Glass FRP-Reinforced Geopolymer Based Columns Comprising Hybrid Fibres: Testing and FEA Modelling

Abstract

:1. Introduction

2. Materials and Methods

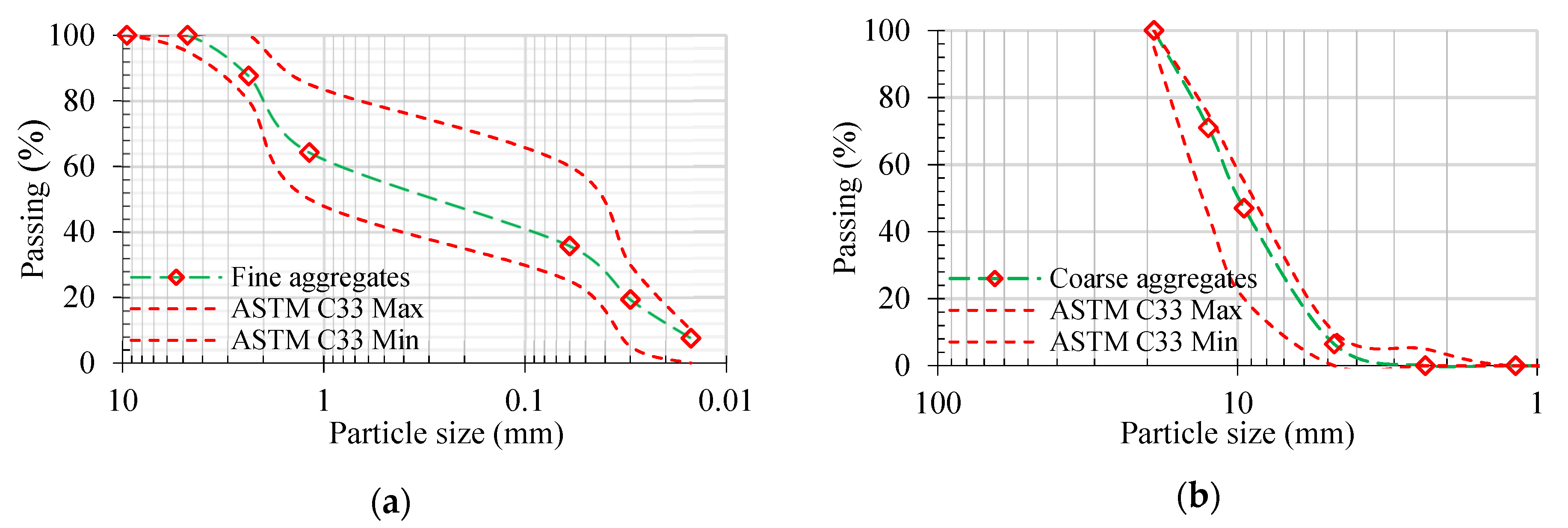

2.1. Materials

2.1.1. Fibre-Reinforced Geopolymer Concrete

2.1.2. Steel and Glass-FRP Rebars

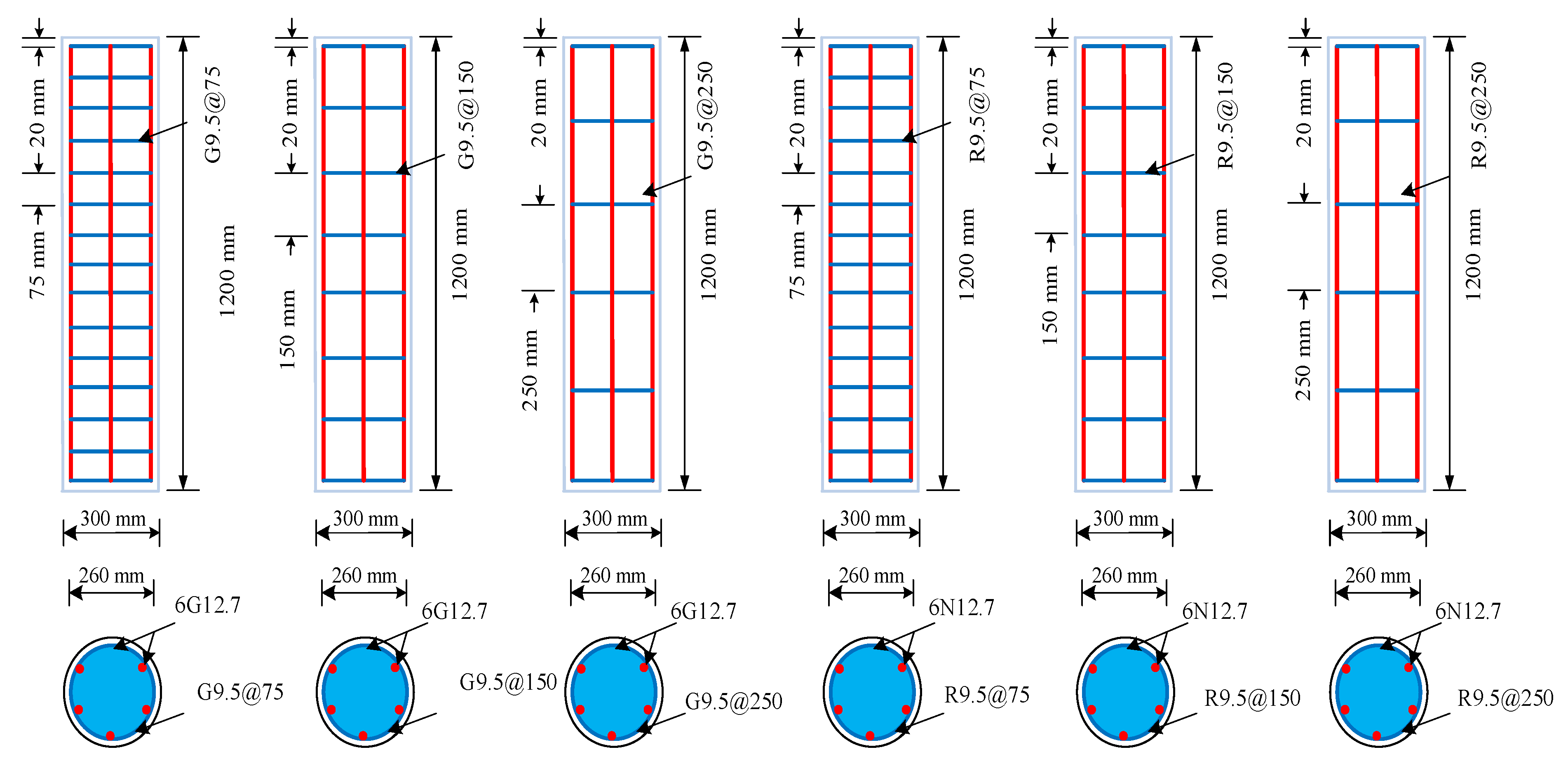

2.2. Specimen Details

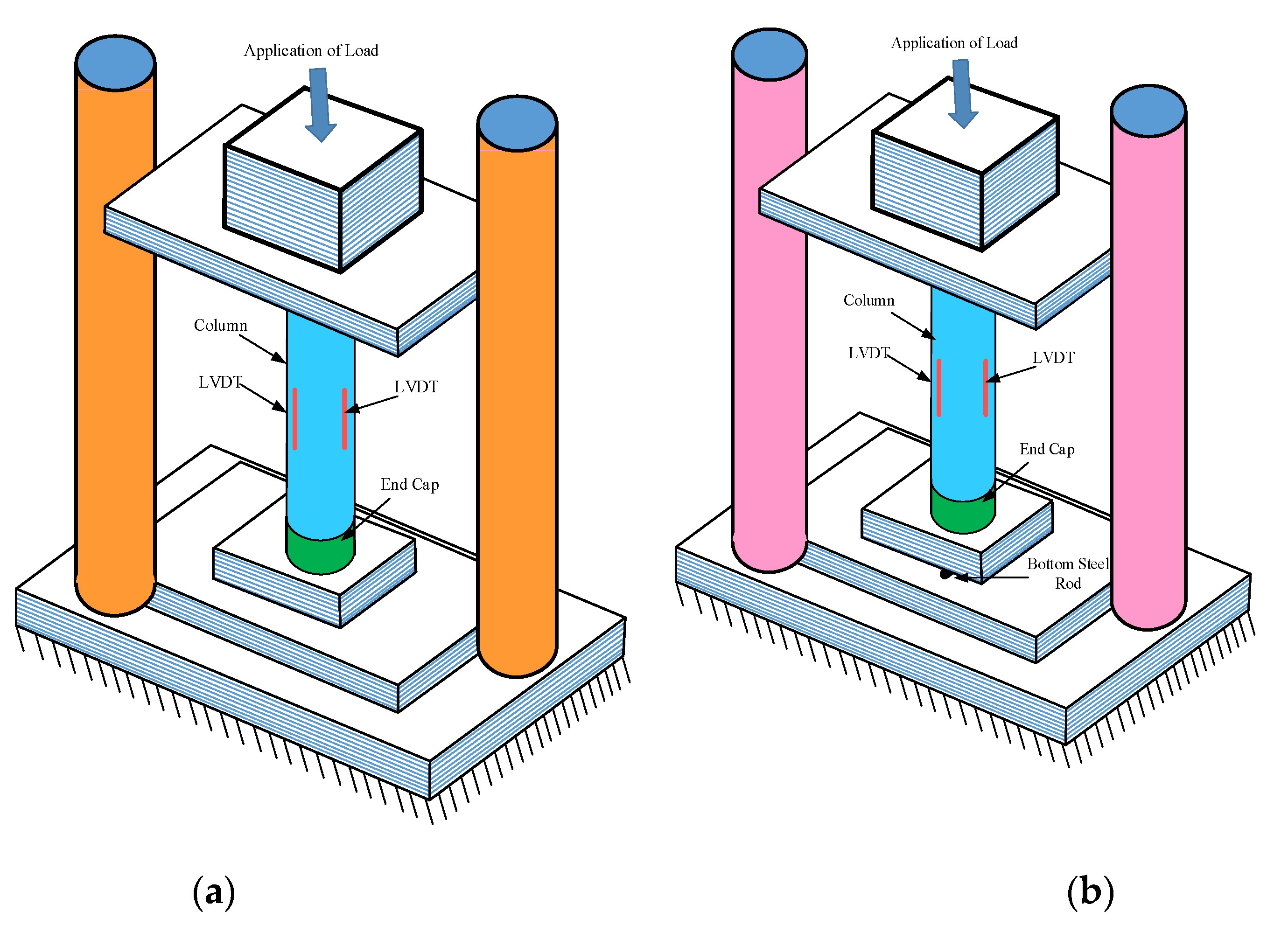

2.3. Testing Arrangement

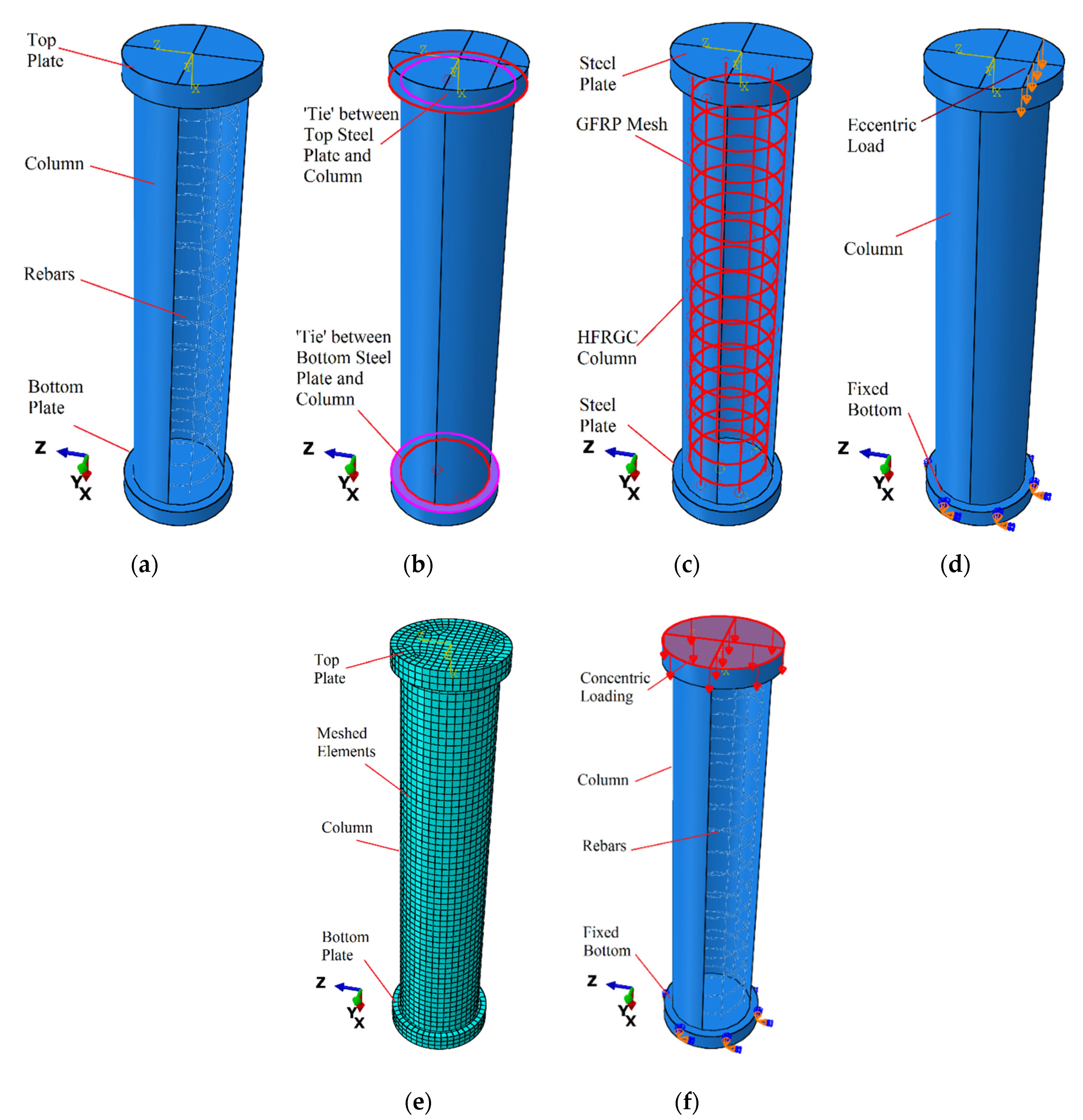

3. Finite Element Modelling

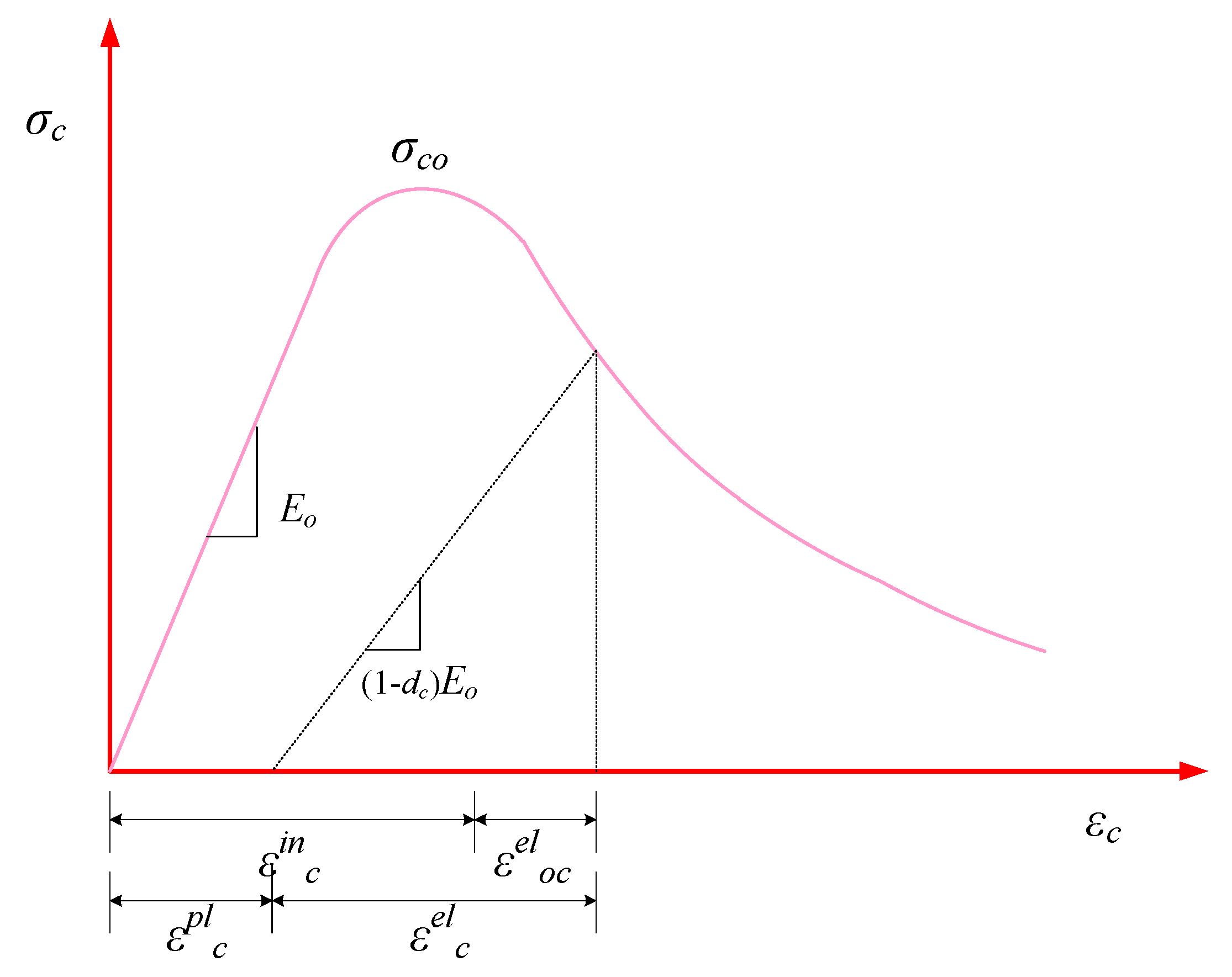

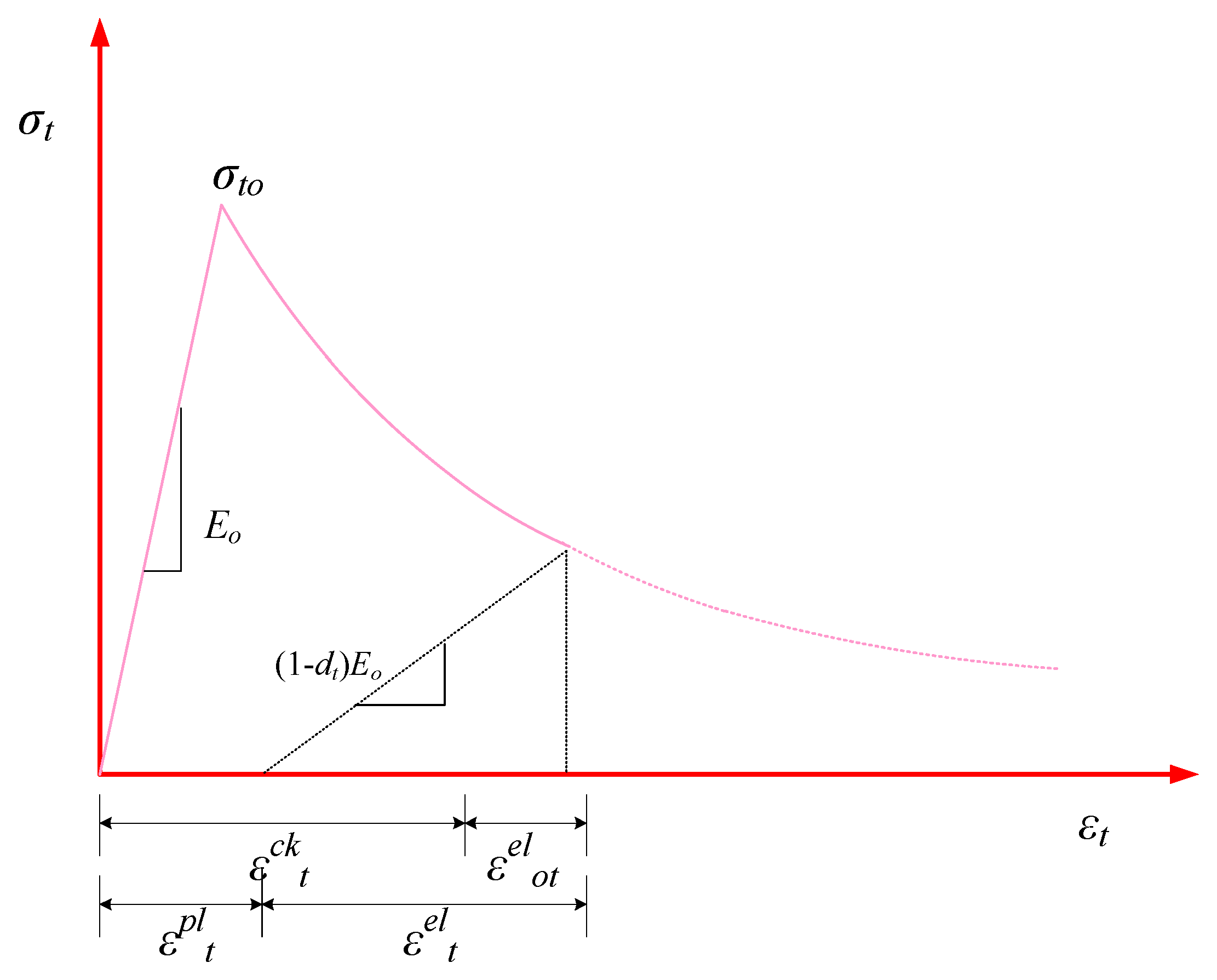

3.1. Modelling of HFRGC

3.2. Modelling of Glass-FRP and Steel Rebars

3.3. Calibration of FEA Model

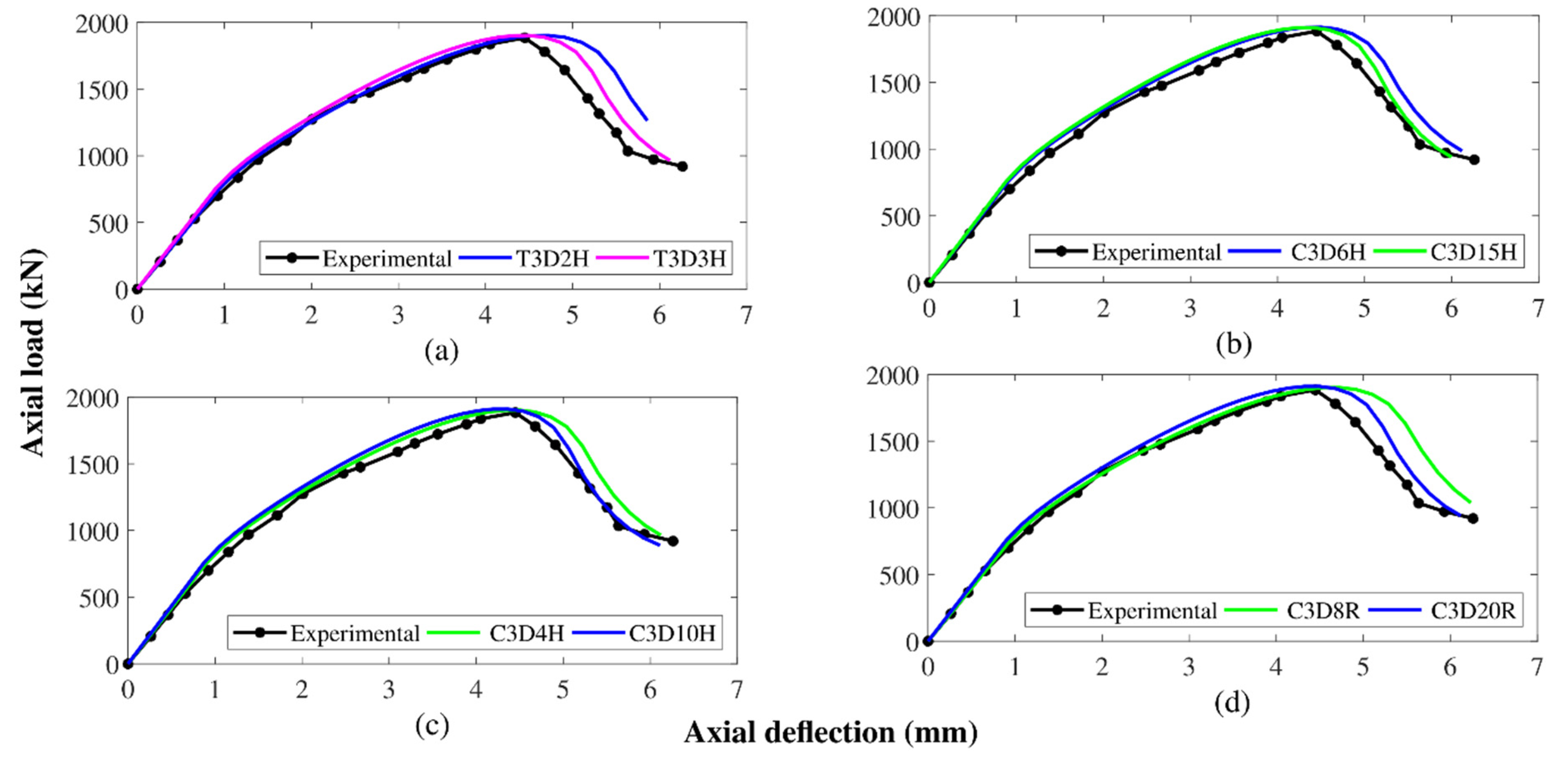

4. Results and Discussion

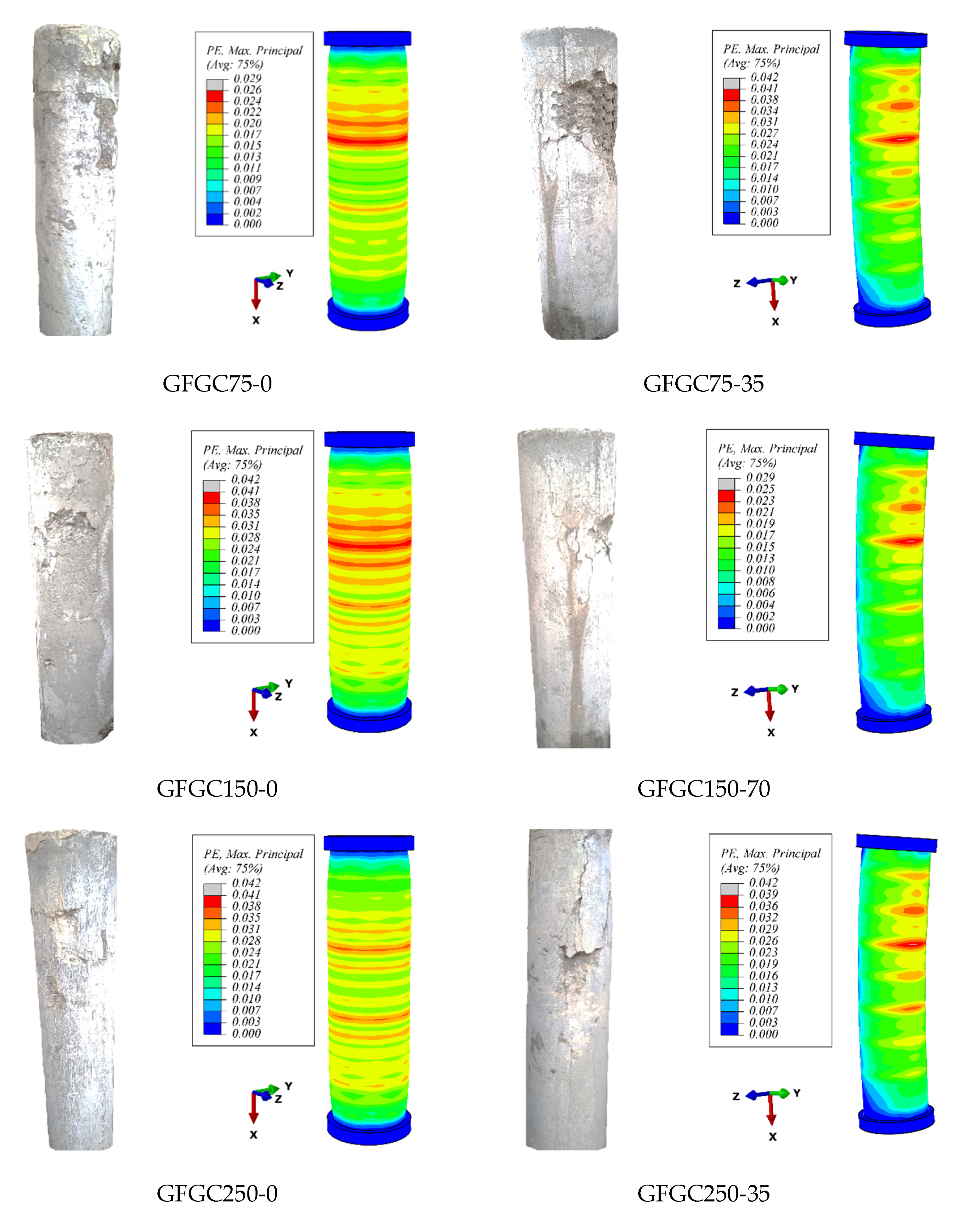

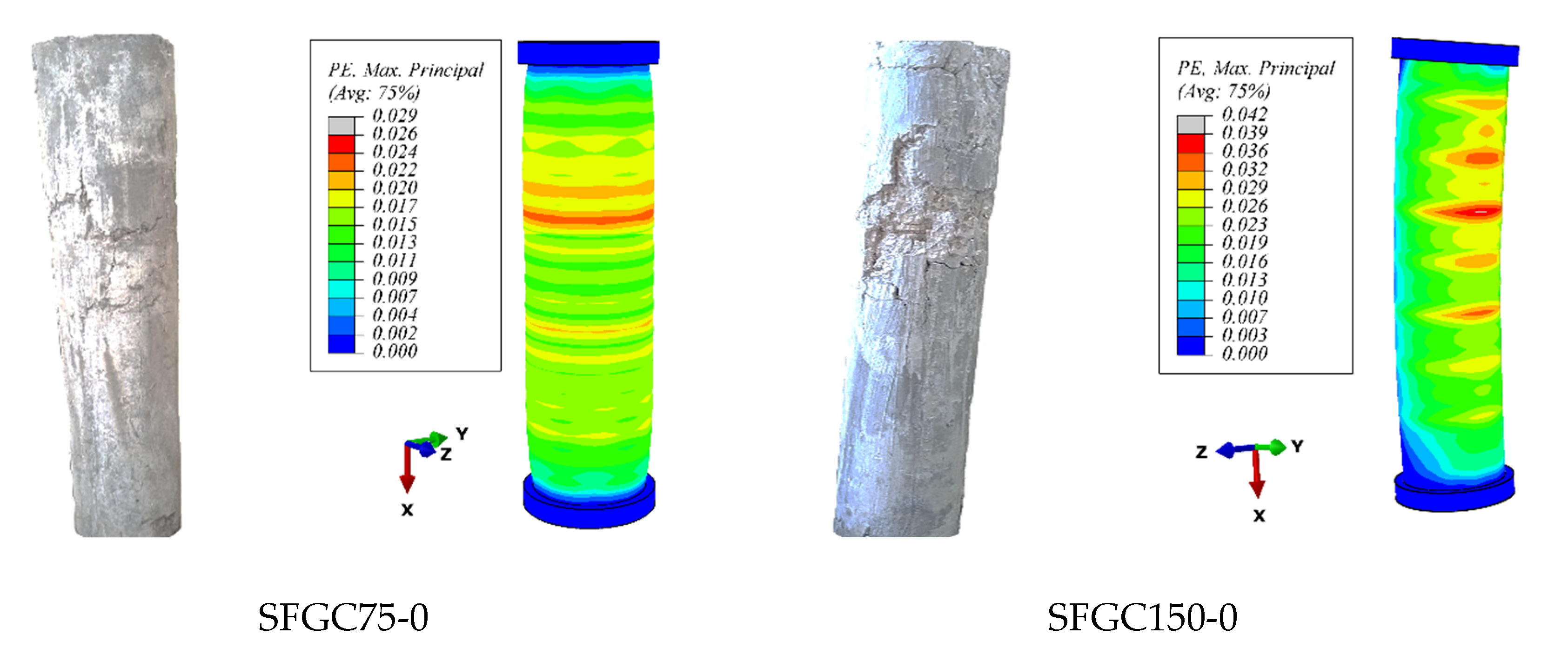

4.1. Failure Modes and Cracking Patterns

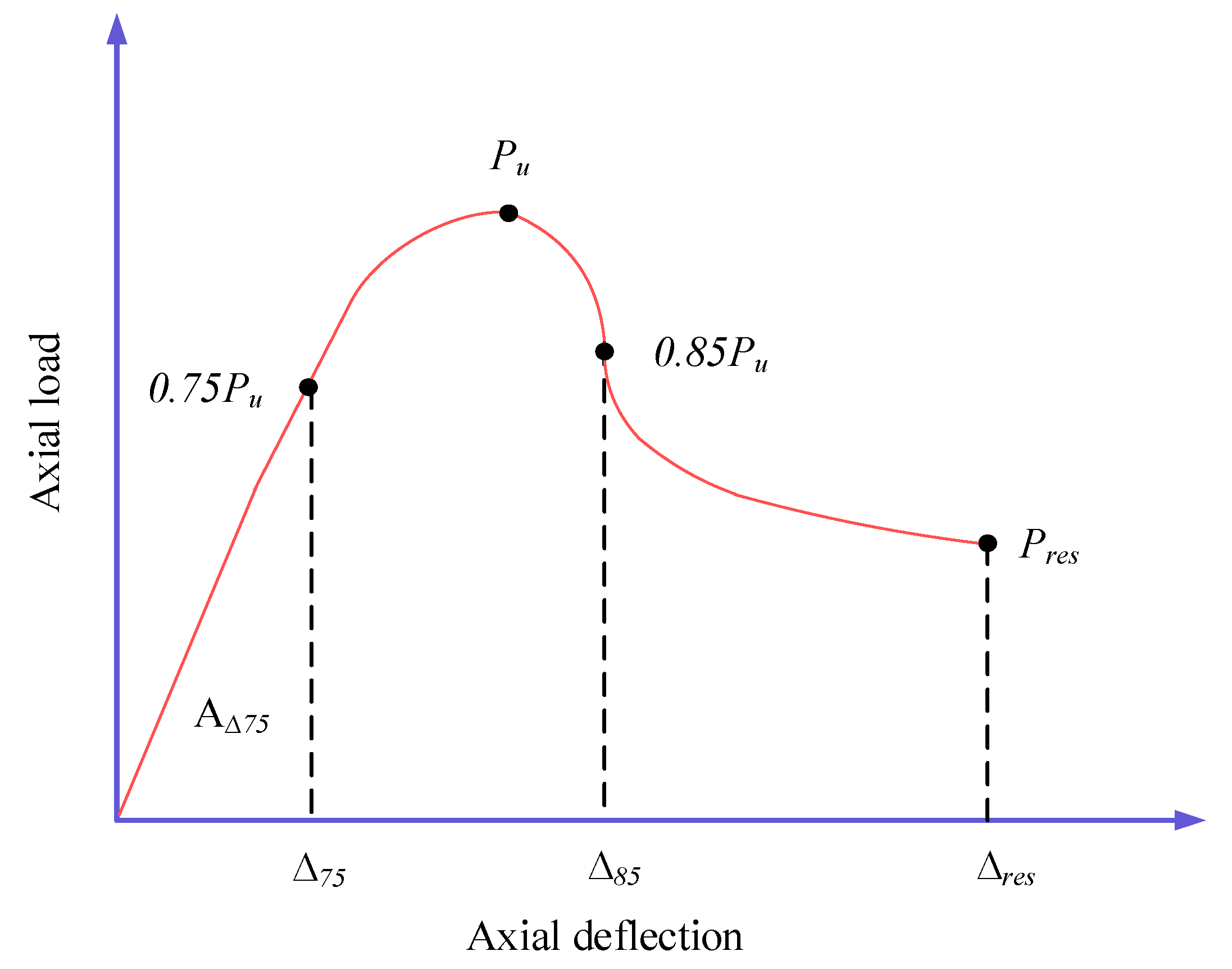

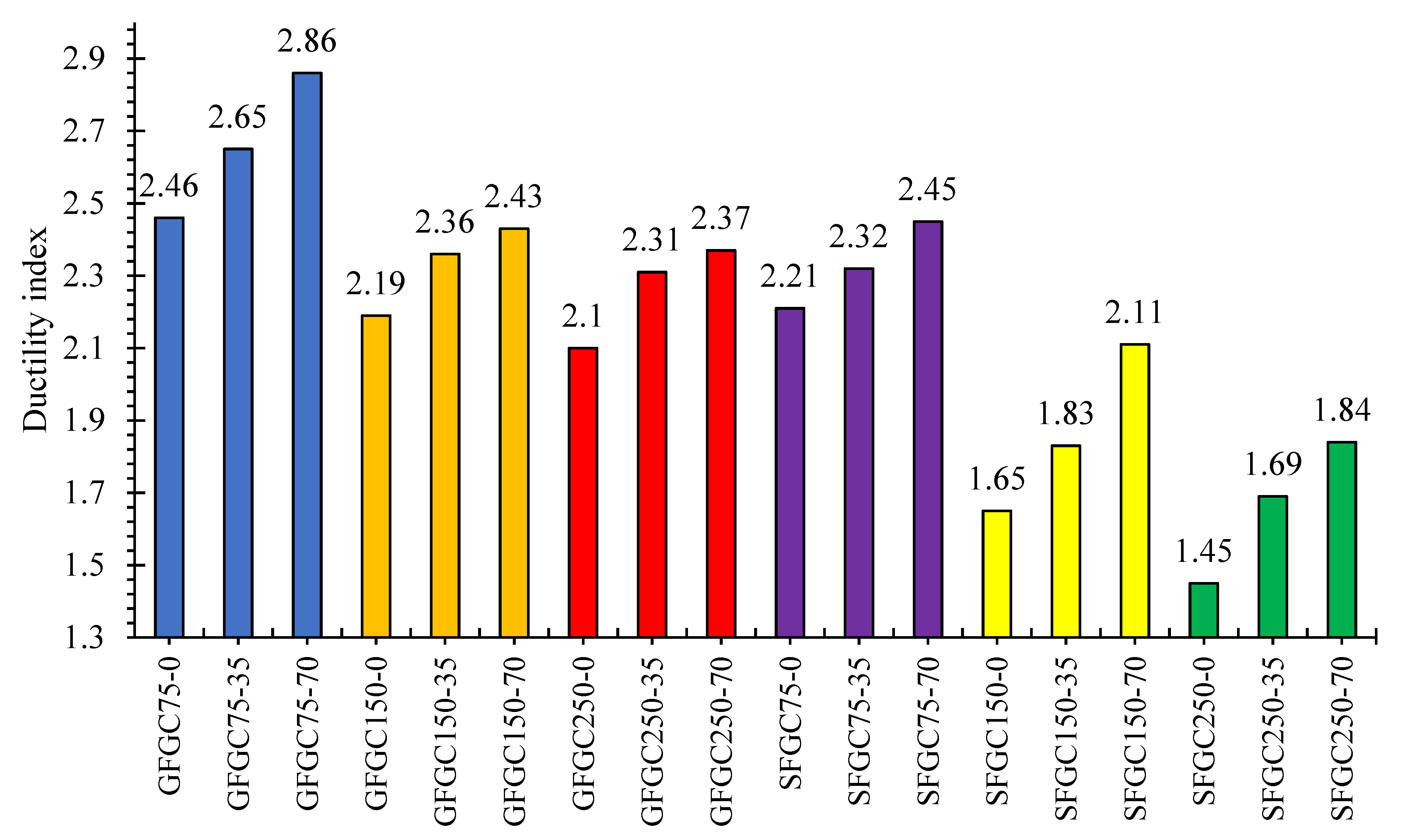

4.2. Ductility Index

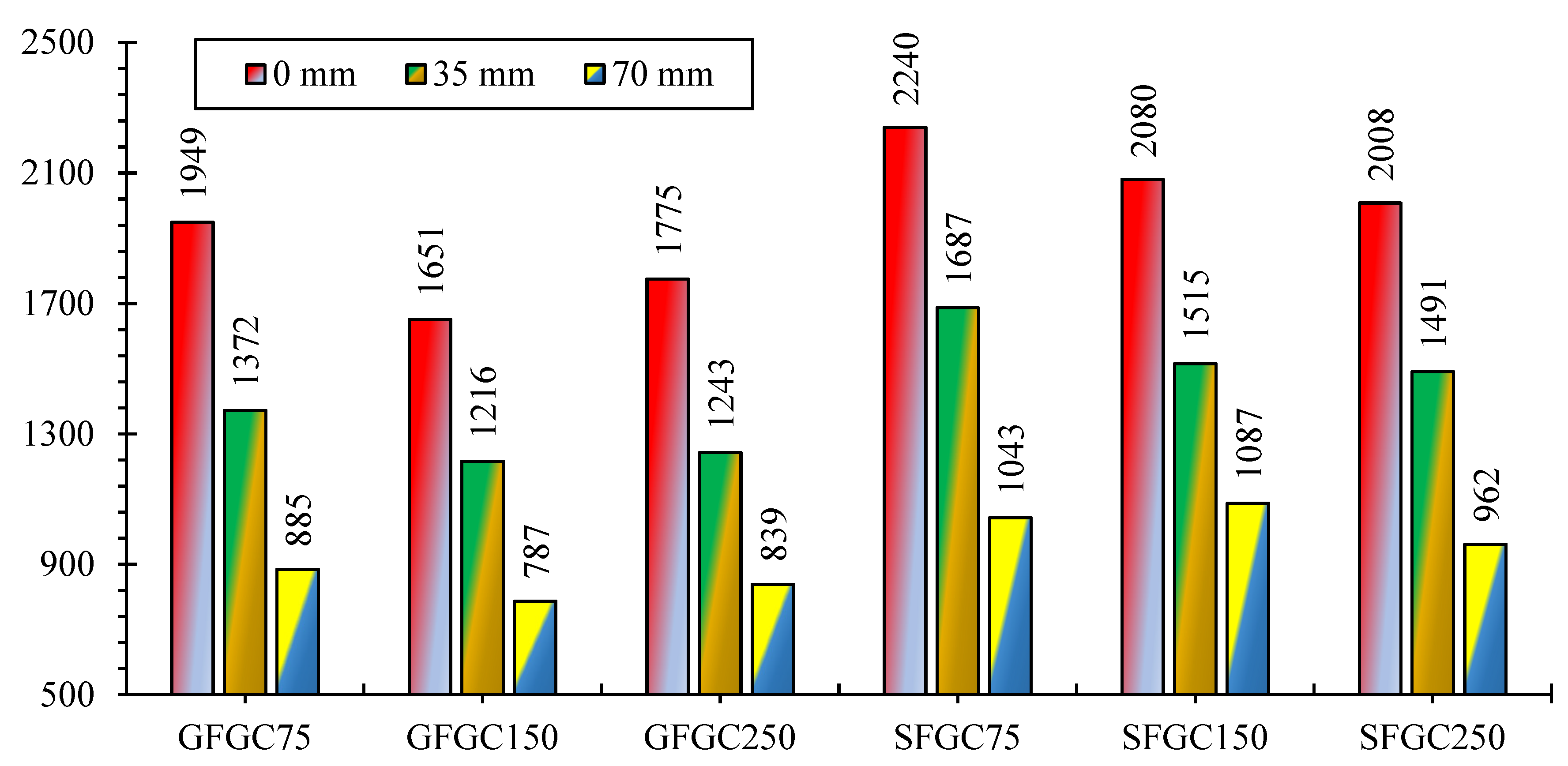

4.3. Reinforcement Type Effect

4.4. Stirrup Spacing Effect

4.5. Eccentricity Effect

5. Finite Element Analysis Predictions

5.1. Control Model

5.2. Ultimate Load against Corresponding Deflection

