Investigation of Hemp and Flax Fiber-Reinforced EcoPoxy Matrix Biocomposites: Morphological, Mechanical, and Hydrophilic Properties

Abstract

:1. Introduction

Research Significance

2. Materials and Methods

2.1. Materials

2.2. Extraction and Chemical Treatment of Natural Fibers

2.3. Materials Weight Percentage

2.4. Fabrication of Composites

2.5. Testing Methods

2.5.1. Interlaminar Shear Properties

2.5.2. Flexural Strength Properties

2.5.3. Hydrophilic Properties

2.5.4. Moisture Absorption

2.5.5. Optical Microscopic Analysis

2.5.6. FTIR Analysis

2.5.7. SEM and EDX Analysis

3. Results and Discussion

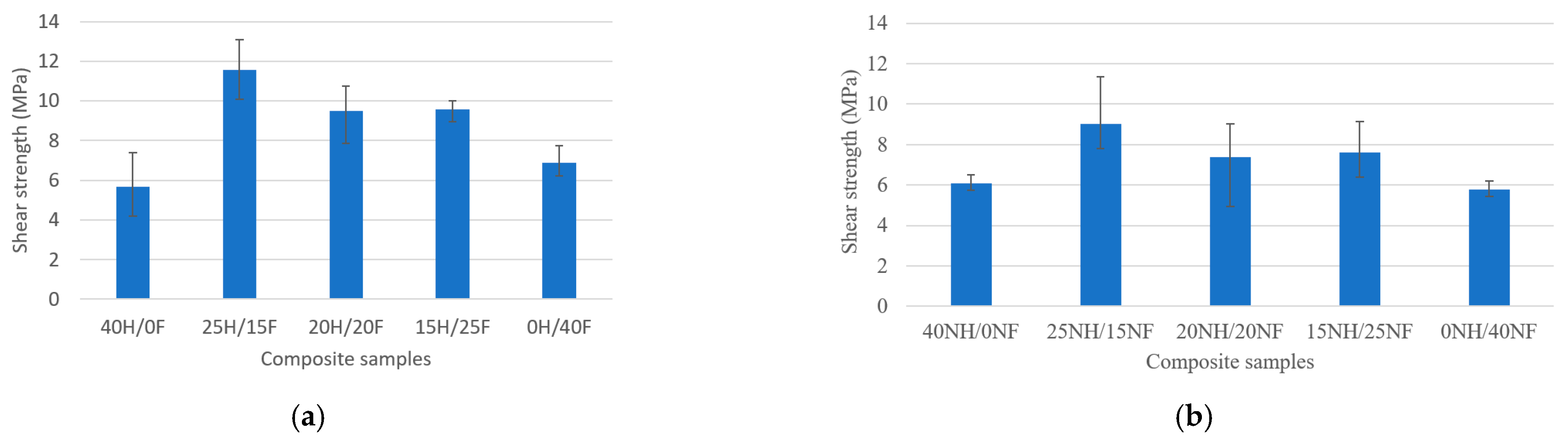

3.1. Interlaminar Shear Strength Test

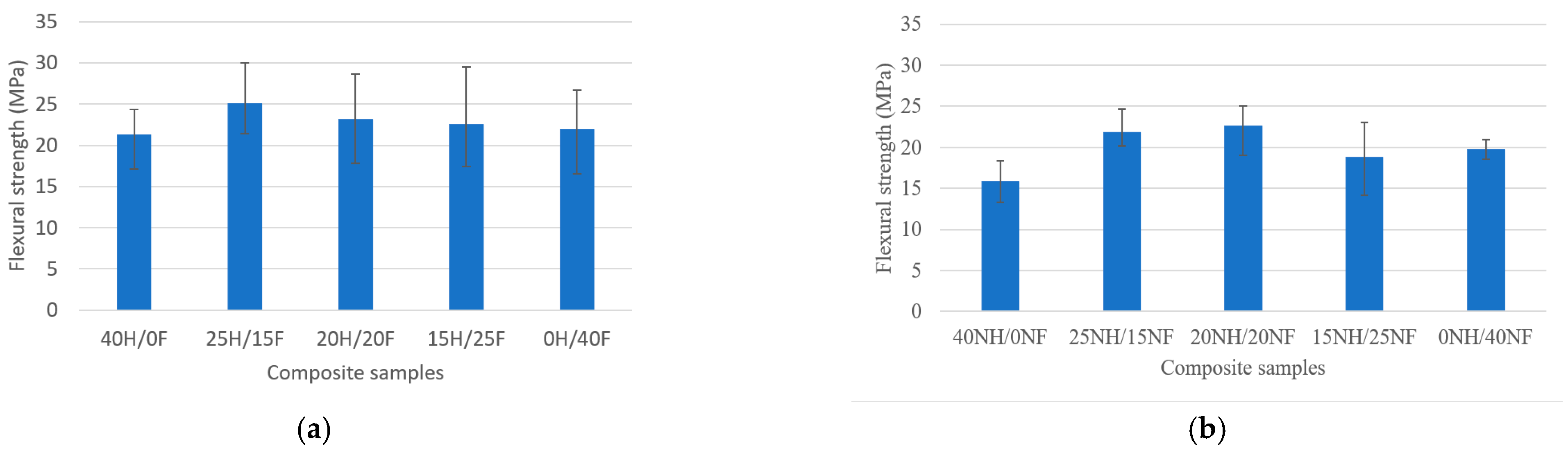

3.2. Flexural Strength Test

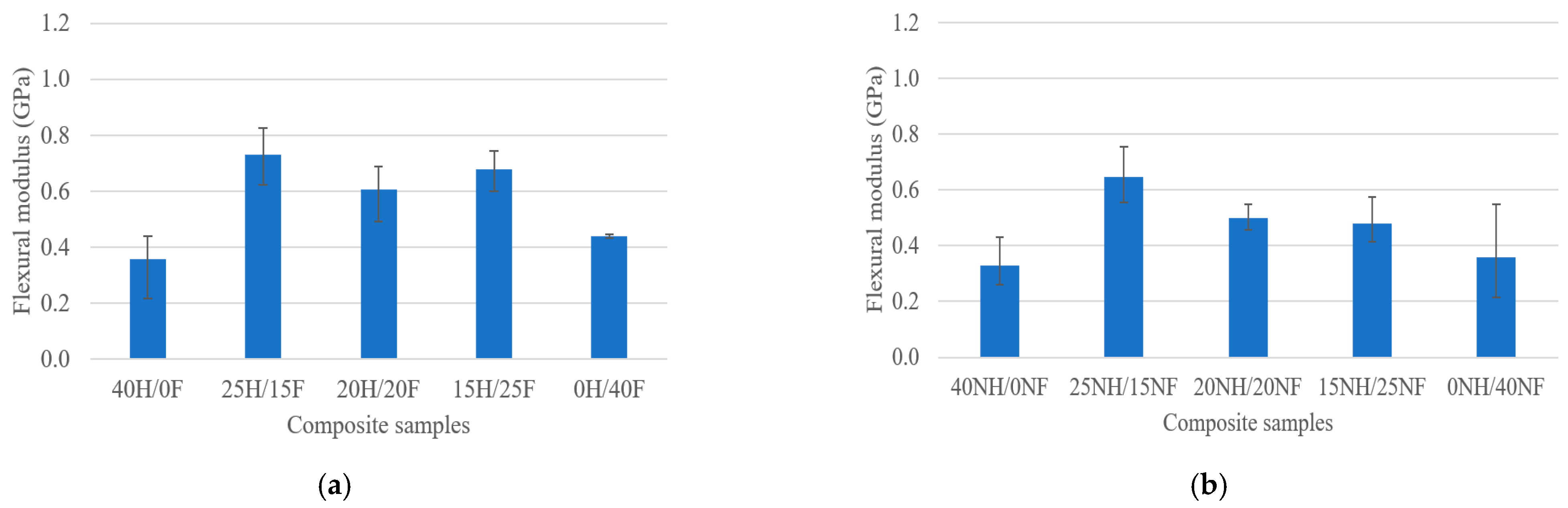

Flexural Modulus

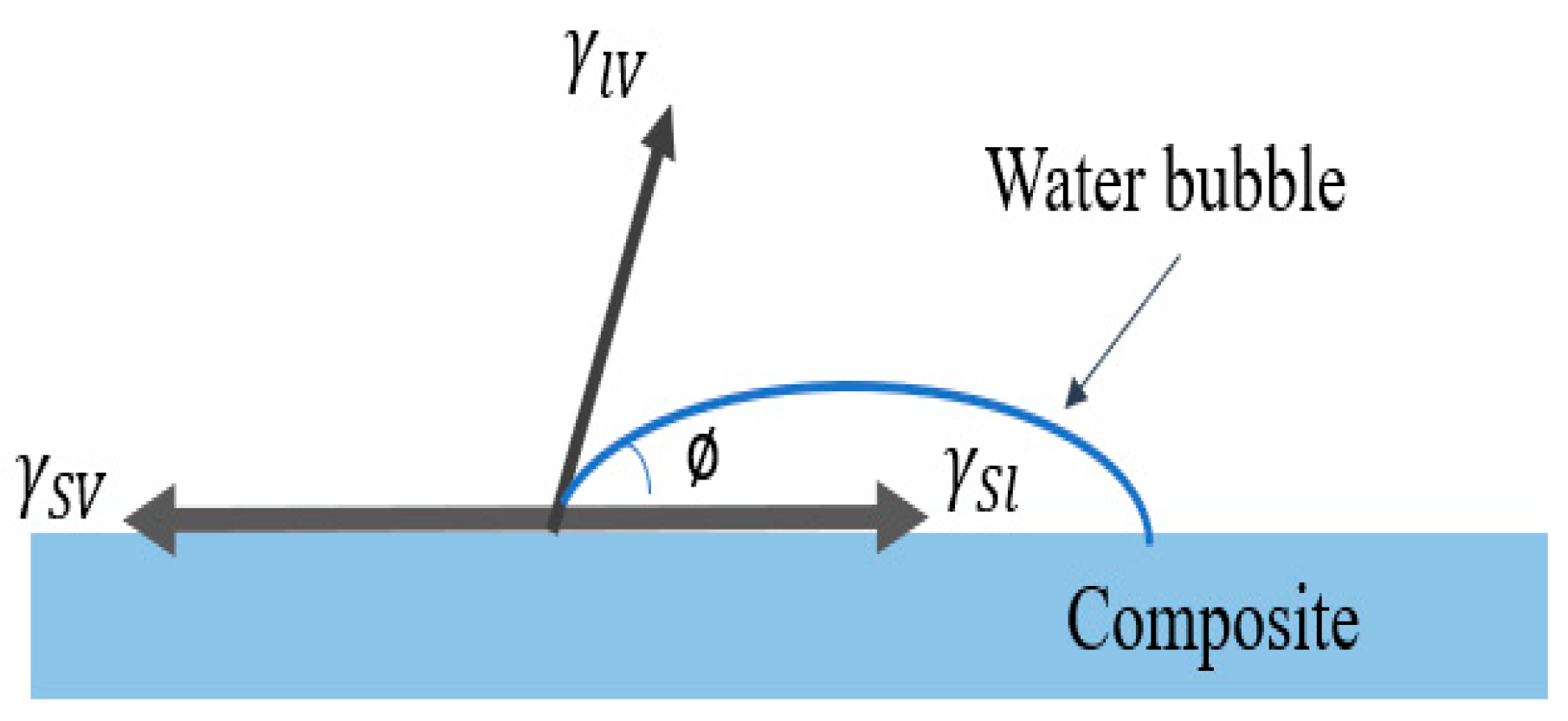

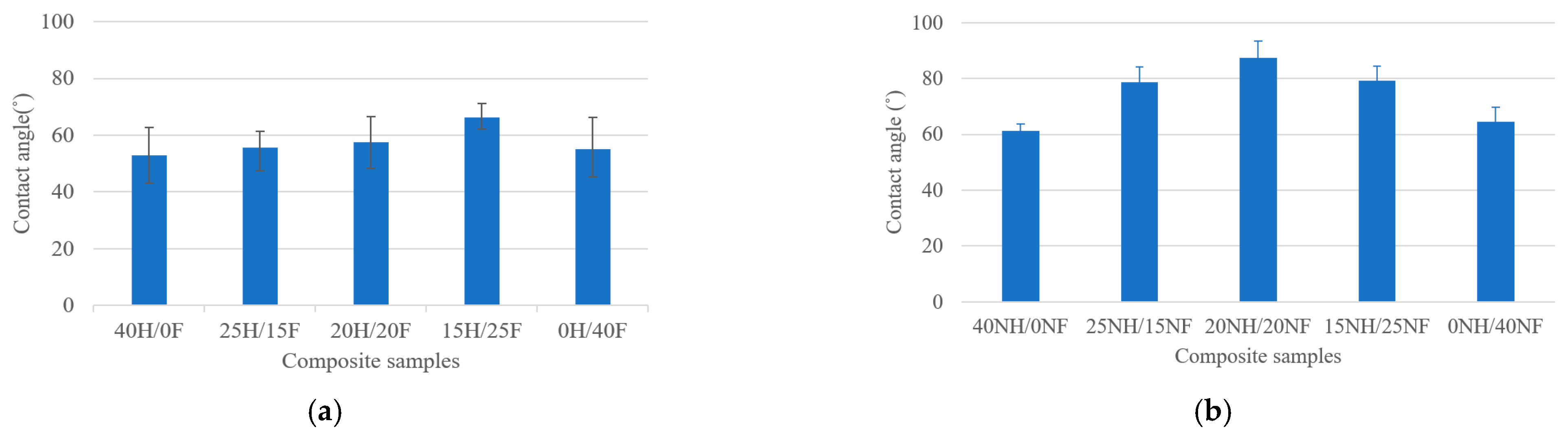

3.3. Contact Angle Measurement Analysis

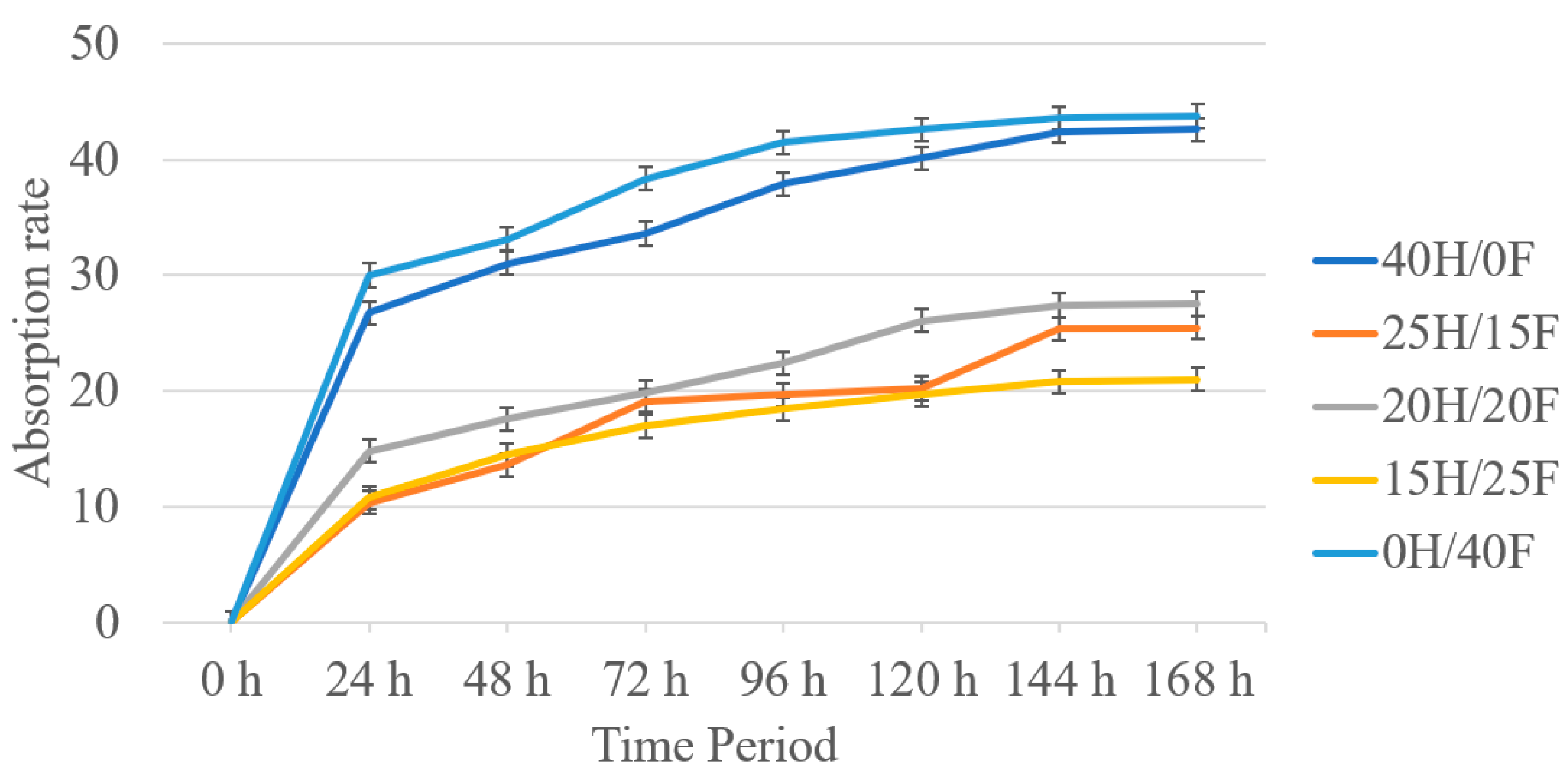

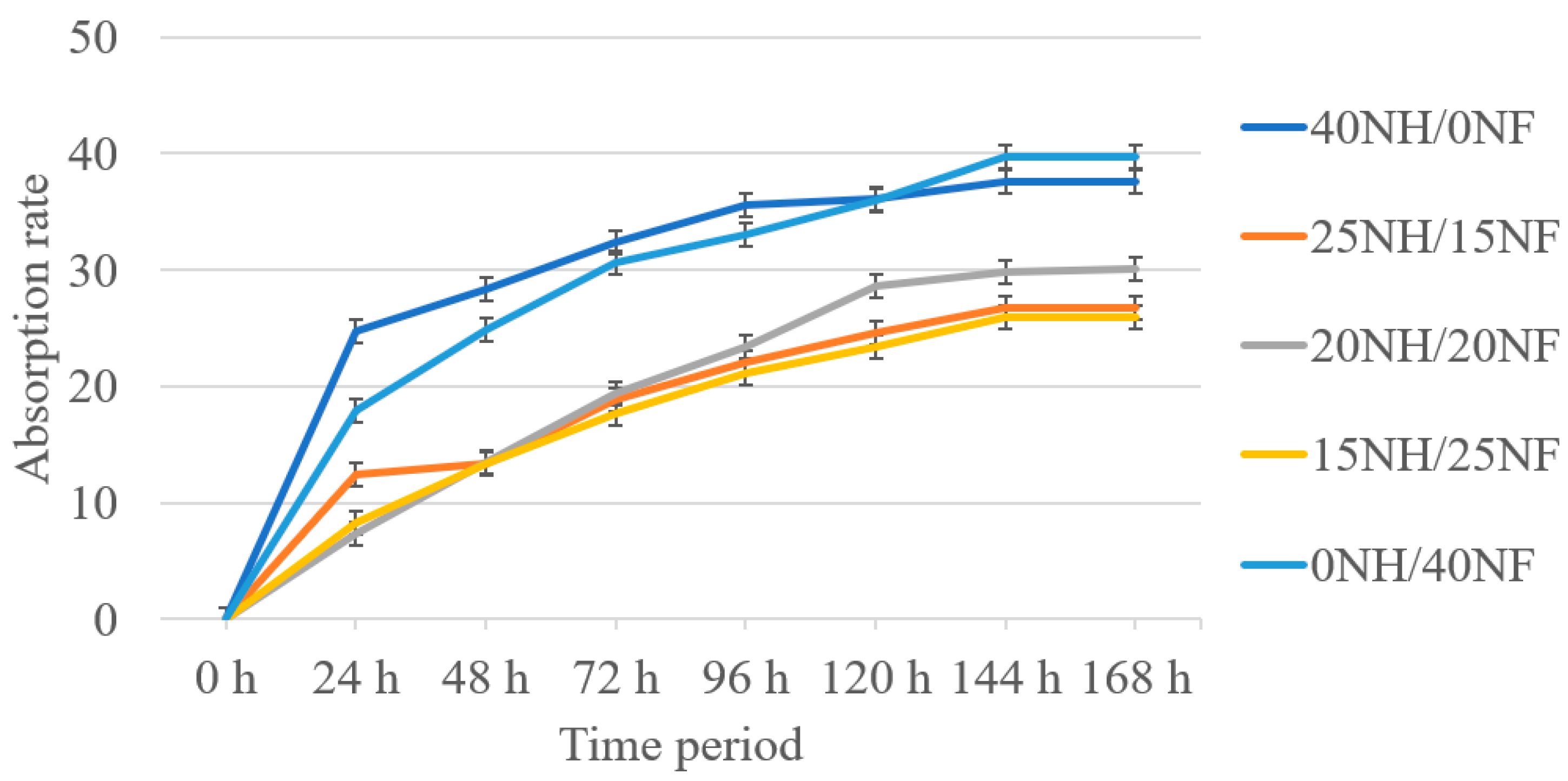

3.4. Moisture Analysis

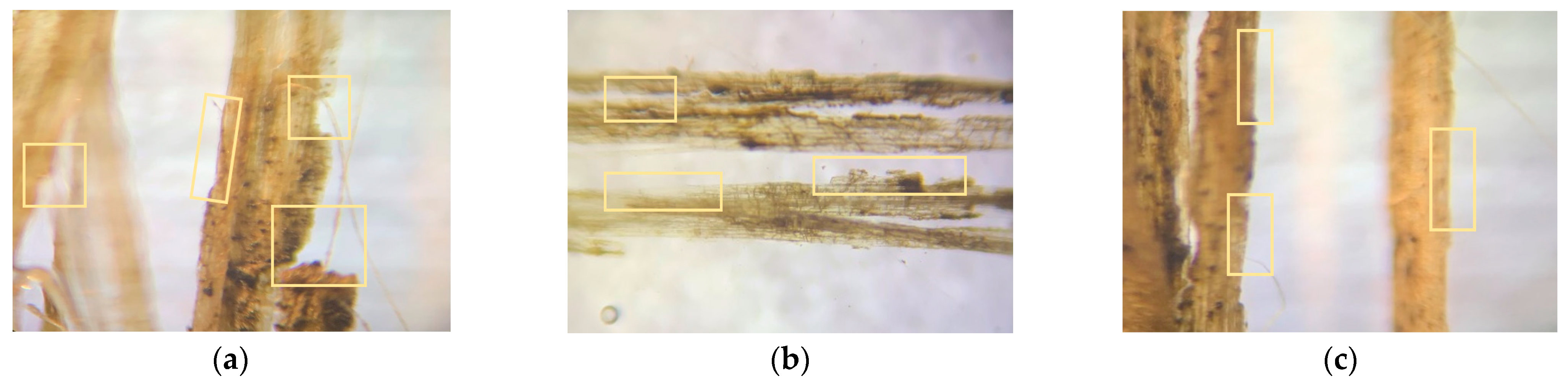

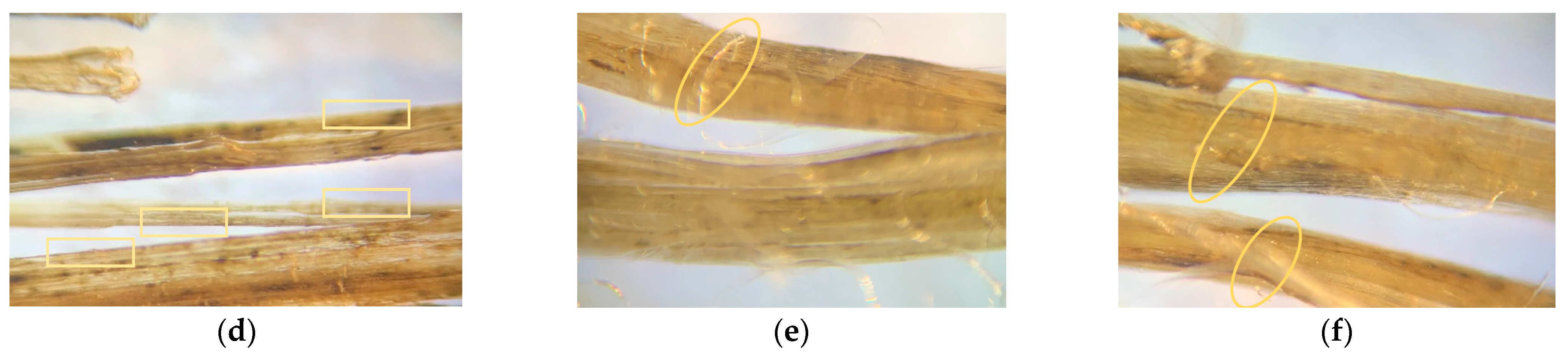

3.5. Fiber Morphology Studies

