Manufacturing of Carbon Fibers/Polyphenylene Sulfide Composites via Induction-Heating Molding: Morphology, Mechanical Properties, and Flammability

Abstract

1. Introduction

2. Experimental

2.1. Materials

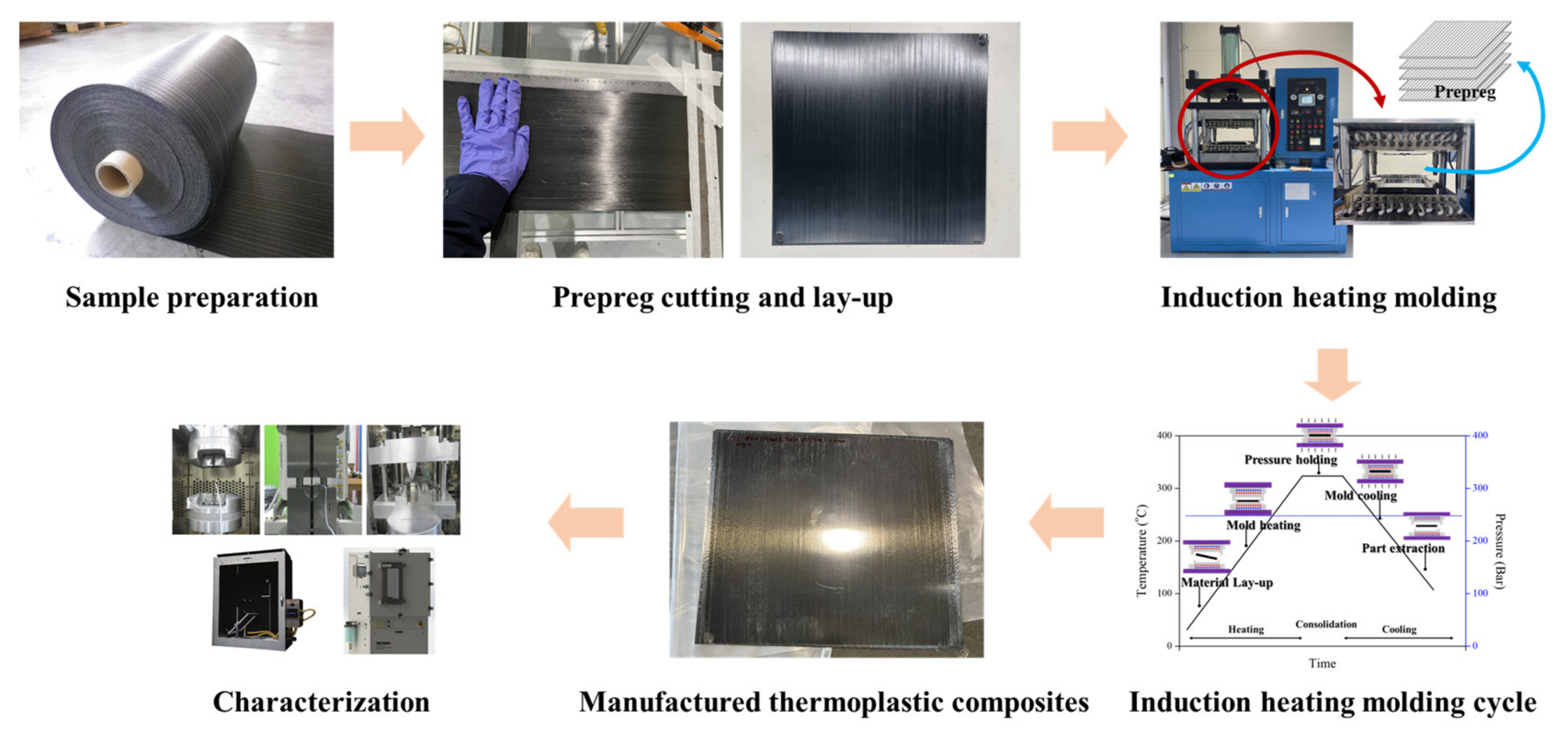

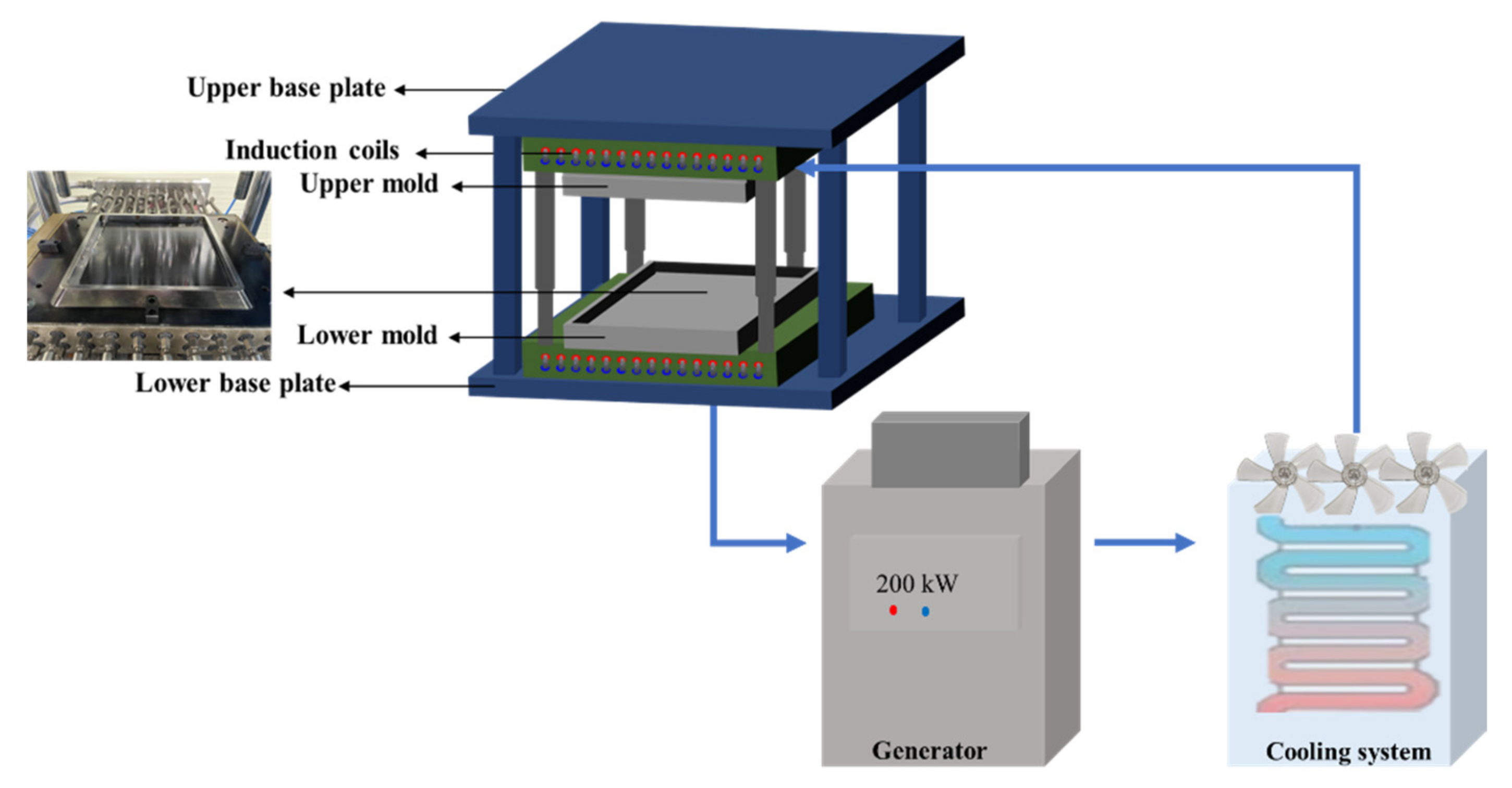

2.2. Composite Manufacturing and Sample Preparation

2.3. Characterization

2.3.1. Microstructural Properties

2.3.2. Thermal Properties

