New Approach for Extrusion Additive Manufacturing of Soft and Elastic Articles from Liquid-PVC-Based Consumable Materials

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

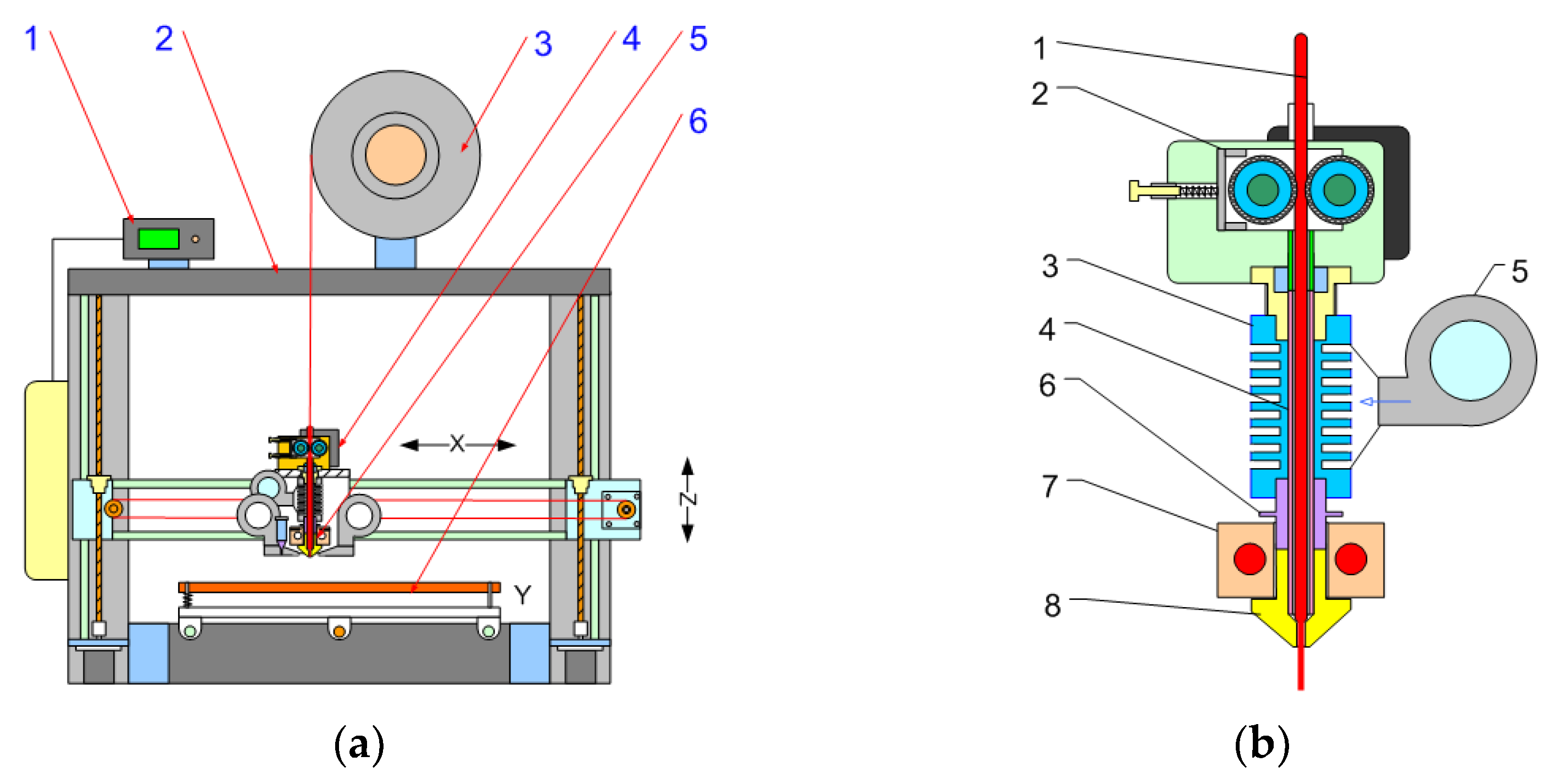

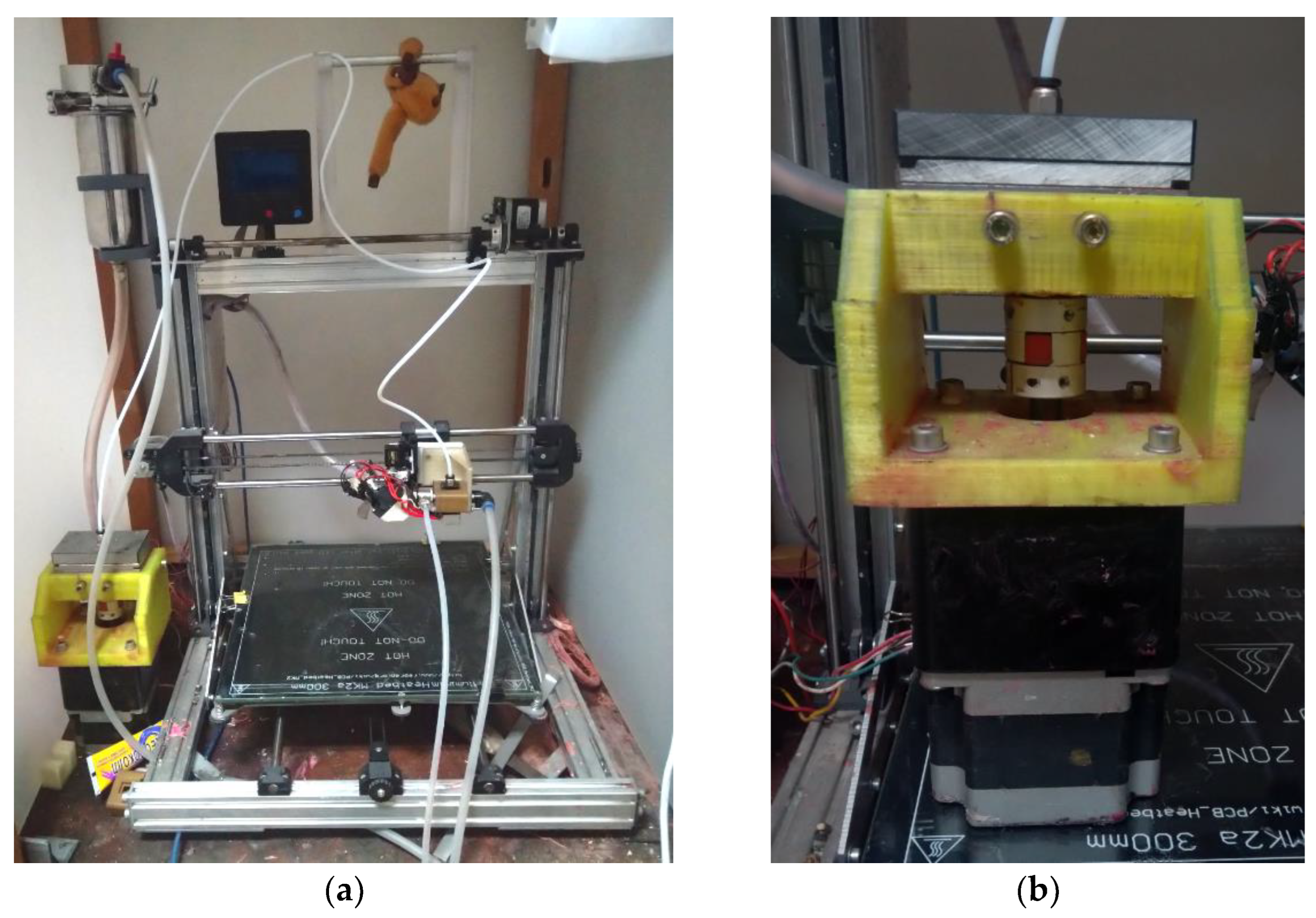

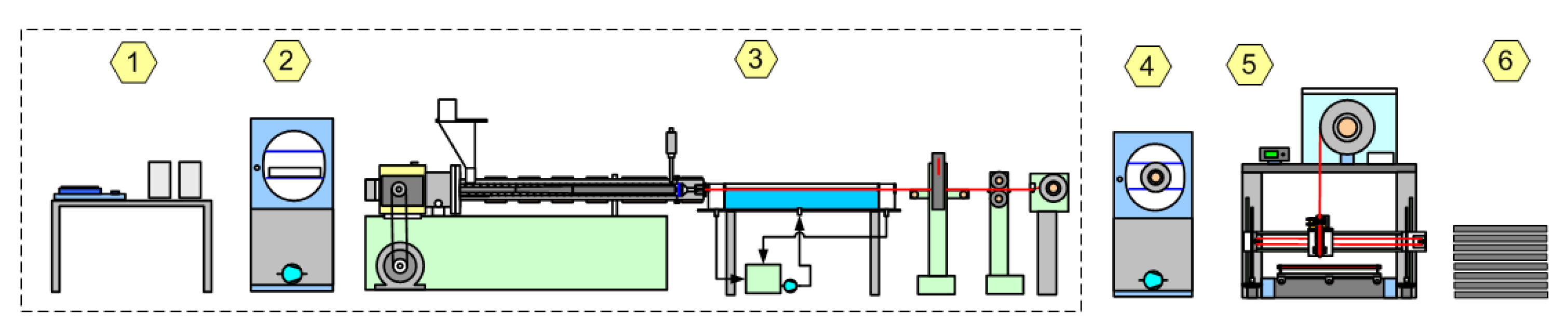

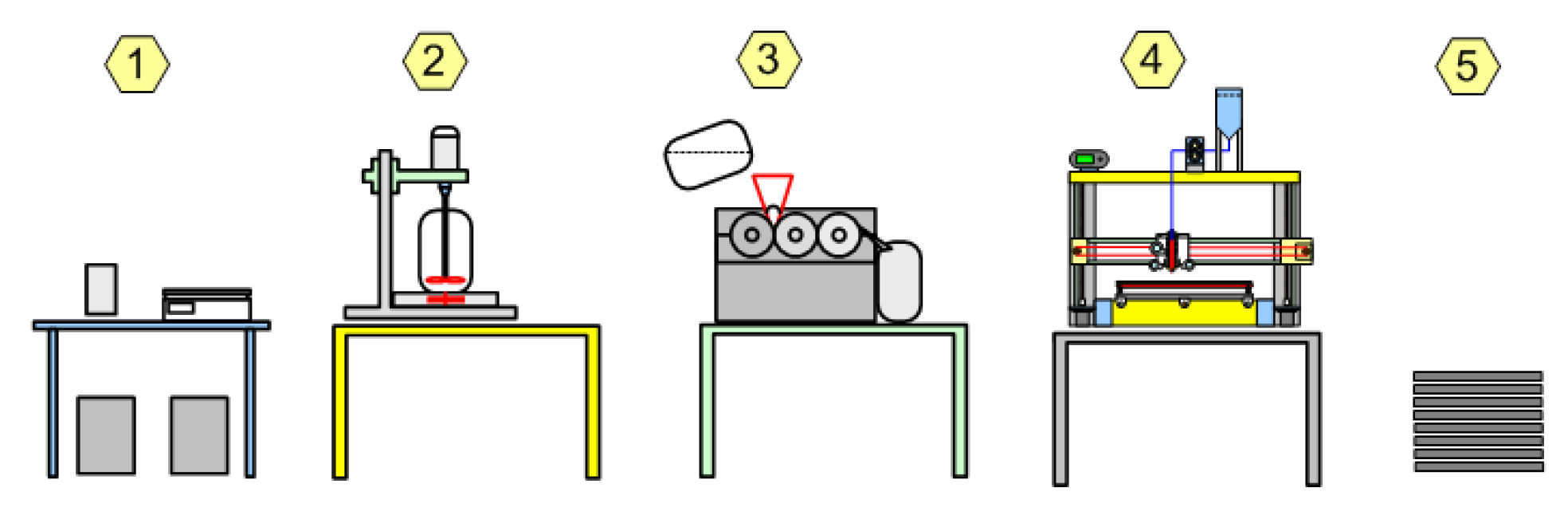

2.2. AM Experimental Setup

2.3. Characterization