3.6. FTIR Analysis

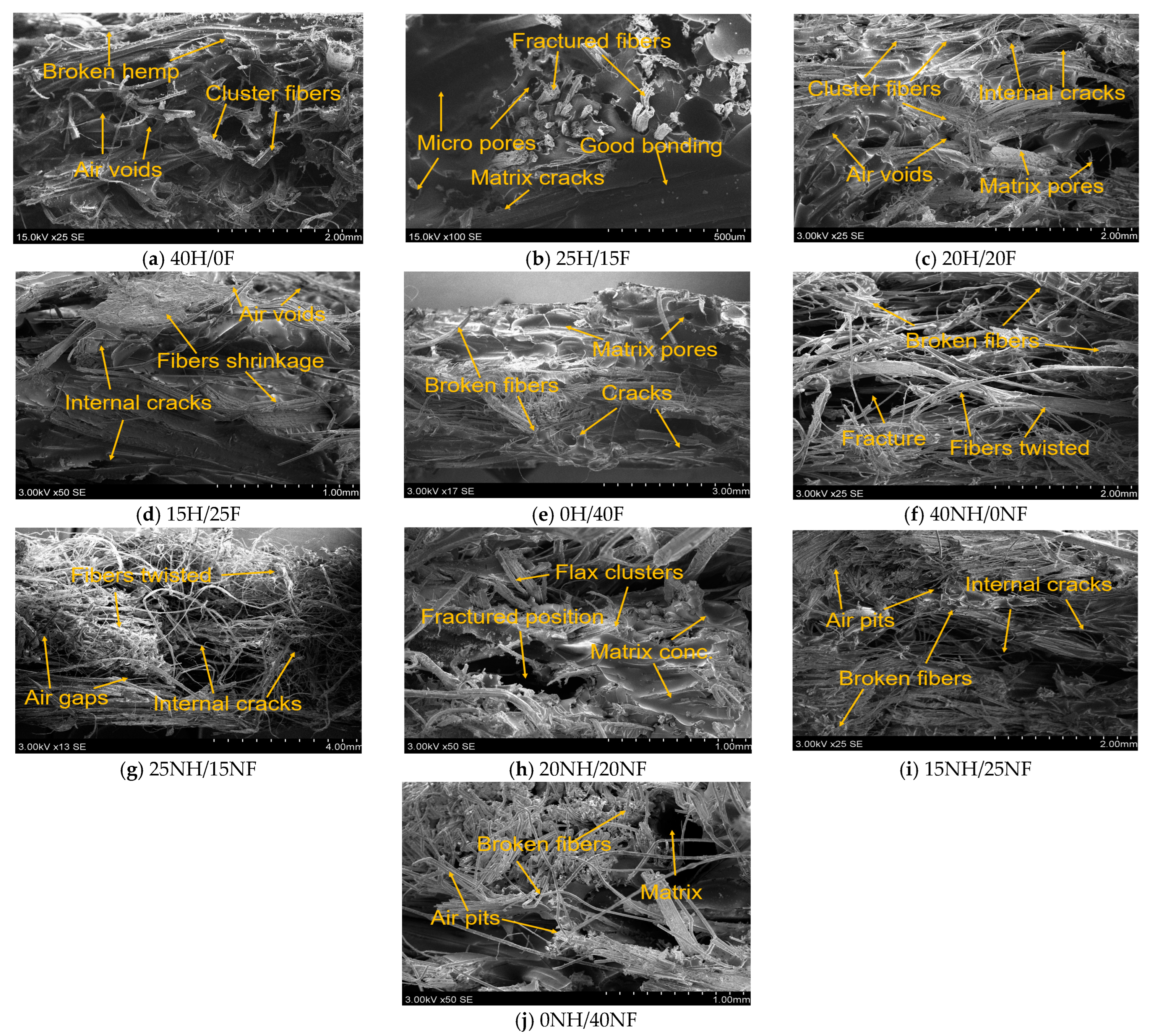

3.7. Scanning Electron Microscope (SEM) Analysis

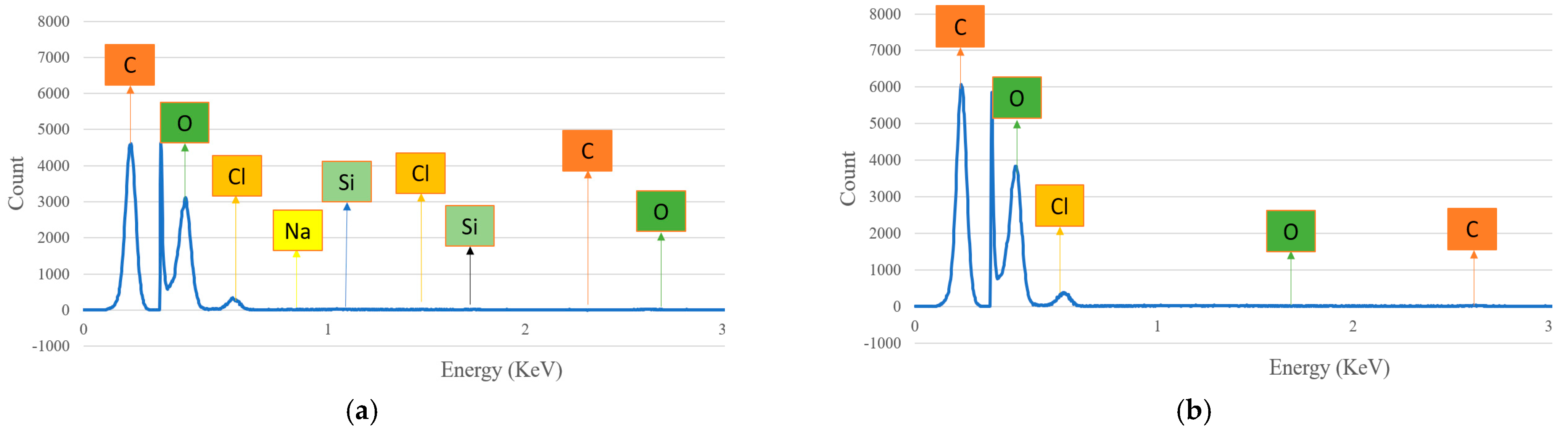

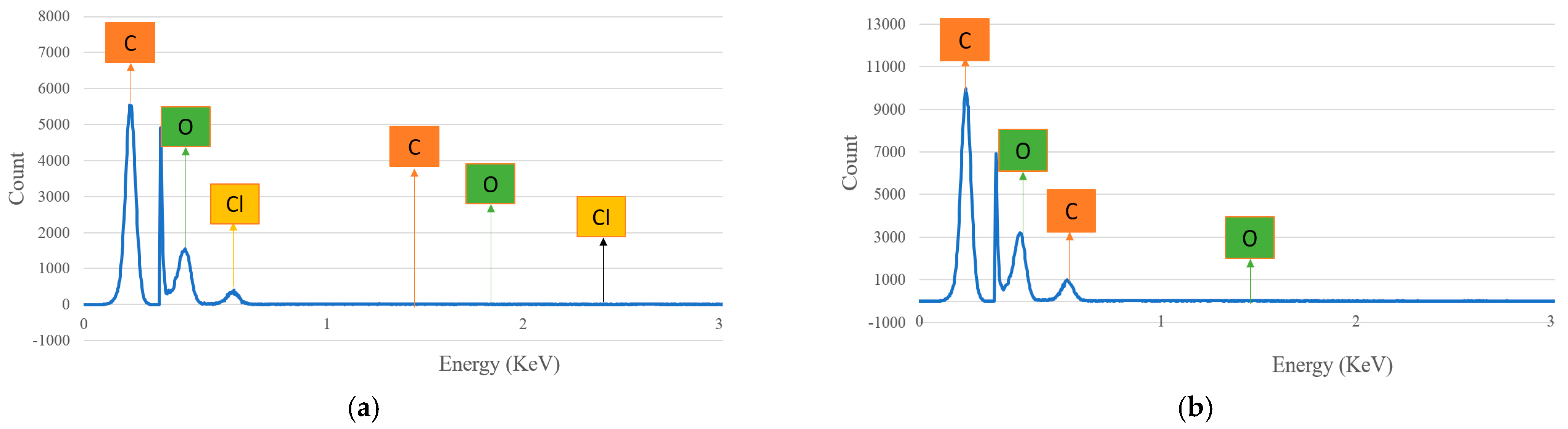

3.8. SEM−EDX Spectrum Analysis

4. Conclusions

- Hemp and flax fiber hybrid biocomposites showed superior mechanical properties to noil hemp and noil flax fiber biocomposites. In both cases, hybrid biocomposites showed improved properties compared to pure biocomposites. From the interlaminar shear test results, hemp and flax fiber biocomposites showed a range between 5.67 and 13.10 MPa, whereas noil fibers were from 4.9 to 11.3 MPa. From the flexural test results, the 25H/15F hybrid biocomposites exhibited the maximum flexural strength and modulus as 30.04 MPa and 0.825 GPa and pure noil hemp (40NH/0NF) fiber biocomposites exhibited the minimum as 13.31 MPa and 3.95 GPa.

- All of the biocomposites had a contact angle of fewer than 90 degrees based on contact angle measurement, indicating that they have hydrophilic surface qualities. The maximum contact angle was observed for 20NH/20NF at 87.31° with the measurement error of ±1.56° and the