On the Evolution of Additive Manufacturing (3D/4D Printing) Technologies: Materials, Applications, and Challenges

Abstract

:1. Introduction

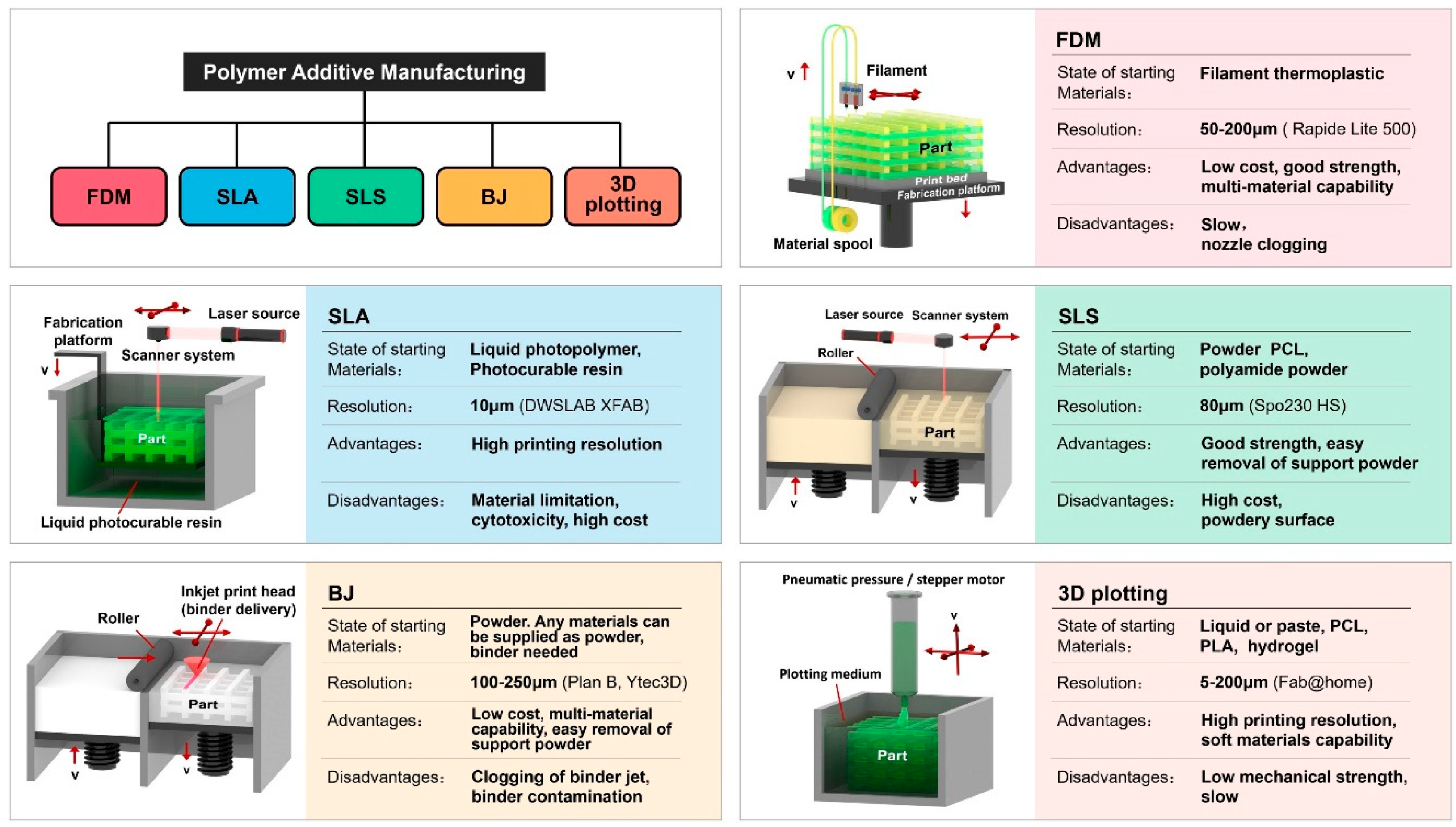

2. Three-Dimensional/Four-Dimensional Printing Process and Materials

2.1. General Process

- Computer-aided Design (CAD): CAD software creates a three-dimensional model of the object. Using scientific data on the particular materials, the program may produce virtual simulations of how the thing would perform under various circumstances. The CAD model is next converted into Standard Tessellation Language (STL) conversion. STL is a file format that was designed for 3D systems in 1987 by their stereolithography apparatus (SLA) machines. STL files are supported by almost all 3D printers.

- STL file manipulation and the transfer to machines: the STL file is then copied by the user to the computer that manages the 3D printer. There, the user may choose the printing’s size and direction. This is comparable to setting up a usual paper printer to print on both sides or in landscape rather than the portrait orientation.

- The next step is to set up the machine. Each machine has specific guidelines for getting ready for a fresh print job. This entails restocking the printer’s polymers, binders, and other consumables.

- Building process: at this point, you may sit back and relax, as the majority of the building process is handled automatically. Although it may be considerably thinner or thicker, each layer is typically 0.1 mm thick. This procedure might take hours or even days to complete, depending on the size of the item, the machine, and the materials utilized.

- Post-processing: the printed object from many 3D printers will need some post-processing finishing. This can include washing the printed item to get rid of any residual powder or brushing off any water-soluble supports. Since certain materials require time to cure at this stage, the printed structure could be fragile, thus care may be needed to prevent it from breaking or disintegrating. Applications are the next steps, where printed structures/objects are installed and put to use.

