Synthesis and Iodine Adsorption Properties of Organometallic Copolymers with Propeller-Shaped Fe(II) Clathrochelates Bridged by Different Diaryl Thioether and Their Oxidized Sulfone Derivatives

Abstract

:1. Introduction

2. Materials and Methods

2.1. Synthesis

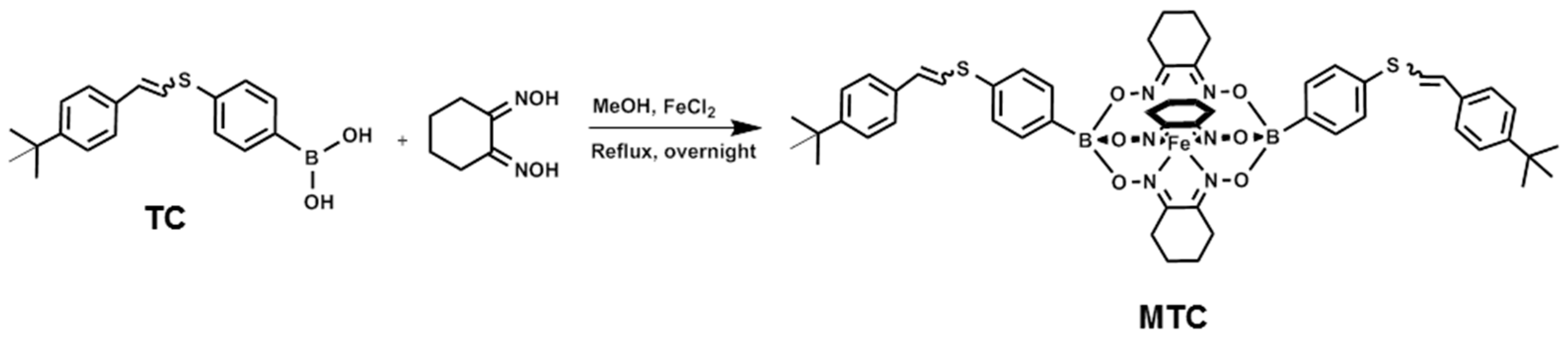

