Impact of Micro Silica Filler Particle Size on Mechanical Properties of Polymeric Based Composite Material

Abstract

:1. Introduction

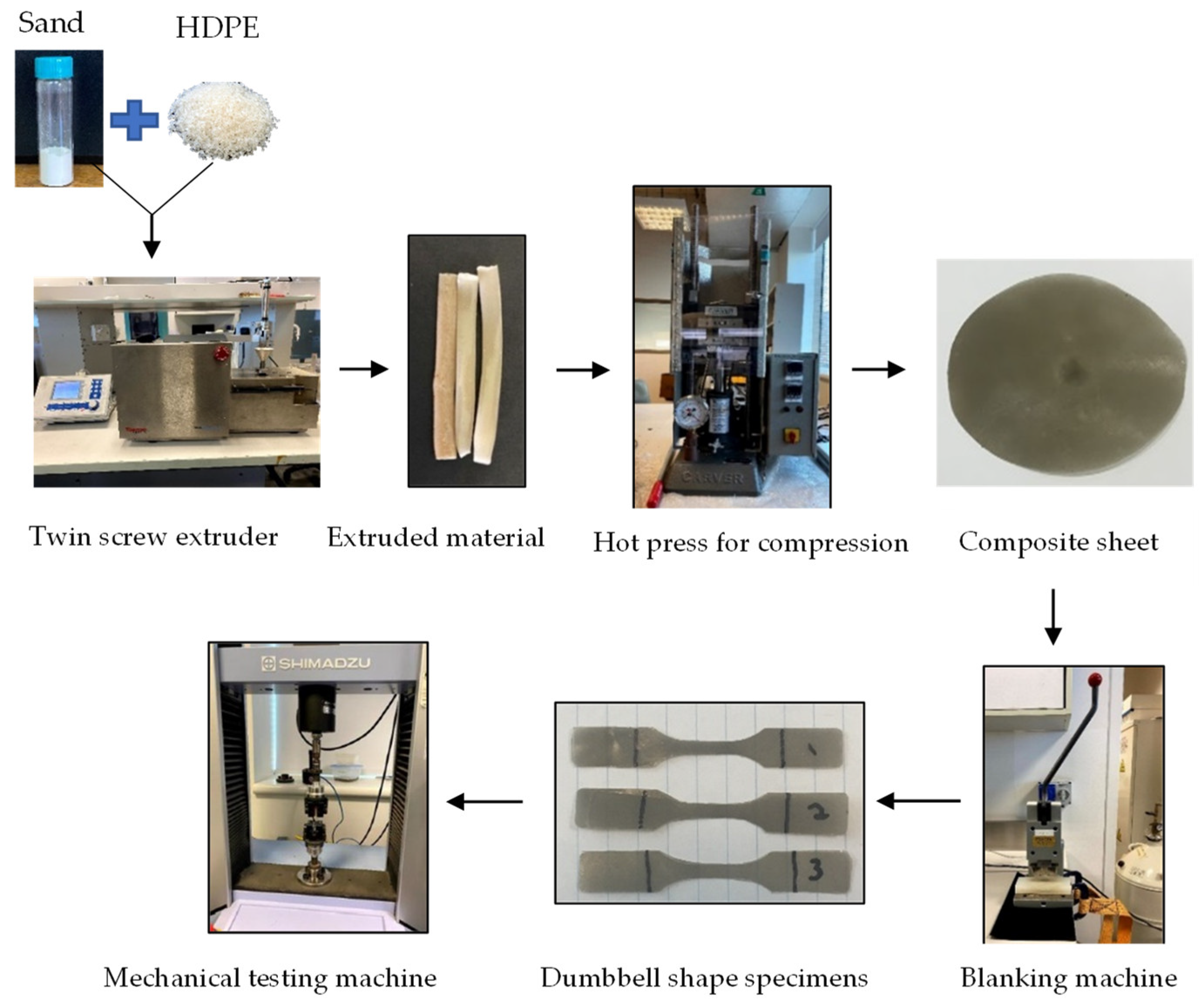

2. Materials and Methods

2.1. Characterization

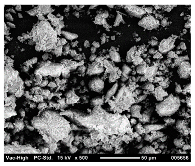

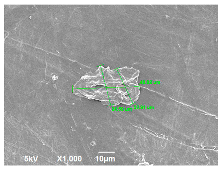

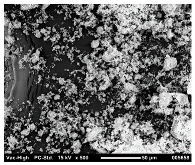

2.1.1. Scanning Electron Microscope (SEM)

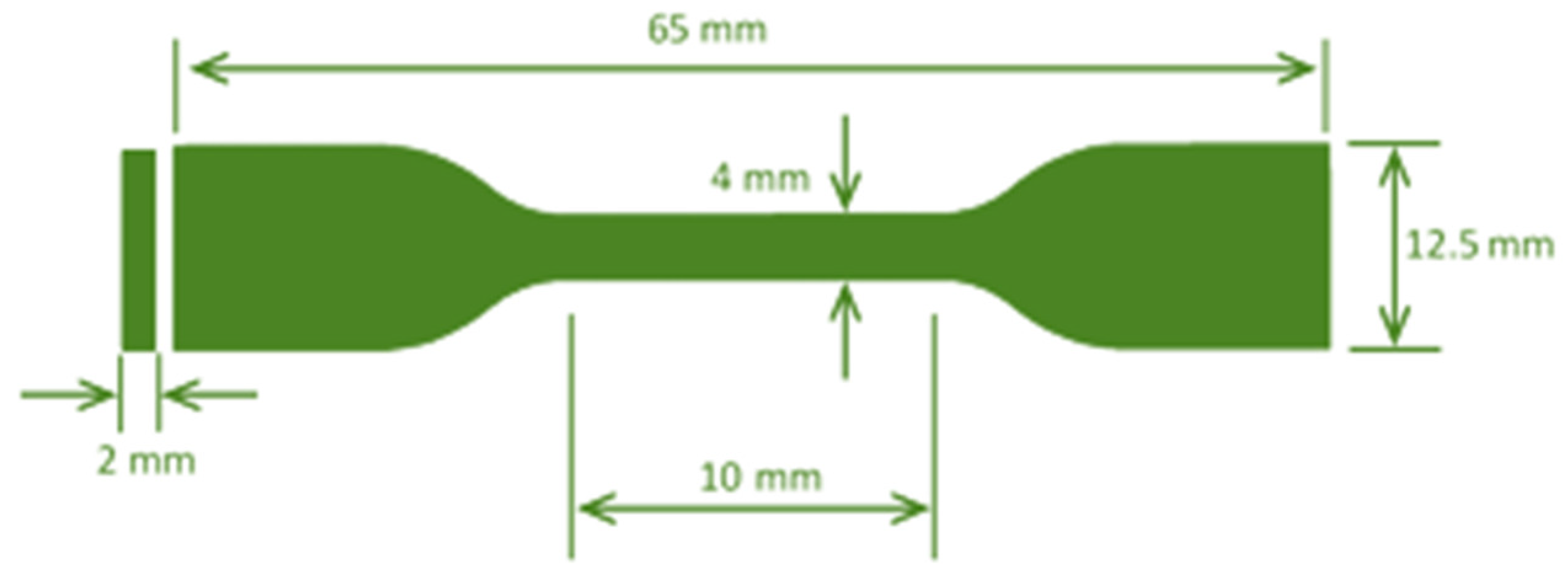

2.1.2. Mechanical Properties