2.3.3. Mechanical Properties

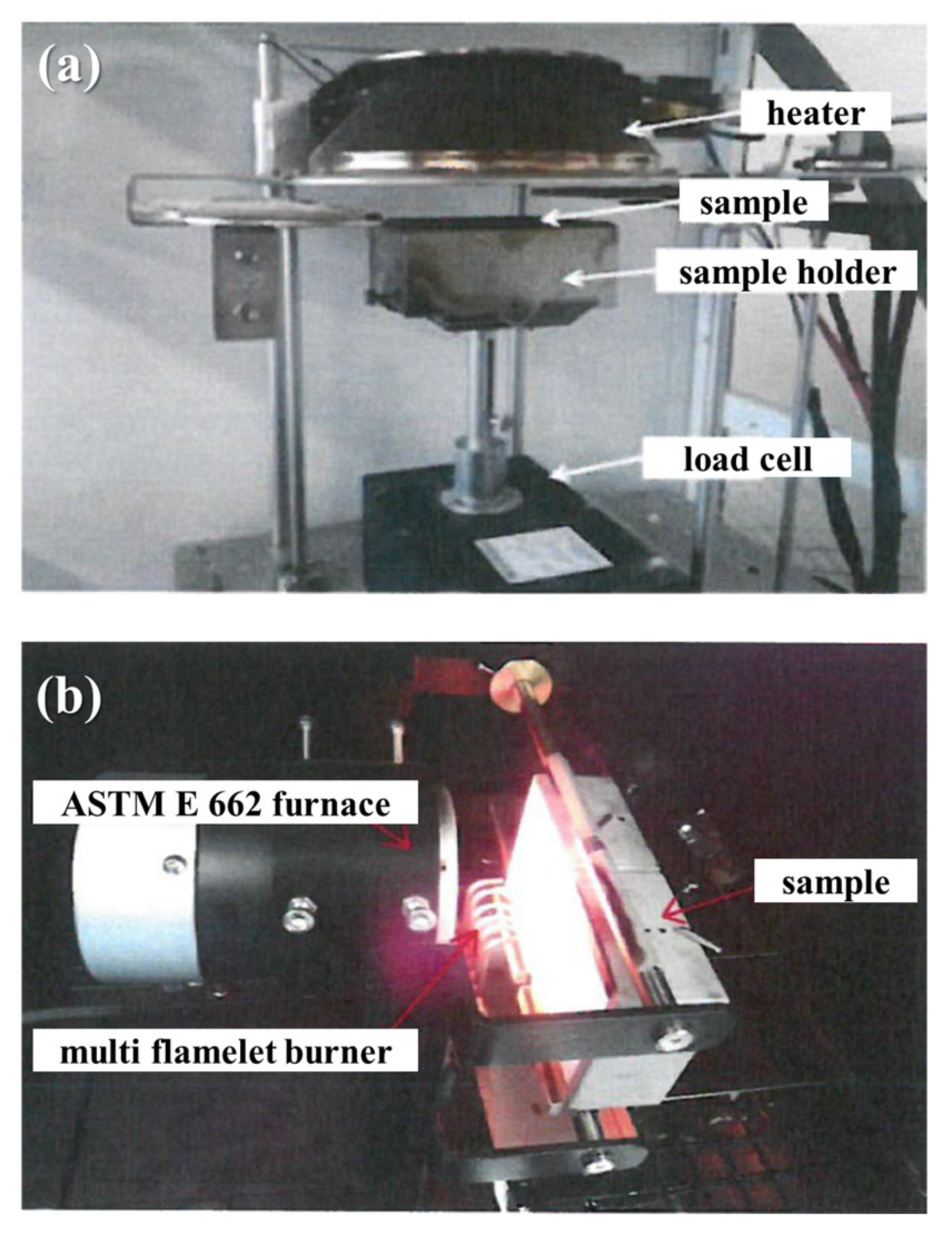

2.3.4. Flammability Properties

3. Results and Discussion

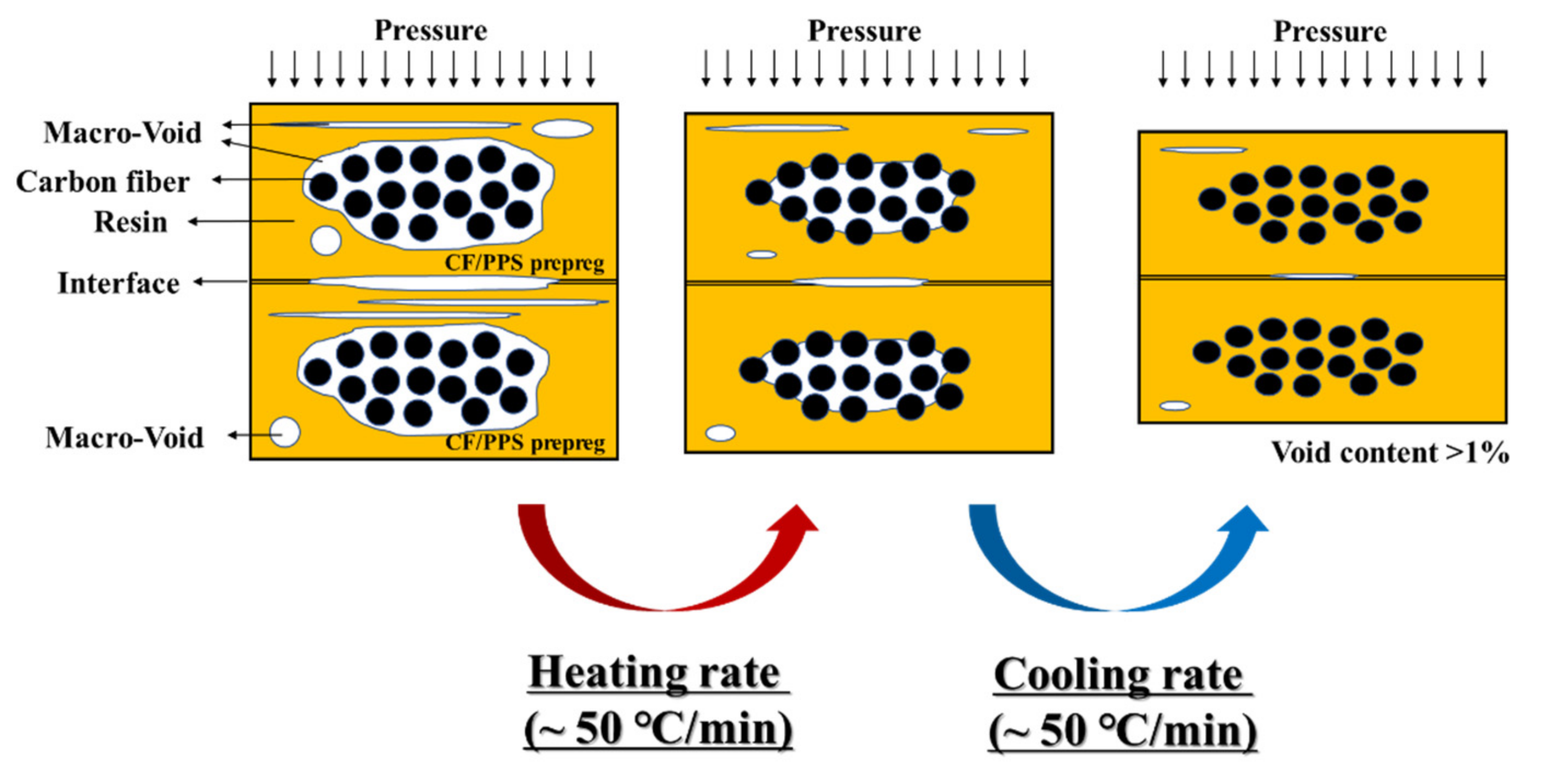

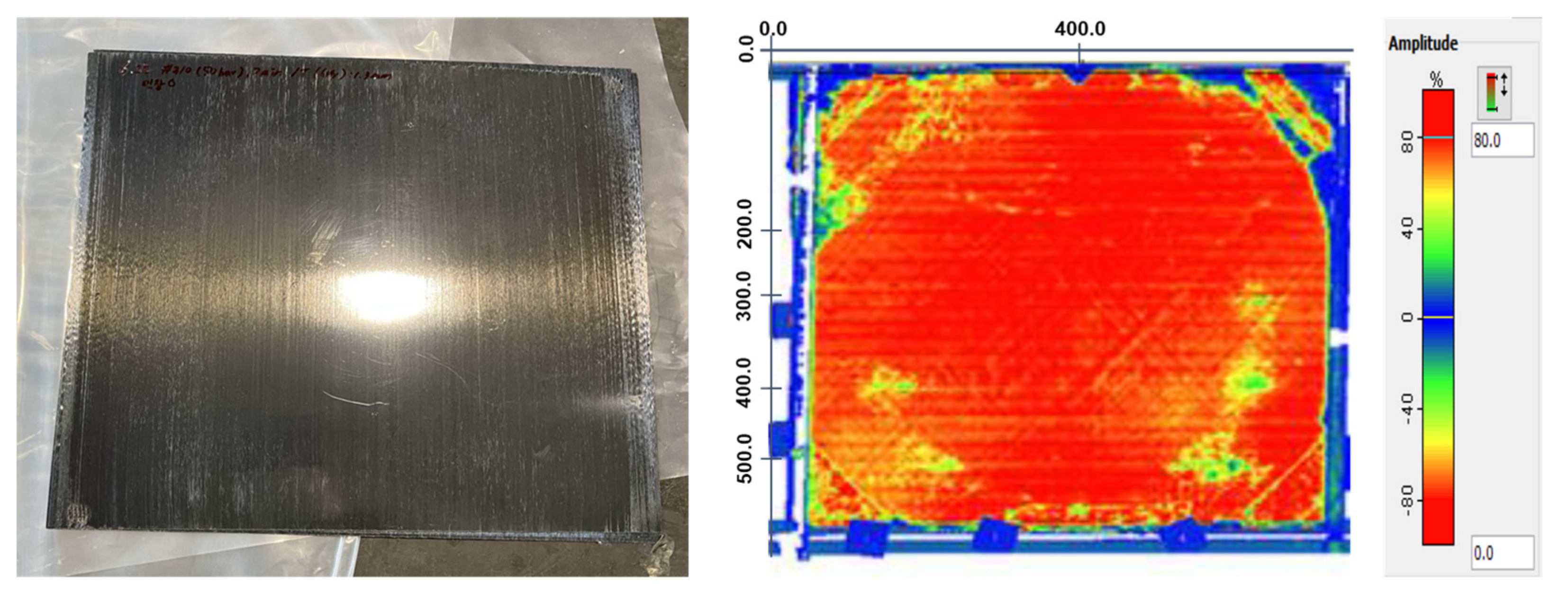

3.1. Microstructural Properties