2.1.1. Synthesis of MTC

2.1.2. Synthesis of ICP1 (Procedure A)

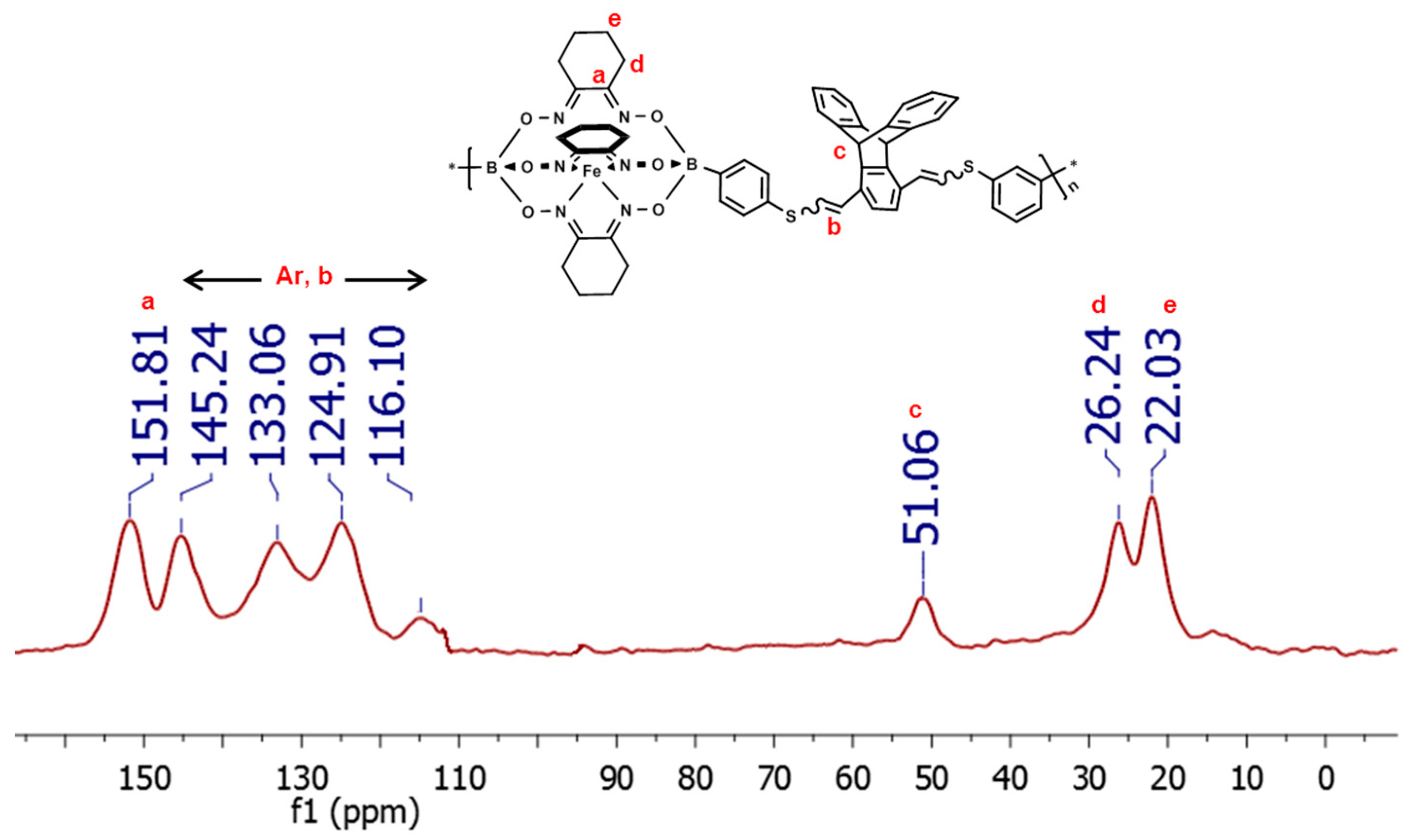

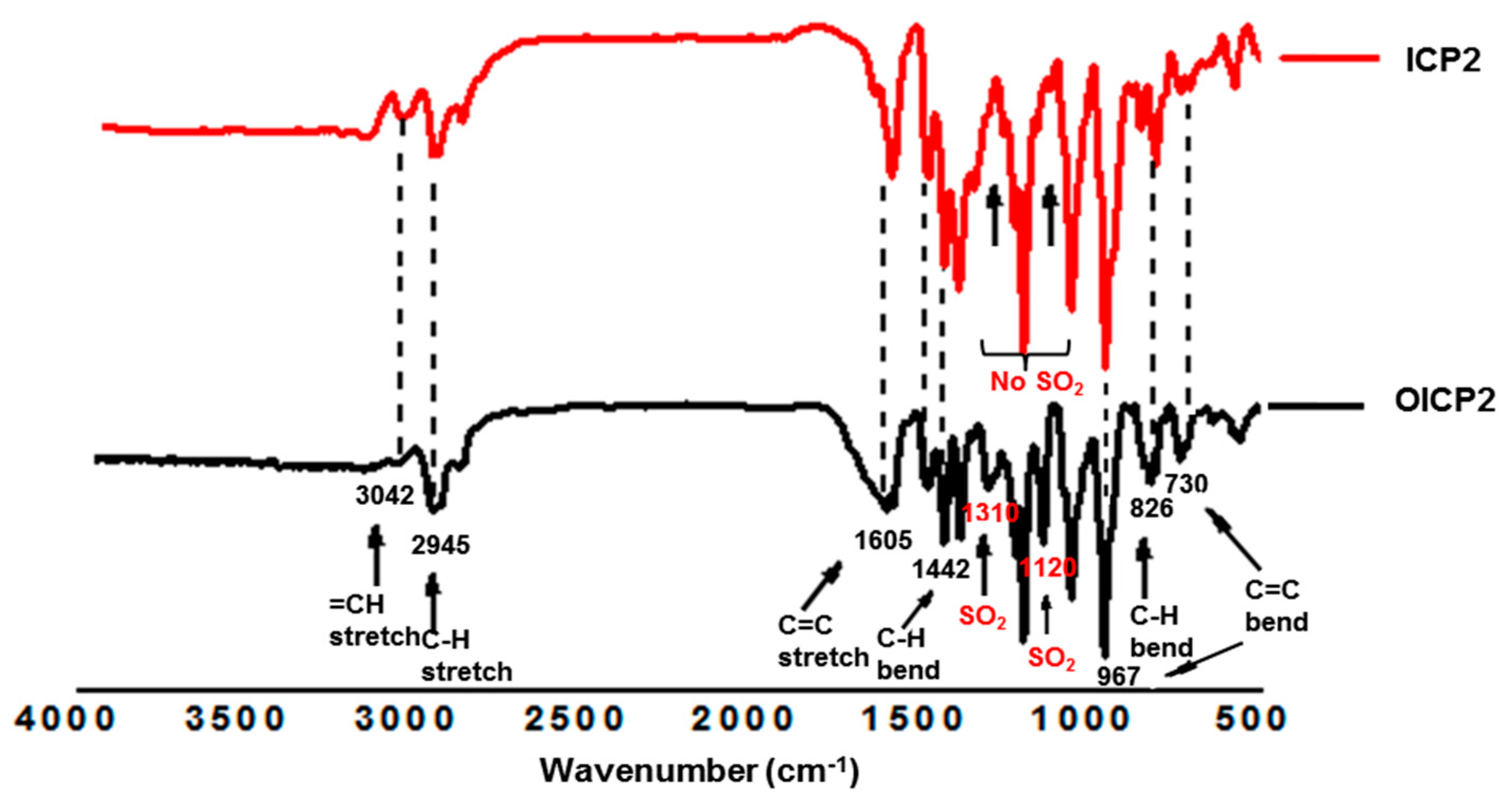

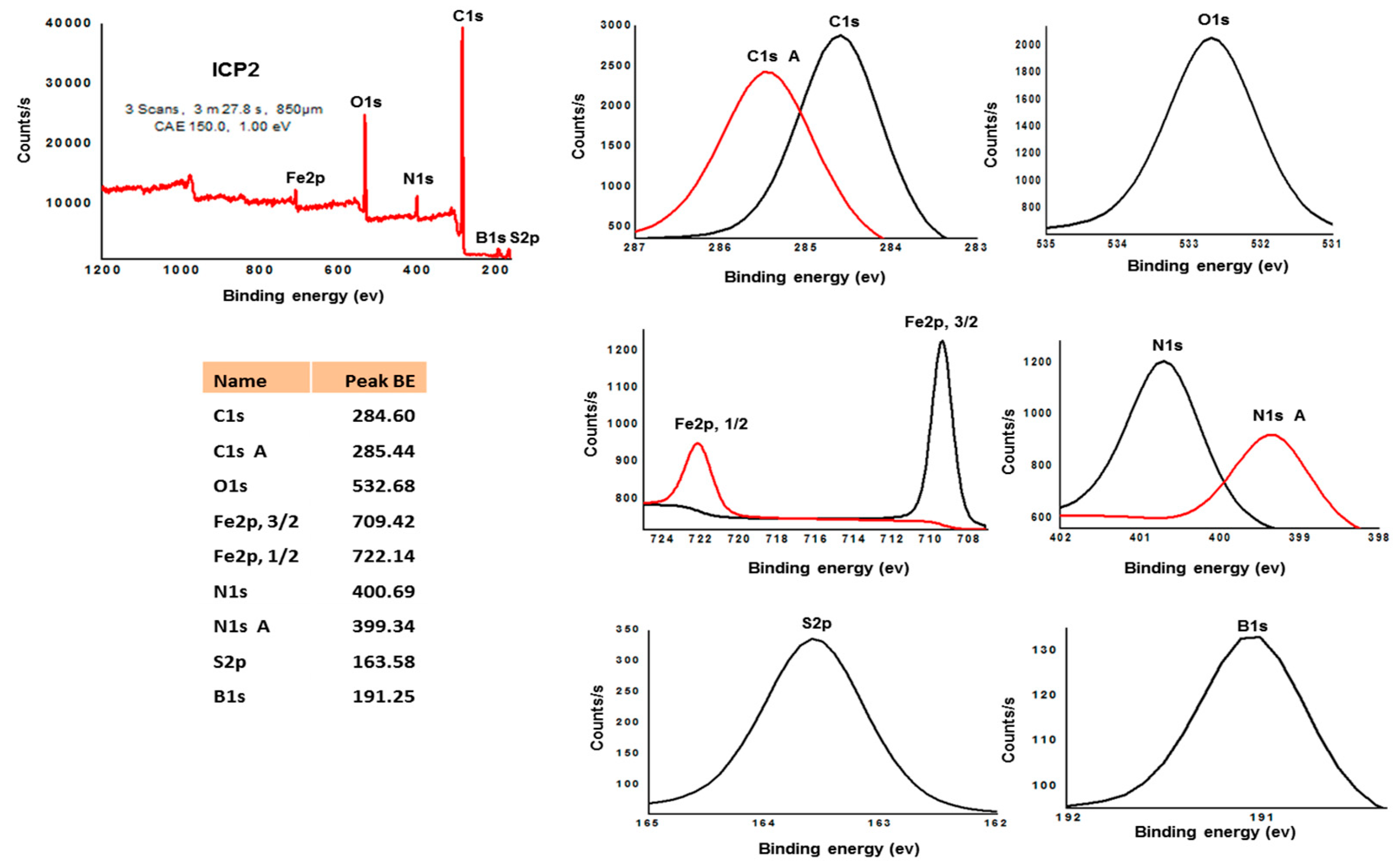

2.1.3. Synthesis of ICP2

2.1.4. Synthesis of ICP3

2.1.5. Synthesis of OMTC (Procedure B)

2.1.6. Synthesis of OICP1

2.1.7. Synthesis of OICP2

2.1.8. Synthesis of OICP3

3. Results

Iodine Adsorption

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chu, S.; Majumdar, A. Opportunities and challenges for a sustainable energy future. Nature 2012, 488, 294–303. [Google Scholar] [CrossRef] [PubMed]

