Optimization of Processing Conditions and Mechanical Properties for PEEK/PEI Multilayered Blends

Abstract

1. Introduction

2. Materials and Methods

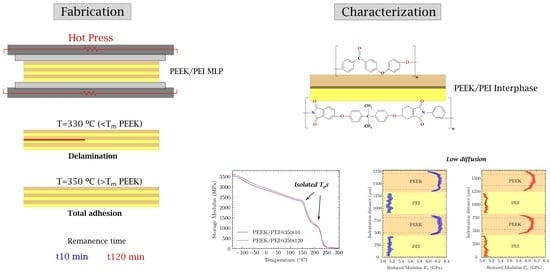

2.1. Samples Preparation

2.2. Experimental Techniques

2.2.1. Three-Point Bending Tests

2.2.2. Differential Scanning Calorimetry

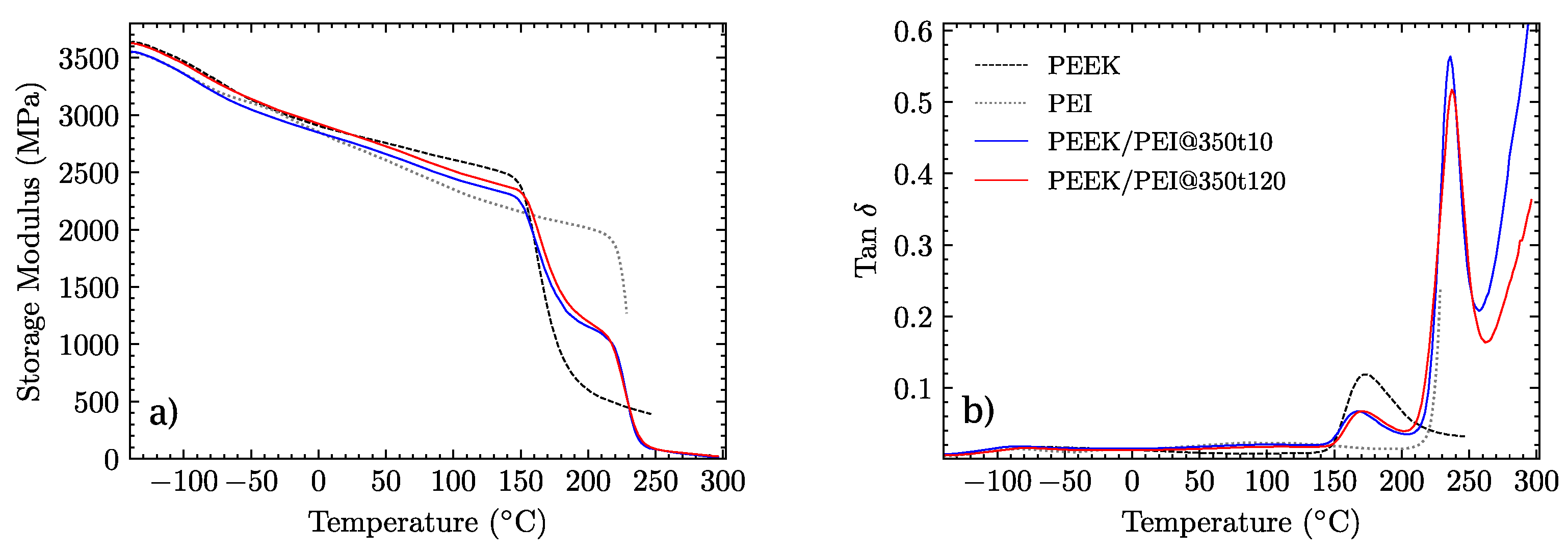

2.2.3. Dynamic Mechanical Analysis

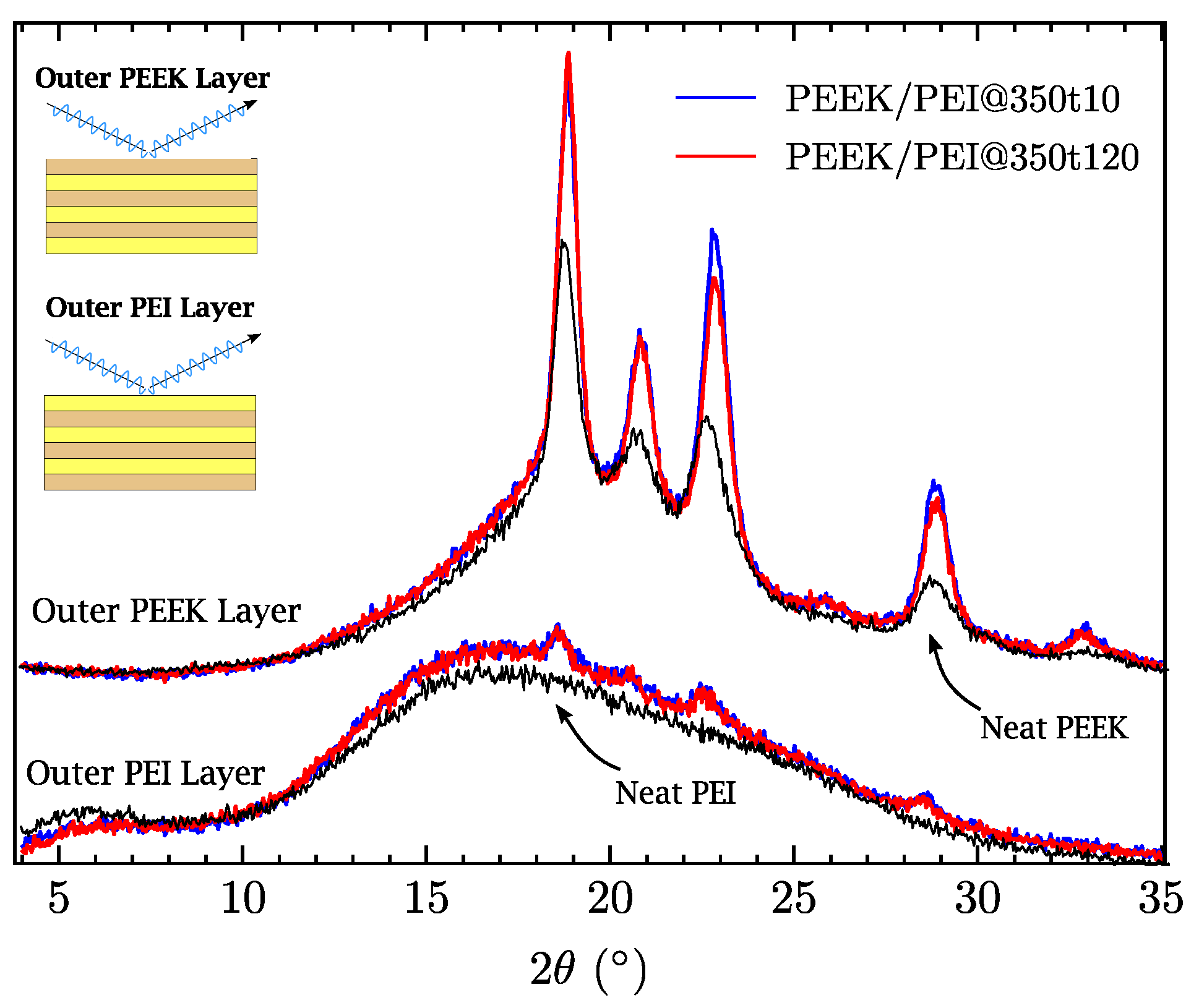

2.2.4. X-ray Diffraction (XRD)

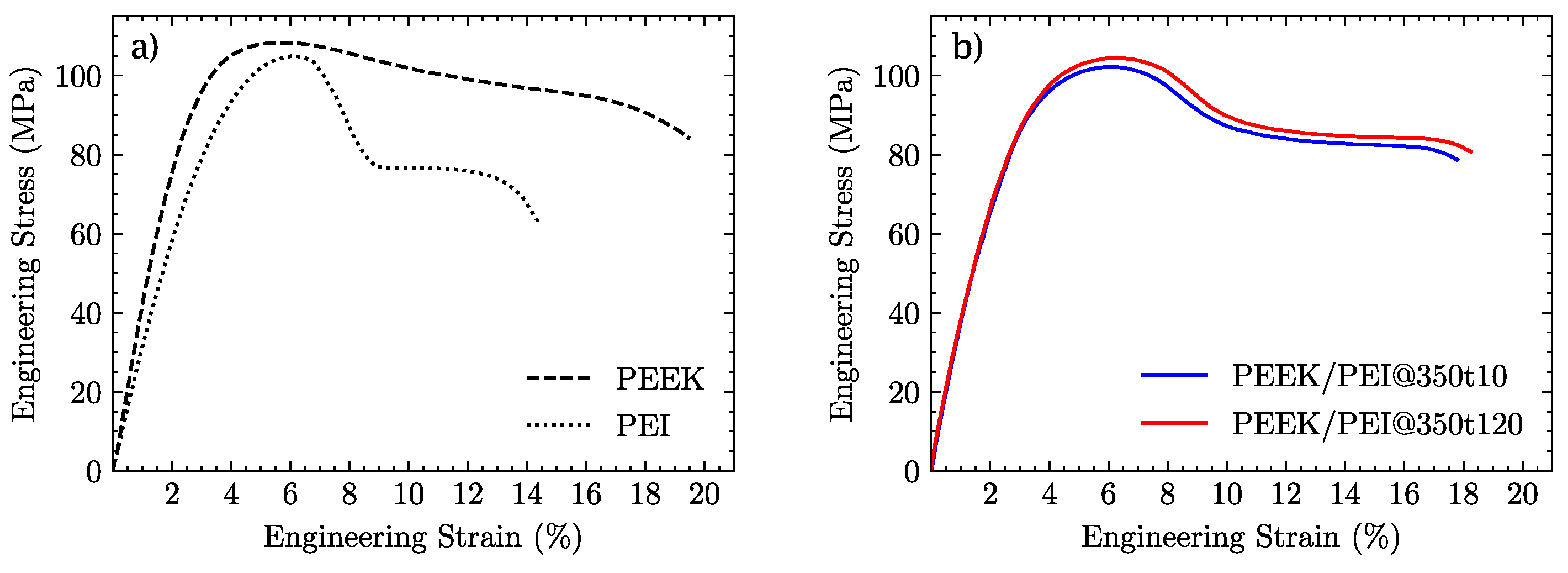

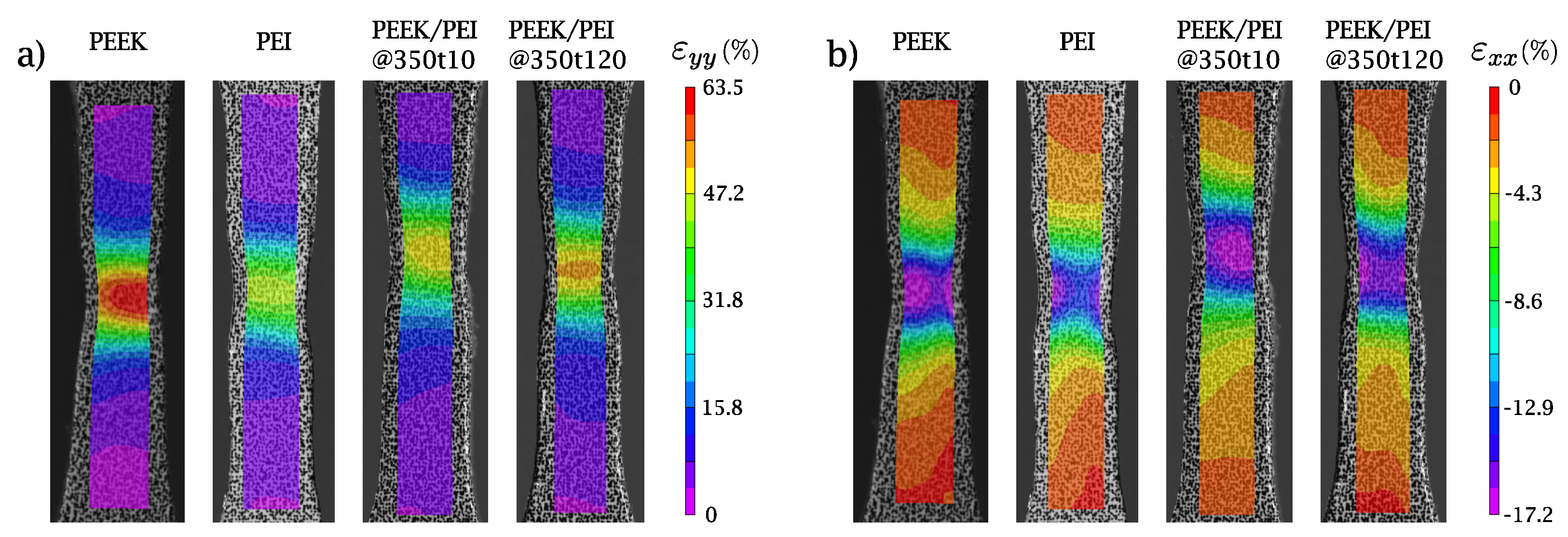