3.2. Thermal Properties

3.3. Mechanical Properties

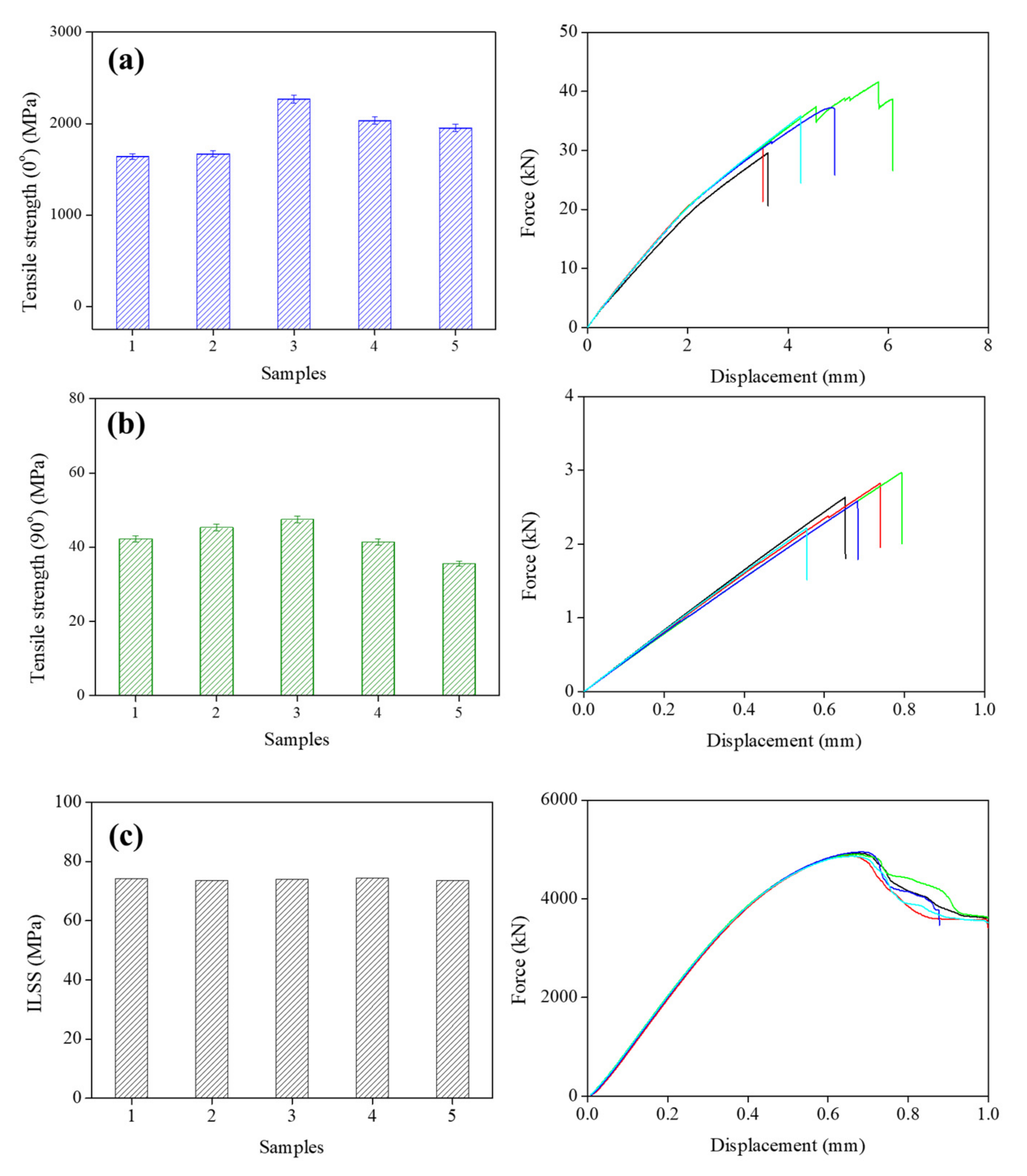

Tensile Strength and ILSS

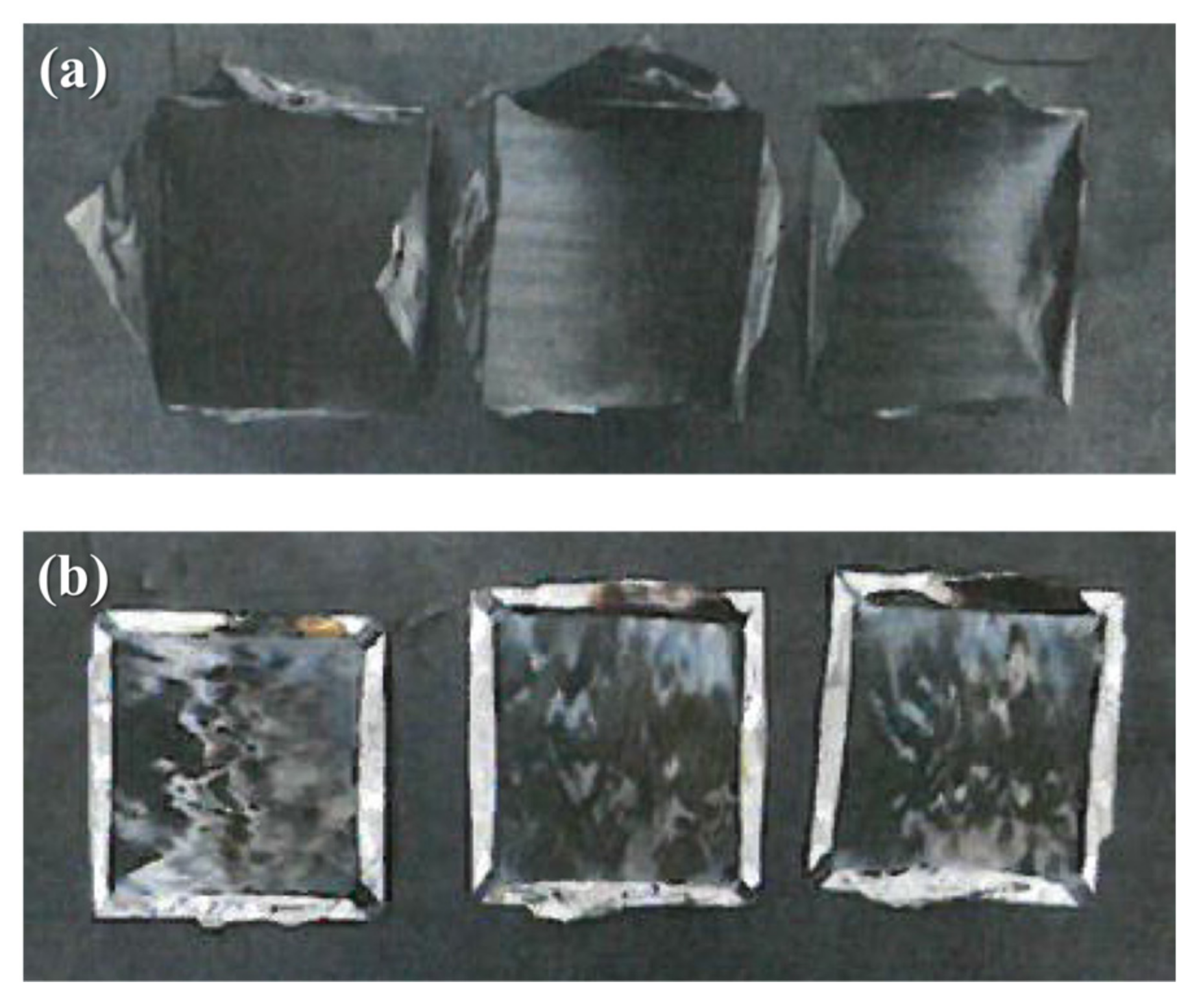

3.4. Flammability Properties

3.4.1. Fire

3.4.2. Smoke Density

3.4.3. Toxicity

4. Conclusions

- (1)

- The void content of the CF/PPS composites treated via the induction process at 280 °C was lower than 1%, which is an acceptable value for the aerospace industry.