- Kiegiel, K.; Herdzik, I.; Fuks, L.; Zakrzewska, G. Management of Radioactive Waste from HTGR Reactors including Spent TRISO Fuel—State of the Art. Energies 2022, 15, 1099. [Google Scholar] [CrossRef]

- Jia, T.; Shi, K.; Wang, Y.; Yang, J.; Hou, X. Sequential Separation of Iodine Species in Nitric Acid Media for Speciation Analysis of 129I in a PUREX Process of Spent Nuclear Fuel Reprocessing. Anal. Chem. 2022, 94, 10959–10966. [Google Scholar] [CrossRef] [PubMed]

- Kenyon, J.A.; Buesseler, K.O.; Casacuberta, N.; Castrillejo, M.; Otosaka, S.; Masqué, P.; Drysdale, J.A.; Pike, S.M.; Sanial, V. Distribution and Evolution of Fukushima Dai-ichi derived 137Cs, 90Sr, and 129I in Surface Seawater off the Coast of Japan. Environ. Sci. Technol. 2020, 54, 15066–15075. [Google Scholar] [CrossRef]

- Huang, Y.; Li, W.; Xu, Y.; Ding, M.; Ding, J.; Zhang, Y.; Wang, Y.; Chen, S.; Jin, Y.; Xia, C. Rapid iodine adsorption from vapor phase and solution by a nitrogen-rich covalent piperazine–triazine-based polymer. New J. Chem. 2021, 45, 5363–5370. [Google Scholar] [CrossRef]

- Obrador, E.; Salvador-Palmer, R.; Villaescusa, J.I.; Gallego, E.; Pellicer, B.; Estrela, J.M.; Montoro, A. Nuclear Radiological Emergencies: Biological Effects, Countermeasures, and Biodosimetry. Antioxidants 2022, 11, 1098. [Google Scholar] [CrossRef]

- Baig, N.; Shetty, S.; Habib, S.S.; Husain, A.A.; Al-Mousawi, S.; Alameddine, B. Synthesis of Iron Clathrochelate-Based Poly with Tetraphenylbenzene Bridging Units Their Selective Oxidation into Their Corresponding Poly Copolymers: Promising Materials for Iodine Capture. Polymers 2022, 14, 3727. [Google Scholar] [CrossRef]

- Hassan, A.; Alam, A.; Ansari, M.; Das, N. Hydroxy functionalized triptycene based covalent organic polymers for ultra-high radioactive iodine uptake. Chem. Eng. J. 2022, 427, 130950. [Google Scholar] [CrossRef]

- Llopart-Babot, I.; Vasile, M.; Dobney, A.; Boden, S.; Bruggeman, M.; Leermakers, M.; Qiao, J.; Warwick, P. On the determination of 36Cl and 129I in solid materials from nuclear decommissioning activities. J. Radioanal. Nucl. Chem. 2022, 331, 3313–3326. [Google Scholar] [CrossRef]

- Gambhir, D.; Venkateswarulu, M.; Verma, T.; Koner, R.R. High Adsorption Capacity of an sp2/sp3-N-Rich Polymeric Network: From Molecular Iodine Capture to Catalysis. ACS Appl. Polym. Mater. 2020, 2, 152–158. [Google Scholar] [CrossRef]

- Shao, L.; Liu, N.; Wang, L.; Sang, Y.; Wan, H.a.; Zhan, P.; Zhang, L.; Huang, J.; Chen, J. Facile preparation of oxygen-rich porous polymer microspheres from lignin-derived phenols for selective CO2 adsorption and iodine vapor capture. Chemosphere 2022, 288, 132499. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Yi, D.; Tu, P.; Yang, S.; Xie, Q.; Gao, Z.; Wu, S.; Yu, G. Boosting radioactive iodine capture of microporous polymers through strengthened host–guest interaction. Microporous Mesoporous Mater. 2021, 321, 111148. [Google Scholar] [CrossRef]

- Luo, D.; He, Y.; Tian, J.; Sessler, J.L.; Chi, X. Reversible Iodine Capture by Nonporous Adaptive Crystals of a Bipyridine Cage. J. Am. Chem. Soc. 2022, 144, 113–117. [Google Scholar] [CrossRef] [PubMed]

- Shetty, S.; Baig, N.; Moustafa, M.S.; Al-Mousawi, S.; Alameddine, B. Sizable iodine uptake of porous copolymer networks bearing Tröger’s base units. Polymer 2021, 229, 123996. [Google Scholar] [CrossRef]