2.1.3. Composite Density

3. Results and Discussion

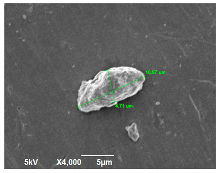

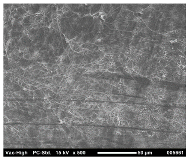

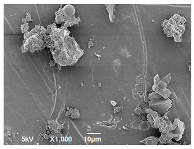

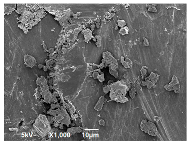

3.1. Morphology

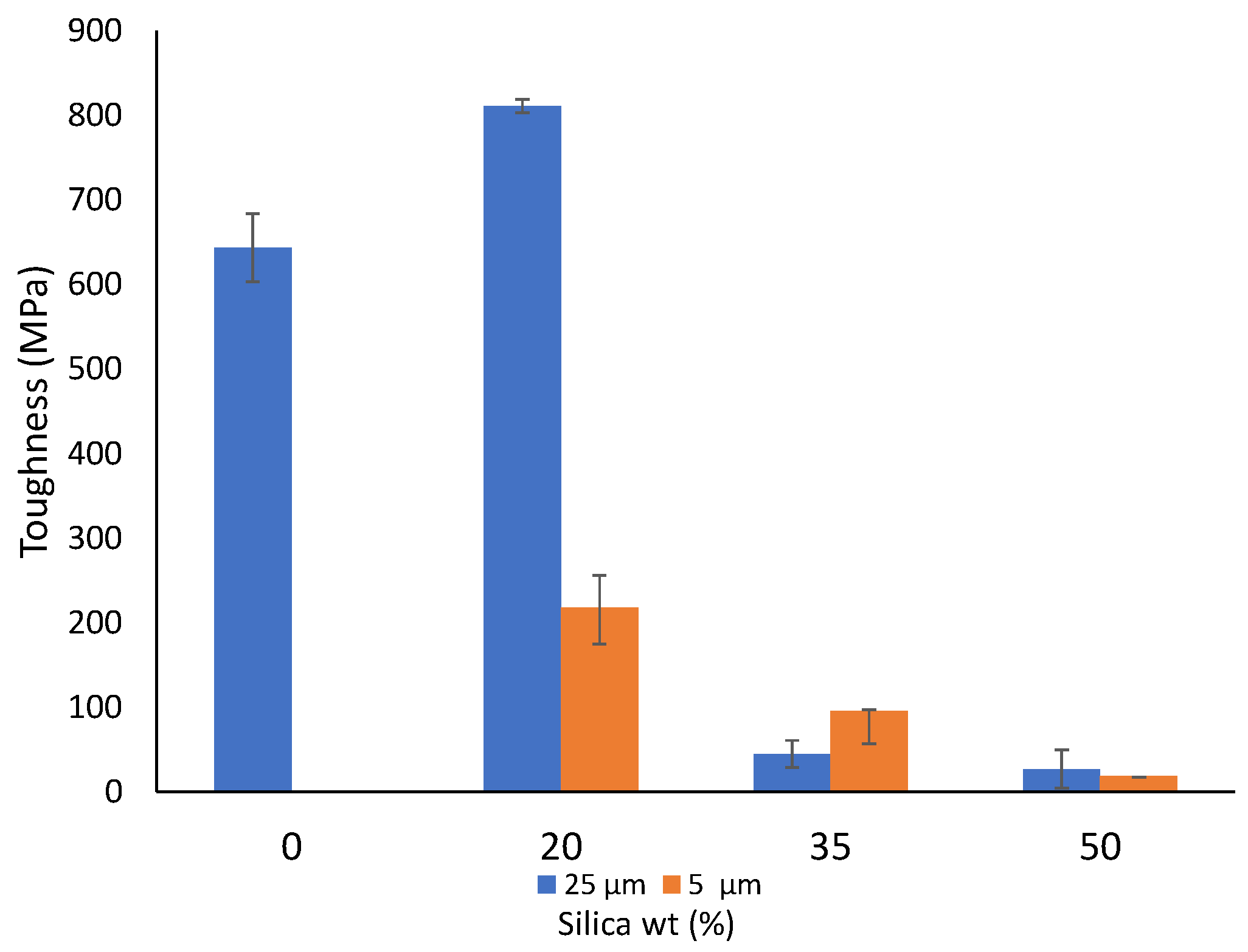

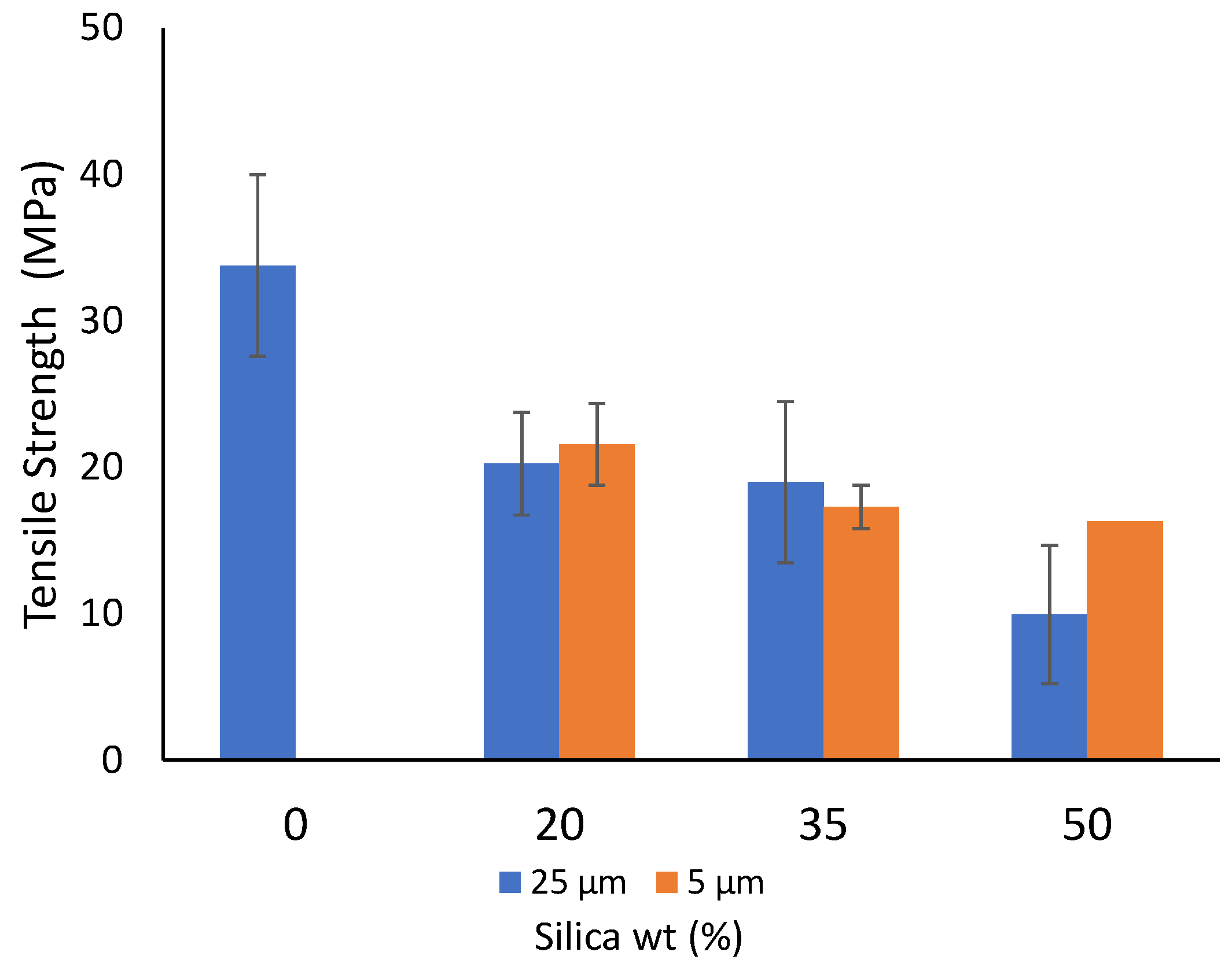

3.2. Mechanical Properties

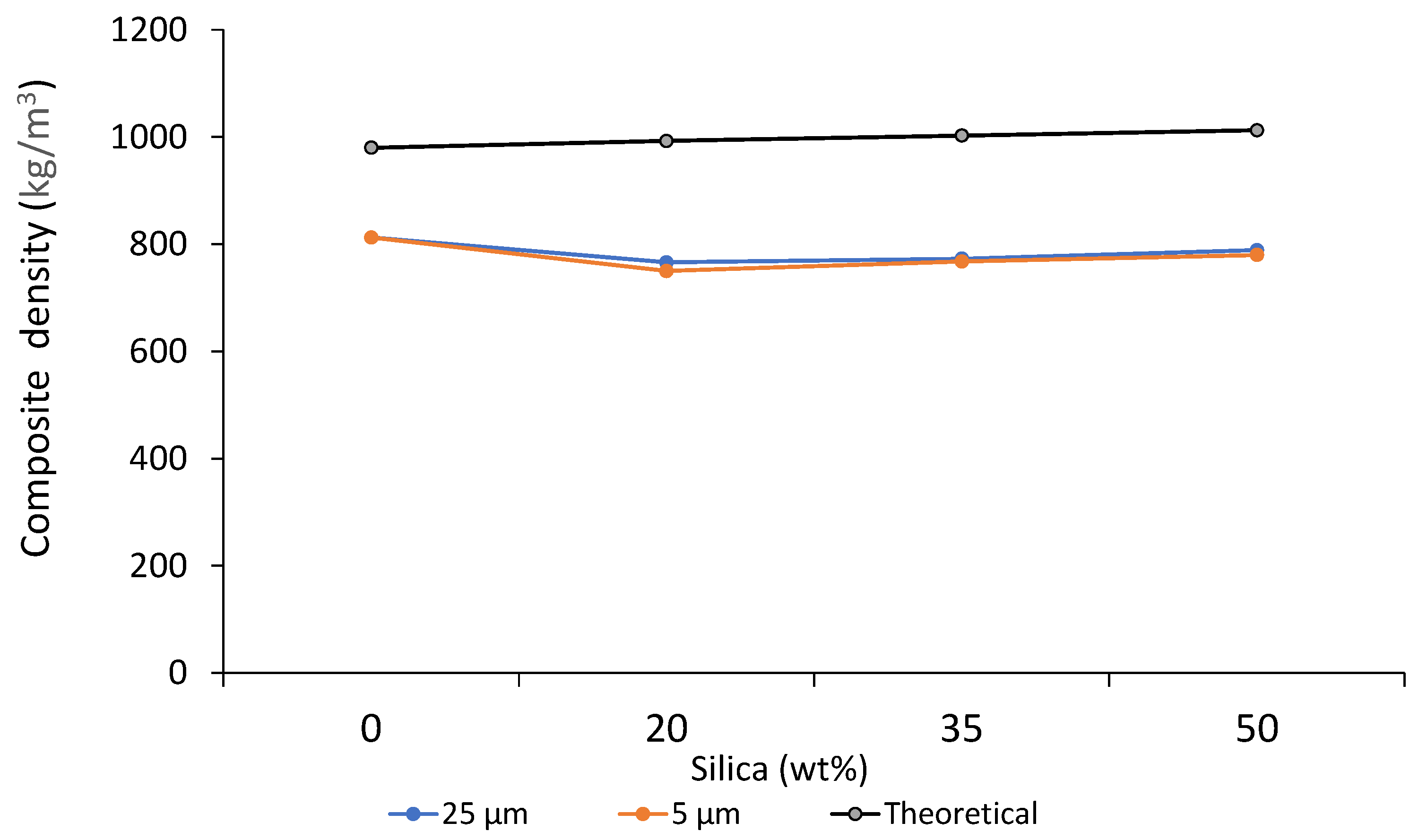

3.3. Composite Density

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- De Santi, C.R.; Correa, A.C.; Manrich, S. Films of post-consumer polypropylene composites for the support layer in synthetic paper. Polímeros 2006, 16, 123–128. [Google Scholar] [CrossRef] [Green Version]

- Rochman, C.M.; Browne, M.A.; Halpern, B.S.; Hentschel, B.T.; Hoh, E.; Karapanagioti, H.K.; Rios-Mendoza, L.M.; Takada, H.; Teh, S.; Thompson, R.C. Classify plastic waste as hazardous. Nature 2013, 494, 169–171. [Google Scholar] [CrossRef] [PubMed]

