Ameliorating the Mechanical Parameters, Thermal Stability, and Wettability of Acrylic Polymer by Cement Filling for High-Efficiency Waterproofing

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

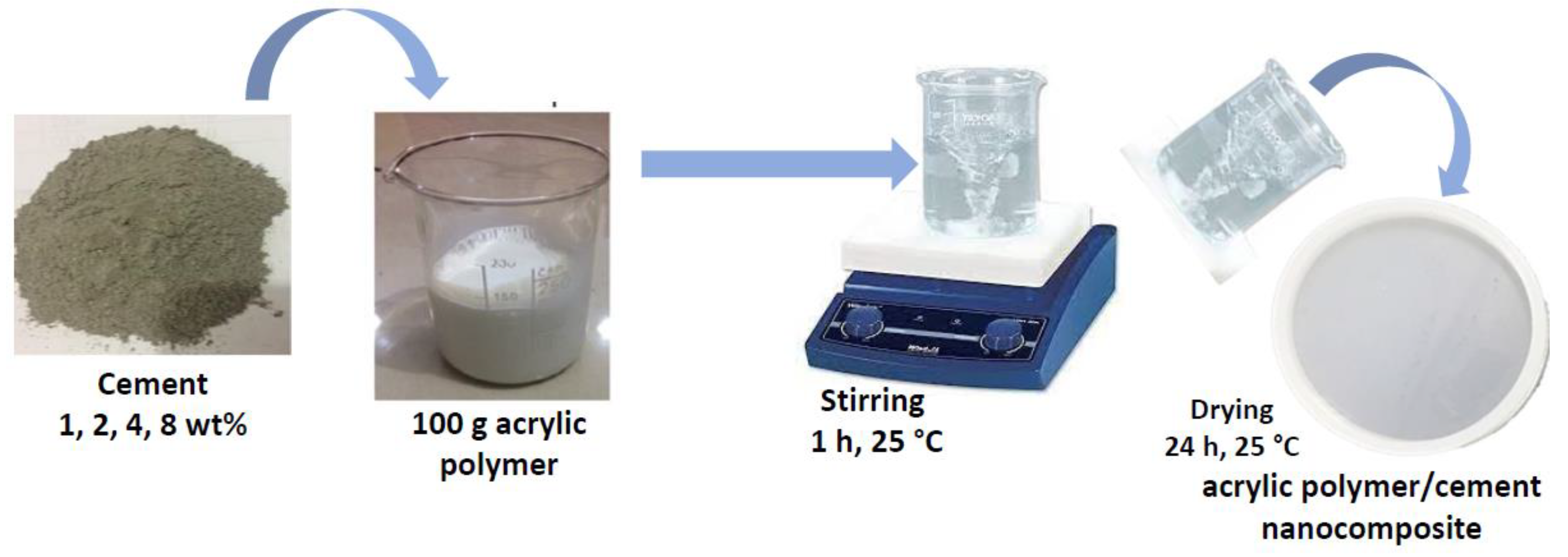

2.2. Preparation of Samples

