Effect of Biomass as Nucleating Agents on Crystallization Behavior of Polylactic Acid

Abstract

1. Introduction

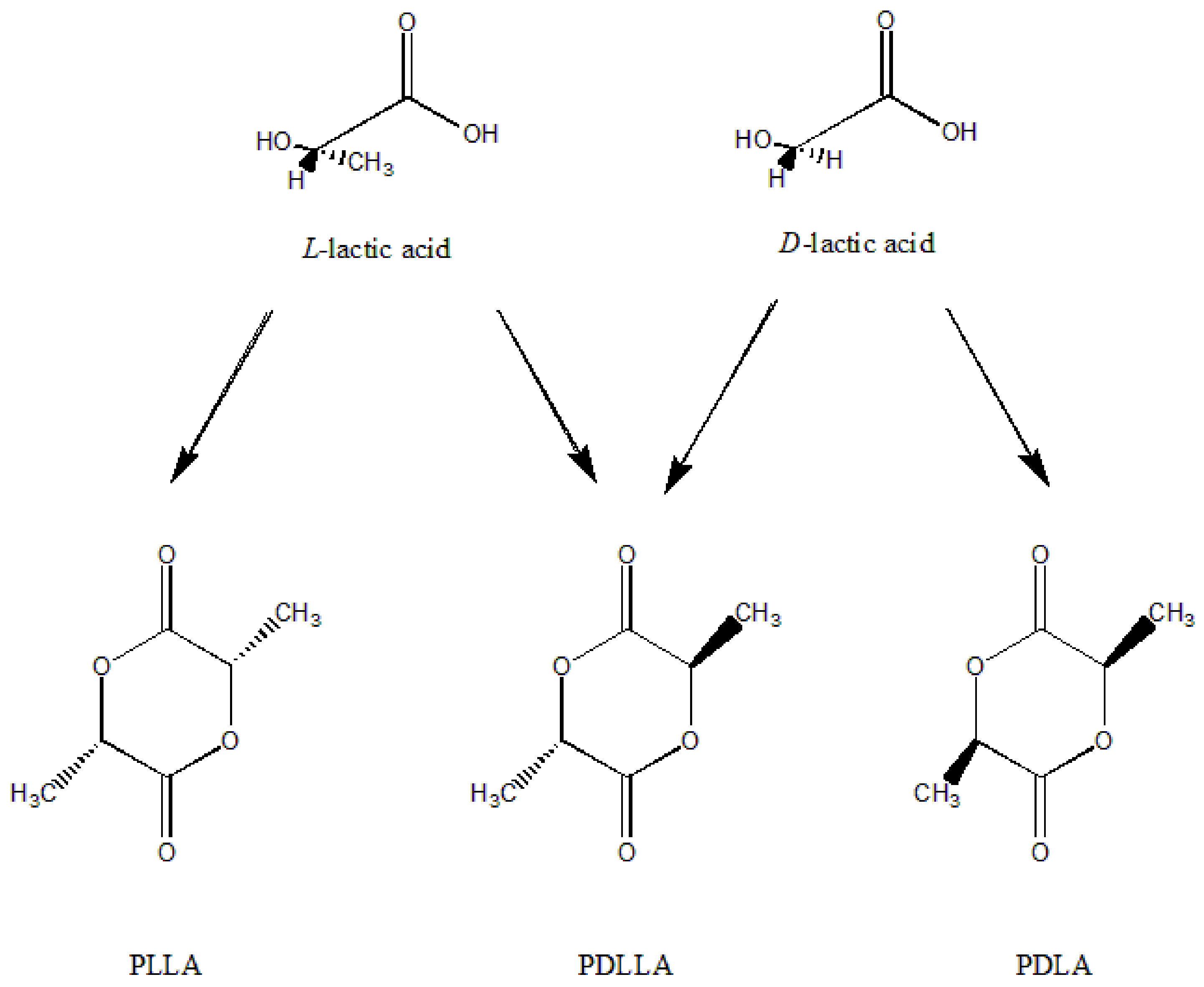

2. PLA

3. Biomass and Biomass Nucleating Agents

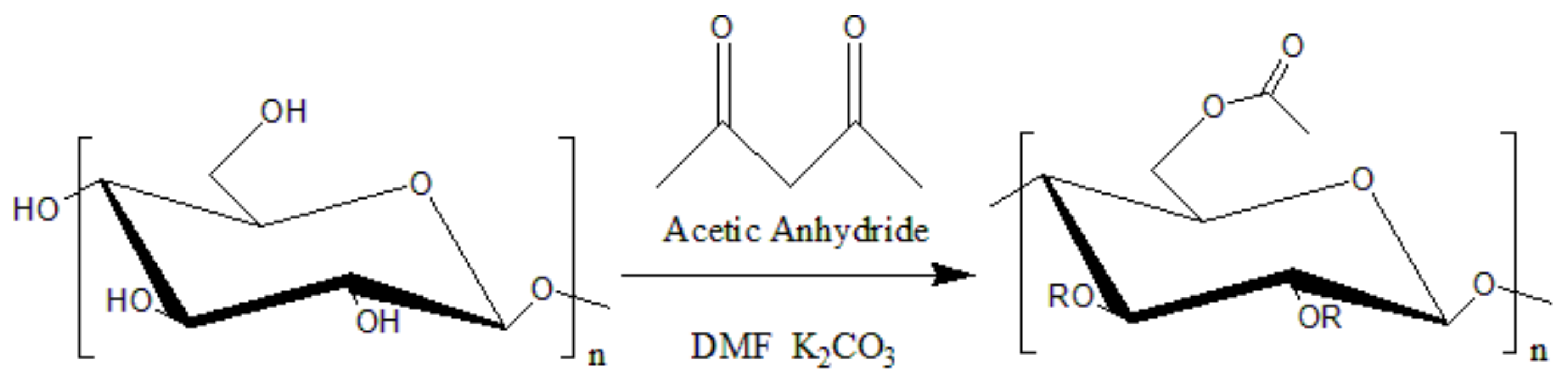

3.1. Cellulose

3.2. Hemicellulose

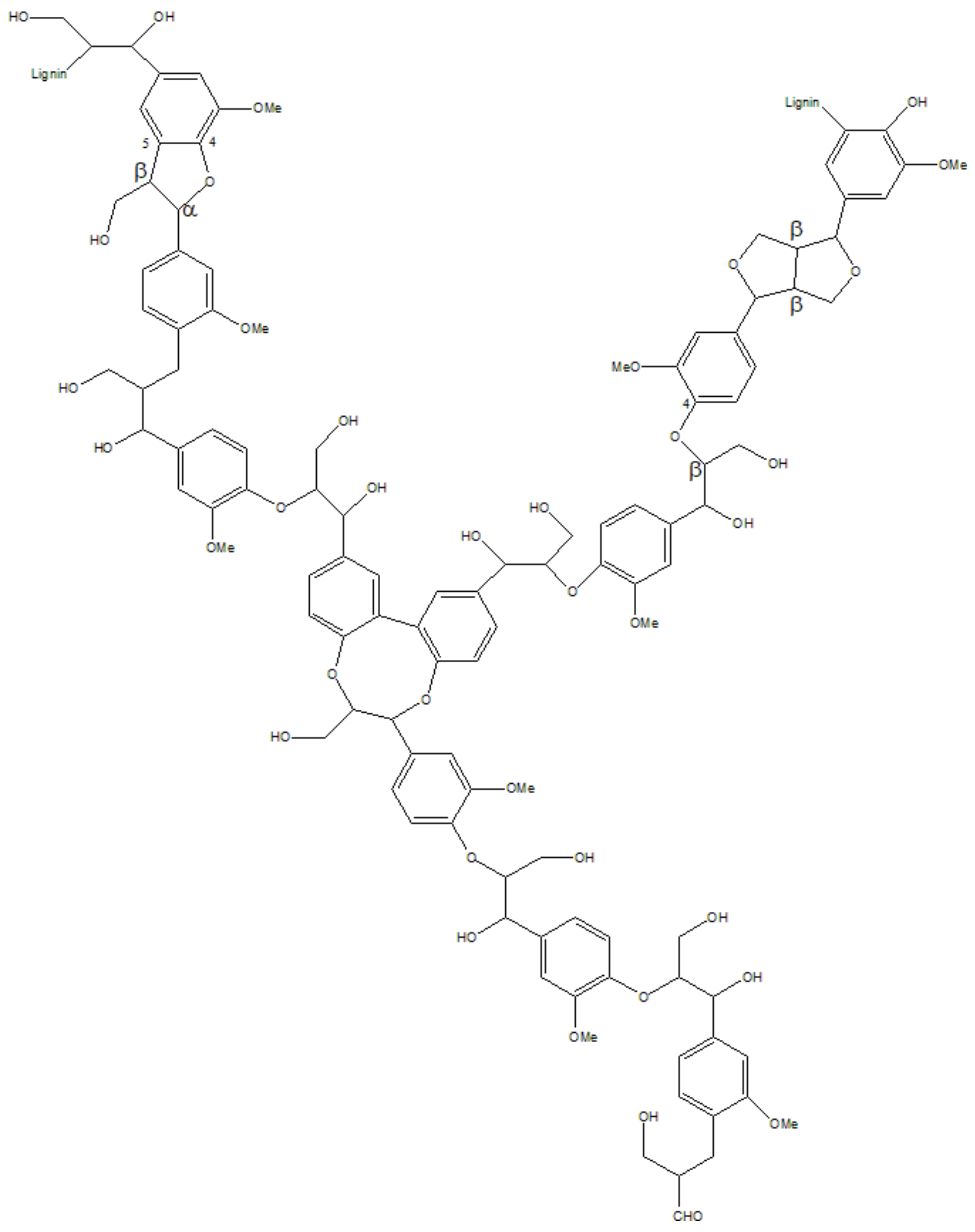

3.3. Lignin

3.4. Amino Acids

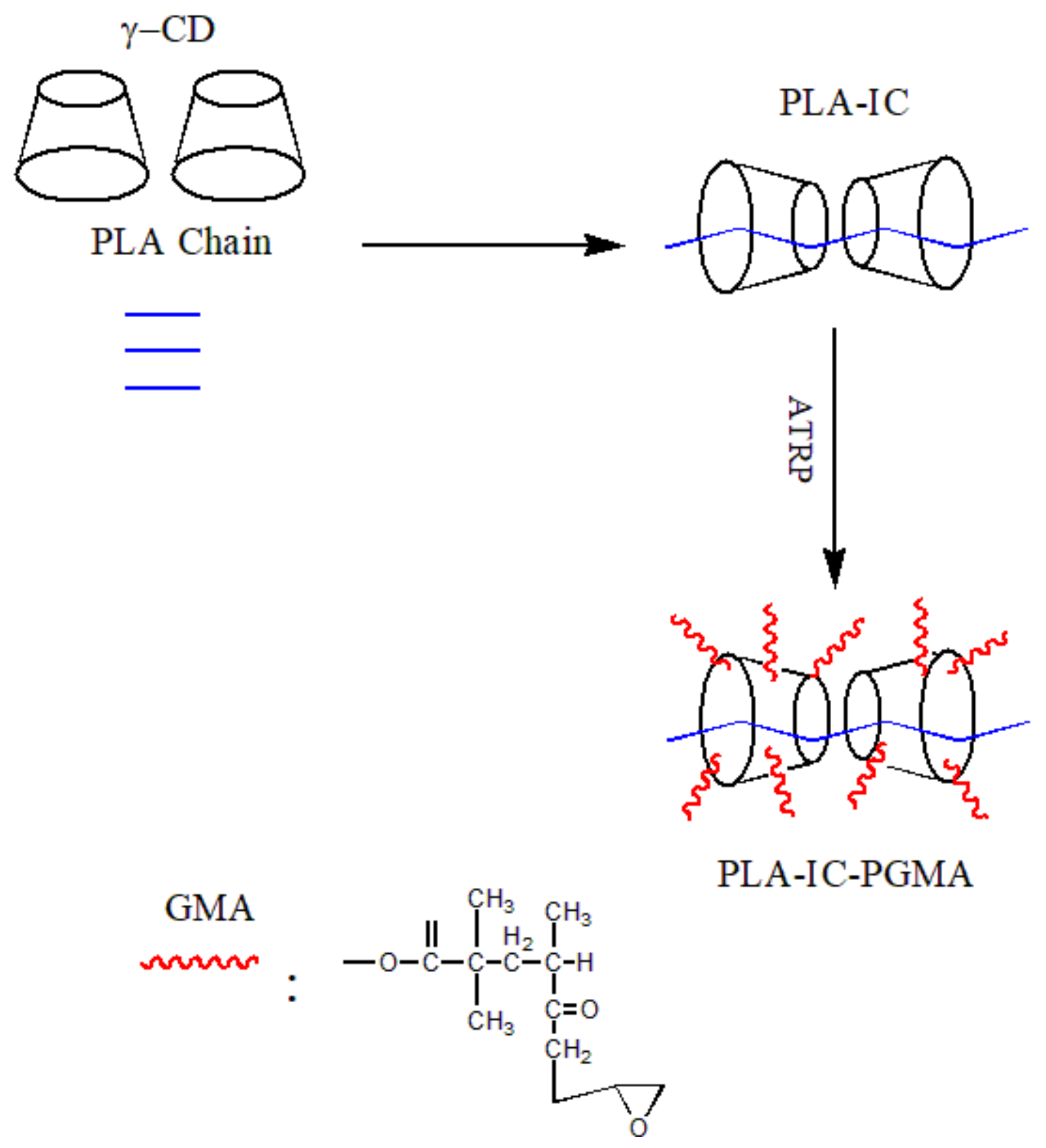

3.5. Cyclodextrin

3.6. Starch

3.7. Wood Powder

3.8. Natural Plant Fiber

4. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cesur, S.; Oktar, F.N.; Ekren, N.; Kilic, O.; Alkaya, D.B.; Seyhan, S.A.; Ege, Z.R.; Lin, C.-C.; Kuruca, S.E.; Erdemir, G.; et al. Preparation and characterization of electrospun polylactic acid/sodium alginate/orange oyster shell composite nanofiber for biomedical application. J. Aust. Ceram. Soc. 2020, 56, 533–543. [Google Scholar] [CrossRef]

