The Physicochemical Characterization of New “Green” Epoxy-Resin Hardener Made from PET Waste

Abstract

1. Introduction

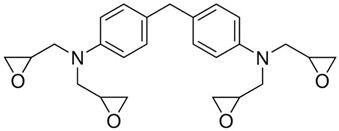

2. Materials and Methods

2.1. Materials

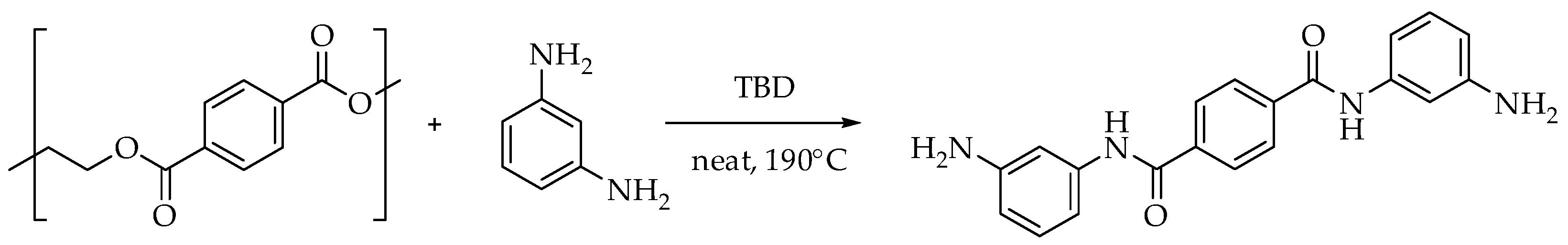

2.1.1. N1,N4-bis(3-aminophenyl)terephthalamide (MPD-TPA-MPD) Hardener Synthesis from PET Waste

2.1.2. N1,N4-bis(3-aminophenyl)terephthalamide (MPD-TPA-MPD) Hardener Synthesis from PET Waste Using Methanol and Water

2.2. Epoxy Matrices Preparation

2.3. Methods

3. Results

3.1. MPD-TPA-MPD Hardener Synthesis from PET Waste

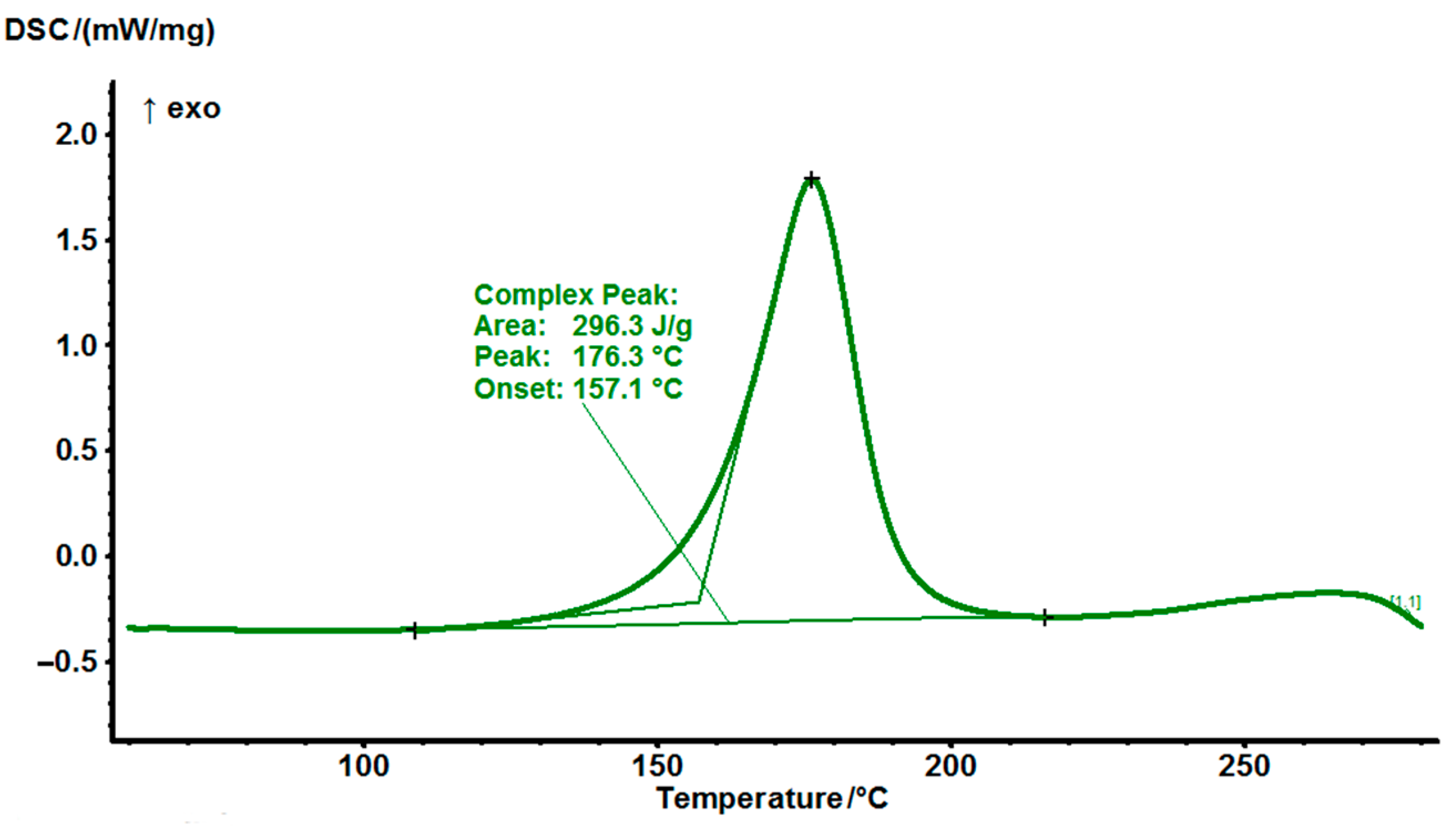

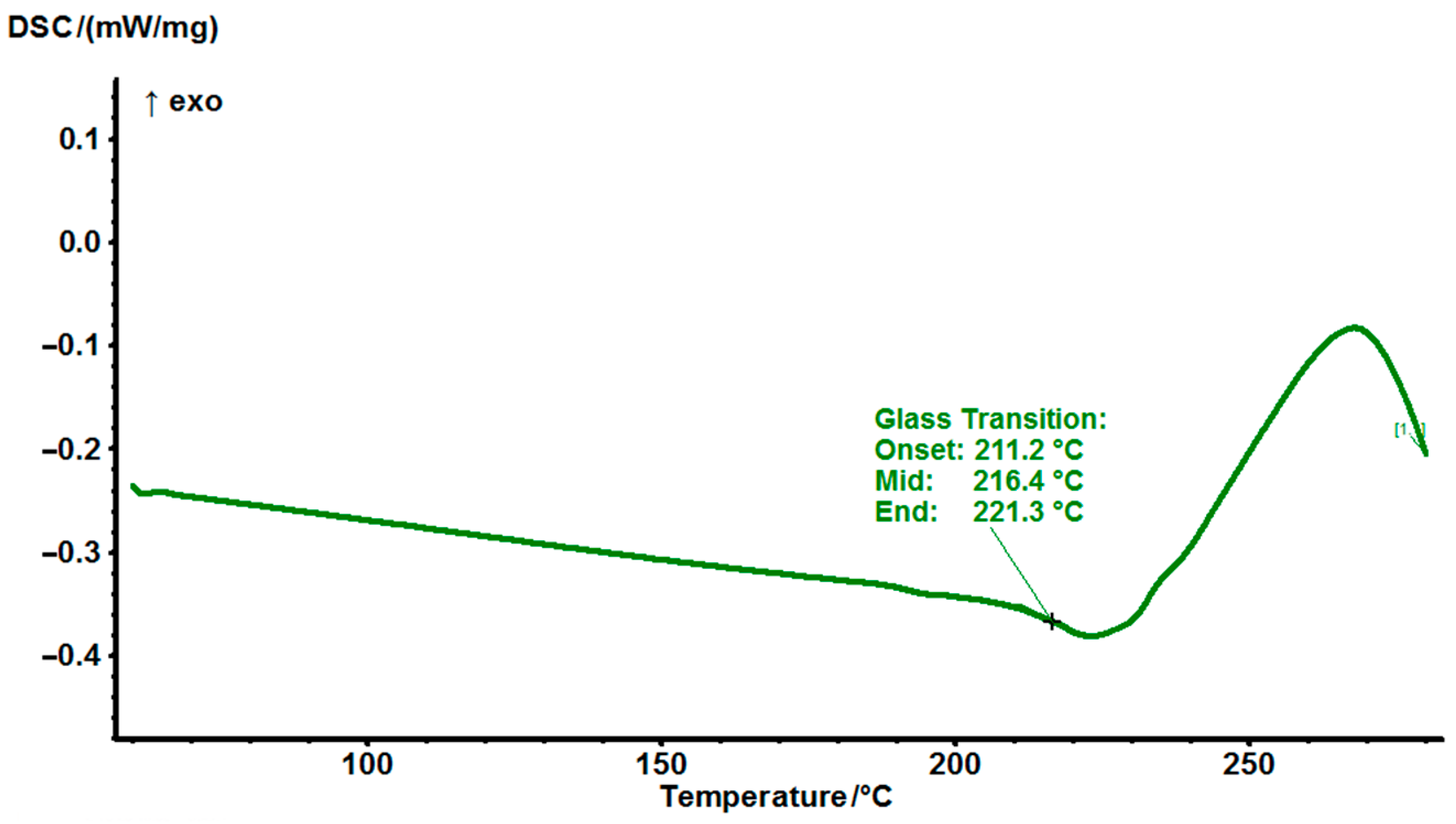

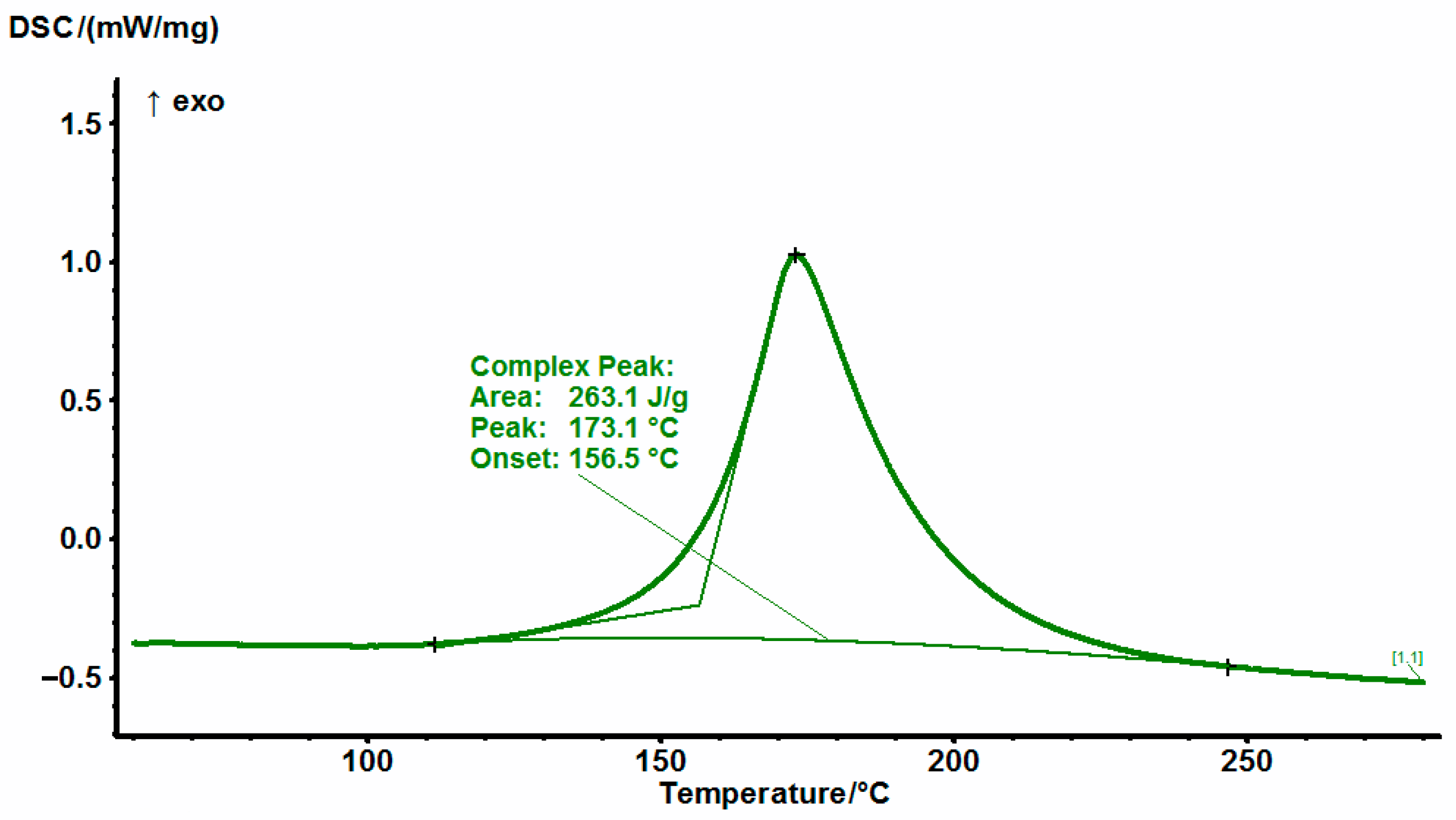

