Processing and Characterization of Bioplastics from the Invasive Seaweed Rugulopteryx okamurae

Abstract

:1. Introduction

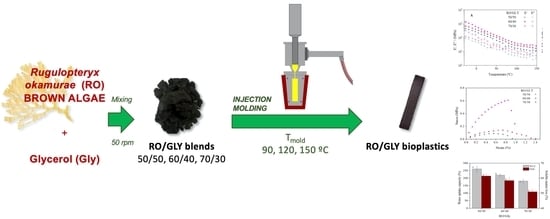

2. Materials and Methods

2.1. Materials and Sample Preparation

2.2. Methods

2.2.1. Rheological Characterization of RO/GLY Blends

Rheological Measurements

2.2.2. Characterization of the RO-Based Bioplastics

Rheological Measurements

Tensile Properties

Water Uptake Capacity (WUC)

Scanning Electron Microscopy (SEM)

2.3. Statistical Analysis

3. Results and Discussion

3.1. Influence of the Rugulopteryx okamurae/Glycerol (RO/GLY) Ratio

3.1.1. Blends

Mixing

Dynamic Mechanical Thermal Analysis (DMTA)

3.1.2. Bioplastics

Dynamic Mechanical Thermal Analysis (DMTA)

Tensile Tests

Water Uptake Capacity (WUC)

Scanning Electron Microscopy (SEM)