3. Results and Discussion

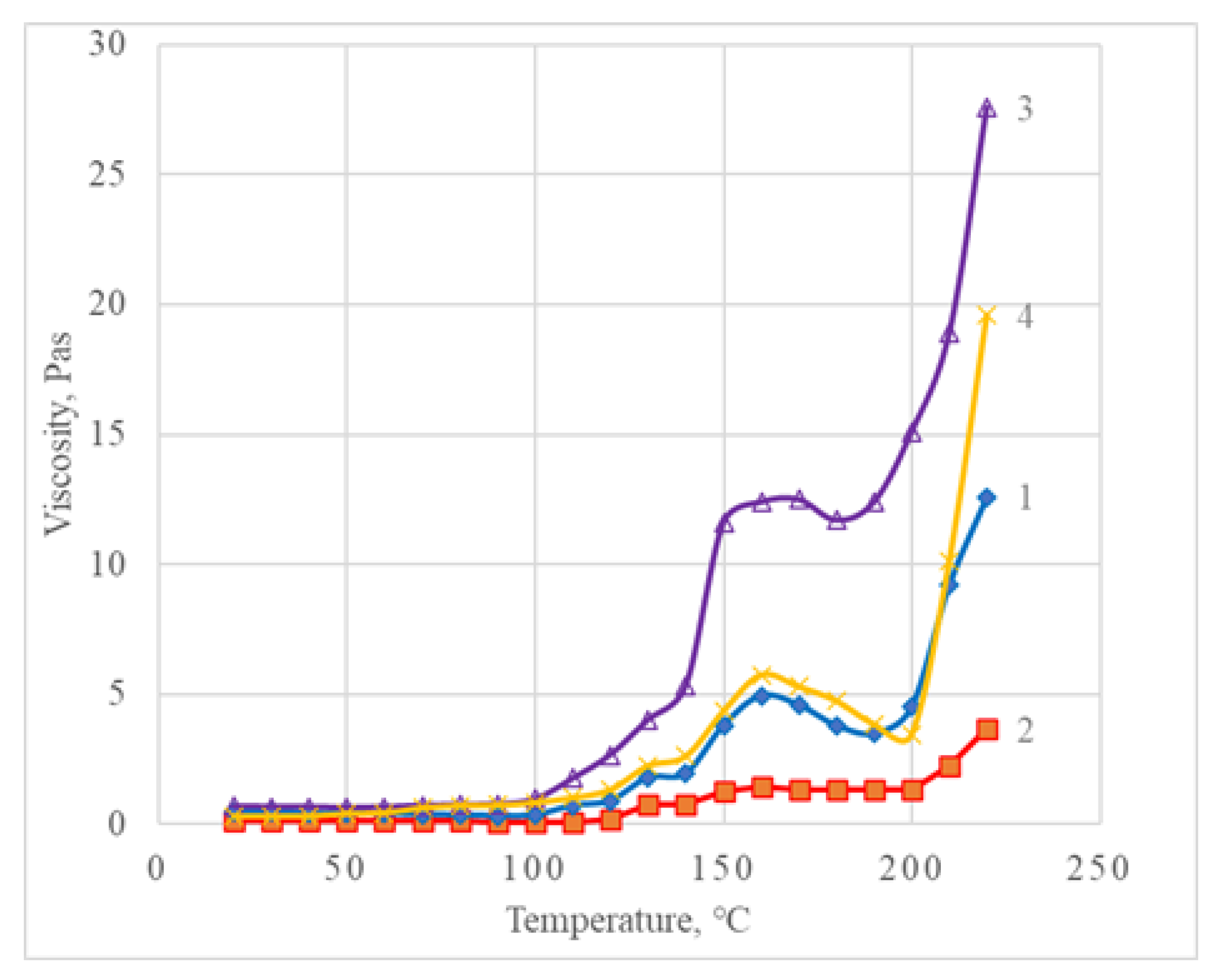

3.1. Material and Process Characterization

3.2. AM Material Characterization

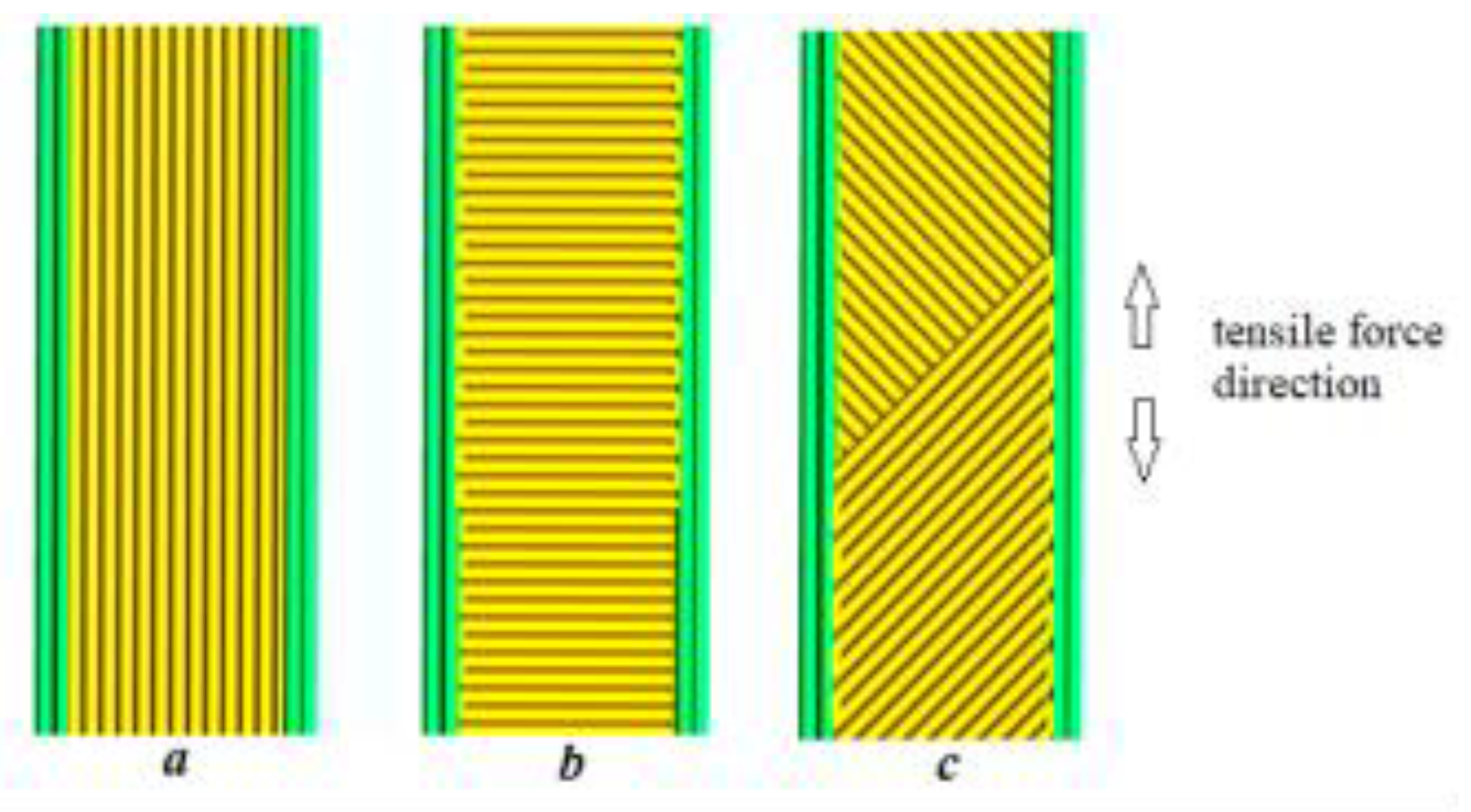

3.3. Influence of AM Layer Orientation

3.4. AM Process Specific Limitations

3.5. Plastisol AM Process Applications

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, M. Additive Manufacturing