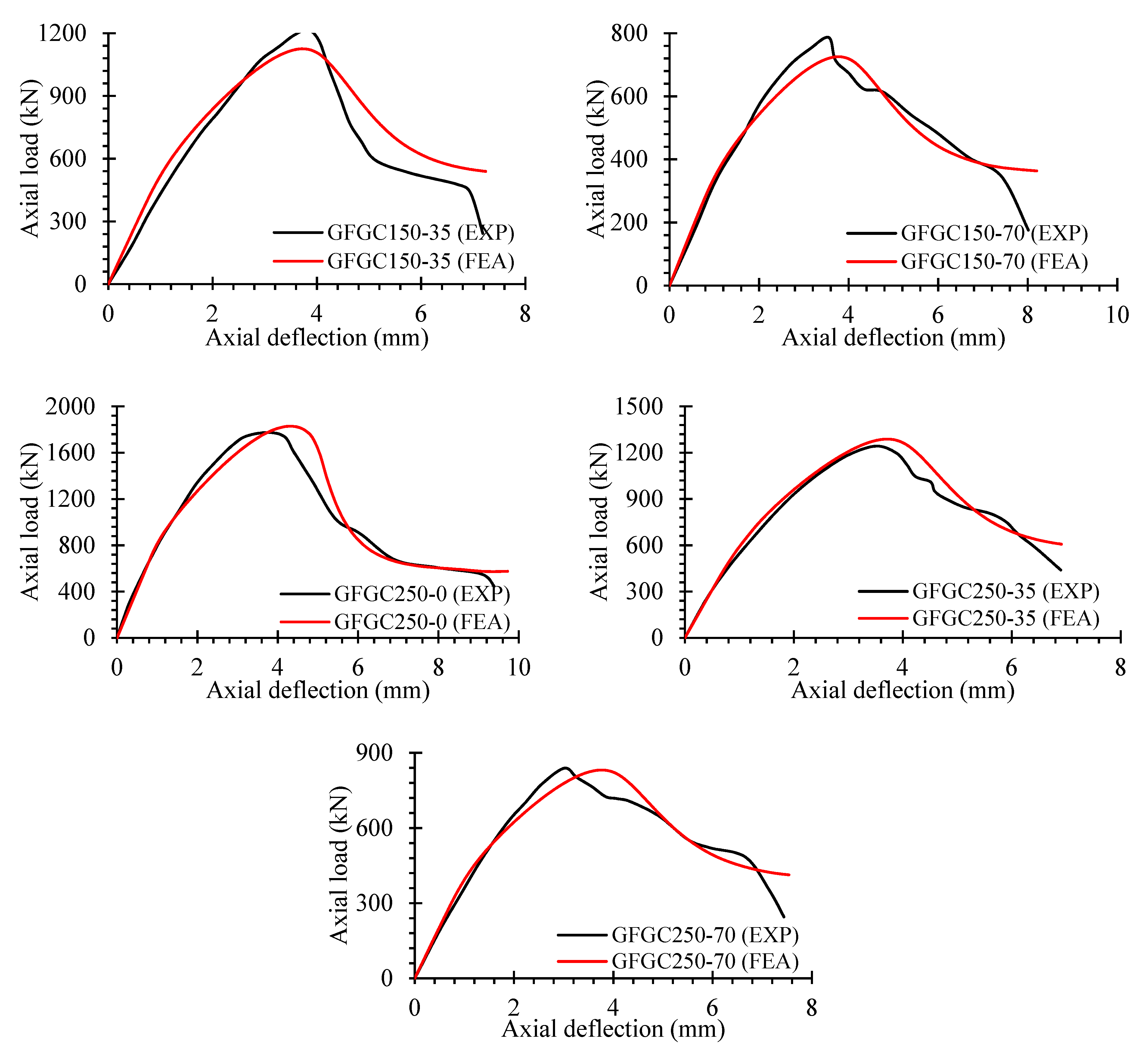

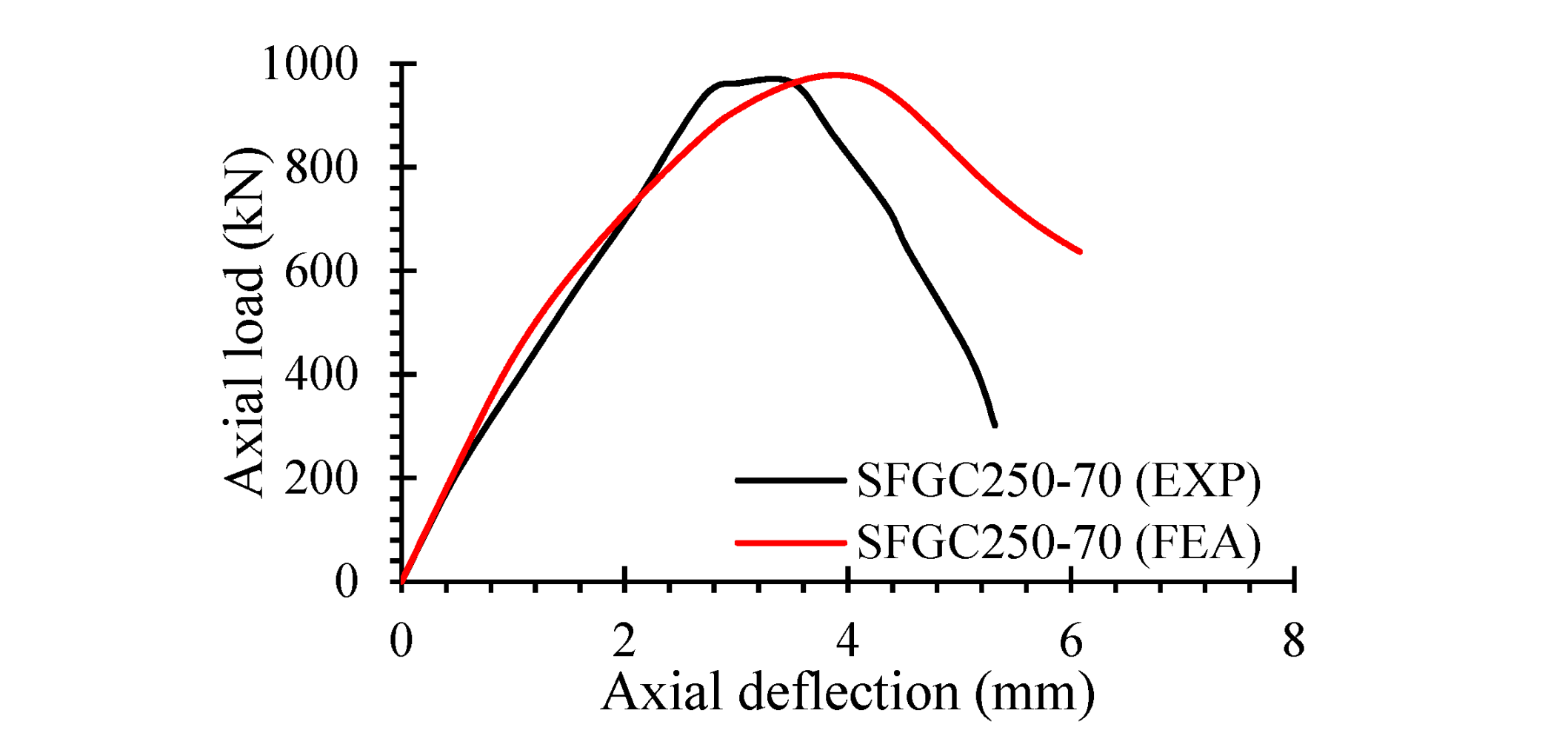

5.3. Load-Deflection Performance

5.4. Crack Patterns and Damage Behavior

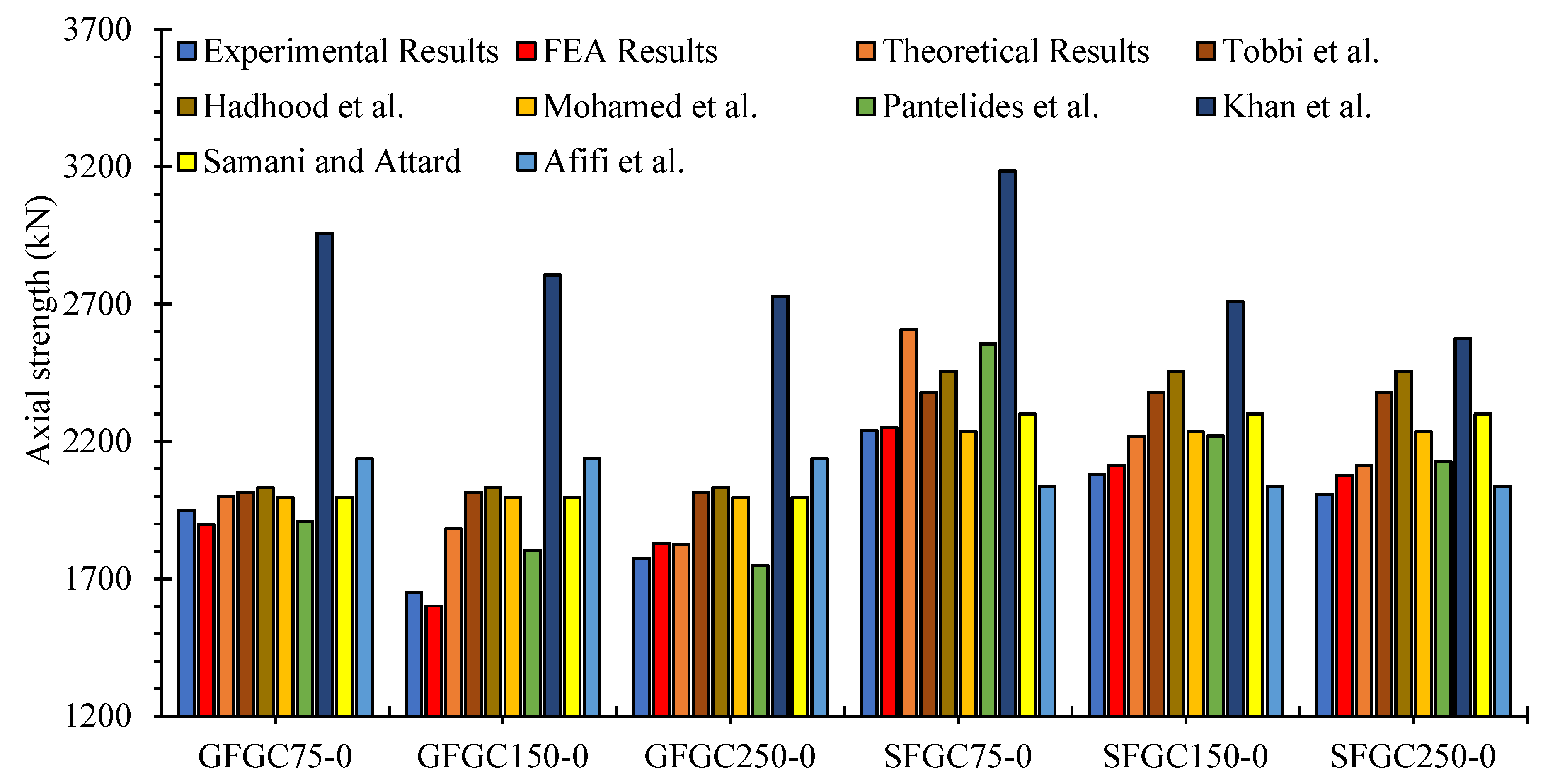

6. Theoretical Investigation

6.1. FRP-Confining Mechanism

6.2. Proposed AST Model

7. Conclusions

- The GFGC columns had a lower AST than the SFGC columns, with an average difference of only 20%. This shows that the inclusion of hybrid fibres in geopolymer concrete can perform efficiently in glass-FRP-reinforced circular columns to obtain sustainable and environmentally friendly structural elements.

- All of the GFGC and SFGC columns had the same failure mechanisms and proceeded through the same process. The collapse was mostly seen in the upper part of both eccentric and concentric columns. The GFGC columns were damaged due to a fracture in the longitudinal rebars, whereas the SFGC columns were damaged due to buckling of the main bars.

- GFGC samples are more ductile than SFGC samples. GFGC samples had an average ductility value 24% higher than SFGC columns. The columns with a shorter stirrup distance exhibited greater ductility values due to well-confined long rebars and good entrapment of the concrete core to retain more energy.