2.2. Materials for 3D/4D Printing

2.2.1. Polymers

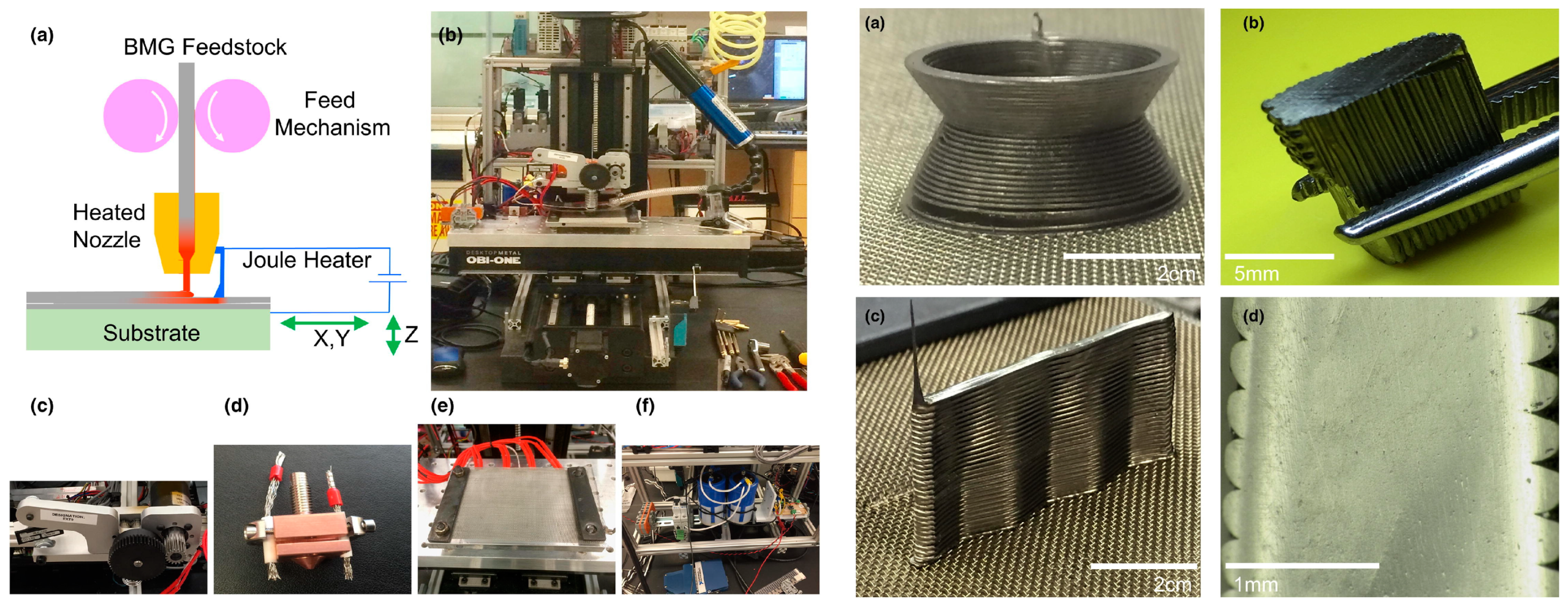

2.2.2. Metallic Materials

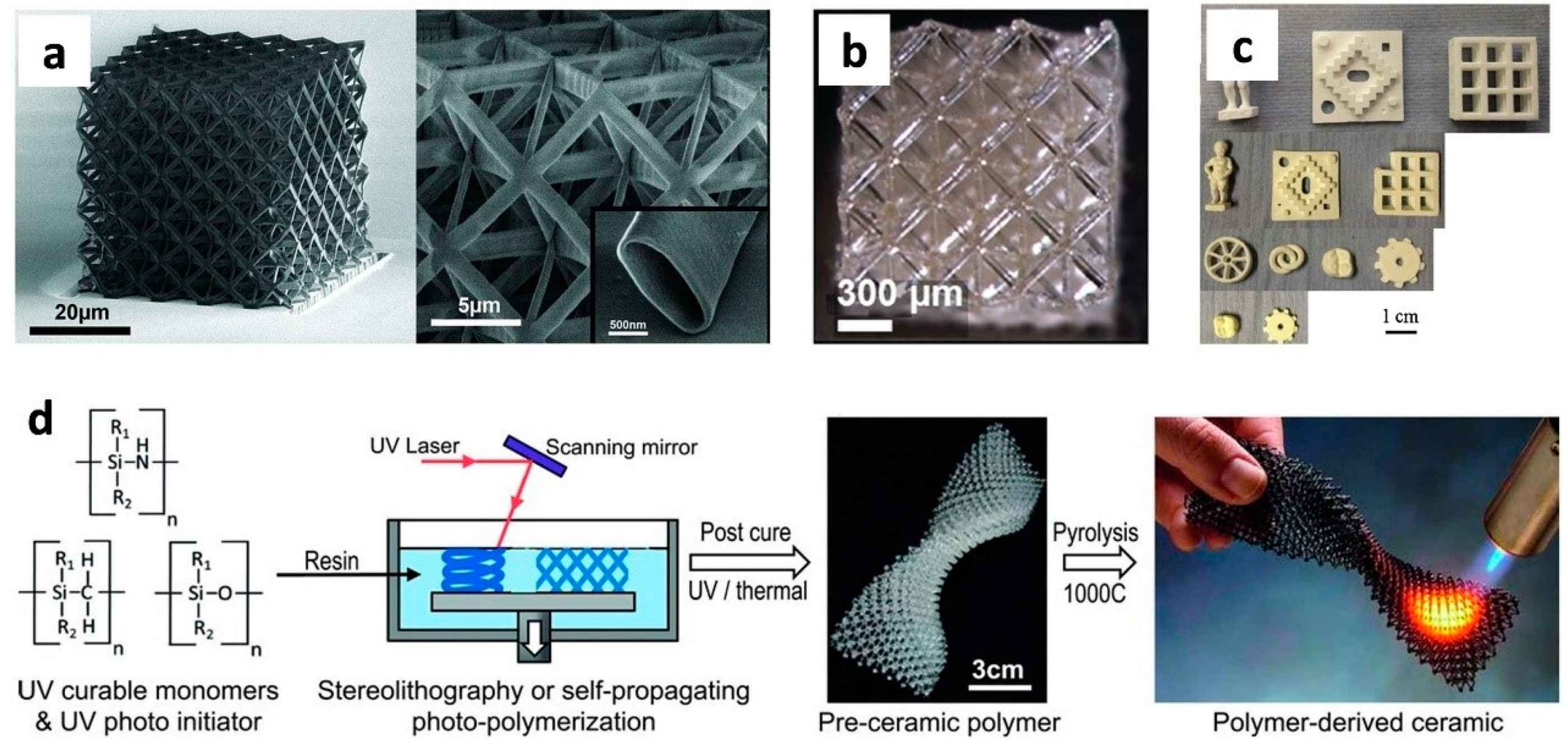

2.2.3. Ceramics

2.2.4. Other Novel Materials for 3D Printing

3. Applications of 3D/4D Printing

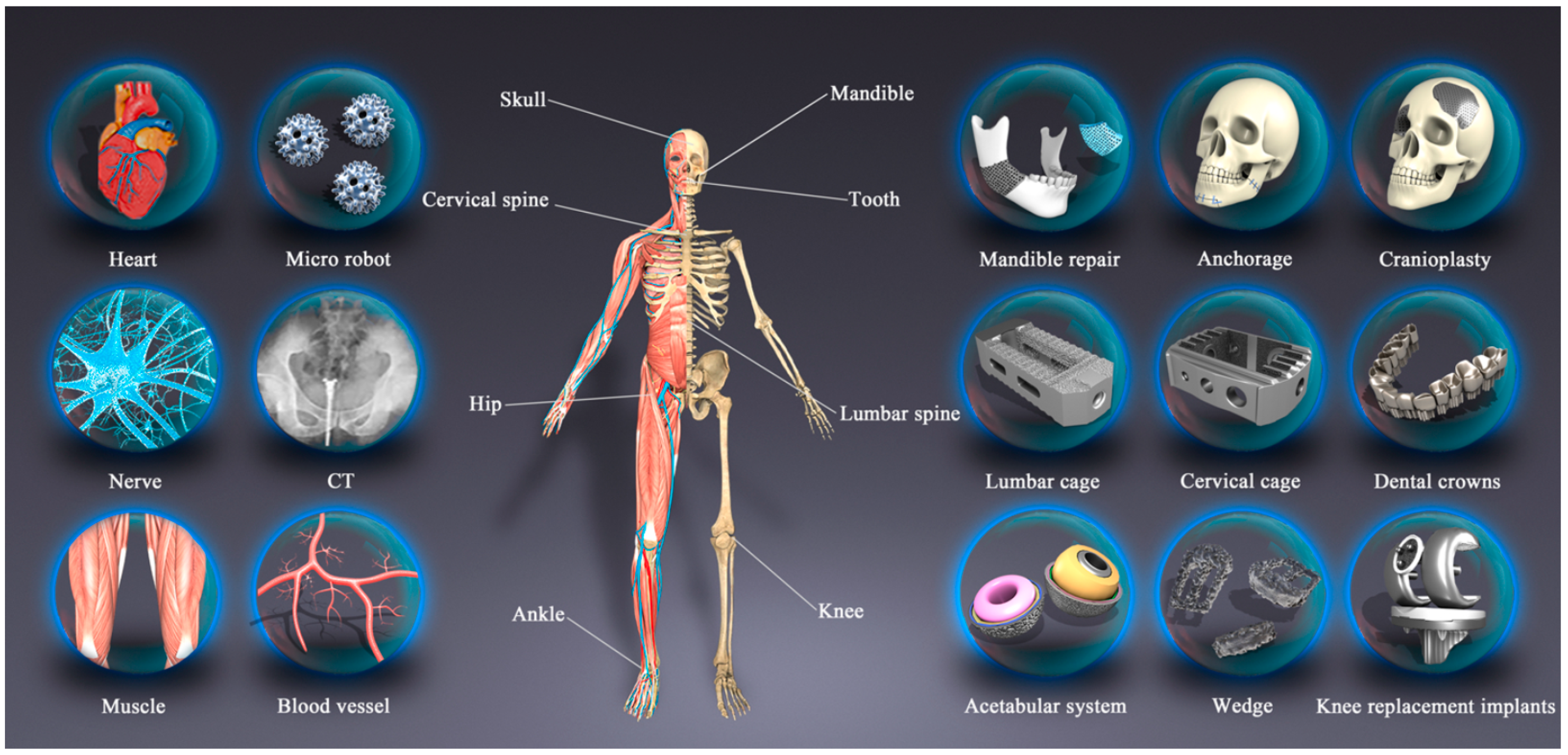

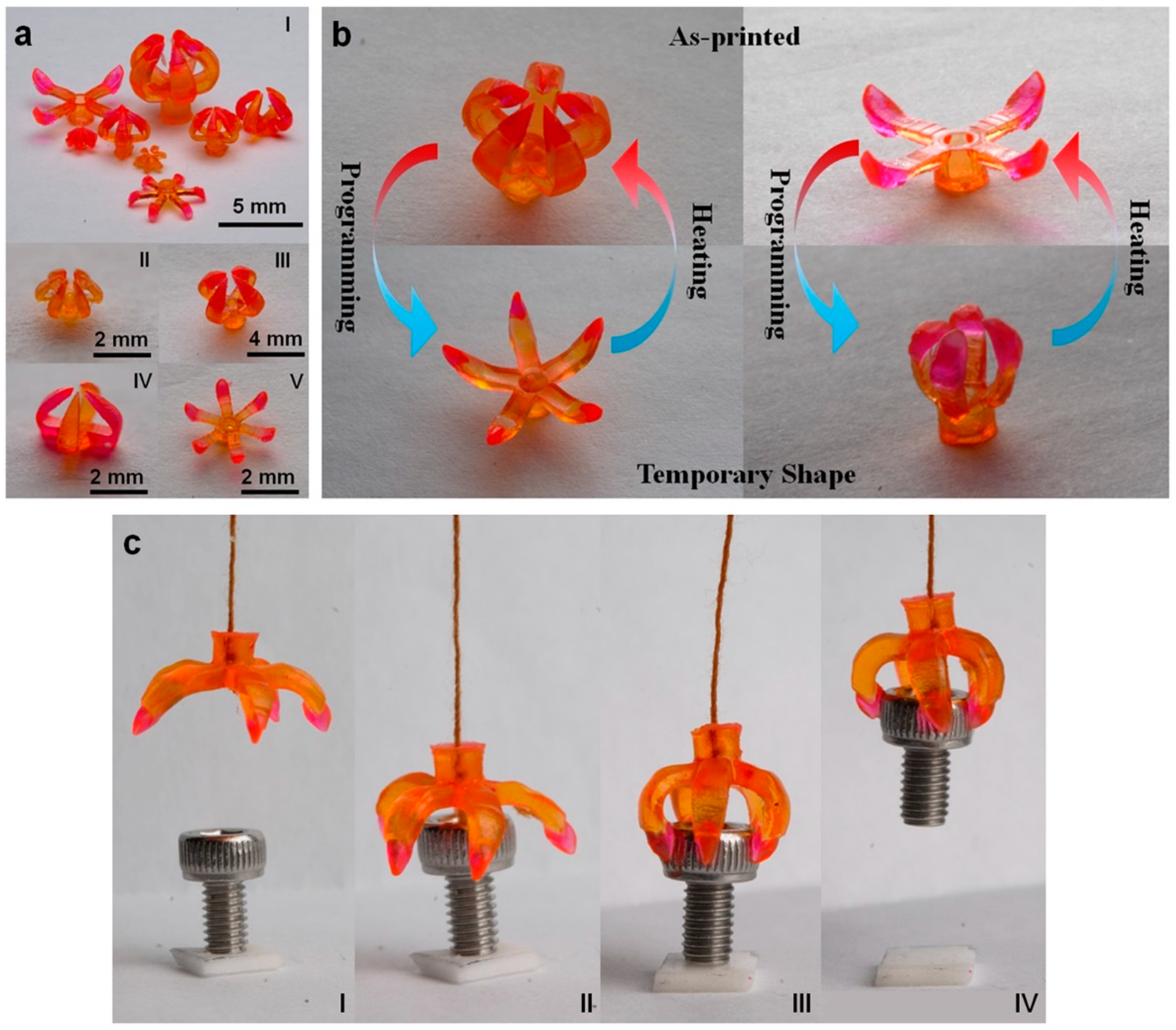

3.1. Biomedical

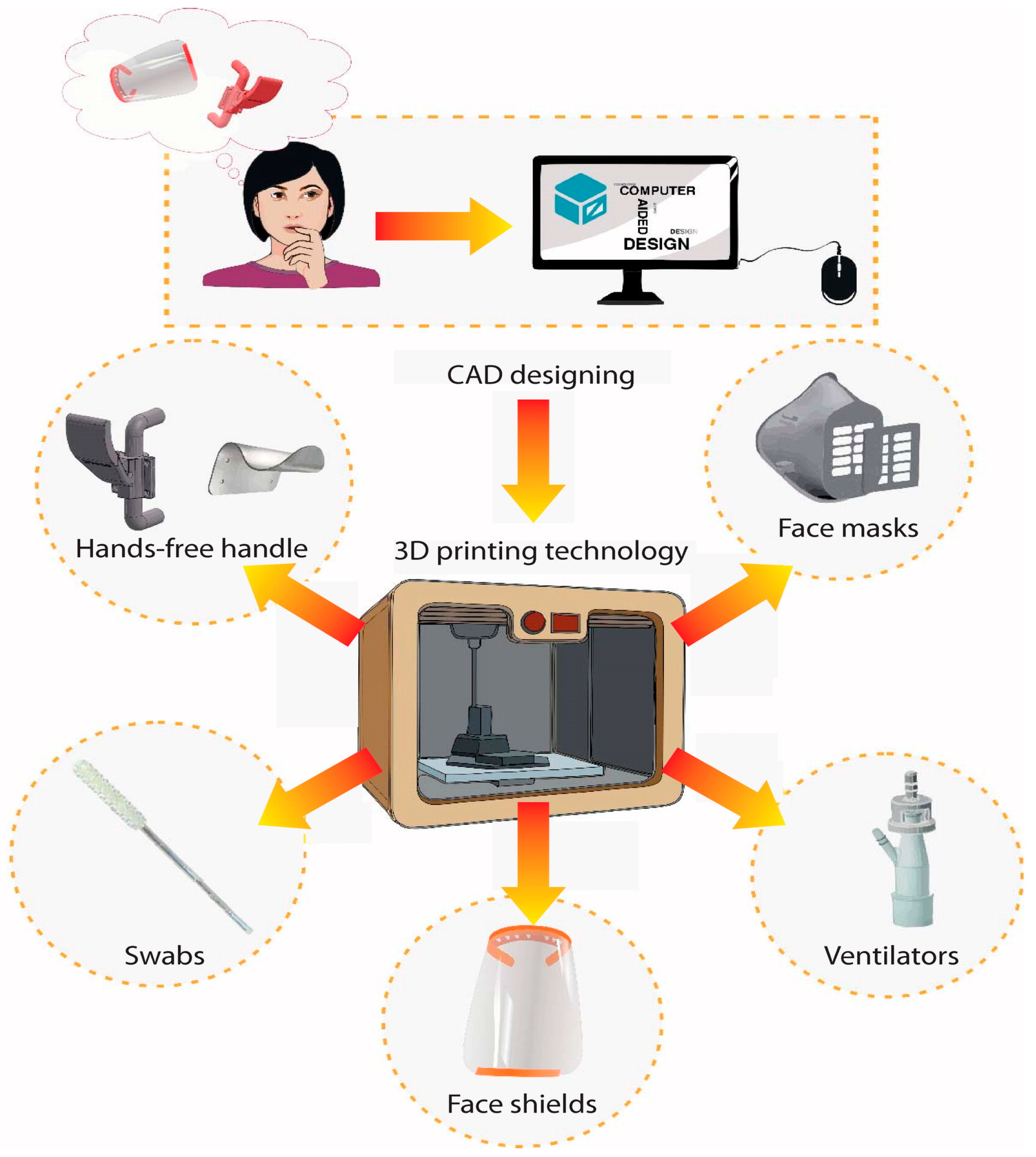

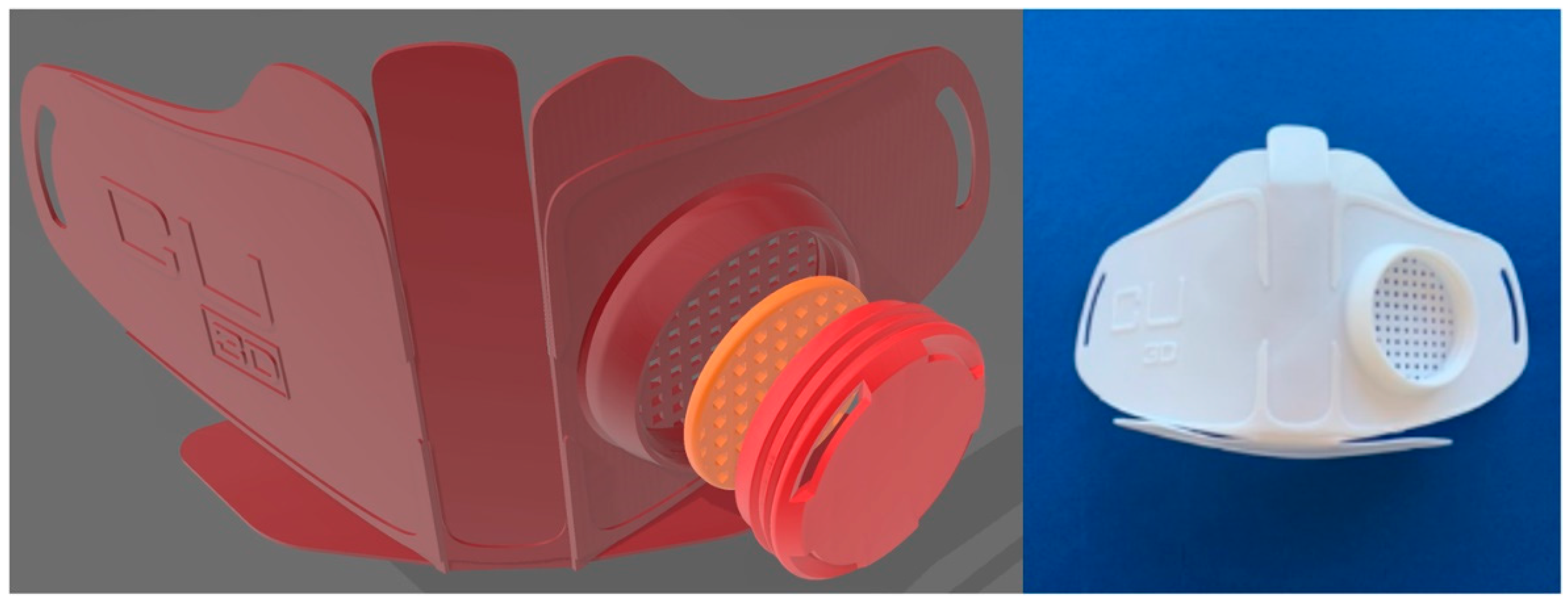

3.2. Three-Dimensional Printing and COVID-19

3.3. Aerospace

3.4. Flexible and Wearable Devices

3.5. Construction Industry

3.6. Art and Jewelery

4. Challenges Ahead

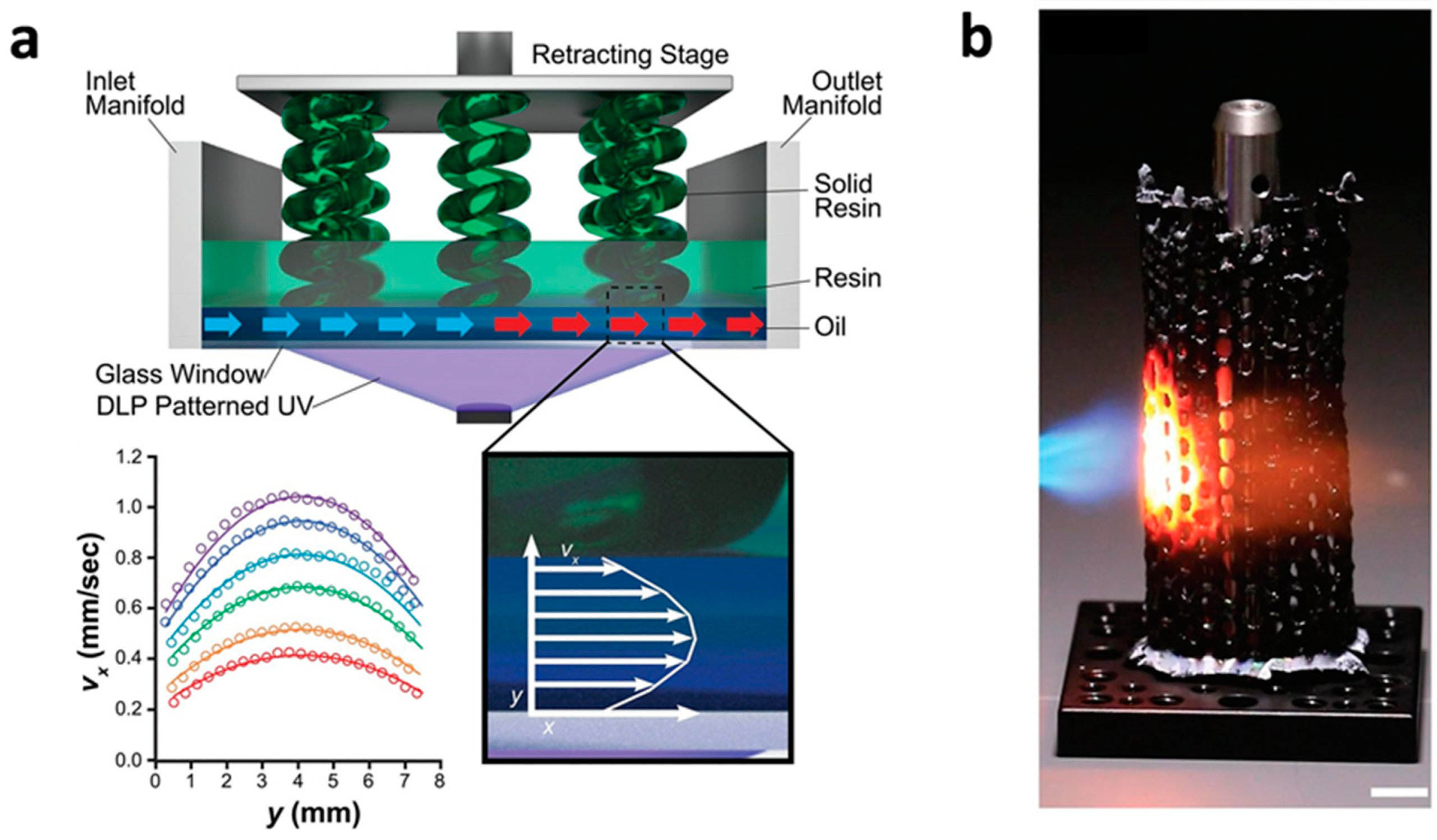

5. Technology Advancement of 3D and 4D Printing

Author Contributions

Funding

Institutional Review Board Statement

Conflicts of Interest

References

- DeSimone, J. What If 3D Printing Was 100× Faster? | TED Talk. Available online: https://www.ted.com/talks/joseph_desimone_what_if_3d_printing_was_100x_faster (accessed on 15 October 2022).

- Hull, C.W. Apparatus for Production of Three-Dimensional Objects by Stereolithography. US Patent 4575330A, 1986. [Google Scholar]

- Yin, H.; Qu, M.; Zhang, H.; Lim, Y.C. 3D Printing and Buildings: A Technology Review and Future Outlook. Technol. Archit. Des. 2018, 2, 94–111. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, Y.; Aghda, N.H.; Pillai, A.R.; Thakkar, R.; Nokhodchi, A.; Maniruzzaman, M. Emerging 3D Printing Technologies for Drug Delivery Devices: Current Status and Future Perspective. Adv. Drug. Deliv. Rev. 2021, 174, 294–316. [Google Scholar] [CrossRef] [PubMed]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yan, Q.; Dong, H.; Su, J.; Han, J.; Song, B.; Wei, Q.; Shi, Y. A Review of 3D Printing Technology for Medical Applications. Engineering 2018, 4, 729–742. [Google Scholar] [CrossRef]