smallest contact angle was observed for 40H/0F at 53.01° with the measurement error of ±1.94°. From the rate of absorption analysis, all the biocomposites responded to the moisture and the rate increased up to 144 h, remaining constant. In both cases, pure biocomposites absorbed more water than hybrid biocomposites.

- The fiber morphology studies of treated and untreated fibers were investigated by using the optical microscope. The results were presented in a way that contrasted the treated and untreated fibers in terms of defects. The fracture mechanisms and the porosity content in the biocomposites were investigated by using scanning electron microscopy. The spectra acquisitions for the chemical composition presented in hemp and flax fiber biocomposites were observed by using SEM−EDX spectrographs.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Oladele, I.O.; Abiodun Makinde-Isola, B.; Agbeboh, N.I.; Iwarere, B.O. Thermal Stability, Moisture Uptake Potentials and Mechanical Properties of Modified Plant Based Cellulosic Fiber-Animal Wastes Hybrid Reinforced Epoxy Composites. J. Nat. Fibers 2020, 19, 4427–4442. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Sanyang, M.L.; Sapuan, S.M.; Jawaid, M.; Ishak, M.R.; Sahari, J. Recent developments in sugar palm (Arenga pinnata) based biocomposites and their potential industrial applications: A review. Renew. Sustain. Energy Rev. 2016, 54, 533–549. [Google Scholar] [CrossRef]

- Etaati, A.; Pather, S.; Rahman, M.; Wang, H. Ground hemp fibers as filler/reinforcement for thermoplastic biocomposites. Adv. Mater. Sci. Eng. 2015, 2015, 513590. [Google Scholar] [CrossRef] [Green Version]

- Etaati, A.; Pather, S.; Fang, Z.; Wang, H. The study of fibre/matrix bond strength in short hemp polypropylene composites from dynamic mechanical analysis. Compos. Part B Eng. 2014, 62, 19–28. [Google Scholar] [CrossRef]

- da Luz, F.S.; da Costa, G.F.F.; Oliveira, M.S.; Cassiano Nascimento, L.F.; Neves Monterio, S. Composites with natural fibers and conventional materials applied in a hard armor: A comparison. Polymers 2020, 12, 1920. [Google Scholar] [CrossRef]

- Peças, P.; Carvalho, H.; Salman, H.; Leite, M. Natural fibre composites and their applications: A review. J. Compos. Sci. 2018, 2, 66. [Google Scholar] [CrossRef] [Green Version]

