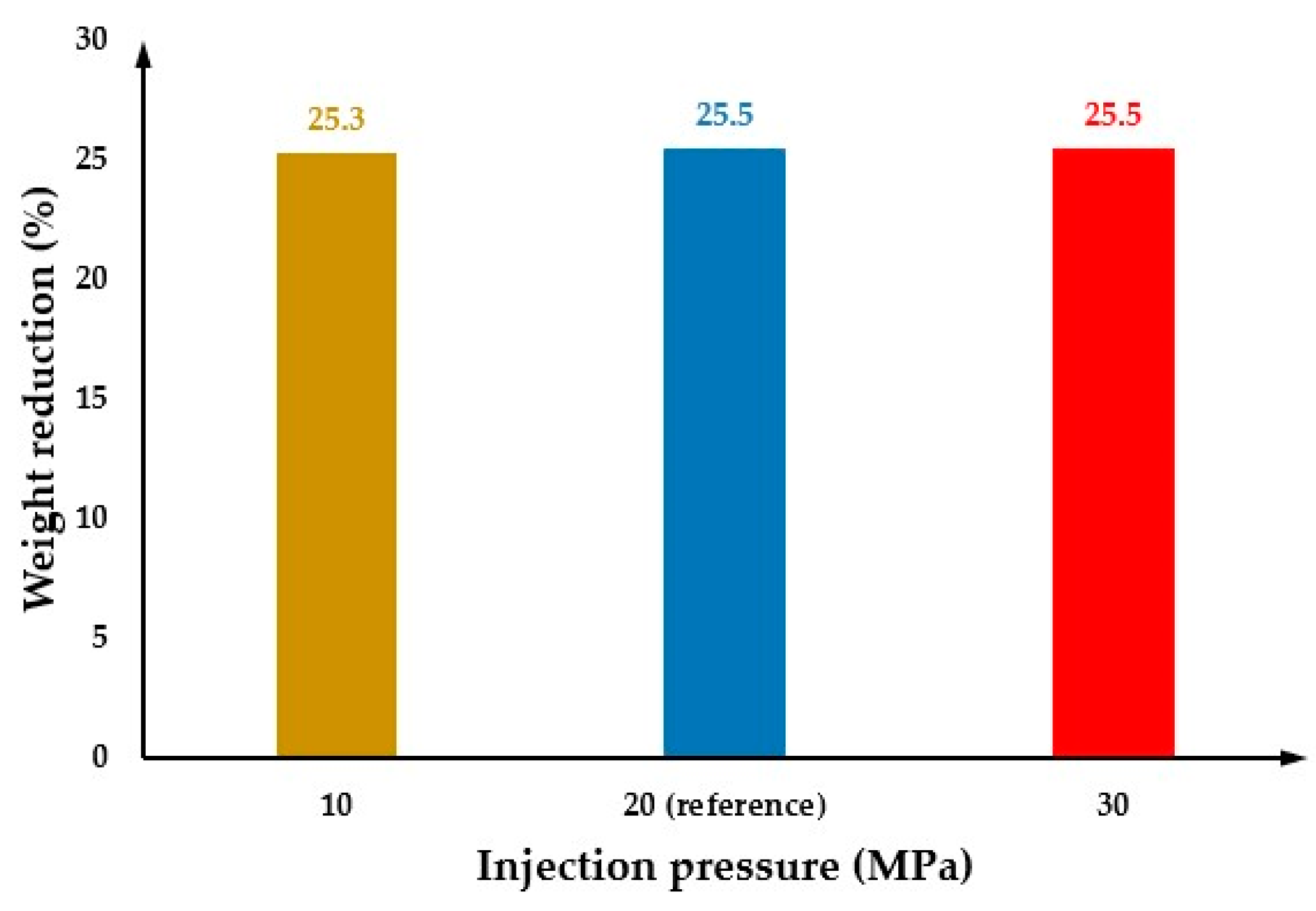

3.5. The Effect of Changing the Injection Pressure

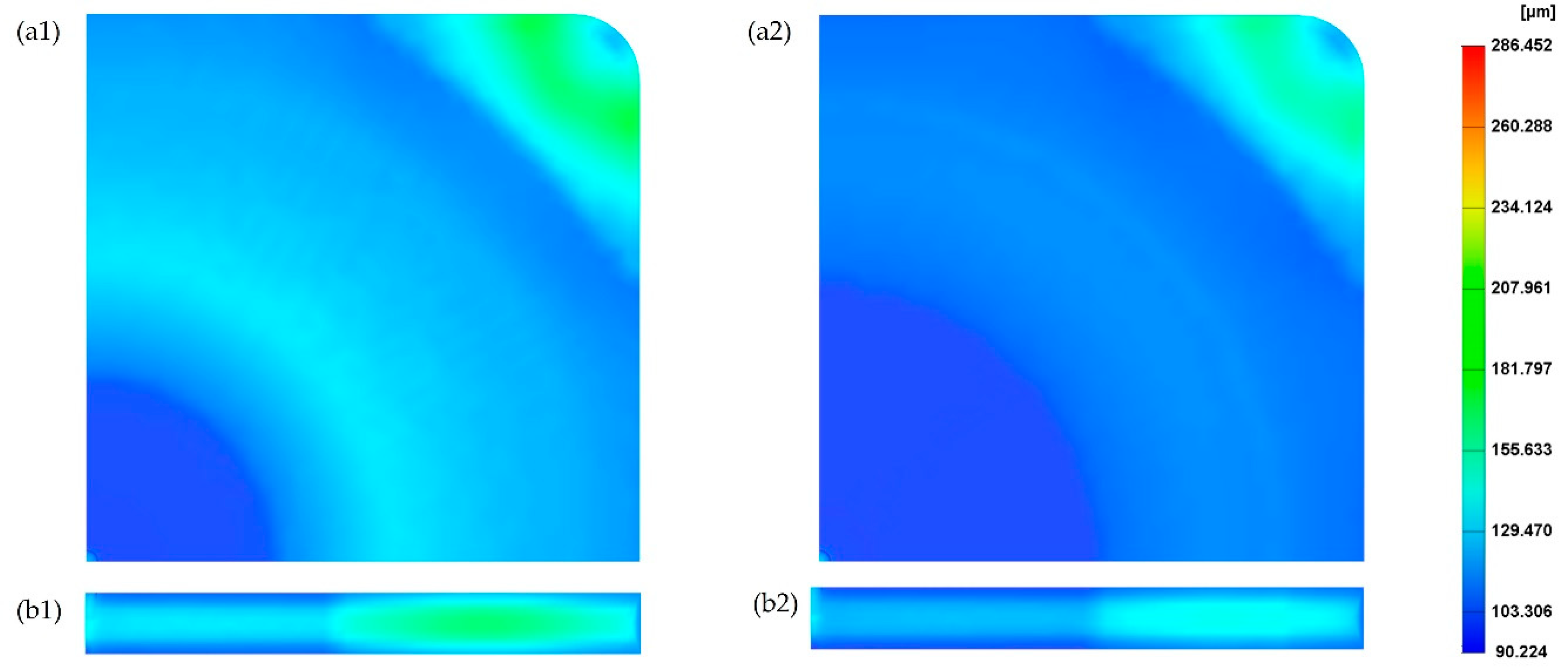

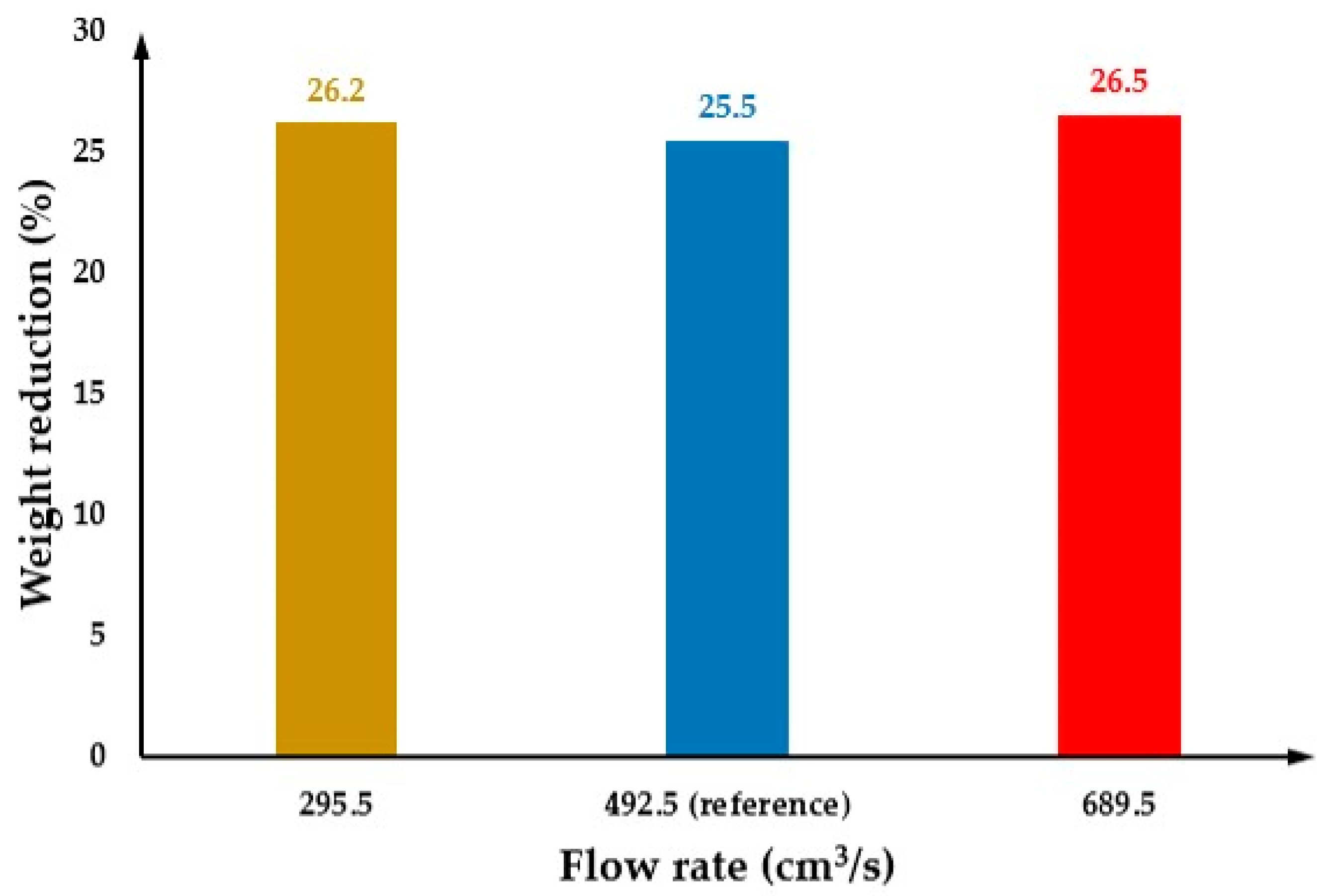

3.6. The Effect of Changing the Flow Rate

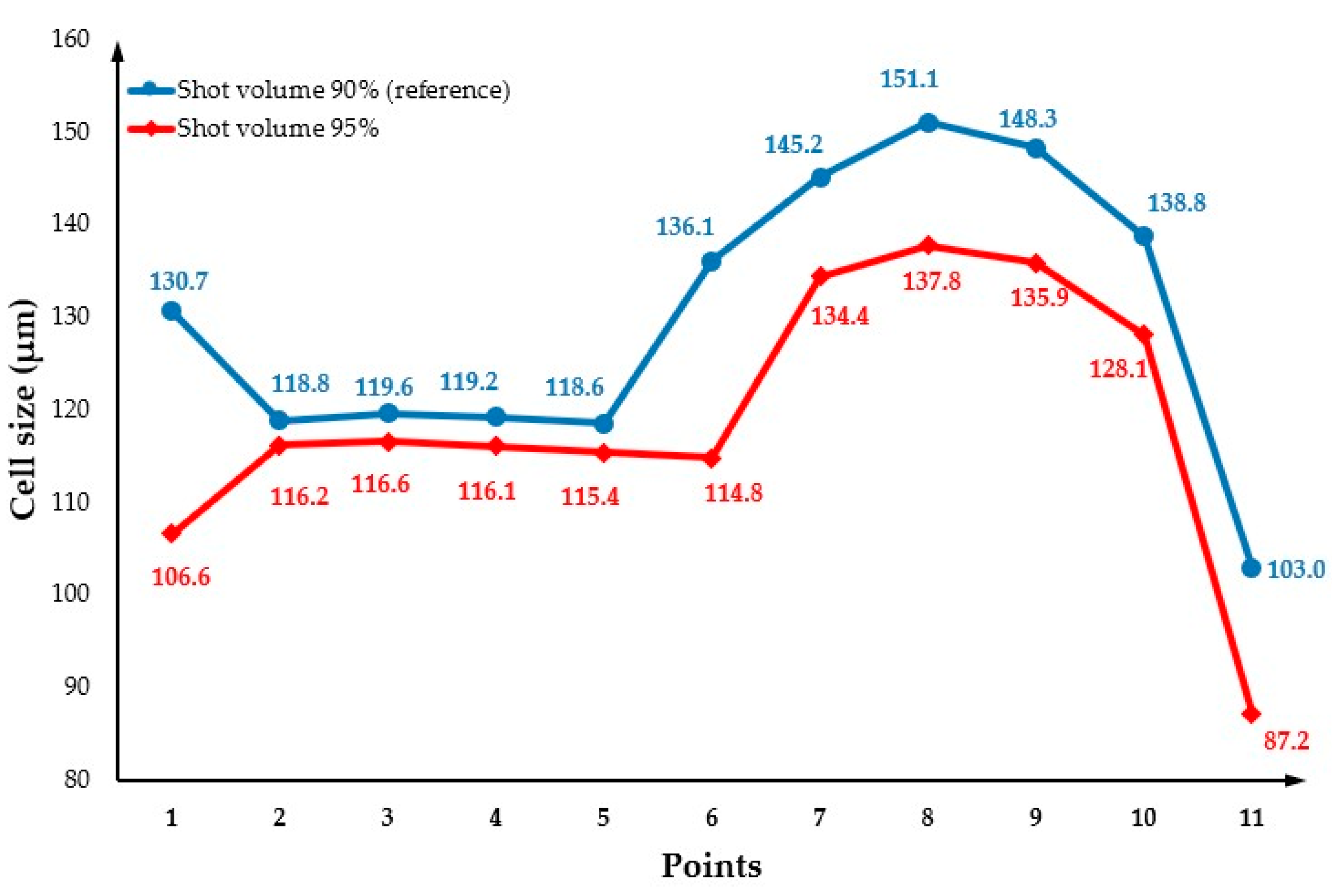

3.7. The Effect of Changing the Shot Volume

4. Conclusions and Future Work

Author Contributions

Funding