2.3. Characterization of Samples

3. Results and Discussions

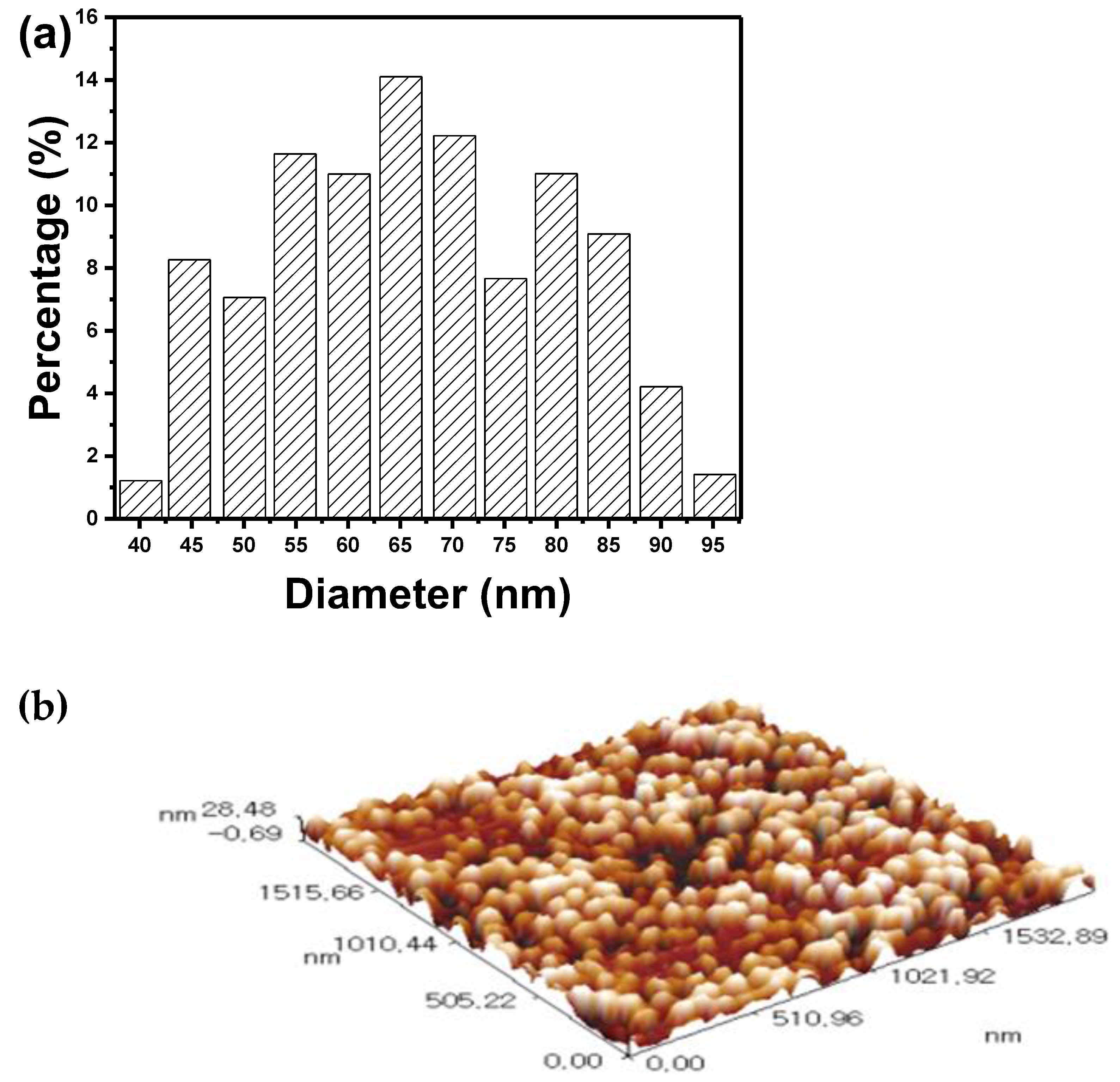

3.1. Structural Properteis

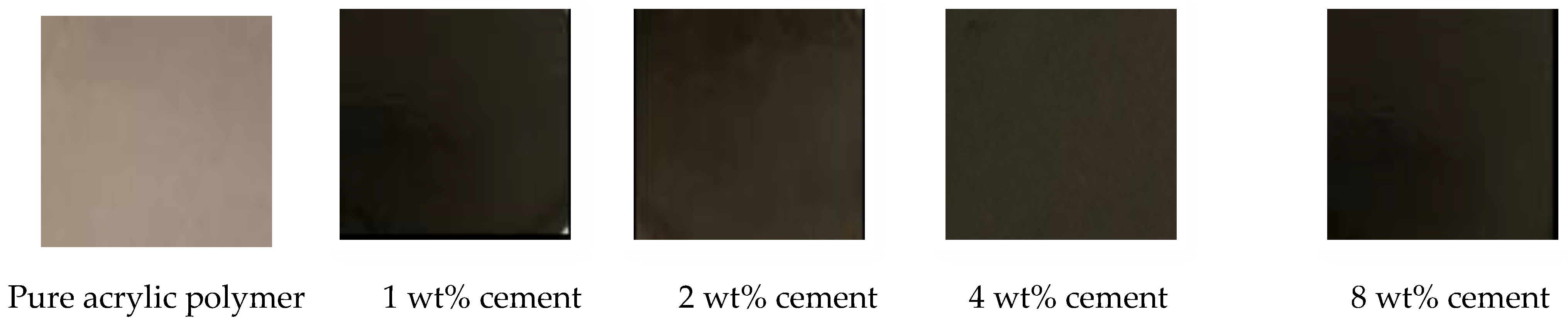

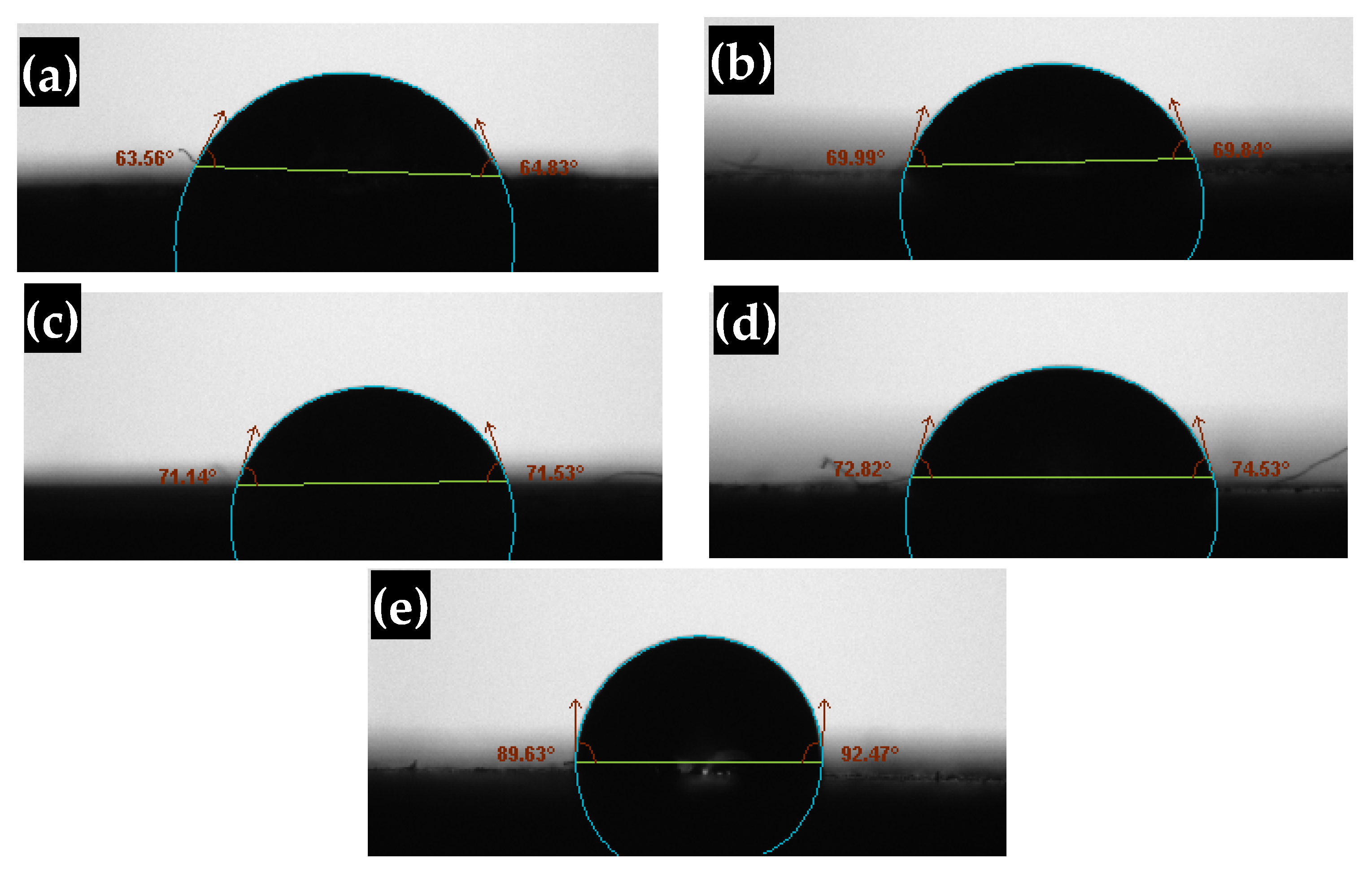

3.2. Surface Roughness and Wettability