- Al-Mazrouei, N.; Ismail, A.; Ahmed, W.; Al-Marzouqi, A.H. ABS/Silicon Dioxide Micro Particulate Composite from 3D Printing Polymeric Waste. Polymers 2022, 14, 509. [Google Scholar] [CrossRef] [PubMed]

- Bouafif, H.; Koubaa, A.; Perré, P.; Cloutier, A.; Riedl, B. Wood particle/high-density polyethylene composites: Thermal sensitivity and nucleating ability of wood particles. J. Appl. Polym. Sci. 2009, 113, 593–600. [Google Scholar] [CrossRef]

- Wang, B.; Ma, H.; Wu, D.; Zhu, L.; Jin, Z. Toughening polypropylene by tiny amounts of fillers. Pigment Resin Technol. 2017, 46, 309–317. [Google Scholar] [CrossRef]

- Srisawat, N.; Nithitanakul, M.; Srikulkit, K. Spinning of fibers from polypropylene/silica composite resins. J. Compos. Mater. 2011, 46, 99–110. [Google Scholar] [CrossRef]

- Ou, Y.; Yang, F.; Yu, Z.-Z. A New Conception on the Toughness of Nylon 6/Silica Nanocomposite Prepared via in Situ Polymerization. J. Polym. Sci. Part B Polym. Phys. 1998, 36, 789–795. [Google Scholar] [CrossRef]

- Siraj, S.; Al Marzouqi, A.; Lqbal, M. Mechanical and Wettability Performance of Sand/HDPE Composite Sheets. Mater. Sci. Forum 2020, 1015, 9–14. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Panchal, H.; Shanmugan, S.; Muthuramalingam, T.; El-Kassas, A.M.; Ramesh, B. Recent Progresses in Wood-Plastic Composites: Pre-Processing Treatments, Manufacturing Techniques, Recyclability and Eco-Friendly Assessment. Clean. Eng. Technol. 2022, 8, 100450. [Google Scholar] [CrossRef]

- Ahmed, W.; Siraj, S.; Alnajjar, F.; Al Marzouqi, A.H. 3D Printed Implants for Joint Replacement. In Applications of 3D Printing in Biomedical Engineering; Sharma, N.R., Subburaj, K., Sandhu, K., Sharma, V., Eds.; Springer: Singapore, 2021; pp. 97–119. [Google Scholar]

- Elsheikh, A. Bistable Morphing Composites for Energy-Harvesting Applications. Polymers 2022, 14, 1893. [Google Scholar] [CrossRef]

- Charinpanitkul, T.; Ruenjaikaen, K.; Sunsap, P.; Wijitamornlert, A.; Kim, K.S. Optical Transmission of Greenhouse Film Prepared from Composite of Polyethylene and Microsilica. J. Ind. Eng. Chem. 2007, 13, 992–996. [Google Scholar]

- Hyun, K.; Chong, W.; Koo, M.; Chung, I.J. Physical properties of polyethylene/silicate nanocomposite blown films. J. Appl. Polym. Sci. 2003, 89, 2131–2136. [Google Scholar] [CrossRef]

- Rangasamy, G.; Mani, S.; Kolandavelu, S.K.S.; Alsoufi, M.S.; Ibrahim, A.M.M.; Muthusamy, S.; Panchal, H.; Sadasivuni, K.K.; Elsheikh, A.H. An extensive analysis of mechanical, thermal and physical properties of jute fiber composites with different fiber orientations. Case Stud. Therm. Eng. 2021, 28, 101612. [Google Scholar] [CrossRef]

- Açıkbaş, G.; Özcan, S.; Açıkbaş, N. Production and characterization of a hybrid polymer matrix composite. Polym. Compos. 2017, 39, 4080–4093. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Elaziz, M.A.; Ramesh, B.; Egiza, M.; Al-Qaness, M.A. Modeling of drilling process of GFRP composite using a hybrid random vector functional link network/parasitism-predation algorithm. J. Mater. Res. Technol. 2021, 14, 298–311. [Google Scholar] [CrossRef]

- Raj, M.K.A.; Muthusamy, S.; Panchal, H.; Ibrahim, A.M.M.; Alsoufi, M.S.; Elsheikh, A.H. Investigation of mechanical properties of dual-fiber reinforcement in polymer composite. J. Mater. Res. Technol. 2022, 18, 3908–3915. [Google Scholar] [CrossRef]

- Kosciuszko, A.; Czyzewski, P.; Wajer, Ł.; Osciak, A.; Bielinski, M. Properties of Polypropylene Composites Filled with Microsilica Waste. Polimery 2020, 65, 99–104. [Google Scholar] [CrossRef] [Green Version]

- Fu, S.-Y.; Feng, X.-Q.; Lauke, B.; Mai, Y.-W. Effects of Particle Size, Particle/Matrix Interface Adhesion and Particle Loading on Mechanical Properties of Particulate—Polymer Composites. Compos. Part B Eng. 2008, 39, 933–961. [Google Scholar] [CrossRef]

- Sahmaran, M.; Yücel, H.E.; Demirhan, S.; Arýk, M.T.; Li, V.C. Combined Effect of Aggregate and Mineral Admixtures on Tensile Ductility of Engineered Cementitious Composites. ACI Mater. J. 2012, 109, 627. [Google Scholar]

- Othman, R.N.R.; Subramaniam, D.K.; Ezani, N.; Abdullah, M.F.; Ahmad, K.Z.K. The Synergistic Effects of Hybrid Micro and Nano Silica in Influencing the Mechanical Properties of Epoxy Composites—A New Model. Polymers 2022, 14, 3969. [Google Scholar] [CrossRef]

- Fu, Q.; Wang, G. Polyethylene toughened by rigid inorganic particles. Polym. Eng. Sci. 1992, 32, 94–97. [Google Scholar] [CrossRef]

- Fu, Q.; Wang, G.; Shen, J. Polyethylene toughened by CaCO3 particle: Brittle-ductile transition of CaCO3-toughened HDPE. J. Appl. Polym. Sci. 1993, 49, 673–677. [Google Scholar] [CrossRef]

- Bartczak, Z.; Argon, A.; Cohen, R.; Weinberg, M. Toughness mechanism in semi-crystalline polymer blends: II. High-density polyethylene toughened with calcium carbonate filler particles. Polymer 1999, 40, 2347–2365. [Google Scholar] [CrossRef]

- Menendez, H.; White, J.L. A Wide-angle X-ray diffraction method of determining chopped fiber orientation in composites with application to extrusion through dies. Polym. Eng. Sci. 1984, 24, 1051–1055. [Google Scholar] [CrossRef]