- Lee, J.Y.; An, J.; Chua, C.K. Fundamentals and Applications of 3D Printing for Novel Materials. Appl. Mater. Today 2017, 7, 120–133. [Google Scholar] [CrossRef]

- Mallakpour, S.; Azadi, E.; Hussain, C.M. State-of-the-Art of 3D Printing Technology of Alginate-Based Hydrogels—An Emerging Technique for Industrial Applications. Adv. Colloid. Interface Sci. 2021, 293, 102436. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, X.; Chen, X.; He, Y.; Cheng, L.; Huo, M.; Yin, J.; Hao, F.; Chen, S.; Wang, P.; et al. Additive Manufacturing of Structural Materials. Mater. Sci. Eng. R Rep. 2021, 145, 100596. [Google Scholar] [CrossRef]

- González-Henríquez, C.M.; Sarabia-Vallejos, M.A.; Sanz-Horta, R.; Rodriguez-Hernandez, J. Additive Manufacturing of Polymers: 3D and 4D Printing, Methodologies, Type of Polymeric Materials, and Applications. Macromol. Eng. 2022, 1–65. [Google Scholar] [CrossRef]

- Tamay, D.G.; Dursun Usal, T.; Alagoz, A.S.; Yucel, D.; Hasirci, N.; Hasirci, V. 3D and 4D Printing of Polymers for Tissue Engineering Applications. Front. Bioeng. Biotechnol. 2019, 7, 164. [Google Scholar] [CrossRef]

- Zhang, C.; Li, X.; Jiang, L.; Tang, D.; Xu, H.; Zhao, P.; Fu, J.; Zhou, Q.; Chen, Y. 3D Printing of Functional Magnetic Materials: From Design to Applications. Adv. Funct. Mater. 2021, 31, 2102777. [Google Scholar] [CrossRef]

- Joshi, S.C.; Sheikh, A.A. 3D Printing in Aerospace and Its Long-Term Sustainability. Virtual Phys. Prototyp. 2015, 10, 175–185. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.L.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The Status, Challenges, and Future of Additive Manufacturing in Engineering. Comput.-Aided Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing; Springer: New York, NY, USA, 2015. [Google Scholar]

