Using PVA and Attapulgite for the Stabilization of Clayey Soil

Abstract

:1. Introduction

2. Materials and Methods

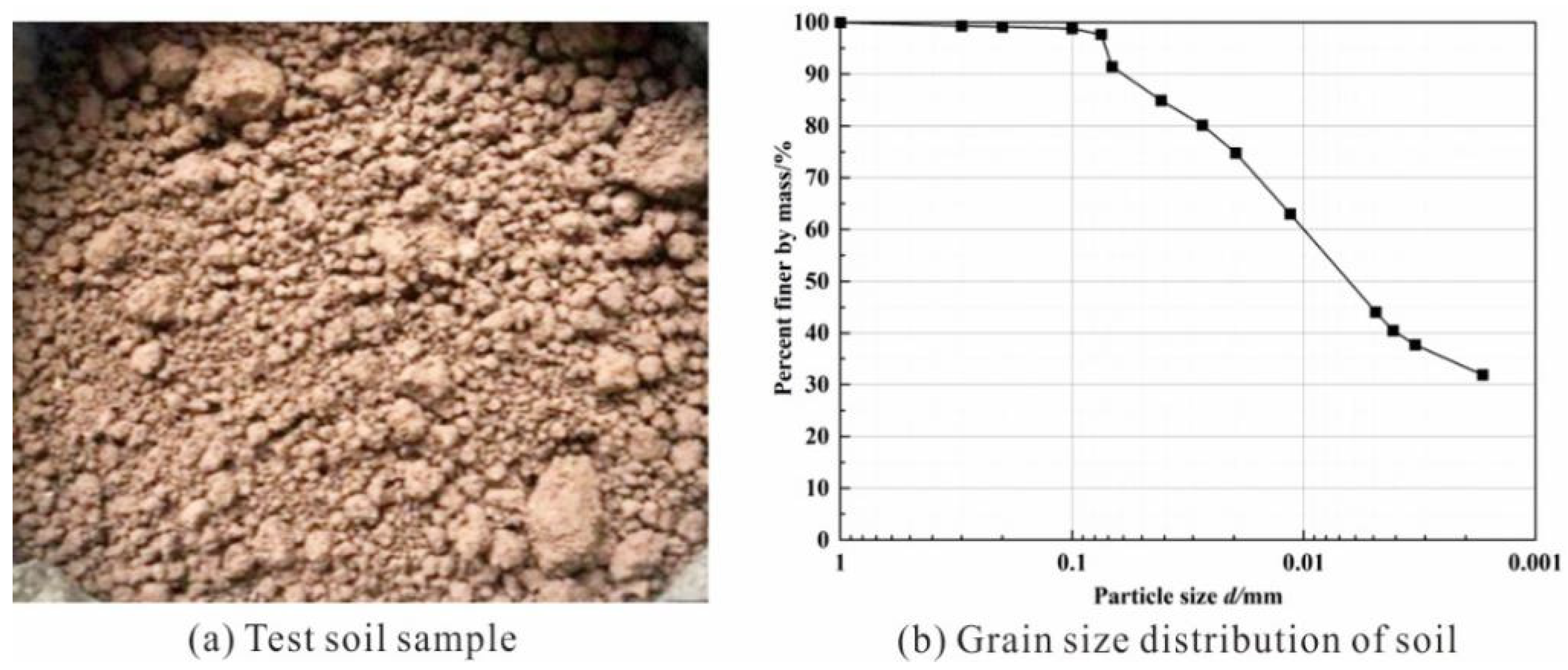

2.1. Test Soil

2.2. Polyvinyl Acetate

2.3. Attapulgite

2.4. Laboratory Tests

2.4.1. Triaxial Test

2.4.2. Water Retention and Vegetation Growth Test

3. Results and Discussion

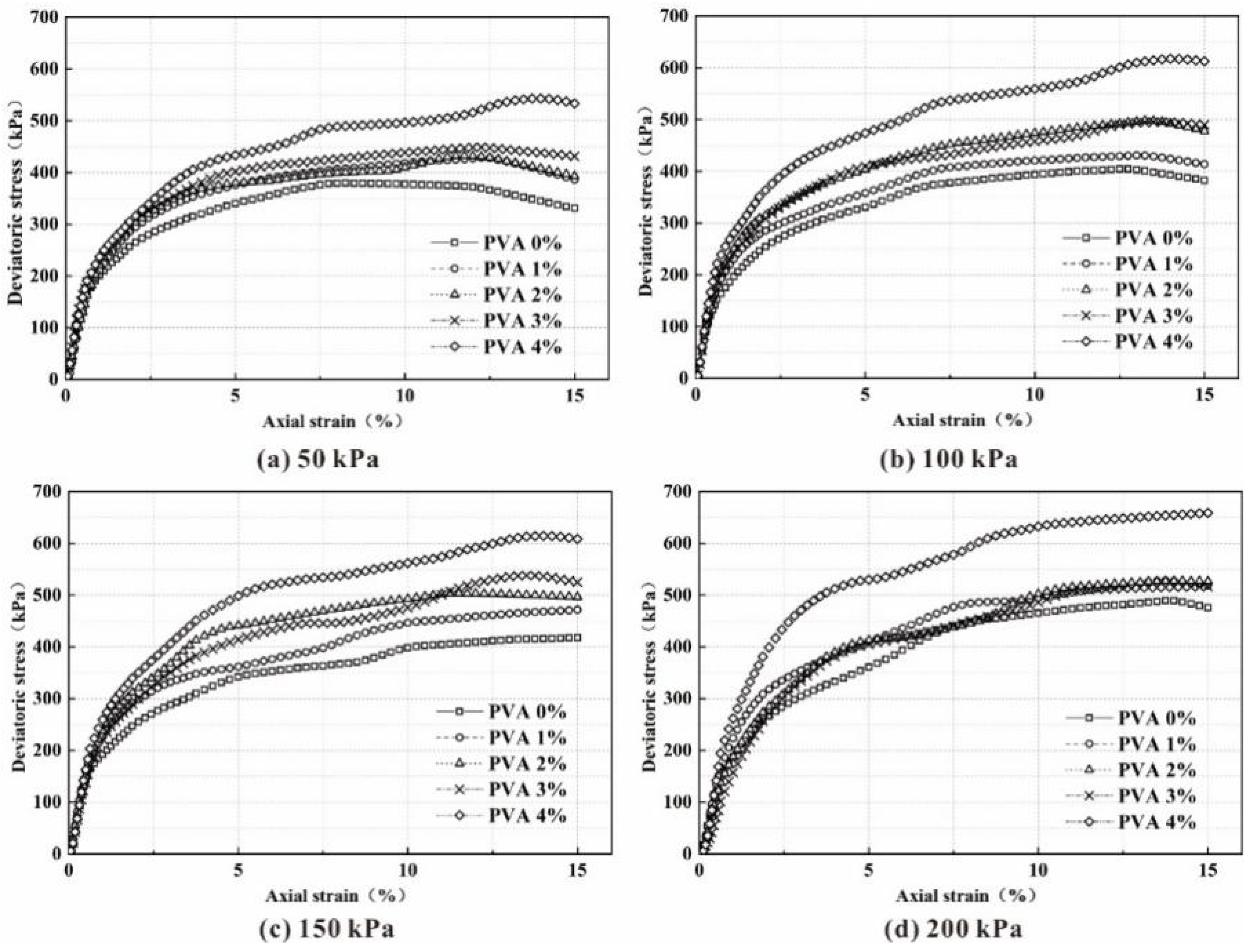

3.1. Results of Triaxial Shear Test of Composite Specimens of Single PVA Material

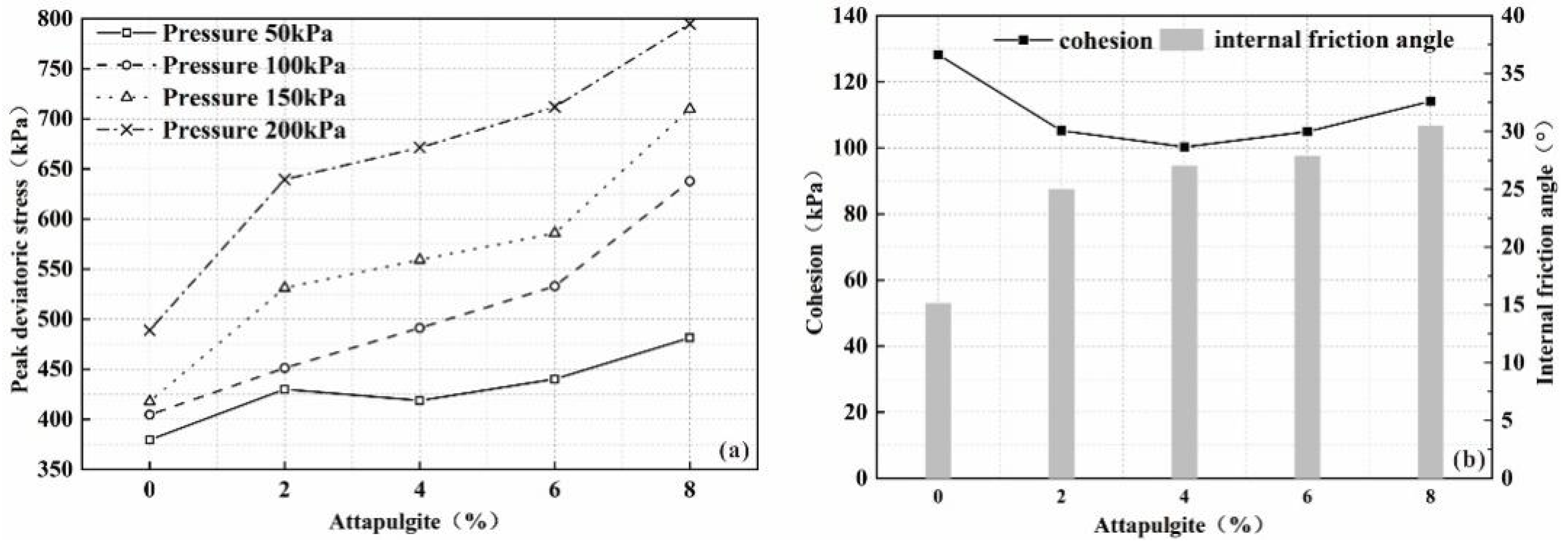