- Liu, Y.; Zhan, Z.; Ye, H.; Lin, X.; Yan, Y.; Zhang, Y. Accelerated biodegradation of PLA/PHB-blended nonwovens by a microbial community. RSC Adv. 2019, 9, 10386–10394. [Google Scholar] [CrossRef] [PubMed]

- Wan, L.; Li, C.; Sun, C.; Zhou, S.; Zhang, Y. Conceiving a feasible degradation model of polylactic acid-based composites through hydrolysis study to polylactic acid/wood flour/polymethyl methacrylate. Compos. Sci. Technol. 2019, 181, 107675. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, G.; Bhat, G.S.; Azari, H.; Pen, H. Electret characteristics of melt-blown polylactic acid fabrics for air filtration application. J. Appl. Polym. Sci. 2020, 137, 48309. [Google Scholar] [CrossRef]

- Mejias, S.H.; López-Martínez, E.; Fernandez, M.; Couleaud, P.; Martin-Lasanta, A.; Romera, D.; Sanchez-Iglesias, A.; Casado, S.; Osorio, M.R.; Abad, J.M.; et al. Engineering conductive protein films through nanoscale self-assembly and gold nanoparticles doping. Nanoscale 2021, 13, 6772–6779. [Google Scholar] [CrossRef]

- Prasong, W.; Ishigami, A.; Thumsorn, S.; Kurose, T.; Ito, H. Improvement of interlayer adhesion and heat resistance of biodegradable ternary blend composite 3D printing. Polymers 2021, 13, 740. [Google Scholar] [CrossRef]

- Brounstein, Z.; Yeager, C.M.; Labouriau, A. Development of antimicrobial PLA composites for fused filament fabrication. Polymers 2021, 13, 580. [Google Scholar] [CrossRef]