2.2.5. Tensile Tests

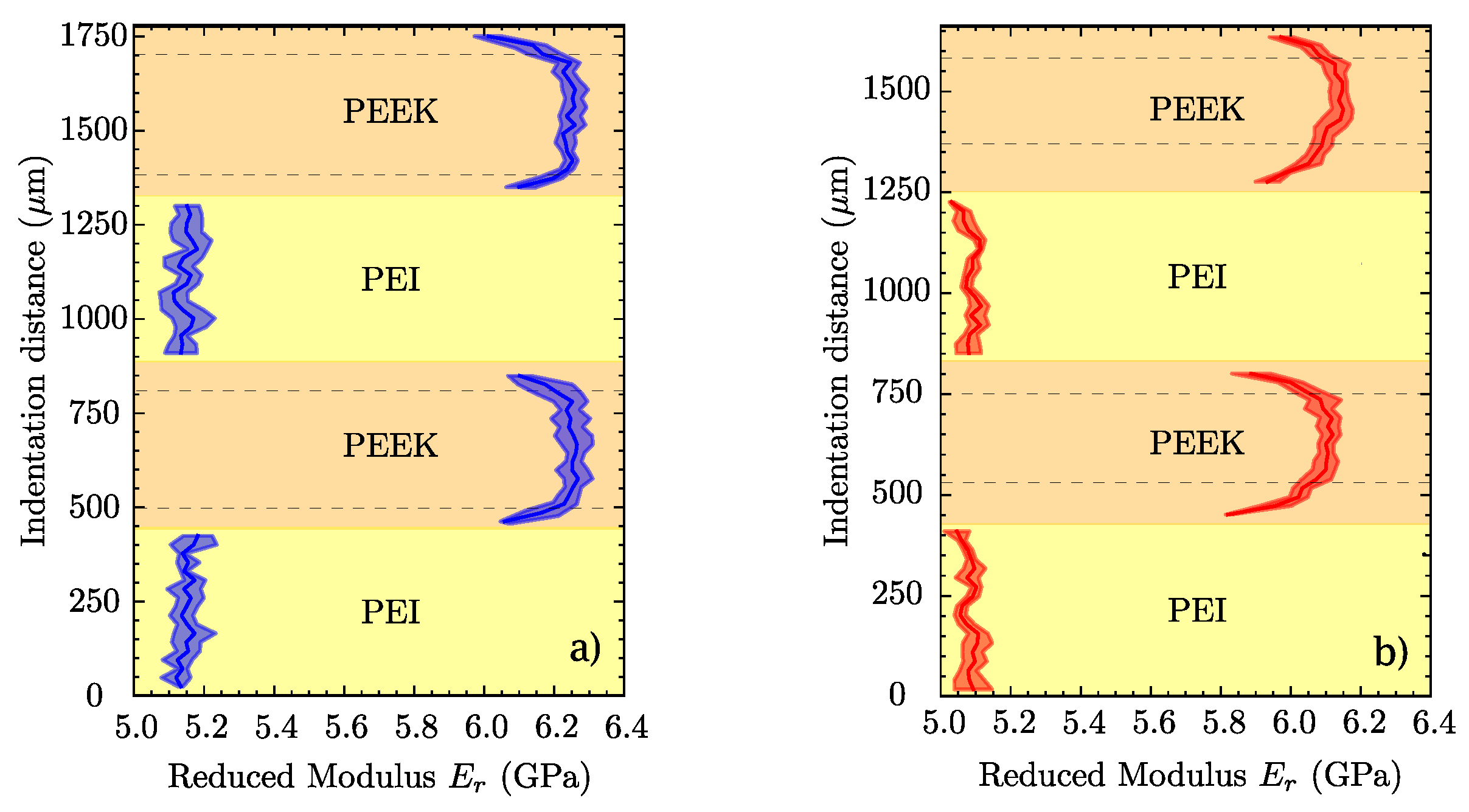

2.2.6. Nanoindentation Tests

3. Results and Discussion

3.1. PEEK/PEI Interface Integrity

3.2. Thermo-Mechanical Properties

3.3. Mechanical Properties of PEEK and PEI