Technologies; Springer Nature Switzerland AG: Cham, Switzerland, 2021; Volume 17. [Google Scholar]

- Lasi, H.; Fettke, P.; Kemper, H.G.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

- Godec, D.; Pilipović, A.; Breški, T.; Ureña, J.; Jordá, O.; Martínez, M.; Gonzalez-Gutierrez, J.; Schuschnigg, S. Introduction to Additive Manufacturing. In A Guide to Additive Manufacturing; Godec, D., Gonzalez-Gutierrez, J., Nordin, A., Pei, E., Ureña Alcázar, J., Eds.; Springer Tracts in Additive Manufacturing; Springer: Cham, Switzerland, 2022; pp. 1–44. [Google Scholar] [CrossRef]

- Alammar, A.; Kois, J.C.; Revilla-León, M.; Att, W. Additive Manufacturing Technologies: Current Status and Future Perspectives. J. Prosthodont. 2022, 31, 4–12. [Google Scholar] [PubMed]

- Paolini, A.; Kollmannsberger, S.; Ernst, R. Additive manufacturing in construction: A review on processes, applications, and digital planning methods. Addit. Manuf. 2019, 30, 100894. [Google Scholar] [CrossRef]

- Bos, F.; Wolfs, R.; Ahmed, Z.; Salet, T. Additive manufacturing of concrete in construction: Potentials and challenges of 3D concrete printing. Virtual Phys. Prototyp. 2016, 11, 209–225. [Google Scholar] [CrossRef]