- Kaavessina, M.; Ali, I.; Elleithy, R.H.; Al-Zahrani, S.M. Crystallization behavior of poly(lactic acid)/elastomer blends. J. Polym. Res. 2012, 19, 9818. [Google Scholar] [CrossRef]

- Xiao, H.; Yang, L.; Ren, X.; Jiang, T.; Yeh, J.-T. Kinetics and crystal structure of poly(lactic acid) crystallized nonisothermally: Effect of plasticizer and nucleating agent. Polym. Compos. 2010, 31, 2057–2068. [Google Scholar] [CrossRef]

- Schäfer, H.; Pretschuh, C.; Brüggemann, O. Reduction of cycle times in injection molding of PLA through bio-based nucleating agents. Eur. Polym. J. 2019, 115, 6–11. [Google Scholar] [CrossRef]

- Coppola, B.; Cappetti, N.; Maio, L.D.; Scarfato, P.; Incarnato, L. 3D printing of PLA/clay nanocomposites: Influence of printing temperature on printed samples properties. Materials 2018, 11, 1947. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, B.; Fan, B.; Sun, H.; Zhang, H. Enhanced Nonisothermal Crystallization and Heat Resistance of Poly(L-lactic acid) by D-Sorbitol as a Homogeneous Nucleating Agent. ACS Macro Lett. 2021, 10, 154–160. [Google Scholar] [CrossRef]

- Nam, J.Y.; Okamoto, M.; Okamoto, H.; Nakano, M.; Usuki, A.; Matsuda, M. Morphology and crystallization kinetics in a mixture of low-molecular weight aliphatic amide and polylactide. Polymer 2006, 47, 1340–1347. [Google Scholar] [CrossRef]

- Wei, X.-F.; Bao, R.-Y.; Cao, Z.-Q.; Yang, W.; Xie, B.-H.; Yang, M.-B. Stereocomplex Crystallite Network in Asymmetric PLLA/PDLA Blends: Formation, Structure, and Confining Effect on the Crystallization Rate of Homocrystallites. Macromolecules 2014, 47, 1439–1448. [Google Scholar] [CrossRef]

- Jin, F.-L.; Hu, R.-R.; Park, S.-J. Improvement of thermal behaviors of biodegradable poly(lactic acid) polymer: A review. Compos. Part B 2019, 164, 287–296. [Google Scholar] [CrossRef]

- Anakabe, J.; Zaldua Huici, A.M.; Eceiza, A.; Arbelaiz, A.; Avérous, L. Combined effect of nucleating agent and plasticizer on the crystallization behaviour of polylactide. Polym. Bull. 2017, 74, 4857–4886. [Google Scholar] [CrossRef]

- Zhang, J.; Tashiro, K.; Tsuji, H.; Domb, A.J. Disorder-to-Order Phase Transition and Multiple Melting Behavior of Poly(L-lactide) Investigated by Simultaneous Measurements of WAXD and DSC. Macromolecules 2008, 41, 1352–1357. [Google Scholar] [CrossRef]

- Zhang, J.; Duan, Y.; Sato, H.; Tsuji, H.; Noda, I.; Yan, S.; Ozaki, Y. Crystal Modifications and Thermal Behavior of Poly(L-lactic acid) Revealed by Infrared Spectroscopy. Macromolecules 2005, 38, 8012–8021. [Google Scholar] [CrossRef]

- Saeidlou, S.; Huneault, M.A.; Li, H.; Park, C.B. Poly(lactic acid) crystallization. Prog. Polym. Sci. 2012, 37, 1657–1677. [Google Scholar] [CrossRef]

- Pan, P.; Kai, W.; Zhu, B.; Dong, T.; Inoue, Y. Polymorphous Crystallization and Multiple Melting Behavior of Poly(L-lactide): Molecular Weight Dependence. Macromolecules 2007, 40, 6898–6905. [Google Scholar] [CrossRef]

- De Santis, P.; Kovacs, A.J. Molecular conformation of poly(S-lactic acid). Biopolymers 1968, 6, 299–306. [Google Scholar] [CrossRef]

- Kobayashi, J.; Asahi, T.; Sakurai, M.; Kagomiya, I.; Asai, H.; Asami, H. The optical activity of lysozyme crystals. Acta Crystallogr. Sect. A Found. Crystallogr. 1998, 54, 581–590. [Google Scholar] [CrossRef]

- Hoogsteen, W.; Postema, A.R.; Pennings, A.J.; Ten Brinke, G.; Zugenmaier, P. Crystal structure, conformation and morphology of solution-spun poly(L-lactide) fibers. Macromolecules 1990, 23, 634–642. [Google Scholar] [CrossRef]

- Puiggali, J.; Ikada, Y.; Tsuji, H.; Cartier, L.; Okihara, T.; Lotz, B. The frustrated structure of poly(L-lactide). Polymer 2000, 41, 8921–8930. [Google Scholar] [CrossRef]

- Cartier, L.; Okihara, T.; Ikada, Y.; Tsuji, H.; Puiggali, J.; Lotz, B. Epitaxial crystallization and crystalline polymorphism of polylactides. Polymer 2000, 41, 8909–8919. [Google Scholar] [CrossRef]

- Perić, M.; Putz, R.; Paulik, C. Influence of nanofibrillated cellulose on the mechanical and thermal properties of poly(lactic acid). Eur. Polym. J. 2019, 114, 426–433. [Google Scholar] [CrossRef]