- Xiong, S.; Tang, X.; Pan, C.; Li, L.; Tang, J.; Yu, G. Carbazole-Bearing Porous Organic Polymers with a Mulberry-Like Morphology for Efficient Iodine Capture. ACS Appl. Mater. Interfaces 2019, 11, 27335–27342. [Google Scholar] [CrossRef]

- Yan, Z.; Song, B.; Fang, G.; Wu, T.; Chen, N.; Zhao, M.; Zou, X.; Liao, G. Bringing Material Concepts into Conventional Biorefineries: Considerations of Sources, Preparations, and Applications of Lignin Nanomaterials. ACS Sustain. Chem. Eng. 2021, 9, 10403–10423. [Google Scholar] [CrossRef]

- Yan, Z.; Wu, T.; Fang, G.; Ran, M.; Shen, K.; Liao, G. Self-assembly preparation of lignin–graphene oxide composite nanospheres for highly efficient Cr(vi) removal. RSC Adv. 2021, 11, 4713–4722. [Google Scholar] [CrossRef]

- Nguyen, N.; Jeong, J.; Shin, D.; Kim, B.-S.; Lee, J.-c.; Pandey, B. Simultaneous Recovery of Gold and Iodine from the Waste Rinse Water of the Semiconductor Industry Using Activated Carbon. Mater. Trans. 2012, 53, 760–765. [Google Scholar] [CrossRef] [Green Version]

- Hao, B.-B.; Qiao, N.; Rong, Y.; Zhang, C.-X.; Wang, Q.-L. Bifunctional Metal–Organic Framework Functionalized by Dimethylamine Cations: Proton Conduction and Iodine Vapor Adsorption. Inorg. Chem. 2022, 61, 9533–9540. [Google Scholar] [CrossRef]

- Miensah, E.D.; Gu, A.; Kokuloku, L.T., Jr.; Chen, K.; Wang, P.; Gong, C.; Mao, P.; Chen, K.; Jiao, Y.; Yang, Y. Strategies for radioiodine capture by metal organic frameworks and their derived materials. Microporous Mesoporous Mater. 2022, 341, 112041. [Google Scholar] [CrossRef]

- Sen, A.; Sharma, S.; Dutta, S.; Shirolkar, M.M.; Dam, G.K.; Let, S.; Ghosh, S.K. Functionalized Ionic Porous Organic Polymers Exhibiting High Iodine Uptake from Both the Vapor and Aqueous Medium. ACS Appl. Mater. Interfaces 2021, 13, 34188–34196. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.-H.; Li, Y.-X.; Zhou, L.; Liu, N.; Wu, Z.-Q. Precise fabrication of porous polymer frameworks using rigid polyisocyanides as building blocks: From structural regulation to efficient iodine capture. Chem. Sci. 2022, 13, 1111–1118. [Google Scholar] [CrossRef] [PubMed]

- Mokhtari, N.; Dinari, M. Developing novel amine-linked covalent organic frameworks towards reversible iodine capture. Sep. Purif. Technol. 2022, 301, 121948. [Google Scholar] [CrossRef]

- Zhang, Z.; Dong, X.; Yin, J.; Li, Z.-G.; Li, X.; Zhang, D.; Pan, T.; Lei, Q.; Liu, X.; Xie, Y.; et al. Chemically Stable Guanidinium Covalent Organic Framework for the Efficient Capture of Low-Concentration Iodine at High Temperatures. J. Am. Chem. Soc. 2022, 144, 6821–6829. [Google Scholar] [CrossRef]

- Pourebrahimi, S.; Pirooz, M.; De Visscher, A.; Peslherbe, G.H. Highly efficient and reversible iodine capture utilizing amorphous conjugated covalent triazine-based porous polymers: Experimental and computational studies. J. Environ. Chem. Eng. 2022, 10, 107805. [Google Scholar] [CrossRef]

- Sun, J.; Zhang, R.; Yao, G.; Zhang, Q.; Gao, F. Easy Fabrication of Amorphous Covalent Organic Nanospheres Using Schiff-Base Chemistry for Iodine Capture. Chem.–Asian J. 2022, 17, e202101214. [Google Scholar] [CrossRef]

- Kovalska, V.; Vakarov, S.; Losytskyy, M.; Kuperman, M.; Chornenka, N.; Toporivska, Y.; Gumienna-Kontecka, E.; Voloshin, Y.; Varzatskii, O.; Mokhir, A. Dicarboxyl-terminated iron(ii) clathrochelates as ICD-reporters for globular proteins. RSC Adv. 2019, 9, 24218–24230. [Google Scholar] [CrossRef] [Green Version]