- Ramakrishnan, G.; Ramnath, B.V.; Elanchezhian, C.; Arun Kumar, A.; Gowtham, S. Investigation of Mechanical Behaviour of Basalt-Banana Hybrid Composites. Silicon 2019, 11, 1939–1948. [Google Scholar] [CrossRef]

- Elsheikh, A. Bistable Morphing Composites for Energy-Harvesting Applications. Polymers 2022, 14, 1893. [Google Scholar] [CrossRef]

- Sair, S.; Oushabi, A.; Kammouni, A.; Tanane, O.; Abboud, Y.; Bouari, A.E.L. Mechanical and thermal conductivity properties of hemp fiber reinforced polyurethane composites. Case Stud. Constr. Mater. 2018, 8, 203–212. [Google Scholar] [CrossRef]

- Moonart, U.; Utara, S. Effect of surface treatments and filler loading on the properties of hemp fiber/natural rubber composites. Cellulose 2019, 26, 7271–7295. [Google Scholar] [CrossRef]

- Moudood, A.; Rahman, A.; Öchsner, A.; Islam, M.; Francucci, G. Flax fiber and its composites: An overview of water and moisture absorption impact on their performance. J. Reinf. Plast. Compos. 2019, 38, 323–339. [Google Scholar] [CrossRef] [Green Version]

- Yan, L.; Chouw, N.; Jayaraman, K. Flax fibre and its composites—A review. Compos. Part B Eng. 2014, 56, 296–317. [Google Scholar] [CrossRef]