3.2. Differential Scanning Calorimetry (DSC) of MPD-TPA-MPD

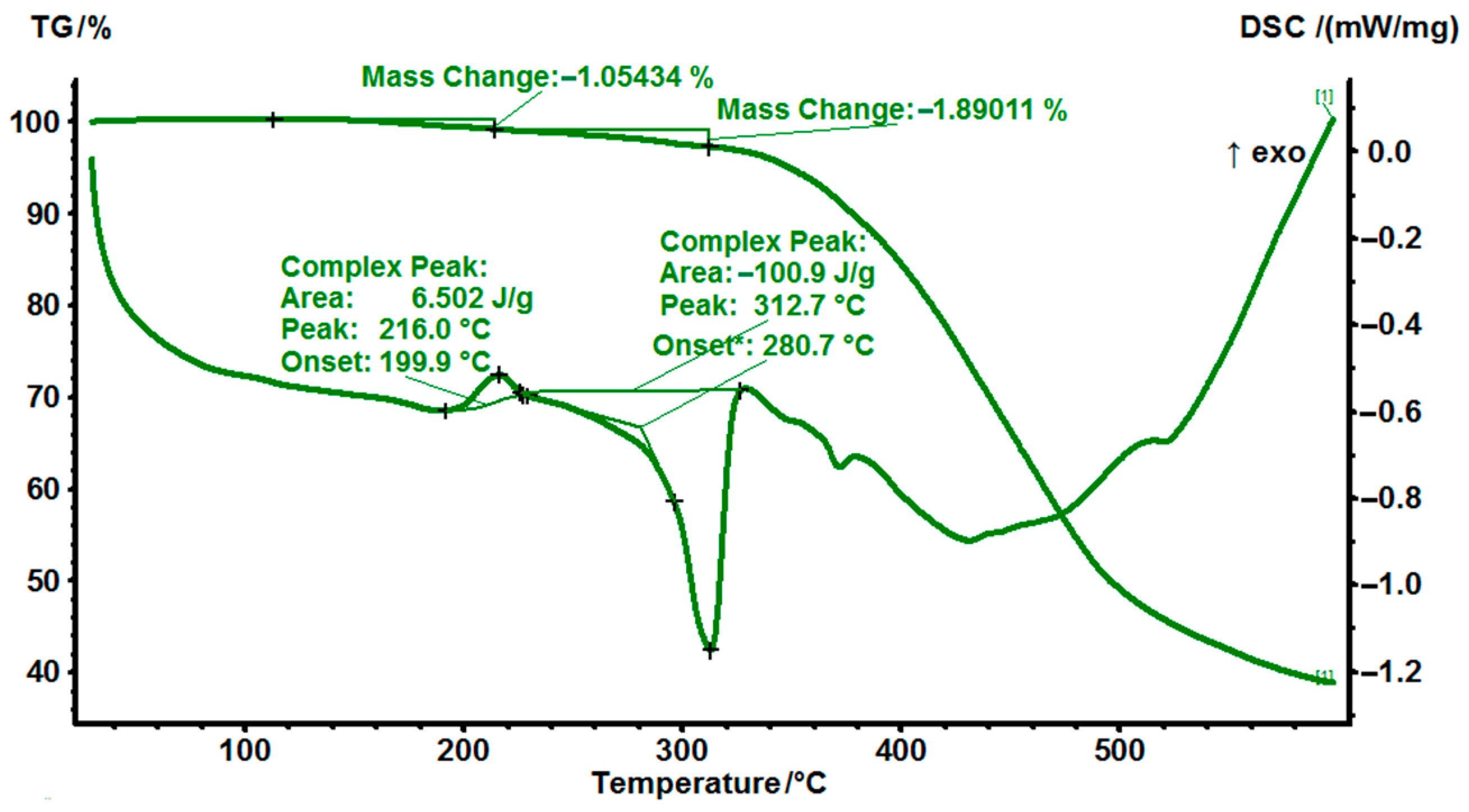

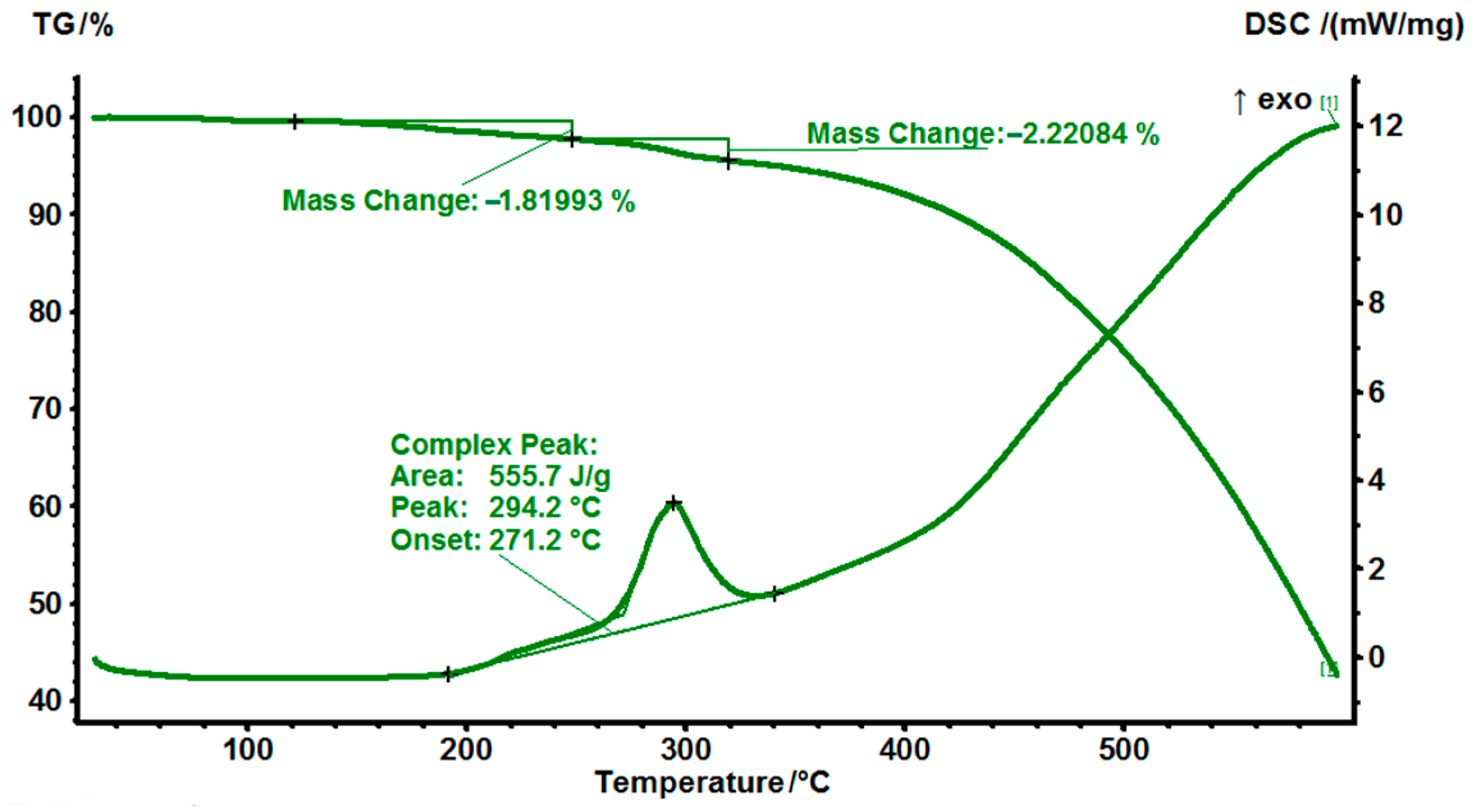

3.3. Simultaneous Thermal Analysis (STA) of MPD-TPA-MPD in a Nitrogen Atmosphere and an Air Atmosphere

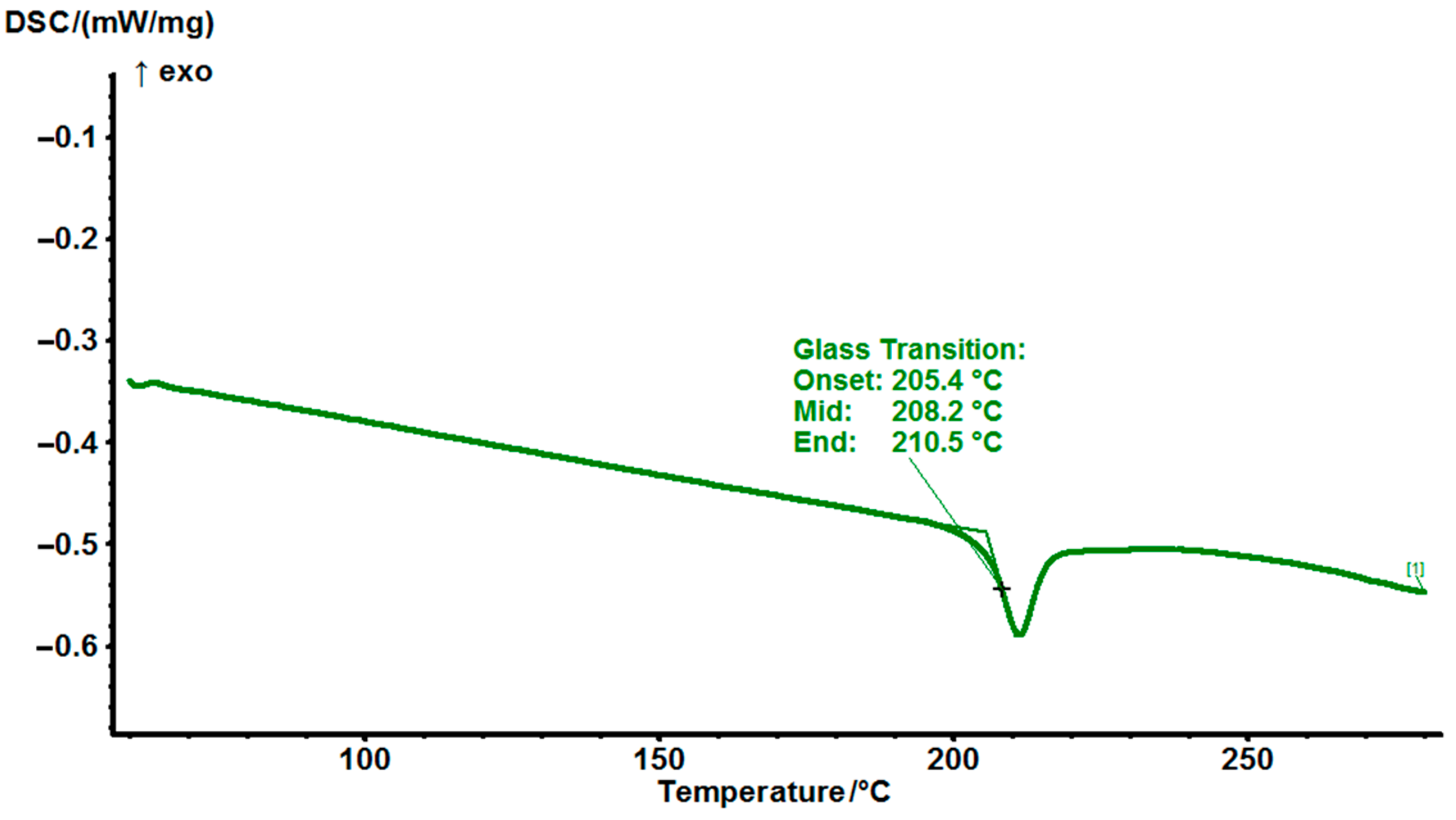

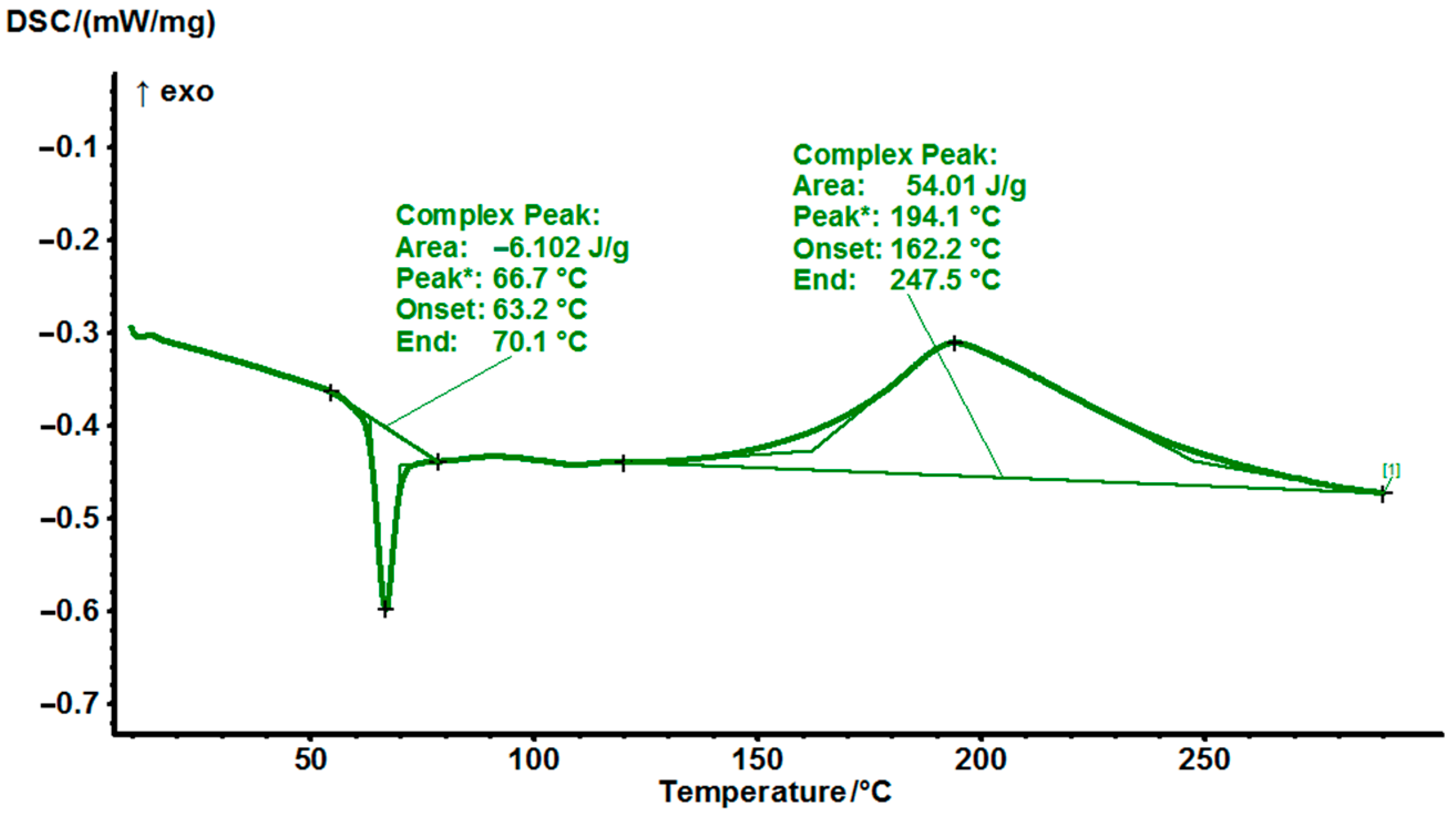

3.4. DSC Analysis of Different Epoxy Resins Compositions with MPD-TPA-MPD as a Hardener

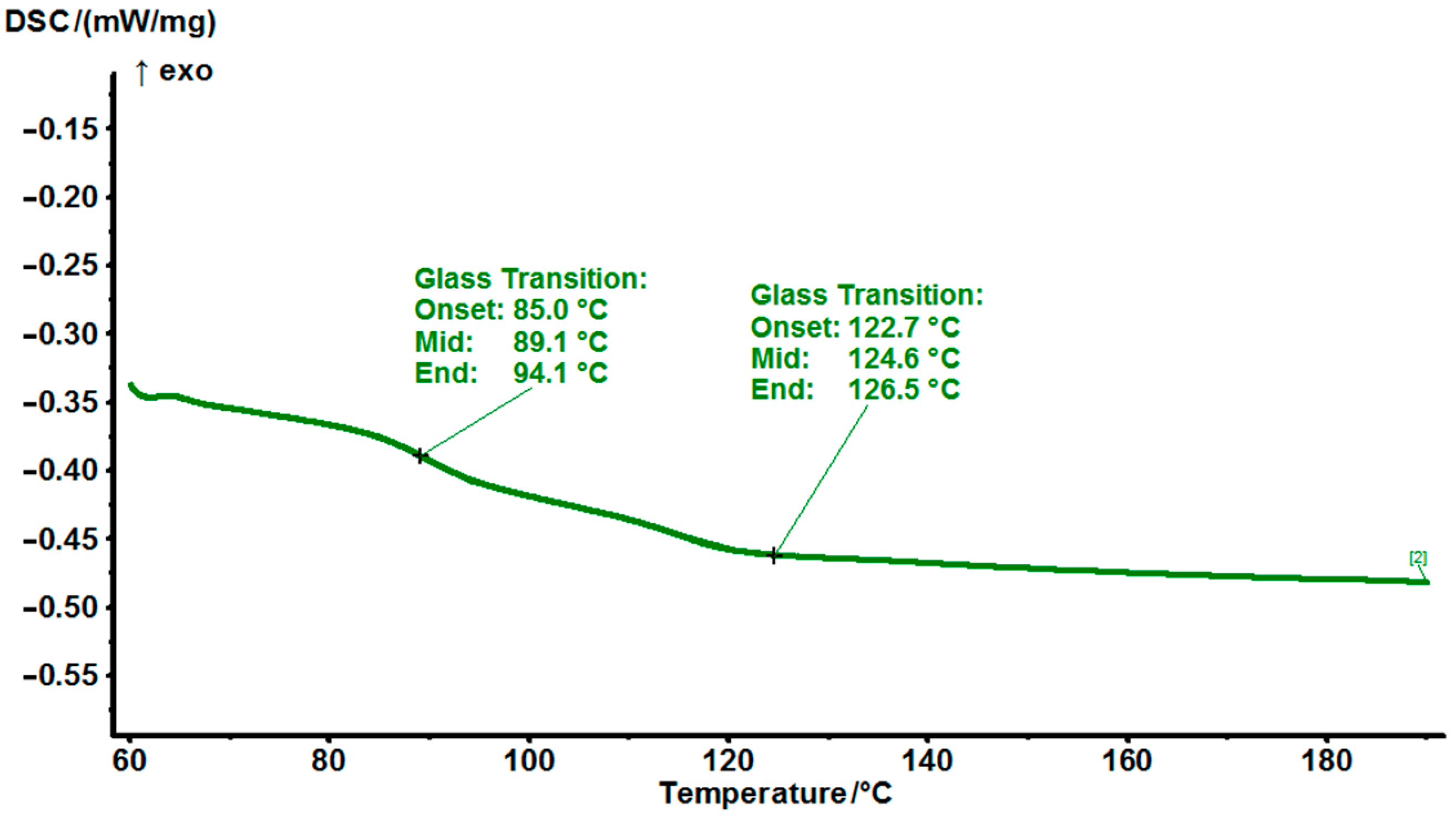

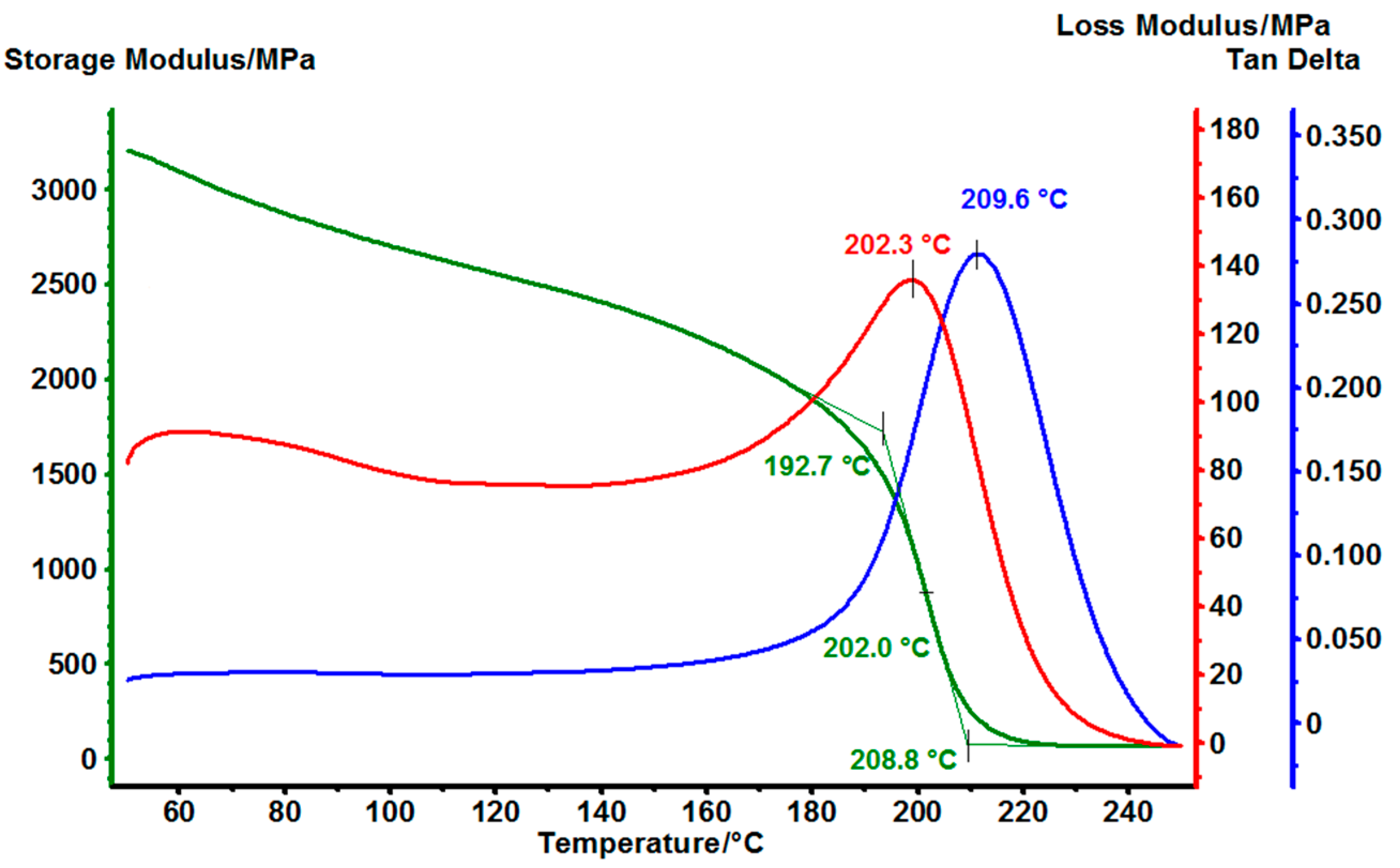

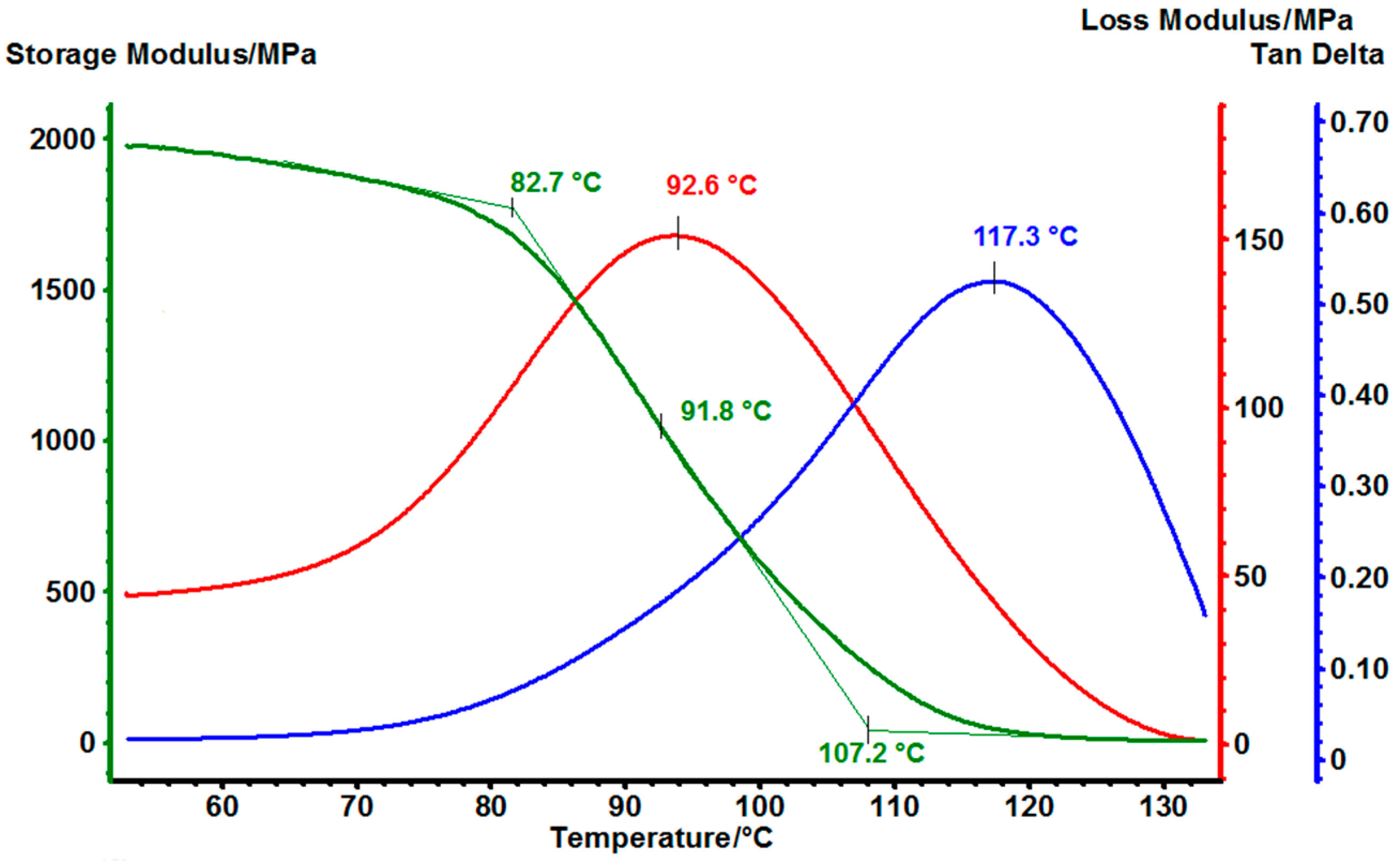

3.5. Dynamic Mechanical Analysis (DMA) of Cured EG514 and EG531

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Acknowledgments

Conflicts of Interest

References