- Nguyen, H.X.; Ishida, H. Poly (Aryl-ether-ether-ketone) and Its Advanced Composites: A Review. Polym. Compos. 1987, 8, 57–73. [Google Scholar] [CrossRef]

- Bhattachrya, S.; Gupta, R.; Kamal, M.R. Polymeric Nanocomposite: Theory and Practice; Hanser: Munich, Germany, 2007. [Google Scholar]

- Elleithy, R.H.; Ali, I.; Ali, M.A.; Al-Zahrani, S.M. High Density Polyethylene/Micro Calcium Carbonate Composites: A Study of the Morphological, Thermal, and Viscoelastic Properties. J. Appl. Polym. Sci. 2010, 117, 2413–2421. [Google Scholar] [CrossRef]

- Siraj, S.; Al-Marzouqi, A.; Ahmed, W. Processing Biodegradable Fused Filament Fabrication Waste with Micro-Silica Particles. Key Eng. Mater. 2022, 907, 156–162. [Google Scholar] [CrossRef]

- Jun, Q.; Ma, L.; Gao, F.; Wen, Y.; Kang, L.; Liu, H.; Zhao, X.; Xie, X.; Jun, C.; Chen, K.; et al. Method for Manufacturing Light Stone Paper from Micro Talcum Powder. CN103102569A (15/5/2013). Available online: https://patents.google.com/patent/CN103102569A/en (accessed on 19 October 2022).

- Chauhan, I.; Chattopadhyay, S.; Mohanty, P. Fabrication of titania nanowires incorporated paper sheets and study of their optical properties. Mater. Express 2013, 3, 343–349. [Google Scholar] [CrossRef]

- Bezerra, E.M.; Joaquim, A.P.; Savastano, H., Jr.; John, V.M.; Agopyan, V. The Effect of Different Mineral Additions and Synthetic Fiber Contents on Properties of Cement Based Composites. Cem. Concr. Compos. 2006, 28, 555–563. [Google Scholar] [CrossRef]

- Hubbe, M.A.; Gill, R.A. Fillers for Papermaking: A Review of Their Properties, Usage Practices, and Their Mechanistic Role. BioResources 2016, 11, 2886–2963. [Google Scholar] [CrossRef] [Green Version]

- Faria, D.L.; Júnior, L.M.; de Almeida Mesquita, R.G.; Júnior, M.G.; Pires, N.J.; Mendes, L.M.; Junior, J.B.G. Production of castor oil-based polyurethane resin composites reinforced with coconut husk fibres. J. Polym. Res. 2020, 27, 249. [Google Scholar] [CrossRef]

- Ślosarczyk, A.; Vashchuk, A.; Klapiszewski, Ł. Research Development in Silica Aerogel Incorporated Cementitious Composites—A Review. Polymers 2022, 14, 1456. [Google Scholar] [CrossRef] [PubMed]

- Corrêa, A.C.; de Santi, C.R.; Manrich, S. Synthetic Paper from Plastic Waste: The Effect of CaCO3 on Physical, Surface Properties and Printability. In Macromolecular Symposia; Wiley Online Library: New York, NY, USA, 2006; pp. 611–620. [Google Scholar]

- Borges, J.R.V.; Santos, A.S.F.E.; Manrich, S. The Influence of Organoclay on Polypropylene Composite Films for Synthetic Paper. Polym. Technol. Eng. 2011, 50, 1443–1451. [Google Scholar] [CrossRef]

- Buddi, T.; Rao, B.N.; Singh, S.K.; Purohit, R.; Rana, R.S. Development and analysis of high density poly ethylene (HDPE) nano SiO2 and wood powder reinforced polymer matrix hybrid nano composites. J. Exp. Nanosci. 2018, 13, S24–S30. [Google Scholar] [CrossRef] [Green Version]

- Ahmed, W.; Ahmed, S.; Alnajjar, F.; Zaneldin, E. Mechanical performance of three-dimensional printed sandwich composite with a high-flexible core. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2021, 235, 1382–1400. [Google Scholar] [CrossRef]

- Almazrouei, N.; Siraj, S.; Al-Marzouqi, A.H.; Ahmed, W. Producing Particulate Composite Using 3D Printing Plastics Waste. In Proceedings of the 2022 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, United Arab Emirates, 21–24 February 2022; pp. 1–6. [Google Scholar]

- Wang, X.; Wu, L.; Yu, H.; Xiao, T.; Li, H.; Yang, J. Modified silica-based isoprene rubber composite by a multi-functional silane: Preparation and its mechanical and dynamic mechanical properties. Polym. Test. 2020, 91, 106840. [Google Scholar] [CrossRef]

- Ahmed, W.; Siraj, S.; Al-Marzouqi, A. Embracing Additive Manufacturing Technology through Fused Filament Fabrication for Antimicrobial with Enhanced Formulated Materials. Polymers 2021, 13, 1523. [Google Scholar] [CrossRef]

- Marković, G.; Samaržija-Jovanović, S.; Jovanović, V.; Marinović-Cincović, M. Thermal stability of CR/CSM rubber blends filled with nano- and micro-silica particles. J. Therm. Anal. 2009, 100, 881–888. [Google Scholar] [CrossRef]

- Kumar, P.; Das, V.; Gupta, A.; Ameta, N.K. Stabilization of Dune Sand Mixed with Plastic (LDPE) Waste Strips for Design of Flexible Pavement in Construction of Roads. Am. J. Eng. Res. 2016, 5, 315–320. [Google Scholar]

- Ding, T.; Xiao, J.; Zou, S.; Yu, J. Flexural properties of 3D printed fibre-reinforced concrete with recycled sand. Constr. Build. Mater. 2021, 288, 123077. [Google Scholar] [CrossRef]

- Bamigboye, G.O.; Ngene, B.U.; Ademola, D.; Jolayemi, J.K. Experimental Study on the Use of Waste Polyethylene Terephthalate (PET) and River Sand in Roof Tile Production. J. Phys. Conf. Ser. 2019, 1378, 042105. [Google Scholar] [CrossRef]

- Kumi-Larbi, A.; Yunana, D.; Kamsouloum, P.; Webster, M.; Wilson, D.C.; Cheeseman, C. Recycling waste plastics in developing countries: Use of low-density polyethylene water sachets to form plastic bonded sand blocks. Waste Manag. 2018, 80, 112–118. [Google Scholar] [CrossRef] [PubMed]

- Dang, X.; Gao, Y.; Yu, Y.; Li, Q.; Wang, S.; Wu, H.; Wang, H.; Zhao, P. Windproof Efficiency with New Biodegradable PLA Sand Barrier and Traditional Straw Sand Barrier. J. Beijing For. Univ. 2015, 37, 118–125. [Google Scholar]