Conflicts of Interest

References

- Martini, J. The Production and Analysis of Microcellular Foam. Master’s Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, January 1981. [Google Scholar]

- Xu, J.; Pierick, D. Microcellular foam processing in reciprocating-screw injection molding machines. J. Inj. Molding Technol. 2001, 5, 152. [Google Scholar]

- Hongbin, W. Microcellular Injection Moulding for an Oesophageal Implant. PhD Thesis, Technische Universität München, Munich, Germany, 2009. [Google Scholar]

- Lee, K.S.; Jeong, P.J.; Lee, H.; Lee, S.J.; Cha, S.W. Conceptual design of microcellular plastics bumper parts using axiomatic approach. Polym. Plast. Technol. Eng. 2009, 48, 1101–1106. [Google Scholar] [CrossRef]

- Dong, G.; Zhao, G.; Guan, Y.; Wang, G.; Wang, X. The cell forming process of microcellular injection-molded parts. J. Appl. Polym. Sci. 2014, 131, 40365. [Google Scholar] [CrossRef]

- Wang, G.L.; Zhao, G.Q.; Wang, J.C.; Zhang, L. Research on formation mechanisms and control of external and inner bubble morphology in microcellular injection molding. Polym. Eng. Sci. 2015, 55, 807–835. [Google Scholar] [CrossRef]