- The lessening in stirrup spacing improved the AST of both GFGC and SFGC columns. When the stirrup distance was reduced from 150 mm to 75 mm, the average percentage increase for both eccentric and concentric GFGC and SFGC columns was 15% and 6%, respectively. Reducing the stirrup distance from 250 mm to 150 mm resulted in a 5% increase in AST for SFGC columns, but a 5.5% drop in AST for GFGC columns.

- The AST of both GFGC and SFGC columns was significantly reduced as a result of loading eccentricity. The AST of GFGC columns with 75 mm stirrup spacing was lowered by 42% and 120%, respectively, due to the application of loads at the eccentricity of 35 mm and 70 mm.

- The proposed FEM predicted the efficiency of HFRGC with high accuracy by considering the hybrid fibre-dependent CDP model. The average errors represented by the proposed FEM for the AST and corresponding axial strain of studied specimens were 3.6% and 6.9%, respectively.

- The proposed new theoretical equation for the AST of GFGC columns functioned well for the experimental measurements of examined samples by taking into account the axial participation of glass-FRP main rebars and the lateral confinement of glass-FRP stirrups. The recent research found that the average deviations of the predictions of the currently proposed theoretical model from experimental data and finite element analysis of AST of samples were 8.1% and 7.5%, respectively.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rashedi, A.; Marzouki, R.; Raza, A.; Rawi, N.F.M.; Naveen, J. Mechanical, Fracture, and Microstructural Assessment of Carbon-Fiber-Reinforced Geopolymer Composites Containing Na2O. Polymers 2021, 13, 3852. [Google Scholar] [CrossRef] [PubMed]

- Raza, A.; Rashedi, A.; Rafique, U.; Hossain, N.; Akinyemi, B.; Naveen, J. On the Structural Performance of Recycled Aggregate Concrete Columns with Glass Fiber-Reinforced Composite Bars and Hoops. Polymers 2021, 13, 1508. [Google Scholar] [CrossRef] [PubMed]

- Benmokrane, B.; El-Salakawy, E.; El-Ragaby, A.; Lackey, T. Designing and Testing of Concrete Bridge Decks Reinforced with Glass FRP Bars. J. Bridg. Eng. 2006, 11, 217–229. [Google Scholar] [CrossRef] [Green Version]

- Raza, A.; Khan, Q.U.Z.; Ahmad, A. Numerical Investigation of Load-Carrying Capacity of GFRP-Reinforced Rectangular Concrete Members Using CDP Model in ABAQUS. Adv. Civ. Eng. 2019, 2019, 1745341. [Google Scholar] [CrossRef] [Green Version]