- (2)

- The tensile strengths along 0° and 90°, and ILSS of the CF/PPS composites were 1912.57 ± 262.58 MPa, 42.37 ± 4.52 MPa, and 73.92 ± 0.41 MPa, respectively.

- (3)

- In addition, the CF/PPS composites exhibited a superior fire performance, with a lower PHRR, mass loss rate, and fire load for THR.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gibson, A.; Torres, M.O.; Browne, T.; Feih, S.; Mouritz, A. High temperature and fire behaviour of continuous glass fibre/polypropylene laminates. Compos. Part A: Appl. Sci. Manuf. 2010, 41, 1219–1231. [Google Scholar] [CrossRef]

- Choi, B.-K.; Choi, W.-K.; Rhee, K.Y.; Park, S.-J.; Seo, M.-K. Influence of heat treatment temperature on structure and exothermic properties of electroless Ni P plating carbon fiber heating elements. Compos. Part B: Eng. 2019, 167, 676–682. [Google Scholar] [CrossRef]

- Dogan, A.; Arikan, V. Low-velocity impact response of E-glass reinforced thermoset and thermoplastic based sandwich composites. Compos. Part B: Eng. 2017, 127, 63–69. [Google Scholar] [CrossRef]

- Katsiropoulos, C.V.; Pantelakis, S.G.; Barile, M.; Lecce, L. Development of a Novel Hybrid Thermoplastic Material and Holistic Assessment of Its Application Potential. Aerospace 2021, 8, 351. [Google Scholar] [CrossRef]

- Oliveux, G.; Dandy, L.O.; Leeke, G.A. Current status of recycling of fibre reinforced polymers: Review of technologies, reuse and resulting properties. Prog. Mater. Sci. 2015, 72, 61–99. [Google Scholar] [CrossRef]

- Schuhler, E.; Coppalle, A.; Vieille, B.; Yon, J.; Carpier, Y. Behaviour of aeronautical polymer composite to flame: A comparative study of thermoset- and thermoplastic-based laminate. Polym. Degrad. Stab. 2018, 152, 105–115. [Google Scholar] [CrossRef]

- Behera, R.P.; Rawat, P.; Singh, K.K.; Ha, S.K.; Gaurav, A.; Tiwari, S.K. Fracture analysis and mechanical properties of three phased glass/epoxy laminates reinforced with multiwalled carbon nanotubes. J. Sci. Adv. Mater. Devices 2019, 4, 299–309. [Google Scholar] [CrossRef]

- Chee, S.S.; Jawaid, M.; Alothman, O.Y.; Yahaya, R. Thermo-oxidative stability and flammability properties of bamboo/kenaf/nanoclay/epoxy hybrid nanocomposites. RSC Adv. 2020, 10, 21686–21697. [Google Scholar] [CrossRef]

- Wu, W.; Wang, Q.; Li, W. Comparison of Tensile and Compressive Properties of Carbon/Glass Interlayer and Intralayer Hybrid Composites. Materials 2018, 11, 1105. [Google Scholar] [CrossRef]

- Vieille, B.; Albouy, W.; Chevalier, L.; Taleb, L. About the influence of stamping on thermoplastic-based composites for aeronautical applications. Compos. Part B: Eng. 2013, 45, 821–834. [Google Scholar] [CrossRef]

- Liu, P.; Dinwiddie, R.B.; Keum, J.K.; Vasudevan, R.K.; Jesse, S.; Nguyen, N.A.; Lindahl, J.M.; Kunc, V. Rheology, crystal structure, and nanomechanical properties in large-scale additive manufacturing of polyphenylene sulfide/carbon fiber composites. Compos. Sci. Technol. 2018, 168, 263–271. [Google Scholar] [CrossRef]

- Li, H.; Wang, Y.; Zhang, C.; Zhang, B. Effects of thermal histories on interfacial properties of carbon fiber/polyamide 6 composites: Thickness, modulus, adhesion and shear strength. Compos. Part A: Appl. Sci. Manuf. 2016, 85, 31–39. [Google Scholar] [CrossRef]

- Kiss, P.; Glinz, J.; Stadlbauer, W.; Burgstaller, C.; Archodoulaki, V.M. The effect of thermally desized carbon fibre reinforcement on the flexural and impact properties of PA6, PPS and PEEK composite laminates: A comparative study. Compos. Part B. 2021, 215, 108844. [Google Scholar] [CrossRef]

- Ren, H.; Xu, D.; Yan, G.; Zhang, G.; Wang, X.; Long, S.; Yang, J. Effect of carboxylic polyphenylene sulfide on the micromechanical properties of polyphenylene sulfide/carbon fiber composites. Compos. Sci. Technol. 2017, 146, 65–72. [Google Scholar] [CrossRef]

- Park, M.; Park, J.H.; Yang, B.J.; Cho, J.; Kim, S.Y.; Jung, I. Enhanced interfacial, electrical, and flexural properties of polyphenylene sulfide composites filled with carbon fibers modified by electrophoretic surface deposition of multi-walled carbon nanotubes. Compos. Part A 2018, 109, 124–130. [Google Scholar] [CrossRef]