- Dong, G.; Zhao, G.; Zhang, L.; Hou, J.; Li, B.; Wang, G. Morphology Evolution and Elimination Mechanism of Bubble Marks on Surface of Microcellular Injection-Molded Parts with Dynamic Mold Temperature Control. Ind. Eng. Chem. Res. 2018, 57, 1089–1101. [Google Scholar] [CrossRef]

- Hopmann, C.; Lammert, N.; Zhang, Y. Improvement of foamed part surface quality with variothermal temperature control and analysis of the mechanical properties. J. Cell. Plast. 2019, 55, 507–522. [Google Scholar] [CrossRef]

- Chen, S.C.; Lin, Y.W.; Chien, R.D.; Li, H.M. Variable mold temperature to improve surface quality of microcellular injection molded parts using induction heating technology. Adv. Polym. Technol. 2008, 27, 224–232. [Google Scholar] [CrossRef]

- Yoon, J.D.; Hong, S.K.; Kim, J.H.; Cha, S.W. A Mold Surface Treatment for Improving Surface Finish of Injection Molded Microcellular Parts. Cell. Polym. 2004, 23, 39–48. [Google Scholar] [CrossRef]

- Chen, H.L.; Chien, R.D.; Chen, S.C. Using thermally insulated polymer film for mold temperature control to improve surface quality of microcellular injection molded parts. Int. Commun. Heat Mass Transf. 2008, 35, 991–994. [Google Scholar] [CrossRef]

- Guo, W.; He, B.; Mao, H.; Zhang, M.; Hua, L.; Meng, Z. Mechanism of Bubble Formation in a Combined In-Mold Decoration and Microcellular Foaming Injection Molding Process. Fibers Polym. 2019, 20, 1526–1537. [Google Scholar] [CrossRef]

- Błędzki, A.K.; Faruk, O.; Kirschling, H.; Kuehn, J.; Jaszkiewicz, A. Microcellular polymers and composites. Polimery 2006, 51, 697–703. [Google Scholar]

- Gómez-Monterde, J.; Hain, J.; Sanchez-Soto, M.; Maspoch, M.L. Microcellular injection moulding: A comparison between MuCell process and the novel micro-foaming technology IQ Foam. J. Mater. Process. Technol. 2019, 268, 162–170. [Google Scholar] [CrossRef]

- Chen, S.C.; Lee, K.H.; Chang, C.W.; Hsu, T.J.; Feng, C.T. Using Gas Counter Pressure and Combined Technologies for Microcellular Injection Molding of Thermoplastic Polyurethane to Achieve High Foaming Qualities and Weight Reduction. Polymers 2022, 14, 2017. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.C.; Jien, M.Y.; Hsu, C.C.; Hwang, S.S.; Feng, C.T. Processing Effects on the Through-Plane Electrical Conductivities and Tensile Strengths of Microcellular-Injection-Molded Polypropylene Composites with Carbon Fibers. Polymers 2022, 14, 3251. [Google Scholar] [CrossRef] [PubMed]

- Ren, J.; Lin, L.; Jiang, J.; Li, Q.; Hwang, S.S. Effect of Gas Counter Pressure on the Surface Roughness, Morphology, and Tensile Strength between Microcellular and Conventional Injection-Molded PP Parts. Polymers 2022, 14, 1078. [Google Scholar] [CrossRef] [PubMed]

- Jong, W.R.; Hwang, S.S.; Wu, C.C.; Kao, C.H.; Huang, Y.M.; Tsai, M.C. Using a visualization mold to discuss the influence of gas counter pressure and mold temperature on the fountain flow effect. Int. Polym. Process. 2018, 33, 255–267. [Google Scholar] [CrossRef]

- Hou, J.; Zhao, G.; Wang, G.; Dong, G.; Xu, J. A novel gas-assisted microcellular injection molding method for preparing lightweight foams with superior surface appearance and enhanced mechanical performance. Mater. Des. 2017, 127, 115–125. [Google Scholar] [CrossRef]