- Lau, K.Y.; Vaughan, A.S.; Chen, G.; Hosier, I.; Holt, A.F. On the dielectric response of silica-based polyethylene nanocomposites. J. Phys. D Appl. Phys. 2013, 46, 095303. [Google Scholar] [CrossRef]

- Ahn, S.H.; Kim, S.H.; Kim, B.C.; Shim, K.B.; Cho, B.G. Mechanical Properties of Silica Nanoparticle Reinforced Poly (Ethylene 2, 6-Naphthalate). Macromol. Res. 2004, 12, 293–302. [Google Scholar] [CrossRef]

- Yadykova, A.Y.; Ilyin, S.O. Rheological and adhesive properties of nanocomposite bitumen binders based on hydrophilic or hydrophobic silica and modified with bio-oil. Constr. Build. Mater. 2022, 342, 127946. [Google Scholar] [CrossRef]

- Moro, S.; Parneix, C.; Cabane, B.; Sanson, N.; de Lacaillerie, J.-B.D. Hydrophobization of Silica Nanoparticles in Water: Nanostructure and Response to Drying Stress. Langmuir 2017, 33, 4709–4719. [Google Scholar] [CrossRef] [Green Version]

- Krzan, M.; Jarek, E.; Petkova, H.; Santini, E.; Szyk-Warszynska, L.; Ravera, F.; Liggieri, L.; Mileva, E.; Warszynski, P. Hydrophobisation of Silica Nanoparticles Using Lauroyl Ethyl Arginate and Chitosan Mixtures to Induce the Foaming Process. Polymers 2022, 14, 4076. [Google Scholar] [CrossRef]

- Dorigato, A.; D’Amato, M.; Pegoretti, A. Thermo-mechanical properties of high density polyethylene—fumed silica nanocomposites: Effect of filler surface area and treatment. J. Polym. Res. 2012, 19, 9889. [Google Scholar] [CrossRef]

- Siraj, S.; Al-Marzouqi, A.H.; Iqbal, M.Z. Development and Mechano-Chemical Characterization of Polymer Composite Sheets Filled with Silica Microparticles with Potential in Printing Industry. Polymers 2022, 14, 3351. [Google Scholar] [CrossRef]

- Tanniru, M.; Yuan, Q.; Misra, R. On significant retention of impact strength in clay–reinforced high-density polyethylene (HDPE) nanocomposites. Polymer 2006, 47, 2133–2146. [Google Scholar] [CrossRef]

- Alshammari, B.A.; Alenad, A.M.; Al-Mubaddel, F.S.; Alharbi, A.G.; Al-Shehri, A.S.; Albalwi, H.A.; Alsuabie, F.M.; Fouad, H.; Mourad, A.-H.I. Impact of Hybrid Fillers on the Properties of High Density Polyethylene Based Composites. Polymers 2022, 14, 3427. [Google Scholar] [CrossRef] [PubMed]

- Agüero, Á.; Garcia-Sanoguera, D.; Lascano, D.; Rojas-Lema, S.; Ivorra-Martinez, J.; Fenollar, O.; Torres-Giner, S. Evaluation of Different Compatibilization Strategies to Improve the Performance of Injection-Molded Green Composite Pieces Made of Polylactide Reinforced with Short Flaxseed Fibers. Polymers 2020, 12, 821. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dalloul, F.; Mietner, J.B.; Navarro, J.R.G. Production and 3D Printing of a Nanocellulose-Based Composite Filament Composed of Polymer-Modified Cellulose Nanofibrils and High-Density Polyethylene (HDPE) for the Fabrication of 3D Complex Shapes. Fibers 2022, 10, 91. [Google Scholar] [CrossRef]

- Alghamdi, M.N. Performance for Fly Ash Reinforced HDPE Composites over the Ageing of Material Components. Polymers 2022, 14, 2913. [Google Scholar] [CrossRef]

- Rane, A.V.; Kanny, K.; Abitha, V.K.; Thomas, S. Methods for Synthesis of Nanoparticles and Fabrication of Nanocomposites. In Synthesis of Inorganic Nanomaterials; Elsevier: Amsterdam, The Netherlands, 2018; pp. 121–139. [Google Scholar]

- Yazıcı, N.; Kodal, M.; Özkoç, G. Lab-Scale Twin-Screw Micro-Compounders as a New Rubber-Mixing Tool: ‘A Comparison on EPDM/Carbon Black and EPDM/Silica Composites’. Polymers 2021, 13, 4391. [Google Scholar] [CrossRef]

- Leprince, J.; Palin, W.; Mullier, T.; Devaux, J.; Vreven, J.; Leloup, G. Investigating filler morphology and mechanical properties of new low-shrinkage resin composite types. J. Oral Rehabil. 2010, 37, 364–376. [Google Scholar] [CrossRef]

- Rueggeberg, F.A.; Caughman, W.F.; Curtis, J.W., Jr.; Davis, H.C. Factors Affecting Cure at Depths within Light-Activated Resin Composites. Am. J. Dent. 1993, 6, 91–95. [Google Scholar]

- Polyethylene High Density, Average Mw 125,000 9002-88-4. Available online: https://www.sigmaaldrich.com/RS/en/product/aldrich/181900 (accessed on 19 October 2022).

- Polyethylene High Density Pellet | Sigma-Aldrich. Available online: https://www.sigmaaldrich.com/AU/en/ (accessed on 19 October 2022).

- Polyethylene High Density, 2.2 g/10 Min 190 °C/2.16 kg 9002-88-4. Available online: http://www.sigmaaldrich.com/ (accessed on 19 October 2022).

- Erbetta, C.D.C.; Manoel, G.F.; Oliveira, A.P.L.R.; Silva, M.E.S.R.E.; Freitas, R.F.S.; Sousa, R.G. Rheological and Thermal Behavior of High-Density Polyethylene (HDPE) at Different Temperatures. Mater. Sci. Appl. 2014, 5, 923–931. [Google Scholar] [CrossRef] [Green Version]

- Lung, M. Stonepaper, Taiwan Lung Meng Technology Co., Ltd. Available online: http://www.taiwanlm.com/ (accessed on 17 February 2020).

