A Flexible Sandwich Structure Carbon Fiber Cloth with Resin Coating Composite Improves Electromagnetic Wave Absorption Performance at Low Frequency

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Materials

2.3. Test Indicators and Methods

3. Results and Discussion

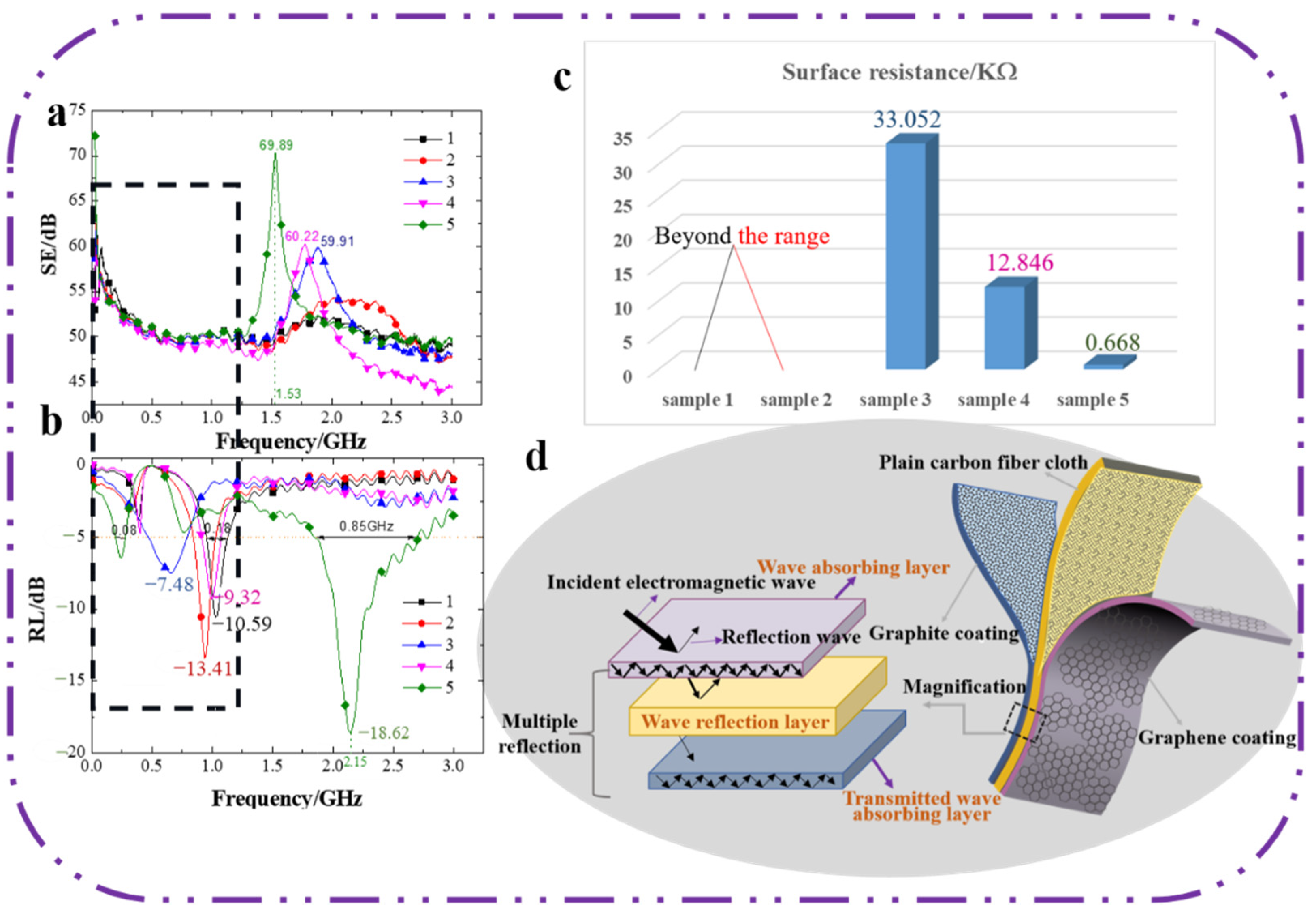

3.1. The Influence of the Content of Graphene on the Shielding, Absorbing, and Conductive Properties of the Composites

3.1.1. The Shielding Performance

3.1.2. Absorbing Performance

3.1.3. Conductive Performance

3.2. The Influence of the Content of Graphene on the Dielectric Properties of the Composites

3.2.1. The Real Part of the Dielectric Constant

3.2.2. The Imaginary Part of the Dielectric Constant

3.2.3. The Loss Tangent Value

3.3. The Influence of the Content of Graphene on the Graphene Layer of the Composite on Mechanical Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lai, W.W.; Wang, Y.; He, J.K. Effects of carbonyl iron powder (CIP) content on the electromagnetic wave absorption and mechanical properties of CIP/ABS composites. Polymers 2020, 12, 1694. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Cui, W.; Wang, B.B.; Xu, B.H.; Liu, X.H.; Liu, X.H.; Jia, Z.R.; Wu, G.L. Morphology-control synthesis of polyaniline decorative porous carbon with remarkable electromagnetic wave absorption capabilities. Compos. Part B Eng. 2021, 204, 108491. [Google Scholar] [CrossRef]

- Majcher, K.; Musial, M.; Pakos, W.; Rozanski, A.; Sobotka, M.; Trapko, T. Methods of protecting buildings against HPM radiation-A review of materials absorbing the energy of electromagnetic waves. Materials 2020, 13, 5509. [Google Scholar] [CrossRef]