- Trache, D.; Tarchoun, A.F.; Derradji, M.; Hamidon, T.S.; Masruchin, N.; Brosse, N.; Hussin, M.H. Nanocellulose: From fundamentals to advanced applications. Front. Chem. 2020, 8, 392. [Google Scholar] [CrossRef]

- Suryanegara, L.; Okumura, H.; Nakagaito, A.N.; Yano, H. The synergetic effect of phenylphosphonic acid zinc and microfibrillated cellulose on the injection molding cycle time of PLA composites. Cellulose 2011, 18, 689–698. [Google Scholar] [CrossRef]

- Magalhaes da Silva, S.P.; Lima, P.S.; Oliveira, J.M. Non-isothermal crystallization kinetics of cork-polymer composites for injection molding. J. Appl. Polym. Sci. 2016, 133, 44124. [Google Scholar] [CrossRef]

- Magalhaes da Silva, S.P.; Silva, M.A.; Oliveira, J.M. Non-isothermal cold crystallization kinetics of cork–polymer biocomposites based on polylactic acid for fused filament fabrication. J. Therm. Anal. Calorim. 2021, 146, 1667–1678. [Google Scholar] [CrossRef]

- Lobos, J.; Iasella, S.; Rodriguez-Perez, M.A.; Velankar, S.S. Improving the stability of polylactic acid foams by interfacially adsorbed particles. Polym. Eng. Sci. 2016, 56, 9–17. [Google Scholar] [CrossRef]

- Yeul, V.S.; Rayalu, S.S. Unprecedented Chitin and Chitosan: A Chemical Overview. J. Polym. Environ. 2013, 21, 606–614. [Google Scholar] [CrossRef]

- Hijazi, N.; Le Moigne, N.; Rodier, E.; Sauceau, M.; Vincent, T.; Benezet, J.-C.; Fages, J. Biocomposite films based on poly(lactic acid) and chitosan nanoparticles: Elaboration, microstructural and thermal characterization. Polym. Eng. Sci. 2019, 59, E350–E360. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, Y.; Wang, K.; Zheng, G.; Li, Q.; Shen, C. Crystallization of poly(lactic acid) accelerated by cyclodextrin complex as nucleating agent. Polym. Bull. 2013, 70, 195–206. [Google Scholar] [CrossRef]

- Li, S.; Xiong, Z.; Fei, P.; Cai, J.; Xiong, H.; Tan, J.; Yu, Y. Parameters characterizing the kinetics of the nonisothermal crystallization of thermoplastic starch/poly(lactic acid) composites as determined by differential scanning calorimetry. J. Appl. Polym. Sci. 2013, 129, 3566–3573. [Google Scholar] [CrossRef]

- Boruvka, M.; Behalek, L.; Lenfeld, P.; Ngaowthong, C.; Pechociakova, M. Structure-related properties of bionanocomposites based on poly(lactic acid), cellulose nanocrystals and organic impact modifier. Mater. Technol. 2019, 34, 143–156. [Google Scholar] [CrossRef]

- Shazleen, S.S.; Yasim-Anuar, T.A.T.; Ibrahim, N.A.; Hassan, M.A.; Ariffin, H. Functionality of cellulose nanofiber as bio-based nucleating agent and nano-reinforcement material to enhance crystallization and mechanical properties of polylactic acid nanocomposite. Polymers 2021, 13, 389. [Google Scholar] [CrossRef]

- Gupta, A.; Simmons, W.; Schueneman, G.T.; Mintz, E.A. Lignin-coated cellulose nanocrystals as promising nucleating agent for poly(lactic acid). J. Therm. Anal. Calorim. 2016, 126, 1243–1251. [Google Scholar] [CrossRef]

- Shi, H.; Chen, X.; Chen, W.; Pang, S.; Pan, L.; Xu, N.; Li, T. Crystallization behavior, heat resistance, and mechanical performances of PLLA/myo-inositol blends. J. Appl. Polym. Sci. 2017, 134, 44732. [Google Scholar] [CrossRef]

- Pan, P.; Yang, J.; Shan, G.; Bao, Y.; Weng, Z.; Inoue, Y. Nucleation effects of nucleobases on the crystallization kinetics of Poly(L-lactide). Macromol. Mater. Eng. 2012, 297, 670–679. [Google Scholar] [CrossRef]

- Fundador, N.G.V.; Enomoto-Rogers, Y.; Takemura, A.; Iwata, T. Xylan esters as bio-based nucleating agents for poly (l-lactic acid). Polym. Degrad. Stab. 2013, 98, 1064–1071. [Google Scholar] [CrossRef]

- Yang, W.; Fortunati, E.; Dominici, F.; Kenny, J.M.; Puglia, D. Effect of processing conditions and lignin content on thermal, mechanical and degradative behavior of lignin nanoparticles/polylactic (acid) bionanocomposites prepared by melt extrusion and solvent casting. Eur. Polym. J. 2015, 71, 126–139. [Google Scholar] [CrossRef]

- Wu, W.; Wu, G.; Zhang, H. Effect of wood flour as nucleating agent on the isothermal crystallization of poly(lactic acid). Polym. Adv. Technol. 2017, 28, 252–260. [Google Scholar] [CrossRef]

- Clarkson, C.M.; El Awad Azrak, S.M.; Schueneman, G.T.; Snyder, J.F.; Youngblood, J.P. Crystallization kinetics and morphology of small concentrations of cellulose nanofibrils (CNFs) and cellulose nanocrystals (CNCs) melt-compounded into poly(lactic acid) (PLA) with plasticizer. Polymer 2020, 187, 122101. [Google Scholar] [CrossRef]