- Peşman, E.; Tufan, M. The Effects of CaCO3 Coated Wood Free Paper Usage as Filler on Water Absorption, Mechanical and Thermal Properties of Cellulose-High Density Polyethylene Composites. Mater. Sci. 2016, 22, 530–535. [Google Scholar] [CrossRef] [Green Version]

- Mittal, V.; Chaudhry, A.U. Effect of amphiphilic compatibilizers on the filler dispersion and properties of polyethylene-thermally reduced graphene nanocomposites. J. Appl. Polym. Sci. 2015, 132, 42484–42494. [Google Scholar] [CrossRef]

- US3788923A—Silica-Filled, High Molecular Weight Polyolefin—Google Patents. Available online: https://patents.google.com/patent/US3788923A/en (accessed on 18 February 2020).

- Ahmed, W.; Siraj, S.; Al-Marzouqi, A.H. 3D Printing PLA Waste to Produce Ceramic Based Particulate Reinforced Composite Using Abundant Silica-Sand: Mechanical Properties Characterization. Polymers 2020, 12, 2579. [Google Scholar] [CrossRef] [PubMed]

- D20 Committee. Guide for Determination of Thickness of Plastic Film Test Specimens; ASTM International: West Conshohocken, PA, USA.

- D18 Committee. Test Methods for Laboratory Determination of Density (Unit Weight) of Soil Specimens; ASTM International: West Conshohocken, PA, USA.

- Lee, I.K.; White, W.; Ingles, O.G. Soil Formation, Classification and Exploration. Princ. Geotech. Eng. 1983, 1, 1–56. [Google Scholar]

- Meyers, R.A. Encyclopedia of Physical Science and Technology; Academic: Cambridge, MA, USA, 2002. [Google Scholar]

- D20 Committee. Practice for Cutting Film and Sheeting Test Specimens; ASTM International: West Conshohocken, PA, USA.

- Li, Z.; Muiruri, J.K.; Thitsartarn, W.; Zhang, X.; Tan, B.H.; He, C. Biodegradable silica rubber core-shell nanoparticles and their stereocomplex for efficient PLA toughening. Compos. Sci. Technol. 2018, 159, 11–17. [Google Scholar] [CrossRef]

- Kotoky, T.; Dolui, S.K. Synthesis and Characterisation of Polyvinyl Alcohol (PVA)/Silica Hybrid Composites Derived Through the Sol-Gel Method in Aqueous Medium: Effect of Acid Content, Silica Content and Viscosity of PVA on the Dispersion Characteristics of Silica and the Physical Properties of the Composites. J. Sol-Gel Sci. Technol. 2004, 29, 107–114. [Google Scholar]

- Peng, Z.; Kong, L.X.; Li, S.-D.; Spiridonov, P. Poly(Vinyl Alcohol)/Silica Nanocomposites: Morphology and Thermal Degradation Kinetics. J. Nanosci. Nanotechnol. 2006, 6, 3934–3938. [Google Scholar] [CrossRef]

- Xia, S.; Liu, X.; Wang, J.; Kan, Z.; Chen, H.; Fu, W.; Li, Z. Role of poly(ethylene glycol) grafted silica nanoparticle shape in toughened PLA-matrix nanocomposites. Compos. Part B Eng. 2019, 168, 398–405. [Google Scholar] [CrossRef]

- Wen, X.; Lin, Y.; Han, C.; Zhang, K.; Ran, X.; Li, Y.; Dong, L. Thermomechanical and optical properties of biodegradable poly (L-lactide)/silica nanocomposites by melt compounding. J. Appl. Polym. Sci. 2009, 114, 3379–3388. [Google Scholar] [CrossRef]

- Liu, L.; Ma, H.; Zhu, X.; Fan, Y.; Jin, Z. Preparation and Properties of Polylactide/Nano-silica in Situ Composites. Pigment. Resin Technol. 2010, 39, 27–31. [Google Scholar] [CrossRef]

- Zdiri, K.; Elamri, A.; Hamdaoui, M.; Harzallah, O.; Khenoussi, N.; Brendlé, J. Reinforcement of recycled PP polymers by nanoparticles incorporation. Green Chem. Lett. Rev. 2018, 11, 296–311. [Google Scholar] [CrossRef] [Green Version]

- Watanabe, R.; Sugahara, A.; Hagihara, H.; Sato, H.; Mizukado, J.; Shinzawa, H. Study of matrix-filler interaction of polypropylene/silica composite by combined infrared (IR) spectroscopic imaging and disrelation mapping. Compos. Part A Appl. Sci. Manuf. 2019, 128, 105658. [Google Scholar] [CrossRef]

- Brostow, W.; Datashvili, T.; Jiang, P.; Miller, H. Recycled HDPE reinforced with sol–gel silica modified wood sawdust. Eur. Polym. J. 2016, 76, 28–39. [Google Scholar] [CrossRef]

- Albano, C.; Cataño, L.; Figuera, L.; Perera, R.; Karam, A.; González, G.; Noris, K. Evaluation of a composite based on high-density polyethylene filled with surface-treated hydroxyapatite. Polym. Bull. 2008, 62, 45–55. [Google Scholar] [CrossRef]

- Bulatović, V.O.; Mihaljević, A.; Bajsić, E.G. Mechanical and interfacial properties of compatibilized polyurethane blends. Polym. Eng. Sci. 2017, 58, 1911–1922. [Google Scholar] [CrossRef]

- Overview of Materials for High Density Polyethylene (HDPE), Sheet/Thermoforming Grade. Available online: https://www.matweb.com/search/ (accessed on 19 October 2022).

- Savini, G.; Oréfice, R.L. Comparative study of HDPE composites reinforced with microtalc and nanotalcs: High performance filler for improving ductility at low concentration levels. J. Mater. Res. Technol. 2020, 9, 16387–16398. [Google Scholar] [CrossRef]

- Wangworn, P.; Wanakamol, P. Mechanical properties of compression-molded electrospun silica fiber/nylon-6 composites. Polym. Compos. 2018, 40, 1123–1131. [Google Scholar] [CrossRef]

- Rodrigue, D.; Kavianiboroujeni, A.; Cloutier, A. Determination of the optimum coupling agent content for composites based on hemp and high density polyethylene. AIP Conf. Proc. 2017, 1914, 030003. [Google Scholar] [CrossRef]

- Meng, Q.; Hetzer, M.; De Kee, D. PLA/clay/wood nanocomposites: Nanoclay effects on mechanical and thermal properties. J. Compos. Mater. 2010, 45, 1145–1158. [Google Scholar] [CrossRef]

- Tsai, P.-A.; Chiu, W.-M.; Lin, C.-E.; Wu, J.-H. Fabrication and Characterization of PLA/SiO2/Al2O3 Composites Prepared by Sol-Gel Process. Polym.-Plast. Technol. Eng. 2013, 52, 1488–1495. [Google Scholar] [CrossRef]

- Rothon, R. Particulate-Filled Polymer Composites; iSmithers Rapra Publishing: Shrewsbury, UK, 2003. [Google Scholar]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and Mechanical Properties of PLA, and Their Functions in Widespread Applications—A Comprehensive Review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef] [Green Version]