- Ayub, S.; Guan, B.H.; Ahmad, F.; Oluwatobi, Y.A.; Nisa, Z.U.; Javed, M.F.; Mosavi, A. Graphene and iron reinforced polymer composite electromagnetic shielding applications: A review. Polymers 2021, 13, 2580. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.Z.; He, X.W.; Yi, C.; Sun, D.M.; Chen, J.H.; Wang, D.; Liu, K.; Li, M.F. Fabrication of ultra-light nickel/graphene composite foam with 3D interpenetrating network for high-performance electromagnetic interference shielding. Compos. Part B Eng. 2020, 182, 107614. [Google Scholar] [CrossRef]

- Jiang, S.; Qian, K.; Yu, K.J.; Zhou, H.F.; Weng, Y.X.; Zhang, Z.W. Controllable synthesis and microwave absorption properties of Fe3O4@f-GNPs nanocomposites. Compos. Commun. 2020, 20, 100363. [Google Scholar] [CrossRef]

- Li, Y.; Yang, H.J.; Hao, X.H.; Sun, N.N.; Du, J.H.; Cao, M.S. Enhanced electromagnetic interference shielding with low reflection induced by heterogeneous double-layer structure in BiFeO3/BaFe7(MnTi)(2.5)O19 composite. J. Alloys Compd. 2019, 772, 99–104. [Google Scholar] [CrossRef]

- Sahu, K.R.; De, U. Polymer composites for flexible electromagnetic shields. Macromol. Symp. 2018, 381, 1800097. [Google Scholar] [CrossRef]

- Zhong, B.; Liu, W.; Yu, Y.L.; Xia, L.; Zhang, J.L.; Chai, Z.F.; Wen, G.W. Enhanced microwave absorption properties of graphite nanoflakes by coating hexagonal boron nitride nanocrystals. Appl. Surf. Sci. 2017, 420, 858–867. [Google Scholar] [CrossRef] [Green Version]

- Liu, P.J.; Yao, Z.J.; Ng, V.M.H.; Zhou, J.T.; Kong, L.B.; Yue, K. Facile synthesis of ultrasmall Fe3O4 nanoparticles on MXenes for high microwave absorption performance. Compos. Part A-Appl. S 2018, 115, 371–382. [Google Scholar] [CrossRef]