- Selin, R.O.; Klemt, I.; Chernii, V.Y.; Losytskyy, M.Y.; Chernii, S.; Mular, A.; Gumienna-Kontecka, E.; Kovalska, V.B.; Voloshin, Y.Z.; Vologzhanina, A.V.; et al. Synthesis and spectral characterization of the first fluorescein-tagged iron(ii) clathrochelates, their supramolecular interactions with globular proteins, and cellular uptake. RSC Adv. 2021, 11, 8163–8177. [Google Scholar] [CrossRef]

- El Ghachtouli, S.; Fournier, M.; Cherdo, S.; Guillot, R.; Charlot, M.-F.; Anxolabéhère-Mallart, E.; Robert, M.; Aukauloo, A. Monometallic Cobalt–Trisglyoximato Complexes as Precatalysts for Catalytic H2 Evolution in Water. J. Phys. Chem. C 2013, 117, 17073–17077. [Google Scholar] [CrossRef]

- Zelinskii, G.E.; Pavlov, A.A.; Belov, A.S.; Belaya, I.G.; Vologzhanina, A.V.; Nelyubina, Y.V.; Efimov, N.N.; Zubavichus, Y.V.; Bubnov, Y.N.; Novikov, V.V.; et al. A New Series of Cobalt and Iron Clathrochelates with Perfluorinated Ribbed Substituents. ACS Omega 2017, 2, 6852–6862. [Google Scholar] [CrossRef]

- Jansze, S.M.; Severin, K. Clathrochelate Metalloligands in Supramolecular Chemistry and Materials Science. Acc. Chem. Res. 2018, 51, 2139–2147. [Google Scholar] [CrossRef] [PubMed]

- Alameddine, B.; Shetty, S.; Baig, N.; Al-Mousawi, S.; Al-Sagheer, F. Synthesis and characterization of metalorganic polymers of intrinsic microporosity based on iron(II) clathrochelate. Polymer 2017, 122, 200–207. [Google Scholar] [CrossRef]

- Planes, O.M.; Schouwink, P.A.; Bila, J.L.; Fadaei-Tirani, F.; Scopelliti, R.; Severin, K. Incorporation of Clathrochelate-Based Metalloligands in Metal–Organic Frameworks by Solvent-Assisted Ligand Exchange. Cryst. Growth Des. 2020, 20, 1394–1399. [Google Scholar] [CrossRef]

- Chen, Z.; Idrees, K.B.; Shetty, S.; Xie, H.; Wasson, M.C.; Gong, W.; Zhang, X.; Alameddine, B.; Farha, O.K. Regulation of Catenation in Metal–Organic Frameworks with Tunable Clathrochelate-Based Building Blocks. Cryst. Growth Des. 2021, 21, 6665–6670. [Google Scholar] [CrossRef]

- Gong, W.; Xie, Y.; Pham, T.D.; Shetty, S.; Son, F.A.; Idrees, K.B.; Chen, Z.; Xie, H.; Liu, Y.; Snurr, R.Q.; et al. Creating Optimal Pockets in a Clathrochelate-Based Metal–Organic Framework for Gas Adsorption and Separation: Experimental and Computational Studies. J. Am. Chem. Soc. 2022, 144, 3737–3745. [Google Scholar] [CrossRef]

- Shetty, S.; Baig, N.; Al-Mousawi, S.; Alameddine, B. Removal of anionic and cationic dyes using porous copolymer networks made from a Sonogashira cross-coupling reaction of diethynyl iron (II) clathrochelate with various arylamines. J. Appl. Polym. Sci. 2022, 139, e52966. [Google Scholar] [CrossRef]

- Shetty, S.; Baig, N.; Hassan, A.; Al-Mousawi, S.; Das, N.; Alameddine, B. Fluorinated Iron(ii) clathrochelate units in metalorganic based copolymers: Improved porosity, iodine uptake, and dye adsorption properties. RSC Adv. 2021, 11, 14986–14995. [Google Scholar] [CrossRef]

- Shetty, S.; Baig, N.; Moustafa, M.S.; Al-Mousawi, S.; Alameddine, B. Synthesis of Metalorganic Copolymers Containing Various Contorted Units and Iron(II) Clathrochelates with Lateral Butyl Chains: Conspicuous Adsorbents of Lithium Ions and Methylene Blue. Polymers 2022, 14, 3394. [Google Scholar] [CrossRef]

- Baig, N.; Shetty, S.; Pasha, S.S.; Pramanik, S.K.; Alameddine, B. Copolymer networks with contorted units and highly polar groups for ultra-fast selective cationic dye adsorption and iodine uptake. Polymer 2022, 239, 124467. [Google Scholar] [CrossRef]