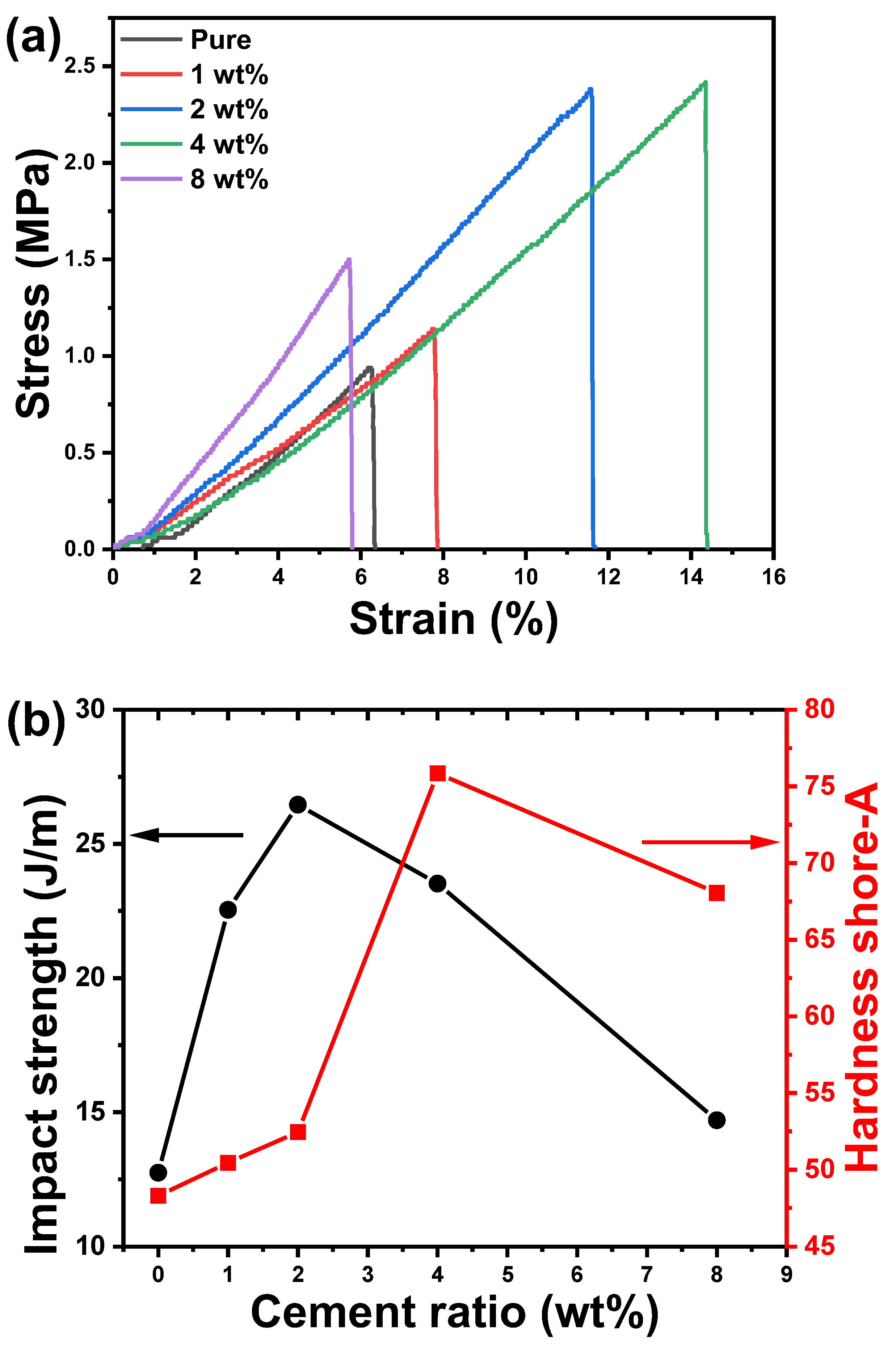

3.3. Mechanical Properties

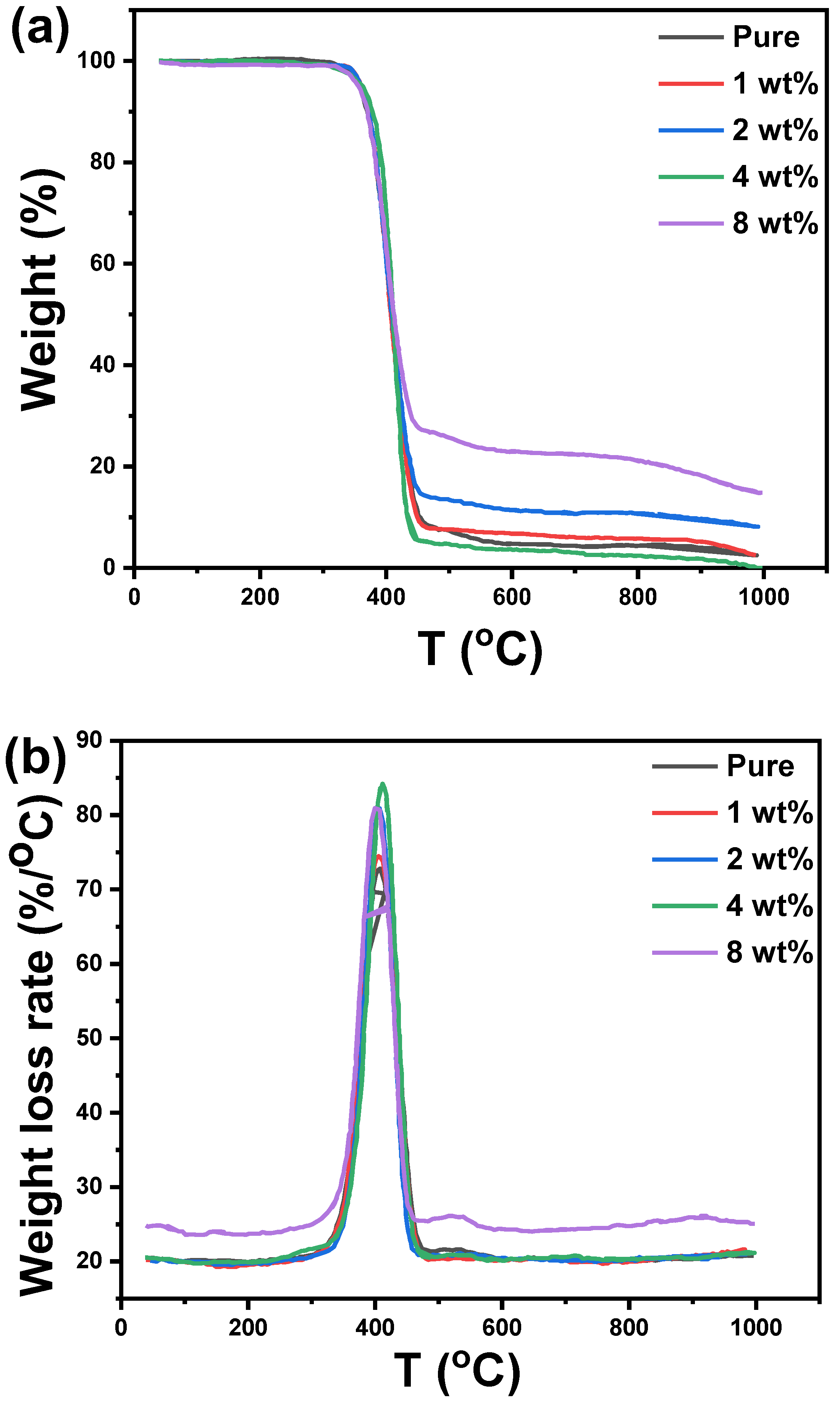

3.4. Thermal Stability

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Jhamb, S.; Enekvist, M.; Liang, X.; Zhang, X.; Dam-Johansen, K.; Kontogeorgis, G.M. A review of computer-aided design of paints and coatings. Curr. Opin. Chem. Eng. 2020, 27, 107–120. [Google Scholar] [CrossRef]

- He, Z.; Shen, A.; Guo, Y.; Lyu, Z.; Li, D.; Qin, X.; Zhao, M.; Wang, Z. Cement-based materials modified with superabsorbent polymers: A review. Constr. Build. Mater. 2019, 225, 569–590. [Google Scholar] [CrossRef]

- Callister, W.D.; Rethwisch, D.G. Materials Science and Engineering: An Introduction; John Wiley & Sons: New York, NY, USA, 2018; Available online: https://lccn.loc.gov/2017029444 (accessed on 1 September 2022).