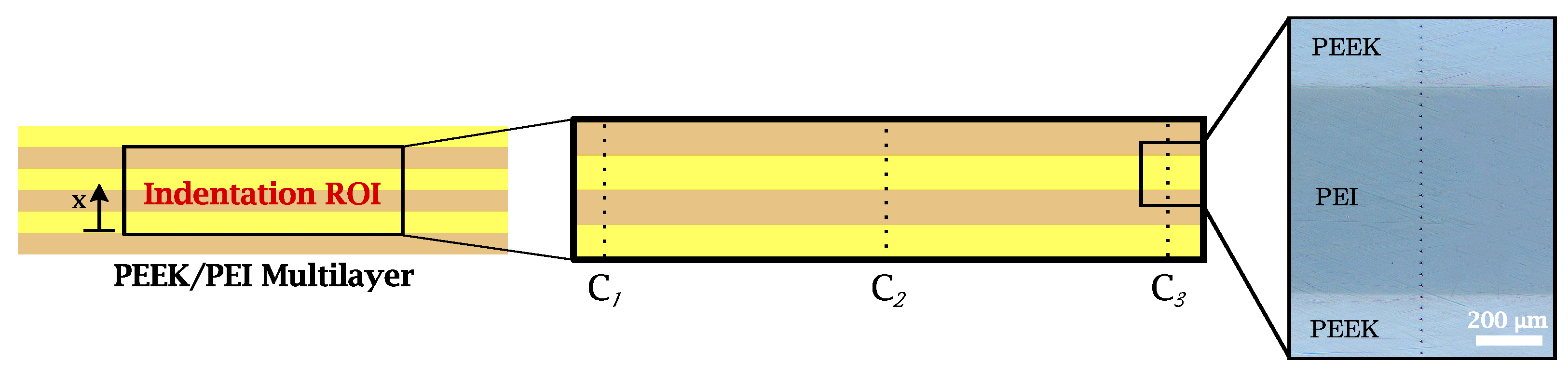

3.4. Nanoindentation across Transversal Section of PEEK/PEI MLPs

4. Conclusions

- Consolidation temperature has to exceed the melting point of PEEK (340 C) so that both polymers are in a viscous state and the molecular chains are mobile enough to achieve interpenetration.

- 350 C seems to be the optimal temperature. On the one hand, it is sufficient to guarantee good adhesion for a consolidation time as short as 10 min. On the other hand, the diffusivity of PEI at this temperature is still relatively low.