- Chen, S.C.; Hsu, P.S.; Hwang, S.S. The effects of gas counter pressure and mold temperature variation on the surface quality and morphology of the microcellular polystyrene foams. J. Appl. Polym. Sci. 2013, 127, 4769–4776. [Google Scholar] [CrossRef]

- Chen, S.C.; Chang, C.W.; Tseng, C.Y.; Shen, E.N.; Feng, C.T. Using P (Pressure)-T (Temperature) Path to Control the Foaming Cell Sizes in Microcellular Injection Molding Process. Polymers 2021, 13, 1843. [Google Scholar] [CrossRef]

- Chen, S.C.; Liao, W.H.; Chien, R.D. Structure and mechanical properties of polystyrene foams made through microcellular injection molding via control mechanisms of gas counter pressure and mold temperature. Int. Commun. Heat Mass Transf. 2012, 39, 1125–1131. [Google Scholar] [CrossRef]

- Gómez-Monterde, J.; Sánchez-Soto, M.; Maspoch, M.L. Influence of injection molding parameters on the morphology, mechanical and surface properties of ABS foams. Adv. Polym. Technol. 2018, 37, 2707–2720. [Google Scholar] [CrossRef]

- Xu, J. Microcellular Injection Molding; John Wiley and Sons: Hoboken, NJ, USA, 2011; pp. 1–632. [Google Scholar]

- Xiao, C.; Huang, H.; Yang, X. Development and application of rapid thermal cycling molding with electric heating for improving surface quality of microcellular injection molded parts. Appl. Therm. Eng. 2016, 100, 478–489. [Google Scholar] [CrossRef]

- Birtha, J.G. Influence of Selected Process Parameters on the Surface Quality of Physically Foamed Polypropylene Parts. Master’s Thesis, Johannes Kepler University Linz, Linz, Austria, July 2019. [Google Scholar]

- Heim, H.P.; Güzel, K. The Effect of Injection Molding Parameters on Microcellular Foam Morphology. In Proceedings of the SPE FOAMS®2021 Conference, Seattle, WA, USA, 13–16 September 2021. [Google Scholar]

- Kastner, C.; Steinbichler, G. A critical view on the role of dynamic solubility limits and large gas contents in injection foam molding. In Proceedings of the PPS2019 Europe-Africa Regional Conference of the Polymer Processing Society, Pretoria, South Africa, 18–22 November 2019. [Google Scholar]

- Llewelyn, G.; Rees, A.; Griffiths, C.; Jacobi, M. A Design of Experiment Approach for Surface Roughness Comparisons of Foam Injection-Moulding Methods. Materials 2020, 13, 2358. [Google Scholar] [CrossRef]

- Pradeep, S.A.; Zheng, T.; Yerra, V.A.; Pilla, S. Automotive Lightweighting via Supercritical Foam Injection Molding of Thermoplastic Olefin. In Proceedings of the SPE ANTEC 2019 Conference, Detroit, MI, USA, 18–21 March 2019. [Google Scholar]

- Kastner, C.; Steinbichler, G.; Kahlen, S.; Jerabek, M. Influence of process parameters on mechanical properties of physically foamed, fiber reinforced polypropylene parts. J. Appl. Polym. Sci. 2018, 136, 47275. [Google Scholar] [CrossRef]

- Gómez-Monterde, J.; Schulte, M.; Ilijevic, S.; Hain, J.; Sánchez-Soto, M.; Santana, O.O.; Maspoch, M.L. Effect of microcellular foaming on the fracture behavior of ABS polymer. J. Appl. Polym. Sci. 2016, 133, 43010. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Chen, Z.; Wang, X.; Liu, T.; Zhou, Y.; Luo, S. Cell morphology and mechanical properties of microcellular Mucell® injection molded polyetherimide and polyetherimide/fillers composite foams. J. Appl. Polym. Sci. 2013, 130, 4171–4181. [Google Scholar] [CrossRef]

- Lohr, C.; Beck, B.; Henning, F.; Weidenmann, K.A.; Elsner, P. Process comparison on the microstructure and mechanical properties of fiber-reinforced polyphenylene sulfide using MuCell technology. J. Reinf. Plast. Compos. 2018, 37, 1020–1034. [Google Scholar] [CrossRef]