- Ramon, E.; Sguazzo, C.; Moreira, P.M.G.P. Review of Recent Research on Bio-Based Epoxy Systems for Engineering Applications Potentialities in the Aviation Sector. Aerospace 2018, 5, 110. [Google Scholar] [CrossRef]

- Wazalwar, R.; Sahu, M.; Raichur, A.M. Mechanical properties of aerospace epoxy composites reinforced with 2D nano-fillers: Current status and road to industrialization. Nanoscale Adv. 2021, 3, 2741–2776. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Krishnan, S.; Mohanty, S.; Nayak, S.K. Synthesis and characterization of petroleum and biobased epoxy resins: A review. Polym. Int. 2018, 67, 815–839. [Google Scholar] [CrossRef]

- Zhu, Y.; Li, Z.; Wang, X.; Ding, N.; Tian, Y. Preparation and Application of Lignin-Based Epoxy Resin from Pulping Black Liquor. ChemistrySelect 2020, 5, 3494–3502. [Google Scholar] [CrossRef]

- Ma, S.; Liu, X.; Fan, L.; Jiang, Y.; Cao, L.; Tang, Z.; Zhu, J. Synthesis and Properties of a Bio-Based Epoxy Resin with High Epoxy Value and Low Viscosity. ChemSusChem 2014, 7, 555–562. [Google Scholar] [CrossRef] [PubMed]

- Kristufek, S.L.; Yang, G.; Link, L.A.; Rohde, B.J.; Robertson, M.L.; Wooley, K.L. Synthesis, Characterization, and Cross-Linking Strategy of a Quercetin-Based Epoxidized Monomer as a Naturally-Derived Replacement for BPA in Epoxy Resins. ChemSusChem 2016, 9, 2135–2142. [Google Scholar] [CrossRef] [PubMed]