- Wang, X.X.; Sun, C.M.; Wen, F.B.; Jiang, S.Y.; Cao, M.S. Strong mechanics and broadened microwave absorption of graphene-based sandwich structures and surface-patterned structures. J. Mater. Sci. Mater. Electron. 2018, 29, 9683–9691. [Google Scholar] [CrossRef]

- Zhang, H.T.; Guo, Y.; Zhang, X.; Wang, X.Q.; Wang, H.; Shi, C.S.; He, F. Enhanced shielding performance of layered carbon fiber composites filled with carbonyl iron and carbon nanotubes in the koch curve fractal method. Molecules 2020, 25, 969. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jin, D.H.; Jang, M.S.; Choi, J.H.; Jang, W.H.; Choi, W.H.; Kim, C.G. Multi-slab hybrid radar absorbing structure containing short carbon fiber layer with controllable permittivity. Compos. Struct. 2021, 273, 114279. [Google Scholar] [CrossRef]

- Zhao, K.; Gupta, S.; Chang, C.; Wei, J.Q.; Tai, N.H. Layered composites composed of multi-walled carbon nanotubes/manganese dioxide/carbon fiber cloth for microwave absorption in the X-band. RSC Adv. 2019, 9, 19217–19225. [Google Scholar] [CrossRef] [Green Version]

- Zhang, K.L.; Li, Y.J.; Zhou, H.; Nie, M.; Wang, Q.; Hua, Z.K. Polyurethane carbon fiber composite tubular electrode featuring three-dimensional interpenetrating conductive network. Carbon 2018, 139, 999–1009. [Google Scholar] [CrossRef]

- Wang, C.; Han, X.J.; Xu, P.; Zhang, X.L.; Du, Y.C.; Hu, S.R.; Wang, J.Y.; Wang, X.H. The electromagnetic property of chemically reduced graphene oxide and its application as microwave absorbing material. Appl. Phys. Lett. 2011, 98, 072906. [Google Scholar] [CrossRef]

- Yuan, H.R.; Yan, F.; Li, C.Y.; Zhu, C.L.; Zhang, X.T.; Chen, Y.J. Nickel nanoparticle encapsulated in few-layer nitrogen-doped graphene supported by nitrogen-doped graphite sheets as High-Performance electromagnetic wave absorbing material. ACS Appl. Mater. Interfaces. 2018, 10, 1399–1407. [Google Scholar] [CrossRef] [PubMed]

- Liu, P.J.; Yao, Z.J.; Zhou, J.T.; Yang, Z.H.; Kong, L.B. Small magnetic Co-doped NiZn ferrite/graphene nanocomposites and their dual-region microwave absorption performance. J. Mater. Chem. C 2016, 4, 9738–9749. [Google Scholar] [CrossRef]

- Liu, Y.J.; Yu, Y.T.; Zhao, X.M. Research on the electromagnetic property of the single-layer graphene-coated fabrics. J. Text. Inst. 2021, 112, 255–263. [Google Scholar] [CrossRef]

- Liu, Y.J.; Zhao, X.M. The preparation and performance of a polyaniline/graphene composite coated fabric. J. Text. Inst. 2021, 112, 1258–1265. [Google Scholar] [CrossRef]

- Liu, Y.J.; Wang, H.H.; Zhang, Y.Q.; Wang, X.C.; Yin, G.; Han, X.H.; Niu, J.R. Study on the electromagnetic and mechanical properties of coated composites. Fibres Text. East. Eur. 2020, 28, 89–97. [Google Scholar]

- Liu, Y.J.; Zhao, X.M.; Xiao, T. Study of graphite/silicon carbide coating of plain woven fabric for electrical megawatt absorbing properties. J. Text. Inst. 2017, 108, 483–488. [Google Scholar] [CrossRef]

- Guo, Z.Z.; Ren, P.G.; Zhang, Z.P.; Dai, Z.; Hui, K.D.; Yan, H.H.; Jin, Y.L.; Gao, J.F.; Ren, F. Simultaneous realization of highly efficient electromagnetic interference shielding and human motion detection in carbon fiber felt decorated with silver nanowires and thermoplastic polyurethane. J. Mater. Chem. C 2021, 9, 6894–6903. [Google Scholar] [CrossRef]