- Liu, T.; Liu, H.; Li, L.; Wang, X.; Lu, A.; Luo, S. Microstructure and properties of microcellular poly (phenylene sulfide) foams by Mucell injection molding. Polym. Plast. Technol. Eng. 2013, 52, 440–445. [Google Scholar] [CrossRef]

- Mi, H.Y.; Jing, X.; Peng, J.; Turng, L.S.; Peng, X.F. Influence and prediction of processing parameters on the properties of microcellular injection molded thermoplastic polyurethane based on an orthogonal array test. J. Cell. Plast. 2013, 49, 439–458. [Google Scholar] [CrossRef]

- Yoon, J.D.; Kuboki, T.; Jung, P.U.; Wang, J.; Park, C.B. Injection molding of wood–fiber/plastic composite foams. Compos. Interfaces 2009, 16, 797–811. [Google Scholar] [CrossRef]

- Volpe, V.; Lanzillo, S.; Affinita, G.; Villacci, B.; Macchiarolo, I.; Pantani, R. Lightweight high-performance polymer composite for automotive applications. Polymers 2019, 11, 326. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yuan, M.; Turng, L.S.; Gong, S.; Caulfield, D.; Hunt, C.; Spindler, R. Study of injection molded microcellular polyamide-6 nanocomposites. Polym. Eng. Sci. 2004, 44, 673–686. [Google Scholar] [CrossRef]

- Ding, Y.; Hassan, M.H.; Bakker, O.; Hinduja, S.; Bártolo, P. A Review on Microcellular Injection Moulding. Materials 2021, 14, 4209. [Google Scholar] [CrossRef] [PubMed]

- Kutz, M. Applied Plastics Engineering Handbook: Processing and Materials; Elsevier Science: Amsterdam, The Netherlands, 2011; pp. 1–574. [Google Scholar]

- Han, C.D.; Yoo, H.J. Studies on structural foam processing. IV. Bubble growth during mold filling. Polym. Eng. Sci. 1981, 21, 518–533. [Google Scholar] [CrossRef]

- Payvar, P. Mass transfer-controlled bubble growth during rapid decompression of a liquid. Int. J. Heat Mass Transf. 1987, 30, 699–706. [Google Scholar] [CrossRef]

- Shafi, M.A.; Lee, J.G.; Flumerfelt, R.W. Prediction of cellular structure in free expansion polymer foam processing. Polym. Eng. Sci. 1996, 36, 1950–1959. [Google Scholar] [CrossRef]

- Rosner, D.E.; Epstein, M. Effects of interface kinetics, capillarity and solute diffusion on bubble growth rates in highly supersaturated liquids. Chem. Eng. Sci. 1972, 27, 69–88. [Google Scholar] [CrossRef]

- Moldex3D Help. 2022. Available online: http://support.moldex3d.com/2021/en/2-7-2_flowandpacktab(advanced).html (accessed on 26 September 2022).

- A Big Step for Foaming Simulation: Bubble Shrinkage No Longer Unpredictable. 2022. Available online: https://www.moldex3d.com/blog/top-story/a-big-step-for-foaming-simulation-bubble-shrinkage-no-longer-unpredictable/ (accessed on 26 September 2022).

- Taki, K. Experimental and numerical studies on the effects of pressure release rate on number density of bubbles and bubble growth in a polymeric foaming process. Chem. Eng. Sci. 2008, 63, 3643–3653. [Google Scholar] [CrossRef]

- Shiu, T.; Chang, Y.J.; Huang, C.T.; Hsu, D.; Chang, R.Y. Dynamic behavior and experimental validation of cell nucleation and growing mechanism in microcellular injection molding process. In Proceedings of the ANTEC 2012 Conference, Orlando, FL, USA, 2–4 April 2012. [Google Scholar]

- Chang, R.Y.; Yang, W.H. Numerical simulation of mold filling in injection molding using a three-dimensional finite volume approach. Int J. Numer. Methods Fluids 2001, 37, 125–148. [Google Scholar] [CrossRef]