- This slow diffusion kinetics entails that under standard industrial consolidation times, the interfacial region that contains the homogeneous blend does not grow excessively and is confined to a thin layer.

- Outside the interfacial region, both polymers remain separate phases. PEEK is able to preserve a high degree of crystallinity, and the mechanical response can be described by the rule of mixtures.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mallick, P. Thermoplastics and thermoplastic–matrix composites for lightweight automotive structures. In Materials, Design and Manufacturing for Lightweight Vehicles; Elsevier: Amsterdam, The Netherlands, 2021; pp. 187–228. [Google Scholar]

- Bajurko, P. Comparison of damage resistance of thermoplastic and thermoset carbon fibre-reinforced composites. J. Thermoplast. Compos. Mater. 2021, 34, 303–315. [Google Scholar] [CrossRef]

- Bernatas, R.; Dagréou, S.; Despax-Ferreres, A.; Barasinski, A. Recycling of fiber reinforced composites with a focus on thermoplastic composites. Clean. Eng. Technol. 2021, 5, 100272. [Google Scholar] [CrossRef]

- Bean, P.; Lopez-Anido, R.A.; Vel, S. Integration of Material Characterization, Thermoforming Simulation, and As-Formed Structural Analysis for Thermoplastic Composites. Polymers 2022, 14, 1877. [Google Scholar] [CrossRef] [PubMed]

- Luo, M.; Tian, X.; Shang, J.; Yun, J.; Zhu, W.; Li, D.; Qin, Y. Bi-scale interfacial bond behaviors of CCF/PEEK composites by plasma-laser cooperatively assisted 3D printing process. Compos. Part A Appl. Sci. Manuf. 2020, 131, 105812. [Google Scholar] [CrossRef]

- Jose, J.V.; Panneerselvam, K. Joining of PEEK plates by friction stir welding process. Mater. Today Proc. 2021, 39, 1635–1639. [Google Scholar] [CrossRef]

- Pitchan, M.K.; Bhowmik, S.; Balachandran, M.; Abraham, M. Process optimization of functionalized MWCNT/polyetherimide nanocomposites for aerospace application. Mater. Des. 2017, 127, 193–203. [Google Scholar] [CrossRef]

- Sun, X.; Zhao, X.; Ye, L. Construction of gradient structure in polyetherimide/carbon nanotube nanocomposite foam and its thermal/mechanical property. Compos. Part A Appl. Sci. Manuf. 2019, 126, 105579. [Google Scholar] [CrossRef]

- Rae, P.; Brown, E.; Orler, E. The mechanical properties of poly (ether-ether-ketone)(PEEK) with emphasis on the large compressive strain response. Polymer 2007, 48, 598–615. [Google Scholar] [CrossRef]

- Fukuhara, M. Temperature dependency of elastic moduli and internal dilational and shear frictions of polyetherimide. J. Appl. Polym. Sci. 2003, 90, 759–764. [Google Scholar] [CrossRef]

- Kim, K.Y.; Ye, L. Effects of thickness and environmental temperature on fracture behaviour of polyetherimide (PEI). J. Mater. Sci. 2004, 39, 1267–1276. [Google Scholar] [CrossRef]

- Ahamad, A.; Kumar, P. Mechanical and thermal performance of PEEK/PEI blend matrix reinforced with surface modified halloysite nanotubes. J. Thermoplast. Compos. Mater. 2021, 08927057211028629. [Google Scholar] [CrossRef]

- Crevecoeur, G.; Groeninckx, G. Binary blends of poly (ether ether ketone) and poly (ether imide): Miscibility, crystallization behavior and semicrystalline morphology. Macromolecules 1991, 24, 1190–1195. [Google Scholar] [CrossRef]

- Ramani, R.; Alam, S. Free volume study on the miscibility of PEEK/PEI blend using positron annihilation and dynamic mechanical thermal analysis. J. Phys. Conf. Ser. 2015, 618, 012035. [Google Scholar] [CrossRef]

