Preparation and Characterization of Electrospun PAN-CuCl2 Composite Nanofiber Membranes with a Special Net Structure for High-Performance Air Filters

Abstract

:1. Introduction

2. Materials and Methods

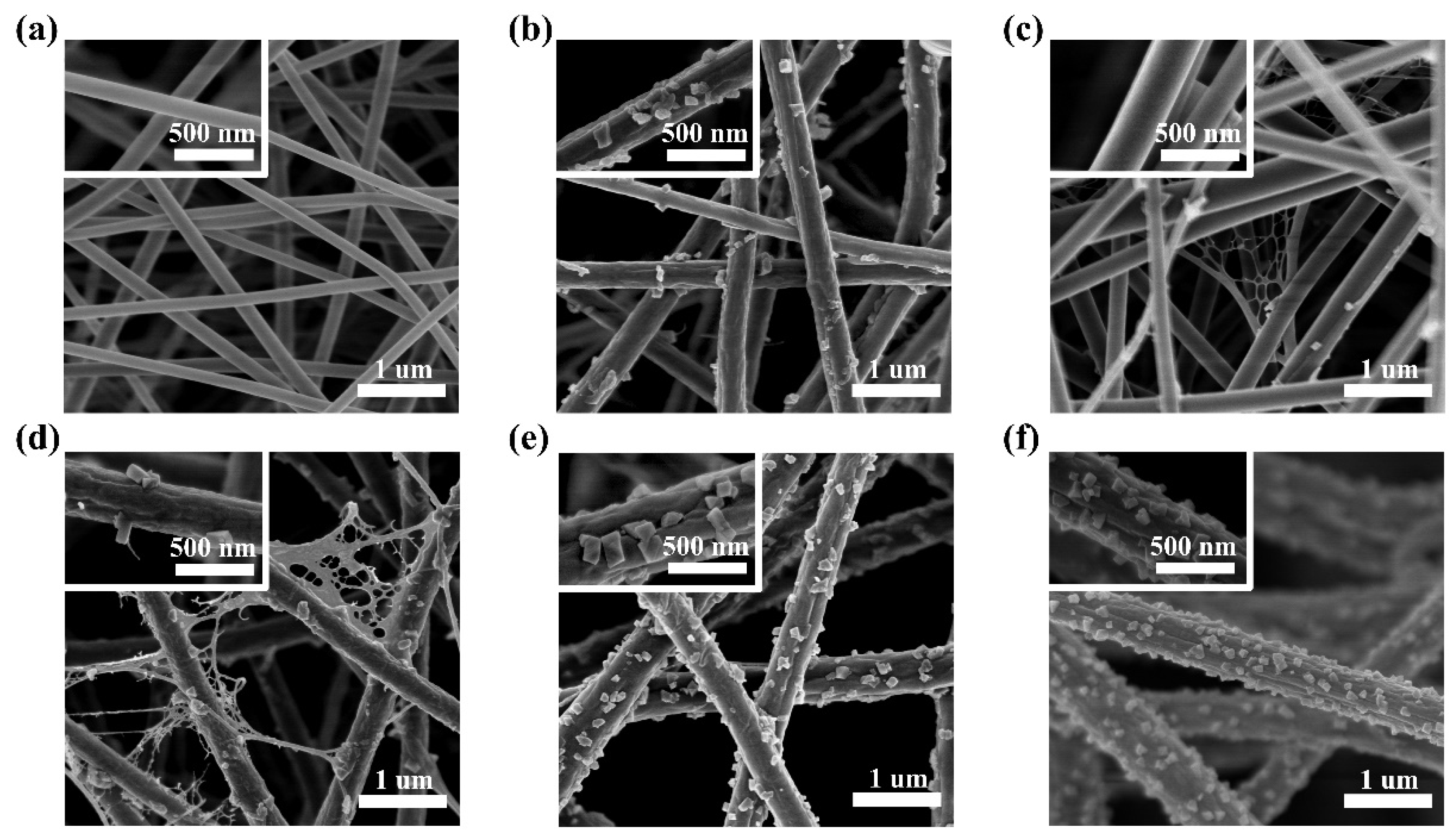

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, R.; Zhang, H.; Wang, M.; Zhang, X.; Gan, Z. Thermoplastic Polyurethane Nanofiber Membrane Based Air Filters for Efficient Removal of Ultrafine Particulate Matter PM0.1. ACS Appl. Nano Mater. 2020, 4, 182–189. [Google Scholar] [CrossRef]