- Hassana, D.J.; Ali, N.A. Evaluation of Mechanical Properties for Epoxy reinforced with palm oil /Zinc oxide composites. Iraqi J. Phys. (IJP) 2022, 20, 26–37. [Google Scholar] [CrossRef]

- Campbell, J.R.; Flake, C. (Eds.) Manufacturing Processes for Advanced Composites; Elsevier: Alpharetta, GA, USA, 2003. [Google Scholar] [CrossRef]

- Mahmood, R.Y.; Alobaedy, A. Enhancement of thermal stability and wettability for epoxy/Cu coated carbon fiber composites. Iraqi J. Phys. (IJP) 2020, 18, 55–61. [Google Scholar] [CrossRef]

- Kickelbick, G. (Ed.) Hybrid Materials: Synthesis, Characterization, and Applications; John Wiley & Sons: New York, NY, USA, 2007. [Google Scholar] [CrossRef]

- Khaleel, A.S. Transverse Direction Loading Effect on the Elasticity and Strength of Micro and Nano Silica Oxide Composites. Iraqi J. Sci. 2022, 63, 1971–1976. [Google Scholar] [CrossRef]

- Chawla, K.K. Composite Materials: Science and Engineering; Springer Science & Business Media: New York, NY, USA, 2012. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, L.; Levänen, E. Superhydrophobic surfaces for the reduction of bacterial adhesion. RSC Adv. 2013, 3, 12003–12020. [Google Scholar] [CrossRef]

- Mircea, C.; Toader, T.-P.; Hegyi, A.; Ionescu, B.-A.; Mircea, A. Early Age Sealing Capacity of Structural Mortar with Integral Crystalline Waterproofing Admixture. Materials 2021, 14, 4951. [Google Scholar] [CrossRef]

- Al-Rashed, R.; Al-Jabari, M. Concrete protection by combined hygroscopic and hydrophilic crystallization waterproofing applied to fresh concrete. Case Stud. Constr. Mater. 2021, 15, e00635. [Google Scholar] [CrossRef]

- Imam, A.; Mohammed, B.; Wilson, D.; Cheeseman, C. Solid waste management in Abuja, Nigeria. Waste Manag. 2008, 28, 468–472. [Google Scholar] [CrossRef]

- Sahal, N.; Ozkan, E. Proposed performance-based laboratory test method for measuring vapour and water permeability of waterproofing membranes under hydrostatic pressure. Constr. Build. Mater. 2004, 18, 701–713. [Google Scholar] [CrossRef]

- Le, T.T.; Nguyen, T.V.; Nguyen, T.A.; Nguyen, T.T.H.; Thai, H.; Tran, D.L.; Dinh, D.A.; Lu, L.T. Thermal, mechanical and antibacterial properties of water-based acrylic Polymer/SiO2–Ag nanocomposite coating. Mater. Chem. Phys. 2019, 232, 362–366. [Google Scholar] [CrossRef]

- Ormsby, R.; McNally, T.; Mitchell, C.; Dunne, N. Incorporation of multiwalled carbon nanotubes to acrylic based bone cements: Effects on mechanical and thermal properties. J. Mech. Behav. Biomed. Mater. 2010, 3, 136–145. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.; Lu, Z.; Hu, X.; Chen, B.; Li, Z.; Liang, R.; Sun, G. A mechanical strong polymer-cement composite fabricated by in situ polymerization within the cement matrix. J. Build. Eng. 2021, 42, 103048. [Google Scholar] [CrossRef]

- Abd-Elnaiem, A.M.; Salman, O.S.; Hakamy, A.; Hussein, S.I. Mechanical Characteristics and Thermal Stability of Hybrid Epoxy and Acrylic Polymer Coating/Nanoclay of Various Thicknesses. J. Inorg. Organomet. Polym. Mater. 2022, 32, 2094–2102. [Google Scholar] [CrossRef]

- Ibraheim, S.M.; Hussein, S.I. Study on the Contact Angle, Adhesion Strength, and Antibacterial Activity of Polymer/Cement Composites for Waterproof Coating. Iraqi J. Sci. 2020, 61, 1971–1977. [Google Scholar] [CrossRef]

- Gholinezhad, F.; Moghbeli, M.R.; Aghaei, A.; Allahverdi, A. Effect of organoclay reinforced acrylate latex particles on the cement paste performance. J. Dispers. Sci. Technol. 2019, 42, 416–431. [Google Scholar] [CrossRef]

- Zapata, M.; Tovar, C.; Hernandez, J. The Role of Chitosan and Graphene Oxide in Bioactive and Antibacterial Properties of Acrylic Bone Cements. Biomolecules 2020, 10, 1616. [Google Scholar] [CrossRef]