- Alameddine, B.; Baig, N.; Shetty, S.; Al-Mousawi, S.; Al-Sagheer, F. Triptycene-containing Poly(vinylene sulfone) derivatives from a metal-free thiol-yne click polymerization followed by a mild oxidation reaction. Polymer 2018, 154, 233–240. [Google Scholar] [CrossRef]

- Baig, N.; Shetty, S.; Moustafa, M.S.; Al-Mousawi, S.; Alameddine, B. Selective removal of toxic organic dyes using Tröger base-containing sulfone copolymers made from a metal-free thiol-yne click reaction followed by oxidation. RSC Adv. 2021, 11, 21170–21178. [Google Scholar] [CrossRef] [PubMed]

- Slaný, M.; Jankovič, L.; Madejová, J. Near-IR study of the impact of alkyl-ammonium and -phosphonium cations on the hydration of montmorillonite. J. Mol. Struct. 2022, 1256, 132568. [Google Scholar] [CrossRef]

- Fuente, E.; Menéndez, J.A.; Díez, M.A.; Suárez, D.; Montes-Morán, M.A. Infrared Spectroscopy of Carbon Materials: A Quantum Chemical Study of Model Compounds. J. Phys. Chem. B 2003, 107, 6350–6359. [Google Scholar] [CrossRef]

- Liu, M.; Yao, C.; Liu, C.; Xu, Y. Thiophene-based porous organic networks for volatile iodine capture and effectively detection of mercury ion. Sci. Rep. 2018, 8, 14071. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yao, C.; Li, G.; Wang, J.; Xu, Y.; Chang, L. Template-free synthesis of porous carbon from triazine based polymers and their use in iodine adsorption and CO2 capture. Sci. Rep. 2018, 8, 1867. [Google Scholar] [CrossRef] [Green Version]

- Shetty, S.; Baig, N.; Al-Mousawi, S.; Al-Sagheer, F.; Alameddine, B. Synthesis of secondary arylamine copolymers with Iron(II) clathrochelate units and their functionalization into tertiary Polyarylamines via Buchwald-Hartwig cross-coupling reaction. Polymer 2019, 178, 121606. [Google Scholar] [CrossRef]

- Bai, H.; Xue, C.; Lyu, J.L.; Li, J.; Chen, G.X.; Yu, J.H.; Lin, C.T.; Lv, D.J.; Xiong, L.M. Thermal conductivity and mechanical properties of flake graphite/copper composite with a boron carbide-boron nano-layer on graphite surface. Compos. Part A Appl. Sci. Manuf. 2018, 106, 42–51. [Google Scholar] [CrossRef]

- Baig, N.; Shetty, S.; Al-Mousawi, S.; Al-Sagheer, F.; Alameddine, B. Influence of size and nature of the aryl diborate spacer on the intrinsic microporosity of Iron(II) clathrochelate polymers. Polymer 2018, 151, 164–170. [Google Scholar] [CrossRef]

- Louette, P.; Bodino, F.; Pireaux, J.-J. Poly(ethylene terephthalate) (PET) XPS Reference Core Level and Energy Loss Spectra. Surf. Sci. Spectra 2005, 12, 1–5. [Google Scholar] [CrossRef]

- Castner, D.G.; Hinds, K.; Grainger, D.W. X-ray Photoelectron Spectroscopy Sulfur 2p Study of Organic Thiol and Disulfide Binding Interactions with Gold Surfaces. Langmuir 1996, 12, 5083–5086. [Google Scholar] [CrossRef]

- Gamal Mohamed, M.; Tsai, M.-Y.; Wang, C.-F.; Huang, C.-F.; Danko, M.; Dai, L.; Chen, T.; Kuo, S.-W.; Iodine, A. Multifunctional Polyhedral Oligomeric Silsesquioxane (POSS) Based Hybrid Porous Materials for CO2 Uptake and Iodine Adsorption. Polymers 2021, 13, 221. [Google Scholar] [CrossRef] [PubMed]

- Hastings, A.M.; Ray, D.; Hanna, S.L.; Jeong, W.; Chen, Z.; Oliver, A.G.; Gagliardi, L.; Farha, O.K.; Hixon, A.E. Leveraging Nitrogen Linkages in the Formation of a Porous Thorium–Organic Nanotube Suitable for Iodine Capture. Inorg. Chem. 2022, 61, 9480–9492. [Google Scholar] [CrossRef] [PubMed]

- Yadollahi, M.; Hamadi, H.; Nobakht, V. Capture of iodine in solution and vapor phases by newly synthesized and characterized encapsulated Cu2O nanoparticles into the TMU-17-NH2 MOF. J. Hazard. Mater. 2020, 399, 122872. [Google Scholar] [CrossRef] [PubMed]