- Liu, Y.; Wu, Y.X.; Li, K.X.; Wang, J.; Zhang, G.L.; Ji, J.L.; Wang, W.J. Amorphous SnS nanosheets/graphene oxide hybrid with efficient dielectric loss to improve the high-frequency electromagnetic wave absorption properties. Appl. Surf. Sci. 2019, 486, 344–353. [Google Scholar] [CrossRef]

- Soleimani, M.; Jalili, S.; Mahfouzi, F. Structural defects influence on the conductance of strained zigzag graphene nanoribbon. Phys. E 2017, 93, 216–223. [Google Scholar] [CrossRef]

- Yao, Y.Y.; Jin, S.H.; Sun, J.; Li, L.J.; Zou, H.M.; Wen, P.; Lv, G.; Lv, X.J.; Shu, Q.H. Sandwich-like sulfur-free expanded graphite/CoNi hybrids and their synergistic enhancement of microwave absorption. J. Alloys Compd. 2021, 862, 158005. [Google Scholar] [CrossRef]

- Su, X.G.; Wang, J.; Zhang, X.X.; Liu, Z.J.; Dai, W.; Chen, W.; Zhang, B. Construction of sandwich-like NiCo2O4/Graphite nanosheets/NiCo2O4 heterostructures for a tunable microwave absorber. Ceram. Int. 2020, 46, 19293–19301. [Google Scholar] [CrossRef]

- Chen, J.B.; Zheng, J.; Huang, Q.Q.; Wang, F.; Ji, G.B. Enhanced microwave absorbing ability of carbon fibers with embedded FeCo/CoFe2O4 nanoparticles. ACS Appl. Mater. Interfaces 2021, 13, 36182–36189. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.X.; Duan, Y.G.; Kang, X.Q. Multi-scale integrated design and fabrication of ultrathin broadband microwave absorption utilizing carbon fiber/Prussian blue/Fe3O4-based lossy lattice metamaterial. J. Mater. Chem. C 2021, 9, 6316–6323. [Google Scholar] [CrossRef]

- Pang, L.; Wang, J.J.; Chen, S.A.; Luo, H.; Fan, X.M.; Li, Y.; Zhou, W.; Xiao, P. Multiple dielectric behavior of C-f-SiCNFs/Si3N4 ceramic composite at high temperatures. Ceram. Int. 2021, 47, 4127–4134. [Google Scholar] [CrossRef]

- Zuo, Y.X.; Su, X.R.; Li, X.W.; Yao, Z.J.; Yu, T.T.; Zhou, J.T.; Li, J.; Lu, J.; Ding, J. Multimaterial 3D-printing of graphene/Li0.35Zn0.3Fe2.35O4 and graphene/carbonyl iron composites with superior microwave absorption properties and adjustable bandwidth. Carbon 2020, 167, 62–74. [Google Scholar] [CrossRef]

- Liang, X.H.; Quan, B.; Sun, B.W.; Man, Z.M.; Xu, X.; Ji, G.B. Extended effective frequency of three-dimensional graphene with sustainable energy attenuation. ACS Sustain. Chem. Eng. 2019, 7, 10477–10483. [Google Scholar] [CrossRef]

- Cheng, Y.H.; Hu, P.; Zhou, S.B.; Yan, L.W.; Sun, B.Q.; Zhang, X.H.; Han, W.B. Achieving tunability of effective electromagnetic wave absorption between the whole X-band and Ku-band via adjusting PPy loading in SiC nanowires/graphene hybrid foam. Carbon 2018, 132, 430–443. [Google Scholar] [CrossRef]

- Yin, P.F.; Zhang, L.M.; Tang, Y.T.; Liu, J.C. Earthworm-like (Co/CoO)@C composite derived from MOF for solving the problem of low-frequency microwave radiation. J. Alloys Compd. 2021, 881, 160556. [Google Scholar] [CrossRef]