- Wei, Z.; Shao, S.; Sui, M.; Song, P.; He, M.; Xu, Q.; Leng, X.; Wang, Y.; Li, Y. Development of zinc salts of amino acids as a new class of biocompatible nucleating agents for poly(L-lactide). Eur. Polym. J. 2019, 118, 337–346. [Google Scholar] [CrossRef]

- Kang, K.S.; Lee, S.I.; Lee, T.J.; Narayan, R.; Shin, B.Y. Effect of bio-based and biodegradable nucleating agent on the isothermal crystallization of poly(lactic acid). Korean J. Chem. Eng. 2008, 25, 599–608. [Google Scholar] [CrossRef]

- Deetuam, C.; Samthong, C.; Choksriwichit, S.; Somwangthanaroj, A. Isothermal cold crystallization kinetics and properties of thermoformed poly(lactic acid) composites: Effects of talc, calcium carbonate, cassava starch and silane coupling agents. Iran. Polym. J. 2020, 29, 103–116. [Google Scholar] [CrossRef]

- Peng, Y.; Gardner, D.J.; Han, Y.; Cai, Z.; Tshabalala, M.A. Influence of drying method on the surface energy of cellulose nanofibrils determined by inverse gas chromatography. J. Colloid Interface Sci. 2013, 405, 85–95. [Google Scholar] [CrossRef]

- Yetiş, F.; Liu, X.; Sampson, W.W.; Gong, R.H. Acetylation of lignin containing microfibrillated cellulose and its reinforcing effect for polylactic acid. Eur. Polym. J. 2020, 134, 109803. [Google Scholar] [CrossRef]

- Shen, F.; Ling, H.; Ge, W.; Yang, Y.; Wang, X.; Ren, J.; Wang, X. Self-assembly behavior and conformation of amphiphilic hemicellulose-graft-fatty acid micelles. Carbohydr. Polym. 2021, 261, 117886. [Google Scholar] [CrossRef]

- Fundador, N.G.V.; Iwata, T. Enhanced crystallization of poly(d-lactide) by xylan esters. Polym. Degrad. Stab. 2013, 98, 2482–2487. [Google Scholar] [CrossRef]

- Tanase-Opedal, M.; Espinosa, E.; Rodríguez, A.; Chinga-Carrasco, G. Lignin: A biopolymer from forestry biomass for biocomposites and 3D printing. Materials 2019, 12, 3006. [Google Scholar] [CrossRef]

- Hossain, M.M.; Aldous, L. Ionic Liquids for Lignin Processing: Dissolution, Isolation, and Conversion. Aust. J. Chem. 2012, 65, 1465–1477. [Google Scholar] [CrossRef]

- Zhao, W.; Simmons, B.; Singh, S.; Ragauskas, A.; Cheng, G. From lignin association to nano-/micro-particle preparation: Extracting higher value of lignin. Green Chem. 2016, 18, 5693–5700. [Google Scholar] [CrossRef]

- Grossman, A.; Vermerris, W. Lignin-based polymers and nanomaterials. Curr. Opin. Biotechnol. 2019, 56, 112–120. [Google Scholar] [CrossRef]

- Ragauskas, A.J.; Beckham, G.T.; Biddy, M.J.; Chandra, R.; Chen, F.; Davis, M.F.; Davison, B.H.; Dixon, R.A.; Gilna, P.; Keller, M.; et al. Lignin Valorization: Improving Lignin Processing in the Biorefinery. Science 2014, 344, 1246843. [Google Scholar] [CrossRef]

- Frangville, C.; Rutkevičius, M.; Richter, A.P.; Velev, O.D.; Stoyanov, S.D.; Paunov, V.N. Fabrication of Environmentally Biodegradable Lignin Nanoparticles. ChemPhysChem 2012, 13, 4235–4243. [Google Scholar] [CrossRef]

- Kovalcik, A.; Pérez-Camargo, R.A.; Fürst, C.; Kucharczyk, P.; Müller, A.J. Nucleating efficiency and thermal stability of industrial non-purified lignins and ultrafine talc in poly(lactic acid) (PLA). Polym. Degrad. Stab. 2017, 142, 244–254. [Google Scholar] [CrossRef]

- Liu, R.; Dai, L.; Hu, L.-Q.; Zhou, W.-Q.; Si, C.-L. Fabrication of high-performance poly(L-lactic acid)/lignin-graft-poly(D-lactic acid) stereocomplex films. Mater. Sci. Eng. C 2017, 80, 397–403. [Google Scholar] [CrossRef]

- Sun, Y.; Yang, L.; Lu, X.; He, C. Biodegradable and renewable poly(lactide)–lignin composites: Synthesis, interface and toughening mechanism. J. Mater. Chem. A 2015, 3, 3699–3709. [Google Scholar] [CrossRef]

- Kumar Singla, R.; Maiti, S.N.; Ghosh, A.K. Crystallization, Morphological, and Mechanical Response of Poly(Lactic Acid)/Lignin-Based Biodegradable Composites. Polym.-Plast. Technol. Eng. 2016, 55, 475–485. [Google Scholar] [CrossRef]

- Carbone, M.J.; Vanhalle, M.; Goderis, B.; Van Puyvelde, P. Amino acids and poly(amino acids) as nucleating agents for poly(lactic acid). J. Polym. Eng. 2015, 35, 169–180. [Google Scholar] [CrossRef]