- Melchels, F.P.W.; Domingos, M.A.N.; Klein, T.J.; Malda, J.; Bartolo, P.J.; Hutmacher, D.W. Additive Manufacturing of Tissues and Organs. Prog. Polym. Sci. 2012, 37, 1079–1104. [Google Scholar] [CrossRef] [Green Version]

- Marchelli, G.; Prabhakar, R.; Storti, D.; Ganter, M. The Guide to Glass 3D Printing: Developments, Methods, Diagnostics and Results. Rapid Prototyp. J. 2011, 17, 187–194. [Google Scholar] [CrossRef]

- Lu, B.H.; Lan, H.B.; Liu, H.Z. Additive Manufacturing Frontier: 3D Printing Electronics. Opto-Electron. Adv. 2018, 1, 17000401–17000410. [Google Scholar] [CrossRef]

- Bose, S.; Vahabzadeh, S.; Bandyopadhyay, A. Bone Tissue Engineering Using 3D Printing. Mater. Today 2013, 16, 496–504. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Li, Y.; Wang, P.; He, Y. 3D Printing of Ceramics: A Review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar] [CrossRef]

- Zhang, F.; Wei, M.; Viswanathan, V.v.; Swart, B.; Shao, Y.; Wu, G.; Zhou, C. 3D Printing Technologies for Electrochemical Energy Storage. Nano Energy 2017, 40, 418–431. [Google Scholar] [CrossRef]

- Layani, M.; Wang, X.; Magdassi, S. Novel Materials for 3D Printing by Photopolymerization. Adv. Mater. 2018, 30, e1706344. [Google Scholar] [CrossRef]

- Bhattacharjee, N.; Urrios, A.; Kang, S.; Folch, A. The Upcoming 3D-Printing Revolution in Microfluidics. Lab Chip 2016, 16, 1720–1742. [Google Scholar] [CrossRef]

- Sydney Gladman, A.; Matsumoto, E.A.; Nuzzo, R.G.; Mahadevan, L.; Lewis, J.A. Biomimetic 4D Printing. Nat Mater. 2016, 15, 413–418. [Google Scholar] [CrossRef] [PubMed]

- Raviv, D.; Zhao, W.; McKnelly, C.; Papadopoulou, A.; Kadambi, A.; Shi, B.; Hirsch, S.; Dikovsky, D.; Zyracki, M.; Olguin, C.; et al. Active Printed Materials for Complex Self-Evolving Deformations. Sci. Rep. 2014, 4, 7422. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, H.; Leow, W.R.; Wang, T.; Wang, J.; Yu, J.; He, K.; Qi, D.; Wan, C.; Chen, X. 3D Printed Photoresponsive Devices Based on Shape Memory Composites. Adv. Mater. 2017, 29, 1701627. [Google Scholar] [CrossRef] [PubMed]

- Kuksenok, O.; Balazs, A.C. Stimuli-Responsive Behavior of Composites Integrating Thermo-Responsive Gels with Photo-Responsive Fibers. Mater. Horiz. 2015, 3, 53–62. [Google Scholar] [CrossRef]

- Ding, Z.; Yuan, C.; Peng, X.; Wang, T.; Qi, H.J.; Dunn, M.L. Direct 4D Printing via Active Composite Materials. Sci. Adv. 2017, 3, e1602890. [Google Scholar] [CrossRef] [Green Version]

- Kotikian, A.; Truby, R.L.; Boley, J.W.; White, T.J.; Lewis, J.A. 3D Printing of Liquid Crystal Elastomeric Actuators with Spatially Programed Nematic Order. Adv. Mater. 2018, 30, 1706164. [Google Scholar] [CrossRef]

- Nadgorny, M.; Xiao, Z.; Chen, C.; Connal, L.A. Three-Dimensional Printing of PH-Responsive and Functional Polymers on an Affordable Desktop Printer. ACS Appl. Mater. Interfaces 2016, 8, 28946–28954. [Google Scholar] [CrossRef]

- Ge, Q.; Dunn, C.K.; Qi, H.J.; Dunn, M.L. Active Origami by 4D Printing. Smart Mater. Struct. 2014, 23, 094007. [Google Scholar] [CrossRef]

- Tanaka, T.; Ishikawa, A.; Kawata, S. Two-Photon-Induced Reduction of Metal Ions for Fabricating Three-Dimensional Electrically Conductive Metallic Microstructure. Appl. Phys. Lett. 2006, 88, 081107. [Google Scholar] [CrossRef] [Green Version]

- Breger, J.C.; Yoon, C.; Xiao, R.; Kwag, H.R.; Wang, M.O.; Fisher, J.P.; Nguyen, T.D.; Gracias, D.H. Self-Folding Thermo-Magnetically Responsive Soft Microgrippers. ACS Appl. Mater. Interfaces 2015, 7, 3398–3405. [Google Scholar] [CrossRef]

- Lantean, S.; Roppolo, I.; Sangermano, M.; Hayoun, M.; Dammak, H.; Rizza, G. Programming the Microstructure of Magnetic Nanocomposites in DLP 3D Printing. Addit. Manuf. 2021, 47, 102343. [Google Scholar] [CrossRef]

- Vaezi, M.; Chianrabutra, S.; Mellor, B.; Yang, S. Multiple Material Additive Manufacturing—Part 1: A Review: This Review Paper Covers a Decade of Research on Multiple Material Additive Manufacturing Technologies Which Can Produce Complex Geometry Parts with Different Materials. Virtual Phys. Prototyp. 2013, 8, 19–50. [Google Scholar] [CrossRef]

- Khare, V.; Sonkaria, S.; Lee, G.Y.; Ahn, S.H.; Chu, W.S. From 3D to 4D Printing—Design, Material and Fabrication for Multi-Functional Multi-Materials. Int. J. Pre. Eng. Manu. GT 2017, 4, 291–299. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Heer, B. Additive Manufacturing of Multi-Material Structures. Mater. Sci. Eng. R Rep. 2018, 129, 1–16. [Google Scholar] [CrossRef]

- Pei, E.; Loh, G.H. Technological Considerations for 4D Printing: An Overview. Prog. Addit. Manuf. 2018, 3, 95–107. [Google Scholar] [CrossRef] [Green Version]

- Ryan, K.R.; Down, M.P.; Banks, C.E. Future of Additive Manufacturing: Overview of 4D and 3D Printed Smart and Advanced Materials and Their Applications. Chem. Eng. J. 2021, 403, 126162. [Google Scholar] [CrossRef]

- Zastrow, M. 3D Printing Gets Bigger, Faster and Stronger. Nature 2020, 578, 20–23. [Google Scholar] [CrossRef] [Green Version]

- Walker, D.A.; Hedrick, J.L.; Mirkin, C.A. Rapid, Large-Volume, Thermally Controlled 3D Printing Using a Mobile Liquid Interface. Science 2019, 366, 360–364. [Google Scholar] [CrossRef]

- Kelly, B.E.; Bhattacharya, I.; Heidari, H.; Shusteff, M.; Spadaccini, C.M.; Taylor, H.K. Volumetric Additive Manufacturing via Tomographic Reconstruction. Science 2019, 363, 1075–1079. [Google Scholar] [CrossRef]

- Saha, S.K.; Wang, D.; Nguyen, V.H.; Chang, Y.; Oakdale, J.S.; Chen, S.C. Scalable Submicrometer Additive Manufacturing. Science 2019, 366, 105–109. [Google Scholar] [CrossRef]

- Grigoryan, B.; Paulsen, S.J.; Corbett, D.C.; Sazer, D.W.; Fortin, C.L.; Zaita, A.J.; Greenfield, P.T.; Calafat, N.J.; Gounley, J.P.; Ta, A.H.; et al. Multivascular Networks and Functional Intravascular Topologies within Biocompatible Hydrogels. Science 2019, 364, 458–464. [Google Scholar] [CrossRef] [PubMed]

- Lee, A.; Hudson, A.R.; Shiwarski, D.J.; Tashman, J.W.; Hinton, T.J.; Yerneni, S.; Bliley, J.M.; Campbell, P.G.; Feinberg, A.W. 3D Bioprinting of Collagen to Rebuild Components of the Human Heart. Science 2019, 365, 482–487. [Google Scholar] [CrossRef] [PubMed]

- Tumbleston, J.R.; Shirvanyants, D.; Ermoshkin, N.; Janusziewicz, R.; Johnson, A.R.; Kelly, D.; Chen, K.; Pinschmidt, R.; Rolland, J.P.; Ermoshkin, A.; et al. Continuous Liquid Interface Production of 3D Objects. Science 2015, 347, 1349–1352. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Qiu, D.; Gibson, M.A.; Zheng, Y.; Fraser, H.L.; StJohn, D.H.; Easton, M.A. Additive Manufacturing of Ultrafine-Grained High-Strength Titanium Alloys. Nature 2019, 576, 91–95. [Google Scholar] [CrossRef]

- Kotz, F.; Arnold, K.; Bauer, W.; Schild, D.; Keller, N.; Sachsenheimer, K.; Nargang, T.M.; Richter, C.; Helmer, D.; Rapp, B.E. Three-Dimensional Printing of Transparent Fused Silica Glass. Nature 2017, 544, 337–339. [Google Scholar] [CrossRef]

- Sun, W.; Starly, B.; Daly, A.C.; Burdick, J.A.; Groll, J.; Skeldon, G.; Shu, W.; Sakai, Y.; Shinohara, M.; Nishikawa, M.; et al. The Bioprinting Roadmap. Biofabrication 2020, 12, 022002. [Google Scholar] [CrossRef]

- Skylar-Scott, M.A.; Mueller, J.; Visser, C.W.; Lewis, J.A. Voxelated Soft Matter via Multimaterial Multinozzle 3D Printing. Nature 2019, 575, 330–335. [Google Scholar] [CrossRef]

- Bhushan, B.; Caspers, M. An Overview of Additive Manufacturing (3D Printing) for Microfabrication. Microsyst. Technol. 2017, 23, 1117–1124. [Google Scholar] [CrossRef]

- Mao, M.; He, J.; Li, X.; Zhang, B.; Lei, Q.; Liu, Y.; Li, D. The Emerging Frontiers and Applications of High-Resolution 3D Printing. Micromachines 2017, 8, 113. [Google Scholar] [CrossRef] [Green Version]

- Ru, C.; Luo, J.; Xie, S.; Sun, Y. A Review of Non-Contact Micro- and Nano-Printing Technologies. J. Micromech. Microeng. 2014, 24, 053001. [Google Scholar] [CrossRef]

- Momeni, F.; Mehdi, M.; Hassani, N.S.; Liu, X.; Ni, J. A Review of 4D Printing. Mater. Des. 2017, 122, 42–79. [Google Scholar] [CrossRef]

- Tibbits, S. 4D printing: Multi-material shape change. Archit. Des. 2014, 84, 116–121. [Google Scholar] [CrossRef]

- Villar, G.; Graham, A.D.; Bayley, H. A tissue-like printed material. Science 2013, 5, 48–52. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wu, J.; Yuan, C.; Ding, Z.; Isakov, M.; Mao, Y.; Wang, T.; Dunn, M.L.; Qi, H.J. Multi-shape active composites by 3D printing of digital shape memory polymers. Sci. Rep. 2016, 6, 24224. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Q.; Zhang, K.; Hu, G. Smart three-dimensional lightweight structure triggered from a thin composite sheet via 3D printing technique. Sci. Rep. 2016, 6, 22431. [Google Scholar]