3.2. Influence of Molding Temperature in Bioplastic Properties

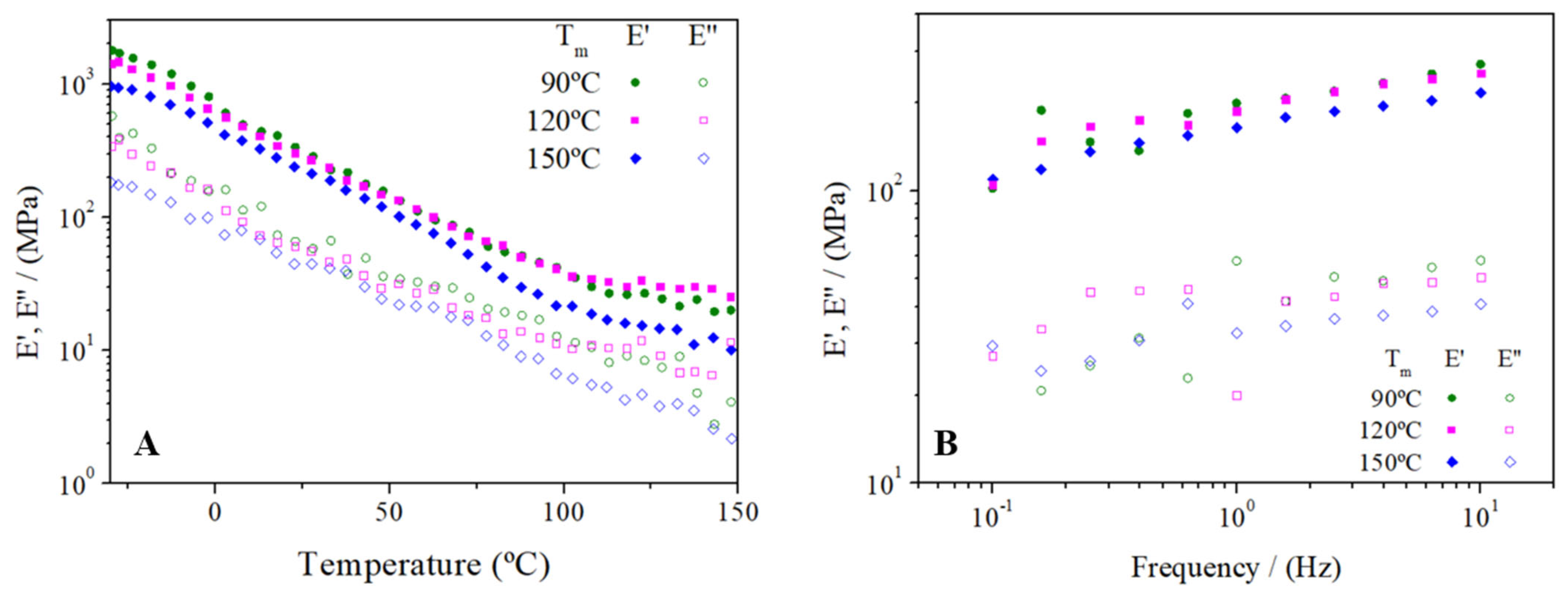

3.2.1. Dynamic Mechanical Thermal Analysis (DMTA)

3.2.2. Tensile Properties

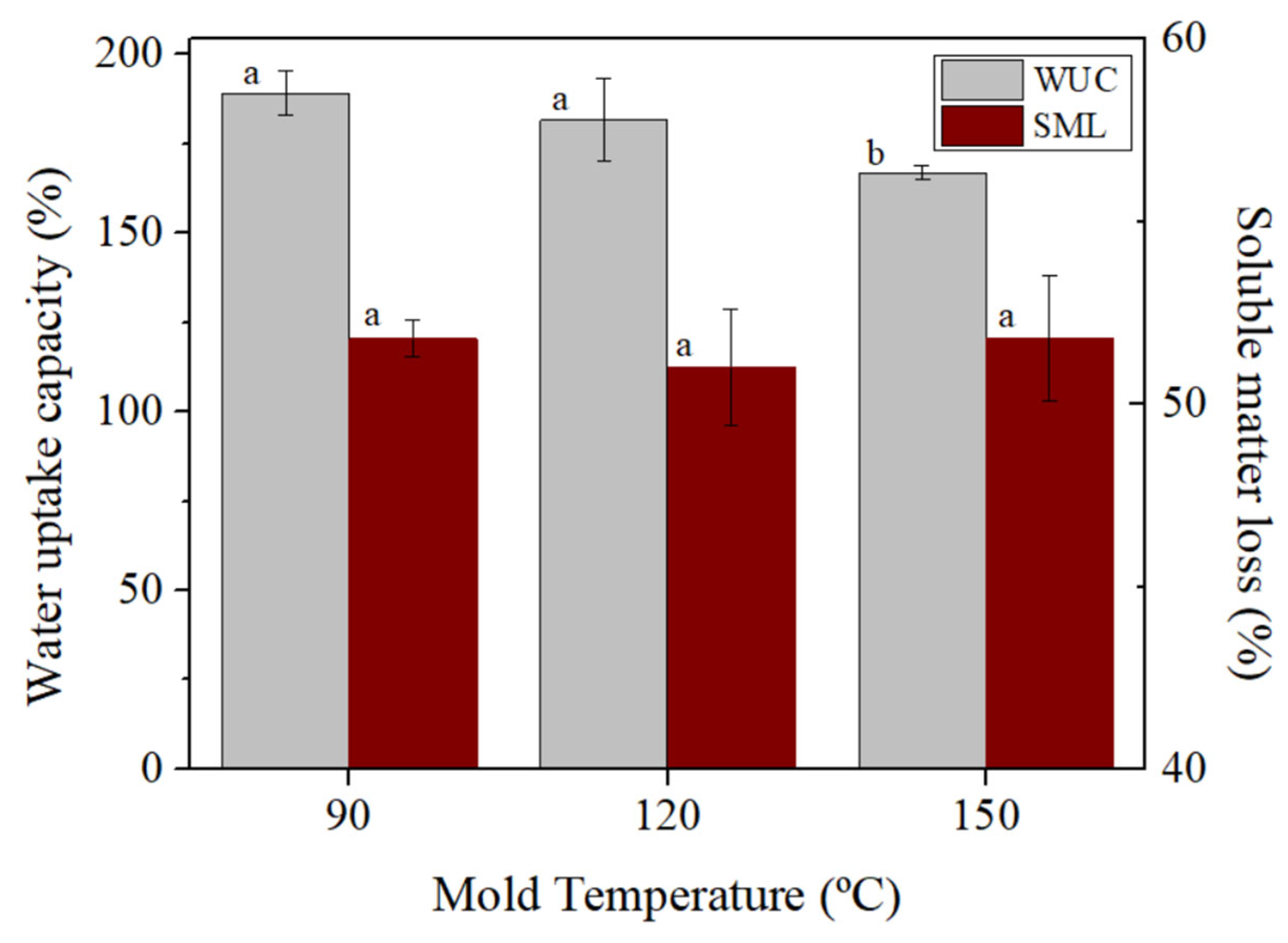

3.2.3. Water Uptake Capacity

3.2.4. Scanning Electron Spectroscopy

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hwang, I.-K.; Lee, W.J.; Kim, H.-S.; De Clerck, O. Taxonomic reappraisal of Dilophus okamurae (Dictyotales, Phaeophyta) from the western Pacific Ocean. Phycologia 2009, 48, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Dawson, E.Y. Notes on Some Pacific Mexican Dictyotaceae. Bull. Torrey Bot. Club 1950, 77, 83. [Google Scholar] [CrossRef]

- Agatsuma, Y.; Kuwahara, Y.; Taniguchi, K. Life cycle of Dilophus okamurae (Phaeophyceae) and its associated invertebrate fauna in Onagawa Bay, Japan. Fish. Sci. 2005, 71, 1107–1114. [Google Scholar] [CrossRef]

- García-Gómez, J.C.; Florido, M.; Olaya-Ponzone, L.; Rey Díaz de Rada, J.; Donázar-Aramendía, I.; Chacón, M.; Quintero, J.J.; Magariño, S.; Megina, C. Monitoring Extreme Impacts of Rugulopteryx okamurae (Dictyotales, Ochrophyta) in El Estrecho Natural Park (Biosphere Reserve). Showing Radical Changes in the Underwater Seascape. Front. Ecol. Evol. 2021, 9, 1–18. [Google Scholar] [CrossRef]

- García-Gómez, J.C.; Sempere-Valverde, J.; González, A.R.; Martínez-Chacón, M.; Olaya-Ponzone, L.; Sánchez-Moyano, E.; Ostalé-Valriberas, E.; Megina, C. From exotic to invasive in record time: The extreme impact of Rugulopteryx okamurae (Dictyotales, Ochrophyta) in the strait of Gibraltar. Sci. Total Environ. 2020, 704, 135408. [Google Scholar] [CrossRef]