- Sinha, A.K.; Narang, H.K.; Bhattacharya, S. Mechanical properties of natural fibre polymer composites. J. Polym. Eng. 2017, 37, 879–895. [Google Scholar] [CrossRef]

- Kamal, A.; Ashmawy, M.; Shanmugan, S.; Algazzar, A.M.; Elsheikh, A.H. Fabrication techniques of polymeric nanocomposites: A comprehensive review. Proc. Inst. Mech. Eng. Part C J. 2022, 236, 4843–4861. [Google Scholar] [CrossRef]

- Rokbi, M.; Osmani, H.; Imad, A.; Benseddiq, N. Effect of Chemical treatment on Flexure Properties of Natural Fiber-reinforced Polyester Composite. Procedia Eng. 2011, 10, 2092–2097. [Google Scholar] [CrossRef]

- Neto, J.S.S.; Lima, R.A.A.; Cavalcanti, D.K.K.; Souza, J.P.B.; Agular, R.A.A.; Banea, M.D. Effect of chemical treatment on the thermal properties of hybrid natural fiber-reinforced composites. J. Appl. Polym. Sci 2019, 136, 47154. [Google Scholar] [CrossRef]

- Shuhimi, F.F.; Abdollah, M.F.; Bin Kalam, M.A.; Masjuki, H.H.; Mat Kamal, A.M.S.E.; Amiruddin, H. Effect of operating parameters and chemical treatment on the tribological performance of natural fiber composites: A review. Part Sci. Technol. 2017, 35, 512–524. [Google Scholar] [CrossRef]