- Wekwejt, M.; Michalska-Sionkowska, M.; Bartmański, M.; Nadolska, M.; Łukowicz, K.; Pałubicka, A.; Osyczka, A.; Zieliński, A. Influence of several biodegradable components added to pure and nanosilver-doped PMMA bone cements on its biological and mechanical properties. Mater. Sci. Eng. C 2020, 117, 111286. [Google Scholar] [CrossRef]

- Zapata, M.E.V.; Rojas, L.M.R.; Hernández, J.H.M.; Delgado-Ospina, J.; Tovar, C.D.G. Acrylic Bone Cements Modified with Graphene Oxide: Mechanical, Physical, and Antibacterial Properties. Polymers 2020, 12, 1773. [Google Scholar] [CrossRef]

- D638-99; Standard Test Method for Tensile Properties of Plastics. ASTM: West Conshohocken, PA, USA, 2000; pp. 1–12. [CrossRef]

- Jose, J.P.; Abraham, J.; Maria, H.J.; Varughese, K.; Thomas, S. Contact Angle Studies in XLPE Hybrid Nanocomposites with Inorganic Nanofillers. Macromol. Symp. 2016, 366, 66–78. [Google Scholar] [CrossRef]

- Wang, X.; Pang, Y.; Wang, C.; Chen, K.; Zhu, Y.; Shen, C.; Ali, J.; Xu, J.; Li, Z. New Candidate Genes Affecting Rice Grain Appearance and Milling Quality Detected by Genome-Wide and Gene-Based Association Analyses. Front. Plant Sci. 2017, 7, 1998. [Google Scholar] [CrossRef] [PubMed]

- Song, H.; Liu, J.; Xue, F.; Cheng, F. Study of inorganic powders used for preparation of waterproof coating to coal mine roadways. Polimery 2016, 61, 844–849. [Google Scholar] [CrossRef]

| Cement Content (wt%) | Contact Angle | Average Contact Angle (θ) | |

|---|---|---|---|

| Left Angle (θ1) | Right Angle (θ2) | ||

| 0 | 63.56 | 64.83 | 64.19 |

| 1 | 69.99 | 69.84 | 69.91 |

| 2 | 71.14 | 71.53 | 71.33 |

| 4 | 72.82 | 74.53 | 73.67 |

| 8 | 89.63 | 92.47 | 91.05 |

| Cement Ratio (wt%) | Total Weight Loss (wt%) | Tg (°C) | Td (°C) |

|---|---|---|---|

| 0 | 97.75 | 406.6 | 450 |

| 1 | 97.68 | 410.08 | 460 |

| 2 | 91.92 | 409.48 | 450 |

| 4 | 100 | 411.85 | 455 |

| 8 | 84.93 | 401.52 | 525 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abd-Elnaiem, A.M.; Hussein, S.I.; Ali, N.A.; Hakamy, A.; Mebed, A.M. Ameliorating the Mechanical Parameters, Thermal Stability, and Wettability of Acrylic Polymer by Cement Filling for High-Efficiency Waterproofing. Polymers 2022, 14, 4671. https://doi.org/10.3390/polym14214671

Abd-Elnaiem AM, Hussein SI, Ali NA, Hakamy A, Mebed AM. Ameliorating the Mechanical Parameters, Thermal Stability, and Wettability of Acrylic Polymer by Cement Filling for High-Efficiency Waterproofing. Polymers. 2022; 14(21):4671. https://doi.org/10.3390/polym14214671

Chicago/Turabian StyleAbd-Elnaiem, Alaa M., Seenaa I. Hussein, Nadia A. Ali, Ahmad Hakamy, and Abdelazim M. Mebed. 2022. "Ameliorating the Mechanical Parameters, Thermal Stability, and Wettability of Acrylic Polymer by Cement Filling for High-Efficiency Waterproofing" Polymers 14, no. 21: 4671. https://doi.org/10.3390/polym14214671

APA StyleAbd-Elnaiem, A. M., Hussein, S. I., Ali, N. A., Hakamy, A., & Mebed, A. M. (2022). Ameliorating the Mechanical Parameters, Thermal Stability, and Wettability of Acrylic Polymer by Cement Filling for High-Efficiency Waterproofing. Polymers, 14(21), 4671. https://doi.org/10.3390/polym14214671