- Ibrahim, A.M.; Fahmy, M.F.; Wu, Z. 3D finite element modeling of bond-controlled behavior of steel and basalt FRP-reinforced concrete square bridge columns under lateral loading. Compos. Struct. 2016, 143, 33–52. [Google Scholar] [CrossRef]

- Zhang, X.; Deng, Z. Experimental study and theoretical analysis on axial compressive behavior of concrete columns reinforced with GFRP bars and PVA fibers. Constr. Build. Mater. 2018, 172, 519–532. [Google Scholar] [CrossRef]

- Zima, B.; Krajewski, M. The vibration-based assessment of the influence of elevated temperature on the condition of concrete beams with pultruded GFRP reinforcement. Compos. Struct. 2021, 282, 115040. [Google Scholar] [CrossRef]

- Magagnini, E.; Capozucca, R.; Vecchietti, M.V. Analysis of static response of RC beams with NSM CFRP/GFRP rods. Frat. E Integrita Strutt. 2021, 15, 402–415. [Google Scholar] [CrossRef]

- Yooprasertchai, E.; Dithaem, R.; Arnamwong, T.; Sahamitmongkol, R.; Jadekittichoke, J.; Joyklad, P.; Hussain, Q. Remediation of Punching Shear Failure Using Glass Fiber Reinforced Polymer (GFRP) Rods. Polymers 2021, 13, 2369. [Google Scholar] [CrossRef]

- Raza, A.; Khan, Q.U.Z. Experimental and numerical behavior of hybrid-fiber-reinforced concrete compression members under concentric loading. SN Appl. Sci. 2020, 2, 701. [Google Scholar] [CrossRef] [Green Version]