- Al Rashid, A.; Koç, M. Experimental Validation of Numerical Model for Thermomechanical Performance of Material Extrusion Additive Manufacturing Process: Effect of Process Parameters. Polymers 2022, 14, 3482. [Google Scholar] [CrossRef]

- Vassilakos, A.; Giannatsis, J.; Dedoussis, V. Fabrication of parts with heterogeneous structure using material extrusion additive manufacturing. Virtual Phys. Prototyp. 2021, 16, 267–290. [Google Scholar]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Palaniappan, S.K.; Chinnasamy, M.; Rathanasamy, R.; Samir Kumar Pal, S.K. Synthetic Binders for Polymer Division. In Green Adhesives: Preparations, Properties and Applications; Inamuddin, R.B., Mohd, I.A., Abdullah, M.A., Eds.; Scrivener Publishing LLC: Beverly, MA, USA, 2020; pp. 227–272. [Google Scholar]

- Volpato, N.; Kretschek, D.; Foggiatto, J.A.; Gomez da Silva Cruz, C.M. Experimental analysis of an extrusion system for additive manufacturing based on polymer pellets. Int. J. Adv. Manuf. Technol. 2015, 81, 1519–1531. [Google Scholar] [CrossRef]

- Zhu, Y.; Ramadani, E.; Egap, E. Thiol ligand capped quantum dot as an efficient and oxygen tolerance photoinitiator for aqueous phase radical polymerization and 3D printing under visible light. Polym. Chem. 2021, 12, 5106–5116. [Google Scholar] [CrossRef]

- Asadi-Eydivand, M.; Brown, T.C.; Bagheri, A. RAFT-Mediated 3D Printing of “Living” Materials with Tailored Hierarchical Porosity. ACS Appl. Polym. Mater. 2022, 4, 4940–4948. [Google Scholar] [CrossRef]

- Chen, J.; Smith, D.E. Filament rheological characterization for fused filament fabrication additive manufacturing: A low-cost approach. Addit. Manuf. 2021, 47, 02208. [Google Scholar]

- Sarabia-Vallejos, M.A.; Rodríguez-Umanzor, F.E.; González-Henríquez, C.M.; Rodríguez-Hernández, J. Innovation in Additive Manufacturing Using Polymers: A Survey on the Technological and Material Developments. Polymers 2022, 14, 1351. [Google Scholar] [CrossRef] [PubMed]

- Awasthi, P.; Banerjee, S.S. Fused deposition modeling of thermoplastic elastomeric materials: Challenges and opportunities. Addit. Manuf. 2021, 46, 102177. [Google Scholar]

- Shaukat, U.; Rossegger, E.; Schlögl, S. A Review of Multi-Material 3D Printing of Functional Materials via Vat Photopolymerization. Polymers 2022, 14, 2449. [Google Scholar] [CrossRef]

- Bagheri, A.; Jin, J. Photopolymerization in 3D Printing. ACS Appl. Polym. Mater. 2019, 1, 593–611. [Google Scholar] [CrossRef]

- Plott, J.; Shih, A. The extrusion-based additive manufacturing of moisture-cured silicone elastomer with minimal void for pneumatic actuators. Addit. Manuf. 2017, 17, 1–14. [Google Scholar] [CrossRef]

- Ziegelmeier, S.; Wöllecke, F.; Tuck, C.J.; Goodridge, R.D.; Hague, R.J.M. Aging behavior of thermoplastic elastomers in the laser sintering process. J. Mater. Res. 2014, 29, 1841–1851. [Google Scholar] [CrossRef]

- Plummer, K.; Vasquez, M.; Majewski, C.; Hopkinson, N. Study into the recyclability of a thermoplastic polyurethane powder for use in laser sintering. J. Eng. Manuf. 2012, 226, 10. [Google Scholar] [CrossRef]

- Altıparmak, S.C.; Yardley, V.A.; Shi, Z.; Lin, J. Extrusion-based additive manufacturing technologies: State of the art and future perspectives. J. Manuf. Processes 2022, 83, 607–636. [Google Scholar] [CrossRef]