- Shao, X.L.; Wang, T.H.; Gan, Z.Y.; Hu, R.; Gong, Y.; Li, X.X.; Zhang, X.; Tian, X.Y. Tailoring of N-doped graphite coated cobalt nanoparticles via arc discharge enables high microwave absorption. Carbon 2021, 177, 171–180. [Google Scholar] [CrossRef]

- Vilatela, J.J.; Marcilla, R. Tough electrodes: Carbon nanotube fibers as the ultimate current collectors/active material for energy management devices. Chem. Mater. 2015, 27, 6901–6917. [Google Scholar] [CrossRef]

- Liu, X.D.; Huang, Y.; Ding, L.; Zhao, X.X.; Liu, P.B.; Li, T.H. Synthesis of covalently bonded reduced graphene oxide-Fe3O4 nanocomposites for efficient electromagnetic wave absorption. J. Mater. Sci. Technol. 2021, 72, 93–103. [Google Scholar] [CrossRef]

- Prasad, J.; Singh, A.K.; Haldar, K.K.; Tomar, M.; Gupta, V.; Singh, K. CoFe2O4 nanoparticles decorated MoS2-reduced graphene oxide nanocomposite for improved microwave absorption and shielding performance. RSC Adv. 2019, 9, 21881–21892. [Google Scholar] [CrossRef] [Green Version]

- Gao, H.; Xu, J.A.; Liu, S.; Song, Z.Q.; Zhou, M.; Liu, S.W.; Li, F.; Li, F.H.; Wang, X.D.; Wang, Z.X. Stretchable, self-healable integrated conductor based on mechanical reinforced graphene/polyurethane composites. J. Colloid Interface Sci. 2021, 597, 393–400. [Google Scholar] [CrossRef]

| Sample | Content of Graphene on Wave Absorbing Layer (%) | Content of Graphite on Re-Absorbing Transmitted Wave Layer (%) | Thickness of Each Absorbing Layer (mm) |

|---|---|---|---|

| 1 | 0 | 30 | 1.0 |

| 2 | 10 | 30 | 1.0 |

| 3 | 20 | 30 | 1.0 |

| 4 | 30 | 30 | 1.0 |

| 5 | 40 | 30 | 1.0 |

| Sample | Maximum Load (kN) | Maximum Load Displacement (mm) | Maximum Load Tensile Stress (kMPa) | Modulus of Elasticity (kMPa) |

|---|---|---|---|---|

| 1 | 5.54 | 3.04 | 3.79 | 146.04 |

| 2 | 5.71 | 3.39 | 3.56 | 141.51 |

| 3 | 5.84 | 2.83 | 3.64 | 147.54 |

| 4 | 5.83 | 3.98 | 3.63 | 126.99 |

| 5 | 6.22 | 3.29 | 3.62 | 149.73 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Lu, Q.; Wang, J.; Zhao, X. A Flexible Sandwich Structure Carbon Fiber Cloth with Resin Coating Composite Improves Electromagnetic Wave Absorption Performance at Low Frequency. Polymers 2022, 14, 233. https://doi.org/10.3390/polym14020233

Liu Y, Lu Q, Wang J, Zhao X. A Flexible Sandwich Structure Carbon Fiber Cloth with Resin Coating Composite Improves Electromagnetic Wave Absorption Performance at Low Frequency. Polymers. 2022; 14(2):233. https://doi.org/10.3390/polym14020233

Chicago/Turabian StyleLiu, Yuanjun, Qianqian Lu, Jing Wang, and Xiaoming Zhao. 2022. "A Flexible Sandwich Structure Carbon Fiber Cloth with Resin Coating Composite Improves Electromagnetic Wave Absorption Performance at Low Frequency" Polymers 14, no. 2: 233. https://doi.org/10.3390/polym14020233

APA StyleLiu, Y., Lu, Q., Wang, J., & Zhao, X. (2022). A Flexible Sandwich Structure Carbon Fiber Cloth with Resin Coating Composite Improves Electromagnetic Wave Absorption Performance at Low Frequency. Polymers, 14(2), 233. https://doi.org/10.3390/polym14020233