- El Ayuntamiento de Tarifa ya ha Retirado Unas 400 Toneladas de Lagas Invasoras en el Último Mes. Available online: https://www.elestrechodigital.com/2020/08/19/el-ayuntamiento-de-tarifa-ya-ha-retirado-unas-400-toneladas-de-algas-invasoras-en-el-ultimo-mes/ (accessed on 30 September 2021).

- Shrivastava, A. Plastic Properties and Testing; Elsevier: Oxford, UK, 2018; ISBN 9780323395007. [Google Scholar]

- Kalia, V.C.; Raizada, N.; Sonakya, V.; Kalia, V.C. Neena Raizada and V Sonakya. J. Sci. Ind. Res. 2000, 59, 433–445. [Google Scholar]

- Gahlawat, S.K.; Salar, R.K.; Siwach, P.; Duhan, J.S.; Kumar, S.; Kaur, P. Plant biotechnology: Recent advancements and developments. In Plant Biotechnology: Recent Advancements and Developments; Springer: Singapore, 2017; pp. 1–390. [Google Scholar] [CrossRef]

- Schmaltz, E.; Melvin, E.C.; Diana, Z.; Gunady, E.F.; Rittschof, D.; Somarelli, J.A.; Virdin, J.; Dunphy-Daly, M.M. Plastic pollution solutions: Emerging technologies to prevent and collect marine plastic pollution. Environ. Int. 2020, 144, 106067. [Google Scholar] [CrossRef] [PubMed]

- Cox, K.D.; Covernton, G.A.; Davies, H.L.; Dower, J.F.; Juanes, F.; Dudas, S.E. Human Consumption of Microplastics. Environ. Sci. Technol. 2019, 53, 7068–7074. [Google Scholar] [CrossRef] [Green Version]

- Ashter, S.A. 5—Types of Biodegradable Polymers. In Introduction to Bioplastics Engineering; Elsevier: Oxford, UK, 2016; pp. 81–151. ISBN 9780323393966. [Google Scholar]

- European Bioplastics Bioplastics Glossary. Available online: https://www.european-bioplastics.org/glossary/ (accessed on 30 September 2021).