- Wypych, G. Handbook of Fillers—Book Reviews. IEEE Electr. Insul. Mag. 2004, 20, 64–65. [Google Scholar] [CrossRef]

- Modjarrad, K.; Ebnesajjad, S. Handbook of Polymer Applications in Medicine and Medical Devices; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Mishra, S.; Mitra, R.; Vijayakumar, M. Structure–property correlation in cellular silica processed through hydrophobized fused silica powder for aerospace application. J. Alloy. Compd. 2010, 504, 76–82. [Google Scholar] [CrossRef]

- Flinn, D.; Guzonas, D.; Yoon, R.-H. Characterization of silica surfaces hydrophobized by octadecyltrichlorosilane. Colloids Surfaces A Physicochem. Eng. Asp. 1994, 87, 163–176. [Google Scholar] [CrossRef]

- Li, Y.; Han, C.; Bian, J.; Han, L.; Dong, L.; Gao, G. Rheology and biodegradation of polylactide/silica nanocomposites. Polym. Compos. 2012, 33, 1719–1727. [Google Scholar] [CrossRef]

- Xiao, M.; Mohler, C.; Tucker, C.J.; Walther, B.W.; Lu, X.; Chen, Z. Structures and Adhesion Properties at Polyethylene/Silica and Polyethylene/Nylon Interfaces. Langmuir 2018, 34, 6194–6204. [Google Scholar] [CrossRef]

- Maris, J.; Bourdon, S.; Brossard, J.-M.; Cauret, L.; Fontaine, L.; Montembault, V. Mechanical recycling: Compatibilization of mixed thermoplastic wastes. Polym. Degrad. Stab. 2018, 147, 245–266. [Google Scholar] [CrossRef]

| Sample | Sand (wt%) | HDPE (wt%) | |

|---|---|---|---|

| Sand/polymer composite sheets prepared from 25 µm and 5 µm sand particles | 0 wt% | 0 | 100 |

| 20 wt% | 20 | 80 | |

| 35 wt% | 35 | 65 | |

| 50 wt% | 50 | 50 |

| Parameters | ||||||

|---|---|---|---|---|---|---|

| Temperature (°C) | Time (min) | Particle Size (µm) | Total Input (g) | Screw Speed (rpm) | Pressure (psi) | |

| Melt extrusion | 170 | 15 | 25 and 5 | 4 | 100 | - |

| Hot press compression | 170 | 10 | 25 and 5 | 1 | - | 5000 |

| 0 wt% | 20 wt% | 35 wt% | 50 wt% | |

|---|---|---|---|---|

| Sand/polymer composite sheets prepared from 25 µm |  |  |  |  |

| Sand/polymer composite sheets prepared from 5 µm |  |  |  |

| Sample | Dimensions (l × w × t) | |

|---|---|---|

| Sand/polymer composite sheets prepared from 25 µm sand particles | 0 wt% | 10 × 4 × 0.62 |

| 20 wt% | 10 × 4 × 0.41 | |

| 35 wt% | 10 × 4 × 0.45 | |

| 50 wt% | 10 × 4 × 0.57 | |

| Sand/polymer composite sheets prepared from 5 µm sand particles | 20 wt% | 10 × 4 × 0.33 |

| 35 wt% | 10 × 4 × 0.44 | |

| 50 wt% | 10 × 4 × 0.53 | |

| 25 µm |  |  | |

| 5 µm |  |  | |

| Sheets |  Pure HDPE |  35 wt%, 25 µm |  35 wt%, 5 µm |

| Sample | Toughness (MPa) | Elastic Modulus (MPa) | Ductility (%) | Tensile Strength (MPa) | |

|---|---|---|---|---|---|

| 0 wt% | 643.5 ± 40.3 | 1200.77 ± 127.3 | 215 ± 49.5 | 33.76 ± 6.2 | |

| Sand/polymer composite sheets prepared from 25 µm sand particles | 20 wt% | 810.75 ± 8.1 | 1298.33 ± 169.8 | 29.67 ± 1.41 | 20.23 ± 3.5 |

| 35 wt% | 44.80 ± 15.9 | 1182.33 ± 328.4 | 3.7 ± 0.72 | 18.96 ± 5.5 | |

| 50 wt% | 26.85 ± 22.7 | 905.72 ± 343.1 | 3.25 ± 1.34 | 9.93 ± 4.7 | |

| Sand/polymer composite sheets prepared from 5 µm sand particles | 20 wt% | 217.33 ± 42.4 | 950.59 ± 86.6 | 20.67 ± 0.58 | 21.56 ± 0.6 |

| 35 wt% | 95.33 ± 38.6 | 887.47 ± 96.2 | 11.87 ± 4.51 | 17.28 ± 2.8 | |

| 50 wt% | 18.85 ± 1.6 | 1137.05 ± 8.2 | 2.07 ± 0.25 | 16.3 ± 1.48 | |

| Sample | Composite Density Theoretical (kg/m3) | Composite Density for Sheets with 25 µm (kg/m3) | Composite Density for Sheets with 5 µm (kg/m3) |

|---|---|---|---|

| 0 wt% | 980.00 | 812.5 | 812.5 |

| 20 wt% | 992.80 | 766.14 | 750.0 |

| 35 wt% | 1002.62 | 772.92 | 767.71 |

| 50 wt% | 1012.64 | 788.82 | 780.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Siraj, S.; Al-Marzouqi, A.H.; Iqbal, M.Z.; Ahmed, W. Impact of Micro Silica Filler Particle Size on Mechanical Properties of Polymeric Based Composite Material. Polymers 2022, 14, 4830. https://doi.org/10.3390/polym14224830

Siraj S, Al-Marzouqi AH, Iqbal MZ, Ahmed W. Impact of Micro Silica Filler Particle Size on Mechanical Properties of Polymeric Based Composite Material. Polymers. 2022; 14(22):4830. https://doi.org/10.3390/polym14224830

Chicago/Turabian StyleSiraj, Sidra, Ali H. Al-Marzouqi, Muhammad Z. Iqbal, and Waleed Ahmed. 2022. "Impact of Micro Silica Filler Particle Size on Mechanical Properties of Polymeric Based Composite Material" Polymers 14, no. 22: 4830. https://doi.org/10.3390/polym14224830

APA StyleSiraj, S., Al-Marzouqi, A. H., Iqbal, M. Z., & Ahmed, W. (2022). Impact of Micro Silica Filler Particle Size on Mechanical Properties of Polymeric Based Composite Material. Polymers, 14(22), 4830. https://doi.org/10.3390/polym14224830