- Ge, Q.; Qi, H.J.; Dunn, M.L. Active materials by four-dimension printing. App. Phy. Lett. 2013, 103, 131901. [Google Scholar] [CrossRef]

- Kokkinis, D.; Schaffner, M.; Studart, A. Multimaterial magnetically assisted 3D printing of composite materials. Nat. Commun. 2015, 6, 8643. [Google Scholar] [CrossRef] [Green Version]

- Bakarich, S.E.; Gorkin, R.; Panhuis, M.i.h.; Spinks, G.M. 4D Printing with Mechanically Robust, Thermally Actuating Hydrogels. Macromol. Rapid Commun. 2015, 36, 1211–1217. [Google Scholar] [CrossRef]

- Mallakpour, S.; Tabesh, F.; Hussain, C.M. 3D and 4D Printing: From Innovation to Evolution. Adv. Colloid. Interface Sci. 2021, 294, 102482. [Google Scholar] [CrossRef]

- Ambrosi, A.; Pumera, M. 3D-Printing Technologies for Electrochemical Applications. Chem. Soc. Rev. 2016, 45, 2740–2755. [Google Scholar] [CrossRef] [Green Version]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Wohlers, T. Wohlers Report 2018: 3d Printing and Additive Manufacturing State of the Industry, Wohlers Associates; Wohlers Associates: Washington, DC, USA; Fort Collins, CO, USA, 2018. [Google Scholar]

- Gundrati, N.B.; Chakraborty, P.; Zhou, C.; Chung, D.D.L. Effects of Printing Conditions on the Molecular Alignment of Three-Dimensionally Printed Polymer. Compos. B Eng. 2018, 134, 164–168. [Google Scholar] [CrossRef]

- Gundrati, N.B.; Chakraborty, P.; Zhou, C.; Chung, D.D.L. First Observation of the Effect of the Layer Printing Sequence on the Molecular Structure of Three-Dimensionally Printed Polymer, as Shown by in-Plane Capacitance Measurement. Compos. B Eng. 2018, 140, 78–82. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D Printing of Polymer Matrix Composites: A Review and Prospective. Compos. B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Hammock, M.L.; Chortos, A.; Tee, B.C.K.; Tok, J.B.H.; Bao, Z. 25th Anniversary Article: The Evolution of Electronic Skin (E-Skin): A Brief History, Design Considerations, and Recent Progress. Adv. Mat. 2013, 25, 5997–6038. [Google Scholar] [CrossRef]

- Chenoweth, K.; Cheung, S.; van Duin, A.C.T.; Goddard, W.A.; Kober, E.M. Simulations on the Thermal Decomposition of a Poly(Dimethylsiloxane) Polymer Using the ReaxFF Reactive Force Field. J. Am. Chem. Soc. 2005, 127, 7192–7202. [Google Scholar] [CrossRef] [Green Version]

- Bîrca, A.; Gherasim, O.; Grumezescu, V.; Grumezescu, A.M. Introduction in Thermoplastic and Thermosetting Polymers. Mater. Biomed. Eng. Thermoplast. Polym. 2019, 1–28. [Google Scholar] [CrossRef]

- Grumezescu, V.; Grumezescu, A. Materials for Biomedical Engineering: Thermoset and Thermoplastic Polymers; Elsevier: Amsterdam, The Netherlands, 2019; Volume 1. [Google Scholar]

- Lin, D.; Jin, S.; Zhang, F.; Wang, C.; Wang, Y.; Zhou, C.; Cheng, G.J. 3D Stereolithography Printing of Graphene Oxide Reinforced Complex Architectures. Nanotechnology 2015, 26, 434003. [Google Scholar] [CrossRef] [Green Version]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive Manufacturing of Metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Hu, Y.; Cong, W.; Wang, X.; Li, Y.; Ning, F.; Wang, H. Laser Deposition-Additive Manufacturing of TiB-Ti Composites with Novel Three-Dimensional Quasi-Continuous Network Microstructure: Effects on Strengthening and Toughening. Compos. B Eng. 2018, 133, 91–100. [Google Scholar] [CrossRef]

- Sheydaeian, E.; Toyserkani, E. A New Approach for Fabrication of Titanium-Titanium Boride Periodic Composite via Additive Manufacturing and Pressure-Less Sintering. Compos. B Eng. 2018, 138, 140–148. [Google Scholar] [CrossRef]

- Carlton, H.D.; Haboub, A.; Gallegos, G.F.; Parkinson, D.Y.; MacDowell, A.A. Damage Evolution and Failure Mechanisms in Additively Manufactured Stainless Steel. Mat. Sci. Eng. A 2016, 651, 406–414. [Google Scholar] [CrossRef] [Green Version]

- Casalino, G.; Campanelli, S.L.; Contuzzi, N.; Ludovico, A.D. Experimental Investigation and Statistical Optimisation of the Selective Laser Melting Process of a Maraging Steel. Opt. Laser Technol. 2015, 65, 151–158. [Google Scholar] [CrossRef]

- Murr, L.E.; Martinez, E.; Hernandez, J.; Collins, S.; Amato, K.N.; Gaytan, S.M.; Shindo, P.W. Microstructures and Properties of 17-4 PH Stainless Steel Fabricated by Selective Laser Melting. J. Mat. Res. Technol. 2012, 1, 167–177. [Google Scholar] [CrossRef] [Green Version]

- Mazumder, J.; Choi, J.; Nagarathnam, K.; Koch, J.; Hetzner, D. The Direct Metal Deposition of H13 Tool Steel for 3-D Components. JOM 1997, 49, 55–60. [Google Scholar] [CrossRef]

- Brice, C.; Shenoy, R.; Kral, M.; Buchannan, K. Precipitation Behavior of Aluminum Alloy 2139 Fabricated Using Additive Manufacturing. Mat. Sci. Eng. A 2015, 648, 9–14. [Google Scholar] [CrossRef]

- Bartkowiak, K.; Ullrich, S.; Frick, T.; Schmidt, M. New Developments of Laser Processing Aluminium Alloys via Additive Manufacturing Technique. Phys. Procedia 2011, 12, 393–401. [Google Scholar] [CrossRef] [Green Version]

- Liang, S.X.; Jia, Z.; Liu, Y.J.; Zhang, W.; Wang, W.; Lu, J.; Zhang, L.C. Compelling Rejuvenated Catalytic Performance in Metallic Glasses. Adv. Mater. 2018, 30, 1802764. [Google Scholar] [CrossRef] [Green Version]

- Jia, Z.; Duan, X.; Qin, P.; Zhang, W.; Wang, W.; Yang, C.; Sun, H.; Wang, S.; Zhang, L.C. Disordered Atomic Packing Structure of Metallic Glass: Toward Ultrafast Hydroxyl Radicals Production Rate and Strong Electron Transfer Ability in Catalytic Performance. Adv. Funct. Mater. 2017, 27, 1702258. [Google Scholar] [CrossRef]

- Jia, Z.; Wang, Q.; Sun, L.; Wang, Q.; Zhang, L.C.; Wu, G.; Luan, J.H.; Jiao, Z.B.; Wang, A.; Liang, S.X.; et al. Attractive In Situ Self-Reconstructed Hierarchical Gradient Structure of Metallic Glass for High Efficiency and Remarkable Stability in Catalytic Performance. Adv. Funct. Mater. 2019, 29, 1807857. [Google Scholar] [CrossRef]

- Jia, Z.; Kang, J.; Zhang, W.C.; Wang, W.M.; Yang, C.; Sun, H.; Habibi, D.; Zhang, L.C. Surface Aging Behaviour of Fe-Based Amorphous Alloys as Catalysts during Heterogeneous Photo Fenton-like Process for Water Treatment. Appl. Catal. B 2017, 204, 537–547. [Google Scholar] [CrossRef]

- Nakahara, S.; Périgo, E.A.; Pittini-Yamada, Y.; de Hazan, Y.; Graule, T. Electric Insulation of a FeSiBC Soft Magnetic Amorphous Powder by a Wet Chemical Method: Identification of the Oxide Layer and Its Thickness Control. Acta Mater. 2010, 58, 5695–5703. [Google Scholar] [CrossRef]

- Liu, D.; Wu, C.; Yan, M.; Wang, J. Correlating the Microstructure, Growth Mechanism and Magnetic Properties of FeSiAl Soft Magnetic Composites Fabricated via HNO3 Oxidation. Acta Mater. 2018, 146, 294–303. [Google Scholar] [CrossRef]

- Farmer, J.; Choi, J.S.; Saw, C.; Haslam, J.; Day, D.; Hailey, P.; Lian, T.; Rebak, R.; Perepezko, J.; Payer, J.; et al. Iron-Based Amorphous Metals: High-Performance Corrosion-Resistant Material Development. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2009, 40, 1289–1305. [Google Scholar] [CrossRef]

- Ouyang, D.; Li, N.; Xing, W.; Zhang, J.; Liu, L. 3D Printing of Crack-Free High Strength Zr-Based Bulk Metallic Glass Composite by Selective Laser Melting. Intermetallics 2017, 90, 128–134. [Google Scholar] [CrossRef]

- Li, H.X.; Lu, Z.C.; Wang, S.L.; Wu, Y.; Lu, Z.P. Fe-Based Bulk Metallic Glasses: Glass Formation, Fabrication, Properties and Applications. Prog. Mater. Sci. 2019, 103, 235–318. [Google Scholar] [CrossRef]

- Gibson, M.A.; Mykulowycz, N.M.; Shim, J.; Fontana, R.; Schmitt, P.; Roberts, A.; Ketkaew, J.; Shao, L.; Chen, W.; Bordeenithikasem, P.; et al. 3D printing metals like thermoplastics: Fused filament fabrication of metallic glasses. Mater. Today 2018, 21, 697–702. [Google Scholar] [CrossRef]

- Eckel, Z.C.; Zhou, C.; Martin, J.H.; Jacobsen, A.J.; Carter, W.B.; Schaedler, T.A. Additive Manufacturing of Polymer-Derived Ceramics. Science 2016, 351, 58–62. [Google Scholar] [CrossRef] [Green Version]

- Zocca, A.; Colombo, P.; Gomes, C.M.; Günster, J. Additive Manufacturing of Ceramics: Issues, Potentialities, and Opportunities. J. Am. Ceram. Soc. 2015, 98, 1983–2001. [Google Scholar] [CrossRef]

- Shahzad, K.; Deckers, J.; Zhang, Z.; Kruth, J.P.; Vleugels, J. Additive Manufacturing of Zirconia Parts by Indirect Selective Laser Sintering. J. Eur. Ceram. Soc. 2014, 34, 81–89. [Google Scholar] [CrossRef]

- Tang, H.H.; Yen, H.C. Slurry-Based Additive Manufacturing of Ceramic Parts by Selective Laser Burn-Out. J. Eur. Ceram. Soc. 2015, 35, 981–987. [Google Scholar] [CrossRef]

- Chartier, T.; Duterte, C.; Delhote, N.; Baillargeat, D.; Verdeyme, S.; Delage, C.; Chaput, C. Fabrication of Millimeter Wave Components Via Ceramic Stereo- and Microstereolithography Processes. J. Am. Ceram. Soc. 2008, 91, 2469–2474. [Google Scholar] [CrossRef]