- Thiruchelvi, R.; Das, A.; Sikdar, E. Materials Today: Proceedings Bioplastics as better alternative to petro plastic. Mater. Today Proc. 2021, 37, 1634–1639. [Google Scholar] [CrossRef]

- Tauer, K. Fundamental principles of polymeric materials, second edition. Stephen L. Rosen. A volume in the SPE monograph series. A wiley-interscience publication. John Wiley & Sons, Inc. 1993, 420 pages. Acta Polym. 1993, 44, 210. [Google Scholar] [CrossRef]

- Wilson, A. Plasticisers: Principles and Practice; Institute of Materials: London, UK, 1995; ISBN 9780901716767. [Google Scholar]

- Wypych, G. Handbook of Plasticizers, 3rd ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2017; ISBN 9781895198973. [Google Scholar]

- Vieira, M.G.A.; da Silva, M.A.; dos Santos, L.O.; Beppu, M.M.; Adeodato Vieira, M.G.; da Silva, M.A.; dos Santos, L.O.; Beppu, M.M.; Vieira, M.G.A.; da Silva, M.A.; et al. Natural-based plasticizers and biopolymer films: A review. Eur. Polym. J. 2011, 47, 254–263. [Google Scholar] [CrossRef] [Green Version]

- Sikora, J.; Majewski, Ł.; Puszka, A. Modern Biodegradable Plastics-Processing and Properties: Part I. Materials 2020, 13, 1986. [Google Scholar] [CrossRef]

- Ashter, S.A. 7—Processing Biodegradable Polymers. In Introduction to Bioplastics Engineering; Elsevier: Oxford, UK, 2016; pp. 211–225. ISBN 9780323393966. [Google Scholar]

- Ashter, S.A. 8—Extrusion of Biopolymers. In Introduction to Bioplastics Engineering; Elsevier: Oxford, UK, 2016; pp. 211–225. ISBN 9780323393966. [Google Scholar]

- Jerez, A.; Partal, P.; Martínez, I.; Gallegos, C.; Guerrero, A. Rheology and processing of gluten based bioplastics. Biochem. Eng. J. 2005, 26, 131–138. [Google Scholar] [CrossRef]

- Fernández-Espada, L.; Bengoechea, C.; Cordobés, F.; Guerrero, A. Thermomechanical properties and water uptake capacity of soy protein-based bioplastics processed by injection molding. J. Appl. Polym. Sci. 2016, 133, 1–10. [Google Scholar] [CrossRef]

- Álvarez-Castillo, E.; Bengoechea, C.; Rodríguez, N.; Guerrero, A. Development of green superabsorbent materials from a by-product of the meat industry. J. Clean. Prod. 2019, 223, 651–661. [Google Scholar] [CrossRef]

- Beacham, W. Algae-Based Bioplastics a Fast-Growing Market; ICIS: Maastricht, The Netherlands, 2010. [Google Scholar]

- Mæhre, H.K.; Malde, M.K.; Eilertsen, K.E.; Elvevoll, E.O. Characterization of protein, lipid and mineral contents in common Norwegian seaweeds and evaluation of their potential as food and feed. J. Sci. Food Agric. 2014, 94, 3281–3290. [Google Scholar] [CrossRef] [PubMed]

- ISO-527-2:2012; Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics. ISO Central Secretariat: Geneva, Switzerland, 2012.

- Cuadri, A.A.A.; Romero, A.; Bengoechea, C.; Guerrero, A. The Effect of Carboxyl Group Content on Water Uptake Capacity and Tensile Properties of Functionalized Soy Protein-Based Superabsorbent Plastics. J. Polym. Environ. 2018, 26, 2934–2944. [Google Scholar] [CrossRef]

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 years of image analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef] [PubMed]

- Bier, J.M.; Verbeek, C.J.R.; Lay, M.C. Thermal transitions and structural relaxations in protein-based thermoplastics. Macromol. Mater. Eng. 2014, 299, 524–539. [Google Scholar] [CrossRef]

- Felix, M.; Perez-Puyana, V.; Romero, A.; Guerrero, A. Development of protein-based bioplastics modified with different additives. J. Appl. Polym. Sci. 2017, 134, 45430. [Google Scholar] [CrossRef]