- Pereira, A.L.; Banea, M.D.; Neto, J.S.S.; Cavalcanti, D.K.K. Mechanical and Thermal Characterization of Natural Intralaminar Hybrid Composites Based on Sisal. Polymers 2020, 12, 866. [Google Scholar] [CrossRef] [Green Version]

- Cavalcanti, D.K.K.; Banea, M.D.; Neto, J.S.S.; Lima, R.A.A.; da Silva, L.F.M.; Carbas, R.J.C. Mechanical characterization of intralaminar natural fibre-reinforced hybrid composites. Compos. Part B Eng. 2019, 175, 107149. [Google Scholar] [CrossRef]

- Ravishankar, B.; Nayak, S.K.; Kader, M.A. Hybrid composites for automotive applications—A review. J. Reinf. Plast. Compos. 2019, 38, 835–845. [Google Scholar] [CrossRef]

- Yahaya, R.; Sapuan, S.M.; Jawaid, M.; Leman, Z.; Jainudin, E.S. Effect of fibre orientations on the mechanical properties of kenaf–aramid hybrid composites for spall-liner application. Def. Technol. 2016, 12, 52–58. [Google Scholar] [CrossRef] [Green Version]

- Ashori, A. Hybrid composites from waste materials. J. Polym. Environ. 2010, 18, 65–70. [Google Scholar] [CrossRef]

- Ashori, A.; Nourbakhsh, A. A comparative study on mechanical properties and water absorption behavior of fiber-reinforced polypropylene composites prepared by OCC fiber and aspen fiber. Polymer Compos. 2008, 29, 574–578. [Google Scholar] [CrossRef]

- Sabuncuoglu, B.; Cakmakci, O.; Kadioglu, F.S. Fiber/matrix interface stress analysis of flax-fiber composites under transverse loading considering material nonlinearity. J. Reinf. Plast Compos. 2020, 39, 345–360. [Google Scholar] [CrossRef]

- Jaafar, J.; Siregar, J.P.; Mohd Salleh, S.; Mohd Hamdan, M.H.; Cionita, T.; Rihayat, T. Important Considerations in Manufacturing of Natural Fiber Composites: A Review. Int. J. Precis Eng. Manuf. Technol. 2019, 6, 647–664. [Google Scholar] [CrossRef]

- Pickering, K.L.; Efendy, M.G.A.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef] [Green Version]

- Bambach, M.R. Compression strength of natural fibre composite plates and sections of flax, jute and hemp. Thin-Walled Struct. 2017, 119, 103–113. [Google Scholar] [CrossRef]

- Ramakrishnan, T.; Senthil Kumar, S.; Samson Jerold Samuel, C.; Gnanasekaran, S.; Geetha, N.K.; Ramesh, A.; Debtera, B. Effect of Moisture Content on Mechanical Properties of AAM Natural Fiber-Reinforced Isophthalic Polyester Composites. Adv. Mater. Sci. Eng. 2022, 2022, 3533143. [Google Scholar] [CrossRef]

- Ramesh, M.; Dhilip, J.D.J.; Akilan, S.; Ganeshprasad, B.; Hari Shankar, G. Influence of Stacking Sequence on Mechanical and Thermal Characteristics of Banana-Pineapple Fiber Reinforced Epoxy Composites. J. Nat. Fibers 2020, 19, 3879–3892. [Google Scholar] [CrossRef]

- Zalinawati, M.; Siregar, J.P.; Tezara, C.; Sazali, N.; Jaafar, J.; Oumer, A.N.; Hamdan, M.H.M. The effect of fibre treatment on water absorption and mechanical properties of buri palm (Corypha utan) fibre reinforced epoxy composites. J. Mech. Eng. Sci. 2020, 14, 7379–7388. [Google Scholar] [CrossRef]

- Torres-Arellano, M.; Renteria-Rodríguez, V.; Franco-Urquiza, E. Mechanical properties of natural-fiber-reinforced biobased epoxy resins manufactured by resin infusion process. Polymers 2020, 12, 2841. [Google Scholar]

- Jamshaid, H.; Mishra, R.; Basra, S.; Rajput, A.W.; Hasan, T.; Petru, M.; Choteborsky, R.; Muller, M. Lignocellulosic Natural Fiber Reinforced Bisphenol F Epoxy Based Bio-composites: Characterization of Mechanical Electrical Performance. J. Nat. Fibers 2020, 19, 3317–3332. [Google Scholar] [CrossRef]

- Rajak, D.; Pagar, D.; Menezes, P.; Linul, E. Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef] [Green Version]

- Terwadkar, A.A.; Walame, M.V. Mechanical Properties of Banana Fabric and Kenaf Fiber Reinforced Epoxy Composites: Effect of Treatment and Hybridization. Int. J. Innov. Technol. Explor. Eng. 2019, 8, 1870–1874. [Google Scholar] [CrossRef]

- Neves, A.C.C.; Rohen, L.A.; Mantovani, D.P.; Carvatho, P.R.G.; Vieira, C.M.F.; Lopes, F.P.D.; Simonassi, N.T.; da Luz, F.S.; Monteiro, S.N. Comparative mechanical properties between biocomposites of Epoxy and polyester matrices reinforced by hemp fiber. J. Mater. Res. Technol. 2020, 9, 1296–1304. [Google Scholar] [CrossRef]

- Thiagamani, S.M.K.; Krishnasamy, S.; Muthukumar, C.; Tengsuthiwat, J.; Nagarajan, R.; Siengchin, S.; Ismail, S.O. Investigation into mechanical, absorption and swelling behaviour of hemp/sisal fibre reinforced bioepoxy hybrid composites: Effects of stacking sequences. Int. J. Biol. Macromol. 2019, 140, 637–646. [Google Scholar] [CrossRef]

- Bazan, P.; Mierzwiński, D.; Bogucki, R.; Kuciel, S. Bio-Based Polyethylene Composites with Natural Fiber: Mechanical, Thermal, and Ageing Properties. Materials 2020, 13, 2595. [Google Scholar] [CrossRef]

- Mochane, M.J.; Mokhena, T.C.; Mokhothu, T.H.; Mtibe, A.; Sadiki, E.R.; Ray, S.S.; Ibrahim, I.D.; Daramola, O.O. Recent progress on natural fiber hybrid composites for advanced applications: A review. Express Polym. Lett. 2019, 13, 159–198. [Google Scholar] [CrossRef]

- Saba, N.; Tahir, P.; Jawaid, M. A Review on Potentiality of Nano Filler/Natural Fiber Filled Polymer Hybrid Composites. Polymers 2014, 6, 2247–2273. [Google Scholar]