- Jazie, A.A.; Albaaji, A.J.; Abed, S.A. A Review on Recent Trends of Antiviral Nanoparticles and Airborne Filters: Special Insight on COVID-19 Virus. Air Qual. Atmos. Health 2021, 14, 1811–1824. [Google Scholar] [CrossRef] [PubMed]

- Essa, W.; Yasin, S.; Saeed, I.; Ali, G. Nanofiber-Based Face Masks and Respirators as COVID-19 Protection: A Review. Membranes 2021, 11, 250. [Google Scholar] [CrossRef] [PubMed]

- Sanyal, A.; Sinha-Ray, S. Ultrafine PVDF Nanofibers for Filtration of Air-Borne Particulate Matters: A Comprehensive Review. Polymers 2021, 13, 1864. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Liu, Y.; Zhang, M.; Feng, Z.; Yu, D.-G.; Wang, K. Electrospun Nanofiber Membranes for Air Filtration: A Review. Nanomaterials 2022, 12, 1077. [Google Scholar] [CrossRef]

- Valencia-Osorio, L.M.; Álvarez-Láinez, M.L. Global View and Trends in Electrospun Nanofiber Membranes for Particulate Matter Filtration: A Review. Macromol. Mater. Eng. 2021, 306, 2100278. [Google Scholar] [CrossRef]

- Maliszewska, I.; Czapka, T. Electrospun Polymer Nanofibers with Antimicrobial Activity. Polymers 2022, 14, 1661. [Google Scholar] [CrossRef]

- Wahed, F.; Shah, S.S.; Hayat, K.; Shah, S.K.; Aziz, A. Conduction Mechanisms and Thermoelectric Applications of La1−xSrxCoO3 Nanofibers. J. Mater. Sci. 2022, 57, 8828–8844. [Google Scholar] [CrossRef]

- Han, W.-H.; Li, X.; Yu, G.-F.; Wang, B.-C.; Huang, L.-P.; Wang, J.; Long, Y.-Z. Recent Advances in the Food Application of Electrospun Nanofibers. J. Ind. Eng. Chem. 2022, 110, 15–26. [Google Scholar] [CrossRef]

- Liu, X.; Wu, A.; Xiong, L.; Yang, Y.; Gao, J.; Li, W.; Liu, Y. Electrospinning Preparation and Adsorption Properties of La2O3 Nanofibers and Photoluminescence Properties of La2O3: Eu Nanofibers. J. Photochem. Photobiol. A Chem. 2022, 431, 114010. [Google Scholar] [CrossRef]

- Sundarrajan, S.; Tan, K.L.; Lim, S.H.; Ramakrishna, S. Electrospun Nanofibers for Air Filtration Applications. Procedia Eng. 2014, 75, 159–163. [Google Scholar] [CrossRef] [Green Version]

- Wang, N.; Wang, X.; Ding, B.; Yu, J.; Sun, G. Tunable Fabrication of Three-Dimensional Polyamide-66 Nano-Fiber/Nets for High Efficiency Fine Particulate Filtration. J. Mater. Chem. 2011, 22, 1445–1452. [Google Scholar] [CrossRef]

- Kenry; Lim, C.T. Nanofiber Technology: Current Status and Emerging Developments. Prog. Polym. Sci. 2017, 70, 1–17. [Google Scholar] [CrossRef]