- Zheng, X.; Lee, H.; Weisgraber, T.H.; Shusteff, M.; DeOtte, J.; Duoss, E.B.; Kuntz, J.D.; Biener, M.M.; Ge, Q.; Jackson, J.A.; et al. Ultralight, Ultrastiff Mechanical Metamaterials. Science 2014, 344, 1373–1377. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Windsheimer, H.; Travitzky, N.; Hofenauer, A.; Greil, P. Laminated Object Manufacturing of Preceramic-Paper-Derived Si-SiC Composites. Adv. Mater. 2007, 19, 4515–4519. [Google Scholar] [CrossRef]

- Fu, Q.; Saiz, E.; Tomsia, A.P. Bioinspired Strong and Highly Porous Glass Scaffolds. Adv. Funct. Mater. 2011, 21, 1058–1063. [Google Scholar] [CrossRef] [Green Version]

- Özkol, E.; Wätjen, A.M.; Bermejo, R.; Deluca, M.; Ebert, J.; Danzer, R.; Telle, R. Mechanical Characterisation of Miniaturised Direct Inkjet Printed 3Y-TZP Specimens for Microelectronic Applications. J. Eur. Ceram. Soc. 2010, 30, 3145–3152. [Google Scholar] [CrossRef]

- Jafari, M.A.; Han, W.; Mohammadi, F.; Safari, A.; Danforth, S.C.; Langrana, N. A Novel System for Fused Deposition of Advanced Multiple Ceramics. Rapid Prototyp. J. 2000, 6, 161–174. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, Z.; Li, J.; Gong, B.; Wang, L.; Lao, C.; Wang, P.; Liu, C.; Feng, Y.; Wang, X. 3D Printing of Ceramic Cellular Structures for Potential Nuclear Fusion Application. Addit. Manuf. 2020, 35, 101348. [Google Scholar] [CrossRef]

- Meza, L.R.; Das, S.; Greer, J.R. Strong, Lightweight, and Recoverable Three-Dimensional Ceramic Nanolattices. Science 2014, 345, 1322–1326. [Google Scholar] [CrossRef] [Green Version]

- Jang, D.; Meza, L.R.; Greer, F.; Greer, J.R. Fabrication and Deformation of Three-Dimensional Hollow Ceramic Nanostructures. Nat. Mater. 2013, 12, 893–898. [Google Scholar] [CrossRef] [Green Version]

- Bauer, J.; Hengsbach, S.; Tesari, I.; Schwaiger, R.; Kraft, O. High-Strength Cellular Ceramic Composites with 3D Microarchitecture. Proc. Natl. Acad. Sci. USA 2014, 111, 2453–2458. [Google Scholar] [CrossRef] [PubMed]

- Colombo, P.; Mera, G.; Riedel, R.; Sorarù, G.D. Polymer-Derived Ceramics: 40 Years of Research and Innovation in Advanced Ceramics. J. Am. Ceram. Soc. 2010, 93, 1805–1837. [Google Scholar] [CrossRef]

- Ionescu, E.; Kleebe, H.J.; Riedel, R. Silicon-Containing Polymer-Derived Ceramic Nanocomposites (PDC-NCs): Preparative Approaches and Properties. Chem. Soc. Rev. 2012, 41, 5032–5052. [Google Scholar] [CrossRef] [PubMed]

- Minas, C.; Carnelli, D.; Tervoort, E.; Studart, A.R. 3D Printing of Emulsions and Foams into Hierarchical Porous Ceramics. Adv. Mater. 2016, 28, 9993–9999. [Google Scholar] [CrossRef] [PubMed]

- Yu, Y.; Liu, Y.; Fang, J.; An, L. Formation of Novel Microstructured SiCNO Films from Block Copolymer Micellar-Templating Approaches. J. Am. Ceram. Soc. 2015, 98, 2894–2901. [Google Scholar] [CrossRef]

- Ionescu, E.; Linck, C.; Fasel, C.; Müller, M.; Kleebe, H.J.; Riedel, R. Polymer-Derived SiOC/ZrO2 Ceramic Nanocomposites with Excellent High-Temperature Stability. J. Am. Ceram. Soc. 2010, 93, 241–250. [Google Scholar] [CrossRef]

- Li, J.; Lu, K.; Lin, T.; Shen, F. Preparation of Micro-/Mesoporous SiOC Bulk Ceramics. J. Am. Ceram. Soc. 2015, 98, 1753–1761. [Google Scholar] [CrossRef]

- Zanchetta, E.; Cattaldo, M.; Franchin, G.; Schwentenwein, M.; Homa, J.; Brusatin, G.; Colombo, P. Stereolithography of SiOC Ceramic Microcomponents. Adv. Mater. 2016, 28, 370–376. [Google Scholar] [CrossRef]

- Mera, G.; Navrotsky, A.; Sen, S.; Kleebe, H.J.; Riedel, R. Polymer-Derived SiCN and SiOC Ceramics-Structure and Energetics at the Nanoscale. J. Mater. Chem. A Mater. 2013, 1, 3826–3836. [Google Scholar] [CrossRef]

- Kaspar, J.; Terzioglu, C.; Ionescu, E.; Graczyk-Zajac, M.; Hapis, S.; Kleebe, H.J.; Riedel, R. Stable SiOC/Sn Nanocomposite Anodes for Lithium-Ion Batteries with Outstanding Cycling Stability. Adv. Funct. Mater. 2014, 24, 4097–4104. [Google Scholar] [CrossRef]

- Kashiwagi, T.; Du, F.; Douglas, J.F.; Winey, K.I.; Harris, R.H.; Shields, J.R. Nanoparticle Networks Reduce the Flammability of Polymer Nanocomposites. Nat. Mater. 2005, 4, 928–933. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, G.; Zhao, Y.; Wu, G.; Lu, J. Origami and 4D Printing of Elastomer-Derived Ceramic Structures. Sci. Adv. 2018, 4, eaat0641. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Studart, A.R. Additive Manufacturing of Biologically-Inspired Materials. Chem. Soc. Rev. 2016, 45, 359–376. [Google Scholar] [CrossRef]

- Koerner, H.; Price, G.; Pearce, N.A.; Alexander, M.; Vaia, R.A. Remotely Actuated Polymer Nanocomposites—Stress-Recovery of Carbon-Nanotube-Filled Thermoplastic Elastomers. Nat. Mater. 2004, 3, 115–120. [Google Scholar] [CrossRef]

- He, Z.; Satarkar, N.; Xie, T.; Cheng, Y.T.; Hilt, J.Z. Remote Controlled Multishape Polymer Nanocomposites with Selective Radiofrequency Actuations. Adv. Mater. 2011, 23, 3192–3196. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.J.; Cha, J.Y.; Ham, H.; Huh, H.; So, D.S.; Kang, I. Preparation of Piezoresistive Nano Smart Hybrid Material Based on Graphene. Curr. Appl. Phys. 2011, 11, S350–S352. [Google Scholar] [CrossRef]

- Arabnejad, S.; Johnston, B.; Tanzer, M.; Pasini, D. Fully Porous 3D Printed Titanium Femoral Stem to Reduce Stress-Shielding Following Total Hip Arthroplasty. J. Orthop. Res. 2017, 35, 1774–1783. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Han, Q.; Zhang, K.; Zhang, Y.; Wang, C.; Yang, K.; Zou, Y.; Chen, B.; Wang, J. Individual Resection and Reconstruction of Pelvic Tumor with Three-Dimensional Printed Customized Hemi-Pelvic Prosthesis: A Case Report. Medicine 2019, 98, e16658. [Google Scholar] [CrossRef]

- EOS. Additive Manufacturing for the Dental Industry—Final Dental Products on the Basis of Industrial 3D Printing. 2021. Available online: https://www.eos.info/dental (accessed on 27 October 2022).

- Xu, N.; Wei, F.; Liu, X.; Jiang, L.; Cai, H.; Li, Z.; Yu, M.; Wu, F.; Liu, Z. Reconstruction of the Upper Cervical Spine Using a Personalized 3D-Printed Vertebral Body in an Adolescent with Ewing Sarcoma. Spine 2016, 41, E50–E54. [Google Scholar] [CrossRef] [PubMed]

- Timbie, P.T.; Grade, J.; van der Weide, D.; Maffei, B.; Pisano, G. Stereolithographed MM-Wave Corrugated Horn Antennas. In Proceedings of the IRMMW-THz 2011—36th International Conference on Infrared, Millimeter, and Terahertz Waves, Houston, TX, USA, 2–7 October 2011. [Google Scholar]

- Dienel, K.E.G.; van Bochove, B.; Seppälä, J.v. Additive Manufacturing of Bioactive Poly(Trimethylene Carbonate)/β-Tricalcium Phosphate Composites for Bone Regeneration. Biomacromolecules 2020, 21, 366–375. [Google Scholar] [CrossRef]

- Ahn, G.; Lee, J.S.; Yun, W.S.; Shim, J.H.; Lee, U.L. Cleft Alveolus Reconstruction Using a Three-Dimensional Printed Bioresorbable Scaffold with Human Bone Marrow Cells. J. Craniofacial Surg. 2018, 29, 1880–1883. [Google Scholar] [CrossRef] [PubMed]

- Lu, M.; Zhou, T.; Liu, X. 3-D Super-Resolution Localization Microscopy Using Deep-Learning Method. In Optics in Health Care and Biomedical Optics IX; SPIE: Bellingham, WA, USA, 2019; Volume 11190, pp. 56–62. [Google Scholar]

- Vasso, M.; Beaufils, P.; Cerciello, S.; Schiavone Panni, A. Bone Loss Following Knee Arthroplasty: Potential Treatment Options. Arch. Orthop. Trauma. Surg. 2014, 134, 543–553. [Google Scholar] [CrossRef] [PubMed]

- Noor, N.; Shapira, A.; Edri, R.; Gal, I.; Wertheim, L.; Dvir, T. 3D Printing of Personalized Thick and Perfusable Cardiac Patches and Hearts. Adv. Sci. 2019, 6, 1900344. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, J.; Li, X.; Luo, T.; Wang, R.; Liu, C.; Chen, S.; Li, D.; Yue, J.; Cheng, S.H.; Sun, D. Development of a Magnetic Microrobot for Carrying and Delivering Targeted Cells. Sci. Robot. 2018, 3, eaat8829. [Google Scholar] [CrossRef] [Green Version]

- von Bieren, A.; de Rijk, E.; Ansermet, J.P.; Macor, A. Monolithic Metal-Coated Plastic Components for Mm-Wave Applications. In Proceedings of the International Conference on Infrared, Millimeter, and Terahertz Waves, IRMMW-THz, Tucson, AR, USA, 14–19 September 2014. [Google Scholar]

- Kim, Y.; Parada, G.A.; Liu, S.; Zhao, X. Ferromagnetic Soft Continuum Robots. Sci. Robot. 2019, 4, eaax7329. [Google Scholar] [CrossRef]

- Guo, C.; Shang, X.; Li, J.; Zhang, F.; Lancaster, M.J.; Xu, J. A Lightweight 3-D Printed X-Band Bandpass Filter Based on Spherical Dual-Mode Resonators. IEEE Microw. Wirel. Compon. Lett. 2016, 26, 568–570. [Google Scholar] [CrossRef]

- Wong, M.H. Singapore Airshow: 5 Ways Aviation Will Change. 2016. Available online: https://edition.cnn.com/travel/article/aviation-emerging-tech-singapore-airshow/index.html (accessed on 14 October 2022).