- Sasaki, S.; Asakura, T. Helix Distortion and Crystal Structure of the α-Form of Poly(L-lactide). Macromolecules 2003, 36, 8385–8390. [Google Scholar] [CrossRef]

- Dalosto, S.D.; Ferreyra, M.G.; Calvo, R.; Piro, O.E.; Castellano, E.E. Structure of bis(L-alaninato)zinc(II) and single crystal EPR spectra of Cu(II) impurities. J. Inorg. Biochem. 1999, 73, 151–155. [Google Scholar] [CrossRef]

- Vargová, Z.; Almáši, M.; Arabuli, L.; Györyová, K.; Zeleňák, V.; Kuchár, J. Utilization of IR spectral detailed analysis for coordination mode determination in novel Zn–cyclen–aminoacid complexes. Spectrochim. Acta Part A 2011, 78, 788–793. [Google Scholar] [CrossRef]

- Ng, C.-H.; Fun, H.-K.; Teo, S.-B.; Teoh, S.-G.; Chinnakali, K. Bis(L-prolinato-N,O)zinc(II). Acta Crystallogr. Sect. C Cryst. Struct. Commun. 1995, 51, 244–245. [Google Scholar] [CrossRef]

- Bognanni, N.; Bellia, F.; Viale, M.; Bertola, N.; Vecchio, G. Exploring charged polymeric cyclodextrins for biomedical applications. Molecules 2021, 26, 1724. [Google Scholar] [CrossRef]

- Li, Y.; Zhen, W. Preparation, structure and performance of poly(lactic acid)/poly(lactic acid)-γ-cyclodextrin inclusion complex-poly(glycidyl methacrylate) composites. Macromol. Res. 2018, 26, 215–225. [Google Scholar] [CrossRef]

- Jullanun, P.; Yoksan, R. Morphological characteristics and properties of TPS/PLA/cassava pulp biocomposites. Polym. Test. 2020, 88, 106522. [Google Scholar] [CrossRef]

- Borhan, A.; Taib, R.M. Non-isothermal crystallization kinetics of poly(lactic acid)/kenaf fiber composites. Sains Malays. 2020, 49, 2169–2185. [Google Scholar] [CrossRef]

- Xu, H.; Liu, C.-Y.; Chen, C.; Hsiao, B.S.; Zhong, G.-J.; Li, Z.-M. Easy alignment and effective nucleation activity of ramie fibers in injection-molded poly(lactic acid) biocomposites. Biopolymers 2012, 97, 825–839. [Google Scholar] [CrossRef]

| Crystal Form | Crystal System | Chain Conformation | Cell Parameters | |||||

|---|---|---|---|---|---|---|---|---|

| a (nm) | b (nm) | c (nm) | α (°) | β (°) | γ (°) | |||

| α [21] | Pseudo-orthorhombic | 103 helical | 1.07 | 0.645 | 2.78 | 90 | 90 | 90 |

| α [22] | Orthorhombic | 103 helical | 1.05 | 0.61 | 2.88 | 90 | 90 | 90 |

| β [23] | Orthorhombic | 31 helical | 1.031 | 1.821 | 0.90 | 90 | 90 | 90 |

| β [24] | Trigonal | 31 helical | 1.052 | 1.052 | 0.88 | 90 | 90 | 120 |

| γ [25] | Orthorhombic | 31 helical | 0.995 | 0.625 | 0.88 | 90 | 90 | 90 |

| Sample * | Tc (°C) | Tcc (°C) | Tm (°C) | Xc (%) | t1/2 ** (min) | Mw (g/mol) | Mn (g/mol) | PDI *** | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| PLA 2500HP | 94.6 | 95.6 | 176.6 | 25.3 | - | 10,812 | 6939 | 1.56 | [12] |

| 0.7%DS | 110.2 | - | 177.5 | 51.4 | - | 10,812 | 6939 | 1.56 | [12] |

| PLA 3251D | 97 | 106 | 169 | 4.4 | - | 83,000 | 51,875 | 1.6 | [36] |

| 1%CNC | 93 | 100 | 169 | 14.5 | - | 83,000 | 51,875 | 1.6 | [36] |

| PLA 2003D | 106.1 | 91.3 | 152.1 | 2.3 | 92.72 | 165,189 | 76,066 | 2.17 | [37] |

| 3%CNF | 114.6 | 71.0 | 147.1 | 44.2 | 1.40 | 165,189 | 76,066 | 2.17 | [37] |

| PLA 4043D | - | 129.3 | 151.5 | 5.8 | 3.02 | - | - | - | [38] |

| 0.3%L-CNCs | - | 112.5 | 146.6 | 40.0 | 1.36 | - | - | - | [38] |

| PLA 4032D | 96.7 | - | 168.2 | 36.9 | 7.90 | 188,000 | 98,000 | 1.92 | [39] |

| 2% Myo-inositol | 137.3 | - | 166.2 | 40.0 | 2.69 | 188,000 | 98,000 | 1.92 | [39] |

| PLA Shimadzu | - | 115.5 | 169 | 45.8 | 16.8 | 186,340 | 121,000 | 1.54 | [40] |