- Centea, T.; Grunenfelder, L.K.; Nutt, S.R. A review of out-of-autoclave prepregs—Material properties, process phenomena, and manufacturing considerations. Compos. Part A 2015, 70, 132–154. [Google Scholar] [CrossRef]

- Comer, A.J.; Ray, D.; Obande, W.O.; Jones, D.; Lyons, J.; Rosca, I.; O’Higgins, R.M.; McCarthy, M.A. Mechanical characterisation of carbon fibre–PEEK manufactured by laser-assisted automated-tape-placement and autoclave. Compos. Part A 2015, 69, 10–20. [Google Scholar] [CrossRef]

- Qureshi, Z.; Swait, T.; Scaife, R.; El-Dessouky, H. In situ consolidation of thermoplastic prepreg tape using automated tape placement technology: Potential and possibilities. Compos. Part B 2014, 66, 255–267. [Google Scholar] [CrossRef]

- Saenz-Castillo, D.; Martin, M.I.; Calvo, S.; Rodriguez-Lence, F.; Guemes, A. Effect of processing parameters and void content on mechanical properties and NDI of thermoplastic composites. Compos. Part A 2019, 121, 308–320. [Google Scholar] [CrossRef]

- Zheng, B.; Li, M.; Deng, T.; Zhou, H.; Huang, Z.; Zhou, H.; Li, D. Process-structure-property relationships of thermoformed woven carbon-fiber-reinforced polyether-ether-ketone composites. Polym. Compos. 2019, 40, 3823–3834. [Google Scholar] [CrossRef]

- Ma, X.-L.; Wen, L.-H.; Wang, S.-Y.; Xiao, J.-Y.; Li, W.-H.; Hou, X. Inherent relationship between process parameters, crystallization and mechanical properties of continuous carbon fiber reinforced PEEK composites. Def. Technol. 2022. In Press. [Google Scholar] [CrossRef]

- Chen, J.; Fu, K.; Li, Y. Understanding processing parameter effects for carbon fibre reinforced thermoplastic composites manufactured by laser-assisted automated fibre placement (AFP). Compos. Part A: Appl. Sci. Manuf. 2020, 140, 106160. [Google Scholar] [CrossRef]

- Ramakrishnan, K.R.; Moigne, N.L.; Almeida, O.D.; Regazzi, A.; Corn, S. Optimized manufacturing of thermoplastic biocomposites by fast induction heated compression moulding: Influence of processing parameters on microstructure development and mechanical behaviour. Compos. Part A 2019, 124, 105493. [Google Scholar] [CrossRef]

- Kim, B.-J.; Cha, S.-H.; Park, Y.-B. Ultra-high-speed processing of nanomaterial-reinforced woven carbon fiber/polyamide 6 composites using reactive thermoplastic resin transfer molding. Compos. Part B: Eng. 2018, 143, 36–46. [Google Scholar] [CrossRef]

- Blond, D.; Vieille, B.; Gomina, M.; Taleb, L. Correlation between physical properties, microstructure and thermo-mechanical behavior of PPS-based composites processed by stamping. J. Reinf. Plast. Compos. 2014, 33, 1656–1668. [Google Scholar] [CrossRef]

- ASTM D 2344. Standard Test Method for Short-Beam Strength of Polymer Matrix Composite Materials and Their Laminates. ASTM International: West Conshohocken, PA, USA, 2000.

- ISO 5660-1; Reaction to Fire Tests-Heat Release, Smoke Production and Mass Loss Rate. Swiss, International Organization for Standardization: Geneva, Switzerland, 2002.

- ASTM E 662; Standard Test Method for Specific Optical Density of Smoke Generated by Solid Materials. ASTM International: West Conshohocken, PA, USA, 2012.

- BS 6853; Code of Practice for Fire Precautions in the Design and Construction of Passenger Carrying Trains/Annex B/Determination of Weighted Summation of Toxic Fume. British Standards Institution: London, UK, 1999.

- Carpier, Y.; Vieille, B.; Coppalle, A.; Barbe, F. About the tensile mechanical behaviour of carbon fibers fabrics reinforced thermoplastic composites under very high temperature conditions. Compos. Part B: Eng. 2019, 181, 107586. [Google Scholar] [CrossRef]

- Dilonardo, E.; Nacucchi, M.; De Pascalis, F.; Zarrelli, M.; Giannini, C. Inspection of Carbon Fibre Reinforced Polymers: 3D identification and quantification of components by X-ray CT. Appl. Compos. Mater. 2021, 29, 497–513. [Google Scholar] [CrossRef]

- Sommacal, S.; Matschinski, A.; Drechsler, K.; Compston, P. Characterisation of void and fiber distribution in 3D printed carbon-fiber/PEEK using X-ray computed tomography. Compos. Part A: Appl. Sci. Manuf. 2021, 149, 106487. [Google Scholar] [CrossRef]

- Gao, S.; Kim, J.-K. Cooling rate influences in carbon fibre/PEEK composites. Part 1. Crystallinity and interface adhesion. Compos. Part A: Appl. Sci. Manuf. 2000, 31, 517–530. [Google Scholar] [CrossRef]

- Durmaz, B.; Aytac, A. Characterization of carbon fiber-reinforced poly(phenylene sulfide) composites prepared with various compatibilizers. J. Compos. Mater. 2019, 54, 89–100. [Google Scholar] [CrossRef]