- Wang, D.; Wang, Y.; Wu, S.; Lin, H.; Yang, Y.; Fan, S.; Gu, C.; Wang, J.; Song, C. Customized a Ti6Al4V Bone Plate for Complex Pelvic Fracture by Selective Laser Melting. Materials 2017, 10, 35. [Google Scholar] [CrossRef]

- Bose, S.; Ke, D.; Sahasrabudhe, H.; Bandyopadhyay, A. Additive Manufacturing of Biomaterials. Prog. Mater. Sci. 2018, 93, 45–111. [Google Scholar] [CrossRef]

- Oldani, C.; Dominguez, A. Titanium as a Biomaterial for Implants. Recent Adv. Arthroplast. 2012, 218, 149. [Google Scholar]

- Shi, Y.; Wang, W. 3D Inkjet Printing of the Zirconia Ceramic Implanted Teeth. Mater. Lett. 2020, 261, 127131. [Google Scholar] [CrossRef]

- Chang Tu, C.; Tsai, P.I.; Chen, S.Y.; Kuo, M.Y.P.; Sun, J.S.; Chang, J.Z.C. 3D Laser-Printed Porous Ti6Al4V Dental Implants for Compromised Bone Support. J. Formos. Med. Assoc. 2020, 119, 420–429. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Müller, R.; Ruffoni, D. Bone Remodeling and Mechanobiology around Implants: Insights from Small Animal Imaging. J. Orthop. Res. 2018, 36, 584–593. [Google Scholar] [CrossRef] [PubMed]

- Giannopoulos, A.A.; Mitsouras, D.; Yoo, S.J.; Liu, P.P.; Chatzizisis, Y.S.; Rybicki, F.J. Applications of 3D Printing in Cardiovascular Diseases. Nat. Rev. Cardiol. 2016, 13, 701–718. [Google Scholar] [CrossRef] [PubMed]

- Rengier, F.; Mehndiratta, A.; von Tengg-Kobligk, H.; Zechmann, C.M.; Unterhinninghofen, R.; Kauczor, H.U.; Giesel, F.L. 3D Printing Based on Imaging Data: Review of Medical Applications. Int. J. Comput. Assist Radiol. Surg. 2010, 5, 335–341. [Google Scholar] [CrossRef]

- Howard, J.D.; Eggbeer, D.; Dorrington, P.; Korkees, F.; Tasker, L.H. Evaluating Additive Manufacturing for the Production of Custom Head Supports: A Comparison against a Commercial Head Support under Static Loading Conditions. Proc. Inst. Mech. Eng. H 2020, 234, 458–467. [Google Scholar] [CrossRef]

- Zarek, M.; Mansour, N.; Shapira, S.; Cohn, D. 4D printing of shape memory-based personalized endoluminal medical devices. Macromol. Rapid Commun. 2017, 38, 1600628. [Google Scholar] [CrossRef]

- Gruber, S.; Stampfl, J.; Felzmann, R.; Springer, S.; Liska, R. Lithographiebasierte fertigung keramischer bauteile. RTejoumal Forum Fur Rapid Technol. 2011, 8, 1. [Google Scholar]

- Tino, R.; Moore, R.; Antoline, S.; Ravi, P.; Wake, N.; Ionita, C.N.; Morris, J.M.; Decker, S.J.; Sheikh, A.; Rybicki, F.J.; et al. COVID-19 and the Role of 3D Printing in Medicine. 3D Print. Med. 2020, 6, 11. [Google Scholar] [CrossRef] [Green Version]

- Radfar, P.; Razavi Bazaz, S.; Mirakhorli, F.; Warkiani, M.E. The Role of 3D Printing in the Fight against COVID-19 Outbreak. J. 3D Print. Med. 2021, 5, 51–60. [Google Scholar] [CrossRef]

- Lu, J. A New, Simple Projection Model for COVID-19 Pandemic. medRxiv 2020. [Google Scholar] [CrossRef] [Green Version]

- About NanoHack. Available online: https://copper3d.com/hackthepandemic/ (accessed on 27 October 2022).

- Yin, L.; Doyhamboure-Fouquet, J.; Tian, X.; Li, D. Design and Characterization of Radar Absorbing Structure Based on Gradient-Refractive-Index Metamaterials. Compos. B Eng. 2018, 132, 178–187. [Google Scholar] [CrossRef]

- Turco, E.; Golaszewski, M.; Giorgio, I.; D’Annibale, F. Pantographic Lattices with Non-Orthogonal Fibres: Experiments and Their Numerical Simulations. Compos. B Eng. 2017, 118, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Noorani, R. Rapid Prototyping: Principles and Applications; Wiley: Hoboken, NJ, USA, 2006. [Google Scholar]

- SLM Solutions, Case Report Monolithic Thrust Chamber. Available online: https://exhibitorsearch.messefrankfurt.com/images/original/userdata/bata/212474/5d3fd794ac6fe.pdf (accessed on 27 October 2022).

- NASA/MSFC, Pogo Z-Baffle for RS-25 Engine. 2013. Available online: https://www.nasa.gov/exploration/systems/sls/j2x/turbocover2.html (accessed on 27 October 2022).

- Ridinger, S. NASA Advances Additive Manufacturing for Rocket Propulsion. 2018. Available online: https://www.nasa.gov/centers/marshall/news/nasa-advances-additive-manufacturing-for-rocket-propulsion.html (accessed on 27 October 2022).

- RollsRoyce, Advance and UltraFan. 2016. Available online: https://www.rolls-royce.com/media/our-stories/innovation/2016/advance-and-ultrafan.aspx#overview (accessed on 27 October 2022).

- Pratt &Whitney, Pratt & Whitney GTF Engine. 2021. Available online: https://prattwhitney.com/products-and-services/products/commercial-engines/pratt-and-whitney-gtf (accessed on 27 October 2022).

- First Titanium 3D-printed Part Installed into Serial Production Aircraft. 2017. Available online: https://www.airbus.com/newsroom/press-releases/en/2017/09/first-titanium-3d-printed-part-installed-into-serial-production-.html (accessed on 27 October 2022).

- Bridging the Gap With 3D Printing. 2018. Available online: https://www.airbus.com/news-room/news/en/2018/04/bridging-the-gap-with-3d-printing.html (accessed on 27 October 2022).

- Amstelveen, From Drink to Ink—KLM Makes Tools from PET Bottles. 2019. Available online: https://news.klm.com/from-drink-to-ink–klm-makes-tools-from-petbottles/ (accessed on 27 October 2022).

- Broda, A. Additive Manufacturing Insight 3D Printing Matures for Tooling. 2019. Available online: https://www.boeing.com/features/innovation-quarterly/2019_q4/btj-additivemanufacturing (accessed on 27 October 2022).

- Prater, T. Study of Material Consolidation at Higher Throughput Parameters in Selective Laser Melting of Inconel 718. In The Materials Society (TMS) Annual Meeting and Exhibition, Nashville; Qualification Nashville: Nashville, TN, USA, 2016. [Google Scholar]

- SpaceX Astronaut Wearing a 3D Printed Helmet. 2020. Available online: https://www.spacex.com/human-spaceflight/ (accessed on 27 October 2022).

- CCTV. 2020. Available online: http://news.cctv.com/2020/05/07/ARTItl3hfFa9IOTnzWAgDlNA200507.shtml (accessed on 27 October 2022).

- Ntouanoglou, K.; Stavropoulos, P.; Mourtzis, D. 4D Printing Prospects for the Aerospace Industry: A Critical Review. Procedia Manuf. 2018, 18, 120–129. [Google Scholar] [CrossRef]

- Cramer, N.B.; Cellucci, D.W.; Formoso, O.B.; Gregg, C.E.; Jenett, B.E.; Kim, J.H.; Lendraitis, M.; Swei, S.S.; Trinh, G.T.; Trinh, K.v.; et al. Elastic Shape Morphing of Ultralight Structures by Programmable Assembly. Smart Mater. Struct. 2019, 28, 055006. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Eichenhofer, M.; Wong, J.C.H.; Ermanni, P. Continuous Lattice Fabrication of Ultra-Lightweight Composite Structures. Addit. Manuf. 2017, 18, 48–57. [Google Scholar] [CrossRef]

- Fasel, U.; Keidel, D.; Baumann, L.; Cavolina, G.; Eichenhofer, M.; Ermanni, P. Composite Additive Manufacturing of Morphing Aerospace Structures. Manuf. Lett. 2020, 23, 85–88. [Google Scholar] [CrossRef]

- Svoboda, F.; Hromcik, M. Construction of the Smooth Morphing Trailing Edge Demonstrator. In Proceedings of the 2019 22nd International Conference on Process Control, Hong Kong, China, 28–30 April 2019; Volume 2019, pp. 136–139. [Google Scholar]

- Keidel, D.; Molinari, G.; Ermanni, P. Aero-Structural Optimization and Analysis of a Camber-Morphing Flying Wing: Structural and Wind Tunnel Testing. J. Intell. Mater. Syst. Struct. 2019, 30, 908–923. [Google Scholar] [CrossRef]

- Menshchikov, A.; Somov, A. Morphing Wing with Compliant Aileron and Slat for Unmanned Aerial Vehicles. Phys. Fluids 2019, 31, 037105. [Google Scholar] [CrossRef]

- Kimaru, J.; Bouferrouk, A. Design, Manufacture and Test of a Camber Morphing Wing Using MFC Actuated Mart Rib. In Proceedings of the 2017 8th International Conference on Mechanical and Aerospace Engineering, ICMAE, Prague, Czech Republic, 22–25 July 2017; Volume 2017, pp. 791–796. [Google Scholar]

- You, H.; Kim, S.; Joe, W.Y.; Yun, G.J. New Concept for Aircraft Morphing Wing Skin: Design, Modeling, and Analysis. AIAA J. 2019, 57, 1786–1792. [Google Scholar] [CrossRef]

- Guo, S.Z.; Qiu, K.; Meng, F.; Park, S.H.; McAlpine, M.C. 3D Printed Stretchable Tactile Sensors. Adv. Mater. 2017, 29, 1701218. [Google Scholar] [CrossRef]

- Wang, Z.; Guan, X.; Huang, H.; Wang, H.; Lin, W.; Peng, Z. Full 3D Printing of Stretchable Piezoresistive Sensor with Hierarchical Porosity and Multimodulus Architecture. Adv. Funct. Mater. 2019, 29, 1807569. [Google Scholar] [CrossRef]

- Lei, Z.; Wang, Q.; Wu, P. A Multifunctional Skin-like Sensor Based on a 3D Printed Thermo-Responsive Hydrogel. Mater. Horiz. 2017, 4, 694–700. [Google Scholar] [CrossRef]

- Valentine, A.D.; Busbee, T.A.; Boley, J.W.; Raney, J.R.; Chortos, A.; Kotikian, A.; Berrigan, J.D.; Durstock, M.F.; Lewis, J.A. Hybrid 3D Printing of Soft Electronics. Adv. Mater. 2017, 29, 1703817. [Google Scholar] [CrossRef]

- Chen, S.; Huang, T.; Zuo, H.; Qian, S.; Guo, Y.; Sun, L.; Lei, D.; Wu, Q.; Zhu, B.; He, C.; et al. A Single Integrated 3D-Printing Process Customizes Elastic and Sustainable Triboelectric Nanogenerators for Wearable Electronics. Adv. Funct. Mater. 2018, 28, 1805108. [Google Scholar] [CrossRef]

- Li, H.; Li, R.; Fang, X.; Jiang, H.; Ding, X.; Tang, B.; Zhou, G.; Zhou, R.; Tang, Y. 3D Printed Flexible Triboelectric Nanogenerator with Viscoelastic Inks for Mechanical Energy Harvesting. Nano Energy 2019, 58, 447–454. [Google Scholar] [CrossRef]