- Ferry, J.D. Viscoelastic Properties of Polymers; Wiley: Hoboken, NJ, USA, 1980; ISBN 9780471048947. [Google Scholar]

- López Rocha, C.J.; Álvarez-Castillo, E.; Estrada Yáñez, M.R.; Bengoechea, C.; Guerrero, A.; Orta Ledesma, M.T. Development of bioplastics from a microalgae consortium from wastewater. J. Environ. Manag. 2020, 263, 110353. [Google Scholar] [CrossRef]

- Zeller, M.A.; Hunt, R.; Jones, A.; Sharma, S. Bioplastics and their thermoplastic blends from Spirulina and Chlorella microalgae. J. Appl. Polym. Sci. 2013, 130, 3263–3275. [Google Scholar] [CrossRef]

- Sanyang, M.L.; Sapuan, S.M.; Jawaid, M.; Ishak, M.R.; Sahari, J. Effect of plasticizer type and concentration on tensile, thermal and barrier properties of biodegradable films based on sugar palm (Arenga pinnata) starch. Polymers 2015, 7, 1106–1124. [Google Scholar] [CrossRef]

- Zhang, Y.; Rempel, C.; Liu, Q. Thermoplastic Starch Processing and Characteristics-A Review. Crit. Rev. Food Sci. Nutr. 2014, 54, 1353–1370. [Google Scholar] [CrossRef] [PubMed]

- Félix, M.; Martín-Alfonso, J.E.; Romero, A.; Guerrero, A. Development of albumen/soy biobased plastic materials processed by injection molding. J. Food Eng. 2014, 125, 7–16. [Google Scholar] [CrossRef]

- Paetau, I.; Chen, C.Z.; Jane, J.L. Biodegradable plastic made from soybean products. 1. Effect of preparation and processing on mechanical-properties and water-absorption. Ind. Eng. Chem. Res. 1994, 33, 1821–1827. [Google Scholar] [CrossRef]

| RO/GLY | SME (kJ/kg) |

|---|---|

| 50/50 | 208 ± 37 |

| 60/40 | 328 ± 50 |

| 70/30 | 805 ± 182 |

| RO/GLY | E (MPa) | εmax (%) | σmax (MPa) |

|---|---|---|---|

| 50/50 | 0.40 ± 0.14 a | 0.88 ± 0.07 a | 0.089 ± 0.021 a |

| 60/40 | 0.70 ± 0.10 b | 1.49 ± 0.21 b | 0.15 ± 0.03 b |

| 70/30 | 2.61 ± 0.51 c | 0.74 ± 0.12 a | 0.68 ± 0.06 c |

| Molding Temperature (°C) | E (MPa) | σmax (%) | εmax (MPa) |

|---|---|---|---|

| 90 | 1.60 ± 0.14 a | 0.73 ± 0.002 a | 0.33 ± 0.022 a |

| 120 | 2.61 ± 0.51 b | 0.74 ± 0.12 a | 0.68 ± 0.057 b |

| 150 | 1.47 ± 0.17 a | 0.69 ± 0.32 a | 0.36 ± 0.045 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santana, I.; Félix, M.; Guerrero, A.; Bengoechea, C. Processing and Characterization of Bioplastics from the Invasive Seaweed Rugulopteryx okamurae. Polymers 2022, 14, 355. https://doi.org/10.3390/polym14020355

Santana I, Félix M, Guerrero A, Bengoechea C. Processing and Characterization of Bioplastics from the Invasive Seaweed Rugulopteryx okamurae. Polymers. 2022; 14(2):355. https://doi.org/10.3390/polym14020355

Chicago/Turabian StyleSantana, Ismael, Manuel Félix, Antonio Guerrero, and Carlos Bengoechea. 2022. "Processing and Characterization of Bioplastics from the Invasive Seaweed Rugulopteryx okamurae" Polymers 14, no. 2: 355. https://doi.org/10.3390/polym14020355

APA StyleSantana, I., Félix, M., Guerrero, A., & Bengoechea, C. (2022). Processing and Characterization of Bioplastics from the Invasive Seaweed Rugulopteryx okamurae. Polymers, 14(2), 355. https://doi.org/10.3390/polym14020355