- Xue, J.; Xie, J.; Liu, W.; Xia, Y. Electrospun Nanofibers: New Concepts, Materials, and Applications. Acc. Chem. Res. 2017, 50, 1976–1987. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Zhang, X.W.; Wang, P.J.; Chen, R.W.; Gu, G.W.; Hu, S.Q.; Tian, R.Y. Laminated Polyacrylonitrile Nanofiber Membrane Codoped with Boehmite Nanoparticles for Efficient Electrostatic Capture of Particulate Matters. Nanotechnology 2021, 32, 235601. [Google Scholar] [CrossRef] [PubMed]

- Lakshmanan, A.; Gavali, D.S.; Venkataprasanna, K.; Thapa, R.; Sarkar, D. Low-Basis Weight Polyacrylonitrile/Polyvinylpyrrolidone Blend Nanofiber Membranes for Efficient Particulate Matter Capture. ACS Appl. Polym. Mater. 2022, 4, 3971–3981. [Google Scholar] [CrossRef]

- Bui, T.T.; Shin, M.K.; Jee, S.Y.; Long, D.X.; Hong, J.; Kim, M.-G. Ferroelectric PVDF Nanofiber Membrane for High-Efficiency PM0.3 Air Filtration with Low Air Flow Resistance. Colloids Surfaces A Physicochem. Eng. Asp. 2022, 640, 128418. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, S.; Liu, L.; Yu, J.; Ding, B. High-Performance PM0.3 Air Filters Using Self-Polarized Electret Nanofiber/Nets. Adv. Funct. Mater. 2020, 30, 1909554. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, S.; Liu, L.; Yu, J.; Ding, B. A Fluffy Dual-Network Structured Nanofiber/Net Filter Enables High-Efficiency Air Filtration. Adv. Funct. Mater. 2019, 29, 1904108. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, H.; Tang, N.; Zhou, S.; Yu, J.; Ding, B. Spider-Web-Inspired PM0.3 Filters Based on Self-Sustained Electrostatic Nanostructured Networks. Adv. Mater. 2020, 32, e2002361. [Google Scholar] [CrossRef]

- Zuo, F.; Zhang, S.; Liu, H.; Fong, H.; Yin, X.; Yu, J.; Ding, B. Free-Standing Polyurethane Nanofiber/Nets Air Filters for Effective PM Capture. Small 2017, 13, 1702139. [Google Scholar] [CrossRef] [PubMed]

- Chen, R.; Zhang, X.; Wang, P.; Xie, K.; Jian, J.; Zhang, Y.; Zhang, J.; Yuan, Y.; Na, P.; Yi, M.; et al. Transparent Thermoplastic Polyurethane Air Filters for Efficient Electrostatic Capture of Particulate Matter Pollutants. Nanotechnology 2018, 30, 015703. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Zhao, C.; Pan, Z. Porous Bead-on-String Poly(Lactic Acid) Fibrous Membranes for Air Filtration. J. Colloid Interface Sci. 2015, 441, 121–129. [Google Scholar] [CrossRef] [PubMed]

- Zampetti, E.; Bearzotti, A.; Macagnano, A. Flexible Piezoelectric Transducer Based on Electrospun PVDF Nanofibers for Sensing Applications. Procedia Eng. 2014, 87, 1509–1512. [Google Scholar] [CrossRef] [Green Version]

- Zong, X.; Kim, K.; Fang, D.; Ran, S.; Hsiao, B.S.; Chu, B. Structure and Process Relationship of Electrospun Bioabsorbable Nanofiber Membranes. Polymer 2002, 43, 4403–4412. [Google Scholar] [CrossRef]

- Reyes, C.G.; Lagerwall, J.P.F. Disruption of Electrospinning due to Water Condensation into the Taylor Cone. ACS Appl. Mater. Interfaces 2020, 12, 26566–26576. [Google Scholar] [CrossRef]

- Walther, M.; Rohde, F.; Kielholz, T.; Windbergs, M. Physico-Chemical Analysis of Electrospun Fibers—A Systematic Approach. Eur. J. Pharm. Biopharm. 2022, 171, 60–71. [Google Scholar] [CrossRef]