- Paultre, P.; Eid, R.; Langlois, Y.; Lévesque, Y. Behavior of Steel Fiber-Reinforced High-Strength Concrete Columns under Uniaxial Compression. J. Struct. Eng. 2010, 136, 1225–1235. [Google Scholar] [CrossRef]

- Hales, T.A.; Pantelides, C.P.; Reaveley, L.D. Analytical buckling model for slender FRP-reinforced concrete columns. Compos. Struct. 2017, 176, 33–42. [Google Scholar] [CrossRef]

- Dong, H.-L.; Wang, D.; Wang, Z.; Sun, Y. Axial compressive behavior of square concrete columns reinforced with innovative closed-type winding GFRP stirrups. Compos. Struct. 2018, 192, 115–125. [Google Scholar] [CrossRef]

- Choo, C.C.; Harik, I.E.; Gesund, H. Strength of rectangular concrete columns reinforced with fiber-reinforced polymer bars. ACI Struct. J. 2006, 103, 452. [Google Scholar]

- Choo, C.C.; Harik, I.E.; Gesund, H. Minimum reinforcement ratio for fiber-reinforced polymer reinforced concrete rectangular columns. ACI Mater. J. 2006, 103, 460. [Google Scholar]

- Afifi, M.Z.; Mohamed, H.M.; Benmokrane, B. Axial Capacity of Circular Concrete Columns Reinforced with GFRP Bars and Spirals. J. Compos. Constr. 2014, 18, 4013017. [Google Scholar] [CrossRef]