| 1%Uracil | 122.4 | - | 164.9 | 53.8 | 1.02 | 186,340 | 121,000 | 1.54 | [40] |

| PLA Shimadzu | - | 125 | 176 | 18.1 | 10.2 | 270,000 | 160,000 | 1.8 | [41] |

| 1%XylPr | - | 97 | 171 | 35.6 | 6.9 | 270,000 | 160,000 | 1.8 | [41] |

| PLA 3251D | - | 100.3 | 169.3 | 15.0 | - | - | - | - | [42] |

| 1%LNP | - | 100.3 | 168.1 | 22.5 | - | - | - | [42] | |

| PLA 4032D | - | 114.6 | 160.7 | 11.5 | 17.4 | - | - | - | [43] |

| 4%WF | - | 102.8 | 160.3 | 15.7 | 2.8 | - | - | - | [43] |

| Nonisothermal Crystallization | Isothermal Crystallization | |||||||

|---|---|---|---|---|---|---|---|---|

| Sample * | Tc (°C) | Tcc (°C) | Heating/Cooling Rate (°C/min) | Xc (%) | t1/2 (min) | K ** (min−n) | n *** | Ref. |

| PLA | - | 104 | 5 | - | 11 | 3.55 × 10−3 | 2.2 | [34] |

| 2%PLA-IC | 94.5 | - | 5 | - | 4.46 | 3.00 × 10−2 | 2.1 | [34] |

| PLA 2003D | 106.1 | 91.3 | 2 | 2.3 | 92.72 | 2.83 × 10−6 | 2.74 | [37] |

| 3%CNF | 114.6 | 71.0 | 2 | 44.2 | 1.40 | 2.45 × 10−1 | 3.11 | [37] |

| PLA 4043D | - | 129.3 | 10 | 5.8 | 3.02 | 1.53 × 10−1 | 1.5 | [38] |

| 0.3%L-CNCs | - | 112.5 | 10 | 40.0 | 1.36 | 3.18 × 10−1 | 1.6 | [38] |

| PLA Shimadzu | - | 125 | 20 | 18.1 | 10.2 | - | - | [41] |

| 1%XylPr | - | 97 | 20 | 35.6 | 6.9 | - | - | [41] |

| PLA 4032D | - | 114.6 | 10 | 11.5 | 17.4 | 2.3 × 10−4 | 2.8 | [43] |

| 4%WF | - | 102.8 | 10 | 15.7 | 2.8 | 4.3 × 10−2 | 2.7 | [43] |

| PLA 4032D | - | 105.3 | 10 | - | 1.66 | 1.61 × 10−1 | 2.9 | [44] |

| 0.05 CNCS | - | 88.0 | 10 | - | 1.16 | 4.36 × 10−1 | 2.7 | [44] |

| PLA SUPLA | - | 98 | 10 | 8.5 | 35.2 | 1.8 × 10−3 | 1.8 | [45] |

| 1%Zn(D-Phe)2 | 130 | - | 10 | 56 | 1.8 | 5.9 × 10−1 | 3.0 | [45] |

| PLA 4032D | - | 129 | 20 | 2.4 | 24.7 | 4.2 × 10−4 | 2.0 | [46] |

| 1%CMPS | - | 113 | 20 | 30.1 | 3.6 | 2.4 × 10−3 | 2.8 | [46] |

| PLA 2003D | - | 125.9 | 10 | 3.3 | 4.6 | 5.43 × 10−3 | 2.9 | [47] |

| 5%Starch | - | 118.2 | 10 | 6.2 | 3.7 | 4.5 × 10−3 | 3.5 | [47] |

| Material | Temperature (°C) | Surface Energy (mJ/m2) |

|---|---|---|

| CNC [48] | 30 | 46.5–66.9 |

| 60 | 37.3–48.8 | |

| CNF [48] | 30 | 44.3–52.5 |

| 60 | 39–44.7 |

| Sample | Crystal System | Cell Parameters | |||||

|---|---|---|---|---|---|---|---|

| a (nm) | b (nm) | c (nm) | α (°) | β (°) | γ (°) | ||

| PLLA [63] | Orthorhombic | 1.066 | 0.616 | 2.888 | 90 | 90 | 90 |

| Zn(L-Ala)2 [64] | Monoclinic | 0.864 | 0.533 | 0.958 | 90 | 90.36 | 90 |

| Zn(L-Pro)2 [65] | Monoclinic | 0.961 | 0.565 | 1.049 | 90 | 91.63 | 90 |

| Zn(L-Phe)2 [66] | Monoclinic | 0.563 | 3.188 | 0.952 | 90 | 90.07 | 90 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, K.; Liu, G.; Sun, H.; Yang, B.; Weng, Y. Effect of Biomass as Nucleating Agents on Crystallization Behavior of Polylactic Acid. Polymers 2022, 14, 4305. https://doi.org/10.3390/polym14204305

Shi K, Liu G, Sun H, Yang B, Weng Y. Effect of Biomass as Nucleating Agents on Crystallization Behavior of Polylactic Acid. Polymers. 2022; 14(20):4305. https://doi.org/10.3390/polym14204305

Chicago/Turabian StyleShi, Kang, Guoshuai Liu, Hui Sun, Biao Yang, and Yunxuan Weng. 2022. "Effect of Biomass as Nucleating Agents on Crystallization Behavior of Polylactic Acid" Polymers 14, no. 20: 4305. https://doi.org/10.3390/polym14204305

APA StyleShi, K., Liu, G., Sun, H., Yang, B., & Weng, Y. (2022). Effect of Biomass as Nucleating Agents on Crystallization Behavior of Polylactic Acid. Polymers, 14(20), 4305. https://doi.org/10.3390/polym14204305