- Chun, Y.S.; Lee, H.S.; Jung, H.C.; Kim, W.N. Thermal properties of melt-blended poly (ether ether ketone) and poly (ether imide). J. Appl. Polym. Sci. 1999, 72, 733–739. [Google Scholar] [CrossRef]

- Kumar, S.; Mishra, R.K.; Nandi, T. Experimental and theoretical investigations of the high performance blends of PEEK/PEI. J. Polym. Eng. 2018, 38, 351–361. [Google Scholar] [CrossRef]

- Jenkins, M. Relaxation behaviour in blends of PEEK and PEI. Polymer 2000, 41, 6803–6812. [Google Scholar] [CrossRef]

- Ramani, R.; Alam, S. Composition optimization of PEEK/PEI blend using model-free kinetics analysis. Thermochim. Acta 2010, 511, 179–188. [Google Scholar] [CrossRef]

- El Magri, A.; El Mabrouk, K.; Vaudreuil, S. Preparation and characterization of poly (ether ether ketone)/poly (ether imide)[PEEK/PEI] blends for fused filament fabrication. J. Mater. Sci. 2021, 56, 14348–14367. [Google Scholar] [CrossRef]

- Chen, G.; Chen, Y.; Huang, T.; He, Z.; Xu, J.; Liu, P. Pore structure and properties of PEEK hollow fiber membranes: Influence of the phase structure evolution of PEEK/PEI composite. Polymers 2019, 11, 1398. [Google Scholar] [CrossRef]

- Ahamad, A.; Kumar, P. Evaluation of mechanical, thermal, and morphological properties of PEEK/PEI matrix reinforced with halloysite nanotubes. Polym.-Plast. Technol. Mater. 2021, 60, 1557–1567. [Google Scholar] [CrossRef]

- El Magri, A.; Vanaei, S.; Vaudreuil, S. An overview on the influence of process parameters through the characteristic of 3D-printed PEEK and PEI parts. High Perform. Polym. 2021, 33, 862–880. [Google Scholar] [CrossRef]

- Hahn, B.; Herrmann-Schönherr, O.; Wendorff, J. Evidence for a crystal-amorphous interphase in PVDF and PVDF/PMMA blends. Polymer 1987, 28, 201–208. [Google Scholar] [CrossRef]

- Talbott, M.F.; Springer, G.S.; Berglund, L.A. The effects of crystallinity on the mechanical properties of PEEK polymer and graphite fiber reinforced PEEK. J. Compos. Mater. 1987, 21, 1056–1081. [Google Scholar] [CrossRef]

- Li, W.; Wang, G.; Jiang, Z.; Liu, C.; Huo, P.; Zhang, S. Preparation and Characterization of high-strength poly (ether ether ketone) films. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Regis, M.; Bellare, A.; Pascolini, T.; Bracco, P. Characterization of thermally annealed PEEK and CFR-PEEK composites: Structure-properties relationships. Polym. Degrad. Stab. 2017, 136, 121–130. [Google Scholar] [CrossRef]

- Gao, S.L.; Kim, J.K. Cooling rate influences in carbon fibre/PEEK composites. Part 1. Crystallinity and interface adhesion. Compos. Part A Appl. Sci. Manuf. 2000, 31, 517–530. [Google Scholar] [CrossRef]

- Gholami, F.; Pakzad, L.; Behzadfar, E. Morphological, interfacial and rheological properties in multilayer polymers: A review. Polymer 2020, 208, 122950. [Google Scholar] [CrossRef]

- Langhe, D.; Ponting, M. Manufacturing and Novel Applications of Multilayer Polymer Films; William Andrew: Oxford, UK, 2016. [Google Scholar]

- Chen, X.; Tseng, J.K.; Treufeld, I.; Mackey, M.; Schuele, D.E.; Li, R.; Fukuto, M.; Baer, E.; Zhu, L. Enhanced dielectric properties due to space charge-induced interfacial polarization in multilayer polymer films. J. Mater. Chem. C 2017, 5, 10417–10426. [Google Scholar] [CrossRef]