3.2. Analysis of Triaxial Shear Test Results of Attapulgite Composite Substrate

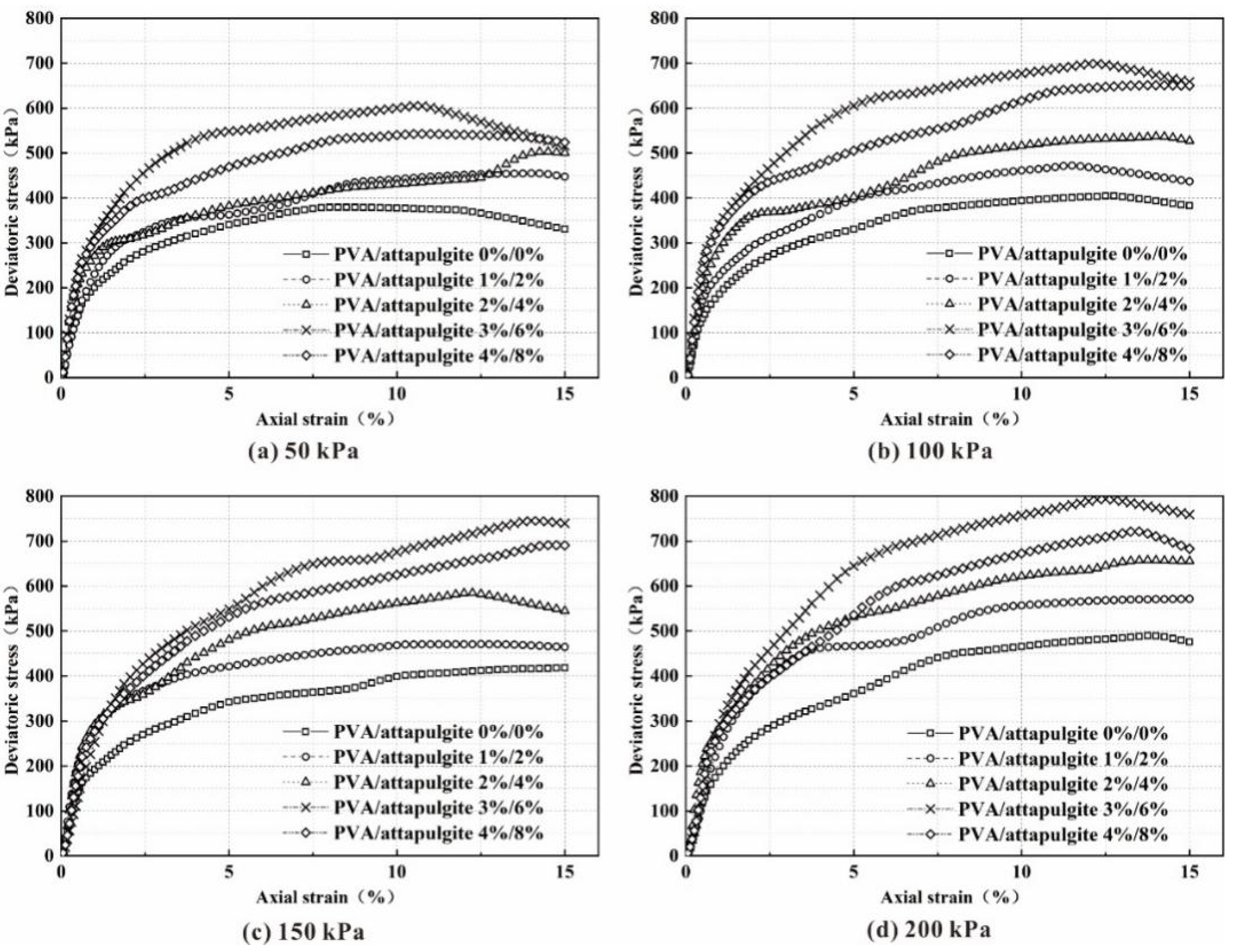

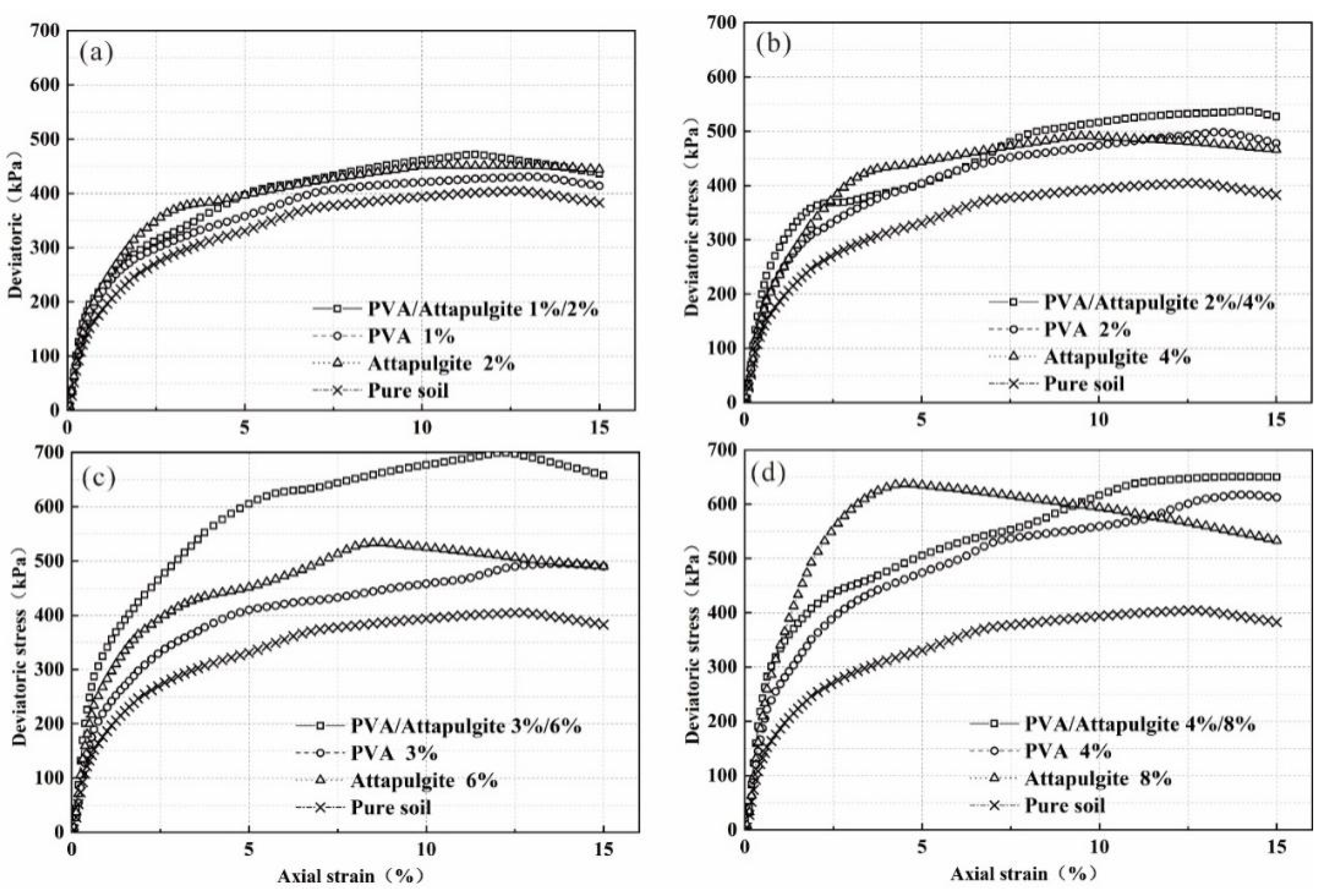

3.3. Analysis of Triaxial Compression Test Results of Polymer and Attapulgite Composite Substrates

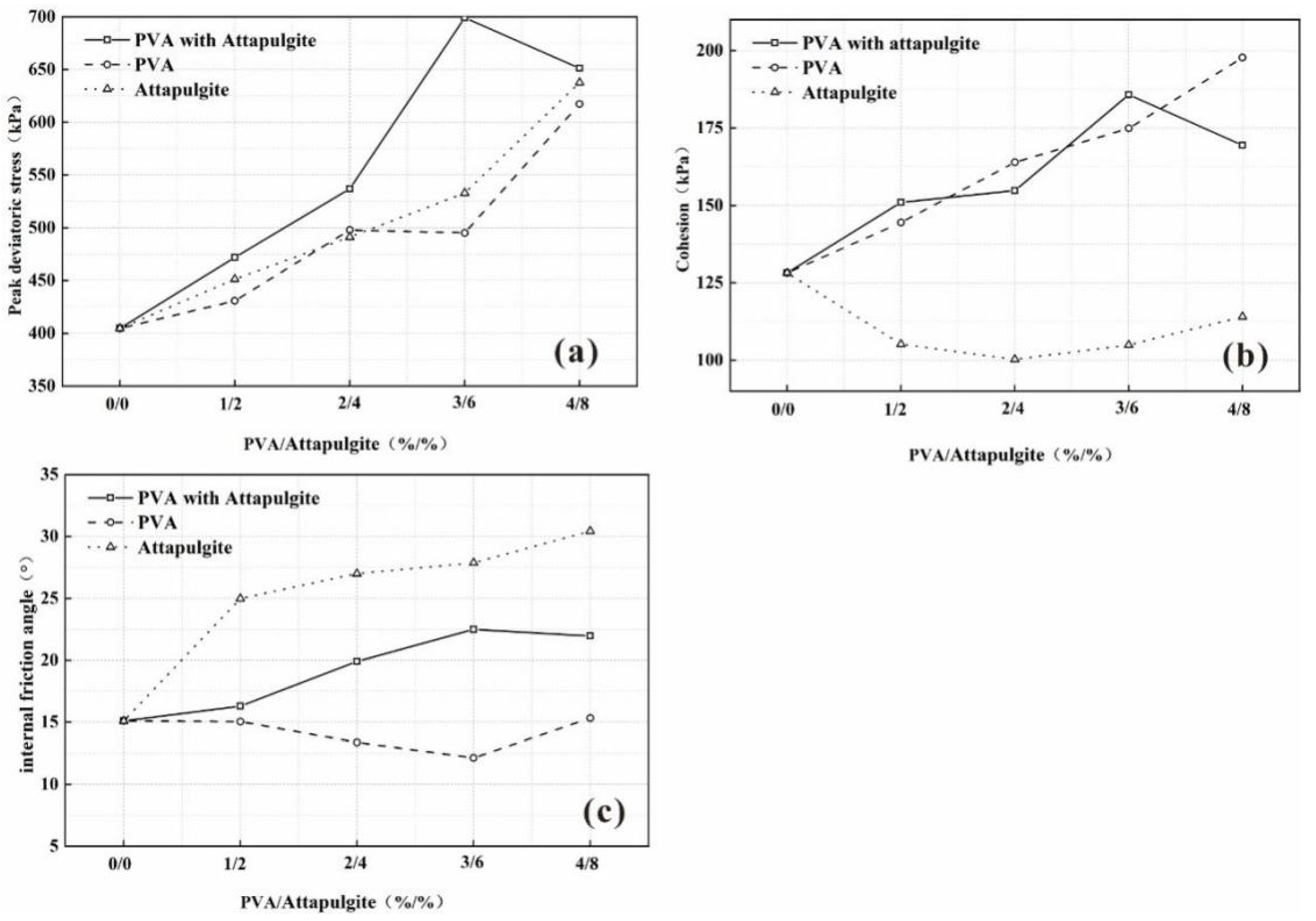

3.4. Comparison of Triaxial Compression Test Results between Composite and Single-Material Composite Substrate

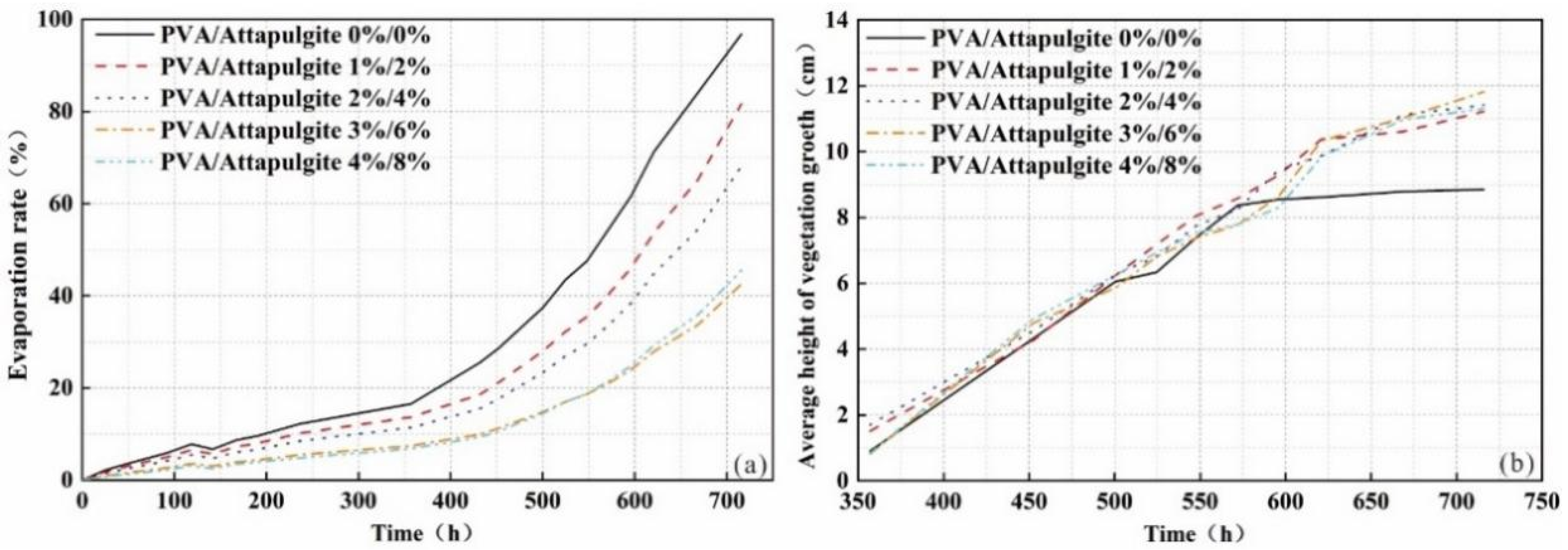

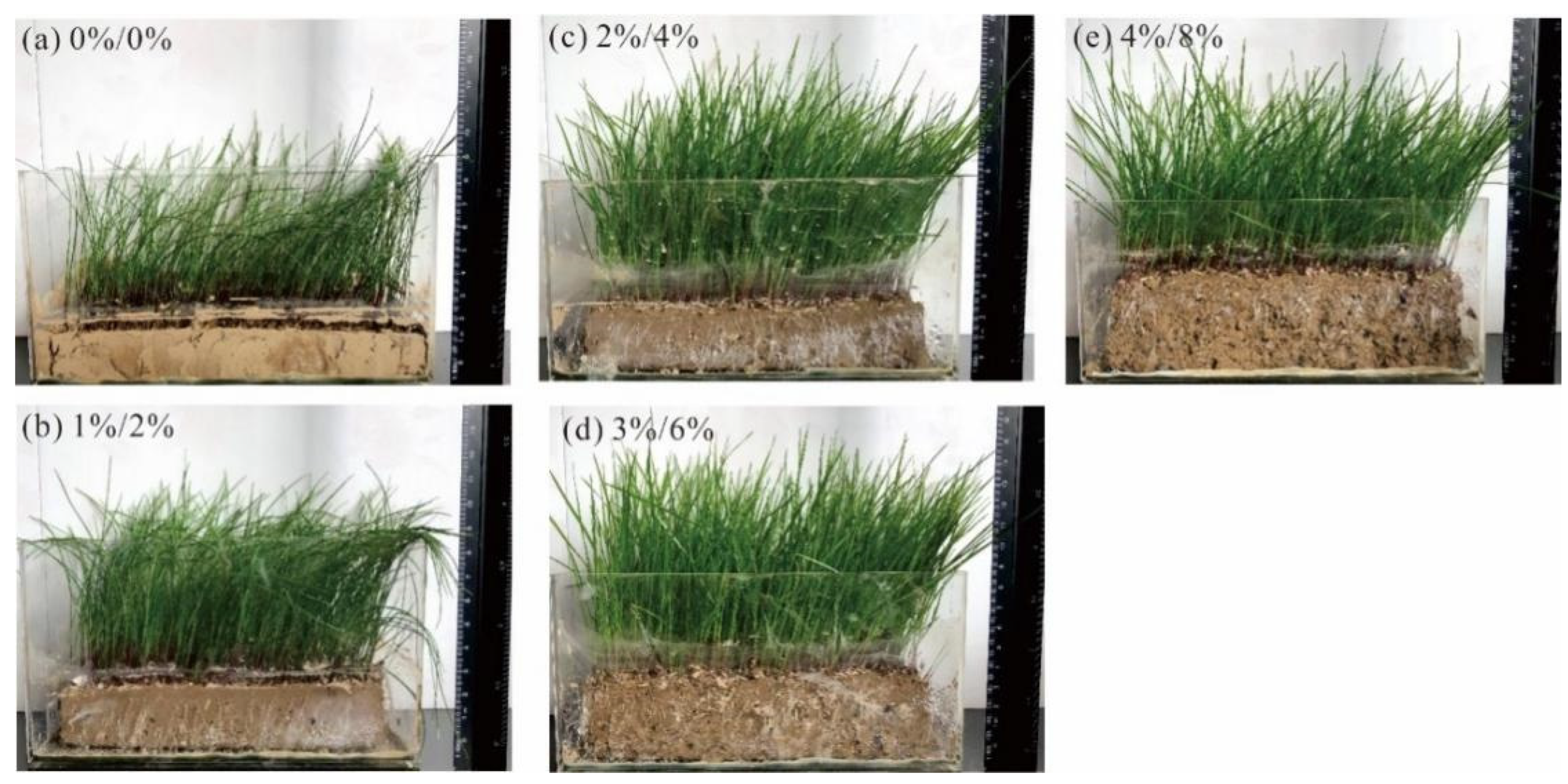

3.5. The Effect of Water Retention and Plant Growth on Soil

3.6. The Effect of PVA and Attapulgite on the Mechanical Properties of Soil

4. Conclusions

- (1)

- The addition of polyvinyl acetate can greatly improve the strain capacity of the sample and resist elastic deformation. With increasing PVA content, the peak partial stress and cohesion of the sample are significant, and the maximum cohesion reaches 197.74 kPa, whereas the internal friction angle of the sample remains basically unchanged, which indicates that the improvement of soil strength by polyvinyl acetate is mainly achieved by improving the cohesion of the sample. With the increasing content of attapulgite, the peak partial stress and internal friction angle of the sample increase significantly, the maximum internal friction angle reaches 30.43°, and the cohesion decreases, which indicates that attapulgite mainly improves the strength of the soil by increasing the internal friction angle of the soil.

- (2)

- Under the condition of curing age of 14 days, with increasing composite material content, the peak deviatoric stress, cohesion and internal friction angle of the sample first increased and then decreased, and the composite material content corresponding to the peak point was 3%/6%. Compared with the single-material composite samples with the corresponding content, the composite materials can improve the soil strength by increasing the cohesion and internal friction angle of the samples at the same time.

- (3)