- Wang, C.; Hashimoto, T.; Wang, Y.; Lai, H.-Y.; Kuo, C.-H. Formation of Dissipative Structures in the Straight Segment of Electrospinning Jets. Macromolecules 2020, 53, 7876–7886. [Google Scholar] [CrossRef]

- Chen, G.; Lai, H.; Lu, P.; Chang, Y.; Wang, C. Light Scattering of Electrospinning Jet with Internal Structures by Flow-Induced Phase Separation. Macromol. Rapid Commun. 2022, 2200273. [Google Scholar] [CrossRef]

- Yang, S.; Wang, X.; Ding, B.; Yu, J.; Qian, J.; Sun, G. Controllable Fabrication of Soap-Bubble-Like Structured Polyacrylic Acid Nano-Nets via Electro-Netting. Nanoscale 2010, 3, 564–568. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, H.; Yin, X.; Li, Z.; Yu, J.; Ding, B. Tailoring Mechanically Robust Poly(m-phenylene isophthalamide) Nanofiber/nets for Ultrathin High-Efficiency Air Filter. Sci. Rep. 2017, 7, 40550. [Google Scholar] [CrossRef] [Green Version]

- Wang, T.; Chen, Y.; Dong, W.; Liu, Y.; Shi, L.; Chen, R.; Pan, T. Fractal Characteristics of Porosity of Electrospun Nanofiber Membranes. Math. Probl. Eng. 2020, 2020, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Tang, M.; Hu, J.; Liang, Y.; Pui, D.Y. Pressure Drop, Penetration and Quality Factor of Filter Paper Containing Nanofibers. Text. Res. J. 2016, 87, 498–508. [Google Scholar] [CrossRef]

- Tornello, P.R.C.; Caracciolo, P.C.; Roselló, J.I.I.; Abraham, G.A. Electrospun Scaffolds with Enlarged Pore Size: Porosimetry Analysis. Mater. Lett. 2018, 227, 191–193. [Google Scholar] [CrossRef]

- Woudberg, S.; Theron, F.; Lys, E.; Le Coq, L. Investigating the Influence of Local Porosity Variations and Anisotropy Effects on the Permeability of Fibrous Media for Air Filtration. Chem. Eng. Sci. 2018, 180, 70–78. [Google Scholar] [CrossRef]

- Amin, A.; Merati, A.A.; Bahrami, S.H.; Bagherzadeh, R. Effects of Porosity Gradient of Multilayered Electrospun Nanofibre Mats on Air Filtration Efficiency. J. Text. Inst. 2016, 1, 1–9. [Google Scholar] [CrossRef]

- Zhu, M.; Han, J.; Wang, F.; Shao, W.; Xiong, R.; Zhang, Q.; Pan, H.; Yang, Y.; Samal, S.K.; Zhang, F.; et al. Electrospun Nanofibers Membranes for Effective Air Filtration. Macromol. Mater. Eng. 2016, 302, 1600353. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, S.; Zheng, Z.; Tian, Y.; Zhang, H.; Wang, M.; Yu, Z.; Zhang, X. Preparation and Characterization of Electrospun PAN-CuCl2 Composite Nanofiber Membranes with a Special Net Structure for High-Performance Air Filters. Polymers 2022, 14, 4387. https://doi.org/10.3390/polym14204387

Hu S, Zheng Z, Tian Y, Zhang H, Wang M, Yu Z, Zhang X. Preparation and Characterization of Electrospun PAN-CuCl2 Composite Nanofiber Membranes with a Special Net Structure for High-Performance Air Filters. Polymers. 2022; 14(20):4387. https://doi.org/10.3390/polym14204387

Chicago/Turabian StyleHu, Shiqian, Zida Zheng, Ye Tian, Huihong Zhang, Mao Wang, Zhongwei Yu, and Xiaowei Zhang. 2022. "Preparation and Characterization of Electrospun PAN-CuCl2 Composite Nanofiber Membranes with a Special Net Structure for High-Performance Air Filters" Polymers 14, no. 20: 4387. https://doi.org/10.3390/polym14204387