- Yin, K.; Zhang, J.; Li, Z.; Feng, J.; Zhang, C.; Chen, X.; Olah, A.; Schuele, D.E.; Zhu, L.; Baer, E. Polymer multilayer films for high temperature capacitor application. J. Appl. Polym. Sci. 2019, 136, 47535. [Google Scholar] [CrossRef]

- Lai, J.; Yuan, H.; Yi, X.J.; Liu, S. Laser bonding of multilayer polymer microfluidic chips. In Proceedings of the Semiconductor Lasers and Applications II, International Society for Optics and Photonics, Beijing, China, 20 January 2005; Volume 5628, pp. 56–62. [Google Scholar]

- Alvaredo-Atienza, Á.; Chen, L.; San-Miguel, V.; Ridruejo, Á.; Fernández-Blázquez, J.P. Fabrication and Characterization of PEEK/PEI Multilayer Composites. Polymers 2020, 12, 2765. [Google Scholar] [CrossRef]

- ASTM International. D790-17; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM International. Standard Test Method for Tensile Properties of Plastics; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- Solutions, C. Vic 2D Reference Manual; Correlated Solutions: Columbia, SC, USA, 2009. [Google Scholar]

- Quino, G.; Chen, Y.; Ramakrishnan, K.R.; Martínez-Hergueta, F.; Zumpano, G.; Pellegrino, A.; Petrinic, N. Speckle patterns for DIC in challenging scenarios: Rapid application and impact endurance. Meas. Sci. Technol. 2020, 32, 015203. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Cafiero, L.; Iannace, S.; Sorrentino, L. Microcellular foams from high performance miscible blends based on PEEK and PEI. Eur. Polym. J. 2016, 78, 116–128. [Google Scholar] [CrossRef]

- Díez-Pascual, A.M.; Díez-Vicente, A.L. Nano-TiO2 reinforced PEEK/PEI blends as biomaterials for load-bearing implant applications. ACS Appl. Mater. Interfaces 2015, 7, 5561–5573. [Google Scholar] [CrossRef]

- Diouf-Lewis, A.; Farahani, R.D.; Iervolino, F.; Pierre, J.; Abderrafai, Y.; Lévesque, M.; Piccirelli, N.; Therriault, D. Design and characterization of carbon fiber-reinforced PEEK/PEI blends for Fused Filament Fabrication additive manufacturing. Mater. Today Commun. 2022, 31, 103445. [Google Scholar] [CrossRef]

- Bicakci, S.; Cakmak, M. Kinetics of rapid structural changes during heat setting of preoriented PEEK/PEI blend films as followed by spectral birefringence technique. Polymer 2002, 43, 2737–2746. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Toro, S.A.; Ridruejo, A.; González, C.; Monclús, M.A.; Fernández-Blázquez, J.P. Optimization of Processing Conditions and Mechanical Properties for PEEK/PEI Multilayered Blends. Polymers 2022, 14, 4597. https://doi.org/10.3390/polym14214597

Toro SA, Ridruejo A, González C, Monclús MA, Fernández-Blázquez JP. Optimization of Processing Conditions and Mechanical Properties for PEEK/PEI Multilayered Blends. Polymers. 2022; 14(21):4597. https://doi.org/10.3390/polym14214597

Chicago/Turabian StyleToro, Sebastián Andrés, Alvaro Ridruejo, Carlos González, Miguel A. Monclús, and Juan P. Fernández-Blázquez. 2022. "Optimization of Processing Conditions and Mechanical Properties for PEEK/PEI Multilayered Blends" Polymers 14, no. 21: 4597. https://doi.org/10.3390/polym14214597

APA StyleToro, S. A., Ridruejo, A., González, C., Monclús, M. A., & Fernández-Blázquez, J. P. (2022). Optimization of Processing Conditions and Mechanical Properties for PEEK/PEI Multilayered Blends. Polymers, 14(21), 4597. https://doi.org/10.3390/polym14214597