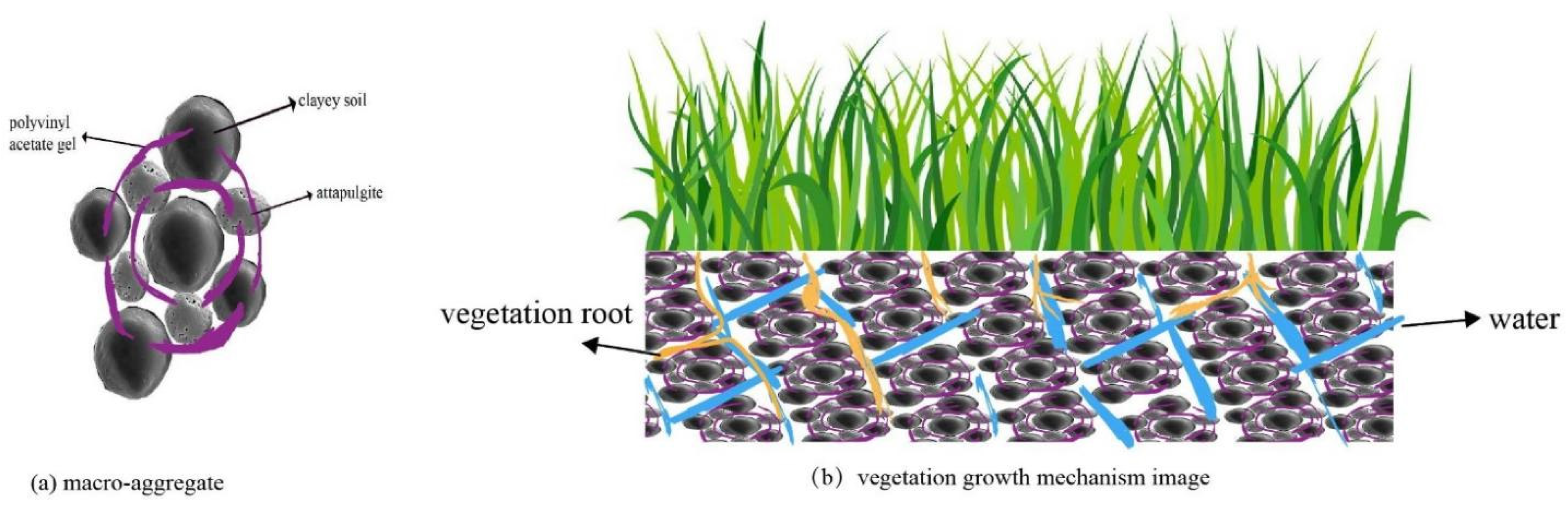

- With increasing composite material content, the water-holding capacity of the samples increased gradually, increasing by 25, 50, 92 and 133%, compared with the plain soil samples, and the average evaporation rate was higher than that of the plain soil samples, which was reduced by 19, 39, 85 and 129%, respectively. Compared with the plain soil samples, the vegetation leaves of the composite samples are fuller and taller, indicating that the incorporation of the composite material improves soil fertility, so that it can still ensure better plant growth under long-term drought conditions.

- (4)

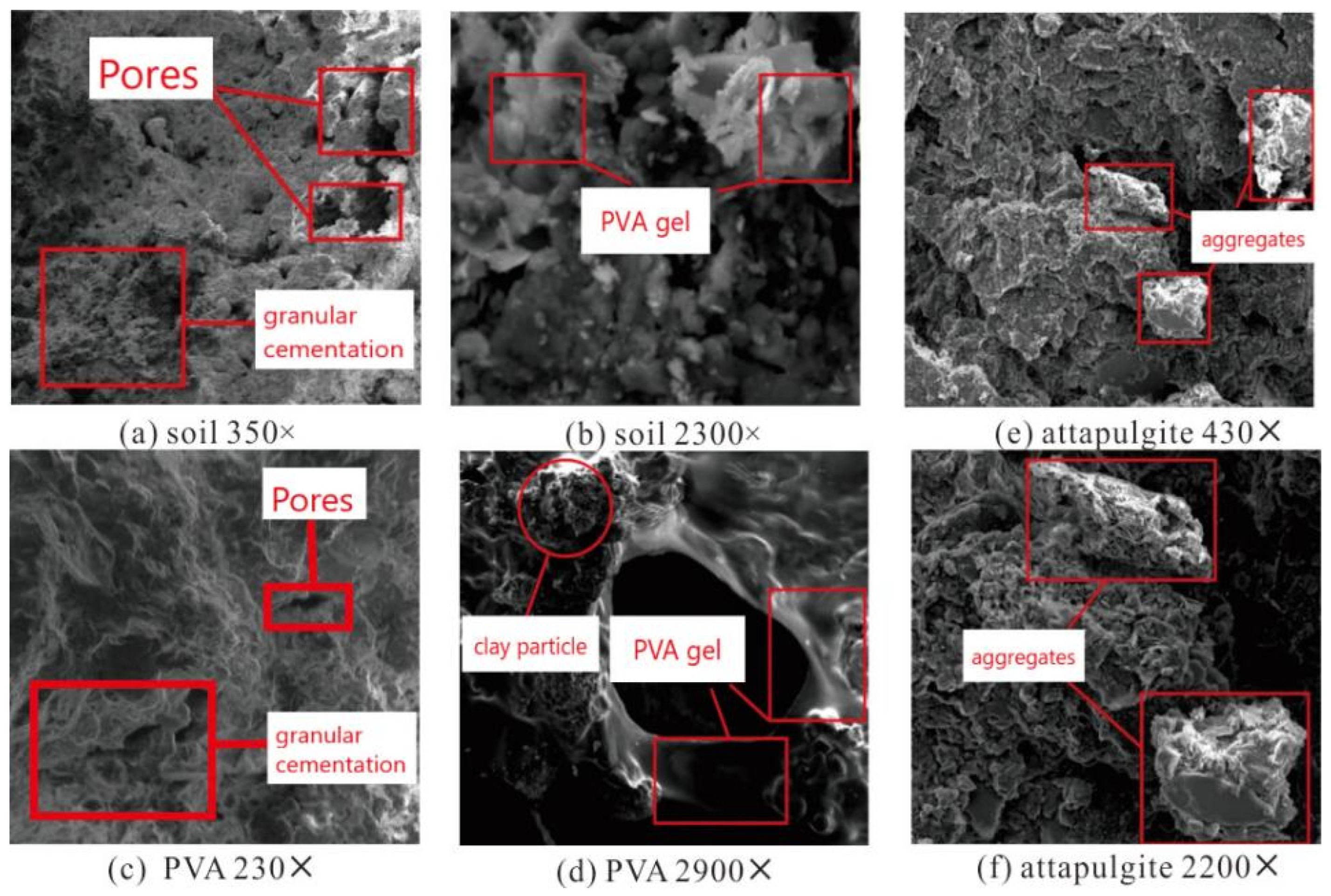

- The effect of PVA gel on the soil structure can be summarized as covering, wrapping and filling, and formed agglomerates increase the integrity of the clay structure and soil structure. The adsorption of attapulgite is mainly divided into three categories: physical adsorption, chemical adsorption and ion-exchange adsorption. The grid structure formed by the interweaving of attapulgite soil particles acts as the skeleton of the aggregate, which absorbs and adheres to the surrounding soil particles and water, increasing the integrity of the aggregate. Therefore, the cohesion of the polyvinyl acetate composite sample is significantly improved, and the internal friction angle of attapulgite composite samples is significantly improved.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Andres, P.; Zapater, V.; Pamplona, M. Stabilization of motorway slopes with herbaceous cover, Catalonia, Spain. Restor. Ecol. 2010, 4, 51–60. [Google Scholar] [CrossRef]

- Huang, Z.Y.; Chen, J.; Ai, X.Y.; Li, R.R.; Ai, Y.W.; Li, W. Enzyme activity and microbial biomass availability in artificial soils on rock-cut slopes restored with outside soil spray seeding (OSSS): Influence of topography and season. J. Environ. Manag. 2018, 211, 287–295. [Google Scholar] [CrossRef]

- Liu, R.; Han, Y.; Xiao, J.; Wang, T. Failure mechanism of TRSS mode in landslides induced by earthquake. Sci. Rep. 2020, 10, 21326. [Google Scholar] [CrossRef] [PubMed]