- Yin, Y.; Liang, D.; Liu, D.; Liu, Q. Preparation and characterization of three-dimensional hierarchical porous carbon from low-rank coal by hydrothermal carbonization for efficient iodine removal. RSC Adv. 2022, 12, 3062–3072. [Google Scholar] [CrossRef]

- Yu, C.-X.; Li, X.-J.; Zong, J.-S.; You, D.-J.; Liang, A.-P.; Zhou, Y.-L.; Li, X.-Q.; Liu, L.-L. Fabrication of Protonated Two-Dimensional Metal–Organic Framework Nanosheets for Highly Efficient Iodine Capture from Water. Inorg. Chem. 2022, 61, 13883–13892. [Google Scholar] [CrossRef]

- Huve, J.; Ryzhikov, A.; Nouali, H.; Lalia, V.; Augé, G.; Daou, T.J. Porous sorbents for the capture of radioactive iodine compounds: A review. RSC Adv. 2018, 8, 29248–29273. [Google Scholar] [CrossRef] [Green Version]

- Zhou, B.; Chen, Z.; Feng, S.; Wang, D.; Liu, H. Engineering Functionality in Organic Porous Networks by Multicomponent Polymerization. Macromolecules 2021, 54, 7642–7652. [Google Scholar] [CrossRef]

- Guan, H.; Zou, D.; Yu, H.; Liu, M.; Liu, Z.; Sun, W.; Xu, F.; Li, Y. Adsorption Behavior of Iodine by Novel Covalent Organic Polymers Constructed through Heterostructural Mixed Linkers. Front. Mater. 2019, 6, 12. [Google Scholar] [CrossRef] [Green Version]

- Baig, N.; Shetty, S.; Al-Mousawi, S.; Al-Sagheer, F.; Alameddine, B. Synthesis of triptycene-derived covalent organic polymer networks and their subsequent in-situ functionalization with 1,2-dicarbonyl substituents. React. Funct. Polym. 2019, 139, 153–161. [Google Scholar] [CrossRef]

- Hassan, A.; Alam, A.; Chandra, S.; Prince; Das, N. Triptycene-based and imine linked porous uniform microspheres for efficient and reversible scavenging of iodine from various media: A systematic study. Environ. Sci. Adv. 2022, 1, 320–330. [Google Scholar] [CrossRef]

- Pourebrahimi, S.; Pirooz, M. Functionalized covalent triazine frameworks as promising platforms for environmental remediation: A review. Clean. Chem. Eng. 2022, 2, 100012. [Google Scholar] [CrossRef]

- Baig, N.; Shetty, S.; Al-Mousawi, S.; Alameddine, B. Synthesis of conjugated polymers via cyclopentannulation reaction: Promising materials for iodine adsorption. Polym. Chem. 2020, 11, 3066–3074. [Google Scholar] [CrossRef]

| Entry | Copolymer | Wt.% I2 Adsorption after 24 h | Oxidized Copolymer | Wt.% I2 Adsorption after 24 h |

|---|---|---|---|---|

| 1 | ICP1 | 170 | OICP1 | 180 |

| 2 | ICP2 | 360 | OICP2 | 310 |

| 3 | ICP3 | 210 | OICP3 | 200 |

| Copolymer | Pseudo-First-Order Model | Pseudo-Second-Order Model | |||||

|---|---|---|---|---|---|---|---|

| qe, exp (mg g−1) | qe, cal (mg g−1) | k1 (min−1) | R2 | qe, cal (mg g−1) | k2 (min−1) | R2 | |

| ICP2@I2 | 3600 | 3344 | −0.0185 | 0.9955 | 4454 | 0.00012 | 0.9880 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shetty, S.; Baig, N.; Alameddine, B. Synthesis and Iodine Adsorption Properties of Organometallic Copolymers with Propeller-Shaped Fe(II) Clathrochelates Bridged by Different Diaryl Thioether and Their Oxidized Sulfone Derivatives. Polymers 2022, 14, 4818. https://doi.org/10.3390/polym14224818

Shetty S, Baig N, Alameddine B. Synthesis and Iodine Adsorption Properties of Organometallic Copolymers with Propeller-Shaped Fe(II) Clathrochelates Bridged by Different Diaryl Thioether and Their Oxidized Sulfone Derivatives. Polymers. 2022; 14(22):4818. https://doi.org/10.3390/polym14224818

Chicago/Turabian StyleShetty, Suchetha, Noorullah Baig, and Bassam Alameddine. 2022. "Synthesis and Iodine Adsorption Properties of Organometallic Copolymers with Propeller-Shaped Fe(II) Clathrochelates Bridged by Different Diaryl Thioether and Their Oxidized Sulfone Derivatives" Polymers 14, no. 22: 4818. https://doi.org/10.3390/polym14224818