- Sun, L.; Wei, M.; Zhang, N. Experimental study on the behavior of GFRP reinforced concrete columns under eccentric axial load. Constr. Build. Mater. 2017, 152, 214–225. [Google Scholar] [CrossRef]

- Hadi, M.N.S.; Karim, H.; Sheikh, M.N. Experimental Investigations on Circular Concrete Columns Reinforced with GFRP Bars and Helices under Different Loading Conditions. J. Compos. Constr. 2016, 20, 4016009. [Google Scholar] [CrossRef] [Green Version]

- Tobbi, H.; Farghaly, A.S.; Benmokrane, B. Concrete Columns Reinforced Longitudinally and Transversally with Glass Fiber-Reinforced Polymer Bars. ACI Struct. J. 2012, 109, 551–558. [Google Scholar] [CrossRef]

- Mohamed, H.M.; Afifi, M.Z.; Benmokrane, B. Performance Evaluation of Concrete Columns Reinforced Longitudinally with FRP Bars and Confined with FRP Hoops and Spirals under Axial Load. J. Bridg. Eng. 2014, 19, 4014020. [Google Scholar] [CrossRef]

- AlAjarmeh, O.S.; Manalo, A.C.; Benmokrane, B.; Karunasena, W.; Mendis, P. Axial performance of hollow concrete columns reinforced with GFRP composite bars with different reinforcement ratios. Compos. Struct. 2019, 213, 153–164. [Google Scholar] [CrossRef]

- AlAjarmeh, O.; Manalo, A.; Benmokrane, B.; Karunasena, W.; Mendis, P.; Nguyen, Q.T. Compressive behavior of axially loaded circular hollow concrete columns reinforced with GFRP bars and spirals. Constr. Build. Mater. 2019, 194, 12–23. [Google Scholar] [CrossRef]

- Hadi, M.N.; Ahmad, J.; Yu, T. Tests of geopolymer concrete columns with basalt-fibre-reinforced-polymer bars and tubes. Proc. Inst. Civ. Eng.-Struct. Build. 2020, 1–41. [Google Scholar]

- Danda, U.K. Experimental study on reinforced geopolymer concrete columns using GGBS. Mater. Today Proc. 2020, 33, 632–636. [Google Scholar] [CrossRef]

- Hassan, A.; Arif, M.; Shariq, M. Use of geopolymer concrete for a cleaner and sustainable environment–A review of mechanical properties and microstructure. J. Clean. Prod. 2019, 223, 704–728. [Google Scholar] [CrossRef]

- Maruyama, I.; Rymeš, J.; Aili, A.; Sawada, S.; Kontani, O.; Ueda, S.; Shimamoto, R. Long-term use of modern Portland cement concrete: The impact of Al-tobermorite formation. Mater. Des. 2020, 198, 109297. [Google Scholar] [CrossRef]

- Saranya, P.; Nagarajan, P.; Shashikala, A. Behaviour of GGBS-dolomite geopolymer concrete short column under axial loading. J. Build. Eng. 2020, 30, 101232. [Google Scholar] [CrossRef]

- Maranan, G.; Manalo, A.; Benmokrane, B.; Karunasena, W.; Mendis, P. Behavior of concentrically loaded geopolymer-concrete circular columns reinforced longitudinally and transversely with GFRP bars. Eng. Struct. 2016, 117, 422–436. [Google Scholar] [CrossRef]

- Shi, Y.; Swait, T.; Soutis, C. Modelling damage evolution in composite laminates subjected to low velocity impact. Compos. Struct. 2012, 94, 2902–2913. [Google Scholar] [CrossRef]

- Correia, J.; Branco, F.; Silva, N.; Camotim, D.; Silvestre, N. First-Order, buckling and post-buckling behaviour of GFRP pultruded beams. Part 1: Experimental study. Comput. Struct. 2011, 89, 2052–2064. [Google Scholar] [CrossRef]

- Silva, N.; Camotim, D.; Silvestre, N.; Correia, J.; Branco, F. First-Order, buckling and post-buckling behaviour of GFRP pultruded beams. Part 2: Numerical simulation. Comput. Struct. 2011, 89, 2065–2078. [Google Scholar] [CrossRef]

- Boscato, G.; Ientile, S. Experimental and numerical investigation on dynamic properties of thin-walled GFRP buckled columns. Compos. Struct. 2018, 189, 273–285. [Google Scholar] [CrossRef]

- Rashedi, A.; Sridhar, I.; Tseng, K.; Srikanth, N. Minimum mass design of thin tubular structures under eccentric compressive loading. Thin-Walled Struct. 2015, 90, 191–201. [Google Scholar] [CrossRef]

- Turvey, G.; Zhang, Y. A computational and experimental analysis of the buckling, postbuckling and initial failure of pultruded GRP columns. Comput. Struct. 2006, 84, 1527–1537. [Google Scholar] [CrossRef]

- Elchalakani, M.; Karrech, A.; Dong, M.; Ali, M.M.; Yang, B. Experiments and Finite Element Analysis of GFRP Reinforced Geopolymer Concrete Rectangular Columns Subjected to Concentric and Eccentric Axial Loading. Structures 2018, 14, 273–289. [Google Scholar] [CrossRef]

- Elchalakani, M.; Karrech, A.; Dong, M.; Ali, M.S.M.; Li, G.; Yang, B. Testing and modelling of geopolymer concrete members with fibreglass reinforcement. Proc. Inst. Civ. Eng.-Struct. Build. 2021, 174, 12–27. [Google Scholar] [CrossRef]

- Hany, N.; Hantouche, E.G.; Harajli, M.H. Finite element modeling of FRP-confined concrete using modified concrete damaged plasticity. Eng. Struct. 2016, 125, 1–14. [Google Scholar] [CrossRef]

- ASTM/C143; Standard Test Method for Slump of Hydraulic Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2005.

- ASTM C807-13; Standard Test Method for Time of Setting of Hydraulic Cement Mortar by Modified Vicat Needle. U.A.I.: West Conshohocken, PA, USA, 2013.

- Raza, A.; Khan, Q.U.Z. Structural Behavior of GFRP-Reinforced Circular HFRC Columns Under Concentric and Eccentric Loading. Arab. J. Sci. Eng. 2020, 46, 4239–4252. [Google Scholar] [CrossRef]

- Raza, A.; Khan, Q.U.Z.; Ahmad, A. Investigation of HFRC columns reinforced with GFRP bars and spirals under concentric and eccentric loadings. Eng. Struct. 2020, 227, 111461. [Google Scholar] [CrossRef]

- Elchalakani, M.; Ma, G. Tests of glass fibre reinforced polymer rectangular concrete columns subjected to concentric and eccentric axial loading. Eng. Struct. 2017, 151, 93–104. [Google Scholar] [CrossRef]

- Raza, A.; El Ouni, M.H.; Ali, L.; Awais, M.; Ali, B.; Ahmad, Z.; Ben Kahla, N. Structural evaluation of recycled aggregate concrete circular columns having FRP rebars and synthetic fibers. Eng. Struct. 2021, 250, 113392. [Google Scholar] [CrossRef]

- Chi, Y.; Xu, L.; Yu, H.-S. Plasticity Model for Hybrid Fiber-Reinforced Concrete under True Triaxial Compression. J. Eng. Mech. 2014, 140, 393–405. [Google Scholar] [CrossRef]

- Guérin, M.; Mohamed, H.M.; Benmokrane, B.; Nanni, A.; Shield, C.K. Eccentric Behavior of Full-Scale Reinforced Concrete Columns with Glass Fiber-Reinforced Polymer Bars and Ties. ACI Struct. J. 2018, 115, 489–499. [Google Scholar] [CrossRef]

- Chi, Y.; Yu, M.; Huang, L.; Xu, L. Finite element modeling of steel-polypropylene hybrid fiber reinforced concrete using modified concrete damaged plasticity. Eng. Struct. 2017, 148, 23–35. [Google Scholar] [CrossRef]

- Lubliner, J.; Oliver, J.; Oller, S.; Onate, E. A plastic-damage model for concrete. Int. J. Solids Struct. 1989, 25, 299–326. [Google Scholar] [CrossRef]

- Wang, J.; Chen, Y. ABAQUS Application in Civil Engineering; Zhejiang University Press: Hangzhou, China, 2006. [Google Scholar]

- Huang, Z.; Liew, J.Y.R. Nonlinear finite element modelling and parametric study of curved steel-concrete-steel double skin composite panels infilled with ultra-lightweight cement composite. Constr. Build. Mater. 2015, 95, 922–938. [Google Scholar] [CrossRef]

- Chi, Y.X.; LHYu, H.S. Constitutive modeling of steel-polypropylene hybrid fiber reinforced concrete using a non-associated plasticity and its numerical implementation. Compos. Struct. 2014, 111, 497–509. [Google Scholar] [CrossRef]

- Özcan, D.M.; Bayraktar, A.; Şahin, A.; Haktanir, T.; Türker, T. Experimental and finite element analysis on the steel fiber-reinforced concrete (SFRC) beams ultimate behavior. Constr. Build. Mater. 2009, 23, 1064–1077. [Google Scholar] [CrossRef]

- Rafique, U.; Ali, A.; Raza, A. Structural behavior of GFRP reinforced recycled aggregate concrete columns with polyvinyl alcohol and polypropylene fibers. Adv. Struct. Eng. 2021, 24, 3043–3056. [Google Scholar] [CrossRef]

- Raza, A.; El Ouni, M.H.; Khan, Q.U.Z.; Berradia, M. Structural assessment of eccentrically loaded GFRP reinforced circular concrete columns: Experiments and finite element analysis. Compos. Struct. 2021, 275, 114528. [Google Scholar] [CrossRef]

- Raza, A.; Manalo, A.C.; Rafique, U.; AlAjarmeh, O.S.; Khan, Q.U.Z. Concentrically loaded recycled aggregate geopolymer concrete columns reinforced with GFRP bars and spirals. Compos. Struct. 2021, 268, 113968. [Google Scholar] [CrossRef]

- Kachlakev, D.I.; Miller, T.H.; Potisuk, T.; Yim, S.C.; Chansawat, K. Finite Element Modeling of Reinforced Concrete Structures Strengthened with FRP Laminates; Oregon Department of Transportation Research Group: Salem, OR, USA, 2001. [Google Scholar]

- Zhou, J.; Du, Q.Q.; Yuan, M.L.; Li, G.X. Experimental study on compressive mechanical properties of GFRP rebars. J. Hohai Univ. (Nat. Sci.) 2008, 4, 542–545. [Google Scholar]