- Haque, U.; da Silva, P.F.; Devoli, G.; Pilz, J.; Zhao, B.; Khaloua, A.; Wilopo, W.; Andersen, P.; Lu, P.; Lee, J.; et al. The human cost of global warming: Deadly landslides and their triggers (1995–2014). Sci. Total Environ. 2019, 682, 673–684. [Google Scholar] [CrossRef] [PubMed]

- Gui, J.; Yuan, J.; Han, R.; Xin, G.; Yang, Z. Characteristics of the optimum combination of synthetic soils by plant and soil properties used for rock slope restoration. Ecol. Eng. 2007, 30, 303–311. [Google Scholar] [CrossRef]

- Gao, G.; Li, Z.; Han, R. Statistical evaluation of sprayed synthetic soils amended with four additive factors used in high-and cut rock slopes. Environ. Eng. Sci. 2016, 34, 281–290. [Google Scholar] [CrossRef]

- Li, R.R.; Zhang, W.J.; Yang, S.Q.; Zhu, M.K.; Kan, S.S.; Chen, J.; Ai, X.Y.; Ai, Y.W. Topographic aspect affects the vegetation restoration and artificial soil quality of rock-cut slopes restored by external-soil spray seeding. Sci. Rep. 2018, 8, 12109. [Google Scholar] [CrossRef]

- Moravej, S.; Habibagahi, G.; Nikooee, E.; Niazi, A. Stabilization of dispersive soils by means of biological calcite precipitation. Geoderma 2017, 315, 130–137. [Google Scholar] [CrossRef]

- Hejazi, S.M.; Sheikhzadeh, M.; Abtahi, S.M.; Zadhoush, A.J.C. A simple review of soil reinforcement by using natural and synthetic fibers. Constr. Build. Mater. 2012, 30, 100–116. [Google Scholar] [CrossRef]

- Hasan, G.; Aida, M.; Malihe, P. Laboratory analyses of Kaolinite stabilized by vinyl polymers with different monomer types. Eng. Geol. 2021, 280, 105938. [Google Scholar] [CrossRef]

- Ghasemzadeh, H.; Mehrpajouh, A.; Pishvaei, M.; Mirzababaei, M. Effects of Curing Method and Glass Transition Temperature on the Unconfined Compressive Strength of Acrylic Liquid Polymer–Stabilized Kaolinite. J. Mater. Civ. Eng. 2020, 32, 04020212. [Google Scholar] [CrossRef]

- Marto, A.; Latifi, N.; Eisazadeh, A. Effect of Non-Traditional Additives on Engineering and Microstructural Characteristics of Laterite Soil. Arab. J. Sci. Eng. 2014, 39, 6949–6958. [Google Scholar] [CrossRef]

- Lichtblau, G.; Wiegel, N.; Herle, I.; Tintelnot, G. Soil improvement with rapidely curing polymers. Bautechnik 2020, 97, 605–614. [Google Scholar] [CrossRef]

- Shafiqu, Q.; Hasan, S.H. Improvement an Expansive Soil using Polymethacrylate Polymer. IOP Conf. Ser. Mater. Sci. Eng. 2018, 454, 012138. [Google Scholar] [CrossRef]

- Louzada, N.D.L.; Malko, J.A.C.; Casagrande, M.D.T. Behavior of Clayey Soil Reinforced with Polyethylene Terephthalate. Int. J. Polym. Sci. 2019, 31, 04019218. [Google Scholar] [CrossRef]

- Liu, J.; Wang, Y.; Lu, Y.; Feng, Q.; Zhang, F.; Qi, C.; Wei, J.; Kanungo, D.P. Effect of polyvinyl acetate stabilization on the swelling-shrinkage properties of expansive soil. Int. J. Polym. Sci. 2017, 2017, 8128020. [Google Scholar] [CrossRef] [Green Version]

- Yang, T.; Xing, X.; Fu, W.; Ma, X. Performances of Evaporation and Desiccation Cracking Characteristics for Attapulgite Soils. J. Plant Nutr. Soil Sci. 2022, 22, 2503–2519. [Google Scholar] [CrossRef]

- Wang, K.; Wang, Y.; Liu, F. Application of the attapulgite in environmental protection. New Chem. Mater. 2016, 44, 224–226. [Google Scholar]

- Cui, M.; Mu, P.; Shen, Y.; Zhu, G.; Luo, L.; Li, J. Three-dimensional attapulgite with sandwich-like architecture used for multifunctional water remediation. Sep. Purif. Technol. 2020, 235, 116210. [Google Scholar] [CrossRef]

- Yang, J.; Gao, X.; Li, J.; Zuo, R.; Wang, J.; Song, L.; Wang, G. The stabilization process in the remediation of vanadium-contaminated soil by attapulgite, zeolite and hydroxyapatite. Ecol. Eng. 2020, 156, 105975. [Google Scholar] [CrossRef]

- Elkady, T.; Shaker, A.A.; Dhowain, A.W. Shear strengths and volume changes of sand–attapulgite clay mixtures. Bull. Eng. Geol. Environ. 2015, 74, 595–609. [Google Scholar] [CrossRef]

- Chai, M.; Zhang, H.; Zhang, J.; Zhang, Z. Effect of cement additives on unconfined compressive strength of warm and ice-rich frozen soil. Constr. Build. Mater. 2017, 149, 861–868. [Google Scholar] [CrossRef]

- Bu, F.; Liu, J.; Bai, Y.X.; Kanungo, D.P.; Song, Z.Z.; Kong, F.X.; Pan, C. Effects of the preparation conditions and reinforcement mechanism of polyvinyl acetate soil stabilizer. Polymers 2019, 11, 506. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Deng, Y.J.; Dixon, J.B.; White, G.N.; Loeppert, R.H.; Juo, A.S.R. Bonding between polyacrylamide and smectite. Colloids Surf. A Physicochem. Eng. Asp. 2006, 281, 82–91. [Google Scholar] [CrossRef]

- Dubey, A.A.; Ravi, K.; Shahin, M.A.; Dhami, N.K.; Abhijit, M. Bio-composites treatment for mitigation of current-induced riverbank soil erosion. Sci. Total Environ. 2021, 800, 149513. [Google Scholar] [CrossRef]

- Yang, Q.W.; Pei, X.Y.; Huang, R.Q. Impact of polymer mixtures on the stabilization and erosion control of silty sand slope. J. Mt. Sci. 2019, 16, 470–485. [Google Scholar] [CrossRef]