- Raimondo, M.; Guadagno, L.; Naddeo, C.; Longo, P.; Mariconda, A.; Agovino, A. New structure of diamine curing agent for epoxy resins with self-restoration ability: Synthesis and spectroscopy characterization. J. Mol. Struct. 2017, 1130, 400–407. [Google Scholar] [CrossRef]

- Varma, I.K.; Gupta, V.B. 2.01—Thermosetting Resin—Properties. Compr. Compos. Mater. 2000, 2, 1–56. [Google Scholar] [CrossRef]

- Blanco, I.; Cicala, G.; Faro, C.L.; Recca, A. Development of a toughened DGEBS/DDS system toward improved thermal and mechanical properties by the addition of a tetrafunctional epoxy resin and a novel thermoplastic. J. Appl. Polym. Sci. 2003, 89, 268–273. [Google Scholar] [CrossRef]

- Levchik, S.V.; Camino, G.; Luda, M.P.; Costa, L.; Costes, B.; Henry, Y.; Muller, G.; Morel, E.M.J. Mechanistic study of thermal behaviour and combustion performance of epoxy resins. II. TGDDM/DDS system. Polym. Degrad. Stab. 1995, 48, 359–370. [Google Scholar] [CrossRef]

- Varley, R.J.; Hodgkin, J.H.; Simon, G.P. Toughening of a trifunctional epoxy system: Part VI. Structure property relationships of the thermoplastic toughened system. Polymer 2001, 42, 3847–3858. [Google Scholar] [CrossRef]

- Fedtke, M.; Domaratius, F.; Walter, K.; Pfitzmann, A. Curing of epoxy resins with dicyandiamide. Polym. Bull. 1993, 31, 429–435. [Google Scholar] [CrossRef]

- Fedtke, M.; Domaratius, F.; Pfitzmann, A. Curing of epoxy resins with dicyandiamide. Polym. Bull. 1990, 23, 381–388. [Google Scholar] [CrossRef]

- Hayaty, M.; Honarkar, H.; Beheshty, M.H. Curing behavior of dicyandiamide/epoxy resin system using different accelerators. Iran. Polym. J. 2013, 22, 591–598. [Google Scholar] [CrossRef]

- Pfitzmann, A.; Schlothauer, K.; Fedtke, M. Epoxy resin curing by dicyandiamide using model compounds. Polym. Bull. 1991, 27, 59–66. [Google Scholar] [CrossRef]

- Liu, X.D.; Kimura, M.; Sudo, A.; Endo, T. Accelerating effects of N-aryl-N′,N′-dialkyl ureas on epoxy-dicyandiamide curing system. J. Polym. Sci. Part A-1 Polym. Chem. 2010, 48, 5298–5305. [Google Scholar] [CrossRef]

- Kim, W.G.; Yoon, H.G.; Lee, J.Y. Cure kinetics of biphenyl epoxy resin system using latent catalysts. J. Appl. Polym. Sci. 2001, 81, 2711–2720. [Google Scholar] [CrossRef]