- Barth, K.E.; Wu, H. Efficient nonlinear finite element modeling of slab on steel stringer bridges. Finite Elements Anal. Des. 2006, 42, 1304–1313. [Google Scholar] [CrossRef]

- Cho, S.K.; Kim, Y.I. Effects steel fibres on short beams loaded in shear. ACI Struct. J. 2003, 100, 765–774. [Google Scholar]

- Hadi, M.N.S.; Youssef, J. Experimental Investigation of GFRP-Reinforced and GFRP-Encased Square Concrete Specimens under Axial and Eccentric Load, and Four-Point Bending Test. J. Compos. Constr. 2016, 20, 4016020. [Google Scholar] [CrossRef] [Green Version]

- Elchalakani, M.; Dong, M.; Karrech, A.; Li, G.; Ali, M.S.M.; Yang, B. Experimental Investigation of Rectangular Air-Cured Geopolymer Concrete Columns Reinforced with GFRP Bars and Stirrups. J. Compos. Constr. 2019, 23, 4019011. [Google Scholar] [CrossRef]

- Afifi, M.Z.; Mohamed, H.M.; Benmokrane, B. Theoretical stress–strain model for circular concrete columns confined by GFRP spirals and hoops. Eng. Struct. 2015, 102, 202–213. [Google Scholar] [CrossRef]

- Mander, J.B.; Priestley, M.J.; Park, R. Theoretical Stress-Strain Model for Confined Concrete. J. Struct. Eng. 1988, 114, 1804–1826. [Google Scholar] [CrossRef] [Green Version]

- Shi, Q.X.; Wang, N.; Tian, J.B.; Shi, J.L. A practical stress-strain model for high-strength stirrups confined concrete. J. Build. Mater. 2014, 17, 216–222. [Google Scholar]

- Ahmad, A.; Khan, Q.U.Z.; Raza, A. Reliability analysis of strength models for CFRP-confined concrete cylinders. Compos. Struct. 2020, 244, 112312. [Google Scholar] [CrossRef]

- Raza, A.; Shah, S.A.R.; Khan, A.R.; Aslam, M.A.; Khan, T.A.; Arshad, K.; Hussan, S.; Sultan, A.; Shahzadi, G.; Waseem, M. Sustainable FRP-Confined Symmetric Concrete Structures: An Application Experimental and Numerical Validation Process for Reference Data. Appl. Sci. 2020, 10, 333. [Google Scholar] [CrossRef] [Green Version]

- Pantelides, C.P.; Gibbons, M.E.; Reaveley, L.D. Axial Load Behavior of Concrete Columns Confined with GFRP Spirals. J. Compos. Constr. 2013, 17, 305–313. [Google Scholar] [CrossRef]

- Khan, Q.S.; Sheikh, M.N.; Hadi, M.N.S. Axial-Flexural Interactions of GFRP-CFFT Columns with and without Reinforcing GFRP Bars. J. Compos. Constr. 2017, 21, 4016109. [Google Scholar] [CrossRef] [Green Version]

- Tobbi, H.; Farghaly, A.S.; Benmokrane, B. Behavior of Concentrically Loaded Fiber-Reinforced Polymer Reinforced Concrete Columns with Varying Reinforcement Types and Ratios. ACI Struct. J. 2014, 111, 375–386. [Google Scholar] [CrossRef]

- Samani, A.K.; Attard, M. A stress–strain model for uniaxial and confined concrete under compression. Eng. Struct. 2012, 41, 335–349. [Google Scholar] [CrossRef]

- Hadhood, A.; Mohamed, H.M.; Benmokrane, B. Axial Load–Moment Interaction Diagram of Circular Concrete Columns Reinforced with CFRP Bars and Spirals: Experimental and Theoretical Investigations. J. Compos. Constr. 2017, 21, 4016092. [Google Scholar] [CrossRef]

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| 10% fine value | 132 | Specific gravity | 2.24 |

| Apparent density | 2589 kg/m3 | Los Angeles abrasion | 40.17% |

| Bulk density | 1278 kg/m3 | Maximum size | 10 mm |

| Water absorption at 24 h | 3.32% | Minimum size | 4.75 mm |

| Material | Quantity (kg/m3) | Material | Quantity (kg/m3) |

|---|---|---|---|

| Coarse aggregates | 1184 | Fly ash | 246 |

| Sand | 500 | GGBS | 162 |

| Water | 123 | Superplasticizer | 38 |

| NaOH solution (14 M) | 39 | Na2SiO3 | 105 |

| Steel fibres | 23.62 | Polypropylene fibres | 1.92 |

| Parameter/Material | Diameter (mm) | Area (mm2) | Yielding Strength (MPa) | Young’s Modulus (GPa) | Ultimate Strain (%) |

|---|---|---|---|---|---|

| Steel rebars | 9.5 | 71 | 428 | 210 | 4.85 |

| 12.7 | 129 | 512 | 210 | 4.51 | |

| Glass-FRP rebars | 9.5 | 70.8 | 822 | 50 | 2.24 |

| 12.7 | 126.7 | 885 | 50 | 2.14 |

| Specimen ID | Rebars Type | Longitudinal Rebars | Eccentricity (e) (mm) | Transverse Rebars | e/D Ratio | ||||

|---|---|---|---|---|---|---|---|---|---|

| Diameter (mm) | No. of Rebars | Reinforcing Ratio (%) | Diameter (mm) | Spacing (mm) | Vol. Ratio (%) | ||||

| GFGC75-0 | Glass-FRP rebars | 12.7 | 6 | 1.10 | 0 | 9.5 | 75 | 1.10 | 0 |

| GFGC75-35 | 35 | 0.12 | |||||||

| GFGC75-70 | 70 | 0.23 | |||||||

| GFGC150-0 | Glass-FRP rebars | 12.7 | 6 | 1.10 | 0 | 9.5 | 150 | 0.55 | 0 |

| GFGC150-35 | 35 | 0.12 | |||||||

| GFGC150-70 | 70 | 0.23 | |||||||

| GFGC250-0 | Glass-FRP rebars | 12.7 | 6 | 1.10 | 0 | 9.5 | 250 | 0.32 | 0 |

| GFGC250-35 | 35 | 0.12 | |||||||

| GFGC250-70 | 70 | 0.23 | |||||||

| SFGC75-0 | Steel rebars | 12.7 | 6 | 1.10 | 0 | 9.5 | 75 | 1.10 | 0 |

| SFGC75-35 | 35 | 0.12 | |||||||

| SFGC75-70 | 70 | 0.23 | |||||||

| SFGC150-0 | Steel rebars | 12.7 | 6 | 1.10 | 0 | 9.5 | 150 | 0.55 | 0 |

| SFGC150-35 | 35 | 0.12 | |||||||

| SFGC150-70 | 70 | 0.23 | |||||||

| SFGC250-0 | Steel rebars | 12.7 | 6 | 1.10 | 0 | 9.5 | 250 | 0.32 | 0 |

| SFGC250-35 | 35 | 0.12 | |||||||

| SFGC250-70 | 70 | 0.23 | |||||||

| Sample ID | Experimental Results | FEA Results | % Age Difference in Pu | % Age Difference in Deflection at Pu | ||

|---|---|---|---|---|---|---|

| Ultimate Load, Pu (kN) | Axial Deflection at Pu (mm) | Pu (kN) | Axial Deflection at Pu (mm) | |||

| GFGC75-0 | 1949 | 4.54 | 1898 | 4.23 | 2.62 | 6.83 |

| GFGC75-35 | 1372 | 3.51 | 1315 | 3.57 | 4.15 | 1.71 |

| GFGC75-70 | 885 | 5.12 | 886 | 5.45 | 0.11 | 6.45 |

| GFGC150-0 | 1651 | 3.91 | 1601 | 4.07 | 3.03 | 4.09 |

| GFGC150-35 | 1216 | 3.61 | 1126 | 3.51 | 7.40 | 2.77 |

| GFGC150-70 | 787 | 3.36 | 726 | 3.58 | 7.75 | 6.55 |

| GFGC250-0 | 1775 | 3.55 | 1829 | 4.05 | 3.04 | 14.08 |

| GFGC250-35 | 1243 | 3.32 | 1288 | 3.44 | 3.62 | 3.61 |

| GFGC250-70 | 839 | 2.86 | 831 | 3.56 | 0.95 | 24.48 |

| SFGC75-0 | 2240 | 4.84 | 2250 | 4.4 | 0.45 | 9.09 |

| SFGC75-35 | 1687 | 3.94 | 1544 | 3.74 | 8.48 | 5.08 |

| SFGC75-70 | 1043 | 3.53 | 1018 | 3.71 | 2.40 | 5.10 |

| SFGC150-0 | 2080 | 4.09 | 2113 | 4.07 | 1.59 | 0.49 |

| SFGC150-35 | 1515 | 3.37 | 1474 | 3.59 | 2.71 | 6.53 |

| SFGC150-70 | 1087 | 4.03 | 986 | 3.7 | 9.29 | 8.19 |

| SFGC250-0 | 2008 | 4.11 | 2077 | 4.13 | 3.44 | 0.49 |

| SFGC250-35 | 1491 | 3.08 | 1454 | 3.45 | 2.48 | 12.01 |

| SFGC250-70 | 962 | 5.15 | 978 | 5.51 | 1.66 | 6.99 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rashedi, A.; Marzouki, R.; Raza, A.; Ali, K.; Olaiya, N.G.; Kalimuthu, M. Glass FRP-Reinforced Geopolymer Based Columns Comprising Hybrid Fibres: Testing and FEA Modelling. Polymers 2022, 14, 324. https://doi.org/10.3390/polym14020324

Rashedi A, Marzouki R, Raza A, Ali K, Olaiya NG, Kalimuthu M. Glass FRP-Reinforced Geopolymer Based Columns Comprising Hybrid Fibres: Testing and FEA Modelling. Polymers. 2022; 14(2):324. https://doi.org/10.3390/polym14020324

Chicago/Turabian StyleRashedi, Ahmad, Riadh Marzouki, Ali Raza, Khawar Ali, Niyi Gideon Olaiya, and Mayandi Kalimuthu. 2022. "Glass FRP-Reinforced Geopolymer Based Columns Comprising Hybrid Fibres: Testing and FEA Modelling" Polymers 14, no. 2: 324. https://doi.org/10.3390/polym14020324

APA StyleRashedi, A., Marzouki, R., Raza, A., Ali, K., Olaiya, N. G., & Kalimuthu, M. (2022). Glass FRP-Reinforced Geopolymer Based Columns Comprising Hybrid Fibres: Testing and FEA Modelling. Polymers, 14(2), 324. https://doi.org/10.3390/polym14020324