- Vieille, B.; Coppalle, A.; Le Pluart, L.; Schuhler, E.; Chaudhary, A.; Rijal, B.; Alia, A.; Delpouve, N.; Bourdet, A. Influence of a flame-retardant on the fire-behaviour and the residual mechanical properties of C/PEKK composite laminates exposed to a kerosene flame. Compos. Part A: Appl. Sci. Manuf. 2021, 152, 106720. [Google Scholar] [CrossRef]

- Wolter, N.; Beber, V.C.; Sandinge, A.; Blomqvist, P.; Goethals, F.; Van Hove, M.; Jubete, E.; Mayer, B.; Koschek, K. Carbon, Glass and Basalt Fiber Reinforced Polybenzoxazine: The Effects of Fiber Reinforcement on Mechanical, Fire, Smoke and Toxicity Properties. Polymers 2020, 12, 2379. [Google Scholar] [CrossRef] [PubMed]

- Oyama, H.T.; Sekikawa, M.; Shida, S. Effect of the interface structure on the morphology and the mechanical, thermal, and flammability properties of polypropylene/poly(phenylene ether)/magnesium hydroxide composites. Polym. Degrad. Stabil. 2012, 152, 105–115. [Google Scholar] [CrossRef]

- Marset, D.; Dolza, C.; Fages, E.; Gonga, E.; Gutierrez, O.; Gomez-Caturla, J.; Ivorra-Martinez, J.; Sanchez-Nacher, L.; Quiles-Carrillo, L. The effect of halloysite nanotubes on the fire retardancy properties of partially biobased polyamide 610. Polymers 2020, 12, 3050–3071. [Google Scholar] [CrossRef]

- Feuillerat, L.; Almeida, O.D.; Fontanier, J.C.; Schmidt, F. Effect of poly(ether ether ketone) degradation on commingled fabrics consolidation. Compos. Part A 2021, 149, 106482. [Google Scholar] [CrossRef]

- Vieille, B.; Coppalle, A.; Schuhler, E.; Chaudhary, A.; Alia, A.; Delpouve, N.; Bourdet, A. Influence of kerosene flame on fire-behaviour and mechanical properties of hybrid Carbon Glass fibers reinforced PEEK composite laminates. Compos. Struct. 2021, 279, 114786. [Google Scholar] [CrossRef]

| Test | Unit | Value |

|---|---|---|

| Density | g/cm3 | 1.35 |

| Glass transition temperature (Tg) | °C | 90 |

| Melting temperature (Tm) | °C | 280 |

| Processing temperature (Tp) | °C | 300–330 |

| Tensile strength (0°) | MPa | 2020 |

| Tensile strength (90°) | MPa | 39 |

| Gas | Reference (g/m2) | Results (g/m2) |

|---|---|---|

| CO2 | 14,000 | 648.6 |

| CO | 280 | 2 |

| HCL | 15 | 0 |

| HBr | 20 | 0 |

| HCN | 11 | 0 |

| HF | 4.9 | 0 |

| SO2 | 53 | 0 |

| NO2 | 7.6 | 0 |

| Toxicity index (R) | 0.06 | |

| Temperature (°C) | Degree of Crystallinity (%) |

|---|---|

| 250 | 23.1 |

| 280 | 25.3 |

| 310 | 26.2 |

| Composites | TTI (s) | PHRR (kW/m2) | THR (MJ/m2) | MARHE (kW/m2) | Refs. |

|---|---|---|---|---|---|

| CF/PPS | 0 | 2.8 ± 0.1 | 0.9 ± 0.1 | 1.1 ± 0.1 | This work |

| CFRP a | 78 ± 1 | 196 ± 9 | 34.9 ± 0.1 | 94.6 ± 1.7 | [26] |

| PP b | 25 ± 2 | 1738 ± 78 | 34 ± 1 | - | [27] |

| PA 610 c | 73.5 ± 0.5 | 743 ± 4 | 128.1 ± 10.2 | 337.8 ± 5.2 | [28] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, C.-S.; Shin, H.-K.; Chung, Y.-S.; Seo, M.-K.; Choi, B.-K. Manufacturing of Carbon Fibers/Polyphenylene Sulfide Composites via Induction-Heating Molding: Morphology, Mechanical Properties, and Flammability. Polymers 2022, 14, 4587. https://doi.org/10.3390/polym14214587

Kang C-S, Shin H-K, Chung Y-S, Seo M-K, Choi B-K. Manufacturing of Carbon Fibers/Polyphenylene Sulfide Composites via Induction-Heating Molding: Morphology, Mechanical Properties, and Flammability. Polymers. 2022; 14(21):4587. https://doi.org/10.3390/polym14214587

Chicago/Turabian StyleKang, Chang-Soo, Hyun-Kyu Shin, Yong-Sik Chung, Min-Kang Seo, and Bo-Kyung Choi. 2022. "Manufacturing of Carbon Fibers/Polyphenylene Sulfide Composites via Induction-Heating Molding: Morphology, Mechanical Properties, and Flammability" Polymers 14, no. 21: 4587. https://doi.org/10.3390/polym14214587

APA StyleKang, C.-S., Shin, H.-K., Chung, Y.-S., Seo, M.-K., & Choi, B.-K. (2022). Manufacturing of Carbon Fibers/Polyphenylene Sulfide Composites via Induction-Heating Molding: Morphology, Mechanical Properties, and Flammability. Polymers, 14(21), 4587. https://doi.org/10.3390/polym14214587