- Yi, X.; Tan, Z.J.; Yu, W.J.; Li, J.; Li, B.J.; Huang, B.Y.; Liao, J. Three Dimensional Printing of Carbon/Carbon Composites by Selective Laser Sintering. Carbon 2016, 96, 603–607. [Google Scholar] [CrossRef]

- Chen, B.; Jiang, Y.; Tang, X.; Pan, Y.; Hu, S. Fully Packaged Carbon Nanotube Supercapacitors by Direct Ink Writing on Flexible Substrates. ACS Appl. Mater. Interfaces 2017, 9, 28433–28440. [Google Scholar] [CrossRef] [PubMed]

- Sun, G.; An, J.; Chua, C.K.; Pang, H.; Zhang, J.; Chen, P. Layer-by-Layer Printing of Laminated Graphene-Based Interdigitated Microelectrodes for Flexible Planar Micro-Supercapacitors. Electrochem. Commun. 2015, 51, 33–36. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, C.; Xie, H.; Gao, T.; Yao, Y.; Pastel, G.; Han, X.; Li, Y.; Zhao, J.; Fu, K.K.; et al. 3D-Printed All-Fiber Li-Ion Battery toward Wearable Energy Storage. Adv. Funct. Mater. 2017, 27, 1703140. [Google Scholar] [CrossRef]

- Sun, K.; Wei, T.S.; Ahn, B.Y.; Seo, J.Y.; Dillon, S.J.; Lewis, J.A. 3D Printing of Interdigitated Li-Ion Microbattery Architectures. Adv. Mater. 2013, 25, 4539–4543. [Google Scholar] [CrossRef] [Green Version]

- Wei, T.S.; Ahn, B.Y.; Grotto, J.; Lewis, J.A. 3D Printing of Customized Li-Ion Batteries with Thick Electrodes. Adv. Mater. 2018, 30, e1703027. [Google Scholar] [CrossRef] [PubMed]

- Yuk, H.; Lu, B.; Lin, S.; Qu, K.; Xu, J.; Luo, J.; Zhao, X. 3D Printing of Conducting Polymers. Nat. Commun. 2020, 11, 1604. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ho, D.H.; Hong, P.; Han, J.T.; Kim, S.Y.; Kwon, S.J.; Cho, J.H. 3D-Printed Sugar Scaffold for High-Precision and Highly Sensitive Active and Passive Wearable Sensors. Adv. Sci. 2020, 7, 1902521. [Google Scholar] [CrossRef] [PubMed]

- Choi, Y.Y.; Ho, D.H.; Cho, J.H. Self-Healable Hydrogel-Liquid Metal Composite Platform Enabled by a 3D Printed Stamp for a Multimodular Sensor System. ACS Appl. Mater. Interfaces 2020, 12, 9824–9832. [Google Scholar] [CrossRef] [PubMed]

- Liu, R.; Kuang, X.; Deng, J.; Wang, Y.C.; Wang, A.C.; Ding, W.; Lai, Y.C.; Chen, J.; Wang, P.; Lin, Z.; et al. Shape memory polymers for body motion energy harvesting and self-powered mechanosensing. Adv. Mater. 2018, 30, 1705195. [Google Scholar] [CrossRef]

- Manti, M.; Hassan, T.; Passetti, G.; D’Elia, N.; Laschi, C.; Cianchetti, M. A bioinspired soft robotic gripper for adaptable and effective grasping. Soft Robot. 2015, 2, 107–116. [Google Scholar] [CrossRef]

- Homberg, B.S.; Katzschmann, R.K.; Dogar, M.R.; Rus, D. Haptic identification of objects using a modular soft robotic gripper. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Hamburg, Germany, 28 September–2 October 2015; pp. 1698–1705. [Google Scholar]

- Shintake, J.; Cacucciolo, V.; Floreano, D.; Shea, H. Soft robotic grippers. Adv. Mater. 2018, 30, 1707035. [Google Scholar] [CrossRef] [Green Version]

- Shian, S.; Bertoldi, K.; Clarke, D.R. Dielectric elastomer based “grippers” for soft robotics. Adv. Mater. 2018, 27, 6814–6819. [Google Scholar] [CrossRef]

- Schreiber, F.; Manns, M.; Morales, J. Design of an additively manufactured soft ring-gripper. Procedia Manuf. 2019, 28, 142–147. [Google Scholar] [CrossRef]

- Ge, Q.; Sakhaei, A.H.; Lee, H.; Dunn, C.K.; Fang, N.X.; Dunn, M.L. Multimaterial 4D printing with tailorable shape memory polymers. Sci. Rep. 2016, 6, 31110. [Google Scholar] [CrossRef] [Green Version]

- Yingchuang Building Technique (Shanghai) Co., Ltd. (Winsun). Available online: http://www.winsun3d.com/En/Product/pro_inner_5/id/90 (accessed on 27 October 2022).

- Labeaga-Martínez, N.; Sanjurjo-Rivo, M.; Díaz-Álvarez, J.; Martínez-Frías, J. Additive manufacturing for a Moon village. Procedia Manuf. 2017, 13, 794–801. [Google Scholar] [CrossRef]

- Wu, P.; Wang, J.; Wang, X. A critical review of the use of 3-D printing in the construction industry. Automa. Const. 2016, 68, 21–31. [Google Scholar] [CrossRef] [Green Version]

- 3D Print Canal House—DUS Architects. Available online: https://houseofdus.com/project/3d-print-canal-house/ (accessed on 14 October 2022).

- Xu, J.; Ding, L.; Love, P.E. Digital reproduction of historical building ornamental components: From 3D scanning to 3D printing. Automat. Constr. 2017, 76, 85–96. [Google Scholar] [CrossRef]

- Tay, Y.W.D.; Panda, B.; Paul, S.C.; Noor Mohamed, N.A.; Tan, M.J.; Leong, K.F. 3D Printing Trends in Building and Construction Industry: A Review. Virtual Phys. Prototyp. 2017, 12, 261–276. [Google Scholar] [CrossRef]

- Zhai, Y.; Lados, D.A.; Lagoy, J.L. Additive Manufacturing: Making Imagination the Major Limitation. JOM 2014, 66, 808–816. [Google Scholar] [CrossRef] [Green Version]

- Pasricha, A.; Greeninger, R. Exploration of 3D Printing to Create Zero-Waste Sustainable Fashion Notions and Jewelry. Fash. Text. 2018, 5, 30. [Google Scholar] [CrossRef] [Green Version]

- Chartier, T.; Dupas, C.; Lasgorceix, M.; Brie, J.; Champion, E.; Delhote, N.; Chaput, C. Additive Manufacturing to Produce Complex 3D Ceramic Parts. J. Ceram. Sci. Technol. 2014, 6, 95–104. [Google Scholar]

- Wu, D.; Zhao, Z.; Zhang, Q.; Qi, H.J.; Fang, D. Mechanics of Shape Distortion of DLP 3D Printed Structures during UV Post-Curing. Soft Matt. 2019, 15, 6151–6159. [Google Scholar] [CrossRef]

- Cooper, F. Sintering and Additive Manufacturing: The New Paradigm for the Jewellery Manufacturer. Johns. Matthey Technol. Rev. 2015, 59, 233–242. [Google Scholar] [CrossRef]

- Dean, L.T.; Niedderer, K. Flex-It: Exploring Emotional Expression through Elasticity in Digital Manufacturing. Craft Res. 2016, 7, 51–77. [Google Scholar] [CrossRef]

- Khan, M.; Dickens, P. Selective Laser Melting (SLM) of Pure Gold. Gold Bull. 2010, 43, 114–121. [Google Scholar] [CrossRef]

- Walker, M.J. Hype Cycle for Emerging Technologies; Gartner: Stamford, CT, USA, 2018. [Google Scholar]

| Fabrication Process | Methods | Materials | Applications | Surface Finish | Merits | Limitations |

|---|---|---|---|---|---|---|

| Extrusion | FDM/FFF | Thermoplastics filaments, e.g., PLA, ABS, Nylon | Rapid prototyping Concept parts Advanced composite parts | Standard | Low cost Versatile Simplicity High speed | Weak mechanical properties Limited materials |

| DIW | Plastics, Ceramics, Composites, Living cells | Packaging Scaffolds for bone regeneration | Standard | Flexible | Requires post processing | |

| Powder-bed fusion | SLS | Fine powders of polymers, alloys, composites, and ceramics | Aerospace components Light-weight structures Electronics | Standard | Fine resolution High quality Best mechanical properties | Low resolution High cost High porosity |

| SLM | Fine powders of metals, alloys, and ceramics | Aerospace components Light-weight structures Electronics | Good | Good mechanical properties Wide range of materials | Slow process | |

| Photopolymerization | SLA | Photopolymers UV curable resins | Biomedical Prototyping | Excellent | High precision Smooth surface finish Low cost | Limited materials Weak mechanical properties Expensive |

| DLP | Elastomers, Photopolymers UV curable resins | Biomedical Prototyping | Good | High resolution High printing speeds | Requires post processing |

| Materials | Main Applications | Benefits | Challenges |

|---|---|---|---|

| Metals and alloys | Aerospace and Automotive Military Biomedical | Multifunctional optimization Mass-customization Reduced material waste Fewer assembly components Possibility to repair damaged or worn metal parts | Limited selection of alloys Dimensional inaccuracy and poor surface finish Post-processing may be required (machining, heat treatment or chemical etching) |

| Polymers and composites | Aerospace and Automotive Sports Medical Architecture Toys Biomedical | Fast prototyping Cost-effective Complex structures Mass-customisation | Weak mechanical properties Limited selection of polymers and reinforcements Anisotropic mechanical properties (especially in fibre-reinforced composites) |

| Ceramics | Biomedical Aerospace and Automotive Chemical industries | Controlling porosity of lattices Printing complex structures and scaffolds for human body organs Reduced fabrication time A better control on composition and microstructure | Limited selection of 3D-printable ceramics Dimensional inaccuracy and poor surface finish Post-processing (e.g., sintering) may be required |

| Concrete | Infrastructure and construction | Mass-customization No need for formwork Less labour required especially useful in harsh environment and for space construction | Layer-by-layer appearance Anisotropic mechanical properties Poor inter-layer adhesion Difficulties in upscaling to larger buildings Limited number of printing methods and tailored concrete mixture design |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahmood, A.; Akram, T.; Chen, H.; Chen, S. On the Evolution of Additive Manufacturing (3D/4D Printing) Technologies: Materials, Applications, and Challenges. Polymers 2022, 14, 4698. https://doi.org/10.3390/polym14214698

Mahmood A, Akram T, Chen H, Chen S. On the Evolution of Additive Manufacturing (3D/4D Printing) Technologies: Materials, Applications, and Challenges. Polymers. 2022; 14(21):4698. https://doi.org/10.3390/polym14214698

Chicago/Turabian StyleMahmood, Ayyaz, Tehmina Akram, Huafu Chen, and Shenggui Chen. 2022. "On the Evolution of Additive Manufacturing (3D/4D Printing) Technologies: Materials, Applications, and Challenges" Polymers 14, no. 21: 4698. https://doi.org/10.3390/polym14214698

APA StyleMahmood, A., Akram, T., Chen, H., & Chen, S. (2022). On the Evolution of Additive Manufacturing (3D/4D Printing) Technologies: Materials, Applications, and Challenges. Polymers, 14(21), 4698. https://doi.org/10.3390/polym14214698