- Messiry, E.M.; Deeb, E.R. Engineering Fiber Volume Fraction of Natural Fiber Staple—Spun Yarn Reinforced Composite. J. Text. Sci. Eng. 2016, 6, 1–6. [Google Scholar]

- Ma, H.; Li, Y.; Wang, D. Investigations of fiber twist on the mechanical properties of sisal fiber yarns and their composites. J. Reinf. Plast. Compos. 2014, 33, 687–696. [Google Scholar] [CrossRef]

- EI Messiry, M. Theoretical analysis of natural fiber volume fraction of reinforced composites. Alexandria Eng. J. 2013, 52, 301–306. [Google Scholar] [CrossRef]

- Rajabipour, A.; Javadian, A.; Bazli, M.; Masia, M. Interlaminar Shear Properties of Bamboo Composite for Structural Applications. Fibers 2022, 10, 59. [Google Scholar] [CrossRef]

- Kumar, S.S. Dataset on mechanical properties of natural fiber reinforced polyester composites for engineering applications. Data Brief 2020, 28, 105054. [Google Scholar] [CrossRef]

- Singh, S.; Deepak, D.; Aggarwal, L.; Gupta, V.K. Tensile and Flexural Behavior of Hemp Fiber Reinforced Virgin-recycled HDPE Matrix Composites. Proc. Mater. Sci. 2014, 6, 1696–1702. [Google Scholar] [CrossRef] [Green Version]

- Ma, Y.; Cao, X.; Feng, X.; Ma, Y.; Zou, H. Fabrication of super-hydrophobic film from PMMA with intrinsic water contact angle below 90. Polymer 2007, 48, 7455–7460. [Google Scholar] [CrossRef]

- Kumar, P.; Khan, N.; Kumar, D. Polyvinyl Butyral (PVB), Versatile Template for Designing Nanocomposite/Composite Materials: A Review. Green Chem. Technol. Lett. 2016, 2, 185. [Google Scholar] [CrossRef]

| Properties | Hemp | Flax |

|---|---|---|

| Cellulose (%) | 70–74 | 64–70 |

| Hemicellulose (%) | 21–24 | 16–18 |

| Lignin (%) | 3.7–5.7 | 2–2.2 |

| Pectin (%) | 7.3 | 2.3 |

| Elongation (%) | 1.6–4.0 | 1.2–1.6 |

| Moisture (%) | 6.2–12 | 8–12 |

| Density (g/cm3) | 1.48 | 1.4 |

| Young’s modulus (GPa) | 70 | 60–80 |

| Microfibrillar angle (°) | 2–6 | 5–8 |

| Tensile strength (MPa) | 550–900 | 800–1500 |

| Specific strength (s/g) | 393–643 | 570–1070 |

| Properties | Ecopoxy | Hardener |

|---|---|---|

| Color | Viscous liquid | Clear |

| Viscosity at 25 °C | 800 = 1000 cP | 100–200 cP |

| Specific gravity | 1.1 | 1.0 |

| Bio content | 36% | - |

| Mix ratio | 2 | 1 |

| Gel time at 25 °C | 20–25 min | 20–25 min |

| Full cure at 25 °C | 72 h | 72 h |

| Composites | Hemp Fiber (%) | Flax Fiber (%) | Total Fiber Vol. (%) | Total Resin Vol. (%) |

|---|---|---|---|---|

| 40H/0F | 40 | 0 | 40 | 60 |

| 25H/15F | 25 | 15 | 40 | 60 |

| 20H/20F | 20 | 20 | 40 | 60 |

| 15H/25F | 15 | 25 | 40 | 60 |

| 0H/40F | 0 | 40 | 40 | 60 |

| Noil Hemp Fiber (%) | Noil Flax Fiber (%) | |||

| 40NH/0NF | 40 | 0 | 40 | 60 |

| 25NH/15NF | 25 | 15 | 40 | 60 |

| 20NH/20NF | 20 | 20 | 40 | 60 |

| 15NH/25NF | 15 | 25 | 40 | 60 |

| 0NH/40NF | 0 | 40 | 40 | 60 |

| Element Type | Element No. | Atomic Weight | Hemp Biocomposite | Flax Biocomposite | ||

|---|---|---|---|---|---|---|

| Weight (%) | Atomic Conc. (%) | Weight (%) | Atomic Conc. (%) | |||

| Carbon (C) | 6 | 12 | 76.29 | 81.61 | 77.17 | 82.18 |

| Oxygen(O) | 8 | 16 | 22.04 | 17.70 | 21.85 | 17.47 |

| Chlorine (Cl) | 17 | 35.5 | 1.03 | 0.37 | 0.97 | 0.35 |

| Sodium (Na) | 11 | 23 | 0.28 | 0.16 | -- | -- |

| Silicon (Si) | 14 | 28 | 0.35 | 0.16 | -- | -- |

| Element Type | Element No. | Atomic Weight | Hemp Biocomposite | Flax Biocomposite | ||

|---|---|---|---|---|---|---|

| Weight (%) | Atomic Conc. (%) | Weight (%) | Atomic Conc. (%) | |||

| Carbon (C) | 6 | 12 | 63.73 | 70.26 | 68.82 | 74.62 |

| Oxygen(O) | 8 | 16 | 35.67 | 29.52 | 31.18 | 25.38 |

| Chlorine (Cl) | 17 | 35.5 | 0.60 | 0.22 | -- | -- |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Atmakuri, A.; Palevicius, A.; Janusas, G.; Eimontas, J. Investigation of Hemp and Flax Fiber-Reinforced EcoPoxy Matrix Biocomposites: Morphological, Mechanical, and Hydrophilic Properties. Polymers 2022, 14, 4530. https://doi.org/10.3390/polym14214530

Atmakuri A, Palevicius A, Janusas G, Eimontas J. Investigation of Hemp and Flax Fiber-Reinforced EcoPoxy Matrix Biocomposites: Morphological, Mechanical, and Hydrophilic Properties. Polymers. 2022; 14(21):4530. https://doi.org/10.3390/polym14214530

Chicago/Turabian StyleAtmakuri, Ayyappa, Arvydas Palevicius, Giedrius Janusas, and Justas Eimontas. 2022. "Investigation of Hemp and Flax Fiber-Reinforced EcoPoxy Matrix Biocomposites: Morphological, Mechanical, and Hydrophilic Properties" Polymers 14, no. 21: 4530. https://doi.org/10.3390/polym14214530

APA StyleAtmakuri, A., Palevicius, A., Janusas, G., & Eimontas, J. (2022). Investigation of Hemp and Flax Fiber-Reinforced EcoPoxy Matrix Biocomposites: Morphological, Mechanical, and Hydrophilic Properties. Polymers, 14(21), 4530. https://doi.org/10.3390/polym14214530