- Reis, J.M.L.; Chianelli-Junior, R.; Cardoso, J.L.; Marinho, F.J.V. Effect of recycled PET in the fracture mechanics of polymer mortar. Constr. Build. Mater. 2011, 25, 2799–2804. [Google Scholar] [CrossRef]

- Ghosal, K.; Nayak, C. Recent advances in chemical recycling of polyethylene terephthalate waste into value added products for sustainable coating solutions—Hope vs. hype. Adv. Mater. 2022, 3, 1974–1992. [Google Scholar] [CrossRef]

- Taniguchi, I.; Yoshida, S.; Hiraga, K.; Miyamoto, K.; Kimura, Y.; Oda, K. Biodegradation of PET: Current Status and Application Aspects. ACS Catal. 2019, 9, 4089–4105. [Google Scholar] [CrossRef]

- Atta, A.M.; El-Kafrawy, A.F.; Aly, M.H.; Abdel-Azim, A.-A.A. New epoxy resins based on recycled poly(ethylene terephthalate) as organic coatings. Prog. Org. Coat. 2007, 58, 13–22. [Google Scholar] [CrossRef]

- Czub, P. Synthesis and modification of epoxy resins using recycled poly(ethylene terephthalate). Polym. Adv. Technol. 2009, 20, 183–193. [Google Scholar] [CrossRef]

- Spychaj, T.; Pilawka, R. The physicochemical characterization of an aminoester-type epoxy-resin hardener prepared from chemical degradation of poly(ethylene terephthalate). Polimery/Polymers 2022, 46, 803–811. [Google Scholar] [CrossRef]

- Fukushima, K.; Lecuyer, J.M.; Wei, D.S.; Horn, H.W.; Jones, G.O.; Al-Megren, H.A.; Alabdulrahman, A.M.; Alsewailem, F.D.; McNeil, M.A.; Rice, J.E.; et al. Advanced chemical recycling of poly(ethylene terephthalate) through organocatalytic aminolysis. Polym. Chem. 2013, 4, 1610–1616. [Google Scholar] [CrossRef]

- Lee, J.K.; Pae, K.D. Mechanical and Thermal Properties of a Diglycidyl Ether of Bisphenol-A (DGEBA)–4,4′-Diaminodiphenyl Sulfone (DDS) System Cured under Hydrostatic Pressure. Polym. J. 1994, 26, 1093–1099. [Google Scholar] [CrossRef][Green Version]

- Su, W.-F.; Huang, H.-W.; Pan, W.-P. Thermal properties of rigid rod epoxies cured with diaminodiphenylsulfone and dicyandiamide. Thermochim. Acta 2002, 392–393, 391–394. [Google Scholar] [CrossRef]

- Kalita, D.; Tarnavchyk, I.; Swarup, S.; Harris, C.; Landis, C.; Chisholm, B.J.; Webster, D.C. Use of high throughput screening methods to study dual-functional crosslinkable latexes. Prog. Org. Coat. 2020, 149, 105898. [Google Scholar] [CrossRef]

- Kalita, D.J.; Tarnavchyk, I.; Chisholm, B.J.; Webster, D.C. Novel bio-based epoxy resins from eugenol as an alternative to BPA epoxy and high throughput screening of the cured coatings. Polymer 2021, 233, 124191. [Google Scholar] [CrossRef]

- Pearson, R.A.; Yee, A.F. Toughening mechanisms in elastomer-modified epoxies. J. Mater. Sci. 1989, 24, 2571–2580. [Google Scholar] [CrossRef]

| Sample Name | Epoxy Resin Name | Formula | Hardener/Resin Mass Ratio |

|---|---|---|---|

| EG513 | TGDMA 4,4′-Methylenebis(N,N-diglycidylaniline) |  | 3.89/5 |

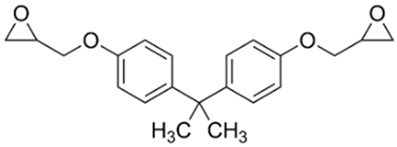

| EG514 | DGEBA Bisphenol A diglycidyl ether |  | 2.54/5 |

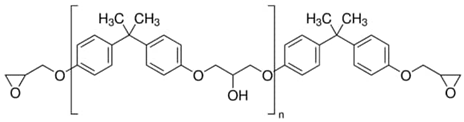

| EG531 | SER Poly(Bisphenol A-co-epichlorohydrin), glycidyl end-capped, n ≈ 4 |  | 0.481/5 |

| Sample | Tg, °C |

|---|---|

| EG513 | 216 |

| EG514 | 208 |

| EG531 | 89 (124) |

| Sample | Tg, °C |

|---|---|

| EG514 | 202 |

| EG531 | 91.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sterligov, G.K.; Rzhevskiy, S.A.; Isaeva, D.K.; Belov, N.M.; Rasskazova, M.A.; Drokin, E.A.; Topchiy, M.A.; Minaeva, L.I.; Babkin, A.V.; Erdni-Goryaev, E.M.; et al. The Physicochemical Characterization of New “Green” Epoxy-Resin Hardener Made from PET Waste. Polymers 2022, 14, 4456. https://doi.org/10.3390/polym14204456

Sterligov GK, Rzhevskiy SA, Isaeva DK, Belov NM, Rasskazova MA, Drokin EA, Topchiy MA, Minaeva LI, Babkin AV, Erdni-Goryaev EM, et al. The Physicochemical Characterization of New “Green” Epoxy-Resin Hardener Made from PET Waste. Polymers. 2022; 14(20):4456. https://doi.org/10.3390/polym14204456

Chicago/Turabian StyleSterligov, Grigorii K., Sergey A. Rzhevskiy, Dilshodakhon K. Isaeva, Nikita M. Belov, Maria A. Rasskazova, Egor A. Drokin, Maxim A. Topchiy, Lidiya I. Minaeva, Alexander V. Babkin, Erdni M. Erdni-Goryaev, and et al. 2022. "The Physicochemical Characterization of New “Green” Epoxy-Resin Hardener Made from PET Waste" Polymers 14, no. 20: 4456. https://doi.org/10.3390/polym14204456

APA StyleSterligov, G. K., Rzhevskiy, S. A., Isaeva, D. K., Belov, N. M., Rasskazova, M. A., Drokin, E. A., Topchiy, M. A., Minaeva, L. I., Babkin, A. V., Erdni-Goryaev, E. M., Kepman, A. V., & Asachenko, A. F. (2022). The Physicochemical Characterization of New “Green” Epoxy-Resin Hardener Made from PET Waste. Polymers, 14(20), 4456. https://doi.org/10.3390/polym14204456