- Streeter, V.; Kestin, J. Handbook of Fluid Dynamics; McGraw-Hill Inc.: New York, NY, USA, 1961; pp. 1–1228. [Google Scholar]

- Xi, Z.; Chen, J.; Liu, T.; Zhao, L.; Turng, L.S. Experiment and simulation of foaming injection molding of polypropylene/nano-calcium carbonate composites by supercritical carbon dioxide. Chin. J. Chem. Eng. 2016, 24, 180–189. [Google Scholar] [CrossRef]

- Gómez-Monterde, J.; Sánchez-Soto, M.; Maspoch, M.L. Microcellular PP/GF composites: Morphological, mechanical and fracture characterization. Compos. Part. A Appl. Sci. Manuf. 2018, 104, 1–13. [Google Scholar] [CrossRef]

| Processing Parameters | Value Range | ||

|---|---|---|---|

| Low | Middle (Reference) | High | |

| Melt temperature (°C) | 200 | 220 | 240 |

| Mould temperature (°C) | 20 | 40 | 60 |

| Flow rate (cm3/s) | 295.5 (30%) | 492.5 (50%) | 689.5 (70%) |

| Injection pressure (MPa) | 10 | 20 | 30 |

| Shot volume (%) | 85 | 90 | 95 |

| Gas dosage amount (%) | 0.1 | 0.3 | 0.5 |

| Name | Material | Parameters, Their Changes and Corresponding Results | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mould Temperature | Gas Dosage Amount | Melt Temperature | Injection Pressure | Flow Rate | Shot Volume | |||||||||||||||

| Changes | Average Cell Size | Changes | Average Cell Size | Changes | Average Cell Size | Changes | Average Cell Size | Changes | Average Cell Size | Changes | Average Cells Size | |||||||||

| Simulation | PP | ↑ | ↓ | no | ↑ | ↓ | ↑ | ↓ | ↑ | no | ↑ | ↓ | no | ↑ | ↑ | ↓ | ↓ | ↑ | ↑ | ↓ |

| Gómez-Monterde et al. [23] | ABS | ↑ | ↓ | ↑ | ↓ | ↑ | ↓ | ↓ | ↓ | |||||||||||

| Kastner et al. [31] and Gómez-Monterde et al. [53] | PP/GF | |||||||||||||||||||

| Li et al. [33] | PEI | ↑ | ↑ | ↑ | ↓ | ↑ | ↓ | |||||||||||||

| Liu et al. [35] | PPS | ↑ | ↓ | ↑ | ↓ | |||||||||||||||

| Mi et al. [36] | TPU | ↑ | ↓ | ↑ | ↑ | |||||||||||||||

| Volpe et al. [38] | PA66/GF | ↑ | ↓ | |||||||||||||||||

| Yuan et al. [39] | PA6 | ↑ | ↓ | |||||||||||||||||

| Chen et al. [20] and Chen et al. [22] | PS | ↑ | ↑ | |||||||||||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, Y.; Vyas, C.; Bakker, O.; Hinduja, S.; Bartolo, P. Modelling and Simulation of MuCell®: The Effect of Key Processing Parameters on Cell Size and Weight Reduction. Polymers 2022, 14, 4215. https://doi.org/10.3390/polym14194215

Ding Y, Vyas C, Bakker O, Hinduja S, Bartolo P. Modelling and Simulation of MuCell®: The Effect of Key Processing Parameters on Cell Size and Weight Reduction. Polymers. 2022; 14(19):4215. https://doi.org/10.3390/polym14194215

Chicago/Turabian StyleDing, Yifei, Cian Vyas, Otto Bakker, Srichand Hinduja, and Paulo Bartolo. 2022. "Modelling and Simulation of MuCell®: The Effect of Key Processing Parameters on Cell Size and Weight Reduction" Polymers 14, no. 19: 4215. https://doi.org/10.3390/polym14194215

APA StyleDing, Y., Vyas, C., Bakker, O., Hinduja, S., & Bartolo, P. (2022). Modelling and Simulation of MuCell®: The Effect of Key Processing Parameters on Cell Size and Weight Reduction. Polymers, 14(19), 4215. https://doi.org/10.3390/polym14194215