- Zhang, Z.; Matlan, S.J.; Wang, H.; Pishro, A.A.; Zhang, L.; Gao, X.; Liang, Z.; Liu, X.Y.; Zhao, P. Geotechnical Evaluation of Loess Modifications as the Sustainable Compacted Soil Liner Material in Solid Waste Landfill. Materials 2022, 15, 4982. [Google Scholar] [CrossRef]

- Chen, N.; Dempere, L.A.; Tong, Z. Synthesis of pH-responsive lignin-based nanocapsules for controlled release of hydrophobic molecules. ACS Sustain. Chem. Eng. 2016, 4, 5204–5211. [Google Scholar] [CrossRef]

- Zhou, C.Y.; Huang, W.; Qiu, S.Y.; Liu, Z. A quantitative study on the amount of water-retaining agent based on adhesive-modified red bed weathered soil. Bull. Eng. Geol. Environ. 2021, 80, 3139–3150. [Google Scholar] [CrossRef]

- Huang, W.; Liu, Z.; Zhou, C.Y.; Yang, X. Enhancement of soil ecological self-repair using a polymer composite material. Catena 2020, 188, 104443. [Google Scholar] [CrossRef]

- Qin, X.C.; Ni, A.C.; Zhang, N.; Chen, Z.H. Erosion Control and Growth Promotion of W-OH Material on Red Clay Highway Slopes: A Case Study in South China. Sustainability 2021, 13, 1144. [Google Scholar] [CrossRef]

- Chang, I.; Im, J.; Prasidhi, A.K.; Cho, G.C. Effects of Xanthan gum biopolymer on soil strengthening. Constr. Build. Mater. 2015, 74, 65–72. [Google Scholar] [CrossRef]

- Al Swaidani, A.; Hammoud, I.; Meziab, A. Effect of adding natural pozzolana on geotechnical properties of lime-stabilized clayey soil. J. Rock Mech. Geotech. Eng. 2016, 8, 714–725. [Google Scholar] [CrossRef]

| Specimen Number | Clay Quality (g) | Polyvinyl Acetate (PVA) Content (g) | Attapulgite Replacement (g) | Water (g) |

|---|---|---|---|---|

| S1 | 670.0 | 0 | 0 | 402 |

| S2 | 656.6 | 6.7 | 13.4 | 503 |

| S3 | 643.2 | 13.4 | 26.8 | 603 |

| S4 | 629.8 | 20.1 | 40.2 | 771 |

| S5 | 616.4 | 26.8 | 53.6 | 938 |

| Curing Time (d) | PVA (%) | Peak Bias Stress of the Triaxial Test Under Each Confining Pressure (kPa) | Internal Friction Angle (°) | Cohesion (kPa) | Correlation Coefficient (R2) | ||||

|---|---|---|---|---|---|---|---|---|---|

| 50 kPa | 100 kPa | 150 kPa | 200 kPa | ||||||

| 14 | 0.00 | 379.52 | 404.58 | 417.75 | 489.12 | 15.10 | 128.21 | 0.8821 | |

| 1.00 | 428.33 | 430.74 | 471.29 | 527.92 | 15.05 | 144.48 | 0.8835 | ||

| 2.00 | 432.53 | 497.86 | 503.39 | 527.27 | 13.38 | 163.92 | 0.8510 | ||

| 3.00 | 448.85 | 495.14 | 537.97 | 546.04 | 12.13 | 174.89 | 0.9310 | ||

| 4.00 | 542.83 | 617.34 | 614.31 | 658.60 | 15.33 | 197.74 | 0.8547 | ||

| Curing Time (d) | Attapulgite Replacement (%) | Triaxial Peak Deviatoric Stress (kPa) | Internal Friction Angle (°) | Cohesion (kPa) | R2 | |||

|---|---|---|---|---|---|---|---|---|

| 50 kPa | 100 kPa | 150 kPa | 200 kPa | |||||

| 14 | 0.00 | 379.52 | 404.58 | 417.75 | 489.12 | 15.10 | 128.21 | 0.8821 |

| 2.00 | 429.97 | 451.27 | 531.18 | 639.52 | 24.99 | 105.20 | 0.9283 | |

| 4.00 | 418.78 | 491.27 | 559.32 | 671.39 | 27.00 | 100.29 | 0.9853 | |

| 6.00 | 440.27 | 532.92 | 585.82 | 711.90 | 27.87 | 104.92 | 0.9762 | |

| 8.00 | 481.54 | 637.66 | 710.00 | 794.92 | 30.43 | 114.09 | 0.9673 | |

| Curing Time (d) | Composite Content (%/%) | Triaxial Peak Deviatoric Stress (kPa) | Internal Friction Angle (°) | Cohesion (kPa) | R2 | |||

|---|---|---|---|---|---|---|---|---|

| 50 kPa | 100 kPa | 150 kPa | 200 kPa | |||||

| 14 | 0/0 | 379.52 | 404.58 | 417.75 | 489.12 | 15.10 | 128.21 | 0.8821 |

| 1/2 | 454.82 | 471.88 | 504.09 | 570.98 | 16.29 | 151.01 | 0.9189 | |

| 2/4 | 503.00 | 536.90 | 584.51 | 657.53 | 19.91 | 154.80 | 0.9711 | |

| 3/6 | 605.12 | 699.18 | 745.18 | 793.61 | 22.49 | 185.75 | 0.9665 | |

| 4/8 | 542.52 | 651.15 | 691.09 | 721.14 | 21.97 | 169.43 | 0.9062 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, C.; Hu, G.; Mei, H.; Zhu, X.; Xue, J.; Liu, J.; Zhang, F.; Che, W.; Chen, Z.; Song, Z. Using PVA and Attapulgite for the Stabilization of Clayey Soil. Polymers 2022, 14, 4752. https://doi.org/10.3390/polym14214752

He C, Hu G, Mei H, Zhu X, Xue J, Liu J, Zhang F, Che W, Chen Z, Song Z. Using PVA and Attapulgite for the Stabilization of Clayey Soil. Polymers. 2022; 14(21):4752. https://doi.org/10.3390/polym14214752

Chicago/Turabian StyleHe, Chengzong, Guochang Hu, Hong Mei, Xiaoyong Zhu, Jian Xue, Jin Liu, Faming Zhang, Wenyue Che, Zhihao Chen, and Zezhuo Song. 2022. "Using PVA and Attapulgite for the Stabilization of Clayey Soil" Polymers 14, no. 21: 4752. https://doi.org/10.3390/polym14214752