- Khan, S.M.; Gull, N.; Khan, R.U.; Butt, M.T.Z. Polyvinylchloride (PVC): Structure and Properties Relationship. In Polyvinylchloride-Based Blends; Darie-Nita, R.N., Visakh, P.M., Eds.; Springer Series on Polymer and Composite Materials; Springer: Cham, Switzerland, 2022. [Google Scholar] [CrossRef]

- Summers, J.W. Lubrication mechanism of poly(vinylchloride) compounds: Changesupon PVC fusion (gelation). J. Vinyl Addit. Technol. 2005, 11, 57–62. [Google Scholar] [CrossRef]

- Visakh, P.M.; Darie-Nita, R.N. Polyvinylchloride (PVC)-Based Blends: State of Art, New Challenges and Opportunities. In Polyvinylchloride-Based Blends; Darie-Nita, R.N., Visakh, P.M., Eds.; Springer Series on Polymer and Composite Materials; Springer: Cham, Switzerland, 2022. [Google Scholar] [CrossRef]

- Godwin, A.D. Plasticizers. In Applied Plastics Engineering Handbook: Processing, Materials, and Applications, 2nd ed.; Kutz, M., Ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2017; pp. 533–553. [Google Scholar] [CrossRef]

- Râpă, M.; Darie-Nita, R.N.; Matei, E.; Predescu, A.M. Bio-Based Plasticizers for Polyvinylchloride (PVC). In Polyvinylchloride-based Blends; Darie-Nita, R.N., Visakh, P.M., Eds.; Springer Series on Polymer and Composite Materials; Springer: Cham, Switzerland, 2022. [Google Scholar] [CrossRef]

- Al-Mosawi, A.I.; Abbas, A.S. Enhancement of thermal characteristics of flexible poly(vinyl chloride) for automotive applications by using environmentally friendly heavy metal-free modifier. J. Thermoplast. Compos. Mater. 2022. [Google Scholar] [CrossRef]

- Truby, R.; Lewis, J. Printing soft matter in three dimensions. Nature 2016, 540, 371–378. [Google Scholar] [CrossRef] [PubMed]

- Zhou, L.-Y.; Jianzhong, F.; Yong, H. A review of 3D printing technologies for soft polymer materials. Adv. Funct. Mater. 2020, 30, 2000187. [Google Scholar] [CrossRef]

- Available online: https://www.prusa3d.com/product/original-prusa-i3-mk3s-3d-printer-3/ (accessed on 12 September 2022).

- Shah, A.; Mikofalvy, B.; Horvath, L.; Grossman, R.F. Plastisol Technology. In Handbook of Vinyl Formulating; Grossman, R.F., Ed.; 2007; pp. 371–377. [Google Scholar] [CrossRef]

- Beloshenko, V.; Beygelzimer, Y.; Chishko, V.; Savchenko, B.; Sova, N.; Verbylo, D.; Voznyak, A.; Vozniak, I. Mechanical Properties of Flexible TPU-Based 3D Printed Lattice Structures: Role of Lattice Cut Direction and Architecture. Polymers 2021, 13, 2986. [Google Scholar] [CrossRef] [PubMed]

| Component | Composition Number | |||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | |

| PVC | 100 | 100 | 100 | 100 | 100 | 100 |

| ESO | 100 | 200 | - | - | 100 | 200 |

| Stabilizer complex | 2 | 2 | 4 | 4 | 2 | 2 |

| DINP | - | - | 50 | 100 | ||

| Filler | - | - | - | - | 20 | 20 |

| Properties | Composition Number | |||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | |

| Melt flow rate, 190 °C | 8 | 26 | 11 | 18 | 9 | 28 |

| Density solid, g/cm3 | 1.08 | 1.05 | 1.11 | 1.07 | 1.12 | 1.09 |

| Hardness Shore A | 49 | 23 | 58 | 42 | 48 | 25 |

| Tensile strength, MPa | 7.1 | 4.3 | 9.4 | 7.5 | 8.2 | 4.6 |

| Tensile elongation at break, % | 270 | 430 | 210 | 305 | 280 | 440 |

| Parameter | AM Process Parameter Set | |||

|---|---|---|---|---|

| AM1 | AM2 | AM3 | AM4 | |

| Extrusion temperature, °C | 180 | 180 | 190 | 190 |

| Extrusion height, μm | 200 | 200 | 200 | 200 |

| Extrusion width, μm | 500 | 500 | 500 | 500 |

| Printing speed, mm/min | 1500 | 1500 | 1500 | 1500 |

| Platform temperature | 80 | 80 | 80 | 80 |

| Extrusion feed rate, mm3/m | 80 | 160 | 80 | 160 |

| Part air cooling, % | 100 | 100 | 100 | 100 |

| Nozzle diameter, μm | 300 | 300 | 300 | 300 |

| Retraction, mm | 0 | 0 | 0 | 0 |

| Top, wall, bottom layers | 2 | 2 | 2 | 2 |

| Infill type | Rectilinear | Rectilinear | Rectilinear | Rectilinear |

| Infill rate, % | 100 | 100 | 100 | 100 |

| Infill layer orientation, deg | 45 | 45 | 45 | 45 |

| Composition | AM Process Parameter Set | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AM1 | AM2 | AM3 | AM4 | |||||||||

| Properties | Properties | Properties | Properties | |||||||||

| σ | ε | SH | σ | ε | SH | σ | ε | SH | σ | ε | SH | |

| 1 | 6.3 | 180 | 48 | 5.8 | 190 | 46 | 6.7 | 170 | 48 | 6.6 | 190 | 47 |

| 2 | 3.9 | 260 | 22 | 4.1 | 240 | 23 | 4.2 | 290 | 22 | 4.1 | 300 | 21 |

| 3 | 7.2 | 200 | 59 | 6.9 | 210 | 57 | 7.4 | 220 | 58 | 6.7 | 210 | 57 |

| 4 | 4.1 | 270 | 40 | 4.3 | 315 | 41 | 4.3 | 310 | 42 | 4.4 | 310 | 42 |

| 5 | 6.2 | 190 | 49 | 5.9 | 200 | 48 | 6.6 | 170 | 50 | 6.4 | 160 | 49 |

| 6 | 4.0 | 240 | 24 | 3.8 | 230 | 24 | 4.1 | 250 | 25 | 3.8 | 280 | 24 |

| Composition | AM Process Layer Orientation | |||||

|---|---|---|---|---|---|---|

| 90 Deg | 0 Deg | 45 Deg | ||||

| σ | ε | σ | ε | σ | ε | |

| 1 | 7.1 | 210 | 2.4 | 120 | 6.7 | 170 |

| 2 | 4.5 | 310 | 1.6 | 100 | 4.2 | 240 |

| 5 | 7.0 | 200 | 1.9 | 110 | 6.6 | 170 |

| 6 | 4.6 | 260 | 1.5 | 100 | 4.1 | 210 |

| Composition | Infill Density,% | |||

|---|---|---|---|---|

| 100 | 90 | 80 | 70 | |

| Shore Hardness A Scale | ||||

| 1 | 48 | 46/45 | 41/37 | 38/37 |

| 2 | 22 | 20/19 | 18/17 | 17/16 |

| 5 | 50 | 48/48 | 45/41 | 41/40 |

| 6 | 25 | 23/22 | 20/17 | 18/18 |

| Rectilinear pattern/Gyroid pattern | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Savchenko, B.; Sova, N.; Beloshenko, V.; Debeluy, B.; Slieptsov, A.; Vozniak, I. New Approach for Extrusion Additive Manufacturing of Soft and Elastic Articles from Liquid-PVC-Based Consumable Materials. Polymers 2022, 14, 4683. https://doi.org/10.3390/polym14214683

Savchenko B, Sova N, Beloshenko V, Debeluy B, Slieptsov A, Vozniak I. New Approach for Extrusion Additive Manufacturing of Soft and Elastic Articles from Liquid-PVC-Based Consumable Materials. Polymers. 2022; 14(21):4683. https://doi.org/10.3390/polym14214683

Chicago/Turabian StyleSavchenko, Bohdan, Nadiya Sova, Victor Beloshenko, Bohdan Debeluy, Aleksander Slieptsov, and Iurii Vozniak. 2022. "New Approach for Extrusion Additive Manufacturing of Soft and Elastic Articles from Liquid-PVC-Based Consumable Materials" Polymers 14, no. 21: 4683. https://doi.org/10.3390/polym14214683

APA StyleSavchenko, B., Sova, N., Beloshenko, V., Debeluy, B., Slieptsov, A., & Vozniak, I. (2022). New Approach for Extrusion Additive Manufacturing of Soft and Elastic Articles from Liquid-PVC-Based Consumable Materials. Polymers, 14(21), 4683. https://doi.org/10.3390/polym14214683